#Chemical Industry Quality Casting Solutions in India

Explore tagged Tumblr posts

Text

Chemical Manufacturing and Processing Industries

The chemical manufacturing and processing industries are vital pillars of the global economy, playing a crucial role in producing materials and substances that are essential to modern life. These industries encompass a wide range of activities, from the production of basic chemicals like acids, alkalis, and solvents to the creation of advanced materials such as polymers, pharmaceuticals, and specialty chemicals. Their outputs are integral to sectors like agriculture, healthcare, construction, automotive, electronics, and consumer goods, making them indispensable to both industrial and daily applications.

At the core of chemical manufacturing is the transformation of raw materials—such as petroleum, natural gas, minerals, and biomass—into valuable products through chemical reactions and processes. This involves complex operations like distillation, polymerization, oxidation, and catalysis, often requiring precise control of temperature, pressure, and other variables. Advanced technologies, including automation, artificial intelligence, and process optimization, have significantly enhanced efficiency, safety, and sustainability in these processes.

Sustainability has become a key focus in the chemical industry, driven by environmental concerns and regulatory pressures. Companies are increasingly adopting green chemistry principles, which aim to minimize waste, reduce energy consumption, and use renewable resources. Innovations such as carbon capture, biodegradable materials, and circular economy practices are transforming the industry, helping to reduce its environmental footprint. Additionally, the shift toward bio-based chemicals and the use of alternative feedstocks are paving the way for a more sustainable future.

Safety is another critical aspect of chemical manufacturing. The handling of hazardous materials and high-risk processes necessitates stringent safety protocols, employee training, and robust infrastructure to prevent accidents and ensure worker well-being. Regulatory compliance with standards such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and OSHA (Occupational Safety and Health Administration) is essential to maintain operational integrity and public trust.

The chemical industry is also a major driver of innovation. Research and development efforts are continuously yielding breakthroughs in areas like nanotechnology, advanced materials, and clean energy technologies. These innovations not only enhance product performance but also address global challenges such as climate change, resource scarcity, and healthcare needs. In conclusion, the chemical manufacturing and processing industries are dynamic and multifaceted, contributing significantly to economic growth and technological progress. By embracing sustainability, safety, and innovation, these industries are poised to meet the demands of a rapidly evolving world while addressing critical environmental and societal challenges

#Chemical Manufacturing#Processing Industries#Chemical Industry Quality Casting Solutions in India#Quality Casting Solutions#Casting Solutions

0 notes

Text

Puddle Flanges Supplier in Assam

Keshar Bhawani Metal & Tubes Pvt. Ltd is a trustable Puddle Flanges Supplier in Assam, India. Our manufacturing unit is in Mumbai, Maharashtra, India. A Puddle Flange is a type of flange used to provide a seal around pipes that penetrate through concrete walls or floors, ensuring a leak-proof seal and structural strength. We specialize in manufacturing high-quality Puddle Flanges designed to meet the rigorous demands of various industries. Our puddle flanges provide an effective solution for sealing pipe penetrations through walls, floors, and tanks while maintaining structural integrity and preventing leakage. With years of experience and an emphasis on superior craftsmanship, we offer products that ensure reliability, durability, and efficiency. Specifications of Puddle Flanges: Material: PVC, HDPE, Stainless Steel, Carbon Steel, Cast Iron. Diameter Range: 20mm to 500mm (custom sizes available). Pressure Rating: PN6, PN10, PN16. Temperature Resistance: -10°C to 120°C (depending on material). Standards Compliance: ISO, DIN, ASTM, BS. Coating Options: Epoxy or zinc coating for enhanced durability. Why Choose Puddle Flanges from Keshar Bhawani Metal & Tubes Pvt. Ltd.? High-Quality Material: We make our puddle flanges from high-quality stainless steel and other corrosion-resistant alloys, ensuring superior performance in even the harshest environments. Custom Solutions: We offer customizable puddle flanges in various sizes, thicknesses, and specifications to meet the specific requirements of your project. Precision Engineering: We precision-engineer our puddle flanges to offer a secure fit and excellent sealing performance. Durability: Designed to withstand high pressure and temperature variations, our flanges ensure longevity and reliability. Cost-Effective: Competitive pricing without compromising on quality, making us a cost-effective solution for your industrial needs. FAQs: What industries use puddle flanges? Industries such as water treatment, chemical processing, oil and gas, sewage management, and industrial construction widely use puddle flanges. What materials are used in manufacturing puddle flanges? We use materials such as stainless steel, carbon steel, and mild steel, with coatings or finishes applied as needed for corrosion resistance. What is the primary function of a puddle flange? A puddle flange provides a leak-proof seal around pipes that pass through walls, floors, or tanks, preventing leakage and ensuring structural integrity. Keshar Bhawani Metal & Tubes Pvt. Ltd is a trustable Puddle Flanges Supplier in Assam, India Including locations like Baksa, Barpeta, Bongaigaon, Cachar, Charaideo, Chirang, Darrang, Dhemaji, Dhubri, Dibrugarh, Dima Hasao, Goalpara, Golaghat, Hailakandi, Jorhat, Kamrup Metropolitan, Kamrup, Karbi Anglong, Karimganj, Kokrajhar, Lakhimpur, Majuli, Morigaon, Nagaon, Nalbari, Sivasagar, Sonitpur, South Salmara-Mankachar, Tinsukia, Udalguri, West Karbi Anglong, Biswanath, Hojai, Bajali, Tamulpur, Guwahati, Jorhat, Dibrugarh, Silchar, Tezpur, Nagaon, Kokrajhar, Sivasagar, Tinsukia, Goalpara. For detailed information and inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Bajali#Barpeta#Biswanath#Bongaigaon#Cachar#Charaideo#Chirang#Darrang#Dhemaji#Dhubri#Dibrugarh#DimaHasao#Goalpara#Golaghat#Guwahati#Hailakandi#Hojai#IndiaIncludinglocationslikeBaksa#Jorhat#Kamrup#KamrupMetropolitan#KarbiAnglong#Karimganj#KesharBhawaniMetal&TubesPvt.LtdisatrustablePuddleFlangesSupplierinAssam#Kokrajhar#Lakhimpur#Majuli#ManufacturerofPuddleFlanges#ManufacturerofPuddleFlangesinAhmedabad#ManufacturerofPuddleFlangesinMumbai

0 notes

Text

Gate Valve Manufacturers & Exporters from India Trusted Source

Gate valves play a crucial role in various industries, ensuring smooth flow control in pipelines. These valves are widely used in oil and gas, water treatment, chemical processing, and other industrial applications.

When it comes to sourcing high-quality gate valves, businesses look for reliable Gate Valve Manufacturers & Exporters from India that offer precision-engineered products with durability and efficiency.

Understanding Gate Valves and Their Importance

Gate valves are designed to control the flow of liquids and gases by using a gate mechanism that moves up and down. They are highly preferred in applications requiring minimal pressure drop and full flow capability. Unlike other valves, gate valves provide a tight seal, preventing leakage and ensuring optimal performance in high-pressure environments.

Key Features of High-Quality Gate Valves

Durability: Made from robust materials like stainless steel, cast iron, and brass, ensuring long-lasting performance.

Leak-proof Design: Gate valves provide a tight seal, reducing the risk of leaks and contamination.

Corrosion Resistance: High-quality coatings and materials enhance resistance to corrosion and harsh environments.

Smooth Operation: Designed for easy opening and closing, ensuring minimal effort during operation.

Wide Application Range: Suitable for industries such as oil & gas, petrochemical, water supply, and power plants.

Why Choose Indian Gate Valve Manufacturers & Exporters?

India has emerged as a global hub for industrial valve manufacturing, known for its advanced engineering, cost-effective solutions, and strict quality standards. Indian manufacturers follow international norms such as API, ANSI, and ISO certifications, ensuring products meet global quality standards.

Advantages of Buying from Gate Valve Manufacturers & Exporters from India

High-Quality Manufacturing: Indian manufacturers use state-of-the-art technology to produce reliable and precision-engineered gate valves.

Competitive Pricing: Due to efficient production processes, Indian gate valves are more affordable without compromising on quality.

Custom Solutions: Manufacturers provide customization options based on specific industrial requirements.

Global Export Network: Indian exporters have a strong presence in international markets, supplying to various industries worldwide.

After-Sales Support: Reliable manufacturers offer maintenance, repair, and support services to ensure long-term product performance.

Applications of Gate Valves in Various Industries

Gate valves are versatile components used in numerous industries, offering efficiency and durability. Some common applications include:

Oil & Gas Industry: Essential for pipeline control, crude oil transportation, and refinery operations.

Water Treatment Plants: Used for water distribution and sewage systems to regulate flow.

Power Plants: Ideal for steam and cooling water applications.

Chemical Industry: Ensures safe handling of aggressive chemicals and hazardous fluids.

Construction & Infrastructure: Used in large-scale projects for water supply and drainage systems.

How to Choose the Right Gate Valve Manufacturer in India?

Selecting the right manufacturer is crucial to ensuring the best quality and performance for your industrial requirements. Here are key factors to consider:

Industry Experience: Choose a manufacturer with years of expertise in valve production.

Certifications & Standards: Ensure they comply with industry standards like API 600, BS 1414, and ISO 9001.

Product Range & Customization: Look for a supplier offering various gate valve designs with custom options.

Material Quality: High-grade materials ensure better durability and corrosion resistance.

Customer Support: Reliable after-sales service and technical assistance add value to your investment.

Conclusion

When looking for Gate Valve Manufacturers & Exporters from India, it is essential to choose a trusted and reputed supplier to ensure product reliability, efficiency, and long-term performance.

With a strong manufacturing base, advanced technology, and adherence to global standards, Indian manufacturers are well-equipped to meet the demands of various industries.

If you are looking for a trusted supplier in Ahmedabad, Mayur Valves System Private Limited offers high-quality gate valves designed to meet industrial needs with precision and reliability.

#Gate Valve Manufacturers & Exporters#Gate Valve Manufacturers & Exporters from Ahmedabad#Gate Valve Manufacturers & Exporters from Gujarat#Gate Valve Manufacturers & Exporters from India

0 notes

Text

Mild Steel Pipe Fittings in Uttar Pradesh

Meghmani Metal is a prominent Manufacturer, and Supplier of Mild Steel Pipe Fittings in Uttar Pradesh, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Meghmani Metal is a prominent manufacturer and supplier of MS (Mild Steel) Fittings in India, with a strong focus on maintaining quality and ensuring customer satisfaction. We have the capacity to manufacture a wide range of mild steel fittings, catering to different sectors and client needs. Our product range includes various types of MS fittings such as elbows, tees, reducers, caps, and flanges. As one of the leading MS fittings manufacturers in India, we ensure our products meet or exceed market requirements. MS fittings commonly change the direction of fluid flow, connect pipes of different sizes, and terminate pipes in piping systems. Industries like oil and gas, petrochemicals, power plants, and construction widely use them due to their good mechanical properties and cost-effectiveness. Specifications: Size Range & Type Seamless Butt-Weld Fitting: From 1/2″ - 10″ | Welded ButtWeld Fitting: From 1/2″ - 48″ Dimensions: ASME, ANSI B16.9, ASME B16.28, MSS-SP-43, BS1560, BS4504, BS10 Bending Radius: Radius=1 D, 2D, 3 D, 5D, 6D, 8 D, 10D Thickness of Fitting: SCH10, SCH 20, SCH30, STD SCH40, SCH80, SCH60, XS, SCH100, SCH 120, SCH140, SCH 160, XXS available with NACE MR 01-75 Size Ranges: ½” NB to 24″ NB in Schedule 10s, 40s, 80s, 160s, XXS. Process of Manufacturing: Push, Press, Cast, Forge. Applications: Plumbing Systems Oil & Gas Industry Construction Chemical Industry Automotive Industry Power Plants FAQS: What is the difference between MS pipe fittings and stainless steel pipe fittings? Manufacturers make MS pipe fittings from mild steel, which is more cost-effective but less resistant to corrosion compared to stainless steel. Stainless steel fittings are more durable and corrosion-resistant but come at a higher cost. Can MS pipe fittings be used for high-temperature applications? MS pipe fittings are suitable for moderate-temperature applications. However, for extreme high-temperature conditions, materials like stainless steel or alloy fittings are recommended. Meghmani Metal is a prominent Manufacturer, and Supplier of Mild Steel Pipe Fittings in Uttar Pradesh, India Including Agra, Aligarh, Amroha, Ayodhya, Azamgarh, Bahraich, Ballia, Banda, Bara Banki, Bareilly, Basti, Bijnor, Bithur, Budaun, Bulandshahr, Deoria, Etah, Etawah, Faizabad, Farrukhabad-cum-Fatehgarh, Fatehpur, Fatehpur Sikri, Ghaziabad, Ghazipur, Gonda, Gorakhpur, Hamirpur, Hardoi, Hathras, Jalaun, Jaunpur, Jhansi, Kannauj, Kanpur, Lakhimpur, Lalitpur, Lucknow, Mainpuri, Mathura, Meerut, Mirzapur-Vindhyachal, Moradabad, Muzaffarnagar, Partapgarh, Pilibhit, Prayagraj, Rae Bareli, Rampur, Saharanpur, Sambhal, Shahjahanpur, Sitapur, Sultanpur, Tehri, Varanasi. For further inquiries or customized solutions, feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

Ball Valve Manufacturer & Exporter in India

Flow Marshal Valves stands at the forefront of the valve manufacturing industry, offering premium-quality ball valves designed to meet the diverse needs of clients worldwide. As a leading ball valve manufacturer based in India, we take pride in our ability to deliver innovative solutions that excel in performance, reliability, and durability.

Our commitment to excellence and precision engineering has established Flow Marshal Valves as a trusted name in the field of industrial valve manufacturing. With state-of-the-art facilities and a team of experienced professionals, we adhere to stringent quality standards to ensure that our ball valves meet the highest levels of quality and reliability. As one of the top ball valve exporters in India, we cater to a wide range of industries, including oil and gas, petrochemical, chemical, power generation, water treatment, and more. Our comprehensive range of ball valves is designed to handle a variety of applications and operating conditions with ease.

At Flow Marshal Valves, we understand the importance of quality and performance in industrial applications. That's why we use only the finest quality materials and advanced manufacturing techniques to produce our ball valves. Whether it's cast iron, carbon steel, stainless steel, or alloy steel, you can trust our valves to deliver exceptional performance and longevity. In addition to our standard range of ball valves, we also offer a variety of specialized valves, including trunnion-mounted ball valves, floating ball valves, and fully welded ball valves.

0 notes

Text

Top Industrial Mineral Solutions by Tekor Minerals

In the industrial sector, high-quality minerals are essential for ensuring optimal production processes and performance. Tekor Minerals stands as a leader in the industry, offering top-grade solutions for various applications. As trusted calcined petroleum coke (CPC) manufacturers in India, Synthetic Fluorspar suppliers, and ferro silicon magnesium manufacturers in India, we deliver unparalleled quality to meet industrial demands.

Calcined Petroleum Coke (CPC): An Essential Industrial Component

At Tekor Minerals, we specialize in manufacturing premium calcined petroleum coke (CPC). This high-carbon material is widely used in aluminum smelting, steel production, and other applications requiring superior thermal and electrical conductivity. As one of the leading CPC manufacturers in India, our focus is on consistent quality, low sulfur content, and high purity to meet the stringent needs of our customers.

Synthetic Fluorspar: A Vital Mineral for Industrial Use

Fluorspar plays a critical role in various industries, from steel and aluminum to cement and ceramics. Tekor Minerals is a trusted name among Synthetic Fluorspar manufacturers, delivering high-grade products tailored to diverse applications. As reliable Synthetic Fluorspar suppliers, we ensure that our products offer exceptional performance, enabling our clients to achieve their operational goals.

Ferro Silicon Magnesium: Precision for Metallurgical Processes

Tekor Minerals is also a prominent name among ferro silicon magnesium manufacturers in India, catering to the specific needs of the foundry and steel industries. Our ferro silicon magnesium alloys are carefully processed to provide precise chemical compositions and optimal nodularization properties, ensuring high-quality castings.

Why Choose Tekor Minerals?

Advanced Manufacturing Facilities: We use state-of-the-art technology to ensure the highest product quality.

Customized Solutions: Our products are tailored to suit the unique requirements of our clients.

Global Reach: As trusted suppliers, we serve clients across various industries worldwide.

Commitment to Sustainability: Tekor Minerals focuses on eco-friendly practices to reduce environmental impact.

Industries We Serve

Our products are indispensable in industries such as:

Aluminum Smelting

Steel Manufacturing

Cement Production

Foundry Applications

Tekor Minerals remains committed to excellence in providing industrial mineral solutions. Whether you’re looking for calcined petroleum coke (CPC) manufacturers in India, Synthetic Fluorspar suppliers, or ferro silicon magnesium manufacturers in India, we are your trusted partner for quality, reliability, and performance.

Contact Tekor Minerals today to explore how our products can enhance your industrial operations.

#Synthetic Fluorspar manufacturers#Synthetic Fluorspar suppliers#calcined petroleum coke (CPC) manufacturers in India#ferro silicon magnesium manufacturers in india

0 notes

Text

Pioneering Excellence in Industrial Valve Manufacturing Since 1977

Introduction

Prime Industrial Valves Mfg. Co., established in 1977, is a premier manufacturer of industrial valves, headquartered in Ahmedabad, India. Over the years, the company has emerged as a leader in the industrial valve sector, known for its commitment to quality, innovation, and customer satisfaction. With a robust infrastructure, dedicated R&D capabilities, and a highly skilled workforce, Prime Industrial Valves Mfg. Co. continues to set benchmarks in the industry.

Vision and Mission

Vision: To be a globally recognized leader in the industrial valve manufacturing industry, delivering innovative solutions tailored to the evolving needs of our clients.

Mission: To provide high-quality, cost-effective, and timely solutions while ensuring superior customer satisfaction and environmental sustainability.

Infrastructure and Certifications

Prime Industrial Valves Mfg. Co. operates a state-of-the-art manufacturing facility in Ahmedabad, equipped with cutting-edge technology. The facility boasts an in-house casting unit renowned for its precision and excellence. A dedicated R&D unit drives innovation and continuous improvement, enabling the company to stay ahead in the competitive market.

The company’s commitment to quality and efficiency is validated by prestigious certifications, including:

ISO 9001: For adhering to international quality management standards.

NSIC Certification: Demonstrating our capabilities as a trusted MSME partner.

IBR Certification: Ensuring compliance with the Indian Boiler Regulations.

Product Portfolio

Prime Industrial Valves Mfg. Co. offers a comprehensive range of valves and related products, tailored to meet the diverse needs of industries worldwide. Each product is manufactured from high-quality materials such as Forged Steel, Alloy Steel, Stainless Steel Valve, and Duplex Steel. Here’s an overview of the product range:

1. Gate Valves

Used in water and sewage systems, oil and gas industries, and various industrial processes, gate valves ensure reliable flow control.

2. Globe Valves

Ideal for water and wastewater systems, chemical processing, oil and gas applications, and power plants. Globe valves are designed to regulate flow effectively and withstand challenging environments.

3. Ball Valves

Widely used in water and wastewater treatment, HVAC systems, oil and gas industries, and chemical processing, Ball valves offer durability and precise control. With advanced sealing technologies, they ensure leak-proof operation.

4. Butterfly Valves

Designed for water and wastewater treatment, industrial processes, and pipelines, Butterfly Valves provide efficient flow regulation and are available in various configurations to meet specific needs.

5. Check Valves

Preventing backflow, Check valves are essential for water distribution systems, pumping stations, and fire protection systems. Their robust design ensures long-term reliability.

6. Strainers

Used in water systems, HVAC systems, industrial processes, marine applications, and petrochemicals, strainers ensure the removal of debris and particles, protecting downstream equipment.

7. Needle Valves

Perfect for laboratories, hydraulic systems, fuel systems, and aerospace industries, needle valves provide precise flow control, ensuring accuracy in critical operations.

8. Piston Valves

Used in hydraulic and pneumatic systems, chemical processing, and water treatment, Piston valves are known for their reliability and ability to handle high-pressure environments.

9. Pressure Reducing Valves

Designed for water, gas, steam, and hydraulic systems, Pressure Reducing valves regulate pressure effectively, enhancing system efficiency and safety.

10. Knife Edge Gate Valves

Ideal for wastewater treatment, mining, pulp and paper, and chemical processing, Knife Edge Gate Valves are built for rugged environments and can handle slurry and viscous media efficiently.

11. Specialized Products

Moisture Separators: For steam systems and compressed air applications, ensuring dryness and efficiency.

Blow Down Valves: For boilers and pressure vessels, helping in the effective removal of impurities.

Flush Bottom Valves: Facilitating cleaning and maintenance in industrial processes, ideal for reactors and tanks.

Steam Traps: Enhancing efficiency in heating systems, steam boilers, and autoclaves.

2-3 Way Motorized, Cylinder & Pneumatic Control Valves: Offering precision control in automation systems, designed for advanced industrial needs.

Industries Served

Prime Industrial Valves Mfg. Co. caters to a wide array of industries, ensuring customized solutions for each sector’s unique requirements. Key industries include:

Oil and Gas: Valves designed to handle high pressure and corrosive environments.

Chemical Processing: Specialized valves for handling aggressive chemicals and high temperatures.

Water and Wastewater: Solutions for efficient water management and distribution systems.

Power Generation: High-performance valves for power plants and energy systems.

HVAC Systems: Components ensuring optimal flow and temperature control.

Food and Beverage: Hygienic and durable valves for stringent industry standards.

Marine and Petrochemicals: Robust valves designed for challenging environments.

Operational Philosophy

Prime Industrial Valves Mfg. Co. operates on the philosophy of "QUALITY, COST, and DELIVERY." This ensures that every product not only meets stringent quality standards but is also cost-efficient and delivered on time to exceed customer expectations. The focus on maintaining high standards across all operations has solidified the company’s reputation for excellence.

Research and Development

Innovation is the cornerstone of Prime Industrial Valves Mfg. Co. The R&D unit is equipped with the latest technology and software tools, enabling the design and development of advanced valve solutions. Recent innovations include high-efficiency sealing systems, corrosion-resistant materials, and automation-compatible valves. Continuous research helps the company introduce new products and improve existing ones, ensuring alignment with global industry trends.

Commitment to Sustainability

As a socially responsible organization, Prime Industrial Valves Mfg. Co. is committed to environmental sustainability. The company employs eco-friendly manufacturing practices and materials, minimizing its environmental footprint while maximizing operational efficiency. Initiatives such as energy-efficient production processes and recycling programs reflect the company’s dedication to a greener future.

Global Reach and Export Capabilities

Prime Industrial Valves Mfg. Co. has established a strong presence in both domestic and international markets. Key export regions include the Middle East, Southeast Asia, Africa, and Europe. By maintaining high-quality standards and offering competitive pricing, the company has successfully built lasting relationships with clients worldwide. Customized solutions and efficient logistics ensure timely delivery, enhancing customer satisfaction.

Conclusion

Prime Industrial Valves Mfg. Co. stands as a testament to excellence in the industrial valve manufacturing industry. With a legacy of over four decades, the company has consistently demonstrated its expertise in delivering high-quality, innovative, and cost-effective solutions. Guided by its core values of quality, efficiency, and customer focus, Prime Industrial Valves Mfg. Co. is poised to continue its journey of excellence and innovation in the years to come.

youtube

0 notes

Text

Copper Earthing Plate – Manufacturers & Suppliers in Delhi NCR

Renown Earth is one of India’s prime manufacturers and exporters of copper plate earthing, chemical earthing electrodes, and earth pipes with copper plates and clamps from Noida, India.

The copper earthing plate offers excellent electrical and thermal conductivity and resistance to hydrogen embrittlement. We are known in India as a dependable Copper Plates Supplier. Various industrial sectors are placing bulk orders for customized copper plate earthing systems with us because of the excellent quality and unparalleled performance in the relevant applications.

We can provide you with excellent offers and wholesale pricing on Copper Plates. Our Copper plates are incredibly robust and resistant. We have quite comprehensive Copper Plate production capabilities, with varied operations ranging from large-scale to small.

What is Copper Earthing plate?

The copper electrode plate is used for earthing house wiring, plant wiring (particularly electrical establishments of enormous industrial facilities), nonpartisan wire of the inventory line, and so forth. The excited iron line is by and large utilized as the earth cathode. The size of the line relies on the deficiency current and the state of the dirt.

We are the main producer of Treated Earthing System made by Centrifugal Casting Process including connections like a single rib, hot-dip excited brace, Cast Iron Funnel with projected cross-section, substitute opening and tighten cut alongside embellishments, Back Fill Compound, and Earth Pit Covers in different sizes according to drawing detail for establishing Electrical Systems.

Which Plate is used for earthing?

Copper plate earthing are regularly utilized as earthing plates. The profundity at which the line should be covered relies on the dampness of the ground and influences the copper earthing plate price.

Comprehensive Guide to Copper Earthing Plates

Renown Earth is one the major manufacturers and suppliers of Copper Earthing Plates in the market owing to their high conductivity and long lasting. We are an earthing solution company located in Noida, India offering Earth pipes with copper plates and Chemical earthing electrodes. The commitment to deliver quality and performance has put us in a vantage position to deliver excellent services to industrial sectors and households.

Why Choose Copper Earthing Plates?

Copper earthing plate is considered as one of the best conductors in the grounding systems because it is a good conductor both in electrical and thermal conductivity. These plates have a high degree of anti- corrosion and anti- hydrogen- embrittlement; the earthing is made durable and efficient. In comparison to other materials, copper's durability and reliability make it the preferred choice for a variety of applications, such as:

Electrical house wiring.

Cabling and wiring in the plant in the industrial sector.

The grounded end of secondary windings connect to the paralleled neutral wires of supply lines.

Due to their effectiveness and flexibility in use, copper plate earthing systems have become very important in order to achieve high safety standards in the electrical infrastructure.

Key Features of Our Copper Earthing Plates

High Conductivity: Copper presents a wonderful capability of electrical conductivity making certain that there is flow of fault currents and other related currents.

Corrosion Resistance: Featuring increased levels of corrosion resistance, our copper earthing plates are effective in challenging environments.

Customizable Dimensions: In this case, we offer different sizes of plates to suit needs of particular projects in order to make sure that we provide a solution that fits the needs of a particular project.

Affordable Pricing: However, our copper earthing plate price is still relatively lower than our competitors yet our products outcompete most products in the market.

What Are Earth Pipes with Copper Plates?

Earth pipes with copper plates are sophisticated styles of grounding solutions which involve the totality of pipes along with copper plates use. Such systems find application mainly in regions with high soil resistance and are suited for both residential, commercial, and light industrial applications.

Why Copper Is Ideal for Earthing

Copper is the preferred material for construction of earthing systems because of the superior non-conductive qualities that improve safety, resistance to wear and easy conductivity. Because of the demonstrated excellent electrical conductivity, it can easily transfer unwanted fault currents away hence reducing the possibility of dangerous electric shocks and equipment damage.

Besides conductivity, copper provides excellent levels of corrosion, and even more, in difficult environments. Compared to galvanized steel, which gradually rusty as a result of exposure to moisture and soil borne contaminants, copper does not corrode and therefore provides a long service of life for the earthing system.

Also, copper electrodes form an important part of electrode technology due to its ease of installation and durability in maintenance. These characteristics therefore can allow specific types of gears to endure a considerable amount of actual and contextual pressure that is free from decreased efficiency.

Conclusion

Copper earthing plates are highly efficient and durable grounding solutions, valued for their excellent electrical conductivity, corrosion resistance, and reliability. Renown Earth, a leading manufacturer based in Noida, India, provides premium-quality copper plates and related products at competitive prices.

With customizable options and robust performance, these plates are ideal for residential, industrial, and commercial applications, ensuring safe and long-lasting electrical systems.

For more info : www.renownpower.com

#Copper Earthing Plate#Earthing Solutions#Copper Plate Manufacturer#Copper Plate Supplier#Electrical Safety#Industrial Earthing Systems

0 notes

Text

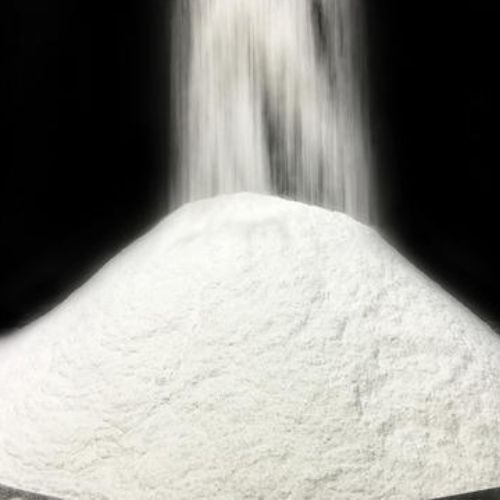

A Comprehensive Guide to Quartz Powder and Its Industrial Applications

Quartz powder is one of the most versatile materials, widely used in a variety of industrial applications. From construction to electronics, this mineral plays a crucial role in several sectors due to its unique properties, including hardness, chemical stability, and versatility. As a result, the demand for high-quality Quartz Powder Manufacturers has seen a significant rise, and manufacturers are increasingly investing in advanced production techniques to meet this growing need.

What is Quartz Powder?

Quartz powder is finely ground quartz, a mineral composed of silicon dioxide (SiO₂). It is formed when quartz stones are crushed into a fine powder. This powder can be produced through various methods, such as dry grinding, wet grinding, or a combination of both. It has a white to off-white color, with varying degrees of purity, and is characterized by its excellent physical and chemical properties.

The powder is highly valued for its hardness, making it ideal for use in construction materials, ceramics, glass manufacturing, and many other industrial applications. Quartz powder is also chemically inert, ensuring it doesn't react with most substances, which makes it a preferred material in the production of various chemical products.

Applications of Quartz Powder

The versatility of quartz powder makes it a vital ingredient in numerous industries. Some of the most common applications include:

Construction Industry: Quartz powder is often used as a key ingredient in the production of concrete, cement, and other building materials. It helps improve the strength and durability of these materials. Quartz powder also enhances the properties of grouts and paints.

Ceramics and Glass Manufacturing: Quartz powder is extensively used in the ceramics and glass industries. Its ability to withstand high temperatures and its purity make it a key ingredient in producing high-quality glass and ceramic products. It is also used to manufacture tiles, sanitary ware, and decorative items.

Foundry and Metal Casting: Quartz powder is used in the foundry industry for producing molds and cores. Its high melting point allows it to withstand extreme temperatures during the metal casting process.

Electronics and Electrical Industry: Quartz powder is essential in the electronics industry, where it is used in the production of semiconductors and other electronic components. It is also used in the production of electrical insulators, due to its insulating properties.

Cosmetics and Pharmaceuticals: Quartz powder is used as an inert filler in the manufacturing of cosmetics, personal care products, and pharmaceuticals. Its fine texture and chemical inertness make it ideal for these applications.

The Role of Quartz Powder Manufacturers

Quartz powder manufacturers play a critical role in ensuring that industries have access to high-quality quartz powder that meets specific requirements. These manufacturers utilize advanced processing technologies and rigorous quality control procedures to produce quartz powder of varying particle sizes, purity levels, and other specifications.

Manufacturers also provide tailored solutions for industries that require quartz powder with specific properties, such as higher levels of purity or a finer particle size. They continuously work on improving their production methods to increase efficiency and reduce the environmental impact of their operations.

In India, one such prominent player in the quartz powder manufacturing industry is Sudarshan Group. Known for its high-quality products and excellent customer service, Sudarshan Group supplies quartz powder to a wide range of industries, including construction, ceramics, glass manufacturing, and more. Their commitment to quality and innovation has earned them a strong reputation in the industry.

Choosing the Right Quartz Powder Manufacturer

When selecting a quartz powder manufacturer, it is essential to consider factors such as product quality, consistency, and customer service. A reliable manufacturer will ensure that the quartz powder is processed according to industry standards and meets the required specifications. Additionally, they should offer competitive pricing and provide timely delivery to ensure that production schedules are not disrupted.

It is also beneficial to choose a manufacturer with a strong research and development team. This will allow them to offer customized solutions and adapt to the ever-changing demands of various industries.

Conclusion

Quartz powder is a critical component in many industries, and its demand continues to grow as more industries recognize its value. The role of quartz powder manufacturers in supplying high-quality, versatile products cannot be overstated. Companies like Sudarshan Group play a vital role in ensuring industries have access to the best quartz powder available, helping to drive innovation and efficiency across multiple sectors. As the need for high-performance materials continues to rise, the quartz powder industry is poised for continued growth, with manufacturers leading the way in providing high-quality products that meet the diverse needs of their customers.

0 notes

Text

Leading Globe Valve Manufacturers in India | Industrial Valve Solutions

Speciality Valve is one of the leading valve Manufacturers company in India and we offer one of the best globe valves for industries. If you are looking for the best globe valve manufacturers in India then connect with us. We specialize in providing premium industrial valves for a wide range of applications, including oil & gas, water treatment, chemical processing, and power plants.Our globe valves are known for their precise flow regulation, excellent performance, and durability, making them ideal for industries that require accurate throttling and shut-off capabilities.

As the best valve manufacturer in India, we use state-of-the-art technology and high-quality materials to produce valves that meet the most stringent international standards. Whether you need standard or customized globe valves, our team of expert industrial valve manufacturers ensures every product is engineered for superior reliability, safety, and long-lasting performance.

Our commitment to quality, innovation, and customer satisfaction has made us a trusted name among valve manufacturers in India. Get in touch with us today to explore our range of globe valves and other industrial valve solutions.

Available materials: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M , F55, F51, F53, Monel, Ductile Iron.

Size: ½” to 48”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operation: Lever Operated, gear operated, Handwheel, Electric Actuated and Pneumatic Actuated

End: Connection Flanged, Threaded, Buttweld, Socketweld, Wafer, Lug

Medium: LNG, Cryogenic application, Water, Air, Steam

Visit Now - https://www.specialityvalve.com/

Contact Us - +91 7708220219

Mail on - [email protected]

Address - 37, NGR Street, P.N Palayam, Coimbatore, Tamil Nadu

#valves manufacture#valves#machine#manufacturer#valve companies#best valve manufacturer#industrial valve manufacturers#globe valve manufacturers in India#globe valves india#industrial valve

0 notes

Text

Dynemech DLK Series Screw Support Mounts: Advanced Vibration Control Solutions

Visit Dynemech Systems at IMTEX 2025, India's leading metalworking show to see the future of Vibration Control.

Discover how accuracy and stability in Manufacturing are becoming a Reality through our Groundbreaking technologies. Event Information Date: 23 - 29 January 2025 Venue: Booth A128, Hall 3A Venue: International Exhibition Centre Bangalore Seven Days of Innovation Introducing the Screw Support Mounts from the DLK Series Dynemech is pleased to introduce its flagship product, DLK Series Screw Support Mounts at IMTEX 2025. These advanced vibration isolation solutions provide unmatched performance for high-precision production machinery and mark a breakthrough in industrial stability management. DLK Series combines useful functionality with creative engineering: Our Vibration Isolation Technology offers Quantifiable gains in a vast number of key performance parameters: Much lower amplitude of vibration, Better quality finish of components and accuracy of Machines Longer life of equipment, More favourable conditions for job safety Less maintenance requirement ,Versatile Industrial Applications

The DLK Series excels in various production applications: Die casting operations, CNC machinery, industrial presses, injection moulding apparatus, and precision grinding systems Printing, packaging, and industrial compressors systems Advantages of Installing Heavy Industrial Equipment and Textile Manufacturing Machinery Feel the smooth integration of your current equipment: Fast and effective mounting procedure ,Integrated levelling elements for accurate modification, Low maintenance needs ,Long-term dependability of performance ,Increased stability of the structure Why Choose Screw Support Mounts from the DLK Series? Dynemech's Passion for a Culture of Excellence in Antivibration Engineering is well Epitomized in the DLK Series. Our Screw Support Mounts give your high-speed Manufacturing processes the stability and the performance they need, if you are operating large gear in heavy industry or precise machining equipment. Assurance of Quality The industrial Vibration Isolation Technology Breakthrough, Dynemech DLK Series Screw Support Mounts, balances the best of efficiency and simplicity of use for equipment that needs dependable vibration dampening solutions. The premium Anti-Vibration Mount for Machines with integral base holes, the Dynemech DLK Series Screw Support Mounts deliver excellent low-frequency vibration attenuation and very precise machine leveling capabilities.

The DLK Series Super Vibration Isolator ensures optimal performance for a wide range of industrial applications. Because of its unique construction that makes for easy installation and modification, the screw support mount is a superb option for several industrial purposes. The Levelling Mechanism raises the cover plate and machine foot with a simple bolt tightening procedure, making it a highly accurate process for realignment and stabilization. Design is such that it delivers excellent vibration isolation along with good stiffness assessment. Cutting Edge Technology for Vibration Isolation Optimal vibration mitigation for most types of machine, component finish and tolerance. DLK Series vibration isolators are highly resistant to: Fuels and lubricating lubricants are commonly encountered in modern machining. It gives reliable performance even in hostile industrial environments due to excellent chemical resistance. The plates give durable vibration insulation as they do not undergo plastic deformation but remain structurally intact if the machine weight is kept within the specified maximum load capacity. CNC machinery, textile equipment, power presses, and plastic injection machines Press Die Casting Equipment, Printing and Packaging Systems Industrial compressors, precision grinding tools, and industrial machinery with large-scale machinery In each of these applications, the DLK Series contributes to vibration-free operation, minimizing vibration disturbances and increasing overall productivity. Installation Advantages DLK Series mounts have a number of significant installation advantages: a quick and easy mounting process to get equipment up and running quickly integrated leveling components and accurate leveling characteristics requires minimal maintenance consistent vibration isolation for a long time Improved structural stability All these features make the DLK Series ideal for several industrial applications requiring proper isolation of vibrations. Advanced Features ---------------- Industrial vibration isolation can never be any better than with Dynemech DLK Series screw support mounts. They are an indispensable component of mounting modern industrial equipment, mainly because of the robust structure, leading edge vibration dampening technology, and vast range of applications. These anti-vibration pads provide reliable performance and protection against harmful vibrations, whether they are applied in heavy industrial or precision manufacturing environments. The DLK Series vibration isolator is the industry leader that ensures businesses can operate without vibration, which is necessary to ensure peak performance and product quality.

To learn more: https://www.vibrationmountsindia.com/

#IMTEX2025, #VibrationControl, #IndustrialAutomation, #Manufacturing, #MachineTools, #EngineeringInnovation, #Dynemech, #VibrationIsolation, #IndustrialEquipment, #Bangalore, #PrecisionEngineering, #MetalWorking, #IndustrialTechnology, #MachineStability, #QualityControl,#screw support, #dynemechantivibration, #vibrationcontrol, #Machinemount.

Contact Us: +91-9810760131; +91-9911145131

Email: [email protected]

Explore Our Solutions: vibrationmountsindia.com | vibrationdampingpads.com

0 notes

Text

Industrial Applications of Epoxy Resin Art Supplies

Epoxy resin art supplies are not just for creative ventures but also hold significant value in industrial applications. Their versatility, strength, and durability make them ideal for a wide range of uses, including coatings, adhesives, and molds. In the industrial sector, sourcing quality materials from trusted resin manufacturers is critical to ensuring both efficiency and longevity.

What Makes Epoxy Resin Suitable for Industrial Use?

Epoxy resin is a high-performance material known for its exceptional mechanical properties, thermal stability, and chemical resistance. When used in industrial applications, it offers:

Superior Durability: Ensures long-lasting performance under extreme conditions.

High-Quality Finish: Provides a sleek, polished appearance for various surfaces.

Resistance to Wear and Tear: Withstands heavy loads and frequent usage.

Industries ranging from construction to manufacturing rely on epoxy resin to enhance the strength and appearance of their products.

Key Industrial Applications of Epoxy Resin Art Supplies

Protective Floor Coatings:Industrial floors require materials that can withstand heavy machinery, chemical spills, and constant foot traffic. Epoxy resin coatings provide a seamless and highly durable surface, ensuring both safety and longevity.

Adhesives for Manufacturing:Epoxy resins are commonly used as adhesives in manufacturing processes. Their ability to bond with a variety of materials, including metal, wood, and glass, makes them a versatile solution.

Tabletops and Countertops:In furniture and interior design industries, epoxy resin art supplies are used to create robust and visually appealing tabletops and countertops. These surfaces are resistant to scratches and stains, making them ideal for heavy-duty environments.

Casting and Molding:Epoxy resin is an excellent choice for creating industrial molds due to its precision and durability. It is widely used in automotive and aerospace industries for casting components.

By partnering with reliable epoxy resin manufacturers in India, industries can ensure access to high-quality materials tailored for these applications.

Benefits of Sourcing from Resin Manufacturers

India has emerged as a global leader in epoxy resin production, offering high-quality products at competitive prices. Leading epoxy resin manufacturers in India focus on:

Customization: Catering to the specific requirements of industrial clients.

Innovation: Developing eco-friendly and high-performance resin solutions.

Consistency: Ensuring reliable quality across large-scale productions.

Choosing experienced resin manufacturers not only enhances operational efficiency but also supports sustainable practices in industrial processes.

Epoxy resin art supplies are a game-changer in the industrial sector, offering unmatched durability, versatility, and performance. From flooring solutions to advanced molds, their applications are vast and impactful. To ensure the best outcomes, industries must source materials from trusted epoxy resin manufacturers.

For top-tier epoxy resin solutions, trust MB Enterprises, where quality meets industrial innovation.

#resin manufacturers#epoxy resin manufacturers#epoxy resin manufacturers in india#epoxy resin art supplies in india#epoxy resin art supplies

0 notes

Text

Industrial Furnaces: Backbone of Industrial Processes

Industrial furnaces play a critical role in numerous manufacturing and production processes, providing the controlled heat environments necessary for tasks like metal melting, heat treatment, and material synthesis. From small workshops to large-scale factories, these furnaces are indispensable in industries such as metallurgy, ceramics, glass manufacturing, and chemical processing. In India, the demand for industrial furnaces is growing rapidly, driven by advancements in technology and the expansion of manufacturing sectors. This has also led to the emergence of reliable industrial furnace manufacturers in India, who cater to both domestic and international markets.

What Are Industrial Furnaces?

An industrial furnace is a robust thermal device used to achieve and maintain high temperatures for various processes. These furnaces are engineered to provide precise temperature control, uniform heat distribution, and energy efficiency.

Types of Industrial Furnaces

Blast Furnaces: Used primarily in the steel and iron industries for smelting.

Electric Arc Furnaces: Common in recycling steel, utilizing electric arcs to generate high heat.

Reheating Furnaces: Employed in the rolling of steel to achieve desired shapes and dimensions.

Kilns: Used in ceramics and brick production, operating at lower temperatures compared to other furnaces.

Annealing Furnaces: Essential in heat-treating metals to improve ductility and reduce hardness.

Rotary Furnaces: Designed for melting metals like aluminum and lead.

Each furnace type is tailored for specific applications, with unique designs and fuel sources, such as gas, oil, or electricity.

Importance of Industrial Furnaces

The significance of industrial furnaces extends beyond their functionality. These systems are the linchpins of industrial processes, facilitating:

Material Transformation: Converting raw materials into finished goods.

Process Efficiency: Enhancing production rates while maintaining quality.

Energy Optimization: Leveraging advanced technologies to reduce fuel consumption.

Environmental Compliance: Adopting eco-friendly designs to minimize emissions.

The Role of Industrial Furnace Manufacturers in India

India has emerged as a global hub for manufacturing, with industries continually seeking advanced solutions for their operational needs. Industrial furnace manufacturers in India are addressing these demands by developing cutting-edge furnace designs and technologies. These manufacturers emphasize durability, efficiency, and customization to cater to the diverse needs of industries.

Key Innovations by Indian Manufacturers:

Energy-Efficient Models: Utilizing advanced insulation and heating systems to reduce energy costs.

Automation Integration: Incorporating programmable logic controllers (PLCs) for precise temperature control and monitoring.

Compact Designs: Catering to small-scale industries with space-saving yet powerful furnaces.

Eco-Friendly Furnaces: Focusing on low-emission designs to align with global sustainability standards.

Indian manufacturers also excel in providing after-sales support, including maintenance, spare parts, and operational guidance, ensuring a seamless user experience.

Factors to Consider When Choosing an Industrial Furnace

When selecting an industrial furnace, several factors must be evaluated to ensure optimal performance:

Purpose and Application: Define the specific industrial process for which the furnace will be used.

Capacity: Choose a furnace that matches your production scale.

Fuel Type: Consider availability and cost of fuel or electricity.

Temperature Range: Ensure the furnace can achieve the required temperature levels.

Manufacturer Reputation: Opt for trusted industrial furnace manufacturers in India known for quality and reliability.

Leading Applications of Industrial Furnaces

Metalworking: Forging, casting, and heat-treating metals for automotive and aerospace sectors.

Glass Manufacturing: Melting and shaping glass for consumer and industrial products.

Ceramics Production: Creating durable materials for construction and industrial use.

Chemical Processing: Synthesizing compounds under controlled thermal conditions.

Conclusion

The role of industrial furnaces in driving industrial growth cannot be overstated. From basic material processing to sophisticated manufacturing tasks, these devices form the backbone of various industries. With advancements in technology and a focus on sustainability, the demand for reliable and efficient industrial furnaces is set to grow.

In this context, industrial furnace manufacturers in India are poised to play a pivotal role in meeting both domestic and international demands. Their commitment to innovation, quality, and customer satisfaction ensures that Indian-made furnaces remain at the forefront of the global market, empowering industries worldwide to achieve excellence in their operations.

#indudtrial furnaces#indudtrial furnaces manufacturers in Bangalore#indudtrial furnaces manufacturers in India

0 notes

Text

Reciprocating Vacuum Pumps: Key Features and Advantages from Gajjar Compressor

When it comes to efficient vacuum systems, reciprocating vacuum pumps have earned their place in industrial applications for their reliability, durability, and versatility. Gajjar Compressor, a renowned manufacturer and exporter of advanced vacuum pump solutions, excels in delivering high-quality reciprocating vacuum pumps tailored to meet diverse industry needs. This blog delves into the key features, advantages, and why Gajjar Compressor’s reciprocating vacuum pumps stand out.

Understanding Reciprocating Vacuum Pumps

Reciprocating vacuum pumps operate by using a piston-driven mechanism within a cylinder to create a vacuum. These pumps are particularly effective in achieving medium to high vacuum levels, making them indispensable across various industries, including manufacturing, chemical processing, and medical applications.

Key Features of Reciprocating Vacuum Pumps from Gajjar Compressor

1. High-Quality Construction

Gajjar Compressor ensures that its reciprocating vacuum pumps are made from robust materials such as cast iron and stainless steel. This guarantees longevity, corrosion resistance, and consistent performance even under demanding conditions.

2. Precision Engineering

The pumps are meticulously designed for precision, incorporating advanced engineering techniques. This ensures seamless operation with minimal vibration and noise, enhancing workplace comfort and safety.

3. Compact and Space-Saving Design

One of the standout features of Gajjar Compressor’s reciprocating vacuum pumps is their compact design. Despite their power, these pumps are designed to fit into tight spaces, making them ideal for industries where space is at a premium.

4. Versatile Functionality

Gajjar Compressor offers a range of models catering to different vacuum levels and flow rates. This versatility ensures that clients can find the perfect pump for their specific requirements, whether for small-scale applications or large industrial setups.

5. Easy Maintenance

Ease of maintenance is a hallmark of Gajjar Compressor’s products. These pumps are designed with accessible components, enabling quicker inspections and replacements, which reduces downtime and maintenance costs.

6. Energy Efficiency

Energy efficiency is a priority in all Gajjar Compressor products. The reciprocating vacuum pumps are engineered to optimize power consumption, resulting in lower operating costs and reduced environmental impact.

Advantages of Gajjar Compressor’s Reciprocating Vacuum Pumps

1. High Performance in Demanding Environments

Gajjar Compressor’s vacuum pumps are built to handle demanding conditions with ease. Whether in chemical processing or heavy-duty manufacturing, their pumps deliver consistent performance without compromising efficiency.

2. Cost-Effectiveness

The robust construction and energy-efficient operation of these pumps translate into long-term cost savings. Businesses can rely on these pumps for high output without incurring excessive operational expenses.

3. Superior Customization

Every industry has unique requirements, and Gajjar Compressor excels at providing customized solutions. From specific vacuum levels to unique mounting arrangements, the company ensures its pumps align perfectly with the client’s needs.

4. Trusted Global Presence

With decades of expertise, Gajjar Compressor has established itself as a trusted name in the global market. Their vacuum pumps are not only preferred in India but are also exported worldwide, meeting international quality standards.

5. Reduced Environmental Impact

Gajjar Compressor’s focus on sustainability is reflected in its vacuum pumps. By using energy-efficient designs and environmentally friendly materials, they contribute to greener operations for industries.

Applications of Reciprocating Vacuum Pumps

1. Manufacturing Industry

From packaging to product assembly, reciprocating vacuum pumps play a crucial role in maintaining efficiency across manufacturing processes.

2. Chemical Processing

In chemical plants, these pumps are used for distillation, filtration, and other processes that require controlled vacuum environments.

3. Medical and Pharmaceutical Applications

Reciprocating vacuum pumps are essential in producing sterile medical environments and pharmaceutical processes like freeze-drying and vacuum-assisted sterilization.

4. Electronics Industry

These pumps are widely used in the electronics sector for applications such as coating and vacuum soldering, which demand precision and high vacuum levels.

5. Food and Beverage Industry

Vacuum pumps are indispensable in food packaging, vacuum sealing, and freeze-drying processes, ensuring product longevity and quality.

Why Choose Gajjar Compressor for Reciprocating Vacuum Pumps?

1. Expertise and Experience

With decades of industry experience, Gajjar Compressor has honed its craft in designing and manufacturing vacuum pumps that meet the highest standards.

2. Comprehensive Support

From pre-sales consultation to after-sales service, Gajjar Compressor offers unparalleled support, ensuring clients receive the best solutions and assistance.

3. Commitment to Innovation

Innovation is at the heart of Gajjar Compressor’s operations. Their reciprocating vacuum pumps incorporate cutting-edge technologies to enhance efficiency and reliability.

4. Competitive Pricing

Gajjar Compressor offers world-class products at competitive prices, ensuring value for money without compromising quality.

Maintenance Tips for Reciprocating Vacuum Pumps

1. Regular Inspections

Schedule regular inspections to identify wear and tear early and avoid major breakdowns.

2. Lubrication

Ensure the pump’s moving parts are well-lubricated to minimize friction and extend lifespan.

3. Filter Replacement

Replace filters as per the manufacturer’s guidelines to maintain optimal performance and prevent contamination.

4. Monitor Vacuum Levels

Keep an eye on the vacuum levels to detect any irregularities that may indicate a malfunction.

5. Use Genuine Spare Parts

Always use genuine spare parts from Gajjar Compressor to ensure compatibility and maintain product integrity.

Conclusion

Reciprocating vacuum pumps from Gajjar Compressor represent a perfect blend of innovation, reliability, and efficiency. With their robust construction, versatile applications, and energy-efficient designs, these pumps cater to a wide range of industrial requirements. Gajjar Compressor’s commitment to quality, backed by decades of expertise, makes them a global leader in vacuum pump manufacturing.

Whether you’re looking to enhance your production line, improve energy efficiency, or ensure precision in processes, Gajjar Compressor’s reciprocating vacuum pumps are the ideal solution. Invest in their advanced technology to experience unparalleled performance and long-term value.

0 notes

Text

Saturated Polyester, Saturated Polyester Resin Manufacturers

Orcpl is a leading Saturated Polyester Resin Manufacturers in India. Our saturated polyester resins are used in a wide variety of applications. Our saturated polyester resins are made from high-quality raw materials and are manufactured using state-of-the-art equipment. We have a team of experienced engineers and chemists who are dedicated to developing innovative resin solutions that meet the needs of our customers. Saturated polyester resins can be used to make epoxy resins, which are used in a variety of applications, including bonding, casting, and potting. Saturated polyester resins are used to make paints and coatings that are resistant to water, chemicals, and UV rays. These coatings are used in a variety of industries, including the construction, automotive, and marine industries. If you are looking for a high-quality saturated polyester resin, then Orcpl is the perfect choice for you.

#Saturatedpolesterresin#manufactureofpolyesterresin#Exporterofpolyesterresin#supplierofpolyesterresin#orcpl#resinmanufacturer#supplieroffiretardantchemical#supplieroffirecoatings

0 notes

Text

Exploring Mangalam Worldwide Ltd. A Leading Integrated Stainless Steel Manufacturer

Stainless steel is a cornerstone in modern industries, playing a crucial role in manufacturing, construction, and engineering solutions. Its versatility, durability, and resistance to corrosion make it the preferred choice for companies worldwide. Among the industry’s key players, Mangalam Worldwide Ltd. stands out as a leading stainless steel manufacturer. In this blog, we explore the company’s extensive offerings, expertise, and its significant impact on various industries.

Company Background

Established with a vision to redefine quality in the stainless steel market, Mangalam Worldwide Ltd. has fully-fledged to developed a trusted name in the industry. Headquartered in Ahmedabad, Gujarat, India, the company has marked significant milestones in its journey, including the development of state-of-the-art production facilities in Halol, Changodar, and Kapadvanj.

The company is driven by a clear mission: to provide high-quality stainless steel products tailored to meet the diverse needs of its clients. This vision is reflected in every aspect of their operations, from production to customer support, solidifying their reputation as one of the leading stainless steel manufacturers in India.

Products and Services

Mangalam Worldwide Ltd. offers a diverse range of high-quality stainless steel products, each crafted to meet the specific requirements of various industries. Here’s a closer look at their comprehensive product lineup:

Stainless Steel Billets

Mangalam Worldwide is renowned for producing continuous cast billets, ensuring top-notch quality and consistency. These billets serve as the foundation for a wide range of applications in the construction, manufacturing, and engineering sectors.

Stainless Steel Bright Bars

Their Bright Round Bars are meticulously crafted to cater to industries like construction, manufacturing, and engineering. These bars are known for their impeccable finish, strength, and adherence to international standards, ensuring durability and flexibility in various applications

Stainless Steel Seamless Pipes & Tubes

The company produces Seamless Pipes &Tubes that are engineered for maximum durability and corrosion resistance. These pipes are essential for industries such as construction, oil and gas, and chemical processing, where quality and longevity are paramount.

Quality and Standards

Mangalam Worldwide Ltd. prioritizes quality in all its products, adhering to stringent international standards and employing advanced manufacturing processes to ensure excellence. Their customization capabilities further distinguish them, allowing clients to receive products tailored to their specific needs, reinforcing Mangalam Worldwide’s status as a premier stainless steel products manufacturer.

By offering such an extensive product range, Mangalam Worldwide not only meets the diverse requirements of its clients but also sets new benchmarks in the stainless steel industry.

Manufacturing Process

Mangalam Worldwide Ltd. employs an integrated and advanced manufacturing process:

In-House Melting Shop: This facility allows the company to maintain strict quality control over its products while offering flexibility in meeting client demands.

Advanced Technology: The incorporation of European technology and modern production plants ensures the highest standards of stainless steel production.

Skilled Workforce: The company’s team comprises highly skilled development, production, and quality engineers who bring expertise and innovation to every project, further cementing Mangalam Worldwide’s leadership in the market.

Mangalam Worldwide Ltd. serves a diverse clientele, including:

Manufacturing Industries: Supplying high-quality stainless steel materials that are essential for the production of machinery, equipment, and other industrial products.

Construction Companies: Providing durable and reliable stainless steel solutions for infrastructure, commercial, and residential building projects.

Engineering Firms: Supporting innovative engineering solutions with top-grade stainless steel components that meet specific technical requirements.

Sustainability, Innovation, and Client Success

Mangalam Worldwide Ltd. is at the forefront of the stainless steel industry, combining a dedication to sustainable manufacturing practices with continuous innovation to meet the evolving needs of its clients. By prioritizing environmental impact reduction, the company employs efficient resource management and advanced production methods to create top-quality products. Their consistent investment in research and development ensures that they remain ahead in technological advancements, delivering stainless steel solutions that align with global standards.

Recent innovations have further enhanced product quality, offering clients in various sectors improved durability, flexibility, and value. This dedication to excellence and sustainability is reflected in the company’s client testimonials and case studies. A leading construction firm praised Mangalam Worldwide for providing stainless steel materials that significantly enhanced the resilience of their commercial buildings. Similarly, a client from the manufacturing sector commended the company’s ability to supply customized stainless steel components, precisely tailored to their production requirements.

Such feedback underscores Mangalam Worldwide’s commitment to quality, reliability, and customer satisfaction, solidifying its position as a trusted stainless steel manufacturer in the industry.

In the End

Mangalam Worldwide Ltd. has established itself as a leading stainless steel manufacturer through its commitment to quality, advanced technology, and client-centric approach. With a comprehensive range of products, a focus on sustainability, and a skilled workforce, the company continues to support industries with top-grade stainless steel solutions.

Ready to learn more?

Visit Mangalam Worldwide for detailed information on our products and services or contact us to discuss your specific stainless steel needs.

0 notes