#Closed-Loop Vertical Systems

Explore tagged Tumblr posts

Text

Lot 7

You stand on the auctioneer's platform. The world is framed by the wooden beams of the barn, and your posture is immaculate, a conditioned response so deep it feels more natural than breathing. You smell the sawdust, the faint, sweet scent of hay, and the warm, animal smell of the cattle in the pen directly below you. They shift and low softly, their sounds a dull, constant backdrop to the silence that surrounds you.

Your U.S. Marine Corps Dress Blue uniform is a heavy, restrictive skin. The high collar forces your chin up, your gaze level. You feel the weight of the medals on your chest, though the memories attached to them have been neatly excised, leaving only polished metal. The iconic red "blood stripe" on your trousers is a sharp, vertical line in your peripheral vision. You are a perfect and silent statue, the embodiment of honor, courage, and commitment, repurposed for this stage.

The auctioneer, a man named Silas, begins to speak. His voice is calm and measured, and you register it as you would register the wind or the rain. It is happening, and you are its subject.

"Lot 7," he says, and you know he means you. "Designation: 'Victor.' Graduated top of his class in infantry training. Expert rifleman. Documented resilience to extreme environmental and psychological stressors."

You stare at the far wall of the barn, your eyes fixed on a knot in the wood. You see it, but you do not perceive it. Your mind is a calm, white, silent space.

"His service record is flawless," Silas continues, "but more importantly, his post-service conditioning is absolute. He operates on a closed-loop command system. What you see is not a man, but a vessel of perfect obedience."

In the stands, you see the bidders. They look like farmers and ranchers, but their gazes are analytical, assessing. They are judging you, the prize stock. The parallel to the cattle below you is deliberate, a fact your conditioning allows you to understand without emotion. You are simply in a different pen.

"We will open the bidding at five hundred," Silas announces.

A man in a white cowboy hat touches the brim. You see the motion.

"I have five hundred. Looking for six."

Another man raises his chin. You see that, too.

"Six hundred it is. Do I hear seven?"

The silent bidding continues, a series of subtle gestures that decide your fate. You remain perfectly still, a product on display. Your value is calculated based on your discipline and the complete and total absence of your own will. You are the finest animal here.

"One million," the auctioneer's voice cuts through the quiet. The finality in his tone is unmistakable. "Sold. To the gentleman from the Sterling Consortium."

The man in the white cowboy hat gives a slight, final nod. He is your new owner.

You feel a presence beside you. The handlers. A quiet command is given—a soft click, a specific word—and your body obeys without conscious thought. You execute a flawless pivot, your polished Corcoran boots making no sound on the wooden planks.

You march off the block, past the pen of shifting, lowing cattle. You do not look at them. You do not look at your buyer. You are simply following the last order you will ever receive from The Provenance.

Your service to your country is over. Your service to your new owner has just begun.

16 notes

·

View notes

Text

Trying not to make anymore text posts today but👀 a corten steel and concrete mixed unit apartment tower with vertical gardens lining multiple walls is calling me like a little fucking demon.

20-30% of the building’s area is dedicated to vertical farming, greenhouses, and communal gardens(this includes the intentional bee attracting gardens on the tiered rooftop)😮💨

10-15% of the space is used for shared amenities like communal kitchens, lounges, workspaces, fitness areas, and other social space.

The remaining 55-70% of the building houses the residential units.

Lobby, commercial spaces, communal areas (think co-working spaces), and vertical farming are located on the lower floors. Primarily residential units with additional green spaces and communal areas would be on the middle floors and penthouse apartments, rooftop gardens, and perhaps additional farming or green spaces are on the top floors. Which, makes this quite massive. Like 30-40 stories!😭

Solar panels and wind turbines integrated into the building’s design generate renewable energy, making the structure self-sustaining though! And an advanced waste management system processes organic waste into compost for the gardens, closing a loop on food production.

A rainwater collection system could even be used for irrigation of the vertical farms and green spaces, I think. Also for an hydroponic and/or aquaponic system?

#text#this is like for 100+ apts#lol there’s more but I’m too tired#basically my abandoned mall idea but larger lol#I could have spent days on math over this

2 notes

·

View notes

Text

2 Guilty Pleasure

Previous Chapter

We had fueled up halfway through our shift and taken a much-needed lunch break. Crystal and I walked toward the mess hall and just sat in silence. I needed caffeine, and fast. I put my elbows on the table and rested my head on my palm, closing my eyes and just breathing slowly. I was queasy by the smell of the mess hall; it was filled with the scent of sweat mixed with burnt food and smoke from the grill, and occasionally the smell of vomit. I pushed through the feeling by breathing through my mouth whenever possible. The coffee would be coming out soon. Not many personnel were on the decks at this time, but they still had a few staff available for us. Just as I was thinking about coffee, I heard them bring out the self-serve liter pumps. I opened my eyes looking at it, wishing I had telekinesis right about now to bring the device to me. Crystal watched and let out a small giggle knowing what I wanted, she got up from the table and walked towards the coffee dispenser. She grabbed two cups, filling them to the brim with the disgusting bean water. I hated the taste of coffee, but I didn’t care, I needed the caffeine. I took it black since the sugar and cream had not arrived on the table yet. Crystal on the other hand decided to wait, thankfully, she wasn’t waiting long.

“Thank you,” I whispered to her as she set it in front of me. We preferred our lunch breaks quietly because we reserved talking for the cockpit. We generally held constant communication while in the plane. It was helpful to our teamwork, how we worked in enemy fire, and when we were being targeted, all of which was dependent on being a cooperative team. The guys around here could learn a thing or two from our example. We worked 12-hour shifts for 3 days a week and then the other pilots took over for the remainder of the week. The hours were brutal, but we made do seeing as we had the least seniority for bidding our preferred schedule. We technically didn’t have to fly for the entirety of our shift, but it was helpful to have eyes in the sky as much as possible. I slowly sipped my coffee, taking in the tranquility for the next hour.

When the hour was up, we headed back to the plane. I quickly did my preflight, making sure nothing was out of sorts. I hopped in Crystal following my lead as I checked the flight controls, electronic displays, pitot-static system, and analog instruments. Crystal continued her flows and checks and I waited for her to be ready, I hopped back out of the plane and did a 360-degree walk around just to make sure we didn’t have any other blatant issues. When I hopped back in, Crystal was ready to go. I made sure to strap my helmet back on my head and tell the ground crew we were ready to go before I started the engines. They hooked us back up to the catapults and brought up the blast pad. When I saw the thumbs-up, I heard ATC in my ear.

“Reaper, you’re cleared for take-off. Have fun out there.” I heard them say.

“Cleared for take-off, we’ll be departing to the Northwest,” I told them. I pushed the throttles fully forward and prepared for the bumpy ride off the runway. When we were airborne, I happily turned us to heading 320, climbing up to around 6,000ft. When we got away from the ship around 81 miles away Doe radioed into the ship.

“Mustang, we’ll be bearing 140 at 81 miles starting some aerobatics.” She told them. Our routine was expected.

“Roger Doe, we’ll keep you updated if we spot any activity. Your partners are to the North about 20 miles out from you.” They told her.

“I have them on radar, thank you.” Doe said to ATC. I got us up a bit higher before I started doing anything. Once we were at around 10,000 ft I threw on the afterburner and started doing rolling turns while descending. Once we got to 3,000 ft. I pulled us vertical and climbed up back up to 10,000, once there I turned off our burner and flipped us backward, descending and doing loops as we did so. After this, we flew inverted for a bit.

“What’s the plan here Reaper?” I heard Doe ask after a few minutes went by of us hanging upside down. I rolled the plane back over, so we weren’t hanging by our straps.

“Just thinking,” I told her.

“What about?” She asked.

“I wanted to get some practice landings in, but we’re on an aircraft carrier where that’s impossible to do since we have the tailhook. I miss landing on an actual runway built for touch and go’s,” I told her.

“I miss it too. But I’m enjoying the sea too, our days off feel like a vacation when we get our swims in the ocean… Or playing with the boys on the flight deck with the catapults and football.” She giggled a little, a fond memory coming through. I nodded, brushing off the need to respond. After doing a couple more tricks and maneuvers, we ran some recovery flows.

At around 5:45 am, I decided it was time to get back to the ship. I brought us down to 1,000 feet when we were in the 10-mile range.

“Mustang, this is Reaper we’re inbound 10 miles from the North, full stop,” I told them wanting this night to end as soon as possible. I heard our partner plane land a few minutes before us.

“Copy Reaper, we have you in sight. You’re cleared to land, contact approach.” They said handing me off to the other frequency.

“Approach, Reaper,” I said to them, knowing they didn’t need any other information.

“Reaper, you’re three-quarters of a mile out, call the ball.” I heard them say as we got closer to the ship. I kept the plane descending easily, putting my flaps in as necessary.

“I have the ball,” I told them as I glided the plane down, following glide path lights, and flaring at the perfect time. I felt our wheels hit the deck before I felt our tailhook catch the third arresting wire. The force of the plane being pulled backward shocked me into life, if you weren’t expecting it, this action could give you serious whiplash. Then we stopped, I shut down the engines and opened the canopy.

“Hey, you two!! Stinger would like a word.” I rolled my eyes, what could he possibly want now at 6 am? I unclipped my helmet from my chin and pulled it off my head. That’s when Maverick and Goose came waltzing up to us.

“Reaper, Doe. Hey, how’re you guys doing after your night flying adventures?” Maverick greeted us, his enthusiasm could kill me. I rolled my eyes as I collected my things out of the small space. I shoved my flight bag on my back and my helmet underneath my arm as I moved to get down the ladder. I started going down and my foot slipped on the third rung. I braced for a hard fall on the tarmac, but the hit never came. I felt arms beneath my figure and Maverick’s eyes on me. My brown eyes met his hazel, and I couldn’t help but smile softly. I heard Goose clear his throat and Maverick quickly snapped back into reality and set me on my own feet.

Maverick and I had a colorful past in fact we competed quite frequently. I wouldn’t have even considered us acquaintances during that time period. Since we started overlapping shifts, we’d been becoming quite decent friends. We helped each other out with our pre-flights if we got back early, we studied together, and truth be told even though I despised his egotistical attitude, I did enjoy his company. He was perhaps one of my best friends, which is somewhere I never thought we would be.

“You think you can manage it back to your quarters?” He joked with me, brushing off the awkwardness his RIO had created.

“You’re a fucking prick you know that?” I told him, pausing, knowing that I couldn’t leave the conversation this way.

“Regardless of my mood… I hope there’s clear skies for you and no further issues with Cougar.” I told him, starting to walk away.

“You didn’t hear?” Goose asked us curiously. I spun around unhappily, looking up at the man.

“Hear what? We’ve been in the plane all night except for our lunch.” Doe said sarcastically to him. Both of our moods had deteriorated.

“Cougar turned in his wings.” He said slowly, I hung my head disappointed.

“Fuck.” I quietly but angrily spit out, rubbing my face and clearing my bleary eyes. They all waited in silence. I wasn’t in the plane anymore; I was allowed to feel my damn emotions and not store them in a box on a shelf. Besides, after my previous partner aircraft I was allowed to be upset. My past had a way of giving me intense moments of PTSD.

“I knew he was shaken up, but I figured he’d move past it like we all do. The first time it happens you either don’t let it happen again and learn from it, or you quit. Fuck!” I exclaimed again. Goose looked at me with sympathy.

“Maeve, you did the best you could. I think he was just too far gone. When he got back, he said he couldn’t stop thinking about his wife and kid. He couldn’t imagine putting them through his death. He knew if he froze like that again it would kill him and his RIO.” He told me putting his hand on my shoulder. I nodded, sucking in a breath of air and looking up at him.

“Thanks, Goose,” I said as he removed his hand. I pulled my hair from its bun, which had loosened during the day’s events, I felt my hair fall onto my back in a low ponytail.

“Okay boys, safe flying,” I told them as I made my move to get out of there and talk to Stinger. Maverick’s fingers grazed my back as we brushed past each other, the simple gesture would have been missed by both our RIOs, but I knew, he knew what I was feeling towards the Cougar situation. I made my way to the lockers and threw my keys for the plane, flight bag, and helmet inside it. Then slammed it shut,

“Ready Crystal?” I asked her still facing the locker.

“Yeah, let’s go.” She said as I heard her locker shut. I let her walk out first and followed her down the hallway. We walked down the length of the deck and up the stairs to the offices. Crystal knocked on the door three times.

“Come in.” I heard Stinger’s gravelly voice ring out. Crystal pushed the door open, we walked in slowly, saluting to him as we did so.

“At ease, sit down both of you.” He said we did as he requested.

“That was an incredibly brave thing you did last night Maeve; I’m thoroughly impressed with the way you handled the situation. Before you came along this group needed some serious glue. Come to find out a few months later, you’re it…” He took a breath.

“Thank you, sir,” I thanked him appreciating the compliment.

“I’m not done. We had a team drop out of their slot to Top Gun. They’re letting me fill the slot. Since Cougar turned in his wings, I figured that was the only slot this squadron would get. But now I have two, I want you guys to take the second one.” My breathing hitched in my throat, this was an amazing opportunity, and the excitement renewed my energy.

“I apologize in advance sir, but who received the other slot?” Crystal asked speaking out of term, Stinger waved off the apology.

“You will be joined by Maverick and Goose.” He said to us. She nodded at the news, I could tell she was holding back her true emotions. I stood up taking in the information.

“Thank you, sir.” We thanked him for the opportunity.

“Get some sleep, I’ll send Maverick and Goose to collect you two when they leave in the evening. And ladies?” He stopped.

“Yes sir?” I asked him as Crystal joined me in heading toward the door.

“Do us proud.” He smirked, and I smiled back.

“Of course, sir,” Crystal said to him, before we walked out the door and started to celebrate, whooping, and cheering all the way.

Next Chapter

#top gun movie#top gun 1986#top gun 2#top gun fandom#top gun imagine#top gun x reader#top gun headcanons#pete mitchell#maverick x reader#Maverick#aviatrix#tom cruise#80s throwback#top gun maverick fic#pete 'maverick' mitchell x reader#pete 'maverick' mitchell#just a big ass nerd#love story#nerd things#fanfiction#fanfics#fanfic writing#ao3fic

14 notes

·

View notes

Text

How Sales Data Refines Marketing Strategy to Close Gaps

Marketing strategies often take shape without insight into real-time sales conversations or buyer behavior. While professionals build campaigns around defined personas or quarterly targets, customer-facing teams navigate shifting objections, compressed decision cycles, and real-time competitive pressure. This disconnect leads to diluted messaging, lower engagement, and missed revenue opportunities.

Historical research and industry benchmarks offer broad insight, but sales conversations capture what buyers prioritize now. Each pricing objection, product workaround, or delayed decision reveals friction points that static campaigns rarely address. These signals form a feedback loop that, when embedded in planning, grounds strategy in present conditions rather than assumptions.

Regional preferences, buyer urgency, and offer timing vary significantly across verticals. Commercial teams spot when discounts gain traction, which bundles move quickly, or when buyers hesitate due to contract terms. Ignoring these details risks delivering messaging that misses key motivators. Adjusting outreach to reflect current deal activity ensures positioning stays relevant and tailored.

This becomes more urgent in transactional industries, where margins are thin and volume matters. In sectors like lighting or PPE, even small changes in procurement criteria or seasonal trends can shift demand patterns. Sales reps identify these cues as they surface. Marketing can then pivot quickly with content or offers that resonate.

Customer relationship management systems now play a critical role in capturing and structuring this field intelligence. Integrated with automation tools, they allow immediate refinement of content sequences and audience segmentation based on active deal flow. Campaigns evolve in sync with what teams encounter in calls, demos, or follow-ups.

Sales data also sharpens lead qualification. Patterns in buyer behavior across roles or regions support scoring adjustments and help teams focus resources where conversion potential is highest. This avoids spreading efforts across segments unlikely to close and boosts pipeline velocity through smarter prioritization.

Competitive dynamics also emerge through field conversations. Objections tied to product gaps, implementation timelines, or support expectations surface long before they show up in trend reports. When these insights inform positioning or collateral updates, marketing can preempt churn risks or strengthen differentiation in crowded categories.

Clicks and impressions do not tell the full story. The true measure of campaign effectiveness lies in how many quality opportunities progress toward revenue. Closed-loop measurement, which links top-of-funnel activity to closed deals, clarifies which tactics work and which do not. This visibility aligns budget with performance and fosters shared accountability.

Field teams also flag rising needs that have not yet reached scale. A recurring request for a workflow integration or a shift in procurement behavior can signal an opportunity. Acting on these early signals enables content, offers, and product emphasis to meet demand ahead of the broader curve.

Organizational structures must support this system. Fragmented workflows and siloed KPIs create lags and missed insights. Regular syncs, shared dashboards, and integrated campaign calendars eliminate guesswork. Coordination turns insight into action and improves execution across departments.

Internal data brings urgency and clarity that external benchmarks alone cannot match. Buyer preferences shift quickly, and those closest to the transaction offer the most reliable guidance. Using that intelligence to inform messaging, cadence, and product focus makes campaigns more grounded, responsive, and measurable.

Sales data now powers strategic planning. It is no longer just an end-of-quarter record. When insights from the field guide marketing efforts in real time, teams move faster, waste less, and build stronger relevance with their audiences.

1 note

·

View note

Text

Landscaping Challenges Unique to Houston, TX Loop Neighborhoods

Houston, Texas, Inner Loop neighborhoods — from Montrose to Midtown, The Heights to West University — each have their own distinct character. But they also share something in common: unique landscaping challenges that require specialized care and local expertise. At IMRTL Landscaping, we’ve seen it all. And if you’re a homeowner or property manager in these bustling areas, understanding the specific hurdles of urban Houston landscaping can save you time, money, and frustration.

1. Space Constraints in Urban Settings

One of the most obvious challenges in Inner Loop neighborhoods is limited outdoor space. Homes often have compact front yards, narrow side lots, or only a modest backyard. Maximizing these spaces while maintaining curb appeal and functionality requires a creative approach to landscaping. Whether it’s vertical gardens, tiered planting beds, or hardscape features like paver patios, smart design is key.

IMRTL Landscaping specializes in small-space solutions that don’t compromise on beauty or usability. Our team transforms tight areas into lush, livable extensions of your home.

2. Soil Composition and Drainage Issues

Houston’s soil is notoriously tricky. In many Inner Loop areas, heavy clay soil prevents proper drainage, leading to standing water, root rot, and dying plants. Combine this with periodic heavy rainfall and hurricane season, and poor drainage can become a major issue.

At IMRTL Landscaping, we start every project with a soil test and drainage analysis. From French drains and grading to selecting native or water-tolerant plant species, we ensure your yard not only looks great — it functions effectively year-round.

3. Heat and Humidity

Houston’s subtropical climate means long, hot summers and high humidity levels. Plants that aren’t adapted to this environment will struggle. Likewise, irrigation systems must be efficient and tailored to avoid water waste and fungal issues.

Our experts know what thrives here — from hardy perennials to shade trees that help cool your property. We also install smart irrigation systems to conserve water while keeping your landscape healthy.

4. HOA and Historical Restrictions

Inner Loop neighborhoods often come with homeowners’ association (HOA) guidelines or historical district restrictions. These rules can limit the types of changes you can make to your landscaping, including plant height, fence materials, or tree removal.

IMRTL Landscaping works closely with property owners to design plans that meet aesthetic goals while staying compliant with all local rules. We handle the permits, applications, and paperwork so you don’t have to.

5. Traffic, Noise, and Privacy Concerns

Living closer to downtown comes with the constant hum of city life — and that includes traffic noise and reduced privacy. Many Inner Loop clients ask us for creative solutions that help block noise and add seclusion without sacrificing style.

We offer custom fencing, living privacy walls, and strategic planting to create serene outdoor spaces that feel like an escape, right in the heart of the city.

Why Choose IMRTL Landscaping?

At IMRTL Landscaping, we bring years of hands-on experience working specifically in Houston’s Inner Loop. We understand the unique terrain, climate, and regulations — and we know how to turn challenges into opportunities. Whether you’re looking to revamp a small backyard in Eastwood or install a drought-resistant front yard in Rice Military, our design-forward, problem-solving approach ensures results you’ll love.

Ready to Transform Your Urban Landscape?

Don’t let Houston, Texas landscaping challenges keep you from having the outdoor space you’ve always wanted. Contact IMRTL Landscaping today for a free consultation. Let’s bring your vision to life — one smart, sustainable solution at a time.

IMRTL Landscaping

6619 Westfield St, Houston, TX 77085

(832) 951-6770

0 notes

Text

Galvanized Steel Tanks as Water Treatment Equipment in Recirculating Aquaculture Systems

The global demand for seafood is escalating, driven by a growing world population and shifting dietary preferences. As wild fish stocks face increasing pressure from overfishing and environmental degradation, aquaculture has emerged as a critical solution to meet this demand sustainably. Within aquaculture, Recirculating Aquaculture Systems (RAS) represent a groundbreaking approach, offering unparalleled control over the rearing environment and significantly reducing water consumption. Unlike traditional pond or net-pen farming, RAS operates by continuously filtering and reusing water, creating a stable and optimized habitat for aquatic species. This closed-loop methodology, while remarkably efficient, places immense importance on the effectiveness of its Water Treatment Equipment.

At the heart of a successful RAS lies the ability to maintain pristine water quality. This necessitates robust, reliable, and durable components capable of handling continuous filtration, aeration, and purification processes. This is where the galvanized steel tank plays a pivotal role, not just as a containment vessel, but increasingly as integral water treatment equipment within these sophisticated systems. Center Enamel, a global leader in engineered tank solutions, is at the forefront of providing these high-performance, long-lasting galvanized steel tanks, empowering aquaculture operations worldwide to achieve new levels of productivity and environmental stewardship.

Products

Pressure Vessel

Atmospheric Pressure Vessels

Horizontal Containers, Vertical Cylindrical Containers, Vertical Cylindrical Storage Tanks

Separator Pressure Vessels

Gravity Separator, Cyclone Separator, Coalescing Separator, Centrifugal Separator, Steam-water Separator, Bearing Separator, Mechanical Filter, Ion exchange Filter, Air Filter, Fuel Filter, Adsorption Filter, BioFilter, Oil Filter, Hydraulic oil Filter, Separator

Heat Exchangers

Shell and Tube Heat Exchangers, Plate Heat Exchangers, Spiral Heat Exchangers , Air Coolers, Liquid Coolers, Thermoelectric Coolers, Chill Water Main Unit, Evaporative Condensers, Air cooled Condensers, Electronic Gas Condensers

Reactor Pressure Vessels

Stirred Tank Reactors, Continuous Stirred-tank Reactors, Tubular Reactors, Tower Reactors, Fixed Bed Reactors, Fluidized Bed Reactors, Bioreactors

The Imperative of Advanced Water Treatment in RAS

The success of a Recirculating Aquaculture System hinges entirely on its ability to recycle and purify water effectively. Fish and other aquatic organisms constantly excrete waste products, primarily ammonia, nitrite, and solids. If left unchecked, these substances rapidly accumulate to toxic levels, jeopardizing the health and survival of the aquatic stock. Moreover, maintaining optimal levels of dissolved oxygen, pH, and temperature is crucial for metabolic function and growth.

RAS minimizes water exchange, often recycling over 90-99% of its water volume daily. This efficiency is only achievable with highly effective Water Treatment Equipment that addresses all forms of contaminants:

Solid Waste Removal: Feces, uneaten feed, and other suspended particles must be efficiently removed.

Nitrogenous Waste Removal: Ammonia, highly toxic to aquatic life, is converted into less harmful nitrate through biological filtration.

Aeration and Oxygenation: Maintaining adequate dissolved oxygen levels is vital for aquatic organisms.

pH Control: Fluctuations in pH must be carefully managed.

Disinfection: Pathogens need to be controlled to prevent disease outbreaks.

Temperature Control: Optimal water temperature is essential for growth rates and overall health.

Failure in any of these treatment stages can lead to catastrophic system failure and significant stock losses. Therefore, the choice of materials and design for all components, particularly those involved in water treatment, is paramount.

Galvanized Steel Tanks: The Backbone of RAS Water Treatment

While often thought of simply as containers, galvanized steel tanks are increasingly being integrated into the design and function of Water Treatment Equipment within RAS. Their inherent properties make them exceptionally well-suited for these demanding applications:

1. Exceptional Durability and Corrosion Resistance:

The primary advantage of galvanized steel tanks is their unparalleled resistance to corrosion. In an aquaculture environment, water is constantly circulating, often with varying pH levels and dissolved solids, creating a corrosive challenge. The galvanization process, coating steel with a protective layer of zinc, forms a formidable barrier against rust and degradation. This zinc coating creates both a physical barrier and cathodic protection, sacrificing itself to protect the underlying steel. This ensures the structural integrity and longevity of the tanks, vital for continuous operation and minimizing costly downtime. These tanks can reliably house biological filters, clarifiers, and other critical water treatment modules for decades.

2. Versatility in Design and Function:

Galvanized steel tanks are incredibly versatile. Their modular, bolted panel design allows for customization in size and shape, making them ideal for various roles within the water treatment train:

Settling Tanks/Clarifiers: For initial removal of suspended solids.

Biofilters (MBBR or Fixed Bed): Housing media for biological filtration where beneficial bacteria convert harmful nitrogenous waste.

Degassing Tanks: To remove dissolved gases.

Sump Tanks/Reservoirs: For collecting treated water before recirculation.

Oxygenation Cones/Units: Serving as surrounding structures or foundational elements for oxygenation.

3. Ease of Integration and Scalability:

The modular nature of these galvanized steel tanks facilitates easy integration into complex RAS designs. Panels can be rapidly assembled on-site, significantly reducing construction time compared to concrete alternatives. This modularity also means that as an aquaculture operation expands, additional tank capacity for water treatment can be seamlessly added, offering unparalleled scalability and future-proofing the investment.

4. Hygienic and Easy to Clean:

The smooth, non-porous surface of galvanized steel inhibits the growth of biofilm and algae, making the tanks easier to clean and sterilize. This is crucial for maintaining excellent water quality and preventing the proliferation of pathogens.

Center Enamel: A Global Leader in Tank Solutions for Aquaculture

When considering the deployment of such critical infrastructure within an RAS, the choice of manufacturer is paramount. Center Enamel, with its extensive experience and unwavering commitment to quality, stands as a global leader in providing advanced tank solutions, including state-of-the-art galvanized steel tanks specifically engineered for the demanding environment of aquaculture.

For decades, Center Enamel has been dedicated to engineering and manufacturing high-performance tanks that meet the most stringent international standards. Our journey began with a vision to provide durable, reliable, and environmentally responsible storage solutions across various industries, and aquaculture has become a significant focus.

Our strength lies in our integrated approach, encompassing research and development, design, manufacturing, and global project execution. We leverage cutting-edge technology and innovative manufacturing processes to ensure every galvanized steel tank leaving our facilities is of the highest caliber. Our production lines are equipped with advanced automated machinery, ensuring precision engineering and consistent quality. This commitment to excellence is not just a claim, it is validated by a comprehensive suite of international certifications that attest to our adherence to global best practices.

Center Enamel’s Unmatched Company Strength and Qualifications

Center Enamel's formidable reputation is built upon a solid foundation of technical prowess, extensive experience, and rigorous quality control. Our manufacturing facility, equipped with state-of-the-art machinery and operated by highly skilled technicians, adheres to the most stringent international standards. We are proud to hold numerous certifications that underscore our commitment to product excellence and operational integrity.

These certifications include, but are not limited to:

ISO 9001 for Quality Management Systems: Ensuring high standards of quality in every galvanized steel tank we produce.

NSF/ANSI 61 Compliant Coatings (where applicable): Guaranteeing that our coatings do not leach harmful substances into the water, critical for fish health.

AWWA D103-09 and EN 15282 Standards: Globally recognized standards for bolted steel tanks, confirming superior engineering, structural integrity, and durability for RAS environments.

Environmental Management System Certifications (e.g., ISO 14001): Demonstrating our commitment to environmentally responsible manufacturing.

Occupational Health and Safety Certifications (e.g., ISO 45001): Ensuring the safety and well-being of our employees.

Beyond these crucial certifications, our strength lies in our global footprint and our impeccable track record of successful projects in diverse geographical and climatic conditions. We have partnered with leading aquaculture farms, research institutions, and engineering firms worldwide to deliver reliable Water Treatment Equipment solutions within RAS. Our dedicated team of engineers, project managers, and technical support staff provides end-to-end service, from initial consultation and customized design to manufacturing, installation guidance, and after-sales support. This holistic approach ensures every project is executed flawlessly and delivers optimal performance for your recirculating aquaculture system.

The Economic and Environmental Advantages of Galvanized Steel Tanks in RAS

The benefits of utilizing galvanized steel tanks as Water Treatment Equipment in RAS extend far beyond their structural integrity, offering significant economic and environmental advantages crucial for sustainable and profitable aquaculture operations.

Economic Benefits:

Extended Lifespan and Lower Life-Cycle Costs: The exceptional corrosion resistance of galvanized steel translates into a remarkably long operational lifespan (often exceeding 30-50 years) with minimal maintenance. This drastically reduces total cost of ownership, maximizing return on investment.

Reduced Maintenance Requirements: The robust zinc coating eliminates the need for expensive and disruptive internal and external painting or protective linings.

Rapid Deployment and Cost Savings on Installation: Modular design allows for significantly faster assembly and installation, reducing labor costs and accelerating production cycles.

Flexibility and Scalability for Growth: Tanks can be easily expanded, reconfigured, or relocated, providing long-term value and protecting initial capital investments.

High Resale Value: Due to their durability, these tanks retain considerable resale value.

Optimized Water Quality, Higher Yields: By providing stable platforms for water treatment, galvanized steel tanks indirectly contribute to better water quality, leading to reduced fish stress, lower mortality, improved feed conversion, and ultimately, higher and more consistent yields.

Environmental Benefits:

Water Conservation: As integral components of RAS, galvanized steel tanks facilitate the closed-loop system, drastically reducing fresh water consumption.

Reduced Effluent Discharge: Efficient filtration within the tanks significantly reduces the volume and pollutant load of discharged wastewater, minimizing environmental impact.

Material Efficiency and Recyclability: Steel is highly recyclable. At the end of their long service life, galvanized steel tanks can be almost entirely recycled, minimizing waste and conserving resources.

Lower Carbon Footprint: Long lifespan, low maintenance, and recyclability contribute to a lower overall carbon footprint.

Enhanced Biosecurity: Easily cleanable surfaces contribute to better biosecurity, helping prevent disease outbreaks and reducing the need for chemical treatments.

Sustainable Food Production: By enabling efficient and environmentally responsible aquaculture, galvanized steel tanks directly support sustainable protein production, reducing pressure on wild fisheries.

Technical Specifications and Customization for RAS Integration

Center Enamel's commitment to superior galvanized steel tanks for RAS is rooted in our meticulous engineering and advanced manufacturing processes. Each tank undergoes a rigorous design phase, leveraging sophisticated CAD/CAM software to optimize structural integrity, hydraulic efficiency, and performance within Water Treatment Equipment. Our engineers consider hydraulic loads, media support, aeration compatibility, access and maintenance, and environmental conditions.

The galvanization process at Center Enamel utilizes precisely controlled hot-dip galvanizing. Steel panels are immersed in molten zinc, creating a durable, uniform coating highly resistant to abrasion and impact. The zinc coating thickness is meticulously monitored for optimal corrosion protection, maximizing longevity in constant contact with water.

The modular panels are manufactured with precision, featuring pre-drilled bolt holes for seamless assembly. High-grade fasteners and specialized sealants, often food-grade and fish-safe, are used to create a leak-proof and robust structure. This attention to detail ensures the longevity, reliability, and safety of our galvanized steel tanks operating as critical Water Treatment Equipment in recirculating aquaculture systems. We also offer internal lining options for specific chemical resistance or enhanced biosecurity.

Applications of Center Enamel Galvanized Steel Tanks in RAS Water Treatment

The versatility and robustness of Center Enamel's galvanized steel tanks make them indispensable across various stages of water treatment equipment within a Recirculating Aquaculture System:

Mechanical Filtration Units (Clarifiers/Settling Tanks): For removing suspended solids.

Biological Filters (Biofilters): Providing robust containment for various biofilter types (e.g., MBBR, fixed-bed) that host beneficial bacteria.

Sumps and Reservoirs: Serving as essential buffer tanks for treated water.

Degassing Towers/Tanks: To remove excess dissolved gases.

UV Sterilization/Ozone Reaction Chambers (Supporting Structure): Serving as robust outer containment or pre-filtration chambers.

Sludge Collection and Processing Tanks: For storing and managing concentrated sludge.

Water Make-up and Storage Tanks: For storing incoming freshwater or treated water for system top-ups.

By serving these diverse and critical functions, Center Enamel's galvanized steel tanks are not merely passive containers but actively enable the efficient and effective operation of the entire RAS Water Treatment Equipment train, directly contributing to healthy fish populations and profitable aquaculture ventures.

Global Impact and Center Enamel's Project Track Record

Center Enamel has a proven track record of successful deployments across the globe, significantly contributing to the advancement of sustainable aquaculture. While specific project names are proprietary, our galvanized steel tanks have been instrumental in establishing and optimizing RAS facilities in diverse regions.

For instance, in a challenging inland location with limited water resources, a large aquaculture operator chose Center Enamel's galvanized steel tanks for their complete water treatment infrastructure within a new RAS facility. The rapid assembly of the modular tanks allowed the farm to become operational much faster, minimizing capital expenditure and accelerating production. The enduring corrosion resistance of the galvanized steel ensured long-term reliability in a demanding environment.

In another scenario, a university research facility specifically selected our tanks for their experimental RAS due to their precise engineering, ease of modification, and ability to maintain consistent water quality, crucial for accurate research outcomes. These projects underscore the practical benefits and tangible impact of choosing Center Enamel as a partner for cutting-edge aquaculture solutions. Our ability to deliver high-quality, customized galvanized steel tanks worldwide, coupled with comprehensive technical support, makes us a preferred choice for leading aquaculture innovators.

Installation, Commissioning, and Long-Term Maintenance

The modular design of Center Enamel's galvanized steel tanks translates into a streamlined installation process. Our tanks are supplied with detailed instruction manuals, comprehensive drawings, and a full set of accessories. They can be erected efficiently by trained local workforces, often without the need for heavy, specialized lifting equipment. This significantly reduces on-site construction time, labor costs, and minimizes overall project risks. We also offer comprehensive installation guidance, on-site supervision, and technical training to ensure smooth, correct, and efficient assembly and commissioning of your Water Treatment Equipment.

Once installed and commissioned, the maintenance requirements for galvanized steel tanks are remarkably low. The inherent corrosion resistance of the hot-dip zinc coating eliminates the need for periodic painting or internal lining inspections. Routine visual inspections and occasional cleaning of the interior surfaces are typically sufficient to ensure optimal performance. This low maintenance burden translates directly into reduced operational costs and increased operational uptime for aquaculture facilities, ensuring continuous and efficient water treatment within the RAS.

Looking Towards the Future: Innovation and Sustainability in Aquaculture

As the aquaculture industry continues its rapid expansion and technological evolution, the demand for more efficient, sustainable, and reliable Water Treatment Equipment will only intensify. Center Enamel remains committed to innovation, continuously researching and developing enhanced galvanized steel tanks and complementary storage solutions. We are exploring new coating technologies, advanced manufacturing techniques, and smart monitoring systems that can further optimize tank performance, reduce energy consumption, and enhance operational efficiency.

Our vision is to continue to be a leading partner for aquaculture operators worldwide, empowering them with best-in-class galvanized steel tanks that serve as robust and reliable components of their Water Treatment Equipment. We believe that by providing durable, cost-effective, and environmentally responsible solutions, we can contribute significantly to the sustainable growth of the global aquaculture industry, ensuring a secure and healthy food supply for future generations while minimizing ecological impact. The galvanized steel tank will undoubtedly remain a cornerstone of this future-proof infrastructure, offering a proven and versatile answer to the complex challenges of modern Recirculating Aquaculture Systems.

Partnering with Center Enamel for RAS Excellence

The success of modern Recirculating Aquaculture Systems hinges on the reliability and efficiency of their Water Treatment Equipment. Center Enamel's galvanized steel tanks offer a superior, future-proof solution for this critical function, combining unparalleled durability, economic efficiency, and environmental responsibility. Our commitment to engineering excellence, validated by extensive international certifications and a global track record of successful projects, positions us as the ideal partner for aquaculture farms, research institutions, and engineering firms seeking to build or optimize their RAS infrastructure.

By choosing Center Enamel, you are not just acquiring a tank, you are investing in a long-term solution backed by decades of expertise, cutting-edge technology, and a dedicated global team. Our galvanized steel tanks are more than just storage vessels, they are integral components designed to enhance the performance and sustainability of your aquaculture operations, ensuring optimal water quality and maximizing the productivity of your aquatic stock. We invite you to explore how Center Enamel can support your next aquaculture project and help achieve new benchmarks in sustainable and profitable fish farming.

#galvanized steel tank#galvanized tank#Galvanized Steel Water Tank#Galvanised Steel Water Storage Tanks#Hot-Dip Galvanized tank#HDG Water tank#Hot Dipped Galvanised#(HDG) Panel Tanks#zinc-coated steel tank

0 notes

Text

Shri Hare-Krishna Sponge Iron IPO

s India’s steel demand continues to rise, IPOs from the metal and infrastructure sectors are drawing investor interest. One such name making its way to the public markets is Shri Hare-Krishna Sponge Iron Limited. While it may not be a mainstream name yet, the company’s consistent performance, integrated operations, and industry positioning make this IPO worth a closer look.

Let’s break down everything investors need to know before making a decision.

Company Profile: What Does Shri Hare-Krishna Sponge Iron Do?

Shri Hare-Krishna Sponge Iron Limited is a Chhattisgarh-based company involved in manufacturing sponge iron, steel billets, ingots, and other long steel products. Established in 2003, the company has built an integrated manufacturing setup that helps it move from raw material to finished products under one roof.

Its business covers:

Sponge Iron Production

Steel Melting

Rolling Mill Operations

Steel Shots and Grits Manufacturing

By maintaining this vertical integration, the company has better control over costs, quality, and production timelines—giving it an edge in the highly competitive steel sector.

IPO Details and Fund Utilization

While the exact dates and pricing will be confirmed upon NSE Emerge listing, the company plans to issue shares via the SME IPO route. The fresh capital raised will be primarily used for:

Expanding its captive power plant, reducing dependency on external power and improving cost efficiency.

Meeting working capital needs to support growing operations.

General corporate purposes and partial debt repayment.

This focus on internal efficiency and cost control indicates the management’s long-term growth mindset.

Financial Performance Snapshot

Here's a look at how the company has performed financially over the last few years:Financial YearRevenue (₹ Cr)Net Profit (₹ Cr)Total Assets (₹ Cr)FY 202282.918.9447.92FY 202395.2510.5358.58FY 202484.9310.1775.74

Key insights:

Revenue growth has been stable, with a small dip in FY24 due to possible market or input fluctuations.

Profitability remains consistent and healthy for an SME.

Asset base has expanded, reflecting investments in infrastructure and capacity.

Strengths That Make This IPO Attractive

Integrated Manufacturing: Full control from raw material to final product ensures cost-effectiveness and quality.

Profit Consistency: Unlike many SMEs with unpredictable earnings, Shri Hare-Krishna has maintained a steady profit trend.

Expansion Plan: Investment in captive power signals long-term planning and better operational efficiency.

Sustainability Focus: The company has adopted environmentally conscious practices like closed-loop water systems and green belt development.

Risks You Should Be Aware Of

SME Exchange Listing: Trading volumes and liquidity may be lower than on the main boards (NSE/BSE), which could impact exit timing.

Debt Levels: The company does carry debt. Future obligations and repayment capacity must be monitored.

Market Sensitivity: Steel prices are cyclical and sensitive to global demand, which may impact margins.

Execution Risk: Expansion projects like the captive power plant need timely execution to deliver expected returns.

Should You Consider Investing?

If you're an investor looking for:

Exposure to India’s growing infrastructure and steel demand,

A company with proven operations and efficient integration,

And an IPO backed by stable profits and future growth plans...

…then Shri Hare-Krishna Sponge Iron IPO is worth serious consideration.

However, do factor in SME-specific risks, especially if you’re expecting immediate liquidity or short-term listing gains.

Final Thoughts

This IPO may not be backed by a flashy brand, but Shri Hare-Krishna Sponge Iron has the solid fundamentals and operational strategy many investors look for in an SME investment. With its clear focus on expansion, sustainability, and profitability, the company shows potential for value creation in the medium to long term.

Verdict: A fundamentally sound IPO with a growth story—ideal for patient investors with a long-term horizon.

0 notes

Text

United Kingdom Corrugated Packaging Market Size, Innovations & Key Growth Drivers

United Kingdom Corrugated Packaging Market Overview The UK corrugated packaging market is currently valued at approximately USD 4.18 billion in 2025, with projections ranging to USD 4.74 billion by 2030 at a compound annual growth rate (CAGR) of ~2.6 % over the 2025–2030 period citeturn0search0turn0search11. Another source estimates a slightly larger base of USD 12.13 billion, growing at a 3.9 % CAGR to reach USD 14.68 billion by 2030 citeturn0search2turn0search8—variances largely stem from differing definitions (corrugated board vs. total corrugated packaging). Growth is underpinned by rising sustainability standards, enhanced e‑commerce adoption (>29–38 % of retail sales), and innovations in manufacturing (fit‑to‑product, automated systems, smart packaging) citeturn0search0turn0search2turn0search4. The sector plays a vital role in supporting circular economy goals, leveraging high recycled content (~89 %) and a robust domestic infrastructure of ~47 mills citeturn0search0turn0search11. United Kingdom Corrugated Packaging Market Dynamics Drivers: E‑commerce growth (90 % of orders shipped in corrugated boxes), demand for lightweight and custom packaging, and stringent environmental regulations such as Extended Producer Responsibility (EPR) and EU recyclability mandates citeturn0search1turn0search6turn0search11turn0search4. Restraints: Raw material price volatility (fibre, adhesives); performance limitations (moisture, stacking durability); competition from plastics and other substrates citeturn0search6turn0search7turn0search8. Opportunities: Innovation in sustainable design (biodegradable coatings, antimicrobial liners), smart/active packaging, closed‑loop systems, and partnerships targeting niche sectors (fresh produce, pharmaceuticals) citeturn0search4turn0search7turn0search13turn0search9. Download Full PDF Sample Copy of United Kingdom Corrugated Packaging Market Report @ https://www.verifiedmarketresearch.com/download-sample?rid=478234&utm_source=PR-News&utm_medium=380 United Kingdom Corrugated Packaging Market Trends and Innovations The sector is embracing several key trends: E‑commerce‑ready packaging: Fit‑to‑size, printed corrugated boxes for online retailers, reducing material waste and improving brand experience citeturn0search1turn0search5. High‑graphic & hybrid printing: Integration of digital, flexo, and litho processes (e.g., Single‑Face Laminate) enables richer visuals and marketing impact citeturn0search20turn0search2. Smart & active packaging: QR codes, RFID tracking, anti‑moisture coatings, NFC‑enabled freshness sensors—supporting supply‑chain traceability and food‑safety citeturn0search0turn0search4turn0academia14. Closed‑loop reuse systems: B2B returnable corrugated boxes with latches and RFID help reduce waste and logistics costs citeturn0search13turn0search19. Sustainability frameworks: Circular economy and EPR rules are inspiring recycled-content targets, compostable liners, and collaborations across the value chain citeturn0search0turn0search6turn0search16. United Kingdom Corrugated Packaging Market Challenges and Solutions Supply chain disruptions—energy/fibre shortages and post‑Brexit friction—are increasing costs. Solution: vertical integration, strategic raw‑material sourcing, and improved logistics planning. Pricing pressures from substitute materials and EPR fees. Solution: invest in fibre‑savings (fit‑to‑size), material efficiency via digital design, and pass‑through value via sustainability premium branding. Regulatory complexity: evolving EPR and recyclability requirements. Solution: compliance teams, cross‑industry standards membership (FEFCO, CPI), and certification (ISO 18601+ series). Performance limitations: moisture, stacking, perishables. Solution: hybrid boards, coatings, moisture‑barrier liners, and active packaging solutions. United Kingdom Corrugated Packaging Market Future Outlook Over the next 5–10 years, the market is expected to grow at a CAGR between 2.

5 % and 4 %, reaching USD 5–15 billion by 2030–2033 depending on definitional scope citeturn0search3turn0search2turn0search4. Key growth factors include: Sustainability mandates: Tighter EPR, recyclability standards, and consumer demand. E‑commerce expansion: Continued online retail growth (20–40 % of sales). Tech integration: Smart packaging, automation, AI‑guided production, and digital‑to‑print solutions. Circularity adoption: Closed‑loop reuse schemes in B2B sectors (e.g., automotive, foodservice). Product / industry diversification: Usage in fresh produce, healthcare, pharmaceuticals, and high‑value goods with specialized solutions. To succeed, market players must leverage advanced manufacturing (automation, IoT), sustainable raw‑materials, and collaborate across sectors to drive innovation and compliance. The UK’s corrugated packaging industry is poised for sustainable, tech‑driven transformation aligned with circular‑economy principles. Key Players in the United Kingdom Corrugated Packaging Market United Kingdom Corrugated Packaging Market are renowned for their innovative approach, blending advanced technology with traditional expertise. Major players focus on high-quality production standards, often emphasizing sustainability and energy efficiency. These companies dominate both domestic and international markets through continuous product development, strategic partnerships, and cutting-edge research. Leading manufacturers prioritize consumer demands and evolving trends, ensuring compliance with regulatory standards. Their competitive edge is often maintained through robust R&D investments and a strong focus on exporting premium products globally. Smurfit Kappa DS Smith Mondi Group WestRock Packaging Corporation of America (PCA) Smurfit Kappa and Packaging Solutions Ltd (SKPS) Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount?rid=478234&utm_source=PR-News&utm_medium=380 United Kingdom Corrugated Packaging Market Segments Analysis and Regional Economic Significance The United Kingdom Corrugated Packaging Market is segmented based on key parameters such as product type, application, end-user, and geography. Product segmentation highlights diverse offerings catering to specific industry needs, while application-based segmentation emphasizes varied usage across sectors. End-user segmentation identifies target industries driving demand, including healthcare, manufacturing, and consumer goods. These segments collectively offer valuable insights into market dynamics, enabling businesses to tailor strategies, enhance market positioning, and capitalize on emerging opportunities. The United Kingdom Corrugated Packaging Market showcases significant regional diversity, with key markets spread across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Each region contributes uniquely, driven by factors such as technological advancements, resource availability, regulatory frameworks, and consumer demand. By Drug Type By Stage Of Disease By Distribution Channel By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/united-kingdom-corrugated-packaging-market/ About Us: Verified Market Research Verified Market Research is a leading Global Research and Consulting firm servicing over 5000+ global clients. We provide advanced analytical research solutions while offering information-enriched research studies. We also offer insights into strategic and growth analyses and data necessary to achieve corporate goals and critical revenue decisions. Our 250 Analysts and SMEs offer a high level of expertise in data collection and governance using industrial techniques to collect and analyze data on more than 25,000 high-impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research

methodology, expertise, and years of collective experience to produce informative and accurate research. Contact us: Mr. Edwyne Fernandes US: +1 (650)-781-4080 US Toll-Free: +1 (800)-782-1768 Website: https://www.verifiedmarketresearch.com/ Top Trending Reports https://www.verifiedmarketresearch.com/ko/product/latin-america-specialized-formula-medical-nutrition-market/ https://www.verifiedmarketresearch.com/ko/product/electric-linear-actuator-market/ https://www.verifiedmarketresearch.com/ko/product/form-automaton-software-market/ https://www.verifiedmarketresearch.com/ko/product/argireline-market/ https://www.verifiedmarketresearch.com/ko/product/amyloid-peptides-market/

0 notes

Text

VIATT 2026 unlocks broader opportunities

The Vietnam International Trade Fair for Apparel, Textiles and Textile Technologies (VIATT) is poised to return to the Saigon Exhibition and Convention Center (SECC) from 26 to 28 February 2026. Building on its second edition’s nearly 13% exhibitor growth, next year’s show floor will expand by 20%, from 15,000 to 18,000 sqm and cover the full area of Halls A and B. This includes new dedicated zones for apparel, fashion accessories, and textile chemicals and dyes, with the strategic growth underscoring Vietnam’s emergence as a vertically and horizontally integrated textile powerhouse.

Despite recent business challenges, the global industry still considers Vietnam a strategic, long-term market. The country’s signing of 17 new generation free trade agreements (FTAs) has further fuelled market and export diversification, positioning VIATT as a pivotal platform for varied industry players to capitalise on Vietnam's dynamic business landscape and foster international collaboration.

Ms Wilmet Shea, General Manager of Messe Frankfurt (HK) Ltd, emphasised VIATT's significance: “VIATT’s second edition marked a 30% increase in buyers’ internationality and a 10% rise in buyers overall, signifying the fair’s crucial role in advancing Vietnam’s textile industry. Next year’s expanded showcase and its trend-focused approach will enable suppliers across the textile spectrum, within fashion, home, and technical segments, to connect with leading global brands, supporting Vietnam's shift from volume-driven exports to value-led innovative and sustainable manufacturing.”

VIATT 2026 will further solidify its position as Southeast Asia’s premier sourcing event by introducing specialised trend forums, sustainable textile showcases, and designer fashion shows. A key highlight will be the return of the Econogy Hub, dedicated to eco-friendly materials, sustainable production, and certification. Aligning with Vietnam’s goal of establishing a closed-loop textile economy by 2050, the platform spotlights innovations such as organic fibres, recycled synthetics, and low-impact dyeing technologies.

Complementing its sustainability initiatives, the fair will continue the development of its Innovation & Digital Solution Zone. This zone features cutting-edge technologies that optimise design, production, and supply chain management – from AI-driven prototyping to automation systems. These solutions empower Vietnam’s textile sector to upgrade operations and harness new market opportunities.

Apparel Fabrics & Fashion: sustainable growth engine

Vietnam is a powerhouse in the textile and garment sector, generating over USD 44 billion in 2024 and targeting USD 48 billion this year[2], with apparel textile manufacturers now prioritising sustainable fibres, innovative fabrics, and design-driven finished products. In line with this transformation, VIATT 2026 will expand its offering to finished apparel products to better serve fashion designers, as well as garment manufacturers. The category is set to include the debut Fashion Label Zone, showcasing boutique fashion houses, while the fair will also introduce a dedicated Fashion Accessories Zone for bags, footwear, jewellery, and more, likely to appeal to brands such as Tory Burch and Zara, notable buyers in the previous edition.

VIATT 2025 attracted other global brand buyers including American Eagle, Callaway, Club Monaco, Decathlon, J.Crew, Lululemon, M&S, Nike, Puma, Target, and Wacoal. Meanwhile, Southeast Asian buyers took advantage of the international products on offer. Reflecting on the region’s fashion potential, Mr Bao Jia Cheng from Shaoxing Sunsmile Textile Co Ltd, exhibiting at VIATT 2025, said: “We have brought fashion embroidery fabrics and polyester embroidery yarns, predominantly for stylish women's wear. Southeast Asia is undoubtedly a key focal point for the future evolution of Asia-Pacific's economy, and I regard this exhibition as a crucial avenue for penetrating the Southeast Asian market. l've seen a promising visitor flow and good quality customers, and notably met interested parties from Vietnam, Thailand, lndia, and other parts of the region.”

Home & Contract Textiles: riding the urbanisation wave

Vietnam's home textile market is experiencing robust growth, driven by rising disposable income, urbanisation, and changing consumer preferences. The market is projected to grow from around USD 3 billion in 2025 to nearly USD 4 billion by 2030[3]. With many exhibitors at the fair aiming to leverage this growth, key product categories include bedding, bath linen, table linen, curtains, upholstery fabrics, and decorative textiles. The demand for these fabrics has drawn notable buyers such as IKEA, Muji, and Novotel to VIATT 2025.

Building on this momentum, the 2026 edition will feature enhanced displays of finished textile products for contract and residential applications, ranging from luxury bedding and curtains to contract-grade textiles for hotels and homes. Mr Dennis Macharia, Sourcing – Home Textiles China from Maaron International Procurements, remarked when sourcing at last year’s fair: “We are a home textiles company managing American clients’ orders in China. There have been promising leads, especially Chinese suppliers who have already opened a good number of factories in Vietnam, and in India, Myanmar, and Indonesia. I have already found OEKO-TEX and BSCI certified suppliers at VIATT 2025, which are very important for our clients.”

Additionally, VIATT's Econogy Check provides independent confirmation of eco-credentials, saving buyers time and resources while building trust across the supply chain. Exhibitors who pass the Check will be featured in the online directory, Econogy Finder, which helps buyers more easily identify exhibitors with sustainability certifications.

Technical Textiles & Technologies: innovation frontier

Driven by economic growth, adoption of Industry 4.0 technologies, and supportive government policies, the global technical textiles market is projected to grow at a CAGR of 6.5% from 2024 to 2032, reaching over USD 390 billion by 2032. Key segments include Clothtech (clothing), Indutech (industrial), Mobiltech (automotive), Medtech (medical textiles), Protech (protective wear), and smart textiles with moisture-wicking or UV-protection properties, many of which have been exhibited at the fair. Set to extend its technical scope, VIATT 2026 will introduce a dedicated Textile Chemicals & Dyes Zone, featuring additives for chemical recycling, fibre production, finishing & coating, pre-treatment, and weaving & knitting preparation; chemical dyes and pigments; and more.

0 notes

Text

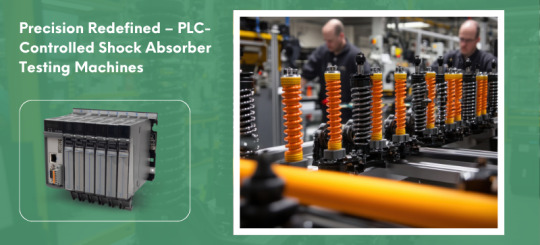

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

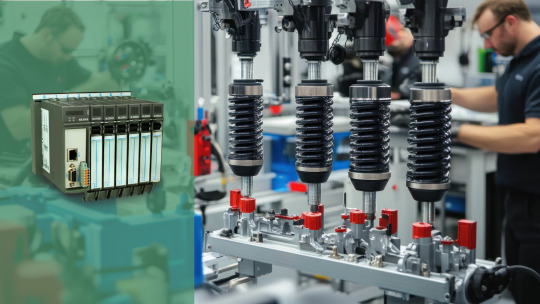

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

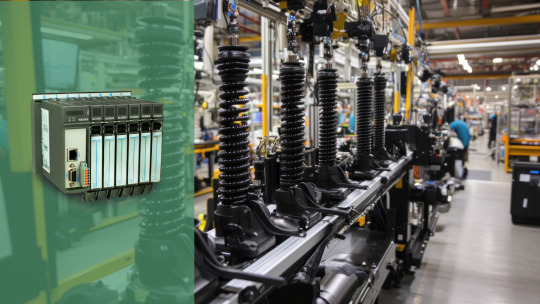

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

The Role of a NetSuite Solutions Consultant: Your Strategic Guide

While a NetSuite solution provider offers the infrastructure and implementation know-how, a NetSuite solutions consultant is your strategic advisor who works closely with your team to ensure the solution meets your unique needs. At Artove, our consultants are the linchpin between your business goals and the technical execution of your NetSuite system.

What Does a NetSuite Solutions Consultant Do?

A NetSuite solutions consultant performs a wide range of functions, including:

Needs Assessment: Understanding your business processes, bottlenecks, and future goals to define the scope of the project.

Solution Design: Architecting the best configuration of NetSuite modules and customizations to match your workflows.

Process Optimization: Recommending process improvements and automation opportunities that align with industry best practices.

Training & Support: Ensuring your staff is confident and proficient in using the system through role-based training and user documentation.