#Chocolate Wrapping Machine Manufacturers

Explore tagged Tumblr posts

Text

Having the right equipment is only the first part of success. Chocolate wrapping machines have redefined success in the chocolate industry by enabling confectioners to produce consistent, high-quality wrapped chocolates, resulting in increased sales. The machines can perform various functions at incredible speeds, allowing manufacturers to wrap chocolates quickly and efficiently, saving time and operational costs.

0 notes

Text

How Packaging Impacts the Shelf Life of Confectionery Products

Have you ever opened a candy pack only to find it stale or sticky? That first disappointing bite says a lot about one overlooked factor — packaging. If you run a candy business, you already know flavor and texture are everything. But how often do you think about the armor protecting your confectionery products? Packaging is not just a box or a wrap — it is the frontline defender of shelf life, freshness, and customer satisfaction.

Let us dig deeper. Are you using the right machinery and packaging to keep your products irresistible from factory to shelf?

Why Does Packaging Matter So Much in Confectionery?

You might have the perfect recipe and high-quality ingredients. But the real question is — will your candy taste just as amazing two months from now? This is where packaging steps in. The packaging you choose directly affects how long your confectionery products stay fresh and safe.

Moisture, air, light, and temperature changes can all spoil your sweets. A poor barrier lets oxygen in, dries out soft centers, and causes sugar bloom or fat migration. Customers notice. And once they lose confidence in your brand’s consistency, regaining it is tough.

Think of packaging as the protective vault for your brand’s promise.

Ask Yourself: Is My Current Packaging Doing Enough?

Let us pause for a moment. When was the last time you reviewed your packaging method? Are you using wrappers, cartons, or pouches that seal out air and humidity? Are they tamper-proof? Can they withstand storage and shipping conditions?

If you feel unsure about any of these, it might be time to explore smarter solutions. After all, you put so much into creating quality confectionery products. Why risk it all at the packaging stage?

The Shelf Life Equation: How Packaging Adds Value

The shelf life of confectionery products is not just about longevity. It is about maintaining quality from production line to end consumer. That means:

Flavor retention: No one likes stale or oxidized chocolate.

Texture preservation: Crisp should stay crisp. Chewy should stay chewy.

Visual appeal: Packaging should protect against melting, blooming, or disfigurement.

Safety: Sealed and secure packaging builds trust in hygiene.

With the right packaging design, you can extend shelf life, reduce waste, and improve your product’s overall value. But let’s not forget, a big part of achieving this lies in your equipment.

Are Your Machines Helping or Holding You Back?

Packaging innovation starts with manufacturing. Is your equipment advanced enough to support your vision?

For example:

Can your machines handle modern materials like biodegradable films or vacuum seals?

Do they allow for airtight sealing, nitrogen flushing, or multi-layered barriers?

Can they automate packaging while maintaining precision?

If not, it may be time to rethink your equipment strategy. Because the truth is — your packaging is only as good as the machine that delivers it.

Real Talk: What Your Customers Actually Notice

Put yourself in your customer’s shoes. What do they see when they pick up your product? Clean design? Secure sealing? Clarity in labeling?

Now think about what they experience after opening it. Is it soft when it should be firm? Is it crunchy or sticky? If packaging fails to preserve the original state of your product, it can damage your brand reputation fast.

With the growing demand for premium confectionery products, expectations are higher than ever. And packaging is the first thing your customer touches. That moment either builds trust or breaks it.

The Future of Confectionery Packaging: Innovation Meets Machinery

So, where do you go from here? The future of packaging is smart, sustainable, and protective. From modified atmosphere packaging to high barrier pouches and intelligent freshness indicators — the possibilities are endless.

But these ideas need backing. And that is where advanced machinery plays a crucial role. The right equipment helps you execute packaging innovations smoothly and consistently.

You can stay ahead of the competition only when your packaging line matches your creativity and quality goals.

Why Dhiman Foods Is the Best Confectionery Products Manufacturer

Now that you understand how packaging can make or break the shelf life of confectionery products, here is one more question — who can help you do it right from the start?

Dhiman Foods has been a trusted name in the confectionery world for years. Why? Because we do not just manufacture confectionery products. We understand what makes them last, what keeps them fresh, and what excites customers from the moment they unwrap the product.

Our state of the art production facilities ensure every product is sealed, stored, and shipped with care. We use advanced packaging techniques and equipment that match the needs of modern candy businesses.

Whether you are just starting or looking to scale, Dhiman Foods is the partner you need — reliable, innovative, and always quality focused.

Want your products to taste great even after weeks on the shelf? Then partner with the best. Dhiman Foods — where every sweet success begins.

Source URL: Blogspot.com

0 notes

Text

Unwrap - Almond Sticks

Chocolate Gift Hampers| Cookies Gift Boxes| Gift Hampers| Dry Fruits Hampers| Snacks Gift Hampers| Wafer Roll Sticks| Customized Gifts| Wedding Gift Hampers| Occasion Hampers| Order Gifts Online| Herbal Tea Boxes

Unwrap the essence of purity and taste with Unwrap Happiness. We bring you confections made from the finest ingredients — real cocoa, sun-ripened fruits, aromatic spices, and handpicked nuts. Every product is a blend of traditional recipes and global gourmet trends, resulting in treats that are both nostalgic and new.

Perfectly packed for all your special moments — be it festive cheer, a business thank-you, or a personal “just because” — our collections make every gesture feel extraordinary.

Manufacturing Process of Almond Sticks

Ingredient Preparation

Almonds are roasted to enhance flavor and crunch.

Chocolate compound or couverture is tempered to achieve the perfect glossy finish and snap.

Base dough (if wafer or biscuit sticks are used) is prepared and shaped into stick forms.

Shaping the Stick Base

Depending on the product type, almond sticks may be:

Pure chocolate molded into sticks with almonds.

Biscuit or wafer sticks coated with almonds and chocolate.

Biscuit or wafer sticks are extruded, baked, and cooled if used as the base.

Coating

The stick base is passed through a chocolate enrobing machine where it's coated with chocolate.

Roasted almond pieces are added either:

Mixed into the chocolate before coating, or

Sprinkled manually or mechanically onto the wet chocolate coating.

Cooling and Setting

The sticks go through a cooling tunnel to let the chocolate and almonds set properly.

Packaging

Once set, almond sticks are individually flow-wrapped or packed in boxes, ensuring protection from humidity and breakage.

Core Ingredients

Roasted Almonds

Chocolate Compound or Couverture Chocolate (milk, dark, or white)

Optional:

Wafer or Biscuit Base

Sugar

Cocoa Mass

Cocoa Butter

Emulsifiers (like lecithin)

Milk solids (for milk chocolate versions)

Vanilla or other flavoring agents

Vegetable oil or cocoa butter substitute (in compound chocolate)

Popular Flavor Variants

Classic Milk Chocolate Almond Sticks

Creamy and sweet with roasted almond crunch.

Dark Chocolate Almond Sticks

Rich and slightly bitter chocolate that complements nutty almond notes.

White Chocolate Almond Sticks

Smooth and sweet with a milky profile, great for contrast with roasted almonds.

Caramel Almond Sticks

Chocolate with caramel-infused coating or a thin caramel layer under the chocolate.

Spiced Almond Sticks

Infused with cinnamon, cardamom, or nutmeg for a festive twist.

Coffee Almond Sticks

Enhanced with espresso or mocha flavor, ideal for coffee lovers.

Sea Salt Almond Sticks

Chocolate and almond with a sprinkle of sea salt for a sweet-salty profile.

Orange or Berry-Infused Almond Sticks

Chocolate flavored with orange zest or berry essence adds a fruity dimension.

For More Details: https://www.unwraphappiness.in/

#cookies gift hampers#chocolate gift hampers#wedding gift hampers#wafers sticks#customized gifts#herbal tea#festival gift hampers#dryfruits#snacks gift hampers

0 notes

Text

Bakemate - Mango Maxx

Chocolates Manufactures| Largest Chocolate Manufactures| Bakemate| Global Chocolate Exports| Biscuits Manufactures| Candies| Mango Maxx| Wafers| Lollipops| Premium Products| Global Biscuits Suppliers

Mango Maxx – Pure Mango Magic! Crafted with care, Mango Maxx combines a smooth outer layer with a rich mango center that melts in your mouth. Infused with authentic mango flavor, natural sweetness, and tropical aroma, it's more than a candy – it’s a mango lover’s dream come true.

Mango Maxx Candy

✅ Manufacturing Process:

Ingredient Preparation:

Mango pulp or mango flavoring (natural or synthetic) is prepared.

Sugar, glucose syrup, and citric acid are weighed and readied.

Food-grade color and preservatives are selected based on the product requirements.

Cooking Stage:

The sugar and glucose syrup are heated in a steam-jacketed kettle to around 135–145°C.

During cooking, the mixture is constantly stirred to ensure even heat distribution and avoid burning.

Flavoring & Coloring:

Once the mixture reaches the desired consistency and temperature, mango flavor and yellow-orange food color are added.

Citric acid is added to provide a tangy taste that mimics real mango.

Cooling & Kneading:

The hot mass is poured onto a cooling table or slab, then kneaded as it cools to mix the flavor and color uniformly.

Sometimes a small amount of butter or oil is added for shine and smoother texture.

Forming:

The candy mass is transferred to a batch roller and rope sizer to shape it into a long, cylindrical rope.

It is then passed through a forming machine to cut into bite-sized candies.

Wrapping & Packaging:

The finished candies are cooled to room temperature, then passed through automatic wrapping machines.

Final packaging may include pillow packs, jars, or pouches depending on the marketing strategy.

Ingredients:

Sugar

Liquid Glucose

Mango Pulp / Mango Flavor (natural or artificial)

Citric Acid (for tartness)

Food-grade Color (e.g., Sunset Yellow FCF or Tartrazine)

Hydrogenated Vegetable Oil (optional, for shine)

Edible Starch (anti-sticking agent)

Emulsifiers and Stabilizers (optional)

Flavors & Variants:

Classic Mango:

Juicy, sweet mango flavor—most popular and traditional.

Raw Mango (Kaccha Aam):

Tangy, spicy, and sour—often includes chili or black salt.

Mango Cream-Filled:

Soft center with mango-flavored liquid or cream for a surprise bite.

Mango & Chili Fusion:

A mix of mango sweetness and a spicy chili kick.

Mango Jelly Center:

Hard candy with a chewy mango-flavored jelly core.

Mango Tamarind Blend:

A unique sweet-sour flavor with a tamarind twist for regional tastes.

For More Details: https://bakemate.in/

#chocolate manufacturers#biscuit manufacturers#bakemate#fmcg#delicious chocolate#biscuits#global biscuit exporters#wafers#global chocolate exporters#lollipops

0 notes

Text

4 Must-Have Candy Manufacturing Machines for Efficient Production

If you're a confectioner aiming to scale up candy production or boost efficiency, the right equipment makes all the difference. Whether you're crafting caramels, gummies, hard candies, or chocolate-coated treats, reliable candy manufacturing equipment helps you maintain consistency, reduce waste, and meet demand without compromising quality.

In this guide, we break down the top four machines every candy business needs to streamline operations and produce top-tier confections.

1. Candy Cooker (Batch or Continuous)

No matter your recipe, cooking sugar mixtures to precise temperatures is the foundation of every successful candy. From glucose syrups to fruit purées, proper heat control ensures flavor, texture, and color remain consistent across batches.

Why it matters:Undercooked candy can be sticky or unstable. Overcooked batches may crystalize or burn. The right candy cooker ensures repeatable results every time.

What to look for:

Accurate digital temperature controls

Vacuum cooking options for moisture control (ideal for gummies and soft candies)

Food-grade stainless steel construction

Choose batch cookers for flexibility and small batches, or continuous cookers for high-volume production

Pro Tip: If you manufacture both hard and soft confections, consider a dual-purpose cooker or modular setup.

2. Candy Depositor or Moulding Machine

The candy depositor is where your mixture takes shape — literally. Whether you're filling molds for gummies or forming chewy pieces, this machine ensures portion control and consistent product sizing.

Why it matters: Uniform size and weight ensure better packaging, setting, and quality control — and help keep your ingredient costs predictable.

What to look for:

Interchangeable mold and nozzle designs

Programmable portion sizes

Heated hoppers (prevents premature crystallization)

Compatibility with various consistencies — from viscous syrups to liquid centers

From tabletop depositors for small-batch candy makers to fully automated moulding systems, there’s a solution for every scale.

3. Cooling Tunnel or Cooling Cabinet

Once formed or coated, your candy must cool under controlled conditions. A cooling tunnel or cooling cabinet stabilizes the product, locking in texture and finish.

Why it matters: Improper cooling can cause chocolate bloom, sticky gummies, or deformed shapes. Temperature and humidity control are crucial at this stage.

What to look for:

Adjustable temperature and airflow settings

Multi-tier or conveyor-style layouts for high output

Easy-to-clean design to meet hygiene standards

Humidity control to prevent condensation and spoilage

Cooling is not just a post-production step — it’s a key quality control point in your candy line.

4. Candy Packaging Machine

Great candy deserves great presentation — and protection. Whether you sell retail-ready treats or bulk packs, the right candy wrapping machine or packaging system helps preserve freshness and appeal.

Why it matters: Modern packaging protects against moisture, oxygen, and tampering. It also improves shelf life and retail acceptance.

What to look for:

Packaging formats: flow wrap, pillow pack, twist wrap, jars, sachets

Throughput speed that fits your production needs

Integration with batch coding or expiry date printing

Compact design with food-grade materials

Startups may benefit from semi-automatic packaging machines that allow manual feeding with automated sealing, balancing cost and efficiency.

Final Thoughts: Start Smart with the Right Candy Equipment

These four essential machines — cooker, depositor, cooling system, and packaging unit — form the backbone of any successful candy production line. Whether you're starting small or scaling up, focus on candy production equipment that is:

Scaled to your current output

Built for future expansion

Easy to clean, operate, and maintain

Certified for food safety and hygiene standards

Need Help Choosing Equipment?

At Latini Hohberger Dhimantec, we specialize in high-performance candy and chocolate manufacturing machinery. Our equipment is used by both artisanal producers and global brands — offering modular, durable, and precision-engineered solutions built to grow with your business.

🔗 Explore Candy Equipment at LatiniUSA.com

Source URL: Blogspot.com

0 notes

Text

Innovative Confectionery Machinery for Seamless Candy Production

Confectionery machinery plays a pivotal role in modern candy and chocolate production, offering streamlined processes, enhanced efficiency, and consistent product quality. These machines are essential in the manufacturing of a wide variety of sweets, from hard candies and toffees to chocolates and jellies. The use of confectionery machinery not only ensures precision in the shaping, cooling, and packaging stages but also enables manufacturers to scale production while maintaining hygiene and safety standards. With advanced automation features, today's confectionery machinery is designed to reduce manual labor, cut down production time, and increase output significantly. Whether it's a small-scale unit or a large production facility, investing in reliable and high-performance confectionery machinery is crucial for meeting market demand and delivering high-quality treats.

From mixing and cooking systems to forming and wrapping units, each machine in the confectionery line is crafted with precision and adaptability in mind. Modern confectionery machinery includes PLC-controlled operations, stainless steel construction for sanitary processing, and user-friendly interfaces for ease of operation. These features ensure not just higher productivity but also compliance with international food safety standards. Moreover, these machines are versatile and can be customized according to the specific needs of different types of candies, allowing manufacturers to maintain uniqueness and consistency in taste and appearance.

The confectionery industry demands innovation, and machinery manufacturers constantly rise to the challenge by integrating energy-efficient technology and smart controls into their equipment. This evolution enables greater consistency in cooking temperatures, texture, and flavor, which are critical in confectionery production. Confectionery machinery such as enrobing lines, cooling tunnels, and candy depositors are now integrated with sensors and automation systems that help monitor real-time operations, identify bottlenecks, and reduce downtime, ultimately improving the overall efficiency of the production cycle.

In addition to production benefits, modern confectionery machinery also supports sustainability initiatives. By minimizing waste, optimizing energy usage, and using recyclable packaging materials, these machines contribute to environmentally responsible manufacturing practices. Businesses that adopt such forward-thinking machinery gain a competitive edge by aligning with eco-conscious consumers and industry regulations. Moreover, advanced confectionery machinery often includes quick-changeover capabilities, allowing for flexible manufacturing that accommodates a variety of product lines with minimal setup time.

The integration of AI and IoT in confectionery machinery is opening new possibilities for predictive maintenance and operational analytics. Manufacturers can now remotely monitor machine performance, anticipate breakdowns, and schedule timely maintenance, which reduces costly downtime and extends equipment lifespan. This level of control over operations not only maximizes output but also enhances product quality and consistency.

Furthermore, confectionery machinery is crucial in ensuring product safety and maintaining health regulations. With hygienic designs, automatic cleaning systems, and precise ingredient handling, these machines prevent contamination and maintain the integrity of the final product. This is particularly vital in today’s health-conscious consumer market where demand for sugar-free, organic, and allergen-free confectionery is growing. Machinery manufacturers have responded by designing specialized equipment capable of producing these niche products with high precision and safety.Overall, confectionery machinery is the backbone of the sweet manufacturing industry. It offers efficiency, innovation, and quality control at every stage of production. For businesses aiming to scale and diversify their product offerings, choosing the right confectionery machinery is not just a necessity—it is a strategic investment. As consumer demand continues to evolve, only those equipped with advanced, flexible, and efficient confectionery machinery will be able to lead the market with quality products and timely delivery.

0 notes

Text

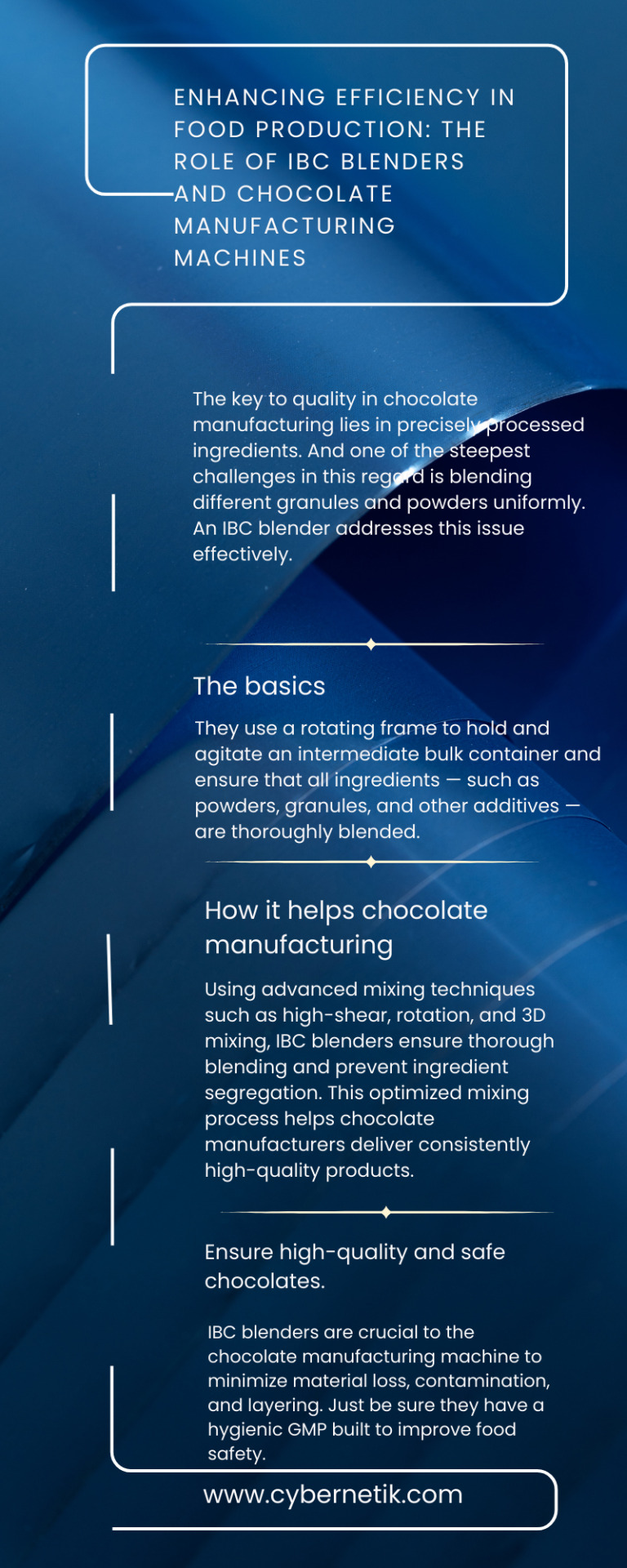

Enhancing Efficiency in Food Production: The Role of IBC Blenders and Chocolate Manufacturing Machines

0 notes

Text

Candy Packaging Machines Market Situation and Forecasting Trends Analysis 2024 - 2032

The candy industry has seen considerable growth over the years, driven by consumer demand for innovative and diverse confectionery products. As the market expands, the need for efficient and reliable packaging solutions becomes increasingly vital. Candy packaging machines play a crucial role in ensuring that products are packed efficiently while maintaining quality and aesthetic appeal. This article explores the candy packaging machines market, examining its growth drivers, types, applications, challenges, and future trends.

Understanding Candy Packaging Machines

The candy packaging machines market is an essential component of the confectionery industry, contributing to efficiency, quality, and sustainability. As the market continues to grow, driven by consumer demand and technological advancements, manufacturers must adapt to new trends and challenges.

What Are Candy Packaging Machines?

Candy packaging machines are specialized equipment designed to package various types of confectionery products, including chocolates, gummies, hard candies, and more. These machines automate the packaging process, ensuring efficiency, consistency, and hygiene.

Types of Candy Packaging Machines

Vertical Form Fill Seal (VFFS) Machines: These machines create bags from a roll of film, fill them with candy, and seal them in a vertical position. They are popular for packaging small, loose candies.

Horizontal Flow Wrappers: Used primarily for bar-shaped candies, these machines wrap products in a continuous flow of packaging material, providing high-speed wrapping capabilities.

Cartoning Machines: These machines package candy into cartons or boxes, offering an effective way to bundle multiple products for retail.

Labeling Machines: Essential for compliance and branding, labeling machines apply labels to packaged products, ensuring they meet regulatory requirements.

Market Dynamics

Current Market Size and Growth

The candy packaging machines market is experiencing significant growth, with an increasing number of confectionery manufacturers seeking automation to enhance production efficiency. Recent market analyses estimate the market to be valued in the billions, with a projected compound annual growth rate (CAGR) in the coming years.

Key Drivers

Rising Demand for Confectionery Products: As consumer preferences shift toward unique and innovative candy options, manufacturers are ramping up production, necessitating efficient packaging solutions.

Technological Advancements: Innovations in packaging technology, such as smart packaging and automation, are driving the demand for modern candy packaging machines.

Focus on Sustainability: Increasing consumer awareness regarding environmental sustainability is pushing manufacturers to adopt eco-friendly packaging solutions, further fueling the market.

Applications of Candy Packaging Machines

Confectionery Manufacturing

In confectionery manufacturing, packaging machines are essential for maintaining product quality and prolonging shelf life. Automated machines reduce human error and increase throughput, allowing manufacturers to meet growing consumer demand.

Retail and Distribution

Candy packaging machines are crucial in preparing products for retail, ensuring that they are attractively packaged and properly labeled. This not only enhances product visibility but also aids in inventory management and distribution.

Exporting

For manufacturers looking to expand internationally, packaging machines ensure that candy products are packaged according to different regional regulations and standards, making them suitable for global markets.

Challenges Facing the Candy Packaging Machines Market

High Initial Investment

The cost of purchasing and maintaining advanced candy packaging machines can be substantial. Smaller manufacturers may struggle to justify these investments, which can limit their ability to compete in the market.

Technological Complexity

The integration of sophisticated machinery into existing production lines can pose challenges, particularly for manufacturers lacking technical expertise. This can lead to operational inefficiencies if not managed correctly.

Regulatory Compliance

Candy packaging is subject to strict regulatory standards, which can vary by region. Manufacturers must ensure their machines are compliant, requiring ongoing investment and adaptation.

Future Prospects

Market Trends

The candy packaging machines market is poised for continued growth, with several key trends expected to shape its future:

Increased Automation: The trend towards automation will likely accelerate, with manufacturers seeking ways to improve efficiency and reduce labor costs.

Sustainable Packaging Solutions: As consumer preference for eco-friendly products grows, manufacturers will increasingly adopt sustainable packaging practices, influencing machine design and functionality.

Smart Packaging Technologies: The integration of IoT (Internet of Things) and smart technologies into packaging machines will allow for better monitoring and data collection, enhancing operational efficiency.

Conclusion

The evolution of candy packaging technology not only enhances production capabilities but also aligns with the broader push towards sustainability, making it a dynamic and promising sector within the food packaging industry. As the industry evolves, embracing innovation will be crucial for manufacturers aiming to thrive in an increasingly competitive landscape.

#Candy Packaging Machines Market Size#Candy Packaging Machines Market Trend#Candy Packaging Machines Market Growth

0 notes

Text

How Chocolate Wrapping Machines Preserve Freshness and Taste

Chocolate is a beloved treat enjoyed by people of all ages around the world. Whether it's a creamy milk chocolate bar, a rich dark chocolate truffle, or a delightful assortment of pralines, one thing is certain - the taste and freshness of chocolate are essential for a delightful experience. Here we will explore the role of Wrapping Machines for Chocolate in preserving the freshness and taste of chocolates, ensuring that every bite is a heavenly delight for consumers.

The Importance of Freshness in Chocolate:

Freshness is a crucial factor in the world of chocolate. High-quality chocolates are crafted with precision, using the finest ingredients and delicate flavors that deserve to be savored in their prime condition. The key challenge for chocolate manufacturers lies in ensuring that their products remain fresh from the production line to the hands of consumers.

The Role of Chocolate Packaging Machines:

Chocolate Packaging Machines play a pivotal role in maintaining the freshness of chocolates. These sophisticated machines are designed to create a protective barrier around the chocolates, shielding them from external elements that can degrade their quality over time. Proper packaging also prevents moisture and air from seeping into the chocolates, ensuring their taste and texture remain intact.

Sealing in Flavor and Aroma:

Chocolate is not just about taste; it's also about aroma. Chocolate Wrapping Machines seal in the natural aroma of the chocolates, keeping them intact until they are unwrapped and ready to be enjoyed. This ensures that consumers experience the full spectrum of flavors and scents intended by the chocolatiers.

Protection from Contaminants:

Chocolate Packaging Machines create a hygienic and contamination-free environment for the chocolates. They prevent exposure to dust, dirt, and other external pollutants that could compromise the quality and safety of the chocolates.

Extended Shelf Life:

By preserving freshness, Chocolate Wrapping Machines extend the shelf life of chocolates. Manufacturers can confidently distribute their products across various locations, knowing that the chocolates will retain their original taste and appeal for an extended period.

Ensuring Consistency:

Consistency is key in the chocolate industry. Chocolate Wrapping Machines ensure that each piece of chocolate is uniformly wrapped, maintaining a consistent appearance that reflects the quality and brand identity of the manufacturer.

Sustainable Packaging Solutions:

Many modern Chocolate Wrapping Machines use eco-friendly and sustainable packaging materials, reducing the environmental impact of the packaging process. This appeals to eco-conscious consumers and aligns with the growing trend of sustainability in the chocolate industry.

Get in touch with Ammar Machinery – one of the best Chocolate Wrapping Machine manufacturers:

Looking for reliable Chocolate Wrapping Machine manufacturers? Look no further! Ammar Machinery is a leading name in the industry, dedicated to crafting state-of-the-art wrapping machines specifically designed for chocolates. With a focus on precision engineering and quality, our machines preserve the freshness and taste of chocolates, ensuring a delightful experience for consumers. Elevate your chocolate packaging process with Ammar Machinery. Visit our website now for cutting-edge solutions and exceptional customer service.

#Chocolate Packaging Machines#Wrapping Machine for Chocolate#Chocolate Wrapping Machine Manufacturers#chocolate packaging#wrapping machine#making machine#machine manufacturer

0 notes

Text

How Candy Manufacturing Equipment Shapes Your Favorite Sweets

Have you ever wondered how that perfectly chewy gummy bear is made? Or how does a chocolate bar get its smooth texture? The answer lies in the candy manufacturing equipment. These machines are like the backbone of the candy factory. Candies are made with ingredients like sugar, chocolate, and fruit flavors. You feed these ingredients to the machine and you get your desired candies and other confectionery.

Mixing

The journey of candy manufacturing begins with mixers. It is the first piece of equipment in the candy manufacturing machine line. These giant vats stir together all the ingredients for the candy. Imagine a giant kitchen mixer, but for candy-sized proportions! The final texture of the candy depends on the way the ingredients are mixed.

If you want to make smooth caramels, you might use a slow and gentle mix. However, if you want to make chewy candies, you may need a more intense mix. You can use different mixing intensities for different kinds of output.

Cooking

Next comes the cooking stage. Depending on the candy, different machines are used. For hard candies, kettles cook sugar syrups to just the right temperature. This high heat creates a glassy texture that's perfect for lollipops and hard candies.

For chocolates manufacturing, you need to use special melting machines. It helps in heating the cocoa butter and other ingredients evenly. This process creates that smooth, melt-in-your-mouth chocolate texture we all crave. You can adjust the cooking process to get different output. If you are into candy manufacturing business, then having this equipment will help you increase your production.

Shaping Candies

Once cooked, the candy mixture needs to be shaped. This is where things get interesting! Different machines create all sorts of fun shapes. Pouring machines fill molds for chocolates and gummies. Extruders push the candy mixture through different shapes, like the long, thin ropes that become licorice.

For candies with centers, special equipment deposits centers into shells. Imagine a tiny robot arm placing a gooey caramel center into a waiting chocolate cup. A high-quality candy shaping equipment can help you get the desired shape and output in your machine line.

Cooling Down

After shaping, the candy needs to cool down. Tunnels with cool air gently bring the candy to the right temperature. This is important to set the texture and make sure the candy keeps its shape.You may also adjust the cooling process so that you get the desired outcome. You can use the latest cooling tunnel equipment to get your desired output.

Remember, a high-quality production unit requires high-quality equipment. If you want to increase the output of your machine line, you need good quality equipment.

Coating and Decorating

Some candies get an extra layer of fun with coating machines. These machines drizzle chocolate, yogurt, or other coatings onto the candy. They can even spray on colorful candy shells.

For decorated candies, special machines deposit tiny dots, stripes, or even faces onto the candy surface. Imagine a high-tech icing decorator, but for candy!

Wrapping

Finally, the finished candy needs to be packaged. Candy manufacturing equipment includes machines that twist, fold, and wrap candies. Colorful packaging is necessary to attract your target customers to try out your candies.

The wrapping machines can perfectly wrap the candies so that they look attractive and also protects the edible item from outside contamination. This keeps the candy fresh and protects it on its journey to stores and, eventually, your mouth!

The Final Touch of Technology in Candy Manufacturing Line

Candy manufacturing equipment has come a long way. Today's machines are controlled by computers, ensuring precise measurements, cooking times, and shaping techniques. This means consistent quality and deliciousness in every single candy piece.

DhimanGroup: Your Partner in Candy Creation

At DhimanGroup, we understand the importance of top-notch candy manufacturing equipment. We offer a wide range of machines to help you enhance your candy manufacturing output. Our machines and equipment are designed to meet all your candy-making needs.

Our equipment is built with the latest technology. Each one offers the highest level of output. So, whether you're a small candy maker or a large-scale producer, we have the perfect machines to help you create your favorite sweet treats.

With DhimanGroup, you can be sure you're getting the best equipment for delicious and successful candy making!

Source: Justpaste.it

0 notes

Text

Why Are Handmade Quilts Trending In Friendswood, Texas?

Quilts are Protector in colder days, agree? When the temperature drops, you first wish to get wrapped all around by a soft, comfy, warm quilt. Enjoying in front of the fireplace, having a hot chocolate cup, and the cozy comfort of a quilt is our only priority whenever the winter days knock on our doors. Isn't it? However, the feeling of relaxation and solace gets doubled when it's about hand-made quilts in Friendswood Texas. As the name suggests, these quilts are handmade, and human hands execute every step of the quilting journey. All the chosen fabrics are sewn by hand and without machinery. But why are they popular in the towns? Continue reading to know.

Reasons Hand-Made Quilts Are Popular

A hand-made quilt is more about love as it is hand-crafted and represents the love from labor. The quilt takes effort and feelings throughout its making journey. The reasons are not limited to this only. But there are many more as follows:

Bedroom Aesthetics

Hand-crafted things always add a sense of aesthetic to your style. Similarly, the hand-made quiltsare a great insertion to your bedroom community, giving your bed and couch an aesthetic look. You can even choose the quilt fabric of your choice concerning your aesthetic designs, bedroom interiors, and other accessories such as pillows, cushions, curtains, and sheets, and then get a hand-crafted quilt made on your order. You also consider the Texas Christmas stocking; it provides the coy and warm experience on colder days.

Unique Designs & Patch Works

It's another reason that hand-crafted quilts are gaining popularity. They are innovative and come with unique designs and patchwork, as they are hand-crafted and not manufactured in bulk. Hand-made quilts are the cup of tea for people who want a unique quilt collection in their bedrooms and don't want the same quilts as anyone else.

Material Choice

Usually, people want quilts with their designs and material choices but need help finding both in machine-made quilts. When you order hand-crafted quilts to the local artisans, you unlock the opportunity to choose everything from fabric, sewing method, and designs to the colors and patterns in your quilt.

Luxury Article Collection

You have always noticed that hand-crafted materials are expensive. But why? It's because hand-made items are all about tons of time, love, effort, and creativity that you won't find in machine-made articles. Buying a hand-made quilt will add a luxury appeal to your bedroom and its accessories. Also, you can go for some signature designs and patterns that speak louder about your personality and taste of your style. For example, you can order a hand-crafted quilt with your quotes, a United States Coast Guard quilt, a hand-made wine quilt, etc.

Local Artisans Collaboration

If you take more interest in buying hand-crafted quilts, it will significantly help the local artisans. They get jobs, their art and creativity are appreciated, and they deserve money for their hard work and talent. People passionate about hand-crafted articles and who appreciate the art of quilting help the economy by praising the artisans and giving them orders for their choice of hand-made quilts. For more information regarding the Dallas Cowboys Christmas stocking. Visit PS Quilting official website.

0 notes

Text

Bakemate - Snap It

Chocolate Manufactures| Largest Chocolate Manufactures| Bakemate| Global Chocolate Exports| Biscuits Manufactures| Global Biscuits Exports| Lollipops| Candies| Wafers| Premium Products| Largest Chocolates Suppliers

Crafted for the discerning snacker, Snap It blends delicate, crisp wafers with a luxurious coating of rich chocolate. Each bar is a bite of balance — the lightness of the wafer dancing with the decadence of chocolate. Elegant in texture and rich in flavor, Snap It transforms an everyday moment into a moment worth savoring.

✅ Manufacturing Process of Snap It (Chocolate-Coated Wafer Bars)

Mixing and Dough Preparation

Wheat flour is blended with leavening agents, sugar, water, and oil to make a smooth batter.

The batter is poured into wafer baking machines.

Wafer Baking

Wafers are baked at high temperatures using heated plates, forming thin, crisp wafer sheets.

Cooling and Conditioning

Baked wafers are cooled and conditioned to reduce moisture content and improve crispness.

Layering and Cream Filling

Layers of cream (flavored cream such as vanilla, hazelnut, or chocolate) are applied between wafer sheets.

Usually, 3–5 wafer sheets are layered to form a sandwich.

Cutting and Shaping

The layered wafer sheets are cut into uniform bar-shaped fingers.

Chocolate Enrobing

Wafer fingers are coated with tempered chocolate using an enrobing machine.

Excess chocolate is removed via vibration and air-blow systems for uniform coating.

Cooling Tunnel

Chocolate-coated bars pass through a cooling tunnel to harden the chocolate coating.

Packing

Once cooled, bars are checked for quality and packed in flow-wrap or foil packaging.

✅ Key Ingredients

Wafer Base:

Wheat flour

Palm oil or vegetable oil

Cornstarch

Baking soda or ammonium bicarbonate

Salt

Cream Filling:

Sugar

Hydrogenated vegetable fat

Cocoa solids (for chocolate-flavored)

Flavorings (vanilla, hazelnut, etc.)

Milk solids

Chocolate Coating:

Milk chocolate or compound chocolate (sugar, cocoa solids, milk solids, cocoa butter or vegetable fats, emulsifiers)

Optional Add-ons:

Crispy rice, caramel, or nut pieces for added texture or variants

✅ Popular Flavors of Snap It

Classic Milk Chocolate

The traditional and most popular variant with a smooth milk chocolate coating.

Dark Chocolate

Rich, slightly bitter coating for those who prefer intense chocolate taste.

White Chocolate

Coated with creamy white chocolate, offering a sweet vanilla-forward profile.

Hazelnut Cream

Wafer layers filled with hazelnut-flavored cream, often combined with milk chocolate coating.

Strawberry or Fruit Cream

Fruity cream-filled wafers for a sweet, tangy variation.

Caramel Crunch

A caramel layer or caramel-infused cream paired with crispy wafer and chocolate.

Cookies & Cream

Cream filling with cookie crumbs inside chocolate-covered wafers.

Mint Chocolate

Refreshing mint-flavored cream with a dark or milk chocolate shell.

For More Details: https://bakemate.in/

#chocolate manufacturers#biscuits#biscuit manufacturers#bakemate#global biscuit exporters#wafers#lollipops#fmcg#delicious chocolate#candies

0 notes

Text

Melt, Form, and Wrap: A Deep Dive into the Candy Making Process

Candy making is a fascinating blend of science, technology, and creativity. From simple hard candies to elaborate chocolate truffles, every sweet treat follows a structured and carefully controlled process. Modern confectionery production depends on reliable, high-performance equipment to deliver consistency, quality, and efficiency. That’s where Latini Hohberger Dhimantec shines—offering precision-engineered candy manufacturing machines that provide exceptional value and output.

Let’s explore how raw ingredients are transformed into delightful confections.

Melting: Building the Candy Base

The journey begins with melting core ingredients such as sugar, glucose syrup, and flavorings in large heated vessels. Accurate temperature control is critical—too much heat can cause premature caramelization, while too little heat prevents proper sugar dissolution.

Latini Hohberger Dhimantec’s advanced cooking systems are designed to precisely monitor and manage temperature, ensuring consistent results every time.

For chocolate-based products, tempering is key. Stabilizing cocoa butter crystals gives chocolate its smooth texture and glossy finish. Without proper tempering, chocolate may become grainy or develop unwanted white streaks (bloom), reducing its visual appeal and shelf stability.

Forming: Shaping the Final Product

After melting, the candy base moves into the forming stage. This is where the candy is shaped into its final form—be it lollipops, drops, or other unique designs. High-speed forming machines from Latini Hohberger Dhimantec provide precision, consistency, and flexibility for a variety of confectionery products.

Cooling tunnels quickly solidify the candy, locking in the desired shape and texture. Different types of forming equipment are used depending on the product. For example, rotary forming systems are ideal for hard candies, while servo-driven die forming machines can handle intricate shapes with ease and speed.

Wrapping: Preserving Freshness and Appearance

Once the candy is fully formed and cooled, it moves to the wrapping stage. Proper packaging is essential—not only for freshness and hygiene, but also for shelf appeal. Wrapping machines from Latini Hohberger Dhimantec support various formats, including twist wraps, flow packs, and foil seals.

With the integration of printing and labeling systems, manufacturers can add batch codes, expiry dates, and branding elements directly onto packaging. These capabilities help maintain product traceability and enhance marketing impact.

Automation: Enhancing Efficiency and Quality

Automation has become a game changer in candy production. With growing consumer demand and tighter production timelines, automated systems help manufacturers scale up while maintaining strict quality control.

Latini Hohberger Dhimantec offers fully integrated systems—from ingredient mixing to final packaging. Automation minimizes human error, reduces labor costs, and improves throughput. Robotic arms can sort, fill, and package various candy types, while smart sensors catch inconsistencies before products reach consumers.

Overcoming Challenges in Candy Manufacturing

Even with advanced machinery, confectionery production has its hurdles. Consistency in taste, texture, and appearance requires constant monitoring. Small variations in ingredient ratios or processing times can significantly impact the final product.

Humidity control is another concern—excess moisture can cause stickiness, while overly dry conditions lead to cracks. Latini’s equipment incorporates precise climate control features to maintain ideal environmental conditions.

Compliance with food safety regulations is also essential. From hygiene standards to allergen labeling, modern equipment must support traceability and recordkeeping. Latini’s automated systems streamline this process and help ensure regulatory adherence.

The Future of Candy Production

The confectionery industry is rapidly evolving. Consumers are seeking healthier, cleaner-label sweets, including sugar-free and organic options. Equipment from Latini Hohberger Dhimantec supports these demands with precision dosing systems that allow for low-sugar, fortified, or functional candy formulations.

Sustainability is another priority. More manufacturers are switching to biodegradable packaging and energy-efficient production methods. Latini’s machines are engineered to optimize material usage and reduce environmental impact—without sacrificing speed or quality.

Conclusion

From melting and forming to wrapping and packaging, every step in the candy-making process requires precision, reliability, and innovation. High-quality candy manufacturing equipment is not just a tool—it’s the foundation of production success.

Latini Hohberger Dhimantec is proud to be a trusted global leader in the confectionery equipment industry. Our machines are designed to deliver top-tier performance, efficiency, and durability—backed by decades of expertise and a commitment to quality.

Source URL: Blogspot.com

0 notes

Text

Bisleri Plant Manufacturer, Bisleri Plant - kceindia.com

Bisleri Plant Manufacturer : kceindia.com is Bisleri Plant Manufacturer, Bisleri Plant Supplier, and Bisleri Plant Exporter in Navi Mumbai, India. Call Now.

Packaging Machineries, Packaging Machinery, Wrapping Machines, Wrapping Machine, Wrap Machine, Sealing Machine, Sealing Machines, Sealing Machinery, Auto Impale Sealing Machine, Foot Operated Direct Heat Sealer, Continuous Pouch Sealing Machine, Shrink Tunnel Machine, Shrink Wrapping Machines, Carton Sealer Machine, Carton Sealing Machine, Carton Taping Machine, Pallet Stretch Wrappling Machine, Stretch Wrapping Machine, Flow Pack Wrapping Machine, Horizonatal Flow Pack Wrapping Machine, Piston Filler, Cup Filler Machine, Form Fill and Seal Machine, Form Fill Seal Machine, Auger Filler, Vertical Flow Pack Machine, Cut and Wrap Machine, Chocolate Cutting Machine, Enrober, Enrober Cooling Tunnel, Packaging Automation, Pouch Sealing Machine, Food Processing Equipments, Packaging Equipments, Air Pillow Making Machines, Auger Filler, Automatic Packaging Machine, Biscuit Packaging Machinery, Biscuit Packing Machines, Bunch Wrapping Machines, Bunch Wrapping Machines, Center Seal Flow Wrapping Machines, Centre Seal Pouch Machines, Chocolate Cutting Machines, Chocolate Packing Machines, Chocolate Wrapping Machinery, Complete Packing Line, Continuous Pouch Sealing Machine, Cup Sealing Machines, Cut And Wrap Machine, Flow Pack Wrapping Machine, Flow Wrap Machinery, Flow Wrap Machines, Flow Wrapping Machine, Form Fill Seal Machines, Four Side Seal Flow Wrapping Machines, Granules Packing Machines, Horizontal Flow Pack Wrapping Machine, Ice Cream Wrapping Machines, Jelly Packing Machines, Liquid Sealing Machines, Liquid Wrapping Machines, Masalas Packaging Machine, Packaging Automation, Packaging Machinery, Packaging Machines, Pickling Plant, Pillow Pack Flow Wrapping Machines, Pillow Pack Machines, Piston Filler, Plastic Bag Sealing and Packaging Machines, Pouch Sealing Machine, Pvc Seaming Machines, Sealing Machinery, Shampoo Wrapping Machines, Soap Banding Machines, Soap Wrapping Machines, Vertical Flow Pack Machine Cup Filler, Wrapping Machinery, Vasai, karjan , khopoli, neral, lonavala, khandala, igatpuri, bhivandi, shahapur , nasik , shirdi, titwala, bhor , sinner, shirdi, Ahamadnagar, kholapur, sangli, ichalkarangi, Ahamadnagar, solapur, jejuri, Baramati, ratnagiri, roha, Talasari, wada,palghar, dahanu , nagpur, nanded, latur, Alibag, pen , vashi , cbd belapur

0 notes

Text

Keto Chocolate Chip Ice Cream Sandwiches

New Post has been published on https://eazywellness.net/keto-chocolate-chip-ice-cream-sandwiches/

Keto Chocolate Chip Ice Cream Sandwiches

Indulge in a frozen symphony of flavor and texture with our Keto Chocolate Chip Ice Cream Sandwiches. They showcase that you don’t have to compromise on flavor or texture to adhere to your dietary goals. Prepare to savor every bite of these frozen delights, knowing that you’re treating your taste buds while staying true to your keto lifestyle.

The cookie portion is specifically made for this recipe – a soft and chewy cookie that stays soft and chewy throughout the freezing process. The most important thing with this recipe is having patience – but it will be worth it! There is a lot of cooling and freezing required. Make sure to allow the cookies to cool completely before making the sandwiches.

Looking for a different ice cream flavor? Use one of our other low-carb ice cream recipes here:

Don’t have an ice cream machine? Don’t worry! Just place in the freezer and stir every 30 minutes until you get to the consistency you want.

Yields 6 servings of Keto Chocolate Chip Ice Cream Sandwiches

The Preparation

Vanilla Ice Cream:

1 cup heavy cream

1/2 cup unsweetened almond milk

1/4 cup unsweetened greek yogurt, 5%

3 large eggs yolks

1/3 cup allulose

1 tablespoon vanilla extract

pinch salt

Cookie Sandwiches:

2/3 cup almond flour

1 teaspoon baking powder

pinch salt

1⁄4 cup allulose

4 tablespoon unsalted butter, softened

1 large egg

1 teaspoon vanilla extract

1/4 cup sugar-free chocolate chips

The Execution

1. Gather and prep all ingredients.

2. Start working on the ice cream. In a saucepan, heat the heavy cream and almond milk over low heat. Add in the egg yolk(s) and whisk until frothy.

3. Continue to whisk over low heat until the temperature of the mixture reaches 140F and thickens enough to coat the back of a spoon.

4. Add the allulose, vanilla extract, and a pinch of salt. Whisk to combine, then remove from heat and place in the refrigerator to cool.

5. Create the cookie sandwich dough. In a bowl, combine the almond flour, baking powder, and salt.

6. In a separate bowl, add the softened butter and allulose, then cream together. Once creamed, add in the egg and vanilla and continue to mix until combined.

7. Add the dry ingredients to the wet and mix together.

8. Slowly fold in the chocolate chips.

9. Scoop the cookie dough into the center of a sheet of plastic wrap. Shape the dough into a log and place in the refrigerator to harden, about 3 hours or overnight.

10. Once ready to assemble everything, pre-heat oven to 350F.

Remove the ice cream base from the fridge and churn in an ice cream maker according to the manufacturer’s instructions. If you do not have an ice cream maker, you can place it in the freezer, stirring every 20-30 minutes for 4-6 hours.

Slice the cookie dough into equal pieces, then lay on a parchment-lined baking sheet.

11. Bake for 8-10 minutes or until the edges are golden brown. Once finished, allow the cookies to cool completely. Sandwich the ice cream between the cookies and enjoy!

Store in the freezer in an air-tight container.

This makes a total of 6 servings of Keto Chocolate Chip Ice Cream Sandwiches. Each cookie comes out to be 371 calories, 34.5g fats, 4.9g net carbs, and 7.4g protein.

NUTRITION CALORIES FAT CARBS FIBER NET CARBS PROTEIN 1.00 cup heavy cream 809 85.7 6.4 0 6.4 6.7 0.50 cup unsweetened almond milk 14 1.3 0.6 0.4 0.2 0.6 0.25 cup full-fat plain greek yogurt 54 2.8 1.7 0 1.7 5.1 3.00 large egg yolk 164 13.5 1.8 0 1.8 8.1 0.33 cup allulose 30 0 0 0 0 0 1.00 tablespoon vanilla extract 37 0 1.6 0 1.6 0 0.00 none salt 0 0 0 0 0 0 0.66 cup almond flour 428 37 16.3 9.6 6.7 15.5 1.00 teaspoon baking powder 2 0 1.3 0 1.3 0 0.00 none salt 0 0 0 0 0 0 0.25 cup allulose 23 0 0 0 0 0 4.00 tablespoon butter 407 46 0 0 0 0.5 1.00 large egg 79 5.2 0.4 0 0.4 6.9 1.00 teaspoon vanilla extract 12 0 0.6 0 0.6 0 0.25 cup low-carb dark chocolate chips 165 15.1 20.2 11.8 8.4 0.8 Totals 2226 206.7 50.9 21.7 29.1 44.2 Per Serving (/6) 371 34.5 8.5 3.6 4.9 7.4

Keto Chocolate Chip Ice Cream Sandwiches

The Preparation

Vanilla Ice Cream:

1 cup heavy cream

1/2 cup unsweetened almond milk

1/4 cup unsweetened greek yogurt, 5%

3 large eggs yolks

1/3 cup allulose

1 tablespoon vanilla extract

pinch salt

Cookie Sandwiches:

2/3 cup almond flour

1 teaspoon baking powder

pinch salt

1?4 cup allulose

4 tablespoon unsalted butter, softened

1 large egg

1 teaspoon vanilla extract

1/4 cup sugar-free chocolate chips

The Execution

Gather and prep all ingredients.

Start working on the ice cream. In a saucepan, heat the heavy cream and almond milk over low heat. Add in the egg yolk(s) and whisk until frothy.

Continue to whisk over low heat until the temperature of the mixture reaches 140F and thickens enough to coat the back of a spoon.

Add the allulose, vanilla extract, and a pinch of salt. Whisk to combine, then remove from heat and place in the refrigerator to cool.

Create the cookie sandwich dough. In a bowl, combine the almond flour, baking powder, and salt.

In a separate bowl, add the softened butter and allulose, then cream together. Once creamed, add in the egg and vanilla and continue to mix until combined.

Add the dry ingredients to the wet and mix together.

Slowly fold in the chocolate chips.

Scoop the cookie dough into the center of a sheet of plastic wrap. Shape the dough into a log and place in the refrigerator to harden, about 3 hours or overnight.

Once ready to assemble everything, pre-heat oven to 350F.

Remove the ice cream base from the fridge and churn in an ice cream maker according to the manufacturer’s instructions. If you do not have an ice cream maker, you can place it in the freezer, stirring every 20-30 minutes for 4-6 hours.

Slice the cookie dough into equal pieces, then lay on a parchment-lined baking sheet.

Bake for 8-10 minutes or until the edges are golden brown. Once finished, allow the cookies to cool completely. Sandwich the ice cream between the cookies and enjoy!

Store in the freezer in an air-tight container.

Notes

This makes a total of 6 servings of Keto Chocolate Chip Ice Cream Sandwiches. Each cookie comes out to be 371 calories, 34.5g fats, 4.9g net carbs, and 7.4g protein.

3.1

https://www.ruled.me/keto-chocolate-chip-ice-cream-sandwiches/

Copyright 2023 | Ruled.Me

Source link

0 notes

Text

Revolutionizing Food Packaging With Flow Wrappers

The emergence of food flow wrappers has left its mark on the packaged food industry. The driving force behind the innovation and efficiency in a food factory has led to engineering marvels like the food flow wrap machine. From their humble beginnings to today's sophisticated designs, flow wrappers have become indispensable in the world of food packaging. Almost all bakery items like chocolate, muffins, nutbars, muesli bars etc, use flow wrappers for maximizing speed and efficiency. Apart from the food industry, non-food products like hardware use flow wrappers to ensure optimal efficiency.

The Introduction Of The Flow Wrappers

The roots of food flow wrappers can be traced back to the mid-20th century when the demand for efficient packaging solutions surged alongside the growth of the food manufacturing sector. As the technology evolved, so did the regulatory landscape. In the modern world, the use of food flow wrappers is suggested by regulatory bodies and widely adopted by factories for their incredible efficiency. These machines not only ensure fast packaging but also the safety of the consumers.

The benefits of flow wrappers are not limited to the food industry. Let us explore how flow wrappers have influenced the modern landscape:

Marketing And Brand Value Improvement: The implementation of food flow wrappers goes beyond the functional aspects of packaging. These machines work as a powerful marketing tool. Brands that invest in high-quality and well-designed packaging, signal to consumers a commitment to quality and innovation. The convenience and freshness ensured by flow wrappers contribute to a positive customer experience, enhancing brand loyalty. The aesthetic appeal of professionally packaged products also elevates a brand's visual identity on store shelves, contributing to greater visibility and recognition. In a competitive market, the use of advanced packaging technology can set a brand apart, making a lasting impression on consumers.

Use Cases In The Food Industry: The use cases of food flow wrappers in the food industry are diverse and expansive. Whether packaging individual snacks, baked goods, or fresh produce, flow wrappers offer a level of efficiency and consistency that traditional packaging methods often struggle to achieve. Their ability to handle a variety of product sizes and shapes makes them ideal for both small and large-scale production. Additionally, flow wrappers are integral in creating eye-catching and informative packaging. The transparent films commonly used with these machines allow consumers to see the product, fostering a connection between the item and the potential buyer. This visual appeal is crucial in a market where packaging often influences impulse buying decisions.

How To Find The Best Flow Wrap Machines?

For Australian food manufacturers seeking the best food flow wrapper solutions, it is crucial to partner with companies specializing in this technology. Contacting industry leaders who understand the unique requirements of the Australian market ensures you get access to tailored solutions for your factory. Having the best flow wrap machines enhances packaging efficiency and contributes to the overall success of your brand in the dynamic food industry landscape.

Some of the other “Packaging Machines”:

Linear Weighers

Multi Head Weighers

Vertical Form Fill Seal Packaging Machines

Pre-Made Bag Packaging Machines

Finishing thoughts on advanced packaging machines

Food flow wrappers represent a pivotal advancement in food packaging technology, driven by a desire for efficiency, safety, and sustainability. The importance of these wrappers extends beyond mere functionality. They serve as catalysts for marketing and brand value improvement. As the food industry continues to evolve, embracing cutting-edge packaging solutions is not just a choice but a necessity for brands aiming to stay competitive and resonate with consumers.

Source: https://optimaweightech.com.au/news/revolutionizing-food-packaging-with-flow-wrappers/

0 notes