#China's automatic sorting equipment

Text

Intelligent sorting logistics equipment manufacturer

With the development of the new economy, express delivery and e-commerce have gradually replaced traditional industries to become the industries with the fastest growth in demand for logistics equipment. Taking automated three-dimensional warehouses as an example, in the past three years, the number of automated three-dimensional warehouses owned by e-commerce and express delivery companies has increased rapidly, and their share in the entire industry has also steadily increased. Among them, e-commerce companies focus more on automation from the perspective of warehouse integration, involving the entire process of warehousing, picking, and packaging, with high system integration requirements, while express delivery companies mainly rely on the automation of sorting operations, with simpler scenarios, which often meet the conditions for batch debugging and installation, so the application of automation is also faster.

As the construction, renovation and expansion of distribution centers of express delivery companies accelerates, the proportion of semi-automatic and automated sorting equipment has steadily increased. Data shows that in 2019, China's express delivery industry has built more than 5,000 kilometers of automated assembly lines, which is equivalent to the total mileage of China's subways. Thanks to the booming development of upstream e-commerce and express delivery industries and the huge market demand of the manufacturing industry, China's automatic sorting equipment market has maintained a high-speed growth trend.

The development of e-commerce has brought about a surge in express delivery business, which has greatly increased the volume and complexity of sorting operations, magnified the defects of manual sorting, and stimulated the need for express delivery companies to transform and upgrade through the layout of intelligent sorting

The increase in the use of electronic waybills, the successful fundraising of express delivery companies, and the rapid decline in the price of intelligent sorting equipment have jointly provided external conditions for the popularization of intelligent sorting.

Gosunm is committed to developing high-tech non-standard automation technology and is currently a leading manufacturer of intelligent sorting and logistics equipment in China. It has a large number of non-standard automation project technology reserves in the fields of intelligent manufacturing, energy, e-commerce, supermarkets, warehousing, etc.

As a Chinese manufacturer of automated sorting equipment, gosunm mainly produces and develops storage systems, conveying systems, sorting systems and software control systems. Compared with manual sorting, automated sorting increases efficiency by 30% and reduces costs by 77%. Compared with the disc-type structure, the three-dimensional cross-type structure saves 67% of area and has a high accuracy rate.

Our products include logistics warehousing sorting solutions, such as dynamic weighing and volume scanning machines; static DWS, belt cross sorters, ring belt sorters, swing wheel sorters and other user-friendly conveyor modules suitable for cost-effective logistics systems. We are involved in various industry sectors such as postal services and warehouse management.

In last over ten years, Gosunm has been serving the clients from more than 30 countries and regions including Malaysia, Germany, the United States, South Korea, Japan, Italy, Turkey, Canada, Portugal, Brazil, Colombia, South Africa, Russia, etc.. And we have been cooperating with some reputed brands such as Watsons, BYD, Sanqi, Robust Medical, etc.

At the same time, we are granted with the titles Including but not limited to "National High-tech Enterprise", "Guangdong Engineering Technology Research Centre", "Guangdong Postgraduate Workstation", and "Dongguan Intelligent Manufacturing Association Chairman Unit"

If you have the same problem and want to complete package sorting efficiently and reduce manual errors, you deserve gosunm logistics sorting equipment!

#gosunm#logistics sorting equipmen#automated sorting equipment#China's automatic sorting equipment#sorting logistics equipment manufacturer

0 notes

Text

Vibrating Sifter Machine Market Top Manufacturers, Global Opportunities by Regions 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Vibrating Sifter Machine Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Vibrating Sifter Machine Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Vibrating Sifter Machine Market?

The vibrating sifter machine market is expected to grow at a CAGR of 5.3% during the forecast period of 2024 to 2032.

What are Vibrating Sifter Machine?

A vibrating sifter machine is a tool that segregates and categorizes materials like powders, liquids, and solids. It uses vibration to guide materials through a mesh screen, separating them based on their particle sizes. This machine's vibrating action aids in efficiently sifting and isolating materials, making it valuable in industries such as food processing, pharmaceuticals, and chemicals. Designed to boost efficiency and precision in material sorting and classification, the vibrating sifter machine enhances overall production processes.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1940

What are the growth prospects and trends in the Vibrating Sifter Machine industry?

The vibrating sifter machine market growth is driven by various factors. The global market for vibrating sifter machines is experiencing significant growth, primarily due to the rising demand for efficient and automated sieving equipment in industries such as food and beverage, pharmaceuticals, and chemicals. These machines are known for their high throughput, improved accuracy, and reduced downtime, which collectively enhance overall productivity. Moreover, technological advancements, such as the incorporation of sensors and digital controls, are further driving market expansion. The Asia-Pacific region is expected to lead the market, driven by rapid industrialization and the increasing adoption of automated solutions in countries like China and India. However, challenges such as high initial costs and maintenance requirements may impede market growth to some extent. Hence, all these factors contribute to vibrating sifter machine market growth

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Rotary Vibrating Sifter Machine

Circular Vibrating Sifter Machine

Linear Vibrating Sifter Machine

Tumbler Vibrating Sifter Machine

By Operation Mode:

Manual Vibrating Sifter Machine

Semi-automatic Vibrating Sifter Machine

Automatic Vibrating Sifter Machine

By End User:

Food and Beverage Industry

Pharmaceutical Industry

Chemical Industry

Mining and Metallurgy Industry

Cosmetics and Personal Care Industry

Others

By Region:

North America

Latin America

Asia Pacific

Europe

Middle East & Africa

Who are the key players operating in the industry?

The report covers the major market players including:

Russell Finex Ltd.

VibraScreener Inc.

SWECO, a business unit of M-I LLC

Kason Corporation

Gough Engineering Ltd.

Rotex Global LLC

Elcan Industries Inc.

Eversun Machinery (Henan) Co., Ltd.

Midwestern Industries Inc.

Xinxiang Dayong Vibration Equipment Co., Ltd.

Xinxiang Gaofu Machinery Co., Ltd.

Virto-Cuccolini S.r.l.

Others

View Full Report: https://www.reportsandinsights.com/report/Vibrating Sifter Machine-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Vibrating Sifter Machine Market share#Vibrating Sifter Machine Market size#Vibrating Sifter Machine Market trends

0 notes

Text

Advantage Of Automated Printed Circuit Board Production

Automated printed circuit board assembly carries a myriad of advantages to your production procedure, like enhanced efficiency and also preciseness. Imagine a circumstance where facility elements are actually perfectly positioned and also soldered in a fraction of the amount of time it will take by hand. The effect on your profits is undeniable, but there is actually even more to this account. Stay tuned to find just how computerized assembly may change your production product line and raise your product quality to unparalleled degrees.

Boosted Speed

To achieve boosted speed in automated China printed circuit board assembly, optimize the placement as well as soldering procedures. When partnering along with a reliable PCB assembly service provider, ensure they have actually reliable machines and also sleek process to make best use of outcome. Search for a provider that gives sophisticated modern technologies such as pick-and-place equipments as well as automated soldering equipment.

These devices can dramatically lessen assembly opportunities as well as improve overall manufacturing rate. Also, correct instruction for team functioning the machines is critical to preserving a smooth as well as fast assembly method.

Enhanced Accuracy

For enhanced precision in automated PCB assembly, focus on calibration of equipment and normal maintenance routines. By ensuring that your machines are actually appropriately calibrated and also well-kept, you can reduce inaccuracies and enhance the accuracy of your production procedures.

Functioning closely with your printed circuit board assembler to set up gradation methods as well as servicing schedules tailored to your particular tools may considerably improve the precision of your assembly line. Regularly booked routine maintenance not just prevents unforeseen breakdowns yet likewise assists maintain the reliability of your equipments with time.

Cost Productivity

Make certain that your automated PCB assembly methods are actually structured and also maximized to obtain optimal cost effectiveness. Through implementing computerization, you can substantially reduce labor costs linked with manual assembly, as makers can easily operate faster and even more consistently.

Additionally, automated assembly decreases component wastage through precisely putting components, lowering the overall production expenses. The first investment in automated equipment might appear high, however in the future, it causes set you back savings by means of increased efficiency as well as minimized mistake rates. Furthermore, automated processes need less maintenance as well as supervision, further lowering operational costs.

Enhanced Quality Management

Automated PCB assembly provides exact and constant manufacturing, minimizing the possibility of human error as well as guaranteeing a greater amount of quality control. Through using automatic inspection systems, flaws can be actually located and improved immediately, resulting in strengthened product quality.

Automated assembly also enables real-time monitoring of the production process, allowing easy corrections to be actually produced if any sort of issues emerge. This practical strategy assists in sustaining high quality standards throughout the production process.

Additionally, automated printed circuit board assembly systems are actually furnished with sophisticated innovations that can easily pinpoint prospective quality concerns at an early stage, protecting against substandard items from reaching the lasts of manufacturing.

Greater Manufacturing Capability

Automated PCB assembly service can considerably enhance your creation capability by improving manufacturing procedures as well as enhancing performance. By automating repeated jobs like component placement and soldering, you may generate PCBs at a much faster cost compared to hands-on assembly. This enhanced velocity allows you to meet greater need levels and also provide items to industry faster.

Automated assembly systems can easily operate regularly without breaks, causing a considerable increase in result. Along with less inaccuracies and consistent quality, you can depend on the automatic procedure to sustain a high level of manufacturing without jeopardizing on the quality of your PCBs.

Streamlined Workflow

Enrich your development productivity along with an efficient process in PCB assembly. Through carrying out automated methods, you may maximize the circulation of your line, minimizing obstructions and also enhancing overall performance.

Automated PCB assembly systems can seamlessly incorporate a variety of measures such as component placement, soldering, and also evaluation, allowing a more reliable and integrated process. Along with automated tools managing repetitive activities, your group can easily concentrate on additional complex and vital components of the assembly process. This enhanced operations makes certain that jobs are completed in a quick fashion, reducing idle time and optimizing result.

Decreased Error Prices

Through executing automated quality control processes, you can substantially reduce error rates in PCB assembly. Automated systems make sure accurate component positioning, soldering, and also evaluation, lessening the odds of individual error.

These systems use sophisticated innovations like maker vision to discover defects with higher precision, ensuring that simply flawless PCBs proceed to the upcoming manufacturing stages. Additionally, automated assembly decreases the necessity for hands-on managing, which is actually a popular resource of errors.

By improving the assembly procedure as well as getting rid of hands-on treatments, automated PCB assembly considerably boosts the total quality and also stability of the end product. With decreased inaccuracy rates, you may expect improved item efficiency, improved client contentment, and also expense discounts in the future.

Conclusion

Lastly, automated PCB assembly delivers a variety of advantages, including boosted rate, enriched precision, as well as cost effectiveness. Along with enhanced quality control solutions and efficient workflows, producers may create top notch items at a quicker pace while lowering mistakes as well as material wastefulness. Through investing in automated assembly processes, business can easily improve their development capability and satisfy high need levels while maintaining high specifications of quality.

0 notes

Text

Advantage Of Automated Printed Circuit Board Creation

Automated printed circuit board assembly takes a myriad of benefits to your production process, including enhanced efficiency as well as accuracy. Envision a case where facility elements are actually beautifully placed and soldered in a fraction of the moment it would take manually. The effect on your profits is actually undeniable, however there is actually additional to this story. Stay tuned to discover exactly how automatic assembly may reinvent your development collection and elevate your item quality to unmatched amounts.

Increased Speed

To accomplish boosted rate in automated China printed circuit board assembly, optimize the positioning and soldering processes. When partnering with a reliable printed circuit board assembler, guarantee they have actually dependable equipment and efficient operations to make the most of outcome. Seek a firm that uses innovative modern technologies including pick-and-place devices and automated soldering equipment.

These tools can dramatically decrease assembly times as well as improve overall creation rate. Also, proper training for personnel working the machines is important to keeping a hassle-free and fast assembly method.

Improved Reliability

For boosted reliability in automated PCB assembly, prioritize calibration of devices and also frequent maintenance schedules. By making sure that your makers are appropriately adjusted and properly maintained, you can decrease mistakes and boost the precision of your production procedures.

Functioning closely along with your printed circuit board assembler to create calibration methods as well as routine maintenance schedules modified to your details tools can dramatically enrich the accuracy of your assembly line. Frequently scheduled upkeep certainly not only protects against unanticipated break downs yet also aids keep the reliability of your equipments gradually.

Price Productivity

Guarantee that your automated PCB assembly methods are efficient and also enhanced to obtain optimal cost effectiveness. By applying computerization, you may significantly minimize work expenses connected with hand-operated assembly, as makers can easily work quicker as well as even more consistently.

Also, automated assembly reduces component waste by correctly placing parts, minimizing the overall production prices. The preliminary assets in automated devices might seem high, however down the road, it brings about set you back savings with boosted efficiency and also lowered mistake costs. Furthermore, automated processes demand less upkeep as well as oversight, further reducing down functional expenses.

Strengthened Quality Management

Automated PCB assembly uses accurate as well as constant production, lowering the probability of human mistake and guaranteeing a greater level of quality assurance. By utilizing automated evaluation systems, problems could be spotted as well as repaired immediately, causing boosted item quality.

Automated assembly likewise allows for real-time tracking of the manufacturing process, enabling fast corrections to be actually made if any sort of problems develop. This positive method assists in keeping high-grade specifications throughout the production method.

Additionally, automated printed circuit board assembly systems are actually outfitted with enhanced modern technologies that can easily identify prospective quality problems early, avoiding malfunctioning items from connecting with the lasts of production.

Much Higher Development Capacity

Automated PCB assembly service may significantly improve your creation ability through simplifying production processes and improving effectiveness. By automating recurring activities such as part placement as well as soldering, you can make PCBs at a faster cost reviewed to hand-operated assembly. This enhanced velocity enables you to satisfy higher demand degrees and supply items to industry much more quickly.

Automated assembly systems may work continuously without breaks, resulting in a substantial boost in result. With fewer errors and also regular quality, you may depend on the automatic process to sustain a higher degree of production without endangering on the quality of your PCBs.

Structured Workflow

Enrich your manufacturing efficiency along with a structured operations in PCB assembly. Through applying automated processes, you may maximize the circulation of your assembly line, lowering hold-ups and also enhancing general efficiency.

Automated PCB assembly systems can perfectly incorporate several measures like component positioning, soldering, as well as inspection, permitting a more dependable and integrated process. With automatic tools dealing with repetitive duties, your staff can concentrate on even more complex and also critical elements of the assembly procedure. This optimized operations makes sure that jobs are actually completed in a well-timed manner, decreasing abandoned time and also making the most of result.

Minimized Inaccuracy Prices

By carrying out automatic quality assurance processes, you can substantially lessen inaccuracy rates in PCB assembly. Automated systems ensure specific component placement, soldering, and evaluation, minimizing the odds of individual mistake.

These systems make use of state-of-the-art modern technologies like device eyesight to discover flaws along with high accuracy, guaranteeing that just remarkable PCBs proceed to the following manufacturing stages. Also, automated assembly decreases the demand for hand-operated managing, which is actually a common resource of mistakes.

Through streamlining the assembly method and also dealing with hands-on interventions, automated PCB assembly significantly improves the total quality and also integrity of the end product. Along with minimized mistake fees, you may anticipate improved item efficiency, enhanced customer contentment, and expense financial savings in the end.

Conclusion

Finally, automated PCB assembly provides an array of perks, consisting of increased velocity, boosted reliability, and also price performance. With enhanced quality control procedures and streamlined process, manufacturers can generate top notch products at a much faster measure while lessening errors and component wastefulness. By purchasing automated assembly processes, business can boost their manufacturing capacity as well as comply with higher demand levels while maintaining high requirements of quality.

0 notes

Text

Navigating the Path to Success: Launching Your Automated Rice Milling Venture

Introduction: In the dynamic world of agriculture, automated rice milling stands as a beacon of innovation and efficiency. This blog post is your guide to establishing a thriving automated rice milling business, from inception to operation. With a focus on turnkey solutions, cutting-edge machinery, and efficient grain handling equipment, let’s embark on this journey towards success.

Understanding the Landscape: The global rice market is ripe with opportunities, driven by the ever-increasing demand for high-quality rice products. With India and China leading the charge, the stage is set for aspiring entrepreneurs to tap into this lucrative industry. Automated rice milling represents the future, blending traditional practices with modern technology to deliver superior results.

Navigating Regulatory Terrain: Before delving into the realm of automated rice milling, it’s essential to navigate the regulatory landscape diligently. Company registration, obtaining licenses, and adhering to industry standards are crucial steps in ensuring compliance and credibility. Certifications such as FSSAI play a vital role in establishing trust and reliability in the market.

Location, Cost, and Permissions: Choosing the right location for your automated rice mill is paramount for operational efficiency. Urban hubs or rural landscapes, each offers its unique advantages and challenges. Estimating rice mill project costs involves meticulous planning, considering machinery procurement, infrastructure setup, and operational expenses. Obtaining permissions and clearances from relevant authorities is vital for smooth operations.

Investing in Turnkey Solutions: At the heart of every successful automated rice milling venture lies turnkey solutions and advanced machinery. From pre-cleaning and de-stoning to de-husking, sorting, polishing, and packaging, each step requires specialized equipment. Companies offering automatic rice mill solutions provide comprehensive packages tailored to meet industry demands.

Embracing Automation: Automation is the cornerstone of efficiency and precision in modern rice milling. With state-of-the-art machinery and advanced technologies, automation streamlines production processes, enhances product quality, and reduces labor costs. Investing in automated solutions not only boosts productivity but also ensures consistency and reliability in output.

Conclusion: As we conclude our exploration of automated rice milling, one thing becomes evident: opportunity abounds for those willing to embrace innovation. By leveraging turnkey solutions, advanced machinery, and efficient grain handling equipment, aspiring entrepreneurs can carve a niche in this dynamic industry. With each grain processed, a new chapter unfolds in the story of agricultural progress. So, seize the opportunity, harness the power of automation, and chart your course towards success in the automated rice milling business.

#rice mill project cost#rice mill machinery#grain processing machinery#grain handling equpment#turnkey rice mill solution#automatic turnkey project

0 notes

Text

Smart Warehousing in China: Enhancing Efficiency and Productivity with the right freight forwarder

China is one of the world’s largest and fastest-growing markets for e-commerce, logistics, and manufacturing. With the increasing demand for online shopping, cross-border trade, and industrial production, the need for efficient and reliable warehousing solutions is also rising.

However, many warehouses in China still rely on manual labor, outdated equipment, and inefficient processes, resulting in high costs, low accuracy, and slow delivery. According to the data of Jingdong Logistics Research Institute, at present, the penetration rate of intelligent equipment in the domestic warehousing industry is not high, and about 49.17% of enterprises still do not use warehousing and logistics automation equipment1.

This is where smart warehousing comes in. Smart warehouses are the representative of automation and robot usage in the Chinese logistics market. The key part of a smart warehouse is to replace people with highly automated machines. By using automatic robots, a smart warehouse can save around 70% labor costs2.

Smart warehouses are also equipped with advanced technologies such as IoT, artificial intelligence, and robotics, which enable real-time data collection, analysis, and optimization of warehouse operations. These innovations increase efficiency, accuracy, and productivity, revolutionizing the way warehouses operate3.

Some of the benefits of smart warehousing include:

Reduced human errors and improved inventory accuracy

Increased storage capacity and space utilization

Faster picking and packing processes and shorter delivery times

Enhanced safety and security of goods and workers

Lower energy consumption and environmental impact

According to the statistics of the Toubao Research Institute, the scale of China’s smart warehousing market in 2021 will be CNY 114.6 billion. Considering the continuous deepening of smart technology and the increasing demand for logistics industry scale and storage link cost reduction and efficiency increase, it is expected that my coChinaart warehousing logistics market will grow by 2022. The scale is about CNY 135.7 billion, reaching CNY 266.5 billion in 20261.

With such a huge potential market, how can you take advantage of smart warehousing in China? The answer is to find the right freight forwarder who can provide you with smart warehousing solutions that suit your specific needs.

A freight forwarder is a company that arranges the transportation of goods from one place to another. They can also offer other services such as customs clearance, insurance, documentation, and warehousing.

A good freight forwarder should be able to provide you with smart warehousing solutions that can help you:

Store your goods in a secure and convenient location

Manage your inventory with real-time visibility and control

Optimize your supply chain with flexible and scalable solutions

Save time and money by reducing labor costs and improving operational efficiency

One example of a freight forwarder that offers smart warehousing solutions in China is Xiaorong. Xiaorong is a professional sourcing agent that helps you source products from China with ease. They also provide smart warehousing services that can help you store your goods in China safely and efficiently.

Xiaorong has partnered with Alibaba’s Cainiao Network to launch an enterprise smart warehouse solution that leverages Cainiao’s technology and expertise in smart warehousing. This solution allows Xiaorong to offer you:

A large network of warehouses across China that can store your goods near your suppliers or customers

A state-of-the-art warehouse management system that integrates with Cainiao’s platform to provide you with real-time data and insights on your inventory

A team of trained warehouse staff that can handle your goods with care and professionalism

A fleet of automated robots that can perform tasks such as sorting, picking, packing, loading, and unloading

A seamless connection with Cainiao’s logistics network that can deliver your goods to anywhere in China or abroad

With Xiaorong’s smart warehousing solution, you can enjoy the benefits of smart warehousing without having to invest in expensive equipment or infrastructure. You can also access Xiaorong’s other services such as product sourcing, quality inspection, shipping arrangement, customs clearance, and after-sales support.

If you are looking for a reliable freight forwarder that can provide you with smart warehousing solutions in China, look no further than Xiaorong. Contact them today to get a free quote and start your smart warehousing journey.

#china freight forwarder#china supplier#china supply chain#logistics#air freight#freight#shipping containers#transportation and shipping

0 notes

Text

Egg Grading Machines Market Analysis, Key Players, Industry Segments & Forecast to 2033

The global egg grading machines market is worth US$ 1.82 Billion as of now and is expected to reach US$ 2.76 Billion by the year 2033 at a CAGR of 4.2% between 2023 and 2033.

Eggs are an indispensable part of meals in various parts of the world; inclusive of the ones hitting the gym and performing athletically. With exorbitant demand for eggs, the poultry farm owners are into adoption of latest technology for enhancing production while strengthening distribution channel and supply chain management.

The small-capacity farms do ask for advanced egg grading machines. They, as the name suggests, work on the principle of grading eggs on the basis of sizes and weight. These machines do offer extra equipment used to clean, test, select, and set the positions of eggs as well. The market participants are on the lookout of working on efficiency and stability of such platforms.

Vendors do go for strategies like adopting grading technology sensing weights and segregating eggs as per size. They also understand that these egg grading machines do need to be professional with respect to maintaining food standards.

Get a Sample Copy of this Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-16077

The newly introduced tagging procedure is inclusive of tagging graded eggs; thereby rendering it simpler for manufacturers to pack them right.

The post-Covid era has restored the egg production units to a greater extent. As such, various organized machines are in demand for simplifying the segregation part. Industry 4.0 has enabled incorporation of machines integrating grading procedure with packaging solutions. This would certainly help in reducing the overheads on the part of key participants. The machines are conducive to various kinds of eggs like goose eggs, hen eggs, duck eggs, and likewise.

Besides, the fact that eggs offer strength to hair and are used to make facial make-up kits and talcum powder could accelerate the market.

At the same time, the egg grading machines market is subject to restraints like incidences of bird flu and the other ailments amongst ducks and hens. Campaigns regarding vegan movement are also expected to hamper the egg grading machines market.

Future Market Insights has walked through these facets along with insights in its latest market study entitled ‘Egg Grading Machines Market’. It has its team of analysts and consultants to deploy a 360-degree approach across its macros and micros.

“With rising demand for whole naturally resourced items, the global egg grading machines market is expected to grow graciously in the near future”, says an analyst from Future Market Insights.

Key Takeaways from Egg grading Machines Market

North America holds the largest market share with the US being subject to higher consumption of eggs. Besides, there are breakfast giants like Burger King, McDonald’s, Subway, and likewise doling out various dishes inclusive of eggs.

Europe holds a significant market share and would continue to do so even in the forecast period due to growth in small-scale businesses related to egg grading machines.

Coming to the Asia-Pacific, China and Japan are ruling the roost. China is into propagation of strengths associated with the intake of eggs. Japan is home to advanced machines with improvised conveyor tables, which help in smooth functioning of egg grading machines. With athletes increasingly consuming high-protein diet, the global egg grading machines market is likely to grow on an unstoppable note in the forecast period. Korea is also expected to add to the growth on the back of an excessive demand for wholesome superfood.

For More Information on this Report @

https://www.futuremarketinsights.com/reports/egg-grading-machines-market

Competitive Machines

Taizy Food Machinery has come up with an advanced and a new-fangled small egg sorting machine automatically distributing eggs that do not align with other bulk.

Sanavo Technology Group, of late, did come up with GraderPro 75 with capacity of 27K eggs/hour and 75 cases/hour. This machine does come with high-end next-generation egg grader on the basis of state-of-the-art egg grading technology. The good part is that every egg does have a tag.

Sime-Tek egg graders have been built with materials of the highest quality.

What does the Report say?

The research study is based on capacity (upto 700 eggs per hour, upto 1000 eggs per hour, upto 3000 eggs per hour, upto 6000 eggs per hour, and 6000+ eggs per hour), by operation (automation and semi-automation), and by sales channel (direct procurement, distributor sales, e-Commerce platforms, and likewise).

With tremendous demand for eggs throughout, the egg grading machines market is expected to grow on a good note in the near future.

0 notes

Text

July 1939: New Home Detailed

July 2, 1939 – Detroit Free Press

For Women Only by Grace Wilcox

The Gables at Home

There is something of a race on among some hundred or so journalists and magazine writers to get a description of the Clark Gable-Carole Lombard estate. There seems to be a distinct catch in it, for the newlyweds absolutely refuse to have their place photographed in detail.

“It isn’t that we want to be mean,” explains Carole, “but we like to feel that our home is our own, and anyway it isn’t finished yet. Possibly it never will be finished. That’s why it keeps us interested.”

Gable admits he has always wanted a farm. It has been a suppressed desire for years and now that he has 14 acres, he feels he has a start, especially with four horses in his stable.

In case you are interested, I can tell you something about the estate in words, if not in pictures. Here are two people who could have practically any sort of place they want. I am happy to say they have the good sense to keep well within bounds. It is a beautiful home, but not ostentatious; it is neither a palace, a castle nor a chateau, but a good early American farmhouse of seven rooms, which may easily be cared for by one or two persons. They have no desire for a large staff of servants and so far, they have done most of the work themselves.

Back in the Valley, about a mile off Ventura Blvd., a winding drive leads up to the house, the gardens of which are surrounded by a split-rail, whitewashed fence.

It is set in the midst of a forest, for Clark has about 900 trees of various kinds, more than 100 of them citrus, planted on the grounds. He takes great pride in the fact that his farm supplies the family table with fresh fruits in season, avocados and all the vegetables. There are 1,000 chickens, a mule, four dogs, a milch cow, the four horses, innumerable cats. There is a pine tack room off the modern, up-to-the-minute stables. In this are the saddles, bridles, and farm equipment.

Each stall is provided with a feed bucket which swings automatically into the stall – the same system used at racetracks for the blooded stock. There are long chicken coops, dog kennels, a milk house; there are several acres of pastureland, a terraced grape vineyard, fig trees, flower gardens, lawns and shrubbery. A garage for four cars houses two coupes and a station wagon. Both Clark and Carole drive their own cars: they have no chauffeur. A complete irrigation system is being installed.

Inside the house, one receives an immediate impression of great comfort and serenity. There is light everywhere, with no heavy drapes to keep it out.

A huge living room extends right across the front of the house. This is furnished in quiet taste, with a special white davenport upholstered in plain, creamish-white whipcord material, several chairs in creams and rust color, tables, divans, carpets, drapes and woodwork carrying forward the light and airy effect, with just enough color to lend contrast. It is the sort of room one would rather sit in and talk, or smoke or read than to write about; it has charm, it is livable and peaceful with a great fireplace, brass andirons and copper kettles.

Off this is the dining room, which is done in knotty pine, with early American dining room furniture of pine. The buffet and set of shelves display Carole’s collection of silver, China and pewter.

To the right of the living room is gable’s gunroom, with one of the finest collections of modern and ancient weapons, from old flintlocks to the newest inventions in pistols and rifles. His most treasured brace of flintlock guns are crossed over the fireplace in the living room. Off the gun room is a specially built ice-box room for hanging his game after a hunting trip.

With the well-equipped office and kitchen, this comprises the downstairs living quarters.

Upstairs the master bedroom is done in leather, with a deep tan color predominating. A huge dressing room with plenty of cupboard and closet space, easy chairs, comfortable reading stands, proper lighting and a generally masculine effect makes an excelling loafing place.

Mrs. Gable’s boudoir is in pastel shades, with a sort of pink-orchid color scheme in upholstery and rugs. Here there is a great deal of white in the pointe d’esprit curtains, walls and furniture. She has a dressing room with revolving mirrors on the dressing table and with mirrors as wall panels. Her closets are also very large, with built-in shelves for hats, shoes, bags, etc. Although her room is delicate and lovely, it is by no means fluffy or hard to live in. Its furnishings have character and are designed for comfort as well as beauty.

So far, they have a man and his wife as caretakers. A bungalow is being built for them on the estate. Later they will have a housekeeper, cook and possibly a butler.

It would seem that Carole Lombard and Clark Gable have everything. It is just a little touching to hear them wistfully plead for privacy.

They laugh all the time, these two, and never seem to tire of ribbing each other. Carole has not lost her whimsical attitude toward life and certainly if Gable isn’t happy as any man can hope to be, he is doing a fine job of pretending.

0 notes

Text

A Tiny Blog Took on Big Surveillance in China—and Won

At a location he keeps secret, John Honovich was on his laptop, methodically scouring every link on a website for a conference half a world away. Hikvision, the world’s largest security camera manufacturer, was hosting the event—the 2018 AI Cloud World Summit—in its hometown of Hangzhou, a city of about 10 million people not far from Shanghai. Honovich, the founder of a small trade publication that covered video surveillance technology, wanted to find out what the latest Hikvision gear could do.

He zeroed in on one section of the conference agenda titled “Eco-Friendly, Peaceful, Relaxed” and found a description of an AI-powered system installed around Mount Tai, a historically sacred mountain in Shandong. A video showed Hikvision cameras pointed at tourists climbing the thousands of stone steps leading to the famous peak. Piano music played as a narrator explained, in Mandarin with English subtitles, that the cameras were there “to identify all visitors to ensure the safety of all.” The video cut to a shot of a computer screen, and Honovich hit pause. He saw a zoomed-in view of one visitor’s face. Below it was data that the camera’s AI had inferred. Honovich downloaded the video and took screenshots of the computer screen, for safekeeping.

Later, with the help of a translator, he scrutinized every bit of text on that screen. One set of characters, the translator explained, suggested each visitor was automatically sorted into categories: age, sex, wearing glasses, smiling. When Honovich pointed at the fifth category and asked, “What’s this?” the translator replied, “minority.” Honovich pressed: “Are you sure?” The translator confirmed there was no other way to read it.

Honovich was shocked. In his many years in the industry, he’d never seen a surveillance company set out to automatically detect racial minorities. The feature seemed completely unethical to him, and he immediately wondered how China might use it against the Uyghur people, a mostly Muslim ethnic minority group, in the province of Xinjiang. Honovich had seen reports trickling out in the West of Uyghurs being subjected to constrictive surveillance and mass detentions. Clicking through the AI Summit website, Honovich couldn’t tell whether Chinese authorities were using this technology to oppress minorities, but he saw that danger coalescing. He quickly wrote up an article about Hikvision’s ethnicity-detection technology, including the video, screenshots, and a no-comment from the company, and posted it on the website of IPVM, the trade publication he had founded.

He talked about the discovery with one of IPVM’s reporters, Charles Rollet, a Frenchman who lives outside the US and also keeps his location secret. Rollet had written about how Hikvision and Dahua, the second-largest video surveillance manufacturer in China, were reaping huge profits from government work in Xinjiang. Rollet had a newspaper background and, though he was 25, talked like an ink-stained newsie twice his age, all “scoops” and “calling out abuses” and “hard-hitting news.” By trawling through publicly available materials online, Rollet had learned that Hikvision had landed a deal to build a mass face-recognition system to cover one Xinjiang county—including a “reeducation” center and some of its mosques—and a contract to install videoconferencing systems in mosques, presumably so attendees could watch sermons broadcast by the government. Dahua won the bigger contract: $686 million to build camera-equipped police stations in another part of Xinjiang. The deals specified that the companies would install these systems, run them for a number of years, and then pass them off to the government. In many aspects of the government’s video surveillance in Xinjiang, Rollet reported, the two companies were “deeply involved.”

Hikvision and Dahua cameras also happened to hang on houses, businesses, and public buildings in the US and much of the world. Security system installers eagerly sold huge numbers of the cheap cameras. Global financial institutions, such as Fidelity International and Norway’s sovereign wealth fund, were enthusiastic investors in the profitable, fast-growing Chinese companies. American chip giants Intel and Nvidia sold them silicon to power their face recognition.

That would all soon change. Over the next few years, IPVM’s writers unearthed one damning detail after another on Chinese surveillance gear. Their scoops would end up influencing national policy, changing those companies’ fortunes, and placing the reporters themselves squarely on the front lines of the US–China cold war.

0 notes

Text

Application of logistics automation equipment technology

The hot link in the integration and application of logistics automation equipment technology is the distribution center, which is characterized by many varieties, batches and large quantities of items that need to be picked every day. Therefore, logistics automation picking equipment has been partially introduced in the distribution centers of domestic supermarkets, medicine, postal parcels and other industries.

One is the automatic application of picking equipment. The picking shelf (tray) is equipped with visual sorting reminder equipment. This kind of sorting shelf is connected with the logistics management information system to dynamically prompt the picked items and quantity to guide the work. The picking operation of personnel improves the accuracy and speed of goods picking.

The other is an automatic sorting device after picking items. Attach a barcode or an electronic tag to the identified object (usually the transport unit after grouping), and send it to the sorting port by the conveyor belt, and then sort the items by a sorter equipped with a reading device, so that the items enter their respective The grouping channel completes the automatic sorting of items. Sorting equipment is used in large domestic distribution centers. However, this kind of equipment and corresponding supporting software are basically imported from abroad, and there are also imported foreign mechanical equipment and domestic configuration software. The three-dimensional warehouse and the associated roadway stacker have developed rapidly in China and are used in machinery manufacturing, automobiles, textiles, railways, cigarettes and other industries.

https://www.gst-automation.com/uploads/allimg/20221230/1-221230152P3a2.jpg

The domestic stacker has been greatly improved in terms of its walking speed, noise, positioning accuracy and other technical indicators, and its operation is relatively stable. However, compared with famous foreign manufacturers, there is still a big gap in some fine indicators of the stacker, such as the high limit of the minimum cargo space, the noise during high-speed (above 80 m/s), and the deceleration performance of the motor.

Logistics equipment tracking mainly refers to the tracking of the transport carrier of logistics and the location of items involved in logistics activities.

There are many ways to track logistics equipment. Traditional communication means such as telephones can be used for passive tracking, and RFID means can be used for phased tracking. However, GPS technology is the most widely used in China at present.

GPS technology tracking utilizes the GPS logistics monitoring and management system, which mainly tracks the transportation of freight vehicles and goods, so that the owner of the goods and vehicles can know the location and status of the vehicles and goods at any time, ensuring the effective monitoring and rapid operation of the entire logistics process.

The composition of the logistics GPS monitoring management system mainly includes GPS positioning equipment on the means of transportation, tracking service platform (including geographic information system and corresponding software), information communication mechanism and other equipment (such as electronic labels or barcodes on goods, alarm devices, etc. ).

0 notes

Text

Bottle & Liquid Filling Machines Inline Filling Methods

The Series 10 VFFS filling head provides the perfect configuration when built-in with a vertical-form-fill-seal bagging system. The sleeved mount permits rotation of the filling head for ease of tooling /hopper removal. An OEM version of the Series 10 filling head which could be integrated with horizontal and vertical-form-fill-seal machines and other OEM equipment. Typical Bulk Feed Option could possibly be from overhead IBC/bulk bin through horizontal cross-feed auger. Modern packaging machines have to be nimble and versatile – they want to find a way to fill quite so much of containers regarding shapes and sizes.

The machine has an electronic photo-cell in order to management the cutting point as per printed mark. It is built on a thick and heavy forged steel frame for maximum torsional rigidity and mounted on wheels. With the help of our state-of-the-art infrastructure unit, we're able to manufacture, export and supply superior high quality Automatic Pouch Packing Machine-High Speed for Snack.

The following info will assist you in choosing the most effective powder filling machine or powder filler to satisfy their budgetary needs and shopper expectations. We will go over everything you need to find out about powder filling machines. Please discover enclosed a self explanatory package contains worth schedule technical information filling and packaging machines for the provision of the identical. However, if you wish to have extra info regarding packaging machines please don’t hesitate to call us. We provide computerized liquid & paste filling & packaging machine, which is used in packaging of pure liquid as nicely as paste products with specially fitted injection pump.

APACKS producers a complete line offilling machinesas nicely ascapping machinesto deal with completely different ranges of container sizes, fill weight or quantity, and product sorts. No matter what you liquid filling problem could additionally be APACKS has machine solutions for all types of liquids and almost filling and packaging machines all industry functions. Inline Filling Systems big selection of liquid filling machines, includes cleansing, filling, capping, conveyors and accumulation gear. ATS Engineering sturdy liquid fill equipment for a variety of functions.

The demand for fruit yogurt has created the need for fruit yogurt filling and packaging machines. To start, there are quite a few elements to consider when selecting a liquid filling machine, together with overflow, gravity, pistons, and pumps, and choosing the proper machine additionally is determined by your goals. They’re perfect for small-scale manufacturing, laboratory use, and different conditions where an exterior energy supply isn’t available or reliable. To maintain the stainless-steel floor of the liquid filling machine bright and clean, by no means scratch it with a pointy or onerous edge instrument. They fill containers with sauces, juice concentrates, and jams. Offer secure, ergonomic grip with multi-prong design for controlling, positioning and tightening.

This kind of machine runs for 24Hours without break to finish the necessities. Inspections of your pouch filling machine ought filling and packaging machines to be accomplished on a frequent basis. The bottle filling machine must be inspected frequently.

You may also be able to be taught what’s the important thing issue deciding the standard as well as good pricing. With the event of internet and logistics, now it’s getting easier and easier to buy from the manufacturer instantly, regardless it's going to take more time to review the machinery via the website. We would like to help you and be good cooperator in China for your automated packing equipment in your factory.

Accutek Auger Fillers are properly suited to the filling of dry merchandise, powders, granules, or seeds. The Accutek All Electric Servo Driven Filler (E-SPF) is a piston filler that accurately delivers a measured quantity of product to each container. This machine may be geared up with nitrogen fuel filling gadget is on the market to be added on for allowing the oxygen present in product to be controlled within fewer than 2%. This machine may also be outfitted with perforating device for steady package output. The packaging system adopts a palm-type sealing mechanism, so that the appearance of the output package is neat, the sealing is tight, and there are no material clamping or pinhole potentialities.

0 notes

Text

Intelligent sorting logistics equipment manufacturer

With the development of the new economy, express delivery and e-commerce have gradually replaced traditional industries to become the industries with the fastest growth in demand for logistics equipment. Taking automated three-dimensional warehouses as an example, in the past three years, the number of automated three-dimensional warehouses owned by e-commerce and express delivery companies has increased rapidly, and their share in the entire industry has also steadily increased. Among them, e-commerce companies focus more on automation from the perspective of warehouse integration, involving the entire process of warehousing, picking, and packaging, with high system integration requirements, while express delivery companies mainly rely on the automation of sorting operations, with simpler scenarios, which often meet the conditions for batch debugging and installation, so the application of automation is also faster.

As the construction, renovation and expansion of distribution centers of express delivery companies accelerates, the proportion of semi-automatic and automated sorting equipment has steadily increased. Data shows that in 2019, China's express delivery industry has built more than 5,000 kilometers of automated assembly lines, which is equivalent to the total mileage of China's subways. Thanks to the booming development of upstream e-commerce and express delivery industries and the huge market demand of the manufacturing industry, China's automatic sorting equipment market has maintained a high-speed growth trend.

The development of e-commerce has brought about a surge in express delivery business, which has greatly increased the volume and complexity of sorting operations, magnified the defects of manual sorting, and stimulated the need for express delivery companies to transform and upgrade through the layout of intelligent sorting

The increase in the use of electronic waybills, the successful fundraising of express delivery companies, and the rapid decline in the price of intelligent sorting equipment have jointly provided external conditions for the popularization of intelligent sorting.

Gosunm is committed to developing high-tech non-standard automation technology and is currently a leading manufacturer of intelligent sorting and logistics equipment in China. It has a large number of non-standard automation project technology reserves in the fields of intelligent manufacturing, energy, e-commerce, supermarkets, warehousing, etc.

As a Chinese manufacturer of automated sorting equipment, gosunm mainly produces and develops storage systems, conveying systems, sorting systems and software control systems. Compared with manual sorting, automated sorting increases efficiency by 30% and reduces costs by 77%. Compared with the disc-type structure, the three-dimensional cross-type structure saves 67% of area and has a high accuracy rate.

Our products include logistics warehousing sorting solutions, such as dynamic weighing and volume scanning machines; static DWS, belt cross sorters, ring belt sorters, swing wheel sorters and other user-friendly conveyor modules suitable for cost-effective logistics systems. We are involved in various industry sectors such as postal services and warehouse management.

In last over ten years, Gosunm has been serving the clients from more than 30 countries and regions including Malaysia, Germany, the United States, South Korea, Japan, Italy, Turkey, Canada, Portugal, Brazil, Colombia, South Africa, Russia, etc.. And we have been cooperating with some reputed brands such as Watsons, BYD, Sanqi, Robust Medical, etc.

At the same time, we are granted with the titles Including but not limited to "National High-tech Enterprise", "Guangdong Engineering Technology Research Centre", "Guangdong Postgraduate Workstation", and "Dongguan Intelligent Manufacturing Association Chairman Unit"

If you have the same problem and want to complete package sorting efficiently and reduce manual errors, you deserve gosunm logistics sorting equipment!

#automated sorting equipment#gosunm logistics sorting equipment#China's automatic sorting equipment#logistics warehousing sorting solutions

0 notes

Text

Vibrating Sifter Machine Market Top Manufacturers, Global Opportunities by Regions 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Vibrating Sifter Machine Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Vibrating Sifter Machine Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Vibrating Sifter Machine Market?

The vibrating sifter machine market is expected to grow at a CAGR of 5.3% during the forecast period of 2024 to 2032.

What are Vibrating Sifter Machine?

A vibrating sifter machine is a tool that segregates and categorizes materials like powders, liquids, and solids. It uses vibration to guide materials through a mesh screen, separating them based on their particle sizes. This machine's vibrating action aids in efficiently sifting and isolating materials, making it valuable in industries such as food processing, pharmaceuticals, and chemicals. Designed to boost efficiency and precision in material sorting and classification, the vibrating sifter machine enhances overall production processes.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1940

What are the growth prospects and trends in the Vibrating Sifter Machine industry?

The vibrating sifter machine market growth is driven by various factors. The global market for vibrating sifter machines is experiencing significant growth, primarily due to the rising demand for efficient and automated sieving equipment in industries such as food and beverage, pharmaceuticals, and chemicals. These machines are known for their high throughput, improved accuracy, and reduced downtime, which collectively enhance overall productivity. Moreover, technological advancements, such as the incorporation of sensors and digital controls, are further driving market expansion. The Asia-Pacific region is expected to lead the market, driven by rapid industrialization and the increasing adoption of automated solutions in countries like China and India. However, challenges such as high initial costs and maintenance requirements may impede market growth to some extent. Hence, all these factors contribute to vibrating sifter machine market growth

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Rotary Vibrating Sifter Machine

Circular Vibrating Sifter Machine

Linear Vibrating Sifter Machine

Tumbler Vibrating Sifter Machine

By Operation Mode:

Manual Vibrating Sifter Machine

Semi-automatic Vibrating Sifter Machine

Automatic Vibrating Sifter Machine

By End User:

Food and Beverage Industry

Pharmaceutical Industry

Chemical Industry

Mining and Metallurgy Industry

Cosmetics and Personal Care Industry

Others

By Region:

North America

Latin America

Asia Pacific

Europe

Middle East & Africa

Who are the key players operating in the industry?

The report covers the major market players including:

Russell Finex Ltd.

VibraScreener Inc.

SWECO, a business unit of M-I LLC

Kason Corporation

Gough Engineering Ltd.

Rotex Global LLC

Elcan Industries Inc.

Eversun Machinery (Henan) Co., Ltd.

Midwestern Industries Inc.

Xinxiang Dayong Vibration Equipment Co., Ltd.

Xinxiang Gaofu Machinery Co., Ltd.

Virto-Cuccolini S.r.l.

Others

View Full Report: https://www.reportsandinsights.com/report/Vibrating Sifter Machine-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Vibrating Sifter Machine Market share#Vibrating Sifter Machine Market size#Vibrating Sifter Machine Market trends

0 notes

Text

30 amp power converter

#30 amp power converter series

Short Circuit Protection: Internally protected High transitionĮfficiency, allowing sustained short-circuit, reset after shorting are its Short-circuit protection, overheat and over current protection. Voltage, larger capacity, well-found protecting function, high stability and longĮmploying soft key technology, it has the functions of fail safe for low-voltage, To install, open circuit operation for long time, lower static power, stable output Technology, it has high transition efficiency, mini-type, easy By adapting the internationally advanced digital analogy

#30 amp power converter series

The TDC High Efficiency Series DC/DC Converter is specificallyĭesigned to provide a reduced voltage supply for auxiliary electrical systems Isolated DC-DC Converter 400W, 13.5V Output 30 Amps Please contact for our replacement option. Market Iota units as US built, when they no longer are.This item has been discontinued by the manufacturer and is no longer available. While still excellent quality units, with aĢ year warranty, they are now built in China to IOTA Engineering specifications. IOTA converter/chargers were built in the US in the past. Use converters as chargers when any sort of amps are involved, or reasonable recharge times expected. While theĬonverters will charge batteries, at a slower rate than a charger with a higher bulk voltage, we won't In small print that the IQ4 controllers are available separately, at additional cost. Some companies sell IOTA convertersĪs chargers, at a lower price, while not indicating that they are one fixed voltage, and sometimes mention The IOTA Engineering power converters are also available with the built in microprocessor controller (the IQ4), Circuit innovations minimize output voltage ripple and RFI.Reliable power with minimum weight and size.Part#: Iota DLS-30 Iota 12 Volt 30 Amp Power Converter $154 Multiple units can be operated in series or parallel to increase voltage or amperage.Ĭlick image for larger picture, "Back" button to return Load demands, the automatic circuitry will activate the fan before thermal stress can occur onĮxternal fuses protect the IOTA unit against improper wiring and can be quickly and easily replaced. Proportional Fan Circuitry provides an extra measure of protection. Substantially longer life and safer operation. Half that of some switch mode electronic models, even in its subcompact size. Interference especially on the lower frequency bands. criteria, minimizing radio and television equipment Protection against low and transient AC line voltage as wellĪs spikes coming from the AC power source or from improperly adjusted generators, a major cause Longer life for any connected load virtually no AC ripple to cause static or premature failure Exceptionally clean DC output insures pumps, motors, fans, and lights work perfectly. The IOTA DLS-30 12 Volt 30 Amp power converter uses state-of-the-art, switch-mode technology, to provide a demand sensed 13.6 volt output at up to 30 amps. IOTA DLS-30 12 Volt 30 Amp Power Converter

0 notes

Text

Market Segments for Optical Sorter and COVID19 Analysis 2019-2028

Numerous food safety, legislation and controls are being implemented to control chemical and microbiological hazards in order to reduce risks to consumer health. A number of federal regulators are developing a food protection policy that will help in the traceability of food products at many stages, including processing, production and distribution. This helps companies involved in the manufacture of food products to set up a control and monitoring unit for the management of the quality of food ingredients. The optical sorting technology, when implemented, would enable food producers to improve the productivity of the business process and separate the inferior-quality materials.

To know the scope of our report get a sample on https://www.axiommrc.com/request-for-sample/10414-optical-sorter-market-report

OPTICAL SORTER MARKET DYNAMICS

Increasing automation of industries in order to improve efficiency and the increasing need to minimize delivery and processing time in the food industry are the key drivers for the global optical sorter market. In addition, strict government legislation and policies on food security and rising labor costs are substantially improving the market. However, high capital investment and consistently rising operating and maintenance costs are major restrictions on the global optical sorter market.

COVID 19 IMPACT ON OPTICAL SORTER MARKET

Covid19, drastically affects the world supply chain and industrial sector growth. At the initial stages of the pandemic, the world experienced, ‘supply shocks’. China who plays a major role in the world’s supply chain was severely affected. There were disruptions to the availability of goods supplied from China. Supply of both finished and unfinished goods reduced. Day by day as the situation worsened, quarantines, social distance practices were imposed and nations have begun instituting lockdowns. Following this, the supply chains experienced demand shocks. The shutdown of economic activities affected all the sectors. The food and mining industry’s sluggish growth, in turn, affected the Optical Sorter market. Major customers of optical sorter belong to the food and recycling industries.

OPTICAL SORTER MARKET SEGMENTAL OVERVIEW

The report analyses the optical sorter market based on type, platform, application, and geography.

OPTICAL SORTER MARKET BY TYPE

By type, the global optical sorter market is segmented into cameras, lasers, NIR sorters, and hyper spectral cameras & combined sorters. Cameras are projected to hold the largest share of the optical sorter market in the forecast period. Camera-based optical sorters are more accurate and can spot minute defects in products; thus, these optical sorters are chosen for different applications. Cameras are commonly used in food sorting applications for the sorting of vegetables and berries, dried fruits and nuts, and cereals, grains and pulses.

OPTICAL SORTER BY PLATFORM

By business platform, the global optical sorter market is segmented into belt, freefall, lane, and hybrid. Among these, the belt platform is projected to grow in the forecast period. In various applications such as food, recycling, and mining, belt sorting devices are widely used as they provide higher sorting accuracy and a low carryover ratio. Belt sorting equipment provides high-performance capabilities for fresh, frozen and dried vegetables.

OPTICAL SORTER MARKET BY APPLICATION

The global optical sorter by application is classified into food, recycling, mining and other. Food application is anticipated to hold the largest share of the optical sorter market during the forecast period. The increasing acceptance of automatic equipment in the food industry is a key driver of the demand for optical sorters, as optical sorters provide benefits such as enhanced food safety, improved food quality, shorter delivery cycles, and increased performance.

OPTICAL SORTER MARKET BY GEOGRAPHY

Geographically, the optical sorter market is studied across the countries of key regions such as, North America, Europe, Asia Pacific and the rest of the world regions which includes Latin America, and Middle East & Africa. Asia pacific is expected to the growing region in the forecast period. Owing to the increasing adoption of intelligent solutions and rapid growth in digitalization. The integration of AI technologies into the equipment provides companies with features such as advanced analytics, tracking and process automation. Manufacturers in this region are involved in the development of AI-based sorting technologies to provide reliable and intelligent solutions for manufacturing operations and processes.

OPTICAL SORTER KEY PLAYERS

Some of the major players operating in this market include National Recovery Technologies (US), TOMRA (Norway), Buhler (Switzerland), Binder+Co (Austria), Satake Corporation (Japan), Allgaier Werke (Germany), Hefei Meyer Optoelectrionic Technology (China), Daewon GSI (South Korea), Cimbria (Denmark), TAIHO (China), CP Global (US), Key Technology (US), GREEFA (Netherlands), and NEWTEC (Denmark)

Buy now Optical Sorter Market Report https://www.axiommrc.com/buy_now/10414-optical-sorter-market-report

About Us:

Axiom Market Research & Consulting™ is a full-service market research and data analytics company providing key market intelligence to global companies to take informed business decisions pertaining to their marketing strategy, investments, new product launches, market competition, consumer or end users, social media trends etc.

Axiom Market Research & Consulting™ offers market research services such as syndicated market research, custom market research, business consulting, and consumer/end user surveys. Under Business to Consumer (B2C) market research offerings, Axiom MRC assists its clients in finding quantitative information/preferences of its brands and services such as, awareness, usages, satisfaction, tracking, ethnicity etc. Axiom MRC offers data collection services through online surveys, social media, data processing and interpretation.

Axiom MRC with its experienced team of research and data analysts, has delivered more than 5000+ Market Research Projects, 3800+ Data Analytics Projects, 1200+ Business Support Projects and has a 800+ Global Client Base. Axiom Market Research & Consulting™ aims to become the preferred market research and data analytics company by providing key market intelligence solutions for client’s business growth.

Contact Us:

Axiom Market Research & Consulting™

3 Germay Dr. Ste 4 - 4666

Wilmington DE 19804

U.S.:- + 1 (845) 875-9786

U.K.:- + 44 (0) 20 3286 9707

Email: [email protected]

Website: https://www.axiommrc.com/

Blog: https://industrywatch24.com/

Follow On

LinkedIn: https://www.linkedin.com/company/axiom-market-research-and-consulting/

Twitter: https://twitter.com/AxiommrcCom

1 note

·

View note

Text

Pavel's pride: 45 years of the inaugural flight of the Su-27

Fernando Valduga By Fernando Valduga 07/10/2022 - 6:28 PM in History, Military

The year 2022 marks the 45th anniversary of the inaugural flight of the prototype Su-27 fighter developed by the Sukhoi Experimental Design Bureau, which marked the birth of the famous Su-27/Su-30 fighter family.

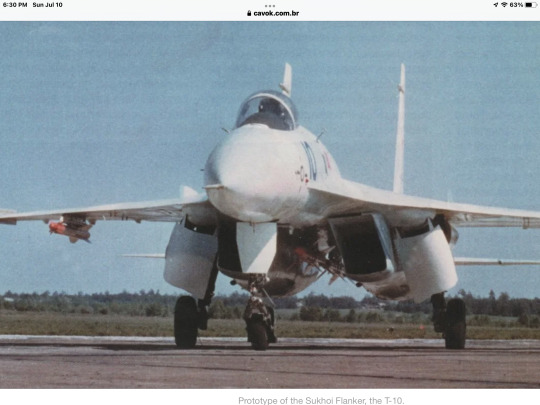

Prototype of the Sukhoi Flanker, the T-10.

In the 21st century, the Su-27/Su-30 became one of the most requested fighters in the world: they were purchased by Angola, Belarus, Venezuela, Vietnam, India, Indonesia, Kazakhstan, China, Malaysia, Uganda and other countries. Much of the credit for this should go both to aircraft designer Pavel Osipovich Sukhoi and to the team of his incomparable Design Bureau, who managed to obtain a technically perfect formula for the overall success of the Sukhoi brand.

"Aerial superiority is a key factor in any confrontation. That's why we pay close attention to the development of new advanced platforms. At the same time, the Su-27 has become a technologically innovative machine and the parent of a whole family of exceptional aircraft: the Su-30, Su-34 and Su-35. Today, these jets are the mainstay of the Russian Aerospace Forces and carry out missions successfully even under especially adverse conditions on a daily basis. This is a vivid demonstration of our technological capabilities," said Vladimir Artyakov, first deputy director general of Rostec State Corporation.

Su-30SM.

Currently, Russia's family of Sukhoi high-performance heavy duty aircraft systems offered for export is represented by aircraft of the 4+/4++ generation, the Su-30SME, Su-34E and Su-35.

"Rosoboronexport has delivered about 700 Su-27/Su-30 combat aircraft abroad since 2000. In 2021, the company's order book was replenished with new contracts for the supply of Su-30SMs," said Alexander Mikheev, Managing Director of Rosoboronexport (part of Rostec State Corporation). "In the last 10 years, the share of aircraft supplies in Russia's total arms exports has stood at 40-50% and even exceeds this number today. Currently, our partners greatly appreciate the fact that engines, avionics, weapons, systems and components in Russian combat aircraft are exclusively manufactured in Russia. This ensures the independence of purchasing countries from unfair actions taken by third countries. In addition, an open architecture of avionics and weapons systems, implemented in Russian fighters, allows foreign customers, with the involvement of the Sukhoi Design Bureau, to integrate some of the national systems and weapons thrown from the air into them."

Su-34.

The Russian Aerospace Forces are the largest operator of Sukhoi combat aircraft. According to the Russian Ministry of Defense, Su-30SM and Su-35 aircraft can effectively intercept air targets and attack military installations with guided weapons with precision at low, medium and high altitudes. Its airborne equipment allows the use of air weapons with maximum precision. According to the fighter pilot "Hero of Russia" Major Viktor Dudin, the Su-35 is a perfect fighter.

Su-35.

The Su-35 is a powerful 4++ generation aircraft system that incorporates fifth-generation fighter technologies. The Su-35 handles the full range of hunting missions at a wide altitude and speed envelope. A large number of hardpoints allow the use of up to 12 medium-range air-to-air guided missiles or 6 air-to-surface missiles in one sort. Its powerful on-board radar can detect aerial targets over long distances (up to 350 km). The Su-35 also effectively engages ground (surface) targets, including without entering the enemy's air defense zone. In addition, the Su-35 is able to control a group of planes in the air, acting as an AWACS aircraft.

Main advantages of Su fighters:

super maneuverability that gives an advantage in approximate air combat, allowing the Sukhoi aircraft to stop retaliatory missile attacks;

powerful missiles and rockets plus a 30 mm automatic cannon;

autonomous base and in-flight refueling capacity;

Open architecture of avionics and weapons systems.

Su-30MKI of the Indian Air Force.

One of the most notable ?? Foreign Su-30 fighter operators is India, where the licensed Su-30MKI fighter production program, which make up the backbone of the country's Air Force, has been successfully implemented. Rosoboronexport, under the Make in India program, is ready to provide additional kits completely disassembled for the assembly of the Su-30MKI and carry out joint work on its modernization, including the integration of the latest air weapons, avionics, etc. At the same time, the existing portfolio of aviation projects allows the company to develop technological cooperation globally in a wide range of areas.

The fighters will be demonstrated this year at the ARMY-2022 International Military and Technical Forum.

Tags: Military AviationRussiaSu-27 FlankerSukhoi

Previous news

Airbus delivers the 7,000th Ecureuil helicopter

Next news

Super Hornet falls into the sea from the USS Harry S. Truman in the Mediterranean

Fernando Valduga

Fernando Valduga