#Cleanroom Construction Services

Explore tagged Tumblr posts

Text

Cleanroom Contractors in Pune: Leading the Way in Cleanroom Construction and Design Services

As the demand for controlled environments continues to rise across industries like pharmaceuticals, biotechnology, healthcare, electronics, and food processing, the need for reliable cleanroom contractors in Pune is more crucial than ever. These specialized contractors provide end-to-end solutions, from cleanroom design services to cleanroom construction services, ensuring that industries maintain the highest standards of cleanliness, contamination control, and regulatory compliance.

Why Choose Cleanroom Contractors in Pune?

Pune, known as an emerging industrial hub, has seen significant growth in sectors that require sterile and controlled environments. With industries like pharmaceuticals, electronics manufacturing, and medical device production thriving in the region, Cleanroom Contractors in Pune play an essential role in ensuring that these industries meet stringent hygiene standards.

Cleanroom contractors in Pune offer a wide array of services tailored to specific client requirements. These contractors bring in-depth expertise in creating ISO-compliant cleanrooms, which are crucial for sectors that need highly controlled environments with strict regulations regarding air quality, temperature, humidity, and particle count.

Whether it's a small-scale laboratory or a large pharmaceutical production facility, cleanroom contractors in Pune possess the necessary skills to design, construct, and maintain facilities that meet the latest international standards. By opting for professionals in the field, industries can ensure that their cleanroom installations are efficient, cost-effective, and long-lasting.

Cleanroom Construction Services: Building Contamination-Free Environments

Cleanroom Construction Services are essential for industries that require contamination-free spaces to conduct their operations. The construction of a cleanroom goes beyond just building walls and ceilings; it involves the installation of specialized HVAC systems, filtration systems, and airflow systems to ensure that the room maintains the required cleanliness levels at all times.

A reputable cleanroom contractor provides comprehensive cleanroom construction services, which include the planning and designing of the cleanroom layout, followed by the construction of the room itself with state-of-the-art materials. These materials include antistatic flooring, smooth wall surfaces, and sealed ceilings, which help minimize the risk of contamination.

Another key aspect of cleanroom construction services is ensuring that all systems are tested and calibrated according to regulatory standards. Contractors use specialized equipment to perform airflow and pressure testing, particle count analysis, and environmental monitoring to ensure that the cleanroom operates efficiently and is in compliance with cleanliness standards such as ISO 14644.

Cleanroom Design Services: Tailored to Your Industry’s Needs

One of the most critical aspects of establishing a cleanroom is the design phase. Cleanroom Design Services provided by experienced contractors involve creating a layout and infrastructure that best meets the specific needs of your industry. Whether you're designing a cleanroom for a pharmaceutical manufacturing facility, a biotech laboratory, or an electronics production plant, the design must consider multiple factors such as space optimization, airflow patterns, and ease of cleaning.

Cleanroom design services focus on providing a flexible solution that adheres to both the functionality and regulatory compliance of the cleanroom. This includes choosing the right materials for walls, floors, and ceilings, selecting efficient air filtration systems, and planning for proper ventilation and humidity control.

Moreover, cleanroom contractors in Pune work closely with clients to understand their operational processes and customize the design accordingly. The design services also encompass integration with the client's existing infrastructure, ensuring that the cleanroom blends seamlessly with the overall building design while meeting cleanliness standards.

Additionally, professional cleanroom designers take into account factors like workflow efficiency, employee safety, and energy conservation when designing a cleanroom. This ensures that the final design not only adheres to regulatory standards but also maximizes productivity and reduces operational costs.

Conclusion: Ensuring Sterile Environments with Expert Cleanroom Contractors in Pune

For industries in Pune that require the highest levels of cleanliness and contamination control, partnering with skilled cleanroom contractors is essential. Whether you're looking for cleanroom construction services or cleanroom design services, these professionals can provide tailored solutions that meet international standards and specific industry needs.

By choosing experienced contractors, businesses can ensure that their cleanroom design and construction are both efficient and compliant, ultimately helping them maintain quality, safety, and profitability. With cleanroom contractors in Pune offering end-to-end solutions, industries can enjoy peace of mind knowing their operations will thrive in contamination-free environments.

0 notes

Text

Building Excellence: The Role of Professional Cleanroom Construction Services

Cleanrooms are vital environments in industries where precision, sterility, and controlled conditions are paramount. From pharmaceutical manufacturing to semiconductor fabrication, cleanrooms ensure that products meet stringent quality standards by minimizing contaminants. At Parsan Engineers And Consultants, we understand the critical role that cleanroom construction plays in achieving these standards. Let's explore the significance of professional cleanroom construction services and how they contribute to building excellence in cleanroom facilities.

Expertise in Cleanroom Design and Engineering: Professional cleanroom construction services begin with meticulous planning and design. At Parsan Engineers And Consultants, our team of experts collaborates closely with clients to understand their specific requirements and industry standards. We leverage our expertise in cleanroom design and engineering to develop customized cleanroom layouts that optimize workflow efficiency, contamination control, and regulatory compliance. By employing advanced design software and simulation tools, we ensure that cleanroom facilities meet or exceed regulatory requirements and industry best practices.

Quality Construction and Materials: The quality of construction and materials used in cleanroom facilities is crucial for their performance and longevity. Professional cleanroom construction services prioritize the use of high-quality materials that are compatible with cleanroom operations and resistant to contamination. At Parsan Engineers And Consultants, we partner with trusted suppliers and contractors to source materials that meet stringent cleanliness and durability requirements. Our construction teams employ specialized techniques and procedures to minimize particulate generation, prevent cross-contamination, and achieve the desired level of cleanliness in cleanroom facilities.

Adherence to Regulatory Standards: Cleanroom construction must comply with strict regulatory standards and guidelines set forth by organizations such as the FDA, ISO, and IEST. Professional cleanroom construction services ensure that cleanroom facilities meet these standards for air cleanliness, temperature and humidity control, pressure differentials, and contamination control. At Parsan Engineers And Consultants, we have extensive experience in navigating regulatory requirements and ensuring compliance with cleanroom construction projects. From initial concept design to final commissioning and validation, we guide our clients through every step of the construction process, ensuring that cleanroom facilities meet regulatory requirements and industry standards.

Comprehensive Project Management: Cleanroom construction projects require meticulous planning, coordination, and project management to ensure timely completion and adherence to budgetary constraints. Professional cleanroom construction services provide comprehensive project management support, including scheduling, budgeting, procurement, and onsite supervision. Parsan Engineers And Consultants assign dedicated project managers to oversee cleanroom construction projects from inception to completion, ensuring that all milestones are met, and potential delays or issues are addressed proactively. Our streamlined project management approach minimizes disruptions to client operations and ensures that cleanroom facilities are delivered on time and within budget.

Integration with Validation and Qualification Services: Cleanroom construction is closely integrated with validation and qualification processes to ensure that facilities meet operational requirements and regulatory standards. Professional cleanroom construction services, such as those offered by Parsan Engineers And Consultants, seamlessly integrate with validation and qualification services to provide end-to-end solutions for cleanroom projects. By coordinating construction activities with validation protocols and testing procedures, we streamline the qualification process and expedite the commissioning of cleanroom facilities. Our holistic approach ensures that cleanroom facilities are not only constructed to the highest standards but also validated and qualified for intended use.

In summary, professional cleanroom construction services are essential for achieving excellence in cleanroom facilities across various industries. At Parsan Engineers And Consultants, we leverage our expertise, experience, and commitment to quality to deliver customized cleanroom construction solutions that meet the unique needs of our clients. From concept design to commissioning, we are dedicated to building cleanroom facilities that uphold the highest standards of cleanliness, compliance, and operational efficiency.

0 notes

Text

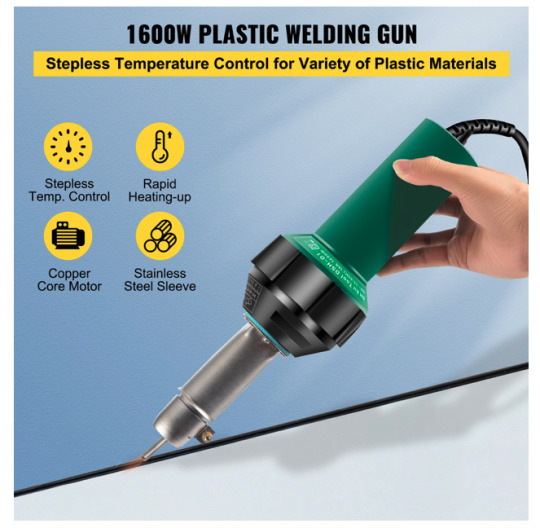

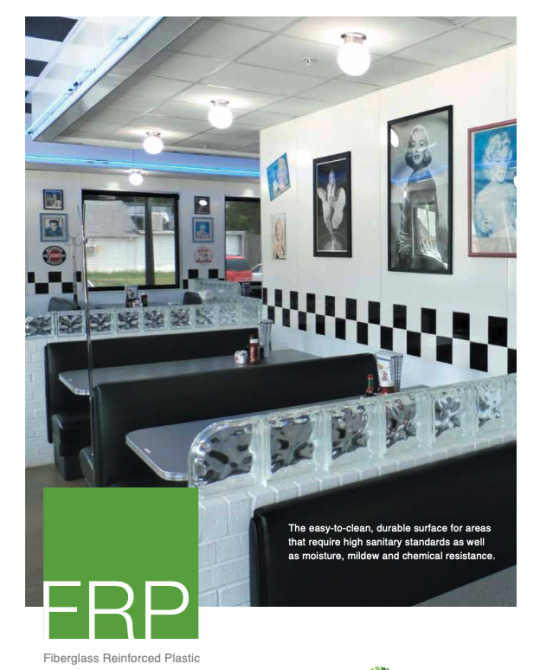

Controlling rising construction costs

In the current landscape of escalating taxes, soaring utility expenses, manufacturing and shipping costs along with the general upkeep of buildings, the construction industry is grappling with a significant surge in material prices. Suppliers, in an attempt to offset their mounting overheads, are passing on the burden to consumers, resulting in an undeniable hike in construction costs. Amidst these challenges, the need for a more streamlined and cost-effective approach becomes increasingly apparent.

Enter www.commwall.ca, a pioneering force reshaping the dynamics of the construction and building materials sector. Recognizing the urgency of the hour, www.commwall.ca is committed to offering a comprehensive range of building materials, tools, and apparel at direct pricing. The platform goes a step further, extending exclusive discounts to registered installation companies and dealers, with even greater incentives for full pallet orders.

Unlike traditional norms that often required bulk truckload purchases for substantial discounts, www.commwall.ca breaks the mold by negotiating smaller quantity bulk deals. This revolutionary approach allows businesses to invest less capital, maintain minimal standing inventory, and simultaneously enhance profit margins. The result is a win-win scenario, where contractors not only optimize their returns but also pass on the savings to clients, making their project bids more competitive.

www.commwall.ca stands out as a leader in the Canadian building materials industry with an ever-expanding array of manufacturers and products. This diversity ensures that Canadian contractors have access to a wide selection, meeting the demands of today's dynamic construction environment. By embracing www.commwall.ca, industry professionals can navigate the challenges of rising costs, ultimately fostering a more efficient and economically viable construction landscape.

In a world where direct shipping and bulk purchases have become essential for cost-conscious construction projects, www.commwall.ca emerges as the clear choice for Canadian contractors. Visit their website to explore the extensive offerings and revolutionize the way you approach construction material procurement.

#business#entrepreneur#economy#construction#building materials#healthcare#startup#ecommerce#hygienic#contractor#project managers#construction estimating services#tools#installation#jack of all trades#commercial#prevention#antimicrobial#cleanroom#mortuary science#veterinary#dental#clinic#safety#food safety#agriculture#cannabis

1 note

·

View note

Text

PUF Panel Supplier in India | High-Quality PUF Sandwich Panels by EPACK Prefab

Introduction

As industries expand and modern infrastructure demands energy-efficient, durable, and cost-effective construction solutions, PUF Panels have become the preferred choice across various sectors. Whether it's cold storage, warehouses, industrial sheds, or commercial buildings, the use of PUF Sandwich Panels ensures excellent insulation, structural strength, and long-term durability.

If you are searching for a trusted PUF Panel Supplier in India, EPACK Prefab provides premium-quality PUF Insulated Sandwich Panels, designed for thermal efficiency, weather resistance, and sustainability.

What is a PUF Panel?

A PUF Panel (Polyurethane Foam Panel) is a lightweight, high-performance insulation panel used for walls, roofing, and cold storage applications. It consists of a rigid polyurethane foam (PUF) core sandwiched between two durable metal sheets, providing superior thermal insulation and structural stability.

✔ Highly durable and lightweight ✔ Excellent thermal and sound insulation ✔ Fire-resistant and weatherproof ✔ Energy-efficient, reducing cooling & heating costs ✔ Quick and easy installation ✔ Environmentally friendly and recyclable

Why Choose EPACK Prefab as Your PUF Panel Supplier?

EPACK Prefab is a leading manufacturer and supplier of PUF Panels in India, offering customized, high-quality, and cost-effective insulation solutions. Our expertise in prefabrication technology enables us to deliver durable and efficient PUF Sandwich Panels for various industrial and commercial applications.

1. Premium-Quality PUF Sandwich Panels

🔹 Manufactured using high-grade materials for long-lasting durability. 🔹 Available in different thicknesses & sizes to meet diverse project needs. 🔹 Customizable insulation panels for varied temperature requirements.

2. Wide Range of PUF Panel Solutions

We offer a comprehensive range of PUF Panels designed for multiple industrial applications, including:

🏗 PUF Roofing Panels – Ideal for industrial & commercial roofing solutions. 🏢 PUF Wall Panels – Suitable for exterior & interior walls. ❄ PUF Cold Storage Panels – High-performance insulation for temperature-controlled environments. 🛠 PUF Partition Panels – Used in modular offices, cleanrooms, and laboratories.

3. Advanced Manufacturing Facility

🔹 State-of-the-art production units ensuring high-precision manufacturing. 🔹 ISO-certified quality standards for unmatched product reliability. 🔹 Eco-friendly production with minimal material wastage.

4. Cost-Effective & Energy-Efficient

🔹 Superior insulation properties reducing energy consumption. 🔹 Quick installation minimizes project timelines and labor costs. 🔹 Long-lasting performance, reducing maintenance expenses.

5. PAN India Delivery & Installation Support

🔹 Nationwide presence, ensuring prompt supply across all locations. 🔹 Professional installation services for seamless project execution. 🔹 Custom-made solutions tailored to client requirements.

Applications of PUF Panels

PUF Insulated Sandwich Panels are widely used across multiple industries for thermal insulation, energy efficiency, and structural durability. Some common applications include:

🏢 Industrial & Commercial Buildings – Offices, factories, warehouses. ❄ Cold Storage & Refrigerated Warehouses – Ensuring temperature control. 🏗 Prefabricated Structures – Modular housing, site offices, clean rooms. 🌡 HVAC Ducting & Insulated Rooms – Maintaining controlled environments. 🚧 Healthcare & Laboratories – Hospitals, pharma units, research centers.

Why PUF Panels are the Best Choice for Insulated Construction?

With the increasing demand for energy-efficient and eco-friendly construction, PUF Panels have become the go-to solution for modern buildings. Here’s why:

✅ Thermal Insulation – Minimizes heat transfer, reducing cooling & heating expenses. ✅ High Strength-to-Weight Ratio – Lightweight yet structurally robust. ✅ Quick Installation – Prefabricated for faster and hassle-free assembly. ✅ Fire & Weather Resistance – Provides protection against fire hazards and extreme weather conditions. ✅ Long-Term Durability – Resistant to corrosion, moisture, and UV radiation.

Why EPACK Prefab is India’s Most Trusted PUF Panel Supplier?

🔹 25+ years of expertise in the prefabrication industry. 🔹 100+ ongoing projects across India. 🔹 Turnkey PUF panel solutions – From manufacturing to on-site installation. 🔹 Serving diverse industries – Cold storage, industrial sheds, cleanrooms, and more.

📌 Client Satisfaction: EPACK Prefab has successfully delivered high-performance insulation solutions for industries, ensuring top-quality, cost-efficiency, and long-lasting performance.

Get in Touch with EPACK Prefab – India’s Leading PUF Panel Supplier!

Looking for high-quality PUF Panels for your next project? EPACK Prefab is your one-stop solution for PUF Insulated Sandwich Panels, Roofing Panels, and Cold Storage Panels at competitive prices.

📩 Email: [email protected] 📞 Call: +91 8130444466 🌐 Website: www.epack.in/puf-panels

🚀 Build faster, smarter, and more energy-efficient with EPACK Prefab – India’s leading PUF Panel Manufacturer & Supplier!

Related Blog - What is a PUF Panel and Why Choose It Over Traditional Construction Materials?

#PUF Panels#PUF Panel Supplier#PUF Sandwich Panels#PUF Roofing Panels#PUF Insulated Panels#PUF Panel Manufacturer#PUF Cold Storage Panels#Prefabricated Insulated Panels#Industrial PUF Panels#Insulated Roofing Sheets#EPACK Prefab

0 notes

Text

Pharmaceutical Engineering Services: Driving Innovation in Healthcare Manufacturing

Pharmaceutical engineering services play a pivotal role in the development, manufacturing, and delivery of healthcare products. From designing state-of-the-art facilities to ensuring compliance with strict regulatory standards, these services provide a foundation for efficiency, safety, and innovation in the pharmaceutical industry.

What Are Pharmaceutical Engineering Services?

Pharmaceutical engineering services encompass a wide range of specialized solutions designed to support drug development and manufacturing processes. These services include facility design, process optimization, equipment validation, quality control, and regulatory compliance. By combining engineering expertise with pharmaceutical knowledge, these services ensure the production of high-quality, safe, and effective products.

Key Areas of Focus in Pharmaceutical Engineering Services

Facility Design and Construction

Creation of GMP-compliant facilities

Cleanroom design for aseptic environments

Integration of advanced HVAC and filtration systems

Process Development and Optimization

Streamlining drug production processes

Implementation of continuous manufacturing technologies

Reduction of operational costs while maintaining product quality

Equipment and System Validation

Equipment qualification (IQ, OQ, PQ)

Calibration and maintenance of machinery

Ensuring adherence to international quality standards

Regulatory Compliance and Quality Assurance

Compliance with FDA, EMA, and WHO regulations

Validation documentation and audits

Risk assessment and management

Sustainability and Automation

Adoption of green engineering practices

Integration of automation and Industry 4.0 technologies

Benefits of Pharmaceutical Engineering Services

Enhanced Product Quality: Ensures consistency and safety in drug production.

Regulatory Compliance: Reduces the risk of non-compliance with global standards.

Cost-Efficiency: Optimizes resources and minimizes waste.

Innovative Solutions: Leverages cutting-edge technologies for advanced healthcare products.

Pharmaceutical engineering services are essential for advancing healthcare manufacturing, ensuring quality, and meeting global demands in the dynamic pharmaceutical sector.

To locate “Pharmaceutical engineering services” effortlessly, download the Justdial app (JD App). Simply search “Pharmaceutical engineering services” within the app to discover nearby outlets , dealers and access detailed information about their offerings and locations. easy and convienient.

0 notes

Text

What Makes a Great Cleanroom Manufacturer in the UAE?

Cleanrooms play a crucial role in various industries, including pharmaceuticals, electronics, and healthcare. Choosing the right cleanroom manufacturers in the UAE is essential to ensure high-quality standards and compliance with industry regulations. With the growing demand for cleanroom solutions, businesses must carefully evaluate manufacturers based on several key factors.

1. Industry Expertise and Experience

One of the most important qualities of a great cleanroom manufacturer is extensive industry experience. Companies with years of expertise understand the specific requirements of different sectors and can design cleanrooms that meet strict regulatory guidelines. A well-established manufacturer in the UAE will have a track record of successfully delivering cleanroom projects for various industries.

2. Compliance with International Standards

A reputable cleanroom manufacturer must comply with global industry standards such as ISO 14644, GMP (Good Manufacturing Practices), and FDA regulations. These standards ensure that cleanrooms maintain the required levels of cleanliness, airflow control, and contamination prevention. Manufacturers that adhere to these guidelines provide reliable and high-performance cleanroom solutions.

3. Customization and Innovative Designs

Different industries have unique requirements for cleanrooms, making customization a critical factor. The best cleanroom manufacturers in the UAE offer tailored solutions, considering factors like room size, air filtration systems, and environmental controls. Additionally, innovative designs incorporating energy efficiency, modular construction, and advanced materials enhance the functionality and durability of cleanrooms.

4. Quality of Materials and Construction

High-quality materials play a significant role in the performance and longevity of cleanrooms. Reliable manufacturers use premium materials such as stainless steel, high-grade PVC, and reinforced glass to construct durable and contamination-free environments. Precision engineering and superior construction techniques ensure that cleanrooms meet the highest quality standards.

5. Advanced Technology and Automation

Modern cleanroom facilities require advanced technology to maintain strict environmental conditions. Leading manufacturers integrate cutting-edge automation systems, HEPA and ULPA filtration, and real-time monitoring solutions to enhance efficiency. Smart cleanroom technology helps businesses maintain compliance and reduce operational costs.

6. Comprehensive Support and Maintenance Services

Building a cleanroom is just the first step; maintaining its efficiency is equally important. The best cleanroom manufacturers in UAE provide after-sales support, regular maintenance, and technical assistance to ensure optimal performance. A strong customer support system helps businesses avoid costly downtime and maintain a contamination-free workspace.

7. Reputation and Client Reviews

A manufacturer’s reputation speaks volumes about its credibility and reliability. Before choosing a cleanroom provider, businesses should check client testimonials, case studies, and industry certifications. A well-reviewed manufacturer with satisfied clients is a strong indicator of quality service and expertise.

Conclusion:

Selecting the right cleanroom provider is essential for businesses that require contamination-controlled environments. The best cleanroom manufacturers in UAE prioritize quality, compliance, customization, and technological innovation. If you are looking for a trusted cleanroom provider, Podtech Company offers top-tier solutions tailored to your industry needs. With a strong presence in the UAE, Podtech Company ensures the highest standards of cleanroom manufacturing, delivering reliable and efficient solutions for businesses across various sectors.

0 notes

Text

The Importance of Pharma Consulting for Cleanroom Solutions

In the pharmaceutical industry, maintaining a controlled and contamination-free environment is critical. Cleanrooms play a pivotal role in ensuring the quality and safety of pharmaceutical products. However, designing, building, and maintaining cleanrooms that meet stringent regulatory standards can be a complex task. This is where pharma consulting for cleanroom solutions becomes indispensable.

What is Pharma Consulting for Cleanroom Solutions?

Pharma consulting for cleanroom solutions involves expert guidance and support in the planning, design, construction, and maintenance of cleanrooms tailored to pharmaceutical applications. Consultants specialize in ensuring that cleanrooms meet industry regulations, such as GMP (Good Manufacturing Practices) and ISO standards, while optimizing operational efficiency.

Key Benefits of Pharma Consulting for Cleanroom

Regulatory Compliance: Cleanrooms in the pharmaceutical sector must adhere to strict guidelines to ensure product safety and quality. Pharma consulting for cleanroom helps navigate complex regulatory requirements, ensuring full compliance.

Custom Solutions: Every pharmaceutical facility has unique needs. Consultants assess your specific requirements and provide tailored cleanroom design solutions, ensuring the perfect balance between functionality and cost-effectiveness.

Expertise in Cleanroom Technology: With advancements in cleanroom HVAC systems and modular cleanroom panels, keeping up with the latest innovations can be challenging. Pharma consultants bring in-depth knowledge of modern cleanroom wall panels, materials, and systems.

Cost and Time Efficiency: By streamlining the design and installation process, consultants help save valuable time and resources, minimizing potential delays and errors in cleanroom installation services.

Risk Mitigation: Consultants proactively identify and address potential risks in cleanroom design for hospitals and other facilities, reducing the likelihood of costly errors or compliance issues.

The Role of Cleanrooms in the Pharmaceutical Industry

Cleanrooms are specialized environments designed to minimize contamination risks during pharmaceutical manufacturing. These environments control factors such as temperature, humidity, air quality, and particle levels to ensure the integrity of sensitive products, such as vaccines, injectable drugs, and sterile formulations. Cleanroom wall panels and HVAC systems play a crucial role in maintaining these controlled environments.

Pharmaceutical manufacturing processes, such as filling, packaging, and testing, require controlled environments to meet stringent regulatory standards. Even minor deviations in cleanroom conditions can result in significant product loss or regulatory penalties, making the role of cleanrooms indispensable in the pharmaceutical industry.

How Pharma Consultants Ensure Cleanroom Excellence

Pharma consulting for cleanroom solutions involves a range of specialized services designed to meet the unique needs of pharmaceutical facilities. Here are some key areas where consultants add value:

1. Site Assessment and Feasibility Studies

Before starting the design process, consultants conduct detailed site assessments to understand the specific requirements of the facility. They evaluate factors such as available space, workflow patterns, and environmental conditions to determine the best layout and cleanroom HVAC manufacturers to partner with.

2. Design and Engineering

Pharma consultants work closely with engineers and architects to develop cleanroom designs that optimize space utilization and ensure compliance with regulatory standards. They consider factors such as airflow patterns, material selection, and the placement of equipment to minimize contamination risks.

3. Vendor Selection and Equipment Procurement

Choosing the right equipment and materials is crucial for cleanroom performance. Consultants assist in selecting reliable HVAC systems, modular cleanroom panels, and filtration systems that meet the specific needs of the facility. They also ensure that all components, including cleanroom wall panels, are sourced from reputable vendors and meet industry standards.

4. Installation and Validation

Pharma consultants oversee the installation process to ensure that cleanrooms are built according to design specifications. They also conduct validation and testing to verify that the cleanroom meets performance standards, such as air cleanliness levels, temperature control, and pressure differentials.

5. Training and Maintenance

Once the cleanroom is operational, consultants provide training to staff on best practices for cleanroom operation and maintenance. They also develop maintenance plans to ensure long-term performance and compliance with standards for cleanroom design for hospitals and pharma facilities.

Challenges in Cleanroom Design and How Consultants Help

Designing and maintaining cleanrooms comes with several challenges, including:

Regulatory Complexity: Navigating the maze of regulatory requirements can be daunting. Pharma consulting for cleanroom solutions ensures compliance with GMP, ISO, and other standards.

Balancing Costs and Quality: Building a cleanroom that meets regulatory standards without exceeding budget constraints is a common challenge. Consultants provide cost-effective solutions, incorporating cleanroom wall panels and HVAC systems, without compromising on quality.

Rapid Technological Advancements: The cleanroom industry is constantly evolving, with new technologies and materials such as modular cleanroom panels emerging regularly. Consultants stay up-to-date with the latest advancements and incorporate them into their designs.

Operational Efficiency: Ensuring smooth workflow and minimizing contamination risks requires careful planning. Consultants design layouts and systems, including cleanroom HVAC systems, that enhance operational efficiency while maintaining cleanliness.

Why Choose Experts for Pharma Cleanroom Consulting?

Pharma consultants bring years of experience and technical expertise to the table. Their role is to simplify the complexities of cleanroom design and maintenance while ensuring compliance with industry standards. Choosing a trusted consulting partner can significantly enhance your operational efficiency and product quality.

With the increasing demand for high-quality pharmaceutical products, the importance of cleanrooms has never been greater. Whether you are planning to build a new cleanroom or upgrade an existing facility, partnering with experienced pharma consultants can make all the difference.

Future Trends in Pharma Cleanroom Solutions

The pharmaceutical industry is evolving rapidly, and cleanroom solutions are no exception. Here are some trends shaping the future of cleanroom consulting:

Sustainable Cleanroom Designs: With a growing focus on sustainability, cleanroom designs now incorporate energy-efficient HVAC systems, eco-friendly materials, and waste reduction strategies.

Modular Cleanroom Systems: Modular cleanroom panels offer flexibility and scalability, making them an increasingly popular choice for pharmaceutical facilities.

Automation and Smart Technology: The integration of automation and IoT (Internet of Things) in cleanroom systems allows for real-time monitoring and control, enhancing efficiency and reliability.

Enhanced Training Programs: As regulations become more stringent, comprehensive training programs are becoming essential to ensure staff compliance and operational excellence.

Conclusion

Investing in pharma consulting for cleanroom solutions is essential for pharmaceutical companies aiming to meet the highest standards of quality and safety. With expert guidance, your cleanroom can become a hub of innovation and reliability, driving success in the competitive pharmaceutical landscape.

If you're planning to design or upgrade your cleanroom, partnering with experienced pharma consultants can make all the difference. Ensure compliance, optimize performance, and achieve your operational goals with professional cleanroom installation services. By staying ahead of industry trends and leveraging expert knowledge, pharmaceutical companies can maintain their competitive edge and deliver high-quality products to the market.

0 notes

Text

Expert Pharma Consultants in India - Quantum Pharmatech Solutions

Quantum Pharmatech stands out as a leading choice for pharma consultants in India, offering comprehensive services for pharmaceutical companies. Whether you need guidance on regulatory compliance, cleanroom construction, or turnkey pharmaceutical projects, our experts are here to provide practical solutions. We focus on helping businesses achieve operational excellence, reduce costs, and enhance product quality.

To learn more visit us :

#quantumpharmatech#quantum pharmatech#pharmaceutical consulting companies#pharma consultants in india#pharma consultancy#pharmaceutical turnkey solutions

0 notes

Text

Why Cleanroom Construction in San Diego Requires Specialized Contractors

Cleanroom construction is a profession that involves so much knowledge, skill, and experience that many people cannot undertake it without professional assistance. Many industries for example laboratory, manufacturing and, healthcare in San Diego require cleanrooms that are constructed to certain standards. These rooms are designed to minimize contamination and to guarantee that delicate functions are affected in a clean environment. The slightest of deviation in construction affects the cleanliness and usability of these areas.

1. Specialized Knowledge in Contamination and Management

**San Diego Commercial Contractor**s who focus on cleanrooms are crucial since they have appropriate knowledge of contamination control. Cleanrooms are areas of extreme delicateness where even a small particle can cause an interruption. Some contractors, for example, have the ability and penchant for installing certain materials and structures that cannot accumulate and transmit undesirable elements.

They also know how to provide appropriate airflow systems that will minimize on the presence of air particles. Since the contractors in cleanroom construction have a rich experience, they guarantee their clients that the cleanroom has met the required standards of cleanliness and safety.

2. Awareness of High Regulatory Compliance

Under special sectors of application like healthcare, pharmaceutical and technology, cleanrooms need to adhere to regulatory compliance. Specialist contractors are aware of the current laws which apply to them and how to apply them into practice. For instance, they observe procedures of airflow, temperature, and pressure for the cleanroom to perform appropriately.

https://jpcdn.it/img/r/485/272/6a0aaaedbe1575853a1960f4003273b7.jpg

These contractors appreciate these regulations, and that is why they have the best knowledge of how to design and construct a cleanroom. Unknowingly, projects are likely not to meet such rigorous standards that are in place to ensure all conditions are met, leading to costly delays or even the facility's closure.

3. Accuracy in Planning and Implementation

Cleanrooms are sensitive structures that require significant construction project management****, especially at the construction design stage. Architects and engineers employ specialized contractors for the project, and everybody ensures every detail is as expected. MSDS has employed advanced technologies and quality materials to develop adequate cleaning standards, product sturdiness, and performance effectiveness.

A specialized contractor understands that measurements and layouts are critical to any construction project. Even the ceiling and the flooring are not exempt from this since everything has to be precise to achieve a controlled environment. Contractors who have work experience and specific training in cleanroom construction can accomplish this level of work.

Conclusion

In particular, for those harbingers of San Diego needing cleanrooms, it is important to select a contractor of a similar nature. Little Brothers Construction has a cleanroom construction service enhanced by its many years of providing general contracting services. Little Brothers Construction is one of the best **San Diego Commercial Contractors—**we know the specific needs of cleanrooms and only work to industry standards.

For your cleanroom construction needs in San Diego, turn to Little Brothers Construction for properly built, HEPA-compliant cleanrooms. With their guidance and assistance, your cleanroom will be as compliant, secure, productive, and dependable as it should be for your most critical operations.

0 notes

Text

Safety Hand Gloves Dealers In Bangalore - Expo Groups

When it comes to workplace safety, the right protective gear is non-negotiable. Among the essential protective equipment, safety hand gloves play a critical role in ensuring the well-being of workers across industries. Expo Groups, one of the leading safety hand gloves dealers in Bangalore, offers a wide range of high-quality gloves tailored to meet diverse industrial requirements.

Why Safety Hand Gloves Are Essential

Safety hand gloves provide protection against hazards such as chemical exposure, sharp objects, extreme temperatures, and contamination. They are indispensable for industries like manufacturing, healthcare, construction, and chemical processing, where worker safety is paramount. Choosing the right gloves can significantly reduce workplace injuries and improve productivity.

Expo Groups: Your Trusted Partner for Safety Hand Gloves

At Expo Groups, we pride ourselves on being a reliable supplier of safety hand gloves in Bangalore. Our inventory includes gloves designed for various applications, including:

Cut-Resistant Gloves: Ideal for handling sharp tools and materials in industries like metal fabrication.

Chemical-Resistant Gloves: Perfect for protecting hands from harmful chemicals in laboratories and chemical plants.

Heat-Resistant Gloves: Designed for industries that involve high-temperature operations, such as welding and glass manufacturing.

Disposable Gloves: Suitable for medical and cleanroom environments, ensuring hygiene and safety.

Why Choose Expo Groups?

Wide Product Range: From lightweight disposable gloves to heavy-duty industrial gloves, we cater to all needs.

Top-Quality Products: We source gloves from trusted brands that meet international safety standards.

Competitive Pricing: We offer premium products at affordable prices to suit your budget.

Customer Support: Our team of experts helps you choose the right gloves for your specific requirements.

Serving Bangalore and Beyond

As one of the top safety hand gloves dealers in Bangalore, we are committed to providing exceptional service to our customers. Our products are trusted by businesses across various industries, ensuring a safer and more efficient workplace.

Contact Expo Groups Today!

Whether you need industrial gloves for construction, healthcare, or chemical processing, Expo Groups is your go-to supplier. Partner with us for high-quality safety hand gloves and ensure maximum protection for your workforce.

0 notes

Text

How Cleanroom Contractors Ensure Compliance and Safety

Cleanrooms are critical environments where air quality, temperature, and humidity are tightly controlled to prevent contamination in processes that require extreme precision. Industries such as pharmaceuticals, biotechnology, electronics, aerospace, and healthcare rely on cleanrooms to maintain sterile and controlled environments. Cleanroom companies and cleanroom contractors are essential players in the design, construction, and maintenance of these spaces, ensuring they meet stringent industry standards and regulatory requirements.

Role of Cleanroom Companies

Cleanroom companies specialize in providing end-to-end solutions for cleanroom environments, from design and engineering to installation and certification. These companies understand the specific needs of industries that rely on cleanrooms and provide customized solutions to ensure the environment remains contaminant-free.

One of the key offerings from cleanroom companies is the design and layout of the cleanroom itself. This involves a deep understanding of airflow patterns, filtration systems, and material selection to prevent particles, dust, and microbes from entering the controlled environment. These companies often work with businesses to develop cleanrooms that meet specific industry standards such as ISO, GMP (Good Manufacturing Practices), or FDA regulations.

In addition to designing and building cleanrooms, many companies also offer ongoing maintenance services. This includes monitoring air quality, calibrating equipment, and performing regular testing to ensure that the cleanroom remains compliant with industry standards. Cleanroom companies may also provide cleaning services, using specialized equipment and materials to maintain sterility in highly sensitive areas.

Expertise of Cleanroom Contractors

Cleanroom contractors are responsible for the physical construction and installation of cleanroom environments. These contractors work closely with cleanroom companies, architects, and engineers to build cleanrooms that adhere to strict design specifications. The construction process involves the integration of advanced HVAC systems, air filtration units (such as HEPA or ULPA filters), cleanroom-grade materials (like anti-static flooring and wall systems), and lighting that minimizes contamination risks.

Cleanroom contractors must ensure that all construction work follows strict guidelines to prevent any compromise in cleanliness or air quality during or after construction. Their expertise is not limited to the build but also extends to system integration, including the installation of air handling units, pressure differentials, and temperature control systems that keep the cleanroom stable and secure.

Meeting Industry Standards

Both cleanroom companies and contractors play a crucial role in ensuring that cleanrooms meet industry-specific standards. From pharmaceutical manufacturing to microelectronics production, any contamination can have devastating consequences on product quality and safety. By combining engineering excellence with a deep understanding of regulatory compliance, cleanroom professionals ensure that businesses can achieve the level of purity required for their processes. In conclusion, cleanroom companies and cleanroom contractors are essential partners for businesses operating in contamination-sensitive industries. They provide tailored, high-quality solutions that ensure precision, safety, and compliance in cleanroom environments.

0 notes

Text

Outdoor Power Equipment Market to Witness Huge Growth by 2030

Outdoor Power Equipment Industry Overview

The global outdoor power equipment market size was valued at USD 46.53 billion in 2021 and is expected to reach USD 76.61 billion by 2030, registering a CAGR of 5.9% during the forecast period, according to a new report by Grand View Research, Inc. The market growth can be credited to the increasing adoption of outdoor power equipment, using lithium-ion batteries and cordless outdoor power equipment.

For instance, in September 2021, DeWalt, one of the brands of Stanley Black & Decker, announced the launch of a 20V MAX lithium-Ion batteries system to support a variety of outdoor power equipment. Furthermore, government and public places need to be maintained and have an aesthetic appeal, additionally stimulating demand for the lawn mowers. Besides, the growing perception that gardening is a leisure activity is a critical factor in the outdoor power equipment demand.

Gather more insights about the market drivers, restrains and growth of the Outdoor Power Equipment Market

The rising technological advancements in outdoor power equipment are increasing the inclination of people toward gardening, which is expected to impact growth. For instance, in February 2022, Makita Corporation launched two new Lawn Mowers, XML10CT1 (21" Lawn Mower Kit) and XML11CT1 (21" Self-Propelled Lawn Mower Kit). These two product features 36V (18V X2) LXT power batteries, which signify their capabilities in the cordless lawn and garden market. Furthermore, the rise in residential construction and rising demand for lawn and electric cordless lawn & garden tools in commercial spaces, parks, and sports fields are the factors expected to drive market growth.

Vendors' rising adoption of ergonomic designs enables people to perform activities with less labor and makes their tasks more manageable. It allows people to perform their functions with much less time than non-ergonomic tools. For instance, in November 2021, The Toro Company launched five new gas and battery-based Super Recycler models for the lawn care market. These products are designed with an ergonomic grip, which enables gardeners to have greater cutting convenience, and are developed with additional safety features, to pack within a folded handle.

A considerable increase in the demand for do-it-yourself (DIY) equipment and do-it-for-me (DIFM) services in the commercial and residential segment are expected to drive market growth. The outdoor power equipment market is seasonally affected by end-customer buying patterns, and most outdoor power equipment is sold during the summer and spring seasons. As a result of seasonality in the industry and short-term fluctuations in demand caused by weather patterns, growth in the market is hindered.

Browse through Grand View Research's HVAC & Construction Industry Research Reports.

The global cleanroom technology market size was valued at USD 7.69 billion in 2024 and is anticipated to grow at a CAGR of 5.9% from 2025 to 2030.

The global flow computers market size was valued at USD 1.23 billion in 2024 and is projected to grow at a CAGR of 8.3% from 2025 to 2030.

Outdoor Power Equipment Market Segmentation

Grand View Research has segmented the global outdoor power equipment market based on the power source, end-use, equipment, and region:

Outdoor Power Equipment Power Source Outlook (Revenue, USD Million, 2018 - 2030)

Gasoline

Battery

Electric Corded

Outdoor Power Equipment End-Use Outlook (Revenue, USD Million, 2018 - 2030)

Residential

Commercial/Government

Outdoor Power Equipment Type Outlook (Revenue, USD Million; Volume, Thousand Units, 2018 - 2030)

Lawn Mower

Walk-Behind Lawn Mowers

Ride-on Lawn Mowers

Robotic Lawn Mowers

Zero -Turn Mowers

Chainsaw

Trimmer & Edger

Trimmers & Brush Cutter

Hedge Trimmers

Walk-Behind Edgers & Trimmers

Blowers

Snow

Leaf

Tillers & Cultivators

Snow Throwers

Others

Outdoor Power Equipment Regional Outlook (Revenue, USD Million; Volume, Thousand Units, 2018 - 2030)

North America

US

Canada

Europe

UK

Germany

France

Italy

Netherland

Denmark

Finland

Spain

Russia

Rest of Europe

Asia Pacific

China

India

Japan

South Korea

Singapore

Australia

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa

UAE

Saudi Arabia

South Africa

Rest of Middle East & Africa

Key Companies profiled:

Husqvarna AB

Makita Corp

Honda Motors Co. Ltd

Briggs & Stratton Corp.

Andreas Stihl AG & Company KG

MTD Holdings Inc.

Stanley Black and Decker Inc.

Andreas Stihl AG & Company KG

CHERVON (China) Trading Co., Ltd

Techtronic Industries Ltd.

Yamabiko Corporation

Robert Bosch

AL-KO Kober Group

Ariens Company

The Toro Company

Deere & Company

Order a free sample PDF of the Outdoor Power Equipment Market Intelligence Study, published by Grand View Research.

0 notes

Text

Stainless Steel 304L Seamless Tubes Exporters In India

Introduction :

Stainless Steel 304 Seamless Tubes, crafted from an austenitic stainless steel of grade 304, represent a pinnacle in quality tubing solutions. With approximately 18% chromium and 8% nickel in its chemical composition, these tubes epitomize durability and resilience. Stainless Steel 304 Seamless Tubes Suppliers to adhere to both national and international specifications such as ASTM, ASME, and API, our Metinox Overseas tubes stand as paragons of precision engineering.

Product Overview :

Our Stainless Steel 304 Seamless Tube solutions boast exceptional weldability, making them ideal for a myriad of applications. At Metinox Overseas, we offer electric fusion tubes of the highest grade to ensure superior performance in any setting. The nominal bore size of our SS 304 Tubes ranges from ½ inches to 16 inches, with customizable shapes, sizes, and dimensions tailored to your specific requirements.

Stainless Steel 304 Tubes Standard Specifications :

Specifications

ASTM A213 / ASME SA213

Outside Diameter

1/8″ OD TO 2″OD 3MM OD TO 38 MM OD

Thickness

1MM TO 3 MM 0.028 TO 0.156 IN, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS

Size

1/2″ NB – 24″ NB

Type

Seamless / Capillary Tubes

Form

Round Tubes, Square Tubes, Rectangular Tubes.

Length

Single Random, Double Random & Required Length

End

Plain End, Beveled End, Treaded

Finish

Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Application of Stainless Steel 304L Seamless Tubes:

1. Industrial Applications:

Chemical Processing: Due to its excellent corrosion resistance, it is used in chemical storage tanks, heat exchangers, and process piping.

Petroleum Refining: Employed in piping systems for transportation of corrosive fluids.

Food and Beverage Industry: Used in equipment and piping due to its sanitary properties and resistance to food acids.

Pharmaceutical Industry: Applied in cleanroom systems and process pipelines, thanks to its high hygienic standards.

2. Construction and Infrastructure:

Structural applications in buildings, bridges, and architectural features due to its strength and durability.

Railings and support structures for its aesthetic and low-maintenance properties.

Conclusion:

Stainless Steel 304L seamless tubes offer a versatile and reliable solution across various industries due to their exceptional corrosion resistance, mechanical properties, and weldability. Their low carbon content enhances resistance to intergranular corrosion after welding, making them ideal for critical applications requiring long service life and high hygiene standards

#Stainless Steel 304L Seamless Tubes Suppliers#Stainless Steel 304L Seamless Tubes Stockists#Stainless Steel 304L Seamless Tubes Exporters#Stainless Steel 304L Seamless Tubes Manufacturers In India#Stainless Steel 304L Seamless Tubes Suppliers In India#Stainless Steel 304L Seamless Tubes Stockists In India#Stainless Steel 304L Seamless Tubes Exporters In India

0 notes

Text

SS 304 Flange Deals – Buy at Low Prices from Udhhyog

If you’re looking for SS 304 flange deals at affordable prices, Udhhyog has the perfect solutions to meet your needs. Our SS 304 flanges are known for their strength, corrosion resistance, and versatility, making them ideal for industries like construction, chemical processing, and water treatment. Take advantage of Udhhyog’s low prices and high-quality products designed for lasting performance.

Benefits of SS 304 Flanges from Udhhyog

Affordable Quality: Our SS 304 flanges are priced competitively without compromising quality.

Durable and Reliable: Made to withstand harsh environments, ensuring long-lasting use.

Wide Selection for Bulk Orders: Find various sizes and options that fit large or small requirements.

Convenient Online Ordering: Easily browse, select, and buy SS 304 flanges through our platform.

Industries That Benefit from SS 304 Flanges

Oil and Gas: Reliable in high-pressure and corrosive environments.

Pharmaceuticals: Ideal for sanitary and cleanroom applications.

Construction: Strong and versatile for infrastructure projects.

Food Processing: Safe for clean and hygienic applications.

How to Get the Best SS 304 Flange Deals on Udhhyog

For exclusive SS 304 flange deals, check out our dedicated SS 304 Flange section to find a wide range of options tailored to your specific industrial needs. Enjoy hassle-free shopping with reliable service and consistent quality.

Why Choose Udhhyog for Your SS 304 Flange Needs?

Competitive Pricing: Udhhyog ensures you get the best deals on quality flanges.

Certified Quality: We offer products that meet stringent industry standards.

Exceptional Customer Support: From product selection to after-sales, our team is here to assist.

Flexible Payment Options: Convenient payment methods for ease of purchase.

Explore additional options in our flanges category and find out why Udhhyog is the preferred choice for SS 304 flange deals at unbeatable prices.

1 note

·

View note

Text

Industrial Vacuum Cleaners- Essential Tools for Heavy-Duty Cleaning

Industrial cleaners are specialized machines built to tackle the demanding cleaning tasks found in factories, warehouses, construction sites, and other large-scale facilities. Unlike household vacuums, industrial vacuums are engineered for durability, power, and adaptability, effectively removing dust, dirt, debris, and even hazardous materials from various surfaces. They not only improve cleanliness and productivity but also enhance worker safety by minimizing air pollutants and tripping hazards.

Types of Industrial Vacuum Cleaners

Wet and Dry Vacuum Cleaners: These machines are versatile and capable of handling both wet and dry debris, making them suitable for various industrial applications. They can be used to clean up water spills, oils, and other liquids in addition to dry materials like dust, wood chips, and metal shavings. This flexibility makes wet and dry vacuums an essential asset for industries ranging from manufacturing to automotive.

Explosion-Proof Vacuum Cleaners: In industries like chemicals, pharmaceuticals, and mining, handling flammable dust and volatile materials is common. Explosion-proof vacuum cleaners are specifically designed for such environments, meeting strict safety standards to prevent accidents. They use specialized components that prevent static discharge and contain potential explosions within the vacuum.

Continuous Duty Vacuum Cleaners: Continuous-duty industrial vacuums are designed for environments that require non-stop cleaning, such as 24/7 manufacturing plants and warehouses. These machines are built with robust motors that can withstand long hours of operation without overheating, ensuring uninterrupted productivity and a consistently clean workspace.

Centralized Vacuum Systems: Centralized vacuum systems are installed as permanent fixtures in large facilities, providing an efficient solution for continuous cleaning. These systems include multiple inlets connected to a single powerful motor, allowing workers to connect hoses and clean various areas without needing individual vacuum units. They are ideal for facilities requiring dust collection across multiple workstations.

Key Features of Industrial Vacuum Cleaners

High Suction Power: Industrial vacuum cleaners are designed with powerful motors, allowing them to pick up heavy debris, large dust particles, and even hazardous materials. High suction power is especially beneficial for cleaning hard-to-reach areas, such as ductwork and machinery crevices, where dust and dirt can accumulate and potentially interfere with equipment performance.

Advanced Filtration Systems: Many industrial vacuum cleaners feature multi-stage filtration systems to trap dust and allergens, including fine particulate matter like PM10 and PM2.5. HEPA (High-Efficiency Particulate Air) filters are often included to meet air quality standards in sensitive environments such as cleanrooms and food production facilities.

Durability and Robust Construction: Made from heavy-duty materials, industrial cleaners are built to withstand the challenging conditions of industrial sites. The construction typically includes corrosion-resistant metals, reinforced plastic casings, and shock-absorbent components, all contributing to a long service life even under intensive use.

Ease of Mobility: To accommodate cleaning across expansive industrial floor cleaning machines, many vacuum cleaners are equipped with sturdy wheels, ergonomic handles, and compact designs, making it easy to transport and maneuver in tight spaces. Some models, like the Dulevo DBF 20 Z22 W, even come with options for mounted systems or wheeled configurations for enhanced portability.

Applications of Industrial Vacuum Cleaners: Industrial vacuum cleaners are essential in a wide range of settings:

Manufacturing Plants: Used for collecting metal shavings, plastic residues, and other manufacturing by-products, these vacuums keep work areas clear and safe.

Warehouses: Warehouses require frequent cleaning due to constant movement of goods. Industrial vacuums remove dust and debris to maintain product quality and improve air quality.

Construction Sites: Construction environments often generate large amounts of dust and debris. Heavy-duty vacuums can handle materials such as cement dust, wood chips, and other bulky debris.

Pharmaceutical and Food Industries: Stringent hygiene and cleanliness standards in these industries make industrial vacuums with advanced filtration systems essential for maintaining contaminant-free environments.

Environmental and Safety Considerations: Modern industrial vacuum cleaners emphasize environmental sustainability through energy-efficient designs and eco-friendly filtration systems. Many machines also include options for dust suppression to minimize airborne contaminants, contributing to a safer work environment. Explosion-proof and HEPA-filtered vacuum cleaners specifically address safety concerns in hazardous and sensitive settings, reducing exposure to harmful dust and other particulates.

Conclusion: Industrial vacuum cleaners play a critical role in maintaining cleanliness, productivity, and safety across a range of industries. With advancements in power, durability, and filtration, these machines are indispensable for efficiently managing the unique cleaning challenges of industrial environments. As the demand for eco-friendly and safe cleaning solutions grows, industrial vacuum cleaner technology will continue to evolve, providing even more effective and specialized options for complex cleaning needs.

For more information on different types of industrial vacuum cleaners, visit Dulevo India.

#industrial cleaner#industrial floor cleaner#industrial cleaning equipment#industrial vacuum cleaner#industrial vacuum cleaners#industrial floor cleaning machines#industrial vacuum

0 notes

Text

A Comprehensive Overview of Semi-Conductor Cleanroom Equipment: Air Shower, Airtech Filter, Clean Bench, FFU, Teardrop Lighting, Pass Box, SS-MAC, Surface Particle Removal Device, Air Curtain, and CHEMI-MAC

The semiconductor industry demands an ultra-clean and controlled environment to ensure the quality and performance of its sensitive components. Cleanrooms, the cornerstone of this industry, rely on advanced technologies to maintain precise contamination control. The following article delves into some essential cleanroom equipment used in semiconductor manufacturing, focusing on their functionalities and importance.

Air Shower

An air shower is a vital component at the entrance of a cleanroom, designed to eliminate dust and particulate matter from the garments of workers. Acting as an airlock between the cleanroom and gowning area, it prevents contaminants from entering the clean zone. AIRTECH's Pulse Jet Air Shower introduces a patented technology that improves particle removal efficiency by an average of 10% compared to conventional air showers. By using a pulsating air stream, the system shakes garments to dislodge surface particles, which are then filtered through HEPA filters before being recirculated. With features like steel construction, HEPA filters, and programmable logic control, the Pulse Jet Air Shower provides a robust solution for semiconductor cleanrooms.

Airtech Filter

Airtech HEPA filters are engineered to meet international standards, ensuring cleanroom environments maintain the highest levels of air purity. Manufactured in a cleanroom setting, these filters offer predictable performance and ensure the removal of particles as small as 0.3 microns. Whether used in air showers, fan filter units, or clean benches, Airtech HEPA filters play an integral role in preserving the cleanliness required in semiconductor manufacturing.

Clean Bench

Clean benches from AIRTECH are an effective solution for maintaining a clean zone around critical work areas. Available in a variety of models, including table top, console, and SS-MAC, these benches ensure horizontal or vertical laminar airflow, keeping the working area free from contaminants. Commonly used in semiconductor, pharmaceutical, and microelectronic industries, AIRTECH’s clean benches are available in different classifications to suit the stringent cleanliness levels required by these industries.

Fan Filter Unit (FFU)

AIRTECH’s Fan Filter Unit (FFU) is a compact and efficient air filtration system, essential for ensuring cleanroom environments meet the necessary cleanliness standards. Built with high-efficiency HEPA or ULPA filters, these units are designed for energy efficiency, reduced noise levels, and long service life. FFUs are ideal for a wide range of applications in cleanrooms, including front-end and back-end semiconductor manufacturing, biological areas, and sterile environments.

Cleanroom Teardrop Lighting

Lighting in cleanrooms must adhere to specific standards to ensure the environment remains contaminant-free while providing optimal visibility. Airtech’s cleanroom teardrop lighting systems are specially designed for installation in cleanroom ceilings and provide adjustable illumination that meets the demands of the semiconductor industry. These lighting systems are compact, can be surface-mounted, and provide ready-to-plug electrical connections, ensuring ease of installation and use in cleanroom environments.

Pass Box

Pass boxes serve as a buffer zone between cleanrooms and adjoining areas, facilitating the transfer of materials without disturbing airflow or air pressure. These boxes prevent cross-contamination by employing an interlocking system that ensures only one door is open at a time. AIRTECH’s auto pass box systems come equipped with HEPA filters, double sliding doors, and fan units to facilitate the smooth transfer of goods into cleanrooms. This setup not only preserves the cleanliness of the environment but also reduces the need for personnel movement, minimizing the risk of contamination.

SS-MAC

SS-MAC fan filter units provide flexible and reliable air filtration for critical cleanroom areas. These units can be mounted horizontally, vertically, or even upside down, offering a customizable solution for cleanroom environments. Each SS-MAC unit comes with either HEPA or ULPA filters, ensuring the removal of 99.99% to 99.999% of particulates as small as 0.12 microns. They can be used in various configurations, including clean booths, buffer booths, and conveyor hoods, providing clean air wherever needed.

Surface Particle Removal Device

Surface particle removal devices are crucial for removing contaminants from equipment or materials entering a cleanroom. AIRTECH’s brush particle remover uses a nylon brush to eliminate dust from hard surfaces, while its negative pressure design prevents particle dispersion. Additionally, the air knife particle remover uses high-speed jets to blow particles off surfaces, ensuring that no contaminants enter the cleanroom environment. These devices maintain the integrity of cleanrooms by ensuring all surfaces are particle-free before entry.

Air Curtain

Air curtains are installed at cleanroom entrances to prevent airborne contaminants and insects from entering. AIRTECH’s air curtain features a patented unbalanced airflow design that creates a barrier at doorways, keeping contaminants out while allowing personnel to move freely. The system is customizable to match door dimensions and can be integrated with high-speed shutters to enhance its effectiveness. These air curtains are essential for maintaining the cleanliness and sterility of semiconductor cleanrooms.

CHEMI-MAC

CHEMI-MAC is a specialized air filtration unit equipped with a HEPA filter and a chemical filter to remove gaseous pollutants in cleanroom environments. With ultra-high-performance PTFE filters that collect more than 99.9995% of 0.1-micron particles, CHEMI-MAC is ideal for semiconductor manufacturing, where maintaining a pristine atmosphere is critical. It features a variable speed control for adjusting airflow and a time counter for tracking usage, ensuring efficient and reliable operation.

Conclusion

The semiconductor industry relies on an array of advanced cleanroom technologies to maintain its strict contamination control standards. From air showers and clean benches to surface particle removal devices and air curtains, each component plays a critical role in preserving the integrity of cleanroom environments. AIRTECH’s innovative solutions, such as the Pulse Jet Air Shower, SS-MAC units, and CHEMI-MAC filtration systems, ensure that semiconductor manufacturers can maintain the cleanliness and control needed to produce high-quality products.

#Surface Particle Removal Device#Laboratory Equipment Suppliers Services in Singapore#Laminar Air Flow#Swing Door

0 notes