#Concrete Admixtures Manufacturers

Text

ECMAS is known as one of the premium concrete admixture manufacturers in India. Get absolute strength, enhanced workability, and durability for your concrete buildings with ECMAS concrete admixtures.

#construction chemical companies#concrete admixtures manufacturers#admixture companies in india#concrete

0 notes

Text

Choosing the Best Concrete Admixture Manufacturers: A Guide

Concrete admixtures are essential additives that can significantly enhance the performance of concrete. They can improve workability, strength, durability, and other properties, making them indispensable in modern construction.

ADT Industries Pvt. Ltd., a leading concrete admixture manufacturers in Mumbai, offers a wide range of high-quality admixtures to meet diverse construction needs. With their expertise and commitment to quality, ADT Industries has established itself as a trusted partner for customers seeking reliable and effective concrete solutions.

Factors to Consider When Choosing a Concrete Admixture:

Desired Properties: Determine the specific properties you want to improve in your concrete, such as workability, strength, durability, or water-reducing capabilities.

Application: Consider the specific application of the concrete, as different admixtures are suitable for various purposes.

Environmental Factors: Evaluate the environmental conditions, such as temperature, humidity, and exposure to chemicals, that may influence the performance of the admixture.

Compatibility: Ensure that the chosen admixture is compatible with the other components of your concrete mix.

Common Types of Concrete Admixtures:

Water reducers: Reduce the amount of water required for a given workability, resulting in stronger and more durable concrete.

Superplasticizers: High-performance water reducers that allow for significantly lower water-cement ratios, leading to even stronger and more durable concrete.

Accelerators: Speed up the setting and hardening of concrete, reducing curing time.

Retarders: Slow down the setting and hardening of concrete, allowing for more working time.

Air-entraining admixtures: Introduce microscopic air voids into the concrete, improving its resistance to freeze-thaw cycles and reducing shrinkage.

Waterproofing admixtures: Enhance the water resistance of concrete, preventing leaks and moisture penetration.

ADT Industries Pvt. Ltd. offers a comprehensive range of concrete admixtures to suit various applications and requirements. Their experienced team can provide expert guidance and recommendations to help you select the most suitable admixture for your project.

Final Words

The best concrete admixture depends on your specific needs and requirements. By carefully considering the factors mentioned above and consulting with a reputable supplier like ADT Industries Pvt. Ltd., you can choose the right admixture to optimize the performance of your concrete and ensure the success of your construction project.

#concrete admixture manufacturers#concrete admixture Suppliers#Concrete Admixture Manufacturers in Mumbai#Concrete Admixture Suppliers in Mumbai

0 notes

Text

What are the Types of Concrete Admixtures?

Admixtures are components of concrete mix designs that modify the characteristics of the concrete. Chemical admixtures come in a range of forms and can modify the permeability, viscosity, water requirements, set time, and other characteristics of the concrete.

Admixtures of concrete that include ATBS monomer are used to improve the performance of cement-based products.

Types of Admixtures Used in Concrete

Water Reducing Admixtures

The phrase "water-reducing additive" implies that water reducers make concrete, cement, and grout workable without adding water. The three types of plasticizers are superplasticizers, mid-range plasticizers, and plasticizers. Common plasticizers use 10% less water, mid-range plasticizers 15% less, and superplasticizers 30% less. Plasticizers like sodium, calcium, and ammonium lignosulphonates are common. These superplasticizers include polycarboxylates, multicarboxylatethers, and acrylic polymers.

Retarding Admixtures

Retarders slow cement hydration and set time. Certain concrete admixtures may be used with frequent temperature changes, and concrete must be transported long distances. Many retarding admixtures include gypsum and calcium sulfate. Other retarders include cellulose derivatives, starch, sugar, acid salts, etc.

Accelerating Admixtures

Accelerating admixtures accelerate concrete setting and early hardening, thus their name. They speed up concrete hydration, increasing early-stage strength. Concrete accelerators include calcium chloride, silica fume, finely split silica gel, etc. Calcium chloride is a cheap and popular accelerator.

Air-entraining concrete admixture

Air-entraining admixtures are aimed at improving the durability of concrete during freezing, dewatering, and thawing. These admixtures add millions of air bubbles to concrete, enhancing its properties. Accelerating additives include calcium formate, triethanolamine, calcium chloride, silica fume, and finely split silica gel. Accelerating additive calcium chloride is inexpensive and popular.

Damp-proof or waterproof Admixtures

Damp or waterproofing admixtures make concrete impervious to water and prevent dampness. Liquid, powder, paste, and other damp-proofing admixtures are available. These admixtures include aluminum, zinc, chloride, calcium chloride, soda sulfate, and other chemically active pore fillers.

Gas forming Admixtures

Gas production frequently uses activated carbon, hydrogen peroxide, and aluminum powder. Tiny hydrogen gas bubbles occur in concrete when gas-forming chemical admixtures react with cement-derived hydroxide. Hydrogen peroxide, aluminum powder, and activated carbon are common gas-producing chemicals. Gas-producing admixtures make lightweight concrete.

Air detraining Admixtures

These admixtures are used to remove excess air from concrete voids. Tributyl phosphate, water-insoluble alcohols, silicones, and others are popular air-entrained admixtures.

Corrosion Inhibiting Admixtures

In reinforced concrete buildings, steel corrosion worsens with chlorides, salty water, industrial odors, etc. Corrosion-preventing additives inhibit the process. Reinforced cement concrete uses corrosion-preventing admixtures such as sodium nitrate, sodium benzoate, and sodium nitrite.

Bonding Admixtures

Bonding admixtures are needed to bind old and fresh concrete. When fresh concrete is poured over hardened concrete, the weak linkages with the old surface increase the likelihood of failure. This admixture, offered by a top concrete admixture manufacturer, is used for pavement overlays, roof screeds, repairs, etc. Bonding admixtures are water emulsions made from synthetic rubber, natural rubber, polyvinyl chloride, and acetate.

Fungicidal, Germicidal, Insecticidal Admixtures

The mix should be fungicidal, germicidal, and insecticidal to prevent bacteria, germs, and fungus from growing on hardened concrete structures. Polyhalogenated phenols, dieldrin emulsions, copper compounds, etc., may improve concrete's properties.

Colouring Admixtures

The concrete's color comes from coloring chemical admixtures. Colorants shouldn't affect concrete strength. Adding coloring admixtures to cement in a ball mill creates colored cement for concrete. This table shows several coloring admixtures and their colors.

Conclusion

Apart from cement, sand, and aggregate, other construction materials may also be used in concrete. They improve concrete's resistance to freezing, sulfate attack, controlled setting, hardening, strength, and workability, etc.

0 notes

Text

Uses and Applications of Concrete Admixtures

Concrete is one of the world's most widely used construction materials because of its strength, resilience, and versatility. However, the properties of concrete may be improved by adding admixtures. Let's discuss the benefits of using concrete admixtures and how to use them to improve the quality and performance of concrete.

To begin with, let's define what we mean when we discuss concrete admixtures:

Substances or materials added to the concrete mixture to improve its properties and functioning are called additives. Whether the concrete is still soft or hardened, it may change or enhance its strength, Workability, setting time, durability, and appearance.

Water reducers, superplasticizers, retarders, accelerators, air-entraining agents, waterproofing agents, corrosion inhibitors, and coloring agents are just a few additives added in small quantities and grouped based on their chemical composition and intended uses. Concrete additives or chemical admixtures are often used in construction to improve the material's quality and efficiency while meeting project requirements.

When Are Admixtures in Concrete Used?

To lower the concrete's unit weight.

To achieve specific properties in concrete more effectively than using other methods.

To keep concrete in good condition while mixed, transported, laid, and cured in inclement weather.

To strengthen the defense against the effects of cold.

To strengthen the defenses against acidic activity.

To lessen concrete's permeability.

To improve concrete's strength.

To increase corrosion resistance.

To strengthen defenses against bleeding and segregation.

To make things more durable.

Applications of Concrete Admixtures

Enhancing Workability

Concrete admixtures are another useful application to improve the Workability of concrete and its overall performance. Additives like plasticizers or water covers are often needed to boost the Workability and make it much simpler for the building workers to deal with and shape the concrete.

Eliminating weakness and the quality of resistance to the applied load.

Moreover, concrete admixtures likewise beef up the strength and longevity of concrete structures. Adjuncts like superplasticizers or pozzolanic materials can improve compressive strength, lower permeability, and increase resistance against chemical attack; in the end, concrete will perform effectively and be long-lasting.

Controlling Setting Time

Concrete curing is vital in construction projects because of its purpose of forming concrete. The concrete as an admixture, comprising retarding or accelerating agents, is introduced to defer or speed up the setting process, respectively. It provides desirable process flexibility regarding the pouring control, placement, and end product surface finish, irrespective of the weather conditions.

Achieving Special Properties

Concrete admixtures are primarily seen as techniques designed to induce specific properties in concrete. Firstly, the air-entraining admixture is an impression that places tiny air bubbles in the concrete, increasing its freeze-thaw resistance. Additionally, using alloying elements such as corrosion inhibitors reduces the corrosion of the reinforcing steel, thus avoiding structural damage for a more extended period.

Conclusion

Concrete admixtures are the leading players valued in the mass of available mixes. As a concrete admixture manufacturer, it is undeniable that additives play an inevitable role in improving concrete mix and providing improved Workability, strength, durability, and desired unique properties. Architectures may use the correct type of admixture to achieve an optimum concrete mixture suited for the project's needs; this results in the quality and durability of structures.

0 notes

Text

Whitespice Chemicals India Pvt Ltd : The Trusted Silica Manufacturer and Concrete Admixture Silica Supplier

In the bustling metropolis of Kolkata, where urbanization is on the rise, the need for durable and resilient concrete structures is more prominent than ever. To meet this demand, construction professionals and builders are constantly seeking innovative solutions and high-quality construction materials. This is where Whitespice Chemicals India Pvt Ltd steps in as a reliable partner in the journey of building a stronger and more sustainable Kolkata. In this blog, we will explore the vital role of Whitespice Chemicals, a leading Silica manufacturer and concrete admixture silica supplier in Kolkata.

Whitespice Chemicals India Pvt Ltd: The Trusted Name

When it comes to sourcing top-notch construction materials, one name stands out in the crowd: Whitespice Chemicals India Pvt Ltd. As a pioneer in the industry, Whitespice Chemicals has established itself as a trusted manufacturer and supplier of silica-based products. Whether you're looking for raw materials to enhance concrete strength or seeking specialized admixtures, Whitespice Chemicals has got you covered.

Silica Manufacturer in Kolkata: A Sustainable Choice

Silica is an essential component in modern construction due to its remarkable properties that improve concrete's durability and performance. Whitespice Chemicals takes pride in being a prominent Silica manufacturer in Kolkata, offering a range of high-quality silica products that have become a preferred choice for builders, contractors, and architects.

Whitespice Chemicals' commitment to sustainability is evident in their silica manufacturing processes. They prioritize eco-friendly practices, ensuring that their products have a minimal environmental impact. This aligns perfectly with the growing awareness of sustainable construction practices in Kolkata, making Whitespice Chemicals a preferred partner for those who value both quality and the environment.

Concrete Admixture Silica Suppliers in Kolkata: Custom Solutions

Whitespice Chemicals India Pvt Ltd is not just a Silica manufacturer; they also excel as concrete admixture silica suppliers in Kolkata. Their comprehensive range of concrete admixtures, infused with silica, offers innovative solutions to meet the evolving needs of the construction industry in the city.

Kolkata's climate can be challenging for concrete structures due to its high humidity and occasional heavy rainfall. To address these issues, Whitespice Chemicals provides advanced concrete admixtures that enhance workability, reduce permeability, and improve the resistance of concrete to harsh weather conditions. As trusted concrete admixture silica suppliers, they enable builders and contractors to create durable, weather-resistant structures that can stand the test of time.

Quality Assurance: The Whitespice Way

In the competitive construction materials market, quality assurance is non-negotiable. Whitespice Chemicals India Pvt Ltd takes quality seriously and ensures that every product that leaves their facility adheres to the highest industry standards. When you source silica or concrete admixtures from Whitespice, you can rest assured that you are investing in materials that will perform reliably and consistently.

To guarantee the quality of their products, Whitespice Chemicals employs rigorous testing and quality control procedures at every stage of the manufacturing process. This meticulous attention to detail is a testament to their commitment to delivering excellence.

Unparalleled Expertise and Support

One of the standout features of Whitespice Chemicals is their dedicated team of experts who are always ready to assist and offer guidance. Whether you have specific requirements or need assistance in choosing the right products for your project, their knowledgeable staff is at your service.

Their expertise doesn't stop at providing quality materials; Whitespice Chemicals goes the extra mile to ensure that their customers are well-informed about product usage, application techniques, and best practices. This level of support is invaluable for construction professionals seeking to optimize their projects.

Conclusion

In a city like Kolkata, where urban development and construction are thriving, having a reliable partner like Whitespice Chemicals India Pvt Ltd is paramount. As a leading Silica manufacturer in Kolkata and concrete admixture silica supplier, Whitespice Chemicals plays a pivotal role in strengthening the city's infrastructure.

Their dedication to quality, sustainability, and expert support makes them the preferred choice for those who demand the best in the industry. By choosing Whitespice Chemicals, builders and contractors are not only investing in superior construction materials but also contributing to a more sustainable and resilient Kolkata. So, for all your silica and concrete admixture needs, remember the name that Kolkata trusts – Whitespice Chemicals India Pvt Ltd.

1 note

·

View note

Text

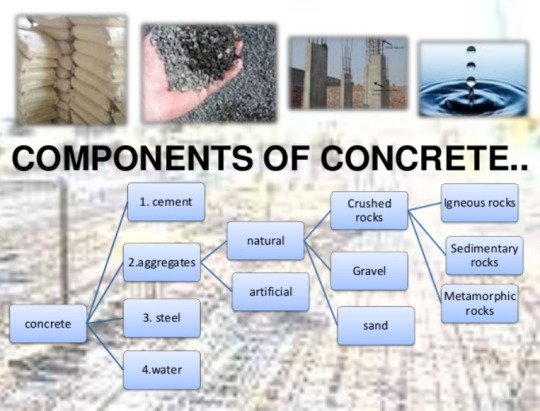

What Are The Components Of Concrete

We will explore the components of concrete and how they work together to create a durable and versatile material. Construction chemical suppliers will discuss the different types of cement, aggregates, and admixtures used in concrete production, as well as their effects on the strength and durability of the finished product.

Finally, we will look at the different methods used to test the quality of concrete so that you can make an informed decision about the best material for your project. By the end of this article, you will better understand the different components of concrete and how they work together to create a robust and reliable material.

Concrete is a composite material composed of various components, including cement, aggregates, and multiple admixtures, blended in specific ratios to create a robust and durable material. As per the top waterproofing companies in India, concrete has become an invaluable part of modern construction, offering various structural and decorative uses in small and large-scale projects.

Concrete is a building material made from cement, aggregate (gravel and sand), water, and other additives combined and poured into molds or forms and allowed to harden.

Types of Concrete:

1. Ready-mix Concrete: Ready-mix concrete is prepared at a concrete plant and then delivered to the worksite in a cement mixer truck.

2. Roller-compacted Concrete: Roller-compacted concrete is a form of concrete made with a stiffer mix and then consolidated with a roller for a denser, more robust final product.

3. Shotcrete: Shotcrete is a type of concrete sprayed from a particular nozzle onto a surface or into a form.

4. Precast Concrete: Precast concrete is a type of concrete that is poured into a form at the concrete plant and then shipped to the worksite in its final form.

Different Components of Concrete and their Functions

1. Aggregates are the most crucial component of concrete and make up the bulk of the mixture. They provide strength, stability, and structural integrity to the concrete mix. Aggregates come in different types, such as sand, gravel, crushed stone, and recycled materials. Depending on the concrete mix, different types of aggregates can be used to enhance the strength and other properties of the material.

2. Cement is the binding agent in concrete and holds the other components together. It also helps to give the concrete mix its strength, workability, and durability. Different types of cement can be used for various applications, depending on the desired strength and other characteristics of the concrete.

3. Water is used to mix and activate the concrete ingredients. It helps to create the chemical reaction necessary for the material to harden and gain strength. Too much or too little water can affect the strength and other properties of the concrete.

4. Admixtures are added to the concrete mix to provide improved workability, increased temperature resistance, and chemical and biological agents. Admixtures can also reduce the amount of cement, water, and other materials required, thus making the concrete mix more economical.

How it Affects the Strength of Concrete

Cement is the crucial ingredient in concrete, which gives it its strength. Cement is a powdery substance made of limestone, clay, and other materials that are heated and ground into a fine powder. As per the best waterproofingcompany, this powder is mixed with water, sand, and gravel to create a paste that binds the materials together.

In conclusion, concrete is a highly durable and versatile material that consists of four essential components: cement, water, aggregate, and admixtures. Each concrete element impacts the material's durability, strength, and workability. Without one of concrete admixture manufacturers, concrete would not have the same properties and would not be as effective as it is today. Therefore, it is essential to understand the concrete components to use the material in construction projects properly.

#concrete admixture manufacturers#best waterproofing company#top waterproofing companies in India#Construction chemical suppliers

0 notes

Text

Why Civil Engineers Prefer Ready-Mix Concrete Over Site-Mixed Concrete in D-Wall Construction

Before the foundation comes the right materials, hence most diaphragm wall construction companies pay high attention to the kind of concrete and slurry used in the construction process. With the right quality and quantity of materials, any construction can stand the test of time. One such vital material of the construction world is concrete, constituting refined and coarse aggregates mixed in a fixed quantity and water.

Though, selecting the right type of concrete is highly essential for any project as it can affect its strength, construction cost and time. This is why diaphragm wall contractors in India prefer using Ready-Mix Concrete (RMC) over Site-Mixed Concrete (SMC) for all deep basement underground construction.

Ready-Mixed Concrete as its name connotes is a tailor-made concrete, manufactured in a plant and delivered to the site in a ready-to-use state. Depending on the specification of the construction project, RMC can be delivered in the plastic state (similar to the concrete dough) in a barrel truck or in the dry state to be mixed on the site itself.

On the other hand, the concrete mix prepared on-site is known as Site-Mixed Concrete. There are various components involved in the preparation of SMC in specific ratios to obtain the desired strength and consistency. Hence it needs to be done under the eye of an expert.

RMC for Diaphragm Wall Construction

Talking specifically about diaphragm wall construction, RMC with cement, sand, 10MM and 20MM aggregate, ad mixer, and potable water works most efficiently. The minimum cement content should range around 330 to 400 kg per cubic meter. It is vital to note that for any high water table or underwater project like diaphragm wall construction for dams, the cement content increases by 10%.

The RMC’s retention time is around 2.5 to 3 hours and can be maintained by using admixtures. To reach optimum workability it is advisable to maintain the slump around 170-190m. The top diaphragm wall contractors in India, suggest that the minimum grading should be M25 and M15 for a diaphragm wall and guide wall respectively.

Continue reading

#ready-mix concrete#d-wall construction#diaphragm wall construction#diaphragm wall construction companies#diaphragm wall contractors#india#RMC for Diaphragm Wall Construction

4 notes

·

View notes

Text

Boost Your Project Efficiency with Ready Mix Concrete in Karachi

Introduction

In today’s fast-paced construction industry, time and quality are two of the most critical factors that can make or break a project. In bustling cities like Karachi, where construction projects are constantly rising, there is an increasing demand for efficient, reliable, and high-quality building materials. Best Ready mix concrete in Karachi has emerged as the top choice for contractors, engineers, and developers due to its ability to boost project efficiency without compromising on quality.

In this article, we will delve into the various benefits of using ready mix concrete in Karachi, how it enhances project efficiency, and why it is the ideal solution for modern construction. We'll also provide insights into sourcing the best ready mix concrete Pakistan for your construction needs.

What is Ready Mix Concrete?

Ready mix concrete (RMC) is a pre-engineered concrete mixture prepared at a batching plant and delivered directly to the construction site in a ready-to-use form. Unlike traditional on-site concrete mixing, where ingredients are manually measured and mixed, ready mix concrete is manufactured under controlled conditions, ensuring consistency in the quality and strength of the concrete.

Key Components of Ready Mix Concrete:

Cement: The binding agent that holds the aggregate and sand together.

Aggregate: Typically crushed stones or gravel that provide strength and bulk.

Water: Activates the cement to create a paste that binds the aggregates.

Admixtures: Chemical additives that can improve specific properties of the concrete, such as its workability, setting time, and durability.

This precise composition is crucial for producing consistent and high-performing concrete. Whether you are working on residential buildings, commercial complexes, or infrastructure projects, ready mix concrete in Karachi offers unmatched benefits.

Why Ready Mix Concrete is Gaining Popularity in Karachi

1. Time-Saving Solution

In large cities like Karachi, where construction projects are bound by tight deadlines, speed is of the essence. Ready mix concrete provides a time-saving solution by eliminating the need for on-site mixing. Since the concrete is delivered to the site fully prepared, you can begin your work as soon as it arrives, drastically reducing the time it would take to mix concrete manually.

Moreover, ready mix concrete is produced in large quantities, making it suitable for projects of all sizes, from small home renovations to massive commercial constructions.

2. Improved Project Efficiency

When it comes to construction, efficiency isn't just about speed; it's about ensuring that each phase of the project runs smoothly. With ready mix concrete, you can streamline your construction processes. Since the concrete is produced off-site and delivered to you in a ready-to-use form, there is less labor involved in mixing, measuring, and handling materials.

Moreover, ready mix concrete helps in minimizing wastage, as precise quantities are delivered to the site. This ensures that you only use what you need, eliminating excess material and reducing costs in the long run.

3. Consistency and Quality Control

One of the biggest challenges in traditional on-site mixing is ensuring consistency in the quality of the concrete. With ready mix concrete, you can be sure of receiving the same high-quality material for every batch. Since the concrete is produced under controlled conditions in a factory environment, the proportions of the mix are precisely measured, resulting in a uniform product.

This consistency is especially important for large projects, where variations in the concrete's strength or durability can lead to structural issues down the line. By using ready mix concrete in Karachi, you ensure that your project is built to last with materials of consistent quality.

4. Reduced Labor Costs

Hiring skilled labor for on-site concrete mixing can be costly. By opting for ready mix concrete, you can reduce the number of workers needed on-site, as the concrete arrives fully prepared. This not only cuts down on labor costs but also minimizes the margin for human error, which can lead to costly mistakes or delays in construction.

5. Environmental Benefits

Ready mix concrete is an eco-friendly solution that can help reduce the environmental impact of construction. By producing concrete in controlled environments, batching plants can optimize the use of raw materials and reduce waste. Additionally, many ready mix concrete suppliers in Karachi incorporate recycled materials into their products, further reducing the carbon footprint of your project.

Moreover, the use of admixtures in ready mix concrete can enhance its durability and longevity, reducing the need for repairs and replacements in the future. This contributes to the overall sustainability of your project by minimizing the use of additional materials over time.

Choosing the Right Ready Mix Concrete Supplier in Karachi

Now that you understand the benefits of ready mix concrete, the next step is choosing the right supplier for your project. With numerous suppliers available in Karachi, it’s essential to select a company that meets your specific needs.

Factors to Consider When Choosing a Supplier:

Reputation and Experience

When looking for ready mix concrete in Karachi, always consider the reputation and experience of the supplier. Established companies with a strong track record are more likely to provide high-quality products and reliable service. Look for customer reviews, testimonials, and references to gauge the reliability of a supplier.

Quality Assurance

Quality control is a critical factor in concrete production. Ensure that your supplier follows strict quality control measures and tests the concrete for consistency, strength, and durability before delivery. Ask about their production process, the types of admixtures they use, and their testing protocols to ensure that you’re getting the best product.

Delivery Capabilities

The timely delivery of ready mix concrete is crucial for maintaining the momentum of your project. Check the supplier’s delivery capabilities, including their fleet size, delivery times, and their ability to handle large orders. A reliable supplier should have the resources to meet your project’s demands without causing delays.

Customization Options

Different construction projects have different requirements. Whether you need concrete with enhanced durability, faster setting times, or increased workability, your supplier should be able to customize the concrete mix to meet your specific needs. Be sure to ask about the range of customization options available.

Pricing and Affordability

While quality should be your top priority, it’s also important to consider the pricing of the ready mix concrete in Karachi. Compare quotes from multiple suppliers to get the best deal for your project. Keep in mind that the cheapest option may not always be the best, so consider the overall value for money, including the quality of the concrete and the reliability of the service.

How Ready Mix Concrete Enhances Project Safety

Safety is a top priority in any construction project. Ready mix concrete enhances site safety in several ways:

Reduced On-Site Activity: Since the concrete is mixed off-site, there’s less machinery, equipment, and labor required at the construction site. This reduces the risk of accidents caused by heavy machinery and manual labor.

Consistent Strength: Ready mix concrete is manufactured under controlled conditions, ensuring consistent strength and durability. This reduces the risk of structural failures or issues caused by inconsistent concrete mixes.

Less Material Handling: With ready mix concrete, you don’t need to handle raw materials like sand, cement, and aggregate on-site. This minimizes the risk of material-related injuries or accidents.

Conclusion

Whether you’re working on a small residential project or a large commercial development, ready mix concrete offers a host of benefits that can significantly boost your project’s efficiency. From saving time and reducing labor costs to ensuring consistent quality and improving site safety, ready mix concrete is the ideal solution for modern construction projects.

By choosing the right supplier of ready mix concrete Pakistan, you can ensure that your project runs smoothly, on time, and within budget. With its time-saving capabilities, superior quality, and environmentally friendly properties, ready mix concrete is the smart choice for anyone looking to enhance their construction project in Karachi.

0 notes

Text

ECMAS is known as one of the premium concrete admixtures manufacturers in India. Get absolute strength, enhanced workability and durability for your concrete buildings with ECMAS concrete admixtures.

visit: https://ecmas.in/

#construction chemical companies#admixture companies in india#concrete admixtures manufacturers#ecmasgroup#concrete admixture manufacturer in India

0 notes

Text

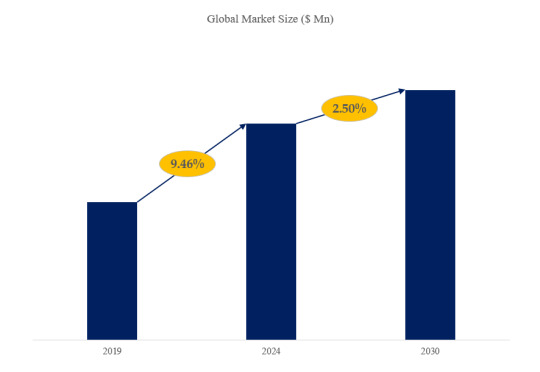

PVA (alcool polyvinylique), Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 13 Premières Entreprises

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de PVA (alcool polyvinylique) 2024-2030”, publié par QYResearch, la taille du marché mondial de PVA (alcool polyvinylique) devrait atteindre 3903 millions de dollars d'ici 2030, à un TCAC de 2.5% au cours de la période de prévision.

Figure 1. Taille du marché mondial de PVA (alcool polyvinylique) (en millions de dollars américains), 2019-2030

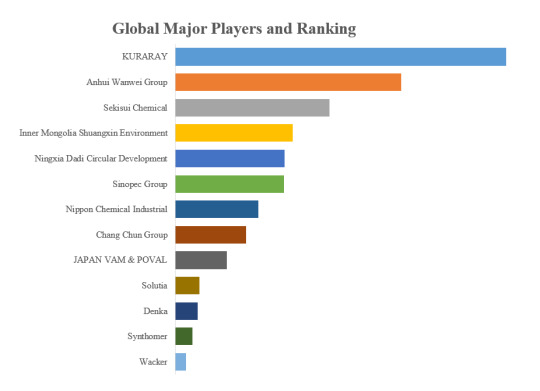

Selon QYResearch, les principaux fabricants mondiaux de PVA (alcool polyvinylique) comprennent KURARAY, Anhui Wanwei Group, Sekisui Chemical, Inner Mongolia Shuangxin Environment, Ningxia Dadi Circular Development, Sinopec Group, Nippon Chemical Industrial, Chang Chun Group, JAPAN VAM & POVAL, Solutia, etc. En 2023, les cinq premiers acteurs mondiaux détenaient une part d'environ 67.0% en termes de chiffre d'affaires.

Figure 2. Classement et part de marché des 13 premiers acteurs mondiaux de PVA (alcool polyvinylique) (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

The key market drivers for the PVA (Polyvinyl Alcohol) market:

1. Increasing Demand for Eco-Friendly and Biodegradable Materials: The growing focus on sustainability and the shift towards environmentally-friendly products have driven the demand for PVA, a water-soluble and biodegradable polymer, as a replacement for traditional petroleum-based materials.

2. Expansion of the Packaging Industry: The increasing use of PVA in various packaging applications, such as water-soluble films, coatings, and adhesives, has been a significant driver for the market growth.

3. Rising Adoption in the Textile and Paper Industry: PVA's versatility in textile and paper applications, including as a sizing agent, binder, and coating material, has contributed to its widespread adoption in these industries.

4. Increasing Demand for Emulsifiers and Dispersants: PVA's ability to act as an effective emulsifier and dispersant in various industrial and consumer applications has driven its demand in the chemicals industry.

5. Expansion of the Construction and Building Materials Sector: The use of PVA in construction materials, such as cement and concrete admixtures, as well as in adhesives and sealants, has been a key driver for the market.

6. Growth of the Personal Care and Cosmetics Industry: PVA's applications in the personal care and cosmetics industry, including as a thickening agent, emulsifier, and film former, have contributed to the market's expansion.

7. Advancements in PVA Production and Processing Technologies: Improvements in PVA manufacturing processes and the development of new, high-performance PVA grades have made these products more accessible and appealing to a wider range of industries.

8. Increasing Demand for Water-Soluble and Dissolvable Products: The growing demand for water-soluble and dissolvable products, such as laundry detergent pods and medical devices, has fueled the need for PVA as a key ingredient.

9. Expansion of the Pharmaceutical and Medical Device Industry: The use of PVA in various pharmaceutical and medical applications, such as drug delivery systems, wound dressings, and medical implants, has been a significant driver for the market.

10. Rising Adoption in the Electronics and Semiconductor Industry: PVA's applications in the electronics and semiconductor industry, including as a protective coating and cleaning agent, have contributed to the growth of the PVA market.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes

Text

Benefits of Using Concrete Admixtures in Construction Projects

Several challenges affect the building sector, including Innovative solutions to meet the commitment to sustainable construction, tight job-site timelines caused by the continuous construction boom and the lack of trained workers, and rising costs resulting from scarcer raw materials. Concrete can be a vital component in helping to tackle the issues that building in the future will provide with a different approach.

Despite being one of the priciest building materials, concrete offered by the concrete admixture manufacturers still has a lot to offer. Concrete admixtures that are potent and creative are needed to realize this potential. Concrete admixtures can speed up the entire construction process, increase flexibility, cut costs, and minimize emissions, although they make up a very small portion of the total concrete mix.

Ensuring concrete's strength, durability, and workability is essential for successful construction projects. Concrete admixtures are necessary for accomplishing these objectives because they improve the functionality of concrete mixtures.

The Benefits Of Using Concrete Admixtures:

Using concrete admixtures in construction projects offers several benefits:

Improved Workability:

Concrete admixtures enhance workability, facilitating easier mixing, placement, and finishing. This improves construction efficiency, reducing labor costs. By optimizing concrete's handling characteristics, admixtures streamline construction processes, enabling smoother operations and minimizing the need for additional workforce, ultimately saving time and money.

Increased Strength and Durability:

Admixtures play a vital role in enhancing the strength and durability of concrete, resulting in the construction of resilient and long-lasting structures. By improving the concrete's resistance to moisture, chemicals, and temperature changes, admixtures ensure the structure's integrity over time. They can increase the concrete's resistance to adverse weather, lowering the possibility of damage and lengthening the building's lifespan. This enhanced resilience results in lower maintenance expenses and an extended lifespan for the building. Admixtures also encourage the use of long-lasting materials and reduce the need for frequent replacements or repairs, which add to the building industry's overall sustainability.

Enhanced Setting and Curing:

Admixtures can accelerate or delay the setting time of concrete, providing greater flexibility in construction schedules. They also improve the curing process, ensuring proper hydration and reducing the risk of cracks or shrinkage.

Improved Finish and Aesthetics:

Certain concrete additives offer additional benefits by enhancing concrete's surface finish and appearance. They can provide a smoother texture, improved color, or reduced permeability, making them ideal for architectural projects that demand a visually appealing finish. These admixtures create aesthetically pleasing structures that stand out in quality and design.

Cost Savings:

In addition to the benefits above, concrete additives offer cost savings by reducing the need for excessive cement or water in concrete mixtures. Furthermore, they mitigate common construction issues like segregation, bleeding, or extreme heat generation. By addressing these challenges, admixtures contribute to significant time and cost savings throughout construction.

Conclusion

Concrete admixtures offer various advantages that significantly contribute to efficient construction processes, improved structural performance, and enhanced aesthetics across multiple construction projects. Their versatile benefits make them indispensable tools for achieving optimal results, ensuring durability, and enhancing the overall quality of concrete structures.

Resource Box:

Vinati Organics is a top acrylic super plasticizer manufacturer. Their high-performance products are popular in buildings. With a focus on quality and innovation, they create reliable solutions to fulfill the different needs of their consumers.

0 notes

Text

Sodium Gluconate Prices | Pricing | Trend | News | Database | Chart | Forecast

Sodium Gluconate Prices is a chemical compound primarily utilized in the construction, food, and pharmaceutical industries due to its excellent chelating properties. In recent years, the demand for sodium gluconate has risen steadily across global markets, influencing its price trends. Various factors contribute to the fluctuation in sodium gluconate prices, including the cost of raw materials, production processes, and supply-demand dynamics. Understanding these trends is essential for businesses and investors keen on navigating the sodium gluconate market effectively.

One of the primary determinants of sodium gluconate prices is the availability and cost of raw materials, particularly glucose, which is derived from corn or other starch-rich crops. Any disruption in the supply chain of these raw materials can lead to price hikes. For instance, adverse weather conditions or agricultural policy changes that affect corn production could result in decreased glucose availability, subsequently driving up sodium gluconate production costs. Additionally, the chemical industry is sensitive to energy prices, as the production of sodium gluconate requires considerable energy input. Fluctuations in the cost of energy, particularly in regions reliant on fossil fuels, can also impact the final price of the compound.

On the supply side, sodium gluconate production is concentrated in a few major countries, notably China, which has emerged as a dominant player in the global market. The Chinese chemical industry benefits from economies of scale, enabling it to produce sodium gluconate at competitive prices. However, any disruption in Chinese manufacturing, whether due to environmental regulations, geopolitical tensions, or economic downturns, could significantly affect the global supply chain, leading to price volatility. Recent years have witnessed environmental crackdowns in China, pushing some chemical manufacturers to either halt or scale back their operations. This reduction in supply can lead to short-term spikes in sodium gluconate prices globally.

Demand-side factors also play a crucial role in shaping sodium gluconate prices. The construction industry is one of the largest consumers of sodium gluconate, as it is used as a concrete admixture to improve workability and delay setting times. Therefore, the health of the construction industry, particularly in emerging markets, directly influences demand for sodium gluconate. When construction activity is booming, particularly in infrastructure projects, the demand for sodium gluconate rises, exerting upward pressure on prices. Conversely, during periods of economic slowdown, when construction projects are delayed or scaled back, the demand for sodium gluconate tends to decline, leading to downward pressure on prices.

Get Real Time Prices for Sodium Gluconate: https://www.chemanalyst.com/Pricing-data/sodium-gluconate-1414

The food and pharmaceutical industries are also significant consumers of sodium gluconate. In the food industry, sodium gluconate is used as a preservative, stabilizer, and flavor enhancer, particularly in processed foods and beverages. As consumer preferences shift towards processed foods with longer shelf lives, the demand for sodium gluconate from food manufacturers has been increasing. In the pharmaceutical sector, sodium gluconate serves as a chelating agent, enhancing the stability of various medications and formulations. The increasing global demand for pharmaceuticals, driven by factors such as population growth and the rise of chronic diseases, also contributes to the steady demand for sodium gluconate. However, stringent regulations governing food and pharmaceutical additives can sometimes restrict market growth, indirectly affecting sodium gluconate prices.

Another critical factor influencing sodium gluconate prices is international trade dynamics, including tariffs and trade barriers. As sodium gluconate is primarily produced in a few countries, it is heavily traded across borders. Trade policies, such as import tariffs or export restrictions, can alter the pricing structure of sodium gluconate. For instance, trade disputes between major economies like the United States and China can lead to the imposition of tariffs on chemical products, including sodium gluconate, making it more expensive for importers in affected countries. Additionally, logistical issues, such as disruptions in shipping routes or port closures due to pandemics or other crises, can lead to delays in supply and subsequently push up prices.

Technological advancements in the production of sodium gluconate also influence price trends. Over the years, manufacturers have been investing in research and development to improve production efficiency and reduce costs. The adoption of new technologies that streamline the production process can lead to lower prices in the long run. However, these innovations often require significant upfront investment, which can lead to temporary price increases as manufacturers seek to recoup their costs.

Environmental sustainability is another emerging factor that could impact sodium gluconate prices. As global awareness of environmental issues grows, many countries are implementing stricter regulations on chemical manufacturing to reduce emissions and minimize waste. Compliance with these regulations often requires manufacturers to invest in cleaner production methods, which can raise production costs. For example, the transition to greener energy sources or the implementation of waste reduction technologies could increase operational expenses for sodium gluconate producers, potentially leading to higher prices. However, the long-term benefits of sustainable production methods, such as enhanced brand reputation and access to eco-conscious markets, may help offset these costs.

Market competition also plays a role in determining sodium gluconate prices. The global market is characterized by the presence of a few dominant players and a large number of smaller, regional producers. Intense competition among manufacturers can lead to price wars, particularly in regions with abundant production capacity. On the other hand, in markets where a few key players control the majority of supply, prices tend to be more stable, albeit higher due to the lack of competitive pressure. The entry of new players into the market can disrupt established pricing structures, particularly if they introduce innovative production methods or offer lower prices to gain market share.

In conclusion, sodium gluconate prices are influenced by a complex interplay of factors, including raw material costs, energy prices, supply chain dynamics, demand from various industries, international trade policies, technological advancements, environmental regulations, and market competition. Businesses operating in industries reliant on sodium gluconate must closely monitor these factors to make informed decisions regarding procurement and pricing strategies. Given the volatility of the global chemical market, staying abreast of industry trends and potential disruptions is crucial for navigating sodium gluconate price fluctuations effectively.

Get Real Time Prices for Sodium Gluconate: https://www.chemanalyst.com/Pricing-data/sodium-gluconate-1414

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Sodium Gluconate#Sodium Gluconate Price#Sodium Gluconate Prices#Sodium Gluconate Pricing#Sodium Gluconate News#Sodium Gluconate Price Monitor

0 notes

Text

The Benefits of Ready Mix Concrete in Pakistan’s Coastal Cities

Introduction:

Ready mix concrete is revolutionizing construction in Pakistan’s coastal cities, offering significant advantages for builders and developers. This article explores the numerous benefits of ready mix concrete Pakistan and ready made concrete Karachi, highlighting why these solutions are ideal for coastal regions.

Understanding Ready Mix Concrete:

Ready mix concrete Pakistan refers to concrete that is manufactured at a central plant and delivered to the construction site in a ready-to-use form. This method offers consistency and high quality, which are crucial for the durability and strength of structures, especially in coastal environments.

Consistency and Quality Control:

One of the primary benefits of ready mix concrete Pakistan is the consistency it offers. Unlike traditional concrete mixing methods, which can vary depending on the site conditions and manual mixing, ready mix concrete is produced under controlled conditions. This results in a uniform mixture that adheres to the required specifications, ensuring the quality of the concrete.

In coastal cities like Karachi, where environmental conditions can be harsh, maintaining the quality of concrete is essential. The controlled production process of ready made concrete Karachi helps mitigate the risks associated with variations in mix proportions and curing processes.

Enhanced Durability:

Coastal environments are challenging for construction due to high humidity and salt content in the air, which can lead to corrosion and degradation of building materials. Ready mix concrete Pakistan is specifically designed to address these issues. The mix can be tailored to include additives that enhance its resistance to moisture and salt, thereby increasing its longevity and performance in coastal conditions.

The use of ready made concrete Karachi in coastal construction projects ensures that structures are better equipped to handle the effects of salty air and high humidity, reducing maintenance costs and extending the lifespan of the buildings.

Time and Labor Efficiency:

Using ready mix concrete Pakistan streamlines the construction process. Since the concrete is pre-mixed and ready to use, it reduces the time spent on-site mixing and preparation. This efficiency is particularly beneficial for large-scale projects in coastal cities where time is a critical factor.

Moreover, ready made concrete Karachi reduces the need for on-site labor to mix concrete, allowing construction teams to focus on other aspects of the project. This not only speeds up construction but also lowers labor costs, making it a cost-effective option for developers.

Environmental Benefits:

Ready mix concrete production is more environmentally friendly compared to traditional methods. The central batching plants for ready mix concrete Pakistan are designed to minimize waste and reduce the carbon footprint of concrete production. Additionally, these plants often use recycled materials, contributing to a more sustainable construction process.

In coastal cities, where environmental regulations are becoming increasingly stringent, opting for ready made concrete Karachi aligns with green building practices and supports efforts to reduce the environmental impact of construction activities.

Customization and Flexibility:

Ready mix concrete Pakistan offers flexibility in terms of mix design and specifications. This customization is particularly valuable for projects in coastal areas, where specific properties like enhanced resistance to corrosion and moisture are required. Builders can work with concrete suppliers to create a mix that meets the unique demands of their projects.

Ready made concrete Karachi can be customized to include various additives and admixtures, allowing for a wide range of applications, from residential buildings to commercial structures, all tailored to withstand the challenges of coastal environments.

Conclusion:

The advantages of ready mix concrete Pakistan and ready made concrete Karachi are evident in the context of coastal construction. From ensuring high-quality and durable structures to enhancing efficiency and supporting environmental sustainability, ready mix concrete is a valuable asset for builders in Pakistan’s coastal cities. By leveraging these benefits, construction projects can achieve greater success and longevity, even in challenging coastal conditions.

0 notes

Text

What Is Commercial Concrete Structuring?

Commercial concreting involves the construction of business structures, such as offices and stores. The concrete used in these structures is often stronger than residential concrete, and the contractors use specialized coatings that can withstand heavy foot traffic and weight.

Commercial concreting is made by mixing cement, water, and aggregate materials to form a paste. This mixture is very versatile and can be modified to create different types of concrete.

It is a durable material

Concrete is a durable material that can resist different factors that may wear down other building materials. This includes erosion, tensile and compressive stress, chemical attacks, and extreme weather conditions. This makes it ideal for commercial buildings, which often have a long lifespan and require structural integrity.

A mix of cement paste and aggregates, concrete is also highly versatile in terms of design. Its varying textures and colors allow designers to create eye-catching architectural features that can fit any aesthetic. Concrete floors are durable and easy to clean, making them an excellent choice for businesses with high traffic. They can be stained or polished to achieve a unique look that complements the rest of the space.

In order to ensure the durability of commercial concrete, it is essential to use highquality mixtures and advanced curing techniques. The addition of fiber reinforcements and admixtures can increase the strength and resistance to environmental factors. Additionally, the use of steam curing blankets can expedite the curing process and improve the early strengths of concreting.

It is affordable

There are a few factors that can impact the cost of commercial concrete projects. For example, permitting and inspection costs can add up quickly and should be considered in your project budget. Fortunately, there are strategies that can be used to mitigate these expenses. These include setting up contingency funds and taking out insurance policies.

A reputable Commercial Concrete Construction Contractor is the magician that transforms your vision into a tangible masterpiece. Their expertise in coordinating subcontractors and managing timelines minimizes delays and keeps your project on budget. They also perform final inspections and facilitate the handover of your new space.

Unlike wood, concrete is not susceptible to pests or weather damage and requires minimal maintenance. It also blocks noise and provides an attractive look to your commercial property. The savings in maintenance costs can be significant over the life of the wall. In addition, concrete is durable and does not burn. This can reduce the need for fire protection systems in your building, lowering your insurance premiums.

It is easy to install

Commercial concrete contractors can be hired for various projects in a variety of settings. They have the equipment and manpower necessary to complete the work in a timely manner. They also have a good understanding of local building codes and regulations. In addition, they are often familiar with insurance requirements and worker safety protocols.

Commercial structures need to be durable and able to stand up to a variety of conditions, including extreme temperatures, fungi, and pests. Concrete is a great option because it can resist many of these factors and is not easily damaged or worn down. It is also very cost-effective and can last for a long time.

Concrete can be molded and colored to create a unique look. This allows architects to express their creativity, as well as provide practical functionality. For example, commercial walls constructed of precast concrete can be stamped with a pattern that mimics the look of brick or stone. There are even epoxies that can change the appearance of concrete dramatically.

It is customizable

When it comes to commercial construction, every project is unique. You can have an office, manufacturing plant, retail shopping center, or anything else built to your exact specifications. If you’re looking for a customized structure, consider working with a design-build firm, which handles the entire process from beginning to end.

When choosing a contractor, be sure to ask about their experience and qualifications. Find out how long they’ve been in business, and ask for a portfolio of previous projects. If you’re still not comfortable, schedule an interview to vet them even further.

Commercial concrete installation involves professionally laying concrete in business establishments. It is known for its durability, low maintenance costs, and customization options, making it ideal for high-traffic areas. Additionally, it provides a safe surface for workers and customers and reduces the risk of accidents. It is also a green option, as it can be recycled and has a low impact on the environment.

0 notes

Text

Digital Commerce Platform Market Developments, Trends & Opportunities till 2032

Digital Commerce Platform Market provides in-depth analysis of the market state of Digital Commerce Platform manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Digital Commerce Platform in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Digital Commerce Platform Market Report:

The report offers a comprehensive and broad perspective on the global Digital Commerce Platform Market.

The market statistics represented in different Digital Commerce Platform segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Digital Commerce Platform are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Digital Commerce Platform.

Major stakeholders, key companies Digital Commerce Platform, investment feasibility and new market entrants study is offered.

Development scope of Digital Commerce Platform in each market segment is covered in this report. The macro and micro-economic factors affecting the Digital Commerce Platform Market

Advancement is elaborated in this report. The upstream and downstream components of Digital Commerce Platform and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/digital-commerce-platform-market-100549

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Laboratory Analytical Instrumentation MarketMarket Size

Global Energy Harvesting System MarketMarket Share

Global Parenteral Packaging MarketMarket Growth

Stem Cells MarketMarket

Clinical Reference Laboratory Services MarketMarket Share

Concrete Waterproofing Admixture MarketMarket Growth Rate

Female Stress Urinary Incontinence Treatment Devices MarketMarket Forecast

Global Ghee MarketMarket Size

Succulent Plant MarketMarket Growth

Vanadium Redox Battery (VRB) MarketMarket Analysis

SASE (Secure Access Service Edge) MarketMarket Size

Global Automotive Inertial Measurement Unit (IMU) Sensors MarketMarket Share

Global Battery Management System MarketMarket Growth

Collaborative Robots MarketMarket

Urometer MarketMarket Share

Automotive Rubber Molded Components MarketMarket Growth Rate

Throat Lozenges MarketMarket Forecast

Global UVC LED MarketMarket Size

Vascular Surgery Minimally Invasive Surgical Instruments MarketMarket Growth

Medicinal Mushroom Extract MarketMarket Analysis

Nickel-plated Steel Sheet in Batteries MarketMarket Size

Global Augmented and Virtual Reality MarketMarket Share

Global C. difficile Infection Therapeutic Drug MarketMarket Growth

Orthopedic Biomaterials MarketMarket

Electric Vehicle Battery Swapping System MarketMarket Share

Capsule Endoscopy System MarketMarket Growth Rate

Fabric Softeners and Conditioners MarketMarket Forecast

Global Civilian Less Lethal and Self Defense Weapons MarketMarket Size

Pharmaceutical Contract Manufacturing and Contract MarketMarket Growth

Automotive Steering Systems MarketMarket Analysis

Cloud Crew Management System MarketMarket Size

Global Silicon Carbide Wafer MarketMarket Share

Global Solution Polymerized Styrene-Butadiene Rubber (SSBR) MarketMarket Growth

Aircraft Interface Device MarketMarket

Beauty Jelly MarketMarket Share

Clone Imager MarketMarket Growth Rate

Graphite Polystyrene Foam Board Market Market Forecast

Global Pneumatic On-off Guns MarketMarket Size

Methyl Chloroform MarketMarket Growth

0 notes