#Ceramic Coating Market Size

Explore tagged Tumblr posts

Text

Understanding the Ceramic Coating Market: Trends, Growth, and Opportunities

Understanding the Ceramic Coating Market: Trends, Growth, and Opportunities

The global ceramic coating market is experiencing significant growth, driven by its increasing applications across various industries. The market size was valued at USD 25.86 Billion in 2024. It is projected to reach from USD 27.20 Billion by 2025 to USD 40.81 Billion by 2033, growing at a CAGR of 5.2% during the forecast period (2025–2033).

Ceramic coatings are inorganic materials known for their durability and resistance to high temperatures, making them ideal for a wide range of applications including automotive, aerospace, healthcare, and industrial goods.

Market Categorization

The ceramic coating market can be categorized into several segments based on product type, technology, and application:

By Product:

Oxide: These coatings are widely used due to their excellent thermal stability and corrosion resistance.

Carbide: Known for their hardness and wear resistance, carbide coatings are commonly applied in cutting tools and industrial applications.

Nitride: These coatings offer superior hardness and thermal stability, making them suitable for high-performance applications.

By Technology:

Thermal Spray: This method involves spraying molten or heat-softened material onto a surface to form a coating.

Physical Vapor Deposition (PVD): A vacuum process that produces thin films of material on substrates through physical means.

Chemical Vapor Deposition (CVD): Involves chemical reactions that deposit a solid material on a substrate.

Others: This category includes various other methods used for applying ceramic coatings.

By Application:

Automotive: Ceramic coatings are used for protective finishes that enhance the aesthetic appeal and durability of vehicles.

Energy: Applications in energy sectors include protective coatings for turbines and other equipment.

Aerospace: Used in components that require high-temperature resistance and durability.

Industrial Goods: Coatings applied to machinery and tools to improve performance and lifespan.

Healthcare: Used in medical devices due to their biocompatibility and resistance to wear.

Geographic Overview

The ceramic coating market exhibits diverse trends across different regions:

North America: Dominated by the United States, this region is witnessing robust growth due to the presence of established automotive and aerospace industries. The demand for high-performance coatings is driving innovation in this sector.

Europe: Countries like Germany and France are leading the market due to stringent regulations regarding emissions and environmental safety, which encourage the adoption of advanced ceramic coatings.

Asia-Pacific: This region is expected to dominate the market owing to rapid industrialization, particularly in countries like China and India. The growing automotive sector is a significant contributor to the demand for ceramic coatings.

Latin America & Middle East & Africa: Emerging markets in these regions are beginning to adopt ceramic coatings in various applications, driven by infrastructure development and increased manufacturing activities.

Key Players in the Ceramic Coating Market

Several key players are shaping the landscape of the ceramic coating market:

Bodycote

Praxair Surface Technologies, Inc.

Aremco Products, Inc.

APS Materials, Inc.

Cetek Ceramic Technologies Ltd.

Keronite Group Ltd.

Saint-Gobain S.A.

Element 119

NanoShine Ltd.

Ultramet, Inc.

These companies are investing heavily in research and development to innovate new products that meet the evolving needs of various industries.

Key Unit Economics for Businesses and Startups

For businesses entering the ceramic coating market, understanding unit economics is crucial for profitability. Factors such as production costs, pricing strategies, and market demand play significant roles in determining success. Startups should focus on niche applications where they can offer specialized solutions or innovative technologies that differentiate them from established players.

Operational Factors Impacting the Ceramic Coating Market

Operational factors such as supply chain management, production efficiency, and technological advancements significantly impact the ceramic coating market. Companies need to streamline their operations to reduce costs while maintaining high-quality standards. Additionally, adopting advanced manufacturing technologies can enhance productivity and product performance.

Why Straits Research?

Straits Research is committed to providing comprehensive insights into the ceramic coating market through detailed reports that analyze trends, growth drivers, challenges, and opportunities. Our expertise in market research enables us to deliver valuable information that helps businesses make informed decisions.As the ceramic coating market continues to evolve with technological advancements and increasing applications across various sectors, stakeholders must stay informed about emerging trends and competitive dynamics. For more detailed insights into the Ceramic Coating Market trends and forecasts, please refer to our full report or contact Straits Research directly. For further information or inquiries regarding this blog or our research services, please contact us at [email protected] or call +1 646 905 0080.

#Ceramic Coating Market Share#Ceramic Coating Market Size#Ceramic Coating Market Growth#Ceramic Coating Market Insights#Ceramic Coating Market Trends#Ceramic Coating Market Analysis#Ceramic Coating Market Industry#Ceramic Coating Market Forecast

0 notes

Text

#Japan Ceramic Coating Market#Market Size#Market Share#Market Trends#Market Analysis#Industry Survey#Market Demand#Top Major Key Player#Market Estimate#Market Segments#Industry Data

0 notes

Text

The Business Research Company offers high performance ceramic coatings market research report 2023 with industry size, share, segments and market growth

#high performance ceramic coatings market research#high performance ceramic coatings market report#high performance ceramic coatings market trends#high performance ceramic coatings market size#high performance ceramic coatings market forecast#high performance ceramic coatings market growth#global high performance ceramic coatings market#high performance ceramic coatings market share#high performance ceramic coatings market analysis#high performance ceramic coatings market segments

0 notes

Text

Day 10 - Winter Market || Murmuring Crowds, Rows of Stalls, and the Smell of Food

Pairing: Kuroo Tetsurou x Reader Genre: Dark Romance with Food Kink

Short and Sweet

The bustling winter market was alive with a vibrant energy that danced in the frosty air, enveloping all who wandered its paths. Sounds collided in a chaotic symphony—murmuring crowds filled with laughter and jovial chatter, the melodic clinking of coins exchanged for goods, and the mouthwatering sizzle of food being prepared at the myriad of stalls. Each bite-sized morsel showcased the culinary delights of the season, and the air was tinged with a concerto of enchanting aromas. The crispness of the winter atmosphere carried the tantalizing scents of roasted chestnuts crackling over open flames, spiced cider simmering to perfection, and freshly baked pastries, their golden-brown crusts glistening under soft lighting like a warm embrace amidst the cold.

You clutched your ceramic mug filled with steaming cider, the warmth radiating through your fingers, providing a small but welcome comfort against the chill that nipped at your cheeks. The market was a sensory overload, but despite the excitement all around you, there was an anchoring presence right behind you—Kuroo. His proximity brought an unusual mix of comfort and nervous energy that sent delightful shivers racing down your spine.

His hand rested lightly on the small of your back, an intimate gesture that guided you effortlessly through the throngs of people. Each step seemed intentional as he maneuvered you toward a stall decorated with an enticing array of candied fruits, their vibrant colors sparkling like jewels in the twilight. “You’ve got to try this one,” he said softly, his voice wrapping around you like a warm scarf. He plucked a sugar-coated strawberry from the display, its crimson flesh gleaming seductively in the golden lights, and raised it to your lips. His amber eyes glinted with mischief and something deeper, catching the soft glow of the fairy lights that adorned the stalls like a canopy of stars. “Come on, open up,” he coaxed gently.

An uncertain flutter of nerves thrummed through you, making you hesitate. The intensity of his gaze was potent, almost magnetic, compelling you to lean in closer. When the moment finally came, you leaned forward, and his fingers lingered a heartbeat longer than necessary, brushing your lips as he fed you the succulent strawberry. The sweetness exploded on your tongue, a luscious burst of flavor that momentarily took your breath away. Yet, it wasn’t just the delicious taste that made your knees weak; it was the way he watched you—his eyes devouring the sight of you enjoying something so simple, yet so intimate.

“Good, right?” he asked, his voice low and smooth, laced with an undercurrent of something tantalizingly dangerous. He leaned in even closer, the warm breath spilling against your ear despite the pervasive cold around you. “I want to see that look on your face again.” The request hung in the air, charged with unspoken promises and heated implications.

You peeled away from the candied fruit stall and moved towards the next one, a charming little booth that was buzzing with the scent of savory dumplings being steamed to perfection. Kuroo’s playful persistence was relentless. Each delectable bite he offered you came with a cleverly laced comment, his fingers brushing against your lips or your cheek, creating sparks that danced on your skin. His possessive streak was unmistakable, manifesting in the way he stood so close, his arm pressing against yours, a tacit reminder of his claim.

“You taste better when you’re happy,” he teased, his grin transforming into something sharp, almost predatory. “But I wonder how you’d look if I made you blush like this somewhere... less public.” The implications of his words ricocheted in your mind, igniting heat in your cheeks that had nothing to do with the cold air or the bustling crowds.

The murmuring crowds faded into a distant hum as Kuroo’s words settled deep within you, a tantalizing promise that made your heart race. His hand slid down your arm, fingers lacing through yours—a warm, secure hold amidst the chaos of the market. The mingling scents of food, laughter, and winter warmth no longer held sway over your senses; instead, it was Kuroo, and the way he seemed to consume you with every lingering glance. The world around you dimmed in significance, narrowing down to the electrifying connection between you two, turning a simple outing into something far more intoxicating.

#Dark Romance#Food Kink#Public Intimacy#Possessive Behavior#Market Setting#Power Dynamics#Sensory Descriptions#yandere haikyuu#yandere kuroo#yandere kuroo x reader#yandere kuroo tetsurou#yandere kuroo tetsurou x reader#kuroo tetsuro x reader#tetsuro kuroo xreader#kuroo tetsurou x reader#tetsurou kuroo x reader#yandere tetsurou kuroo#yandere kuroo tetsuro x reader#haikyuu#yandere haikyuu x reader#haikyuu imagines#yandere x reader#yandere x you#yandere#yandere scenario#yandere imagines

33 notes

·

View notes

Text

I just got done my ceramics class. And I have such a nice time. I used almost all of my clay. Literally had like three little teeny tiny pieces the size of a quarter left. I gave them to Sandy because she had a reclaim bag right there and I just feel really nice right now. I am very excited to go home though because I'm so tired.

I didn't sleep well again last night but it's really just because I can't breathe. I wake up in the morning and I can't breathe out of my nose and I just feel so tired. I don't know what I can do to make myself breathe better at night. I'm either too hot or it's too dry. Ridiculous.

So because of that I let myself sleep an extra hour. And I did benefit from that greatly. Wednesdays are great because I can do that. And I just tried to not cry. James left a little bit before I got up for real. They had laid it with me for a little while but honestly I was just not in a good spot and I was just really frustrated.

But they left and I pulled myself together. I got dressed and I felt pretty good. My hair is very dirty and my head is itchy but it looked nice. And I just pulled myself together and I left and I went to work.

I was still thinking about the house a lot. And I I'm still thinking about it now. But I tried to put it out of my head and think about other stuff because focusing on and isn't going to help me much.

So I got to camp and I got to work on fixing some of the things on the schedule. Cuz that is just going to be a project I'm going to continuously tinker with for the next 3 months. I worked on starting to write down the lessons and ideas I have for the new programs that we're trying to develop. It was a good time.

But very quickly I became very bored. They're just wasn't enough for me to do today. But it was also way too cold outside to do anything. On my drive in it started to flurry which was so nice and it was so pretty. But I left my gloves at home and so being outside was too painful. Thankfully I have an extra sweatshirt in the car so I was able to layer later in the day when it got doing colder. But I did not want to be out in the world doing much. I wanted to stay in the office where it was at least warm.

I was very distracted this morning though I was just thinking about the house and I was working on lesson plans and I was playing on my phone and eventually I walked up to the art building and I did put some stuff away and I spray painted a pallet easel box I have that someone had poorly painted. So I would go up there twice to do a couple coats. And then I put away all the stuff that we got from the attic. But then my hands hurt really bad so I went back to the office.

I was so bored that I just was eating all day. Just trying to keep myself awake. I had my lunch early and I just tried to have a nice day because it was very difficult when I was so bored.

Eventually I would go up to arts and crafts and get some of my beating stuff and brought that down to work on just to have something to do.. periodically Heather would have something for me to change your ad on the schedule so I kept fussing with that and working on my lesson plans. And eventually we got an email from Harold about the house.

Apparently the current owner, seller, got a home inspection done in September. I guess in preparation for putting a house in the market. And there are issues. A lot of issues. It's hard though because there are two codes essentially there's orange and there is red. And the orange ones are kind of all over the place. Like some are stuff that is concerning to me and stuff that I'm just like oh well like that's fine. Like for instance some of the orange ones are about the length of the handrails. And then others are about the gutters touching electrical wires. And this has issues. It will need work if we get this one. Some of it bigger than others. But honestly I don't know if it dissuades me from this particular house. I'm going to kind of lean on our realtor on this one and kind of take his advice at this point because any home inspection we get is going to have these problems because we're looking at houses that are old. But even the house is that are old but flipped are not flipped well so they're also going to have issues. So it's really hard to know how much money it's going to take to fix any of these places. And like yesterday I watched a TikTok about someone who just bought a brand new house and it's leaking all over the place and it's just got water coming from every pipe essentially and they've had to replace the entire flooring and so many things have gone wrong. And honestly I think that's probably going to be the case in any place we end up. They're all going to have the potential for catastrophe. And you got to hope that it's not going to happen and be proactive and I think that's one of the things that's nice about the home inspection because now at least we know and we can start attacking those problems. I just need to believe in myself that I wouldn't take on something that I don't think I can handle either by fixing it myself or financially.

But honestly getting that home inspection just made me more stressed because now I don't know what the right answer is. There's so many things I like about this house but I still think I want to see the couple more. I am more secure in what my overall budget is though and what I'm comfortable with taking out lone wise. I don't want to be stupid about it but it is not a buyer's market and I am also being realistic about that. It's really hard to know what the right call is in the end

I just focused on my beating though and tried to finish out the day. Chris would come up from his house to have a meeting with Alexi and me him and Heather talked a little bit. I told him he's going to be leaving a program and he was like haha and I'm like apparently you were supposed to do it beforehand so I'm going to make you do it this year and I think it will be good for everybody. I hope that I can actually make that happen. And I chatted with Heather after he went into his meeting and we talked about enthusiasm and getting people on board with stuff and the things that we hope to do and it was really nice.

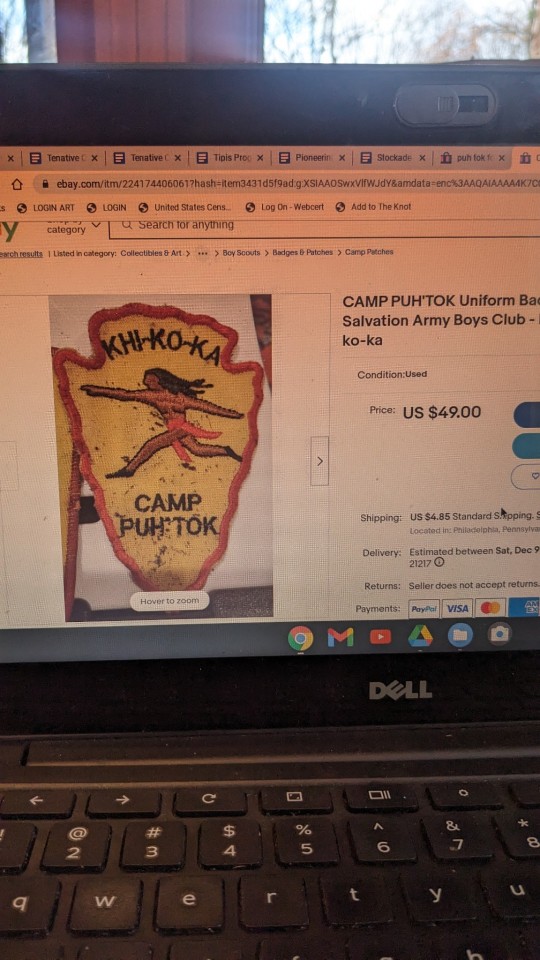

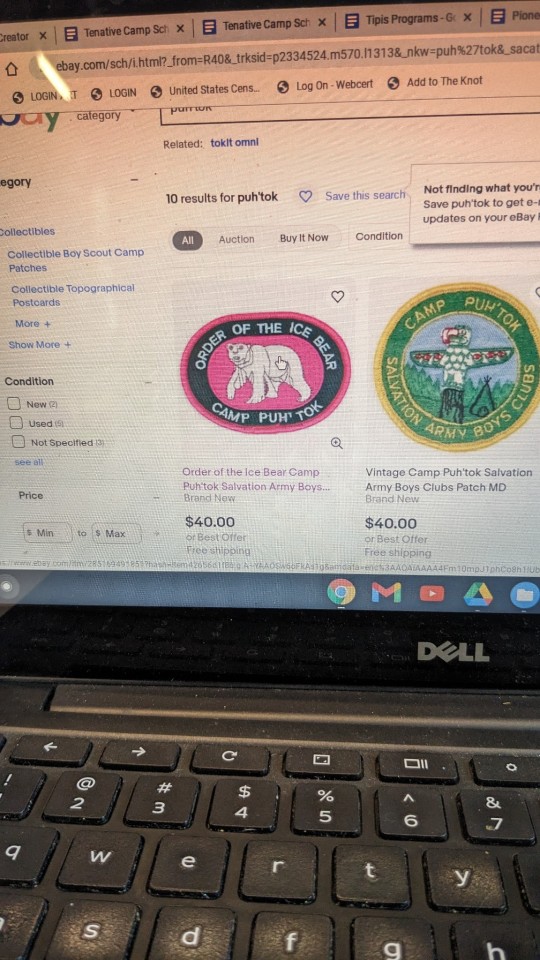

Me and Heather were also laughing because earlier in the day I had found someone had posted two of our badges / awards on eBay for like 40 and $50 a piece. that is hilarious. Which one of our people are doing that because that is so funny. What I think happened is something we donated had a patch on it and it ended up in somebody's hands that thought it was worth something and was vintage and put it online. But these things are modern and it was really funny to see.

But it was time for me to go. And annoyingly I wasn't really hungry anymore but I knew that I should eat something where I was not going to make it through my class. I said goodbye to everyone and decided to drive out to cockeysville to go get Taco Bell. But you didn't really make my stomach feel amazing. I accidentally got two different potato products. But it was okay. I ate my car and watched a video and then I went to my class.

And it was a really nice class. We only have one more after this and I'm really glad I took this class but I still don't think I really like throwing on a wheel and if I did a ceramics again I would just want to be a handworking class. They do have other types of classes at the millville and so I'm going to look into those because I think I would still enjoy taking something. Periodically but weekly I think might be a little bit much for me right now. I'm just a little stretched thin.

I started the class by finishing waxing the bottoms of all of my fire pieces to get ready to be dipped. I chose a couple colors I haven't done before and when I have. I am really excited to see how they come out and I really hope they come out well. And then I trimmed the pieces I made last week. I decided I really liked the rough texture so I left a lot of that natural roughness to them and I think that they will come out very interestingly in the end. And then it was time to start working on my Christmas ornaments!

I really like to doing the Christmas ornaments with cookie cutters. I thought I would enjoy the temporary tattoo underglazes more but it just didn't do anything for me. Like I made a couple that I think will be nice gifts but I really enjoyed making the cookie ones and then I wanted to paint them like actual cookies. My favorite ones I made look like the Little Debbie's Christmas tree cakes. And I'm really hoping they come out nice because I just think that they were a really good idea and I am very excited about them.

I still had some clay left so I rolled that out and I cut a whole bunch more cookies and I did drop a wooden tray on the ground of some of them and squished them so I had to start those again. But it was fine. I talked to Lindsey about finishing them next week since I'm going to have stuff to glaze but that's not going to take very long and I want to have something to work on so I have a few pieces that I'm going to let continue to dry in the next week I'll under glaze them and then she said even though the class is over we can come back and do clear dip places on all of our pieces if we need to. Very very nice of her.

I didn't have much clean up because I never turned the wheel on and so I was able to pick up pretty quickly and now I'm on my way home. It's very cold outside and I kept my clay covered sweatshirt on under my jacket. But I'll be home soon and I'm going to wash my hair and try to sleep better tonight. Fingers crossed. Tomorrow me and Sarah are hoping to go up to the art building to do some crafts but we'll see what happens. It's so cold up there I can't really see us being very comfortable doing that but we will see. I just hope it's a good day. And I hope that we get to see some houses tomorrow. Maybe it'll give me a little bit more clarity.

I hope that you all sleep well tonight. Be safe out there. Until next time. Wash your hands.

3 notes

·

View notes

Text

Automotive Films Market: Trends, Growth, and Future Outlook

How Advanced Films are Transforming the Automotive Industry

Introduction

The automotive films market is experiencing substantial growth due to increasing demand for vehicle protection, aesthetics, and energy efficiency. With advancements in film technology, these solutions are widely used for UV protection, heat reduction, and vehicle wrapping. The automotive films market size was valued at approximately $6.5 billion in 2023 and is expected to reach $10.2 billion by 2030, growing at a CAGR of 6.8%. The global automotive films market is driven by the rising adoption of window tinting, paint protection films, and smart films in passenger and commercial vehicles.

Key Market Drivers

Rising Demand for Vehicle Protection: Paint protection films and window tints help in safeguarding vehicles from UV rays, scratches, and heat.

Stringent Regulations on Sun Control Films: Governments worldwide are enforcing rules to enhance energy efficiency and reduce glare.

Aesthetic Customization Trend: Vehicle wrapping films are gaining traction among car owners for personalization.

Advancements in Smart Films: Innovations such as switchable and self-healing films are fueling market growth.

Challenges and Market Innovations

While the automotive films market is growing, challenges such as regulatory restrictions on tinting and high installation costs persist. However, innovations in nano-ceramic films, graphene-based coatings, and self-repairing protective layers are making these films more efficient and durable.

Why is the Automotive Films Market Expanding Rapidly?

The demand for automotive films is increasing due to their multifunctional benefits. Window films improve privacy and energy efficiency, while paint protection films extend the lifespan of vehicle exteriors. Additionally, the rise of electric and luxury vehicles is further driving the adoption of high-performance films.

Regional Insights and Future Outlook

North America and Europe dominate the market due to strict regulations on sun control and growing demand for premium vehicles.

Asia-Pacific is the fastest-growing region, with increasing automotive production and rising consumer awareness of vehicle protection solutions.

The future of the global automotive films market is shaped by continued advancements in nanotechnology and smart coatings.

For expert insights into the evolving market landscape, Mark & Spark Solutions provides in-depth research and strategic analysis.

0 notes

Text

Global Rubber Liner Market [2025-2031] | Market Size, Growth, Dynamics and Trends

Rubber liner is a tough, elastic polymeric material used to coat the exterior or interior of vessels containing fluids to prevent corrosion, such as tanks, pipes, and other containers. Rubber linings are used to protect against corrosion, material contamination, fire and explosion.

This report is a detailed and comprehensive analysis for global Rubber Liner market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2025, are provided. Global Info Research’s report on the Global Rubber Liner Market offers profound understanding of the market's structure, dynamics, and prevalent trends. This report offer a contemporary snapshot of the market's current size and its potential for growth in the future. The report pinpoints the key competitors within the market, their respective market shares, and the emerging opportunities they can capitalize on. Additionally, the report delves into the impact of technological advancements on the market and how these can be harnessed for competitive advantage. Market segment by Type: Ball Mill Rubber Liner、Rod Mill Rubber Liner、Grinding Machine Rubber Liner、Self-grinding Machine Rubber Liner、Mixer Rubber Liner、Mining Machine Rubber Liner、Ceramic Mill Rubber Liner Market segment by Application:Mine、Chemical、Transporter、Others Major players covered: Weir Minerals、Liner Rubber srl、Blair Rubber、Metso、Trelleborg、Corrosion Engineering、Duratray International、Tega Industries、Salem-Republic Rubber、Progressive Rubber Industries、REMA TIP TOP、Valley Rubber、Cabot Corporation、Beaver Process Equipment、HuiFeng Wear Resistant Group、Naipu Mining Machinery、HuiFeng Wear Resistant Group、Naipu Mining Machinery

Moreover, the report provides a comprehensive analysis of the significant drivers, challenges, and opportunities within the Rubber Liner Market. It takes into consideration the macroeconomic factors and regulatory frameworks prevailing in each region encompassed by the market. A thorough examination of the industry's supply chain is also conducted to identify key players and assess the influence of recent developments on their market positioning. The report offers a clear perspective on how to leverage the evolving market conditions for maximum gain.

The report on the Global Rubber Liner Market meticulously scrutinizes the competitive landscape, offering valuable insights for market participants. The report identifies and appraises the leading players, providing a holistic view of their market presence and strategies.

Through meticulous analysis, we identify market leaders, challengers, and niche players, evaluating them based on factors such as market share, product offerings, and recent developments. This comprehensive understanding enables businesses to gain a deeper insight into their competitive positioning within the industry.

To provide a comprehensive overview of the Global Rubber Liner Market, Global Info Research adopts a segmentation approach and also categorizes the market into distinct segments, considering various criteria like product types, geographical regions, and consumer demographics.

By closely examining each segment, we reveal specific trends, growth potential, and challenges. This segmented analysis allows businesses to tailor their strategies to meet the unique needs of different market segments, thereby enhancing their competitive edge. Our segmentation analysis serves as a strategic tool, guiding market participants in navigating the complexities of the Global Rubber Liner Market effectively.

The content of the study subjects, includes a total of 13 chapters: Chapter 1, to describe Rubber Liner product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top players of Rubber Liner, with revenue, gross margin and global market share of Rubber Liner from 2020 to 2025. Chapter 3, the Rubber Liner competitive situation, revenue and global market share of top players are analyzed emphatically by landscape contrast. Chapter 4 and 5, to segment the market size by Type and application, with consumption value and growth rate by Type, application, from 2020 to 2031. Chapter 6, 7, 8, 9, and 10, to break the market size data at the country level, with revenue and market share for key countries in the world, from 2020 to 2025.and Rubber Liner market forecast, by regions, type and sales channel, with consumption value, from 2026 to 2031. Chapter 11, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 12, the key raw materials and key suppliers, and industry chain of Rubber Liner. Chapter 13, to describe Rubber Liner research findings and conclusion.

Reasons for Acquiring This Report:

The conducted research offers valuable insights to top executives, policymakers, industry professionals, product developers, sales managers, and stakeholders within the Global Rubber Linermarket. The report presents a comprehensive analysis of the market, enabling companies to assess their market share, analyze projections, and identify new growth opportunities. The report provides detailed revenue data for the Global Rubber Linermarket at the global, regional, and country levels. This comprehensive analysis covers the period up to 2031, allowing companies to make informed decisions based on market trends and projections. The research divides the Global Rubber Linermarket into various segments based on type, application, technology, and end-use. This segmentation offers a clear understanding of each segment's growth potential, enabling leaders to plan their product development and financial strategies accordingly. Investors can benefit from the Global Rubber Linermarket analysis by gaining insights into the market's scope, position, key drivers, challenges, restraints, expansion opportunities, and potential threats. This information helps investors make informed decisions when allocating funds. The report provides a detailed analysis of competition within the Global Rubber Linermarket, including key strategies employed by competitors. This analysis helps businesses understand their competitors better, enabling them to plan their market positioning effectively. The study evaluates business predictions for the Global Rubber Liner market based on region, key countries, and leading companies. This information assists investors in channeling their investments strategically, targeting areas with the highest growth potential.

Global Info Research��is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Zirconium Oxide Market, Global Outlook and Forecast 2025-2032, by Manufacturers, Regions, Technology, Application

Zirconium Oxide, commonly referred to as zirconia (ZrO₂), is a white crystalline oxide of zirconium known for its exceptional thermal stability, corrosion resistance, and high mechanical strength. It is widely used in advanced ceramics, dental materials, coatings, and catalytic applications due to its superior properties, such as high fracture toughness and wear resistance. The material is essential in various industrial and commercial applications, making it a crucial component in numerous sectors, including electronics, aerospace, and biomedical fields.

Click Here to Download a free Sample Report PDF

Market Size

The global Zirconium Oxide market was valued at US$ 3.5 billion in 2024 and is projected to reach US$ 5.2 billion by 2032, growing at a CAGR of 5.7% from 2024 to 2032. This growth is driven by increasing demand for advanced ceramics in electronics, healthcare, and industrial applications. The market has witnessed steady growth due to technological advancements, particularly in the biomedical and aerospace sectors. The rise in demand for dental ceramics and prosthetics has also fueled market expansion.

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

Download a free Sample Report PDF

Drivers

Growing Demand in Advanced Ceramics: The increasing use of zirconium oxide in high-performance ceramics for automotive, aerospace, and electronics industries is a key driver.

Expansion in Dental and Biomedical Applications: Zirconium oxide’s biocompatibility has led to its widespread use in dental implants, crowns, and medical devices.

Rising Industrial Applications: The material’s resistance to high temperatures and corrosive environments boosts its demand in foundries, refractories, and thermal barrier coatings.

Technological Advancements: Innovation in material processing and nanotechnology enhances zirconium oxide’s properties, driving its adoption across industries.

Restraints

High Production Costs: The extraction and refining process of zirconium oxide is energy-intensive, leading to higher costs.

Environmental Regulations: Stringent regulations on mining and processing may hinder market growth.

Raw Material Supply Constraints: The dependence on limited sources of zirconium minerals poses a challenge to market stability.

Opportunities

Expanding Applications in Electronics: The growing semiconductor and electronics industry presents new opportunities for zirconium oxide applications.

Increased Research in Nanostructured Materials: Nanotechnology advancements open up possibilities for new uses in coatings, sensors, and catalysts.

Sustainability Initiatives: The shift towards eco-friendly materials encourages the development of greener zirconium oxide production methods.

Challenges

Volatility in Zirconium Prices: Market fluctuations in zirconium ore prices can impact overall product costs.

Intense Market Competition: The presence of established players and the entry of new competitors create pricing pressures.

Complex Manufacturing Processes: High-temperature processing and stringent quality control add to production challenges.

Regional Analysis

North America

Strong demand from the biomedical and aerospace industries.

The United States leads the region with substantial investments in dental ceramics.

Europe

Major players like Saint-Gobain and Imerys drive market growth.

Rising demand for automotive and industrial ceramics.

Asia-Pacific

China and Japan are dominant players due to high production and consumption.

Increasing use in electronics and medical applications.

South America

Emerging market with growing foundry and industrial applications.

Brazil leads regional demand.

Middle East & Africa (MEA)

Moderate growth, driven by construction and manufacturing sectors.

Competitor Analysis

Key players in the Zirconium Oxide market include:

Imerys

Saint-Gobain

Tosoh

Treibacher Industrie AG

Resonac

Daiichi Kigenso Kagaku Kogyo (DKKK)

DFM

Foskor Zirconia

Sanxiang Advanced Materials

Guangdong Orient

These companies focus on capacity expansion, mergers & acquisitions, and technological advancements to maintain market leadership.

Market Segmentation Analysis

Market Segmentation (by Application)

Advanced Ceramics

Foundry

Antifriction Material

Chemicals

Others

Market Segmentation (by Type)

Monoclinic Zirconia

Tetragonal Zirconia

Cubic Zirconia

Key Company Profiles

Each company’s profile includes:

Business Overview

SWOT Analysis

Production Capacity

Revenue

Pricing Strategies

Market Share

Geographic Segmentation

Key countries covered in the report include:

United States

China

Japan

India

Germany

France

UK

Brazil

FAQ

What is the current market size of the Zirconium Oxide market?

➣ As of 2024, the global Zirconium Oxide market is valued at US$ 3.5 billion and is projected to reach US$ 5.2 billion by 2032.

Which are the key companies operating in the Zirconium Oxide market?

➣ Major players include Imerys, Saint-Gobain, Tosoh, Treibacher Industrie AG, Resonac, Daiichi Kigenso Kagaku Kogyo (DKKK), and Foskor Zirconia.

What are the key growth drivers in the Zirconium Oxide market?

➣ The market is driven by demand in advanced ceramics, dental applications, aerospace, and industrial coatings.

Which regions dominate the Zirconium Oxide market?

➣ Asia-Pacific, led by China and Japan, dominates the market due to high production and consumption.

What are the emerging trends in the Zirconium Oxide market?

➣ Key trends include nanotechnology advancements, increased use in electronics, and sustainable production methods.

Click Here to Download a free Sample Report PDF

0 notes

Text

Thermal Barrier Coatings Market Analysis: Key Challenges and Opportunities

Growing Demand for High-Temperature Resistance and Energy Efficiency Drives Growth in the Thermal Barrier Coatings Market.

The Thermal Barrier Coatings Market size was valued at USD 16.9 Billion in 2023 and is expected to reach USD 25.9 Billion by 2032 and grow at a CAGR of 4.9% over the forecast period 2024-2032.

The Thermal Barrier Coatings (TBC) Market is driven by increasing demand for high-temperature resistance coatings across industries such as aerospace, automotive, power generation, and industrial manufacturing. Thermal barrier coatings are advanced ceramic-based coatings designed to protect components from extreme heat, improve fuel efficiency, and enhance durability. As industries push for energy efficiency and enhanced material performance, the adoption of TBCs continues to rise globally.

Key Players in the Market

Leading companies in the Thermal Barrier Coatings Market are investing in nanotechnology, advanced materials, and innovative application techniques. Key players include:

Praxair Surface Technologies (Praxair TBC Coating)

MesoCoat Inc.

ASB Industries Inc.

Oerlikon Metco (Metco 204NS YSZ)

Sulzer Ltd. (HVOF Thermal Spray Coatings)

Flame Spray Technologies (FST) (FS 35 YSZ)

Cincinnati Thermal Spray Inc.

General Electric (GE Power) (GE HA Gas Turbines TBC)

Mitsubishi Power (M701JAC TBC System)

APS Materials, Inc. (APS Yttria-Stabilized Zirconia Coating)

These companies focus on developing next-generation coatings to improve thermal resistance, oxidation protection, and extended component lifespan in high-temperature environments.

Future Scope and Emerging Trends

The Thermal Barrier Coatings Market is expected to grow steadily as industries increasingly rely on high-performance coatings for temperature control and efficiency enhancement. In the aerospace sector, TBCs are crucial for turbine engines and aircraft components, ensuring improved fuel efficiency and longer operational life. The automotive industry is also adopting these coatings in high-performance engines and electric vehicle (EV) components, reducing thermal stress and enhancing performance.

Moreover, the power generation sector is embracing thermal barrier coatings in gas turbines and industrial boilers, optimizing energy efficiency while reducing maintenance costs. Technological advancements, such as nanostructured TBCs and multi-layered ceramic coatings, are further revolutionizing the market by providing higher thermal shock resistance and lower thermal conductivity. Additionally, the shift towards eco-friendly and plasma-sprayed coatings is gaining momentum, aligning with sustainability initiatives and regulatory compliance.

Key Market Points:

✅ Growing Demand in Aerospace & Defense: Increasing use in aircraft turbines, jet engines, and space exploration equipment. ✅ Rising Adoption in Automotive Industry: Enhanced thermal protection in turbochargers, pistons, and EV battery components. ✅ Expansion in Power Generation Sector: Extensive use in gas turbines, boilers, and heat exchangers for efficiency optimization. ✅ Advancements in Coating Technologies: Development of nano-ceramic, plasma-sprayed, and multi-layered TBCs for superior heat resistance. ✅ Sustainability & Environmental Compliance: Shift toward low-emission, energy-efficient, and eco-friendly coatings.

Conclusion

The Thermal Barrier Coatings Market is set for robust expansion, fueled by technological innovations, increasing industrial applications, and sustainability efforts. As industries prioritize thermal efficiency, material longevity, and environmental responsibility, companies investing in cutting-edge formulations, advanced application methods, and next-gen coatings will lead the market.

Read Full Report: https://www.snsinsider.com/reports/thermal-barrier-coatings-market-size-4120

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Thermal Barrier Coatings Market#Thermal Barrier Coatings Market Size#Thermal Barrier Coatings Market Share#Thermal Barrier Coatings Market Report#Thermal Barrier Coatings Market Forecast

0 notes

Text

Rolling Bearing Ball Market, Global Outlook and Forecast 2025-2032

Rolling Bearing Balls are precision-engineered spherical components used in ball bearings to reduce friction and support radial and axial loads. These balls, typically made from steel, ceramic, or plastic, ensure smooth rotation in various industrial applications such as automotive, aerospace, and heavy machinery. The high durability, corrosion resistance, and load-bearing capabilities of rolling bearing balls make them indispensable in mechanical systems worldwide.

Market Size

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286594/global-rolling-bearing-ball-forecast-market-2025-2032-556

The global Rolling Bearing Ball market was valued at USD 2,443.80 million in 2023 and is expected to reach USD 3,005.57 million by 2032, exhibiting a CAGR of 3.00% during the forecast period.

North America held a significant share, with the regional market valued at USD 636.78 million in 2023, projected to grow at a CAGR of 2.57% from 2025 to 2032.

Asia-Pacific is anticipated to witness the highest growth due to rapid industrialization and increasing demand in automotive and manufacturing industries.

Europe remains a key market, driven by technological advancements and high adoption rates of precision bearings.

North America held a significant share, with the regional market valued at USD 636.78 million in 2023, projected to grow at a CAGR of 2.57% from 2025 to 2032.

Asia-Pacific is anticipated to witness the highest growth due to rapid industrialization and increasing demand in automotive and manufacturing industries.

Europe remains a key market, driven by technological advancements and high adoption rates of precision bearings.

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

Drivers

Growing Demand in the Automotive Industry: The increasing production of automobiles and the need for high-performance bearings are driving market growth.

Industrial Automation & Robotics: The surge in automation and robotic applications has created a higher demand for precision rolling bearing balls.

Advancements in Bearing Technologies: Innovations in materials, coatings, and lubrication systems are improving performance and lifespan, fueling market expansion.

Growing Demand in the Automotive Industry: The increasing production of automobiles and the need for high-performance bearings are driving market growth.

Industrial Automation & Robotics: The surge in automation and robotic applications has created a higher demand for precision rolling bearing balls.

Advancements in Bearing Technologies: Innovations in materials, coatings, and lubrication systems are improving performance and lifespan, fueling market expansion.

Restraints

Volatility in Raw Material Prices: Fluctuations in steel and ceramic material costs impact production expenses and profit margins.

Stringent Quality Regulations: Compliance with stringent industrial and environmental standards can slow down production processes and increase costs.

Volatility in Raw Material Prices: Fluctuations in steel and ceramic material costs impact production expenses and profit margins.

Stringent Quality Regulations: Compliance with stringent industrial and environmental standards can slow down production processes and increase costs.

Opportunities

Expansion in Emerging Economies: Developing regions in Asia and South America present growth opportunities due to industrialization and infrastructure development.

Rising Demand for Energy-Efficient Solutions: Innovations focusing on reducing friction and improving energy efficiency are expected to drive adoption.

Expansion in Emerging Economies: Developing regions in Asia and South America present growth opportunities due to industrialization and infrastructure development.

Rising Demand for Energy-Efficient Solutions: Innovations focusing on reducing friction and improving energy efficiency are expected to drive adoption.

Challenges

Competition from Low-Cost Manufacturers: The market faces challenges from cheaper alternatives and counterfeit products, especially in unregulated markets.

Supply Chain Disruptions: Global disruptions, such as the COVID-19 pandemic, highlight vulnerabilities in raw material supply and logistics.

Competition from Low-Cost Manufacturers: The market faces challenges from cheaper alternatives and counterfeit products, especially in unregulated markets.

Supply Chain Disruptions: Global disruptions, such as the COVID-19 pandemic, highlight vulnerabilities in raw material supply and logistics.

Regional Analysis

North America

Strong demand in the aerospace and defense sector.

Presence of key market players and technological advancements.

Strong demand in the aerospace and defense sector.

Presence of key market players and technological advancements.

Europe

High adoption of precision-engineered bearings in industrial and automotive applications.

Germany, UK, and France are major contributors to market revenue.

High adoption of precision-engineered bearings in industrial and automotive applications.

Germany, UK, and France are major contributors to market revenue.

Asia-Pacific

China, Japan, and India lead in production and consumption.

Rapid industrialization and growing manufacturing sector boost demand.

China, Japan, and India lead in production and consumption.

Rapid industrialization and growing manufacturing sector boost demand.

South America

Brazil and Argentina see increasing demand in heavy machinery and railway sectors.

Growing automotive production fuels market growth.

Brazil and Argentina see increasing demand in heavy machinery and railway sectors.

Growing automotive production fuels market growth.

Middle East & Africa

Investments in infrastructure and construction industries drive demand.

Increasing focus on local manufacturing to reduce dependency on imports.

Investments in infrastructure and construction industries drive demand.

Increasing focus on local manufacturing to reduce dependency on imports.

Competitor Analysis

Key Players in the Market

Tsubaki Nakashima - Leading manufacturer of high-precision bearing balls.

Amatsuji Steel Ball Mfg. Co., Ltd. - Focuses on advanced steel ball production.

Jiangsu LiXing General Steel Ball Co., Ltd. - Major supplier of industrial and automotive bearings.

Dong'e Shandong Steel Ball Group Co., Ltd. - Specialized in high-performance steel ball manufacturing.

Sunan Weijie Steel Ball Co., Ltd. - Offers a diverse range of bearing ball solutions.

Tsubaki Nakashima - Leading manufacturer of high-precision bearing balls.

Amatsuji Steel Ball Mfg. Co., Ltd. - Focuses on advanced steel ball production.

Jiangsu LiXing General Steel Ball Co., Ltd. - Major supplier of industrial and automotive bearings.

Dong'e Shandong Steel Ball Group Co., Ltd. - Specialized in high-performance steel ball manufacturing.

Sunan Weijie Steel Ball Co., Ltd. - Offers a diverse range of bearing ball solutions.

Market Segmentation (by Application)

Industrial Equipment

Automotive Industry

Railway & Aerospace

Others

Industrial Equipment

Automotive Industry

Railway & Aerospace

Others

Market Segmentation (by Type)

Ceramic Ball

Plastic Ball

Steel Ball

Ceramic Ball

Plastic Ball

Steel Ball

Geographic Segmentation

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

FAQ

What is the current market size of the Rolling Bearing Ball Market?

⣠The market was valued at USD 2,443.80 million in 2023 and is projected to reach USD 3,005.57 million by 2032, with a CAGR of 3.00%.

Which are the key companies operating in the Rolling Bearing Ball Market?

⣠Major players include Tsubaki Nakashima, Amatsuji Steel Ball Mfg. Co., Jiangsu LiXing General Steel Ball Co., Dong'e Shandong Steel Ball Group, and Sunan Weijie Steel Ball Co.

What are the key growth drivers in the Rolling Bearing Ball Market?

⣠Growth is driven by increasing demand in automotive, industrial automation, and robotics, alongside advancements in material technologies.

Which regions dominate the Rolling Bearing Ball Market?

⣠Asia-Pacific leads the market due to rapid industrialization, followed by North America and Europe due to their strong manufacturing sectors.

What are the emerging trends in the Rolling Bearing Ball Market?

⣠Trends include the adoption of ceramic and hybrid bearings, the rise of energy-efficient bearing solutions, and growing demand in automated and high-speed applications.

Key Benefits of This Market Research:

• Industry drivers, restraints, and opportunities covered in the study

• Neutral perspective on the market performance

• Recent industry trends and developments

• Competitive landscape & strategies of key players

• Potential & niche segments and regions exhibiting promising growth covered

• Historical, current, and projected market size, in terms of value

• In-depth analysis of the Rolling Bearing Ball Market

• Overview of the regional outlook of the Rolling Bearing Ball Market:

Key Reasons to Buy this Report:

• Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

• This enables you to anticipate market changes to remain ahead of your competitors

• You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

• The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

• Provision of market value (USD Billion) data for each segment and sub-segment

• Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

• Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

• Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

• Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players

• The current as well as the future market outlook of the industry concerning recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

• Includes in-depth analysis of the market from various perspectives through Porter’s five forces analysis

• Provides insight into the market through Value Chain

• Market dynamics scenario, along with growth opportunities of the market in the years to come

• 6-month post-sales analyst support

Customization of the Report

In case of any queries or customization requirements, please connect with our sales team, who will ensure that your requirements are met.

Chapter Outline

Chapter 1 mainly introduces the statistical scope of the report, market division standards, and market research methods.

Chapter 2 is an executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the Rolling Bearing Ball Market and its likely evolution in the short to mid-term, and long term.

Chapter 3 makes a detailed analysis of the market's competitive landscape of the market and provides the market share, capacity, output, price, latest development plan, merger, and acquisition information of the main manufacturers in the market.

Chapter 4 is the analysis of the whole market industrial chain, including the upstream and downstream of the industry, as well as Porter's five forces analysis.

Chapter 5 introduces the latest developments of the market, the driving factors and restrictive factors of the market, the challenges and risks faced by manufacturers in the industry, and the analysis of relevant policies in the industry.

Chapter 6 provides the analysis of various market segments according to product types, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 7 provides the analysis of various market segments according to application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 8 provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and capacity of each country in the world.

Chapter 9 introduces the basic situation of the main companies in the market in detail, including product sales revenue, sales volume, price, gross profit margin, market share, product introduction, recent development, etc.

Chapter 10 provides a quantitative analysis of the market size and development potential of each region in the next five years.

Chapter 11 provides a quantitative analysis of the market size and development potential of each market segment in the next five years.

Chapter 12 is the main points and conclusions of the report.

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/286594/global-rolling-bearing-ball-forecast-market-2025-2032-556

Table of content

Table of Contents 1 Research Methodology and Statistical Scope 1.1 Market Definition and Statistical Scope of Rolling Bearing Ball 1.2 Key Market Segments 1.2.1 Rolling Bearing Ball Segment by Type 1.2.2 Rolling Bearing Ball Segment by Application 1.3 Methodology & Sources of Information 1.3.1 Research Methodology 1.3.2 Research Process 1.3.3 Market Breakdown and Data Triangulation 1.3.4 Base Year 1.3.5 Report Assumptions & Caveats 2 Rolling Bearing Ball Market Overview 2.1 Global Market Overview 2.1.1 Global Rolling Bearing Ball Market Size (M USD) Estimates and Forecasts (2019-2032) 2.1.2 Global Rolling Bearing Ball Sales Estimates and Forecasts (2019-2032) 2.2 Market Segment Executive Summary 2.3 Global Market Size by Region 3 Rolling Bearing Ball Market Competitive Landscape 3.1 Global Rolling Bearing Ball Sales by Manufacturers (2019-2025) 3.2 Global Rolling Bearing Ball Revenue Market Share by Manufacturers (2019-2025) 3.3 Rolling Bearing Ball Market Share by Company Type (Tier 1, Tier 2, and Tier 3) 3.4 Global Rolling Bearing Ball Average Price by Manufacturers (2019-2025) 3.5 Manufacturers Rolling Bearing Ball Sales Sites, Area Served, Product Type 3.6 Rolling Bearing Ball Market Competitive Situation and Trends 3.6.1 Rolling Bearing Ball Market Concentration Rate 3.6.2 Global 5 and 10 Largest Rolling Bearing Ball Players Market Share by Revenue 3.6.3 Mergers & Acquisitions, Expansion 4 Rolling Bearing Ball Industry Chain Analysis 4.1 Rolling Bearing Ball Industry Cha

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/286594/global-rolling-bearing-ball-forecast-market-2025-2032-556

𝗠𝗼𝗿𝗲 𝗔𝗿𝘁𝗶𝗰𝗹𝗲𝘀 𝗙𝗿𝗼𝗺 𝟮𝟰𝗖𝗵𝗲𝗺𝗶𝗰𝗮𝗹 𝗥𝗲𝘀𝗲𝗮𝗿𝗰𝗵

𝟮𝟰𝗖𝗵𝗲𝗺𝗶𝗰𝗮𝗹𝗥𝗲𝘀𝗲𝗮𝗿𝗰𝗵: https://www.linkedin.com/company/24chemicalresearchold/

𝗖𝗵𝗲𝗺𝗶𝗰𝗮𝗹 𝗥𝗲𝘀𝗲𝗮𝗿𝗰𝗵 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀: https://www.linkedin.com/company/chemical-research-insights/

𝗔𝘀𝗶𝗮-𝗣𝗮𝗰𝗶𝗳𝗶𝗰 𝗖𝗵𝗲𝗺𝗶𝗰𝗮𝗹 𝗥𝗲𝘀𝗲𝗮𝗿𝗰𝗵 | 𝟮𝟰𝗖𝗥: https://www.linkedin.com/showcase/asia-pacific-chemical-research-24cr/

𝗠𝗲𝘁𝗮𝗹𝗹𝗶𝗰 𝗠𝗮𝘁𝗲𝗿𝗶𝗮𝗹𝘀 | 𝟮𝟰𝗖𝗥: https://www.linkedin.com/company/metallic-materials-24cr/

𝗣𝗼𝗹𝘆𝗺𝗲𝗿 | 𝟮𝟰𝗖𝗵𝗲𝗺𝗶𝗰𝗮𝗹𝗥𝗲𝘀𝗲𝗮𝗿𝗰𝗵: https://www.linkedin.com/company/polymer-24-chemicalresearch/

𝗢𝗿𝗴𝗮𝗻𝗶𝗰 𝗠𝗮𝘁𝗲𝗿𝗶𝗮𝗹𝘀 | 𝟮𝟰𝗖𝗵𝗲𝗺𝗶𝗰𝗮𝗹𝗥𝗲𝘀𝗲𝗮𝗿𝗰𝗵: https://www.linkedin.com/company/organic-materials-24chemicalresearch/

𝗘𝘂𝗿𝗼𝗽𝗲 - 𝗖𝗵𝗲𝗺𝗶𝗰𝗮𝗹 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀 | 𝟮𝟰𝗖𝗥: https://www.linkedin.com/company/europe-chemical-insights-24cr/

𝗡𝗼𝗿𝘁𝗵 𝗔𝗺𝗲𝗿𝗶𝗰𝗮 - 𝗖𝗵𝗲𝗺𝗶𝗰𝗮𝗹 𝗜𝗻𝘀𝗶𝗴𝗵𝘁𝘀 | 𝟮𝟰𝗖𝗥: https://www.linkedin.com/company/north-america-chemical-insights-24cr/

𝗣𝗮𝗶𝗻𝘁 𝗮𝗻𝗱 𝗖𝗼𝗮𝘁𝗶𝗻𝗴 - 𝟮𝟰𝗖𝗥: https://www.linkedin.com/company/paint-and-coating-24cr/

0 notes

Text

#Vietnam Ceramic Coating Market#Market Size#Market Share#Market Trends#Market Analysis#Industry Survey#Market Demand#Top Major Key Player#Market Estimate#Market Segments#Industry Data

0 notes

Text

Boehmite Market Future and Demand, Global Trends by 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Boehmite Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Boehmite Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Boehmite Market?

The boehmite market is expected to grow at a CAGR of 8.1% during the forecast period of 2024 to 2032.

What are Boehmite?

Boehmite is an aluminum oxide hydroxide mineral with the chemical formula AlO (OH). It is an important component in the production of alumina, which is used to manufacture aluminum metal. Boehmite generally appears as a white, pale yellow, or grayish mineral and is commonly found in bauxite deposits alongside other aluminum-rich minerals like gibbsite and diaspore. Its primary significance lies in its role in the Bayer process, which extracts aluminum oxide from bauxite ore.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1681

What are the growth prospects and trends in the Boehmite industry?

The boehmite market growth is driven by various factors and trends. The boehmite market is primarily driven by its critical role in the aluminum industry, especially in the production of alumina through the Bayer process. The demand for boehmite is closely tied to the growth of the aluminum sector and its use in manufacturing advanced materials like ceramics, refractories, and catalysts. Increasing aluminum usage across industries such as automotive, aerospace, and construction further boosts market demand. As global industrial activities continue to expand and technological advancements progress, the boehmite market is anticipated to grow accordingly. Hence, all these factors contribute to boehmite market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Monohydrate Boehmite

Trihydrate Boehmite

By Application:

Catalysts

Coatings

Ceramics

Polymers

Adhesives

Others

By End-Use Industry:

Automotive

Electronics

Aerospace

Construction

Pharmaceuticals

Energy

Others

By Particle Size:

Nano Boehmite

Micro Boehmite

Segmentation By Region:

North America:

United States

Canada

Asia Pacific:

China

India

Japan

Australia & New Zealand

Association of Southeast Asian Nations (ASEAN)

Rest of Asia Pacific

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX (Belgium, the Netherlands, Luxembourg)

NORDIC (Norway, Sweden, Finland, Denmark)

Rest of Europe

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

The Middle East & Africa:

Saudi Arabia

United Arab Emirates

South Africa

Egypt

Israel

Rest of MEA (Middle East & Africa)

Who are the key players operating in the industry?

The report covers the major market players including:

Sasol Limited

Nabaltec AG

CHALCO

TOR Minerals International

Showa Denko K.K.

Xuancheng Jingrui New Material Co., Ltd.

Zhengzhou Research Institute of Chalco

TABALUX GmbH

Zibo Xinglu Chemical Co., Ltd.

Kawai Chemicals Corporation

AnHui Estone Materials Technology Co., Ltd.

AluChem, Inc.

View Full Report: https://www.reportsandinsights.com/report/Boehmite-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Cristobalite Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2032 Revenue Forecast, Future Scope, Challenges, Growth Drivers

Cristobalite Market Size And Forecast by 2032

According to Data Bridge Market Research The global cristobalite market size was valued at USD 42.50 million in 2024 and is projected to reach USD 76.36 million by 2032, with a CAGR of 7.60% during the forecast period of 2025 to 2032.

Our comprehensive Cristobalite Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://www.databridgemarketresearch.com/reports/global-cristobalite-market

**Segments**

- Based on form, the cristobalite market can be segmented into powder and granule. The powder segment is anticipated to dominate the market as it is widely used in applications such as ceramics, glass, and construction due to its high thermal stability and low thermal expansion coefficient. The granule form of cristobalite is also essential in various industries, including foundry and refractory.

- On the basis of application, the market can be categorized into ceramics, paints and coatings, construction, foundry, refractory, and others. The ceramics segment is expected to hold a significant share owing to the increasing demand for high-performance ceramics in the electronics and automotive industries. The paints and coatings segment is also projected to witness substantial growth due to the growing construction activities globally.

- By end-use industry, the cristobalite market can be divided into glass, automotive, electronics, construction, and others. The glass industry is set to be a major consumer of cristobalite, especially in the production of high-quality glass for architectural and automotive applications. The electronics sector is also driving the market growth with the rising demand for advanced electronic components.

**Market Players**

- Sibelco - Silmer - Quartz Corporation - Kyshtym Mining - SCR-Sibelco NV

These key players in the cristobalite market are focusing on strategic initiatives such as mergers and acquisitions, product innovations, and capacity expansions to strengthen their market position. Sibelco, one of the prominent market players, recently introduced advanced cristobalite products to cater to the increasing demand from end-use industries. Silmer is another leading player known for its high-quality cristobalite offerings that meet stringent industry standards. The Quartz Corporation has been expanding its production capacity to meet the growing market requirements for cristobalite. Kyshtym Mining and SCR-Sibelco NV are also actively involved in the cristobalite market, supplying top-grade products to a wide range of industries.

https://www.databridgemarketresearch.com/reports/global-cristobalite-market The global cristobalite market is expected to witness significant growth in the coming years due to the increasing demand for high-quality materials in various industries. One of the key drivers of market growth is the rising adoption of cristobalite in applications such as ceramics, glass, construction, foundry, and refractory. The properties of cristobalite, including high thermal stability and low thermal expansion coefficient, make it a preferred choice for use in these industries. Additionally, the growing construction activities worldwide are driving the demand for cristobalite in paints and coatings applications, further boosting market growth.

In terms of segments, the cristobalite market can be categorized based on form, application, and end-use industry. The powder form of cristobalite is expected to dominate the market due to its wide utilization in ceramics, glass, and construction industries. The granule form of cristobalite also plays a crucial role in foundry and refractory applications. Moreover, the ceramics segment is projected to witness significant growth, driven by the increasing demand for high-performance ceramics in sectors such as electronics and automotive. The glass industry is set to be a major consumer of cristobalite, particularly for manufacturing high-quality glass for architectural and automotive purposes.

Key market players in the cristobalite market, such as Sibelco, Silmer, Quartz Corporation, Kyshtym Mining, and SCR-Sibelco NV, are focusing on strategic initiatives to strengthen their market position. These initiatives include mergers and acquisitions, product innovations, and capacity expansions to meet the growing demand from various industries. Sibelco has introduced advanced cristobalite products to cater to the increasing market requirements, while Silmer is known for its high-quality offerings that meet stringent industry standards. The Quartz Corporation is expanding its production capacity to address the rising market demand for cristobalite. Furthermore, Kyshtym Mining and SCR-Sibelco NV are actively supplying top-grade cristobalite products to a diverse range of industries.

In conclusion, the global cristobalite market is poised for significant growth, driven by the widespread utilization of cristobalite in key industries such as ceramics, glass, construction, foundry, and refractory. With key market players focusing on strategic initiatives to enhance their market presence, the cristobalite market is expected to witness further expansion in the coming years, catering to the evolving needs of various end-use industries.**Segments** Global Cristobalite Market, By Type (Whole Kernel or Grain, Crushed), Form (Sand, Milled Flour), Application (Construction Activities, Glass and Ceramics, Paints and Coatings, Foundry Castings, Sports and Leisure Goods, Metallurgical Application, Industrial Chemicals, Oil Field Chemicals, Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2032

In the global cristobalite market, the whole kernel or grain type and crushed type hold significance due to their applications in various industries. The form of cristobalite, whether in the form of sand or milled flour, plays a crucial role in determining its usability in different applications such as construction activities, glass and ceramics production, paints and coatings, foundry castings, sports and leisure goods, metallurgical applications, industrial chemicals, oil field chemicals, and others across different countries around the world. The industry trends and forecast indicate a promising future for the cristobalite market with increasing demand and technological advancements driving growth.

**Market Players** The major players covered in the cristobalite market report are Sibelco, C.E.D. Process Minerals, Inc., Hoben International Limited, Goldstar Powders India., Silmer SAS, Quarzwerke Gmbh, Donghai Changtong silica powder CO.,LTD., Lianyungang Changtong Silica Powder Co. Ltd, Heraeus Holding, Jinyu Advanced Material Co., Ltd., Momentive, Solvay, Evonik Industries AG, Tosoh Corporation, among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. These market players are instrumental in shaping the cristobalite market landscape through their competitive strategies, including mergers, acquisitions, product developments, and expansions. The competitive analysis conducted by DBMR analysts provides insights into the strengths of each competitor, enabling a deeper understanding of the market dynamics.

The cristobalite market is witnessing significant growth globally, driven by its widespread applications in key industries such as ceramics, glass, construction, foundry, and refractory. The properties of cristobalite, such as high thermal stability and low thermal expansion coefficient, make it a preferred choice for various applications, leading to an increased demand for different forms of cristobalite across multiple geographies. With key market players continuously innovating and expanding their product portfolios, the cristobalite market is poised for further expansion and evolution to meet the evolving needs of industries worldwide.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies in Cristobalite Market : https://www.databridgemarketresearch.com/reports/global-cristobalite-market/companies

Key Questions Answered by the Global Cristobalite Market Report:

What is the current state of the Cristobalite Market, and how has it evolved?

What are the key drivers behind the growth of the Cristobalite Market?

What challenges and barriers do businesses in the Cristobalite Market face?

How are technological innovations impacting the Cristobalite Market?

What emerging trends and opportunities should businesses be aware of in the Cristobalite Market?

Browse More Reports:

https://www.databridgemarketresearch.com/reports/global-ferritin-testing-markethttps://www.databridgemarketresearch.com/reports/global-aircraft-ejection-seat-markethttps://www.databridgemarketresearch.com/reports/global-citrullinemia-markethttps://www.databridgemarketresearch.com/reports/global-brain-abscess-drugs-markethttps://www.databridgemarketresearch.com/reports/global-sporotrichosis-treatment-markethttps://www.databridgemarketresearch.com/reports/global-automotive-electronic-expansion-valve-markethttps://www.databridgemarketresearch.com/reports/global-direct-current-dc-switchgear-markethttps://www.databridgemarketresearch.com/reports/global-vertebroplasty-needles-markethttps://www.databridgemarketresearch.com/reports/sub-saharan-africa-gps-tacking-devices-markethttps://www.databridgemarketresearch.com/reports/global-id-barcode-readers-in-factory-automation-markethttps://www.databridgemarketresearch.com/reports/global-bed-monitoring-system-and-baby-monitoring-systemhttps://www.databridgemarketresearch.com/reports/global-automotive-in-cabin-air-quality-improvement-solutions-markethttps://www.databridgemarketresearch.com/reports/global-benign-and-malignant-soft-tissue-tumors-treatment-markethttps://www.databridgemarketresearch.com/reports/global-nitrogen-trifluoride-nf3-and-fluorine-gas-f2-markethttps://www.databridgemarketresearch.com/reports/global-non-cloud-personal-and-entry-level-storage-pels-markethttps://www.databridgemarketresearch.com/reports/global-point-of-care-poc-clinical-chemistry-and-immunodiagnostic-markethttps://www.databridgemarketresearch.com/reports/global-anion-sanitary-pads-markethttps://www.databridgemarketresearch.com/reports/global-overall-equipment-effectiveness-software-markethttps://www.databridgemarketresearch.com/reports/global-medical-device-tray-markethttps://www.databridgemarketresearch.com/reports/global-bookbinding-materials-markethttps://www.databridgemarketresearch.com/reports/global-vibration-system-markethttps://www.databridgemarketresearch.com/reports/global-robotic-vision-markethttps://www.databridgemarketresearch.com/reports/global-uv-inkjet-printing-markethttps://www.databridgemarketresearch.com/reports/global-electrically-conductive-epoxy-adhesive-markethttps://www.databridgemarketresearch.com/reports/global-board-to-board-connectors-markethttps://www.databridgemarketresearch.com/reports/global-grape-seed-flour-markethttps://www.databridgemarketresearch.com/reports/global-cloud-native-storage-markethttps://www.databridgemarketresearch.com/reports/global-automotive-hardware-markethttps://www.databridgemarketresearch.com/reports/global-metoprolol-tartrate-markethttps://www.databridgemarketresearch.com/reports/global-manual-car-charger-markethttps://www.databridgemarketresearch.com/reports/global-inertial-sensor-mems-markethttps://www.databridgemarketresearch.com/reports/global-decorticator-machine-markethttps://www.databridgemarketresearch.com/reports/global-low-voltage-motor-markethttps://www.databridgemarketresearch.com/reports/global-grinding-fluids-markethttps://www.databridgemarketresearch.com/reports/global-potassium-iodide-markethttps://www.databridgemarketresearch.com/reports/global-buy-now-pay-later-services-market

Data Bridge Market Research:

☎ Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 982

✉ Email: [email protected]

0 notes

Text

What are the key features of the Milwaukee polisher?

Introduction

When it comes to professional-grade polishing tools, the Milwaukee Polisher is a name that stands out. Known for its powerful motor, ergonomic design, and durability, this tool is widely used by car detailers, woodworkers, and metalworkers alike. Whether you need to polish cars, buff metal, or finish woodworking projects, the Milwaukee Polisher provides smooth, high-performance results with ease.

In this guide, we’ll explore key features, benefits, applications, and maintenance tips for the Milwaukee Polisher, along with answers to frequently asked questions.

Key Features of the Milwaukee Polisher