#Commercial Grade Hydrochloric Acid

Explore tagged Tumblr posts

Text

Innovative and Superior Chemistry: AR Grade Distilled Chlorosulfonic Acid by Maruti Fine Chemicals

In the field of chemical manufacturing, Maruti Fine Chemicals is considered a pioneer in innovation and quality. The company's latest breakthrough development of AR Grade Distilled Chlorosulfonic Acid will redefine industry standards and enhance the capabilities of researchers and industry alike.

Chlorosulfonic acid is an important reagent in a variety of chemical processes, and at Multi Fine Chemicals it undergoes a careful distillation process to achieve the highest level of purity. It is called analytical reagent (AR). This means researchers and professionals can rely on unparalleled quality products for their most critical applications.

The benefits of AR Grade Distilled Chlorosulfonic Acid Maruti Fine Chemical AR Grade are numerous. The increased purity significantly reduces impurities and contaminants, minimizing the risk of unwanted side reactions and ensuring experimental reproducibility. This high-quality product is intended to become an essential tool in laboratories, research facilities, and production facilities.

Maruti Fine Chemicals has always been committed to sustainability and this commitment extends to our AR Grade Distilled Chlorosulfonic Acid. The production process is designed to be environmentally friendly and is subject to strict quality and safety standards. The company's commitment to responsible manufacturing practices ensures that customers not only receive first-class products, but also contribute to a greener and more sustainable future.

customers can trust Multi Fine Chemical not only for product quality but also for comprehensive customer support. The company's team of experts is always available to provide technical support to help customers maximize the potential of his AR grade distilled chlorosulfonic acid in their applications.In conclusion, Maruti Fine Chemicals' AR Grade Distilled Chlorosulfonic Acid is revolutionizing the chemical industry. Its exceptional purity, combined with the company's commitment to sustainability and customer care, sets a new standard of excellence. This cutting-edge product from Maruti Fine Chemicals enables researchers, scientists and industry professionals to take their research to a new level.

#Fuming Sulphuric Acid ( Oleum Acid )#AR Grade Distilled Chlorosulfonic Acid#Fuming Nitric Acid + AR Grade Sulphuric Acid#AR Grade Hydrochloric Acid#Commercial Grade Hydrochloric Acid

0 notes

Text

Hastelloy C276 SB575 Thick Plate Manufacturers in Oman - Mehta Metals

One of the most trustworthy substances within the commercial corporation for excessive-common performance alloys designed to withstand difficult instances is the Hastelloy C276 SB575 Thick Plate. Known for its splendid resistance to corrosion, oxidation, and pressure corrosion cracking, Hastelloy C276 is considerably used in industries that call for long-lasting, excellent substances for hard applications. Mehta Metals is a relied-on name in Oman for manufacturing and offering top-rate Thick Plates of Hastelloy C276 SB575, making sure that groups all through some sectors have access to top-grade substances for their responsibilities.

What Makes Hastelloy C276 SB575 Unique?

Hastelloy C276 is a nickel-molybdenum-chromium alloy designed especially to offer unmatched corrosion resistance. This alloy is highly effective in managing harsh conditions, such as exposure to chemical environments, excessive temperatures, and lowering or oxidizing media. Thick Plates of Hastelloy C276 SB575 are mostly utilized in industries that deal with competitive chemical materials, high-stress systems, and excessive-temperature environments. The key capabilities of Hastelloy C276 SB575 embody:

Superior Corrosion Resistance: Hastelloy C276 is famous for its exquisite resistance to an extensive range of corrosive materials, together with seawater, acetic acid, sulfuric acid, and hydrochloric acid. Additionally, it resists stress corrosion cracking, pitting, and crevice corrosion—all of which can be common problems inside the chemical and maritime sectors.

Reliable High-Temperature Power: Because of its awesome performance at immoderate temperatures, the alloy may be used in response vessels, heating exchangers, and particular applications that might be exposed to high temperatures.

The versatility of Hastelloy in Various Industries: Hastelloy C276 is adaptable enough to be used in loads of industries, from aerospace to chemical processing, way to its distinctly high weldability and formability.

Extending Long Service Life: The alloy’s durability and resilience ensure long-lasting performance, decreasing the need for commonplace replacements and protection.

Given these properties, Hastelloy C276 SB575 is in reality ideal desire for annoying applications in industries like chemical processing, strength generation, aerospace, and environmental technology.

Why Choose Us for Hastelloy C276 SB575 Thick Plates in Oman?

We have installed ourselves as a leading producer and dealer of superb Thick Plates of Hastelloy C276 SB575 in Oman. Here are some motives why organizations in Oman and beyond agree with us for their alloy desires:

1. Premium-Quality Products

At our organization, we make sure that each one of our Thick Plates of Hastelloy C276 SB575 is synthesized with the use of simplest the exceptional materials sourced from licensed vendors. Our product goes through rigorous terrific test processes, which include finding out for tensile strength, hardness, and corrosion resistance, to make certain they meet the best industry standards. We take pride in providing products that might resist the most tough environments.

2. Customization to Your Specifications

Understanding that high-quality industries require specific dimensions and finishes, we offer custom-made Thick Plates of Hastelloy C276 SB575 to satisfy your precise needs. Whether you require plates of numerous thicknesses, periods, or floors to give up, we can offer tailor-made solutions to shape your task necessities. This flexibility guarantees you get the right product for your applications, minimizing waste and slicing down on machining time.

3. Wide Range Availability: Fulfilling Customized Needs

We offer a complete range of Thick Plates of Hastelloy C276 SB575 in several thicknesses, from thinner sheets to heavy-responsibility plates designed for excessive-pressure applications. Our significant stock permits us to cater to industries ranging from chemical processing to nuclear strength, making sure we meet each small-scale and large-scale wish efficaciously.

4. Hastelloy Thick Plates at Affordable Pricing

As a dependent producer of Thick Plates of Hastelloy C276 SB575 in Oman, we give competitive pricing without compromising on tremendous. Our rate-powerful solutions are designed to healthy internal your challenge’s finances, making us a wonderful preference for agencies trying to maximize their investment without sacrificing fabric performance.

5. Delivering Your Needs On-Time

In industries where time is of the essence, we ensure well-timed transport of all orders. Our inexperienced logistics community in Oman and internationally permits us to satisfy large and customized orders on a table, ensuring you can hold your tasks on route at once.

6. We Offer Technical Support and Expertise

Choosing the right material for your applications can be a complicated choice. Our organization presents professional technical help to guide you via the choice method. Our organization can offer advice on the amazing alloy grades, dimensions, and fabrication strategies for your needs, ensuring you are making an informed choice each time.

Applications of Hastelloy Thick Plates: Excellent for High-Temperature and Corrosive Environments

Thick Plates of Hastelloy C276 SB575 are utilized in a wide variety of applications where performance at high temperatures and corrosion resistance are critical. Typical uses include the following:

Chemical Manufacturing Plants: Reactors, heating exchangers, and pipe systems that cope with harsh chemical substances like chlorine, sulfuric acid, and hydrochloric acid all use chemical processing.

Power Generation Equipment: Hastelloy C276 plates are perfect for energy plant applications, which comprise stress vessels, heat exchangers, and additives subjected to excessive temperatures.

Aerospace and Marine Technologies: The alloy’s immoderate electricity and resistance to oxidation make it a desired product for additives in the aerospace and marine industries, together with exhaust systems and structural additives.

Environmental and Waste Treatment: Hastelloy C276 is utilized in structures that control unsafe waste, consisting of incinerators and waste treatment vegetation, because of its great resistance to corrosive gases and beverages.

Why Mehta Metals is the Ideal Partner for Thick Plates of Hastelloy C276 SB575 in Oman

When it entails sourcing exquisite Thick Plates of Hastelloy C276 SB575 in Oman, we are your trusted associate. We are committed to presenting our clients with top-grade products, custom-designed answers, aggressive prices, and first-rate customer support. Our willpower to first-class and client pride makes us a preferred preference for businesses in Oman and across the globe.

For more information or to locate an order, reach out to Mehta Metals today. Let us assist you meet the demands of your task with the best Hastelloy C276 SB575 Thick Plates to be had in the marketplace.

0 notes

Text

In a commercial-grade hydrochloric acid (HCl) production process, a synthesis unit utilizes a 2000°C top-fired combustion chamber made from impervious graphite (steel-jacketed) to process hydrogen and chlorine. The unabsorbed HCl gases are subsequently directed to a Tail Gas Tower (TGT), where the majority of HCl traces are absorbed. The remaining vent gas, which contains trace amounts of HCl (<5 ppbv) and water vapor, is then vented out of the system.

Challenge:

The customer encountered difficulty in installing a flowmeter for measuring the vent gas, which contains:

Trace amounts of HCl (<5 ppbv).

Water vapor.

Very low gas velocity.

The customer reported that no existing flow measurement solution was capable of handling these specific conditions effectively, particularly due to the corrosive nature of HCl and the low velocity of the vent gas.

Proposed Solution:

After thorough analysis of the customer's requirements and challenges, the expert proposes a customized flow measurement solution that incorporates a HALAR-coated sensor probe.

HALAR coating (perfluoroalkoxy) offers several advantages:

Chemical Resistance: HALAR is known for its excellent resistance to a wide range of chemicals, including hydrochloric acid. This makes it an ideal choice for the sensor probe exposed to the corrosive vent gases.

Water Vapor Compatibility: The coating also performs well in environments containing water vapor, preventing issues such as condensation or corrosion in the measurement system.

Durability: The HALAR coating enhances the longevity and durability of the sensor probe, especially in the harsh conditions of the vent gas stream.

The wetted parts of the flowmeter, which come into direct contact with the vent gas, will be coated with HALAR to ensure they can withstand the corrosive effects of HCl and water vapor. This customized solution will allow for accurate flow measurement, even at very low gas velocities, while also ensuring the longevity of the equipment.

The HALAR-coated sensor probe provides a practical and durable solution to the flow measurement challenge in the vent gas stream, offering accurate results while withstanding the harsh chemical and environmental conditions. This customized approach ensures reliable operation, even in a challenging industrial setting where traditional flowmeters would not perform adequately.https://leomi.in/vent-process-gas-flow-measurement-in-chemical-industry/

0 notes

Text

What is Titanium Alloy GR 2, GR 5, GR7 Round Bar?

In the arena of material technology, titanium alloys have received substantial interest for their extraordinary properties and diverse uses. Among the ones, Titanium Alloy GR 2, GR 5, and GR 7 round bars stand out for their precise characteristics. This post explores the titanium grades, their abilities, and why they're critical in numerous industries. As a prominent provider of titanium products, collectively with Titanium Alloy GR 2 round bars, Titanium Alloy GR 5 round bar exporters, and Titanium Alloy GR 7 round bar manufacture, Jay Steel Corporation is dedicated to offering pinnacle-awesome materials for various applications.

What is Titanium Alloy?

Titanium alloys are metals made in most cases from titanium and encompass various portions of different factors to decorate precise properties. These alloys are renowned for their high strength-to-weight ratio, superb corrosion resistance, and functionality to face a lot of severe temperatures. As a result, titanium alloys are extensively applied in aerospace, marine, scientific, and chemical industries.

Grades of Titanium Alloy

Titanium Alloy GR 2 Round Bar

Titanium Alloy GR 2 is a commercially natural titanium grade identified for its corrosion resistance and formability. This grade is regularly applied in environments that require immoderate corrosion resistance but does not call for the electricity of alloyed titanium grades. GR 2 is especially effective in:

Aerospace Applications: These are utilized in aircraft and engine components wherein lightweight and corrosion resistance are crucial.

Chemical Processing: Its resistance to a wide range of chemicals makes it perfect for heating exchangers, tanks, and pipe systems.

Medical Devices: Commonly positioned in implants and surgical gadgets manner to their biocompatibility and non-reactivity.

Titanium Alloy GR 5 Round Bar

Titanium Alloy GR 5 is one of the maximum well-known titanium alloys and is often called Ti 6-4. This alloy consists of about 90% titanium, 6% aluminum, and 4% vanadium. GR 5 is understood for its excessive power, mild-weight properties, and exact corrosion resistance, making it appropriate for annoying applications, together with:

Aerospace Industry: Widely utilized in aircraft structures and jet engines in which weight financial savings and power are paramount.

Marine Applications: Effective in seawater environments, making it ideal for marine components like propellers and hulls.

Oil and Gas Sector: Utilized in drilling devices and valves because of its sturdiness below extreme conditions.

As a leading Titanium Alloy GR 5 round bar exporters, we ensure that our products meet stringent quality standards, making them appropriate for numerous high-performance applications.

Titanium Alloy GR 7 Round Bar

Titanium Alloy GR 7 is an alloy that contains titanium at the side of small portions of palladium. This addition complements the corrosion properties of the alloy, especially in decreasing environments. GR 7 is commonly used in industries that require strong corrosion resistance, including:

Chemical Processing: Suitable for applications involving hydrochloric acid and other hostile chemical compounds.

Marine Environments: Used in additives uncovered to seawater and different corrosive environments, ensuring sturdiness and reliability.

Power Generation: Utilized in heat exchangers and other additives in the nuclear and fossil fuel sectors.

As a depended-on Titanium Alloy GR 7 round bar producer, we prioritize the manufacturing of incredible materials tailored to meet the desires of our customers.

Why Choose Titanium Alloys?

Titanium alloys provide severa benefits, making them an appealing choice for diverse applications:

1. High Strength-to-Weight Ratio

Titanium alloys personal an advanced energy-to-weight ratio in comparison to other metals, permitting engineers to design lighter and more inexperienced systems without sacrificing energy.

2. Excellent Corrosion Resistance

Titanium in all fairness evidence of corrosion, specifically in harsh environments. These belongings make titanium alloys great for applications in chemical processing, marine, and aerospace industries.

3. Biocompatibility

Titanium alloys, especially commercially natural grades like GR 2, are biocompatible, making them suitable for scientific implants and devices. This guarantees they do now not react adversely to the human frame.

4. Versatility

The capacity to alloy titanium with other elements allows for the personalization of its properties, permitting the advent of substances tailor-made to particular applications.

Applications of Titanium Alloy Round Bars

Titanium alloy round bars are applied in a huge variety of applications across numerous industries:

Aerospace: Components together with aircraft, touchdown gears, and turbine engines benefit from the lightweight and immoderate-electricity properties of titanium alloys.

Medical: Implants, surgical units, and dental devices are generally made from titanium alloys due to their biocompatibility and corrosion resistance.

Chemical Processing: Piping systems, reactors, and garage tanks are regularly constituted of titanium alloys to face up to competitive chemical substances.

Marine: Parts exposed to seawater, alongside propellers and hulls, make use of titanium alloys for his or her corrosion resistance.

Why Choose Jay Steel Corporation?

As the best provider of titanium alloys, we are dedicated to handing over amazing merchandise to our customers. Here’s why you ought to pick out us:

1. Quality Assurance

We prioritize wonderful in our products. Our titanium round bars are sourced from professional producers and go through rigorous findings to satisfy international requirements.

2. Extensive Inventory

Our complete stock ensures that you can discover the precise titanium alloy round bars you want for your tasks.

3. Expert Guidance

Our informed institution is ready that help you in choosing the right materials for your applications, providing insights and pointers tailor-made for your desires.

4. Timely Delivery

We understand the importance of meeting closing dates. Our logistics organization guarantees that your orders are delivered on time, helping you keep your responsibilities on the agenda.

5. Competitive Pricing

We agree that high-quality materials should be reachable. Our aggressive pricing ensures you acquire extraordinary prices without compromising exceptional.

Conclusion

Titanium alloys like GR 2, GR 5, and GR 7 are vital materials in various industries because of their particular properties. As a main Titanium Alloy GR 2 round bar, Titanium Alloy GR 5 round bar exporter, and Titanium GR 7 Alloy round bar producer, Jay Steel Corporation is dedicated to supplying top-high-quality products that meet excellent necessities. Contact us nowadays to analyze more about our services and the way we are capable of assisting your tasks with the notable titanium alloy round bars to be had. We are properly here to help you be successful.

0 notes

Text

Did You Know the Advantages of Inconel Alloy Bolts?

Inconel alloy fasteners like Inconel alloy bolts consist of nickel, molybdenum, chromium, iron, niobium, titanium, and cobalt. The material quantity in the alloy varies per their grade. Inconel alloy fasteners are known for their high strength, corrosion resistance, durability, and strength, making them perfect for critical applications. Inconel alloy bolts, like other Inconel fasteners, offer extensive benefits in multiple applications. To know more, continue reading.

Advantages of Inconel Alloy Bolts

High-Temperature Resistance

Inconel alloy works well at extreme temperature conditions. They can maintain their mechanical properties, allowing the Inconel alloy 600 fasteners like bolts to function well in critical applications like power generation and aerospace. These fasteners operate well in severe atmospheric conditions and do not require frequent replacement like other materials. For instance, Inconel 718 fasteners do not lose strength at temperatures up to 704 degrees Celsius. Following are some of the highlights of using Inconel bolts with high-temperature resistance:

High durability across different temperatures.

Unaffected by thermal fluctuation.

Provide scaling and oxidation resistance at extremely high temperatures.

Withstands high load at high temperatures due to its high-stress rupture and creep strength

Inconel bolts have high endurance in critical environments.

Applications: Heat exchangers, Furnace components, Commercial applications, oil and gas

extraction, and processing

Enhanced strength

Inconel alloys are known for their high tensile strength, making Inconel bolts one of the sought-after Inconel 625 fasteners. These bolts find applications that deal with high stress, like power generation and aerospace. The tensile strength of the Inconel bolts also prevents issues like warping or shearing. Apart from tensile strength, Inconel alloy also has high yield strength. It makes Inconel alloy 718 fasteners like bolts to spring back to their original form. They can also sustain permanent deformation under high loads.

Following are some of the highlights of using Inconel bolts with high strength:

Maintains toughness at high temperature

Does not crack like other material fasteners

Constant thermal functioning (non-fluctuating)

Inconel bolts have high creep resistance, especially Inconel 625 bolts at high temperatures and stress.

The moderate impact strength of Inconel 725 fasteners is a contributing factor to its toughness, ultimately offering shatter-proof functioning.

Applications: Power generation, aerospace, jet engine casings, nuclear reactor components, gas turbines, heat exchangers, etc.

Corrosion resistance

Inconel bolts showcase seamless functioning in applications dealing with corrosive surroundings. Inconel 625 bolts have high chemical resistance and do not react in environments dealing with sulfuric acid, hydrochloric acid, chlorides, etc. These bolts and other Inconel fasteners like nuts and bolts also provide sea-water corrosion resistance. They are perfect in the marine sector and they do not corrode easily. Inconel 718 fasteners, like bolts, have high crevice and pitting corrosion resistance due to chloride ions. Following are some of the highlights of using Inconel bolts with excellent corrosion resistance:

High performance in marine applications.

High compatibility in reductive and oxidizing environments.

Enhanced safety and reliability.

Compatible for sour gas environments as Inconel bolt adaptors.

They offer sulfide stress cracking and hydrogen embrittlement resistance in sour gas

· applications.

Applications: Scrubbers, chemical storage tanks, reactors, oil rigs, subsea machinery, naval ships, petrochemical processing, etc.

Extended service life

Inconel alloy bolts do not loosen at high temperatures. Inconel 625 fasteners are unaffected by extensive exposure to high stress and temperature conditions. Their stress and temperature resistance ensures additional safety and avoids loosening or degradation issues, leading to optimal outcomes over time. Following are some of the highlights of using Inconel bolts in context to durability:

Excellent performance in extreme conditions, leading to a longer lifespan.

High wear resistance.

Ease of replacement and seamless operation.

Inconel fasteners provide high fatigue and creep resistance at high stress and temperatures

Applications: Jet engines, oil and gas exploration, nuclear reactors, etc.

Final thoughts!

Inconel alloy bolts have extensive industrial applications due to their benefits. They are available in multiple grades at Inconel Bolts manufacturer in Mumbai, like Fasteners and Fixtures LLP.

0 notes

Text

Nickel 200 Flanges Manufacturers in India

Nickel 200 is a commercially pure wrought nickel alloy known for its exceptional corrosion resistance, high thermal and electrical conductivity, and excellent mechanical properties, making it a versatile material for various industrial applications. Nickel 200 flanges, specifically, play a crucial role in piping systems where corrosion resistance and reliability are paramount. This article delves into the characteristics, applications, and advantages of Nickel 200 flanges.

Properties of Nickel 200: Nickel 200 is a solid-solution alloy that offers outstanding resistance to corrosive environments, particularly reducing conditions. Here are key properties that make Nickel 200 a preferred choice:

Corrosion Resistance: Nickel 200 exhibits exceptional resistance to various corrosive environments including acids, alkalis, and neutral salts. It performs well in both reducing and oxidizing conditions.

High Thermal and Electrical Conductivity: This alloy has high thermal and electrical conductivity, making it suitable for applications involving heat transfer and electrical components.

Mechanical Properties: Nickel 200 retains its mechanical properties over a wide range of temperatures. It remains ductile and tough even at cryogenic temperatures.

Low Gas Content: Nickel 200 has low gas content, which helps maintain its properties in high-temperature applications.

Applications of Nickel 200 Flanges: Nickel 200 flanges are widely used in industries where resistance to corrosive environments is critical. Some common applications include:

Chemical Processing: Nickel 200 flanges are used in chemical processing plants for handling corrosive chemicals such as sulfuric acid, hydrochloric acid, and alkalis.

Electronics: Due to its excellent electrical conductivity and resistance to corrosion, Nickel 200 flanges are used in electrical and electronic applications, such as battery components and electrical connectors.

Marine Industry: Flanges made from Nickel 200 are employed in marine environments where exposure to seawater and salt spray can cause corrosion in conventional materials.

Food Processing: Nickel 200 flanges are utilized in food processing equipment where resistance to food acids and sanitation requirements are critical.

AISI 200 Nickel Alloy Flanges Specification

Dimensions : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Standards : ASTM, ASME Flanges, ANSI Flanges, DIN Flanges, EN Flanges, BS Flanges etc.

Specifications : ASTM B564 / ASME SB 564

Length : 100 mm To 3000 mm Long & Above

Size : 1 / 2″NB TO 60″NB

Class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, ASA 150#, ASA 300# DIN ND 6,10,16,25,40 Etc.

Grade : Nickel Alloy 200 (UNS No. N02200)

Our Nickel Alloy 200 Flanges conforms to NACE MR0175/ISO 15156

0 notes

Text

High-Performance Alloys in Piping Systems: Monel 400, Hastelloy C276, Copper Nickel, and the Role of Titanium Pipe Manufacturers in India

Titanium is a relatively sought-after steel in several industries, and bicycle producers are no exception. Because of its light weight and extraordinary sturdiness, a titanium motorcycle frame can offer riders of all talent tiers with a remarkable revel in. Furthermore, the highest caliber and accuracy of titanium tube are required at the same time as constructing a titanium bike’s body.

Sealed grade 9 titanium tube is the first-class material to make use of whilst constructing a titanium motorcycle body. Your frame’s resistance to corrosion and wear will ensure that it lasts for a completely lengthy length. Additionally, the seamless creation guarantees that the frame has no possible vulnerable points.

One of the principle benefits of the usage of seamless Grade nine titanium tubing is its first-rate power-to-weight ratio. Consequently, you may create a body that is sturdy and sturdy without sacrificing weight or power. For professional riders, who need a motorcycle that may navigate all terrains speedy and easily, that is crucial.

The seamless grade nine titanium tubing used to make bicycle frames also has the introduced advantage of being suitable with lots of welding strategies. It’s smooth to weld this fabric into a strong, elegant seamless body the usage of TIG or MIG welding strategies.

Building a titanium bike frame with seamless grade 9 titanium tubing ensures a long lasting, stylish, and practical ride. Therefore, in case you’re wanting to improve your motorcycle, consider buying a titanium body made completely of seamless grade nine titanium tubing. It has several benefits to offer.

Monel 400 Alloy

Pipes are unrivaled in terms of typical performance and resistance to corrosion. When exposed to gaseous fluorine, hydrochloric acid, sulfuric acid, hydrofluoric acid, and their derivatives, the Monel 400 pipes reveal notable resistance to corrosion. The alloy finds application in numerous industries, such as the chemical and maritime ones. General uses include pipelines, boiler feed water warmers, substitute warmers, drive-shafts, chemical apparatus, water and fuel storage tanks, crude oil distillation vessels, processing vessels, pipelines, and naval tools.

Hastelloy C276 metal

This Hastelloy C276 wrought nickel-chromium-molybdenum alloy happens to be the most pliable anti-corrosion alloy available. Because it does not readily form grain boundary precipitates in the heat-affected weld zone, this alloy is perfect for use in the majority of chemical processes in its welded state. Furthermore, in temperatures as high as 1900°F, Hastelloy C276 pipes exhibit exceptional resistance to oxidation, stress-corrosion cracking, and coring. Alloy C-276 keeps its exceptional resistance even when subjected to a wide variety of substances.

Copper-Nickel Pipe

The technique used to manufacture Nickel 200 flanges is vital to the final product’s efficacy and fine. Copper-nickel alloy pipes have many commercial uses due to their energy, resistance to corrosion, and warmth conductivity. We’ll talk about making copper-nickel alloy pipes here.

Titanium pipe manufacturers in India

Products made with titanium tubes are renowned for their outstanding mechanical properties, great strength, and light weight. Many heat exchange devices, such as transportation pipes, condensers, evaporators, coil heat exchangers, serpentine tube heat exchangers, and tube and tube heat exchangers, use it extensively. The industry standard for many nuclear power reactors is titanium tubes.

As a producer and supplier of premium titanium tubes, ASTM B564 UNS N06625 handle skinning on all tube surfaces, even if it lowers the rate of completed products and raises costs.

0 notes

Text

Processional usage of hastelloy fasteners

Selecting the pleasant fasteners in your tasks might be difficult due to the fact there are so many alternatives available. Due to its extremely good qualities, hastelloy fasteners have observed substantial application across numerous industries. They not best tolerate incredibly high pressures and temperatures, however they also display superb resistance to corrosion. This article will state the benefits of making use of Hastelloy fasteners and a way to pick the satisfactory type to your project.

What precisely are Hastelloy Fasteners, then?

Comprising of a few stuffs, the Hastelloy fastener exhibits splendid strength and resistance to corrosion. The nickel and chromium alloys that make up the majority of their makeup are what deliver them the functionality to face as much as oxidation and special forms of degradation over prolonged intervals of time. The several packages for hastelloy fasteners encompass rings, nuts, bolts, screws, washers, and clamps, to name just a few. Alloys are considerably greater resistant to wear and tear added on by using temperature variations or publicity to particular chemicals in difficult commercial conditions, which gives them a far longer lifespan than more traditional fastener materials like stainless-steel and iron.

A Complete Guide to Selecting the Best Hastelloy Fastener for Your Special Project

Establish the requirements that your project need.

Selecting the right Hastelloy C276 flanges calls for first figuring out the wishes of the assignment. The type of situations that the fasteners have to withstand, which includes temperature and strain, need to be cautiously studied. Due to its particular qualities, different grades of hastelloy are higher proper for different settings. In the event that your venture will come into contact with corrosive substances, for example, pick a Hastelloy grade with strong corrosion resistance. Selecting the appropriate Hastelloy fastener is critical for your challenge as it may substantially impact its toughness and achievement. You should be clean about your needs and specs so as for a fastener to keep your challenge robust and harm-unfastened. Before you proceed, you need to confirm in case you require the Hastelloy C22 or C276 alloy grade. Better corrosion resistance or greater power and performance—that is more big? That's what makes the distinction.

Don't forget to consider the range of sizes required for every component

This includes variables like body size, diameter, length, and thread length. It may be helpful to investigate specialized coatings like Lavalox® HTXTM, which provides robust protection up to 1500 degrees Fahrenheit (815 degrees Celsius) in order to guarantee the highest degree of dependability in high-temperature situations. In conclusion, a study to determine the operating pressure is necessary in order to meet the given proof loads. The loads for the conditional use case scenarios must already be in place for this analysis to be valid.

Because in their nickel-molybdenum-chromium alloy, Hastelloy C276 Fasteners are immune to a full-size form of corrosion. These corrosives encompass sulfuric acid, hydrochloric acid, and chlorine. This material has the added advantage of being surprisingly proof against pitting and cracking, and it is able to tolerate temperatures as high as 1900 stages Fahrenheit. In addition to its excessive mechanical electricity, Hastelloy C276 Fasteners are rather clean to manufacture, as in keeping with the recent cast fasteners manufacturer in India.

0 notes

Text

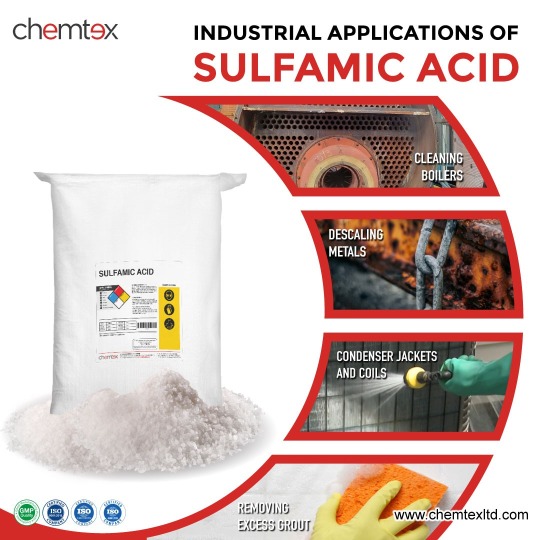

What makes Sulfamic Acid an effective descaling agent in industrial applications?

Heavy engineering industries like Iron & Steel, Alloy Manufacturing, Thermal Power, etc face one common issue i.e., formation of scales and deposits over metal surfaces in their boilers, condensers and heat exchangers. These industries undergo descaling process using acids. Why? Because, acids are cheap and easily available. And the most common acids available this process are Hydrochloric Acid, Nitric Acid and Sulfuric Acid. But these acids are highly corrosive and causes adverse effect on metal surfaces.

Sulfamic Acid, also known as amido sulfuric acid (H3NSO3), commercially available in white crystalline solids, is produced from urea and fuming sulphuric acid and finds extensive application in industrial maintenance and cleaning solutions and can be thought of as a replacement to the use of commonly used cheap acids for enhanced efficacy and results. Let us understand some of the unique properties.

Highly Acidic: Highly effective at dissolving and removing mineral deposits, scales, and rust from various surfaces, especially metal and ceramic surfaces, particularly useful for equipment and pipelines that come into contact with hard water or other scaling minerals.

Less Corrosiveness: Unlike some other strong acids, such as hydrochloric acid or sulfuric acid, sulfamic acid is relatively less corrosive to metals. It can efficiently remove scale without causing significant damage to the underlying metal surface.

High Temperature Stability: It can be used effectively at high temperatures where industrial settings often operate at elevated temperatures.

Metal Compatibility: Compatible with a wide range of materials, including metals, ceramics, glass, and plastics. This versatility allows it to be used on different surfaces without causing damage to the materials being cleaned.

Inhibitor Addition: In some formulations, it can be combined with inhibitors that further enhance its descaling performance by providing protection to metal surfaces against corrosion.

Due to these favourable characteristics, it is commonly used in industries such as water treatment, cooling tower maintenance, metal cleaning, chemical manufacturing, and many other industrial processes where scale and mineral deposits can cause operational inefficiencies and equipment damage. However, as with any chemical substance, proper safety measures and handling procedures should be followed when using sulfamic acid in industrial applications.

How Sulfamic Acid works as a descaling agent?

It works by eliminating calcium and magnesium ions from water through its acidic nature. When it comes in contact with water, it releases hydrogen ions that reacts with mineral deposits such as limescale, calcium sulphate, and rust, dissolving and breaking down the molecular bond that holds these deposits together.

Common application areas

A crucial ingredient for various household cleaning products, as it provides an excellent alternative to harmful chemicals.

Metal surface treatment by removing rust, scale, and other contaminants from metal surfaces.

It prevents mineral build-up on heat exchanger surfaces, ensuring efficient heat transfer and minimizing energy consumption.

In the world of chemical manufacturing, Chemtex Specialty Limited boasts a rich legacy of expertise in the chemical industry. With decades of experience, we share a strong market presence as a manufacturer of Sulfamic Acid GP Grade, commonly used for removing scales obtained from water in heating and cooling systems such as boilers, heat exchangers, condensers, jackets, and coils.

For more information, visit https://www.chemtexltd.com/products-and-solutions/performance-chemicals/general-chemicals/sulfamic-acid/

1 note

·

View note

Text

A Spin Coating of Thymol Blue Indicator on F-SnO2 Glass to fabricate a Novel Sensor Electrode in Potentiometric Acid-Base Titration

Authored by: Nasser M Abu Ghalwa

Abstract

This study deals with the investigation for preparation of conductive glass / thymol blue TB sensor electrode by spin coating of the thymol blue (TB) indicator on conductive glass formed from F-SnO2, and it’s using as indicator electrode in potentiometric acid-base titration in aqueous solution at 298K. The change of the open circuit potential with pH (E-pH) curve is linear with slope of 0.052V/dec at 298K. The standard potential of the above electrode E0, was determined with respect to the SCE as reference electrode. The recovery percentage for potentiometric acid-base titration using G/TB as indicator electrode was calculated.

Keywords: Potentiometry; Thymol blue; Sensor; Conducting glass; Titration; Indicator electrode

Introduction

Chemical sensors are devices that convert the concentration of target compounds into an analytical signal. The term analytical implies the concept of measurability. Then a chemical sensor converts the information about the presence of target compounds into a measurable quantity [1]. Chemical sensors play a big role in checking the environment we live in, contributing information on industrial production processes, quality management of food stuffs and beverages, detection and analysis of some ions and many other applications [2]. Transparent conducting oxides possess a unique combination of optical transparency and metallic conductivity in a single material. Their properties are widely exploited in a host of energy, optical, and electrical applications [3-5]. SnO2 is a wide band-gap semiconductor with a band gap of 3.6eV and was the first transparent conducting oxides to receive significant commercialization. It exhibits good transparency and can be easily n-type doped. Degenerate carrier densities can be achieved by doping with fluorine [6,7]. Potentiometric titrations are the basic chemistry laboratory technique for the quantitative analysis of substances with unknown concentrations using standard solutions of known concentration. The substance with unknown concentration and the standard solution are termed analyte and titrant respectively [8]. This method widely used in different fields such as the food industry, scientific research, and chemical, clinical and pharmaceutical laboratories. Titrimetric procedures based on a detection of the endpoint, i.e., the point at which volumetric titration is completed, are successfully employed over a wide range of concentrations and are popular because of their simplicity, speed, accuracy and good reproducibility [9]. Recently, many studies developed some types of electrodes in potentiometric acid base titration [10-13]. Thymol blue (thymolsulphonephthalein) is used as a pH indicator. A solution of thymol blue exhibits three form (red color), Neutral form (yellow color) and basic form (blue color) show Figure 1 [14].hone radiation can lead to adverse effects [10-16]. Thus, the public concern is that increasing the frequency of the radiation will also increase the effects of the radiation [14-16].

The aim of this study for preparing a spin coating of thymol blue indicator TB on conducting glass formed from F-SnO2 to prepare a new modified electrode sensor (glass / indicator electrode), for used in potentiometric acid base titration.

Experimental

Chemicals

The chemicals used in potentiometric titrations and preparation the electrode was tetraethyl orthosilicate (TEOS), Thymol blue (TB), hydrochloric acid, ammonia, Acetic acid, phosphoric acid, sodium hydroxide, sulfuric acid, citric acid and disodium phosphate. The chemicals are of analytical pure grade (Merck) Where the F-SnO2 glass from (Sigma Aldrich).

Synthesis of Materials

Preparation of Hydrolyzed TEOS

A mixture of 2. ml of absolute ethanol, 0.86ml of 0.1M of HCl were added to 2.5ml of TEOS under stirring. The obtained solution was kept under stirring at room temperature until a homogeneous clear solution was obtained. The solution was aged at least for 24 hours before used in the coating process. The hydrolyzed TEOS solution was used as a host matrix for the indicators.

Preparation of Indicators

Indicators solution (1×10-2M) thymol blue indicator (TB) were prepared using absolute ethanol as solvent.

Stock solution of indicators

The sample solution was prepared by mixing 1ml of blank hydrolyzed TEOS solution and 1ml for each indicator.

Preparation of Silica-immobilized Thin Films

Substrate Cleaning

Glasses were activated by concentrated H2SO4 for 24 hours, then washed with distilled water and ethanol. The surface was finally rubbed with cleaning paper.

Preparation of glass/TB electrodes using Spin coating method

All thin films layers prepared in this work were made by spinning three drops of the solutions onto a clean glass slide. The coating process was performed using the spin coater machine at 900rpm spinning speed for 1 min. period time. To obtain multilayers of thin films a subsequent spin coating method was performed after gradually drying of the previous layer at room temperature for 24 hours, then dried at 80oC for another 48 hours. And repeat the spin coating two or three time. Where the conducting substrate is usually conducting glass, consisting of glass coated with a thin layer of F-doped SnO2.

Sensor design of potentiometric cell

The potential of the indicator electrode relative to that of the reference electrode was measured on a digital multimeter model YDM 302C (China). Potentials were measured to ±5mv. The potential of Thymol blue, sensor indicators electrodes was measured vs. a saturated calomel electrode (SCE). The error in the measurement of the potential due to liquid- junction potentials in these electrolytes is estimated to be about 0.001V.

The solution in a beaker is stirred by means of a magnetic stirrer. The electrodes (indicator and reference) were dipped slowly into aqueous solution (acid or reductant). After the steady state potential was attained, the titration of the acid was carried out by addition of 1ml of the base to the acidic solution, waiting until the steady potential is established and then measured. The potential variation depends on the type of the base, the progress of neutralization process and on the initial concentration of the acid to be titrated. The results were reproducible to satisfactory value of ±5 mV for potential measurements. The process of addition of the titrant was repeated until the equivalence point was reached.

The E-pH relation of Thymol blue electrode:

The E-pH relation of Thymol blue electrode

According to Figure 2 the change of the open circuit potential (E) of the G/ TB indicator electrode with pH . The E-pH plot of the G/TB indicator electrode fits straight line with slope of 53.11mV at 298K. This value is close to the magnitude of the term 2.303RT/F at the corresponding temperature (59.1mV at 298 K). This value is close to the magnitude of the term 2.303RT/F (where: R gas constant, T absolute temperature and F Faraday constant) at the corresponding temperature (59.1mV at 288K). From Figure 2 the E0 value of the sensor electrode, i.e., the potential at [H+] = 1, is computed as 279.1mV relative to the saturated calomel electrode and can determination by:

This equation is applicable for the reversible behavior of working electrode. From the developed Nernst equation, we indicate that working electrodes can be used as pH-indicator. At high or low pH, the electrode indicates pH less than true value as pH glass electrode, it may be due to damage in electrode or existence of alkali metal ions in solution too.

The response time of the sensor

In general, the response time was defined as the time of sensor’s output reach to 90% of the equilibration after the measurement was started, especially to electrochemical sensors [15-17]. Figures 3a-3e show the response time of the G/TB sensor at different concentration of phosphoric acid, acetic acid, Hydrochloric acid, ammonia and NaOH respectively. Response time, in the range of (100-450) seconds was achieved, which rendered the sensor highly practical.

Effect of temperature on the response characteristics:

The importance of temperature measurement when performing pH measurements has already been mentioned in reference to slope correction. Temperature also has an effect of both pH buffers and solutions, as the hydrogen ion activity will increase with increasing pH [18].

The Thymol blue sensor response was evaluated at different temperatures, Figure 4. At lower temperatures, like 288K, the slope of the sensor was about 33.54mV/decade and the sensor would be used for pH measurements in the range from (2-11). However, when the temperature of the test solutions was adjusted to 298K, the slope significantly increased to 53.11mV/decade. By raising the temperature to 313K and 323 K the slope increased to 54.11mV/ decade and 59.75mV/decade respectively. Figure 4 shows the square of the correlation coefficient (r2) for pH measurements using the solid-state sensor, at different temperatures, as compared to pH values obtained by a conventional pH electrode (Hanna Instruments HI 1131 pH combination electrode) was found to change as the temperature increases where as r2 values for measurements at 283K, 298K, 308K, and 318K were 0.9655, 0.9386, 0.9482, 0.9876, respectively. This indicates that better results could be obtained at 298K due to easy and settable to use without heating.

The relation between conventional glass PH electrode and G/ TB indicator electrode

All potential values were converted with respect to the standard hydrogen electrode (SHE). During experiments, pH was also monitored with a commercial glass electrode that was calibrated daily using commercial standard buffer solutions (2-9) [19]. Figure 5 represents the correlation between the conventional glass PH electrode and G/Thymol blue indicator electrode, it can be easily recognized that excellent correlation between the results obtained by the solid-state pH sensor and the conventional glass pH electrode could be achieved. The slope of this relation was 0.947 and the r2 was 0.947. This indicate that G/TB indicator electrode potential values are closed to the values of conventional glass pH electrode.

Potentiometric of weak acids against NaOH

Figures 6a & 6b represent the potentiometric titration of 0.1M NaOH with different concentrations of acetic acids and phosphoric acid. The variation of G/TB electrode potential at 298K with the different volumes of standard 0.1M NaOH followed typical potentiometric titration curves. These curves show slight decrease in potential (to more negative values) with the addition of the titrant. Where Figure 6c show the potentiometric titration between the volume of 0.1M standard HCl against ammonia. The variation of the TB electrode potential at 298K with the different volumes of standard HCl followed typical potentiometric titration curves. These curves show slight increase in potential (to more positive values) with the addition of the titrant.

Location of endpoints

Figure 7a represent ΔE/ΔV against V plot for the potentiometric titrations of CH3COOH and H3PO4 with 0.1 M standard NaOH. From the plots the values of end points were determined. The obtained results and calculated values of (R%) are listed in Tables 1 & 2 for acetic acid and phosphoric acid respectively. The values of pKa for different concentration of acetic acid and phosphoric acid were calculated using the method of half neutralization as shown in Table 3. There are two jumps in the titration of phosphoric acid with NaOH using G/TB sensor. i.e two end points appear by using this electrode. The obtained values of pKa for the investigated bases are close to the previously reported values. Where Figure 7b represent ΔE/ΔV against V for the potentiometric titrations of ammonia and 0.1M standard HCl respectively. From the plots the values of end points are determined.

Finally, the values of pKb for different concentration of ammonia can be determined using the method of half neutralization. They are listed in Table 3 for the tested bases. The obtained values of pKb for the investigated bases are close to the previously reported values.

Conclusion

This study investigated the preparation of the modified electrodes of type glass/ thymol blue G/TB and their use as sensor indicator electrodes in the potentiometric acid-base titrations in aqueous solution at 298K. E-pH curve is linear with slope of 0.053.1V/decade for the G/BTB electrode at 298K. This value is close to the theoretical value 2.303RT/F (0.059V at 298K) and the recovery percentage for potentiometric acid-base titration using G/TB as indicator electrode was calculated.

i. On other hand the standard potential of the tested electrode, E0, is computed as 279mV with respect to SCE as reference electrode. Acetic acid, phosphoric acid, hydrochloric acid and ammonia were successfully potentiometric titration with NaOH as titrant in aqueous medium at 298K. Finally, this study is applied in different temperatures like 283K, 298K, 308K, and 318K were the correlation coefficient (r2) 0.9655, 0.9383, 0.9482, 0.9876, respectively.

To Know More About Juniper Online Journal Material Science Please click on: https://juniperpublishers.com/jojms/index.php

For more Open Access Journals in Juniper Publishers please click on: https://juniperpublishers.com/index.php

#Juniper Publishers#Material Science#Materials Theory#Structural Materials#Juniper publisher reviews#Juniper publisher journals

0 notes

Text

Unveiling Excellence in Chemical Solutions: AR Grade Hydrochloric Acid

Introduction: In the realm of chemical industries, the quality and purity of acids play a pivotal role in ensuring precise and reliable outcomes. Maruti Fine Chemical emerges as a beacon of excellence, offering top-notch AR Grade Hydrochloric Acid and LR Grade Sulphuric Acid. In this blog, we delve into the unique characteristics of these chemical solutions and shed light on how Maruti Fine Chemical is revolutionizing the industry.

AR Grade Hydrochloric Acid: Hydrochloric Acid, a powerful and versatile chemical, finds applications across various industries, from pharmaceuticals to metallurgy. Maruti Fine Chemical's AR Grade Hydrochloric Acid stands out for its exceptional purity, making it suitable for critical laboratory applications and analytical techniques.

Key features of AR Grade Hydrochloric Acid:

High Purity: Maruti Fine Chemical ensures that their AR Grade Hydrochloric Acid meets stringent purity standards, minimizing impurities that could affect experimental outcomes.

Precise Concentration: The acid is formulated with precise concentrations, allowing for accurate and reproducible results in various laboratory processes.

Stringent Quality Control: Maruti Fine Chemical employs rigorous quality control measures to guarantee the consistency and reliability of their AR Grade Hydrochloric Acid, providing researchers and scientists with peace of mind.

LR Grade Sulphuric Acid: Sulphuric Acid, an essential component in numerous industrial processes, demands a high level of purity and precision. Maruti Fine Chemical's LR Grade Sulphuric Acid is designed to meet these exacting standards, ensuring optimal performance in various applications.

Key features of LR Grade Sulphuric Acid

Impurity-Free Composition: Maruti Fine Chemical employs advanced manufacturing processes to create LR Grade Sulphuric Acid with minimal impurities, enhancing its suitability for laboratory and industrial uses.

Consistent Quality: The acid is manufactured under strict quality control measures, ensuring a consistent and reliable product that meets the needs of diverse industries.

Versatile Applications: LR Grade Sulphuric Acid by Maruti Fine Chemical finds applications in laboratories, educational institutions, and industries requiring a reliable and pure form of this essential acid.

Promoting Maruti Fine Chemical: Maruti Fine Chemical's commitment to excellence extends beyond the quality of their products. The company's customer-centric approach, timely delivery, and competitive pricing make them a preferred choice in the chemical industry.

Why Choose Maruti Fine Chemical?

Quality Assurance: Maruti Fine Chemical prioritizes quality, ensuring that their products consistently meet or exceed industry standards.

Customer Satisfaction: With a focus on customer needs, Maruti Fine Chemical strives to provide personalized service, understanding and addressing the unique requirements of each client.

Innovation and Sustainability: Maruti Fine Chemical is dedicated to staying at the forefront of industry trends, embracing innovation, and promoting sustainable practices in chemical manufacturing.

Conclusion: In the world of chemical solutions, Maruti Fine Chemical sets itself apart through its unwavering commitment to quality, precision, and customer satisfaction. The AR Grade Hydrochloric Acid and LR Grade Sulphuric Acid offered by Maruti Fine Chemical exemplify the company's dedication to providing reliable and high-quality chemical solutions. As a partner in progress, Maruti Fine Chemical continues to shape the future of the chemical industry with its innovative approaches and steadfast commitment to excellence.

#Fuming Sulphuric Acid ( Oleum Acid )#AR Grade Distilled Chlorosulfonic Acid#Fuming Nitric Acid + AR Grade Sulphuric Acid#AR Grade Hydrochloric Acid + LR Grade Sulphuric Acid#Commercial Grade Hydrochloric Acid

0 notes

Text

Different Types of Stainless Steel

Normally, the commercial kitchens are established using 1.2 mm or 1.5 mm 303/4 stainless steel. However, there are several more grades of stainless steel that are available all over the world. Another most widely used type of stainless steel is the one known as acid resistant 316/4 stainless steel and the 430 stainless steel for the exhaust canopies and fridges. The thickness of the stainless steel used depends on the strength that is required in the equipment.

Generally, the minimum thickness required for the exhaust canopies is .07 mm. As far as the thickness of the wall sheeting is concerned, the minimum thickness required must be .9 mm or 1.2 mm based upon the use. Similarly, for the shelves, under shelves and a few timbers backed benches, the minimum thickness must be 1.2 mm. However, for the benchtops having sound deadener and frames, the stainless steel thickness has to be 1.5 mm. Following are a few common types of the stainless steel:

304 Stainless Steel

The type 304 stainless steel is the variation of the fundamental 8-8 grade. It is an advancement of Type 302, with a lower amount of carbon content and a greater amount of chromium. The lessened amount of carbon reduces the chromium carbide precipitation because of welding. In addition, it minimizes its susceptibility to intergranular corrosion. This type of stainless steel can be used in the “as welded” situation in several instances. However, Type 302 should be annealed for the purpose of retaining adequate resistance to corrosion.

The Type 304L is an additional low-carbon variation of the Type 304 stainless with a maximum carbon content of 0.03% which terminates the carbide precipitation because of welding. Because of this, such alloy can be utilized in the condition of “as welded”, even when the conditions are quite corrosive. Most of the times, it terminates the need for annealing weldments excluding for the applications that specify the stress relief. It tends to have slightly lesser mechanical properties as compared to the Type 304. The most common users of this type of stainless steel incorporate kitchen equipment, architectural trim and mouldings, paper, textile, chemical industry processing tools, and welded chemical components.

316 Stainless Steel

The type 6 Stainless steel can be regarded as an austenitic chromium-nickel steel that specifically contains molybdenum. Such addition enhances the normal resistance to the corrosion, enhances the resistance to pitting from the solutions of chloride ions, and offers enhanced strength at the elevated temperatures. The properties of Type 316 stainless steel are quite identical to the ones possessed by the Type 304 stainless steel excluding that this alloy is a lot powerful at the elevated temperatures. However, in this type of stainless steel, the resistance to corrosion is quite improved, specifically against hydrochloric, sulfuric, tartaric, formic and acetic acids; alkaline chlorides and acid sulfates.

The Type 1316L is an additional lessened carbon version of Type 316 Stainless steel that reduces the damaging carbide precipitation because of welding. The most common uses of this type of stainless steel incorporate furnace parts, jet engine parts, exhaust manifolds, heat exchangers, photographic equipment, pharmaceutical equipment, chemical equipment, pump and valve trim, paper, pulp, tanks, digesters, textile processing equipment, tanks, and parts exposed to tubing and marine atmospheres. This type of stainless steel is widely used for weldments where it is immunity to carbide precipitation because of welding assures optimum resistance to corrosion.

430 Stainless Steel

The type 430 Stainless steel is among the most commonly used ferritic and non-hardenable stainless steels. It tends to combine better resistance to corrosion, and oxidation and heat resistance to around 816°C (1500°F) with effective mechanical properties. The most common product applications incorporate automotive molding and trim, dishwashers, flatware, steam iron bases, downspouts and gutters, furnace combustion chambers, range hoods, and gas burners on the heating units. The commercial and industrial applications include nitric acid plant tools to interior architectural applications, restaurant equipment, roofing equipment, and oil refinery equipment.

For more details please visit the website here: https://flatpackstainless.com.au/.

#Flatpack Stainless#Stainless Steel Cabinets#Steel Shelving#Stainless Steel Sink#Stainless Steel Benches#Sink Bench#Kitchen Trolleys

1 note

·

View note

Text

Xylitol Market Segmentation And Forecast Report By 2028

Xylitol Industry Overview

The global xylitol market size was valued at USD 447.88 million in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 6.4% from 2020 to 2028.

Growing demand for xylitol in food and nutraceutical applications is expected to be a key driving factor for the market over the forecast period. Low-calorie, crystalline xylitol is a natural sweetener found in fibrous plant foods and hardwood trees. It is the only sugar that has the same sweetness intensity as compared to sucrose. It can be produced by chemical or enzymatic hydrolysis from different plant sources having polysaccharides. It is largely produced through a chemical process at an industrial scale, which is based upon catalytic xylose dehydrogenation. The process is not only cost and energy-intensive but also environmentally risky due to the use of a toxic catalyst and high-pressure hydrogen gas.

The U.S. is anticipated to witness a surge in product demand over the forecast period owing to the growing demand for low-calorie foods and ingredients. Moreover, the rising awareness about the natural products that play a key role in general health management is further accelerating the product demand in the U.S. market. The U.S. is among the leading producing countries of xylitol. The producers have been targeting various potential application industries, such as nutraceutical and cosmetics & personal care, to strengthen the market positions in the U.S. market.

Gather more insights about the market drivers, restrains and growth of the Global Xylitol Market

In the enzymatic process, different microorganisms like yeast, bacteria, and fungi are used, which helps in a sustainable environment. Due to a low glycemic index sweetener, it is being used as a food additive in confectionery, bakery, drinks, and dairy products as well as in the nutraceutical and pharmaceutical industries. The most commonly used raw materials for the commercial production of xylose are corn cobs and birch barks. The production of xylose from corn cob is less expensive and thus the price of xylitol sourced from corn cob is lower than that of the one derived from the birch trees.

The hydrolysis of corn cob biomass uses hydrochloric acid whereas hydrolysis of birch bark requires sulfuric acid for hydrolysis. Xylitol produced from corn cob is considered pharmaceutical-grade and the standard is checked rigorously for compliance. On the other hand, birch bark-sourced product is considered as food-grade. Manufacturers located in North America focus on using birch bark as a key raw material owing to the abundance of birch trees in the region. Producers in China use corn cobs as a major xylan source.

Browse through Grand View Research's Nutraceuticals And Functional Foods Industry Research Reports.

• Lactoferrin Market: The global lactoferrin market size was valued at USD 219.2 million in 2020 and is expected to expand at a compound annual growth rate (CAGR) of 8.2% from 2021 to 2028. The rising awareness amongst consumers regarding health and diet, along with the rising prevalence of skin-related health conditions, is expected to boost the demand.

• Moringa Ingredients Market: The global moringa ingredients market size was estimated at USD 6.9 billion in 2020 and is expected to expand at a compounded annual growth rate (CAGR) of 9.5% from 2020 to 2028. The availability of a wide variety of product applications across food & beverages, dietary supplements, pharmaceuticals, wastewater treatment, and animal feed industry along with their increasing consumption is driving the demand for moringa ingredients.

Xylitol Market Segmentation

Grand View Research has segmented the global xylitol market on the basis of form, application, and region:

Xylitol Form Outlook (Volume, Tons; Revenue, USD Million, 2017 - 2028)

• Powder

• Liquid

Xylitol Application Outlook (Volume, Tons; Revenue, USD Million, 2017 - 2028)

• Chewing Gum

• Confectionery

• Bakery & Other Foods

• Oral Care

• Others

Xylitol Regional Outlook (Volume, Tons; Revenue, USD Million, 2017 - 2028)

• North America

• Europe

• Asia Pacific

• Central & South America

• Middle East & Africa

Key Companies profiled:

Some prominent players in the Global Xylitol Market include

• Cargill, Inc.

• DuPont Danisco

• Roquette Freres

• ZuChem, Inc.

• Thomson Biotech (Xiamen) Co., Ltd.

• NovaGreen, Inc.

• DFI Corp.

• Zhejiang Huakang Pharmaceutical Co., Ltd.

• Jining Hengda Green Engineering Co., Ltd.

• Shandong Biobridge Technology Co., Ltd.

• Shandong Futaste Co., Ltd.

• Foodchem International Corp.

• Mitsubishi Shoji Foodtech Co., Ltd.

• A & Z Food Additives Co., Ltd.

• Herboveda India

• Shandong Lujian Biological Technology Co. Ltd.

• Godavari Biorefineries Ltd.

• Shandong Longlive Bio-Technology Co., Ltd.

Order a free sample PDF of the Xylitol Market Intelligence Study, published by Grand View Research.

0 notes

Text

Inconel bar- Highly useful in aerospace industries

About Inconel

Inconel is an austenitic nickel-chromium super alloy which is typically used in applications where high temperatures are present due to a stable and thick passivating oxide layer formed after heating Inconel. This layer protects the Inconel’s surface making it resistant to heat. Inconel has excellent resistance to pressure, corrosion and oxidation. Inconel superalloys have good mechanical properties and are used in aerospace and chemical industries.

Inconel bar is used in various industries such as

· Commercial Gas Turbines

· Aerospace

· Cryogenic Storage Tanks

· Jet Engine Components

· Chemical Processing

· Food Processing

· Chemical processing

· Nuclear

· Marine

· Petrochemical

Aerospace

The aerospace industry needs excellent quality and innovative metals & alloys to withstand the elements at altitude both for carrying precious cargoes or commercial passengers. Inconel is available in various grades and forms to fulfill your aerospace needs. Uses of Inconel bar are turbine exhaust ducting, aircraft engines, gaseous fluid ducting, internal combustion liner allocation, landing gear, aircraft fasteners & hinges, parts with high temperature use & corrosion-resistance, exhaust & injection nozzles.

Space & rocketry

The modern space and rocketry systems industry needs innovative and excellent quality metals & alloys to withstand elements. Inconel bar is used in various grades in the rocketry & space requirements. Inconel alloy is available in the form of plate, sheet & bar to provide tubing & forgings. Objects moving in & out of the sun’s direct heat are in constant temperature flux causing expansion & contraction. Components used for spacecrafts & their engines, structures and satellites in space are produced from strong temperature-resistant materials.

There are various applications of Inconel bar such as

· Flare stacks on offshore oil platforms

· Chemical and petrochemical processing

· Pollution control equipment

· Components where exposure to high mechanical stress and sea water are required

· Nuclear reactors

· Gas turbines, rocket motors/engines and space craft

There are various characteristics of Inconel bar that make it widely useful such as

· Excellent mechanical properties at both extremely low and extremely high temperatures.

· Good resistance to acids such as sulfuric, phosphoric, nitric, and hydrochloric.

· High resistance to oxidation at elevated temperatures.

· Free from chloride induced stress corrosion cracking.

· Excellent resistance to crevice corrosion, pitting and intercrystalline corrosion.

Resistance to corrosion

Inconel alloy has resistance to many organic & inorganic compounds and shows excellent resistance in reducing conditions due to minimum 72% nickel. It has a lower predisposition for stress corrosion cracking in the annealed condition due to its high nickel content. Inconel alloy has high temperature resistance to sulfur compounds & oxidizing compounds at elevated temperatures or in corrosive media due to presence of chromium. Inconel alloy has resistance to alkalies and is appropriate for use in strong solutions of magnesium chloride at elevated temperatures.

Fabrication & heat treatment

Typical processes are used for hot forming and cold forming of the Inconel alloy. Hot working is performed between temperatures of 1600°F and 2250°F avoiding any work between 1200°F and 1600°F as the ductility decreases in this temperature range. The cold work hardening rate is less than that of 304 stainless steel but higher than that of mild steel. Welding Inconel alloy is obtained via shielded metal-arc welding using AWS ENiCrFe-3 electrode. Filler metal AWS ERNiCr-3 can be used during TIG and MIG welding. Inconel alloy is slightly more machinable than stainless steel and is machined using large tools to handle the loads. Heavy-duty equipment is used along with sharp tooling and adequate cooling. Inconel alloy can be annealed without excessive grain growth at 1850°F for 15 minutes. Fine grain material has higher corrosion resistance, fatigue, tensile and impact properties.

2 notes

·

View notes

Text

The Nitric acid

Nitric acid (HNO3), also known as aqua fortis (Latin for "strong water") and spirit of niter, is a highly corrosive mineral acid.

The pure compound is colorless, but older samples tend to acquire a yellow cast due to decomposition into oxides of nitrogen and water. Most commercially available nitric acid has a concentration of 68% in water. When the solution contains more than 86% HNO3, it is referred to as fuming nitric acid. Depending on the amount of nitrogen dioxide present, fuming nitric acid is further characterized as red fuming nitric acid at concentrations above 86%, or white fuming nitric acid at concentrations above 95%.

Nitric acid is the primary reagent used for nitration – the addition of a nitro group, typically to an organic molecule. While some resulting nitro compounds are shock- and thermally-sensitive explosives, a few are stable enough to be used in munitions and demolition, while others are still more stable and used as pigments in inks and dyes. Nitric acid is also commonly used as a strong oxidizing agent.

Niche uses

Metal processing

Nitric acid can be used to convert metals to oxidized forms, such as converting copper metal to cupric nitrate. It can also be used in combination with hydrochloric acid as aqua regia to dissolve noble metals such as gold (as chloroauric acid). These salts can be used to purify gold and other metals beyond 99.9% purity by processes of recrystallization and selective precipitation. Its ability to dissolve certain metals selectively or be a solvent for many metal salts makes it useful in gold parting processes.

Analytical reagent

In elemental analysis by ICP-MS, ICP-AES, GFAA, and Flame AA, dilute nitric acid (0.5–5.0%) is used as a matrix compound for determining metal traces insolutions. Ultrapure trace metal grade acid is required for such determination, because small amounts of metal ions could affect the result of the analysis.

It is also typically used in the digestion process of turbid water samples, sludge samples, solid samples as well as other types of unique samples which require elemental analysis via ICP-MS, ICP-OES, ICP-AES, GFAA and flame atomic absorption spectroscopy. Typically these digestions use a 50% solution of the purchased HNO

3 mixed with Type 1 DI Water.

In electrochemistry, nitric acid is used as a chemical doping agent for organic semiconductors, and in purification processes for raw carbon nanotubes.

Woodworking

In a low concentration (approximately 10%), nitric acid is often used to artificially age pine and maple. The color produced is a grey-gold very much like very old wax- or oil-finished wood (wood finishing).

Etchant and cleaning agent

The corrosive effects of nitric acid are exploited for some specialty applications, such as etching in printmaking, pickling stainless steel or cleaning silicon wafers in electronics.

A solution of nitric acid, water and alcohol, Nital, is used for etching metals to reveal the microstructure. ISO 14104 is one of the standards detailing this well known procedure.

Nitric acid is used either in combination with hydrochloric acid or alone to clean glass cover slips and glass slides for high-end microscopy applications.It is also used to clean glass before silvering when making silver mirrors.

Commercially available aqueous blends of 5–30% nitric acid and 15–40% phosphoric acid are commonly used for cleaning food and dairy equipment primarily to remove precipitated calcium and magnesium compounds (either deposited from the process stream or resulting from the use of hard water during production and cleaning). The phosphoric acid content helps to passivate ferrous alloys against corrosion by the dilute nitric acid.[citation needed]

Nitric acid can be used as a spot test for alkaloids like LSD, giving a variety of colours depending on the alkaloid.

Nuclear fuel reprocessing

Nitric acid plays a key role in PUREX and other nuclear fuel reprocessing methods, where it can dissolve many different actinides. The resulting nitrates are converted to various complexes that can be reacted and extracted selectively in order to separate the metals from each other.

Safety

Nitric acid is a corrosive acid and a powerful oxidizing agent. The major hazard posed by it is chemical burns, as it carries out acid hydrolysis with proteins (amide) and fats (ester), which consequently decomposes living tissue (e.g. skin and flesh). Concentrated nitric acid stains human skin yellow due to its reaction with the keratin. These yellow stains turn orange when neutralized. Systemic effects are unlikely, however, and the substance is not considered a carcinogen or mutagen.

0 notes

Text

What materials are available for CNC machining in the future workshop? What technology is CNC machining?