#Centrifugal Oil Cleaning

Explore tagged Tumblr posts

Text

Restore Transformer Oil Quality with Transformer Oil Reclamation Units

Maintaining the health of transformer oil is crucial for the effective performance of transformers. Transformer Oil Reclamation Units by AR Engineering provide a reliable solution to reclaim and purify transformer oils, extending their lifespan and improving the overall performance of electrical transformers.

As India's most trusted brand in oil filtration machines, AR Engineering offers state-of-the-art transformer oil reclamation units that efficiently remove impurities such as water, gases, and particulate matter from used transformer oil. By reclaiming and purifying oil, these systems ensure your transformers perform optimally and have a longer operational life.

Key Features of Transformer Oil Reclamation Units

🔧 Efficient Filtration: Removes dirt, water, and other contaminants from transformer oils 🔧 Improved Oil Performance: Restores the quality of transformer oil for better performance 🔧 Cost-Effective Solution: Reclaims used oil, reducing the need for frequent oil replacement 🔧 Versatile Applications: Works with turbine oils, gear oils, and other industrial oils 🔧 Easy Integration: Can be easily integrated with oil filtration plants, mobile oil filtration systems, and portable oil filtration systems

Our transformer oil filtration systems are designed to remove harmful contaminants from transformer oil and restore it to its original condition, ensuring improved electrical insulation and cooling properties. Whether it's a double-stage oil transformer machine or a two-stage transformer oil filtration plant, AR Engineering provides top-notch equipment that guarantees long-lasting, high-performance results.

For a reliable solution to oil purification and reclamation, look no further than AR Engineering's transformer oil reclamation units. Learn more about how our innovative machines can restore your transformer oil's quality: https://oilfiltermachineindia.com/transformer-oil-reclamation-units.html

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes

Text

Chapter 202 Trivia (Part 1)

I missed the food-focused chapters… 🤤

The brand parody here is Coosur, which is made in the Jaén province of southern Spain (=nowhere near Barcelona). The brand is quite popular, and is also international.

Additionally, Spain produces around half of the world's olive oil, the most of any country!

If you've forgotten the Age of Exploration arc, "desire is noble" is both the name of Francois' debut chapter and their motto!

The tagline for this chapter is "olive in floriography means wisdom (知恵) and victory (勝利)", however all the sources I found said that olive meant peace rather than victory.

Ryusui's holding a dirty martini, a drink known for the unique garnish of an olive. To make it, you need gin, vermouth, and a splash of olive brine.

The brooch he's wearing seems to be a dragon's wing and a flower that I can't identify (it's not related to Spain or olives).

Barcelona is one of the largest metropolises on the Mediterranean Sea and 5th most populated city in the EU. It has two rivers running through it that have survived the 3700+ years, and a mountain range to the west.

The stone world seems to have given it new islands though!

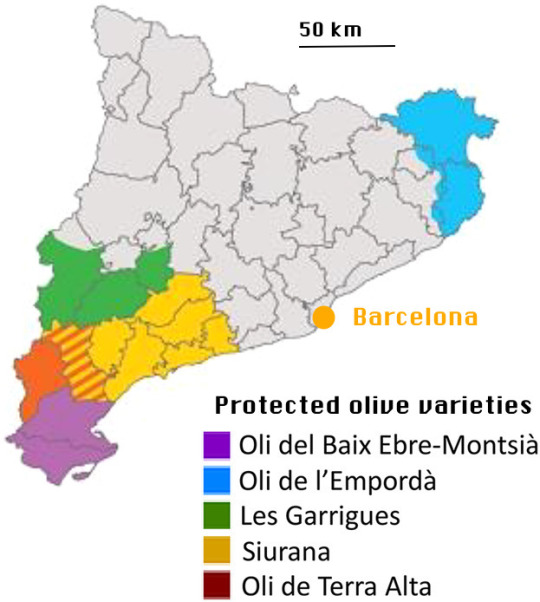

Most Spanish olives are harvested from the south, but Catalonia still accounts for ~5% of all olives produced in Spain. It is a bit of a trek to get to the olive growing regions from Barcelona though!

The olive harvest is normally from November to March, across the winter.

The modern way to harvest olives is by shaking the tree so that all of the olives fall into a net. Ryusui is shown using the traditional way where you knock the fruit off with a pole (Hyoga would have been great for this).

The olives are then cleaned, crushed into a paste, and spun in a horizontal centrifuge like the one Kaseki made to separate the oil from the solids. Do this a few times to make sure everything is properly separated and you get olive oil!

There's couple joke sound effects this chapter, first is Kohaku's "grrlla" (it literally says "gōrira", so "gorilla" with a slightly longer 'o' sound), then Suika's "mlllk" (literally "gyunyu", the word "milk" in Japanese is pronounced "gyūnyū").

Ajillo is an olive-oil-based sauce that is flavoured by frying garlic ("ajo") and guajillos chillis in it. Other things can be added as well, such as salt, pepper, lime juice or wine.

Ajillo dishes are simply things that have been cooked in this sauce.

Since Francois stayed on Isla Martin Garcia rather than at Araxá, they had the opportunity to learn Spanish.

As usual, Francois' foresight of what will be needed is incredible.

Chelsea has also expanded her language repertoire by learning Japanese. Hers is more slang-filled, as she takes Chrome's "baaad", Gen's pig latin and Ryusui's usage of "desire".

Ukyo must have taught Chrome to use a bow and arrow at some point, possibly during the Age of Exploration?

That, or Chrome is just pretending to know how to use it.

(Next part)

20 notes

·

View notes

Text

Fast and Low-Cost Construction Aluminum Floating Roof for Crude Oil Storage Tanks

Fast and Low-Cost Construction Aluminum Floating Roof for Crude Oil Storage Tanks

Crude oil storage demands efficient, cost-effective, and environmentally sustainable solutions. Among the various options available, Aluminum Floating Roofs stand out as a superior choice for reducing vapor loss, preventing contamination, and optimizing operational efficiency. Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel) is a leading provider of fast and low-cost construction aluminum floating roofs for crude oil storage tanks, ensuring superior performance, durability, and cost-effectiveness.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose an Aluminum Floating Roof for Crude Oil Storage Tanks?

Floating roofs are essential for crude oil storage, as they sit directly on the liquid surface, reducing vapor space and minimizing evaporation losses. Compared to traditional steel floating roofs, Aluminum Floating Roofs offer multiple advantages in terms of construction speed, cost-effectiveness, durability, and regulatory compliance.

1. Fast and Cost-Effective Construction

Prefabricated for Quick Installation – Our aluminum floating roofs are manufactured in modular sections, allowing for rapid on-site assembly. This reduces installation time and labor costs.

Lightweight and Easy to Handle – Aluminum’s high strength-to-weight ratio makes transportation and installation more efficient than heavier steel alternatives.

Minimal Site Preparation Required – The floating roof’s design allows for direct deployment without extensive tank modifications, cutting overall construction time and expenses.

2. Reduced Maintenance and Long-Term Cost Savings

Corrosion-Resistant Aluminum Alloy – Unlike steel floating roofs, which are prone to rust, our aluminum floating roofs resist corrosion, ensuring a longer service life and reducing maintenance costs.

Self-Cleaning Surface – The smooth aluminum surface prevents the accumulation of dirt, reducing the need for frequent cleaning.

Low Operational Costs – By minimizing evaporation losses and reducing the need for additional vapor recovery systems, aluminum floating roofs lead to significant cost savings over time.

3. Enhanced Environmental and Safety Performance

Minimization of VOC Emissions – Our floating roofs significantly reduce volatile organic compound (VOC) emissions, helping operators meet strict environmental regulations while reducing product losses.

Elimination of Flammable Vapor Buildup – By maintaining a minimal vapor space, aluminum floating roofs decrease the risk of flammable vapor accumulation, improving fire safety.

Leak Prevention Design – Equipped with high-performance seal systems, our floating roofs prevent crude oil leakage, ensuring environmental compliance.

4. High Structural Integrity and Durability

Superior Load Resistance – Designed to withstand wind loads, heavy rain, and extreme temperature variations, our aluminum floating roofs ensure long-term structural stability.

Compatible with Large-Diameter Storage Tanks – Our aluminum floating roofs are customizable to fit various crude oil tank sizes, making them ideal for refineries, terminals, and oil storage facilities.

Key Features of Center Enamel’s Aluminum Floating Roofs

Fast Installation – Prefabricated components enable quick and cost-effective assembly.

Lightweight Yet Durable – Aluminum alloy construction ensures strength while reducing tank load.

Corrosion-Resistant – Long service life with minimal maintenance required.

Improved Safety – Reduces fire hazards and minimizes vapor loss.

Eco-Friendly Solution – Helps storage facilities comply with environmental regulations.

Customizable to Tank Size – Designed to fit various crude oil storage tank dimensions.

Applications of Aluminum Floating Roofs in Crude Oil Storage

Oil Refineries – Ensuring efficient and safe crude oil storage.

Petroleum Terminals – Reducing product losses due to evaporation.

Tank Farms & Oil Depots – Enhancing storage efficiency with minimal maintenance.

Chemical & Petrochemical Plants – Meeting environmental compliance requirements.

Why Choose Center Enamel?

With over 30 years of experience, Center Enamel is a trusted name in high-quality crude oil storage solutions. Our Aluminum Floating Roofs are engineered for rapid installation, long-term reliability, and cost savings. We are committed to delivering customized, innovative, and environmentally friendly storage solutions that meet international standards, including API 650, AWWA, NFPA, and OSHA.

Global Expertise – Serving customers in 100+ countries worldwide.

Precision Engineering – Manufactured to the highest industry standards.

Cost-Effective Solutions – Designed for fast installation and long-term savings.

Custom-Tailored Designs – We provide floating roof solutions customized to your specific project needs.

Conclusion

The Aluminum Floating Roof is the ultimate fast and low-cost solution for crude oil storage tanks, ensuring reduced evaporation losses, enhanced safety, and long-term cost savings. With Center Enamel’s innovative and high-quality aluminum floating roofs, you can optimize your storage operations while ensuring regulatory compliance and environmental sustainability.

Contact us today to learn how our Aluminum Floating Roofs can enhance the efficiency and safety of your crude oil storage tanks!

age Tanks

0 notes

Text

How Robotic Tank Cleaning Works

In the oil and gas industry, maintaining storage tanks is a critical aspect of operations. Crude oil tanks accumulate sludge, hydrocarbons, and sediments over time, which can reduce storage capacity and affect operational efficiency. Traditionally, tank cleaning was performed manually, exposing workers to hazardous conditions. However, advancements in automation have introduced robotic tank cleaning, revolutionising the process by improving safety, efficiency, and environmental compliance.

The Process of Robotic Tank Cleaning

Robotic tank cleaning involves deploying remotely controlled robots equipped with advanced sensors and cleaning mechanisms inside crude oil tanks. These robotic systems follow a well-defined procedure to ensure effective sludge removal without human entry.

1. Initial Inspection and Setup

Before starting the cleaning process, a thorough inspection of the tank is conducted. Robotic cleaning companies use advanced inspection tools such as ultrasonic sensors and cameras to assess sludge accumulation, internal conditions, and possible obstructions.

The robotic system is then introduced into the tank through a designated entry point. Operators control the robot remotely using a specialised control unit, ensuring precision and safety.

2. Sludge Loosening and Mobilisation

Once inside, the robot utilises high-pressure water jets and chemical agents (if required) to loosen and break down hardened sludge deposits. The robotic arm, equipped with rotating nozzles, ensures thorough sludge mobilisation across the tank’s interior.

Some robotic tank cleaning systems are designed with suction units that continuously extract loosened sludge, preventing re-deposition and reducing cleaning time.

3. Sludge Extraction and Separation

The mobilised sludge is removed from the tank using vacuum pumps or integrated suction units. This extracted material is then processed using crude oil tank cleaning equipment, such as centrifuges or decanters, to separate recoverable hydrocarbons from waste sludge. This step not only maximises oil recovery but also minimises environmental impact.

4. Final Cleaning and Inspection

After sludge removal, the robot performs a final wash using high-pressure water jets to ensure no residues remain. Advanced robotic systems also feature onboard cameras and sensors that help operators verify the cleanliness of the tank.

A post-cleaning inspection is conducted to confirm compliance with industry standards, ensuring the tank is ready for use without any operational risks.

Advantages of Robotic Tank Cleaning

Enhanced Safety — The biggest advantage of robotic tank cleaning is the elimination of human entry into confined spaces filled with toxic gases and hazardous sludge.

Improved Efficiency — Robots clean tanks faster than manual methods, reducing downtime and improving operational efficiency.

Better Oil Recovery — The process effectively separates recoverable crude oil from sludge, increasing overall resource utilisation.

Eco-Friendly Approach — Robotic cleaning reduces waste generation and ensures compliance with environmental regulations.

Cost-Effective — Though initial investment in robotic cleaning may be high, it significantly reduces long-term maintenance and labour costs.

Conclusion

Robotic tank cleaning is transforming the crude oil tank cleaning procedure by making it safer, more efficient, and environmentally sustainable. As the oil and gas industry continues to embrace automation, robotic cleaning technology is becoming the preferred choice for crude oil tank cleaning worldwide.

For advanced robotic tank cleaning solutions, visit Arham Oil. For inquiries, contact us at +917486042707 or +917486042709.

Read More:

Magnetic Robotic Crawler for Tank Cleaning | Arham Oil

Oil Recovery from Tank Sludge | Arham Oil

#robotic tank cleaning#arham oil#oily sludge tank cleaning#mechanized tank cleaning#crude oil tank cleaning

0 notes

Text

Types of Dewatering Pumps and Their Applications

Dewatering pumps play a crucial role in various industries, helping to remove unwanted water from construction sites, mines, tunnels, and other areas prone to water accumulation. Whether dealing with flood control, groundwater management, or wastewater treatment, choosing the right dewatering pump ensures efficient water removal and prevents potential damage.

With numerous pump types available, it’s essential to understand their applications to select the best one for your needs. If you're looking for a dewatering pump supplier in UAE, knowing the different pump types will help you make an informed decision.

1. Submersible Dewatering Pumps

Overview:

Submersible dewatering pumps are designed to operate underwater, making them ideal for applications where water needs to be pumped from deep or confined spaces. These pumps are fully sealed and placed directly in the water source.

Applications:

Construction Sites: Removing water from excavations and foundations.

Mines and Quarries: Pumping out groundwater seepage.

Flood Control: Draining water from basements, tunnels, and low-lying areas.

Municipal Wastewater Management: Handling sewage and stormwater.

Benefits:

✔ Compact and easy to install ✔ Operates quietly ✔ Efficient in deep water applications ✔ Minimal risk of cavitation (air bubbles that can damage the pump)

2. Centrifugal Dewatering Pumps

Overview:

Centrifugal pumps use rotational energy to move water, making them one of the most common types for dewatering. They work best when there is a continuous flow of water and are available in electric or diesel-powered versions.

Applications:

Construction and Civil Engineering: Removing water from trenches and foundations.

Irrigation and Agriculture: Pumping water from reservoirs or lakes.

Industrial Plants: Handling water circulation and cooling processes.

Stormwater Management: Draining flooded streets and parking lots.

Benefits:

✔ High flow rate and efficiency ✔ Suitable for large-scale operations ✔ Handles clear and lightly contaminated water ✔ Available in various power options (electric, diesel, gasoline)

3. Trash Pumps (Self-Priming Dewatering Pumps)

Overview:

Trash pumps are designed to handle dirty water with large debris, sand, and sludge. They are commonly used in tough environments where regular pumps would clog.

Applications:

Construction and Demolition: Removing muddy water from excavation sites.

Municipal Water Treatment: Handling wastewater containing solids.

Flood Management: Pumping out floodwater mixed with debris.

Agriculture: Clearing out irrigation ditches with high sediment levels.

Benefits:

✔ Can handle solids and debris without clogging ✔ Self-priming (starts automatically without needing water in the pump) ✔ Durable and built for harsh conditions

4. Diaphragm Dewatering Pumps

Overview:

Diaphragm pumps use air or mechanical force to create suction, making them ideal for pumping thick or viscous liquids. Unlike centrifugal pumps, they don’t require priming and can run dry without damage.

Applications:

Oil & Gas Industry: Pumping sludges and chemicals.

Construction Sites: Handling thick mud and slurry.

Industrial Cleaning: Removing wastewater from storage tanks.

Flooded Basements: Draining dirty water with sediments.

Benefits:

✔ Handles thick, viscous liquids and mud ✔ Can run dry without damage ✔ Works well in remote locations without electricity

5. Well-Point Dewatering Pumps

Overview:

Well-point dewatering systems consist of multiple small-diameter wells connected to a central pump, creating a vacuum that lowers the water table. This type is widely used in excavation projects where controlling groundwater is essential.

Applications:

Deep Excavations: Keeping foundation pits dry.

Tunneling and Underground Projects: Controlling groundwater seepage.

Docks and Ports: Lowering water levels for construction work.

Pipeline Projects: Preventing water interference during pipe installation.

Benefits:

✔ Effective for controlling groundwater levels ✔ Suitable for deep excavation projects ✔ Helps prevent soil instability

Choosing the Right Dewatering Pump

Selecting the right dewatering pump supplier in UAE is crucial for ensuring reliable performance and efficiency. When choosing a pump, consider:

The type of water to be pumped (clean, muddy, or with debris).

The depth and distance the water needs to be moved.

Power source availability (electric, diesel, or air-powered).

Durability and maintenance requirements.

Whether you need a submersible pump for deep excavation or a trash pump for handling debris-laden water, working with a trusted dewatering pump supplier in UAE ensures you get high-quality equipment tailored to your project’s needs.

1 note

·

View note

Text

Top 5 Industries Benefiting from Centrifugal Oil Water Separators

Centrifugal Oil-water separators are essential apparatuses employed throughout numerous industries for the separation of oil and water from fluids. These separators employ centrifugal force to filter out oils, water, and other impurities in enhanced fluid qualities and minimize harm to the environment. Some of the many industries that apply this equipment include maritime, oil and gas, food and beverage, manufacturing, and automotive among others. In this article, emphasis will be placed on the five major Centrifuge Oil Separator industries that harness the uses of these vital machines.

1. Marine Industry

The marine industry is one of the largest user industries of centrifugal separators. Ships and boats after a day at sea, release oil-contaminated water through the engine room bilges and ballast water. This can only be done in compliance with international regulations which require ships to discharge water that has the minimal possible quantity of oil. It also points out that marine vessels can benefit from centrifugal separators as they are very capable of removing oil from water thereby meeting today’s strict environmental compliance requirements. This ensures that the waste water is clean and safe for discharge without causing pollution to our seas. This keeps equipment in use for a longer period and consumes less maintenance, making a great impact on the general running of the company.

2. Oil & Gas Industry

Centrifuge Oil separators are also of great importance to the oil and gas industry. Drilling operations involve the extraction of oil which comes as a mixture of liquid and gas; water most of the time accompanies the oil and the two have to be separated before the fluid can be disposed of or recycled. Centrifugal oil water separators are very useful in separating oil and watering the production, refining, and transportation of oil.

These separators assist in enhancing the nature of oil by filtering out water which is hostile to equipment and decreases proficiency in pipelines. Also, they assist oil and gas industries achieve environmental benchmarks by checking the level of oil in water before allowing it to be discharged back into the environment. The use of these separators reduces the water-oil mixture to standard limits, thus minimizing the pollution of water sources and making the industry more sustainable.

3. Food Processing Industry

The food processing industry uses liquid and oils in the production of their manufactured products. However, in food production processes such as frying, oil dissolves with water forming emulsions that require to be demulsified for recirculation or dumping. Centrifugal water separator applies to food production plants for example it helps to separate water from oil and food-grade liquids to enhance the quality of products and also to sort waste.

Besides enhancing product quality, all these separators go a long way in reducing operational costs. Manufacturers who obtain oils from water can reuse the oils sparingly thereby cutting on expenses of buying new oils. Making centrifugal separators a valuable asset in implementing efficiency and high levels of hygiene in the food industry.

4. Manufacturing Industry

Oil and water emulsion are expected in manufacturing processes especially where metal is involved and in industrial processes. Machines for example lathes, grinders, and milling machines, use coolant oils to reduce the friction and heat during operations. In the long run, these oils dilute with water and form emulsions that cause such issues as rust, breakdowns of machinery, and decline in efficiency.

Centrifugal oil water separator help to separate the water from oil in manufacturing plants and this cost cutting aid in maintaining the manufacturing equipment and also assists in meeting environmental requirements.

5. Automotive Industry

The automotive industry also uses centrifugal water separators in many ways as noted below. Oils and water are utilized in the automobile manufacturing process; for instance in the testing of engines and washing engines. When combined it leads to operational problems such as inefficiencies and contamination. Centrifuge Oil separators are used in removing oil from water to ensure that the line of production and the equipment are not affected.

Final Thoughts

Centrifuge Oil Separator have become indispensable in various industries that require efficient separation of oil and water from liquids. Industries such as marine, oil & gas, food processing, manufacturing, and automotive rely on these separators to improve efficiency, reduce waste, and comply with environmental standards. These separators not only ensure that operations run smoothly but also contribute to sustainability efforts by reclaiming valuable oils and minimizing pollution.

For businesses looking for reliable and effective centrifugal oil water separators, Reyes Machinery offers state-of-the-art solutions that meet industry standards.

0 notes

Text

Wet Scrubber System Manufacturers

In an era where environmental concerns have become more urgent than ever, industrial processes are facing increasing scrutiny for their impact on air quality. Wet scrubbers, a key technology for controlling air pollutants, have emerged as an effective solution to this challenge. These systems are integral in industries where toxic, particulate-laden gases need to be cleaned before being released into the atmosphere. Wet scrubber system manufacturers are at the forefront of designing and producing these essential devices, which play a critical role in maintaining environmental standards and safeguarding public health.

What is a Wet Scrubber System?

A wet scrubber system is a device that uses a liquid, typically water or a chemical solution, to remove harmful gases, vapors, and particulates from exhaust streams. The basic principle of operation involves passing polluted air through a scrubbing liquid, where the contaminants are either absorbed, dissolved, or physically captured by droplets of the liquid. Once the pollutants are trapped, the clean air is released back into the atmosphere, often meeting the regulatory emission standards set by environmental agencies.

Types of Wet Scrubber Systems

Wet scrubbers come in a variety of designs, each suited to specific types of pollutants and industries. Manufacturers typically offer several types of scrubber systems:

Packed Bed Scrubbers: These systems use a vertical column filled with packing material that increases the surface area for the liquid to interact with the gas stream. As air moves through the packing, the pollutants are absorbed into the liquid. Packed bed scrubbers are highly efficient for removing gases like sulfur dioxide, ammonia, and volatile organic compounds (VOCs).

Venturi Scrubbers: This type utilizes a high-velocity jet of air that creates a vacuum, causing the liquid to mix with the gas stream in a narrow, constricted throat. The Venturi scrubber is particularly effective for capturing fine particulates, such as dust and smoke, from industrial exhaust.

Spray Tower Scrubbers: These systems consist of a vertical chamber where the polluted gas is sprayed with a fine mist of liquid. Spray towers are versatile and can handle a wide range of pollutants, including acid gases and particulates.

Electrostatic Wet Scrubbers: These combine wet scrubbing with electrostatic precipitation, where particles are given an electric charge and then collected on oppositely charged surfaces. This hybrid method is highly effective for removing fine particles, oil mist, and other contaminants that traditional scrubbers might miss.

Centrifugal Scrubbers: These scrubbers use centrifugal force to separate liquid and gas phases, ensuring that the particles are trapped within the liquid. This design is best suited for systems with high particulate concentrations.

Role of Wet Scrubber Manufacturers

Wet scrubber manufacturers design, fabricate, and supply these advanced systems to meet the specific needs of industries such as power generation, chemical manufacturing, oil and gas, cement production, and waste incineration. The role of these manufacturers extends beyond just producing equipment; they play a crucial part in customizing scrubber solutions for each client’s requirements, ensuring that they comply with stringent environmental regulations while optimizing performance.

Design and Engineering: The first step in manufacturing a wet scrubber system is a detailed analysis of the air pollution characteristics in a specific industry. Wet scrubber manufacturers collaborate with clients to understand the type and concentration of pollutants, the flow rate of exhaust gases, and any specific chemical requirements. Based on these factors, they design a system tailored to the client's needs.

Material Selection: Durability is key when selecting materials for wet scrubbers. Since these systems are often exposed to corrosive gases and high moisture levels, manufacturers must choose materials like stainless steel, fiberglass, and specialized alloys that can withstand harsh operating conditions and minimize maintenance needs.

Efficiency Optimization: To ensure that the wet scrubber system is as efficient as possible, manufacturers incorporate advanced technologies like energy recovery systems, automated monitoring, and maintenance features. This ensures that the scrubbers not only clean exhaust gases effectively but also operate cost-efficiently over time.

Regulatory Compliance: Wet scrubber systems are often essential for compliance with environmental standards, such as those set by the U.S. Environmental Protection Agency (EPA) or the European Union’s Industrial Emissions Directive (IED). Manufacturers play a critical role in ensuring their systems meet these regulatory requirements, offering clients the peace of mind that they are in full compliance with air quality laws.

Maintenance and Support: Providing ongoing maintenance and technical support is a core aspect of the service offered by wet scrubber system manufacturers. Regular inspections, part replacements, and system upgrades help keep the scrubbers functioning optimally throughout their lifespan.

Importance of Wet Scrubber Systems in Industry

The importance of wet scrubbers cannot be overstated. These systems help industries reduce harmful emissions, ensuring cleaner air for surrounding communities and the environment at large. Some of the key pollutants that wet scrubbers target include:

Sulfur Dioxide (SO2): A major contributor to acid rain, sulfur dioxide is removed from industrial exhaust through scrubbing processes.

Nitrogen Oxides (NOx): These gases can cause smog and respiratory problems. Wet scrubbers help minimize their release into the air.

Particulate Matter: Fine particles, including dust, smoke, and soot, are captured by wet scrubbers to prevent them from being dispersed into the atmosphere.

Volatile Organic Compounds (VOCs): These can contribute to ozone formation and have serious health effects. Wet scrubbers help mitigate these pollutants, particularly in industries like chemical processing and petroleum refining.

Challenges Faced by Wet Scrubber Manufacturers

Despite their effectiveness, wet scrubbers come with a set of challenges. Manufacturers must continuously innovate to improve scrubber performance, minimize operational costs, and ensure that systems can handle a wide variety of pollutants. Some of the challenges include:

Energy Efficiency: While wet scrubbers are effective, they require significant energy to pump liquid and circulate air. Manufacturers are continually seeking ways to reduce the energy consumption of these systems.

Wastewater Disposal: The water used in wet scrubbers must be treated before disposal to avoid contaminating the environment. Manufacturers must design scrubbers that minimize the amount of water used and optimize water treatment processes.

Complexity of Design: As industries become more specialized, wet scrubber systems need to be increasingly customized. Manufacturers must be able to create complex designs to address specific pollutants while adhering to cost and space constraints.

Conclusion

Wet scrubber system manufacturers are key players in the global effort to combat air pollution. Through innovative designs, custom solutions, and the use of advanced materials, these manufacturers help industries meet stringent environmental standards while minimizing their environmental impact. As the world faces growing challenges related to air quality, the importance of effective pollution control systems like wet scrubbers will only continue to grow, making the work of manufacturers crucial to a cleaner and more sustainable future.

0 notes

Text

A Beginner’s Guide to Operating a Centrifuge Separator

Centrifuge separators are a crucial component in various industries, including wastewater treatment, oil and gas, mining, and food processing. These machines use centrifugal force to separate solids from liquids, enabling the efficient removal of contaminants and pollutants from wastewater. Operating a centrifuge separator requires a good understanding of its components, principles, and procedures. In this article, we will provide a beginner's guide to operating a centrifuge separator, covering the essential steps and considerations for safe and effective operation.

Pre-Operational Checks

Before starting the centrifuge separator, it is essential to perform pre-operational checks to ensure that the machine is in good working condition. This includes checking the power supply, lubrication system, and cooling system. The operator should also inspect the centrifuge separator's components, such as the rotor, bearings, and seals, for any signs of wear or damage. Additionally, the operator should review the operating manual and manufacturer's instructions to understand the specific requirements and procedures for the particular centrifuge separator model.

Start-Up Procedure

The start-up procedure for a centrifuge separator involves several steps. First, the operator should ensure that the machine is properly installed and levelled. Next, the operator should connect the power supply and turn on the machine. The centrifuge separator will then begin to rotate, and the operator should monitor the machine's performance, checking for any unusual vibrations or noises. Once the machine has reached its operating speed, the operator can start feeding the wastewater or liquid into the centrifuge separator.

Operating Parameters

To ensure optimal performance, the operator should monitor and adjust the operating parameters of the centrifuge separator. This includes the rotational speed, flow rate, and pressure. The rotational speed should be adjusted to achieve the desired separation efficiency, while the flow rate should be adjusted to match the capacity of the centrifuge separator. The pressure should be monitored to ensure that it is within the recommended range, as excessive pressure can damage the machine.

Maintenance and Troubleshooting

Regular maintenance is essential to ensure the longevity and performance of the centrifuge separator. The operator should perform routine checks and maintenance tasks, such as cleaning the machine, replacing worn-out parts, and lubricating the bearings. Additionally, the operator should be able to troubleshoot common issues, such as vibration, noise, or reduced separation efficiency. The operator should consult the operating manual and manufacturer's instructions for guidance on maintenance and troubleshooting procedures.

Safety Considerations

Operating a centrifuge separator can be hazardous if proper safety precautions are not taken. The operator should wear personal protective equipment, such as gloves, safety glasses, and a face mask, to protect against potential hazards. The operator should also ensure that the machine is properly installed and levelled to prevent accidents. Additionally, the operator should follow proper lockout/tagout procedures when performing maintenance or repairs to prevent accidental start-up.

Shut-Down Procedure

The shut-down procedure for a centrifuge separator involves several steps. First, the operator should stop feeding the wastewater or liquid into the machine. Next, the operator should reduce the rotational speed and allow the machine to come to a complete stop. The operator should then disconnect the power supply and perform a final inspection of the machine to ensure that it is in good working condition.

Conclusion

In conclusion, operating a centrifuge separator requires a good understanding of its components, principles, and procedures. By following the pre-operational checks, start-up procedure, operating parameters, maintenance and troubleshooting, safety considerations, and shut-down procedure, operators can ensure safe and effective operation of the centrifuge separator. Remember to always consult the operating manual and manufacturer's instructions for specific guidance on operating and maintaining your centrifuge separator.

0 notes

Text

Types and Applications of Air Compressors

An air compressor transforms power also known as pneumatic device (from diesel engine, electric motor, another engine, etc.) into potential energy stored in pressured air. By 2030, it is predicted that the air compressor industry would be worth $45,888.0 million.

The increased need for environmentally friendly air compressors throughout the world, the availability of cutting-edge manufacturing facilities, growing industrialization, and technical breakthroughs will all play a significant role in this.

Rotary Screw Compressors

Rotary screw air compressors are frequently big, industrial-sized devices that may either run on oil or without oil for lubrication.

Moreover, two internal, counter-rotating rotors in rotary screw air compressors provide energy. A pressure buildup occurs inside the housing as a result of the air becoming trapped among the two opposing rotors. These air compressors, which have a power range of 5 to 350 horsepower, are made for continuous usage thanks to their inbuilt cooling system.

Reciprocating Compressor

The reciprocating compressor is another popular type of displacement compressors. These are often seen at smaller building sites, including garages and residential homes. Such compressors are not intended for continuous usage, in contrast to the rotary screw compressor.

Further, the moving components of a reciprocating air compressor are more numerous than those in a rotary screw compressor, and they are maintained with oil to ensure smoother operation.

These air compressors function by compressing and displacing the air inside a cylinder to increase pressure. The pressure ranges that reciprocating compressors may reach might be single- or multi-stage variations.

Centrifugal Compressors

To create potential energy, centrifugal air compressors delay and cool the incoming air as it passes through a diffuser. Centrifugal compressors can generate a large quantity of energy in a comparatively compact machine because of the multi-phase compression process.

They need less care than reciprocating or rotary screw compressors, and certain varieties may create air without oil. Since they have a maximum horsepower of 1,000, they are often employed for more difficult building sites like chemical factories or steel manufacturing facilities.

What Are The Applications of Air Compressor?

Air compressors can be used for a variety of tasks, such as providing high-pressure, clean air to fill gas cylinders, clean air to a submerged surface supplied diver, moderate-pressure, and moderate-pressure, clean air to drive some pneumatic HVAC control system valves in office and educational buildings.

It is providing a significant quantity of moderately pressured air to fuel pneumatic equipment like jackhammers, fill HPA tanks, fill tires, and generate significant amounts of moderately pressured air for significant amounts of industrial operations.

In addition, air compressors are frequently used in drilling, mining, and the oil

and gas industries to aerate drilling fluids, flush out pipelines, and flush out flushing medium.

Most air compressors are either rotary vane, rotary screw, or reciprocating piston types. While reciprocating, rotary screws and scroll air compressors are preferred for small and medium-sized applications, centrifugal compressors are frequently used in very large applications.

Source: P&S Intelligence

#Air Compressor Market Share#Air Compressor Market Size#Air Compressor Market Growth#Air Compressor Market Applications#Air Compressor Market Trends

1 note

·

View note

Text

Enhance Oil Quality with Laser Particle Counters

Maintaining clean oil is vital to ensuring the smooth operation of machinery and extending its lifespan. Laser Particle Counters from AR Engineering are the perfect solution for real-time monitoring of oil cleanliness. These advanced devices are designed to measure particles in oils, such as turbine oils, transformer oils, gear oils, and more, helping industries maintain oil purity and reduce wear and tear on machinery.

AR Engineering is India's most trusted brand in oil filtration machines, offering high-quality laser particle counters for precise oil testing. These counters use laser technology to detect particles in the oil, providing an accurate count of contaminants in real time. With this data, industries can take proactive measures to maintain the health of their systems.

Key Benefits of Laser Particle Counters

��� High-precision particle detection in turbine oil cleaning systems ✅ Continuous real-time monitoring of oil quality ✅ Easy integration with oil filtration machines, including mobile oil filtration plants and portable oil filtration systems ✅ Ideal for oil filtration systems and oil cleaning machines to maintain operational efficiency ✅ Reduces equipment downtime by detecting contamination early

Laser particle counters are critical tools for industries that rely on clean oil to power their machinery. Whether used in industrial oil filtration systems, transformer oil filtration plants, or gear oil filtration systems, these counters help you ensure optimal performance, reducing the risk of failure due to oil contamination.

At AR Engineering, we specialize in providing innovative and reliable solutions, such as laser particle counters, that make oil filtration and cleaning more effective. By incorporating these counters into your operations, you ensure your machinery remains protected, efficient, and long-lasting.

👉 Learn more: https://oilfiltermachineindia.com/laser-particle-counters.html

#Turbine Oil Cleaning System#Oil Cleaning Machines#Turbine Oil Cleaning Systems#Oil Filtration Plant#Gear Oil Filtration Systems#Industrial Oil Filter Machine#Oil Filtration Systems#Double Stage Oil Transformer Machine#Oil Filtration Elements#Oil Filtration Machine#Oil Filtration & Cleaning Systems#Thermic Oil Filtration Systems#On Site Oil Testing#Online Oil Cleaning Systems#Hydraulic Oil Online Filters#Mobile Oil Filtration Plant#Portable Oil Filtration Plant#Portable Oil Filtration System#Turbine Oil Filtration Plant#Turbine Oil Filtration Machine#Transformer Oil Filtration System#Transformer Oil Cleaning Systems#Evacuation System for Transformers#Transformer Oil Filtration Plant#Two Stage Transformer Oil Filtration Plant#Transformer Evacuation System#Transformer Oil Filtration Machine#Transformer Oil Filter Machine#Turbine Oil Flushing System#Centrifugal Oil Cleaner

0 notes

Text

Zero Hold Up Filter Press

Zero Hold Up Filter Press uses for filtration of liquid by separating solid from the liquid. Adhering cGMP and FDA compliance, out filter press machine equipped with gear pump, centrifugal pump or lobe pump as specific process requirements. Filtration assembly has modern design to achieve optimum process output. Perforated screens, filter plates, spacers and filter pad organized in such a way to obtain hassle free productivity.

The Zero Hold Up Filter Press mostly uses for syrup and suspension filtration in pharmaceutical industry. Syrup Filter Press also find usage in other wide range of industries such as distillery, food ingredients, organic chemicals, resin, ink, oil and many more. Filter pad and disc organized in a manner which separates solid cake from the flow of liquid. Dome structure at top enables easily removing of cartridge assembly for cleaning of pad and cake removal. Variety of pad can be use depending upon different product types requirements. Features of continuous process and zero holding material within chamber named it Zero Hold Up Filter Press.

Syrup Filter Press uses to achieve absolute filtration results of high value products. Notably equipments meets cGMP and FDA requirements laid down in pharmaceuticals, nutraceuticals and allied industries. Apart from Syrup, Suspension & Oral Liquid these Filter Press Machine having wide usage in beverage industry for filtration of aerated beverages. Equipment proved its importance in food industry for filtration of pulp based drinks with utmost accuracy. Toxic, dangerous, and explosive liquids can readily be filtered thanks to the press’s included cake filter aid and solids. Due to reverse flow of liquid there is zero hold up in chamber which ensure complete filtration of load. It offers one pass clarity, homogeneous cake distribution across all plates. Design is so simple that drying of the cake can be performed with simple air and nitrogen purging.

0 notes

Text

Maintenance and Cost Efficiency of Glass-Fused-to-Steel Tanks as Sedimentation Tanks for Municipal Wastewater Treatment

Maintenance and Cost Efficiency of Glass-Fused-to-Steel Tanks as Sedimentation Tanks for Municipal Wastewater Treatment

At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we are committed to providing top-quality storage solutions for various industries, including municipal wastewater treatment. Our Glass-Fused-to-Steel (GFS) tanks are widely recognized for their durability, efficiency, and long lifespan, making them the ideal choice for critical applications such as sedimentation tanks in municipal wastewater treatment plants.

As a global leader in Glass-Fused-to-Steel tank technology, Center Enamel has developed cutting-edge solutions for sedimentation and other wastewater treatment processes. Our tanks are designed with a focus on maintenance and cost efficiency, offering a reliable and sustainable solution for municipal treatment systems worldwide.

What Are Glass-Fused-to-Steel Sedimentation Tanks?

Sedimentation tanks are an essential part of the wastewater treatment process, designed to remove suspended solids from raw or treated wastewater. The process works by allowing wastewater to flow into a large tank, where gravity causes particles to settle to the bottom, separating them from the clearer water. The settled particles, called sludge, are then removed, leaving the clean water to undergo further treatment.

Glass-Fused-to-Steel (GFS) tanks are constructed by bonding glass to steel at high temperatures, creating a highly durable and corrosion-resistant tank. This fusion results in a tank that combines the strength of steel with the non-corrosive, smooth surface of glass, making it ideal for challenging wastewater treatment environments.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Glass-Fused-to-Steel Tanks for Sedimentation?

1. Superior Durability and Corrosion Resistance

One of the most significant benefits of Glass-Fused-to-Steel tanks is their superior corrosion resistance. Wastewater treatment environments are often exposed to harsh chemicals, acids, and alkalis that can cause other materials to degrade over time. The glass coating protects the steel tank from corrosion, ensuring it lasts much longer than traditional steel or concrete tanks.

Additionally, GFS tanks can withstand fluctuations in pH levels and the chemical composition of wastewater, making them a reliable choice for sedimentation purposes in municipal wastewater treatment plants.

2. Low Maintenance Costs

Glass-Fused-to-Steel tanks require far less maintenance compared to other types of tanks used in wastewater treatment. The glass coating provides a smooth, non-porous surface that resists algae growth, scale, and other forms of contamination that commonly accumulate in tanks. This minimizes the need for frequent cleaning and repairs, ultimately reducing maintenance costs.

Moreover, the bolted construction of GFS tanks ensures that they can be easily repaired or expanded if necessary. Unlike welded tanks, GFS tanks allow for quick and cost-effective maintenance, further driving down the total cost of ownership over their long lifespan.

3. Quick Installation and Operational Efficiency

GFS tanks feature bolted construction, which allows for faster and more efficient installation compared to welded or concrete tanks. This reduces construction timelines and labor costs, enabling municipalities to begin using the sedimentation tanks sooner.

The modular design of GFS tanks also means that they can be customized in size and capacity to meet the specific needs of a given wastewater treatment plant. This flexibility allows for easy integration into existing treatment systems or for future expansions as treatment requirements grow.

Key Benefits of GFS Sedimentation Tanks

1. Long Service Life

With resistant glass coating and steel’s inherent strength, GFS sedimentation tanks are designed to last for decades. Their longevity not only ensures that they remain functional and efficient throughout their service life but also minimizes the need for costly replacements or repairs.

2. Enhanced Performance in Sedimentation

The smooth, glass-coated surface of the tank reduces friction and turbulence, allowing for more efficient sedimentation of suspended solids. This means that the water flows through the tank more evenly, and particles settle at the bottom faster, improving the overall performance of the wastewater treatment process.

3. Environmentally Friendly

GFS tanks contribute to environmentally sustainable wastewater treatment. By effectively removing suspended solids from wastewater, they help protect local water resources from pollution. Additionally, the long lifespan of GFS tanks means that they reduce the environmental impact associated with the disposal of aging or degraded tanks.

4. Cost Efficiency

The low maintenance, quick installation, and long-lasting durability of GFS tanks make them highly cost-effective over the long term. Municipalities can save money on repair and replacement costs, as well as on energy usage and labor for maintenance activities. Furthermore, GFS tanks require fewer resources to manufacture compared to traditional materials like concrete, making them an environmentally and economically sustainable choice.

Why Center Enamel is the Preferred Choice for GFS Sedimentation Tanks

At Center Enamel, we have been leading the Glass-Fused-to-Steel tank industry for over 30 years, providing reliable storage solutions to more than 100 countries. Our products are engineered to meet the highest standards of quality, safety, and performance, ensuring that municipal wastewater treatment systems benefit from cutting-edge technology.

Here’s why municipalities and wastewater treatment plants prefer our GFS sedimentation tanks:

Proven Expertise: With a track record of successful installations in over 100 countries, we understand the unique needs of wastewater treatment projects and offer tailored solutions to meet local requirements.

World-Class Manufacturing: Our tanks are manufactured according to the AWWA D103-09 and ISO 28765 standards, ensuring they meet the highest quality and performance benchmarks.

Comprehensive Support: From consultation to installation and after-sales service, Center Enamel offers full project support to ensure the success of every installation.

Sustainable Solutions: We are committed to promoting environmental sustainability, and our GFS tanks contribute to cleaner water and reduced operational costs.

Applications of GFS Sedimentation Tanks in Municipal Wastewater Treatment

Our Glass-Fused-to-Steel sedimentation tanks are suitable for a wide range of applications in municipal wastewater treatment, including:

Primary Sedimentation: Removing large particles and suspended solids from raw wastewater before biological treatment.

Secondary Sedimentation: Further treatment of effluent after the biological process, helping remove remaining solids before discharge.

Sludge Management: Storing and managing sedimentation sludge in a safe, efficient manner.

Case Studies of Successful GFS Sedimentation Tank Installations

1. Hong Kong Municipal Wastewater Treatment Project

Center Enamel provided GFS sedimentation tanks for a major municipal wastewater treatment plant in Hong Kong. The tanks successfully handled large volumes of wastewater, providing efficient sedimentation and helping the plant meet stringent environmental regulations. The low maintenance requirements of the GFS tanks ensured long-term cost savings for the municipality.

2. Saudi Arabia Wastewater Treatment Facility

In Saudi Arabia, our GFS sedimentation tanks were used in a wastewater treatment facility serving a large urban population. The tanks demonstrated excellent corrosion resistance and operational efficiency, even under extreme environmental conditions, contributing to the plant’s success in providing high-quality treated water.

The Future of Sedimentation in Municipal Wastewater Treatment

Center Enamel’s Glass-Fused-to-Steel sedimentation tanks offer a combination of long-lasting durability, low maintenance, and cost efficiency that make them the ideal choice for municipal wastewater treatment plants. Our tanks are engineered to meet the highest standards of quality and performance, ensuring they continue to operate reliably for decades.

Whether you are designing a new wastewater treatment facility or upgrading an existing one, Center Enamel provides the perfect storage solution to optimize your sedimentation process and help you achieve clean, sustainable water management.

Contact us today to learn more about how our Glass-Fused-to-Steel sedimentation tanks can improve your wastewater treatment operations!

0 notes

Text

Oil and water separator: an essential equipment

Oil and water separator: an essential equipment

The oil-water separator is an important equipment that is used to separate oil and water. It is widely used in industrial, marine, and environmental applications. In this blog, we will discuss the importance, function, and different types of oil and water separators.

What is an oil-water separator?

An oil and water separator is a device designed to separate water from oil-mixed liquids. Its main objective is to prevent water pollution and protect the environment.Procedure

An oil and water separator separates oil from water using gravity and other physical principles. Oil is less dense than water, so when the mixture is poured into the separator, the oil floats on the surface of the water. The purified water is separated and collected by pumping it out.Kind of

Gravity Separator: This is the simplest type of separator, which works on the principle of gravity. It is useful for separating large particles and oil droplets. Coplaser Separator: This separator collects the small oil particles and converts them into larger particles, making it easier to separate the oil. Virtex separator: This separator uses a special design in which the rotating fluid creates a centrifugal force, separating oil and water. Membrane-Based Separator: This separator uses a membrane that allows only water to pass through and blocks oil. Use

Industrial Sector: It is widely used in the oil refining, petrochemical, and food processing industries. It helps in wastewater treatment and ensures compliance with environmental standards. Marine Applications: Used to prevent oil spills on ships and clean up the sea. Vehicle Service Center: Used in automobile workshops for oil extraction and recycling. Catering Industry: Helps in the disposal and recycling of cooking oil.

Environmental importance

Oil and water separators play an important role in protecting the environment. It protects water from oil pollution, which can be harmful to aquatic life and human health. This will reduce the risk of pollution and keep the water clean.

Conclusion

Oil and water separators are important equipment that helps prevent pollution and protect the environment in various industries. Its effective functionality and versatility make it suitable for a wide range of uses. Choosing the right type and proper maintenance ensures its effectiveness. The need of the hour is to increase the use of oil and water separators, considering environmental safety.

Final Thoughts In the future, technological advancements in oil and water separators may further increase their efficiency. This will lead us towards a clean and safe environment. Efforts in this direction will ensure a healthy and green future for our coming generations.

0 notes

Text

The Power of Centrifugal Screens: Enhancing Efficiency and Quality in Filtration

In various industries, the need for effective separation processes is critical to ensuring product quality and operational efficiency. One technology that has gained significant traction in filtration applications is the centrifugal screen. These innovative devices harness centrifugal force to separate solids from liquids, making them invaluable in sectors such as food processing, pharmaceuticals, and chemical manufacturing. In this article, we’ll explore the fundamentals of centrifugal screens, their applications, and their benefits.

What Are Centrifugal Screens?

Centrifugal screens are filtration devices designed to separate solid particles from liquid streams. They operate on the principle of centrifugal force, which is generated when the screen is spun at high speeds. As the liquid enters the screen, the centrifugal force pushes the solids against the screen’s mesh, allowing the clean liquid to pass through while retaining the larger particles.

Key Components:

Rotating Drum: The heart of the centrifugal screen, where the separation occurs. The drum spins at high RPMs, generating the necessary centrifugal force.

Mesh Screen: The filtration medium that retains solids while allowing liquids to flow through. Different mesh sizes can be selected based on the application requirements.

Inlet and Outlet: These allow for the introduction of the liquid mixture and the collection of the filtered liquid, respectively.

Applications of Centrifugal Screens:

Centrifugal screens are versatile and can be utilized across various industries. Here are some common applications:

Food Processing

In the food industry, centrifugal screens are used for separating pulp from juices, filtering oils, and clarifying liquids. They ensure that products meet safety and quality standards while optimising yield.

Pharmaceuticals

In pharmaceutical manufacturing, maintaining purity is paramount. Centrifugal screens help in the filtration of active ingredients and solvents, ensuring that the final products are free from contaminants.

Chemical Manufacturing

Chemical processes often involve the separation of solids from liquids. Centrifugal screens facilitate this process, improving efficiency and reducing waste.

Wastewater Treatment

Centrifugal screens play a crucial role in municipal and industrial wastewater treatment by separating solids from effluents, thus helping in compliance with environmental regulations.

Benefits of Using Centrifugal Screens:

High Efficiency

Centrifugal screens operate at high speeds, allowing for rapid and efficient separation. This leads to increased throughput and reduced processing times compared to traditional filtration methods.

Customization

These screens can be tailored to fit specific applications, with options for different mesh sizes, materials, and designs. This customization ensures optimal performance based on the unique needs of each process.

Reduced Maintenance

Centrifugal screens are designed for easy cleaning and maintenance. Their straightforward design allows operators to quickly disassemble and reassemble the equipment, minimizing downtime.

Improved Product Quality

By effectively removing unwanted solids, centrifugal screens enhance the quality of the final product. This is especially important in industries where purity and safety are critical.

Conclusion

Centrifugal screens represent a powerful solution for solid-liquid separation across multiple industries. Their high efficiency, customization options, and ability to improve product quality make them an essential tool in modern filtration processes. As industries continue to evolve and demand greater efficiency, the role of centrifugal screens will undoubtedly expand, contributing to more streamlined operations and enhanced product integrity.

If you're considering upgrading your filtration systems, centrifugal screens from Fine Perforators, the premier manufacturers and exporters of Centrifugal screens, might be the key to unlocking new levels of efficiency and quality in your operations.

Source: https://www.linkedin.com/pulse/power-centrifugal-screens-enhancing-efficiency-fine-perforators-tomac/

#centrifugal screen#fundamentals of centrifugal screens#principle of centrifugal force#role of centrifugal screens#manufacturers and exporters of Centrifugal screens

0 notes

Text

How to Choose the Right Compressor Oils for Maximum Efficiency

Choosing the right compressor oil is essential for maintaining maximum efficiency, reducing wear, and extending the lifespan of a compressor. The performance and reliability of compressors are directly influenced by the type and quality of oil used, making it critical for users to understand the factors involved in selecting the optimal lubricant. One of the first aspects to consider is the compressor type—whether it is a rotary screw, reciprocating piston, or centrifugal compressor. Different compressors have unique operational demands, Vacuum Hoses and selecting an oil designed specifically for the type ensures better lubrication and thermal management. For instance, rotary screw compressors often benefit from synthetic oils due to their excellent high-temperature stability and resistance to oxidation, whereas reciprocating piston compressors may perform well with mineral-based oils designed for lower operating temperatures.

The oil’s viscosity grade is another crucial parameter to evaluate. Viscosity affects how well the oil coats the moving parts of the compressor and maintains a sufficient film strength under varying loads and temperatures. A lubricant that is too thin may fail to protect the components adequately, leading to accelerated wear, while an oil that is too thick can increase energy consumption and reduce efficiency. Manufacturers typically recommend specific viscosity grades based on their equipment’s design specifications and intended operating conditions. It is advisable to follow these guidelines closely to ensure optimal performance.

Compressor oils are also classified based on their base stock—mineral, synthetic, or semi-synthetic. Mineral oils are refined from crude oil and generally cost less, making them suitable for applications where budget is a concern and operating conditions are moderate. However, for higher efficiency and prolonged oil change intervals, synthetic oils are often the better choice. These oils are engineered to offer superior resistance to thermal breakdown, better flow characteristics at varying temperatures, and lower volatility, which translates to fewer top-offs and longer service life. Semi-synthetic blends can offer a balance between cost and performance, providing enhanced protection and stability compared to mineral oils while being more budget-friendly than full synthetic options.

Additives play an essential role in the overall performance of compressor oils. Anti-wear agents, antioxidants, and anti-foaming additives help in reducing the formation of sludge and varnish, which can impede efficiency and clog the system. Anti-corrosion agents also protect metal surfaces from rust and oxidation, ensuring that internal parts remain intact over time. Users should choose oils with high-quality additive packages tailored to the specific demands of their operations, as this can significantly impact both efficiency and the lifespan of the equipment.

Environmental and operating conditions are key factors to keep in mind. High temperatures, humid environments, and heavy-duty use can demand oils with exceptional thermal and oxidation stability. Conversely, compressors used in clean and climate-controlled environments may not require oil with as robust a formulation, allowing for more flexible oil choices. It is also important to consider the oil’s compatibility with seals and gaskets in the compressor to prevent leaks and maintain efficient operation.

Regular monitoring and maintenance complement the choice of the right compressor oil. Oil analysis programs can help detect changes in viscosity, contamination, and the breakdown of additives, allowing users to proactively replace or top up oil before performance is compromised. By taking a strategic approach to oil selection and maintenance, businesses can achieve maximum efficiency, minimize downtime, and extend the overall operational life of their compressors.

1 note

·

View note

Text

Pumps in Industrial Automation and Marine Automation: A Comprehensive Guide

Introduction:

What is Pumps?

A pump is a mechanical device designed to move fluids (liquids, gases, or slurries) from one place to another by creating pressure or a vacuum. It operates by converting mechanical energy from a power source (e.g., electric motor, engine) into hydraulic energy, resulting in fluid flow. Pumps are used across various industries to manage and regulate the flow of substances, making them vital for maintaining processes like water circulation, fuel transfer, chemical processing, and wastewater management.

In simple terms, a pump acts as the “heart” of many systems, ensuring the movement and distribution of fluids to keep processes running smoothly and efficiently.

Understanding Pumps in Automation:

In the realm of automation, pumps are integral components that ensure the seamless and efficient movement of fluids within a system. Whether used in industrial processes or marine operations, pumps facilitate automated systems by regulating the flow and pressure of fluids in real-time. Let’s delve into how pumps function in automation and their role in enhancing efficiency:

Role of Pumps in Automation Systems

Fluid Management: Pumps in automation manage the transport of liquids and gases, which is essential for cooling, lubrication, heating, and cleaning processes.

System Efficiency: By maintaining consistent flow and pressure, pumps ensure that automated systems operate smoothly, reducing the chances of downtime or failures.

Remote Control and Monitoring: In advanced automation setups, pumps are often integrated with control systems like PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition), enabling remote monitoring, operation, and adjustments.

Types of Pumps Used in Automation

Centrifugal Pumps: These pumps use rotational energy to move fluids. Commonly used in industries like chemical processing and water treatment, centrifugal pumps offer high flow rates and are ideal for handling low-viscosity fluids.

Positive Displacement Pumps: These pumps move a fixed volume of fluid per cycle, making them ideal for precise fluid control in automated systems. They are often used for high-viscosity fluids, chemical dosing, and hydraulic applications.

Submersible and Vacuum Pumps: Used for specific tasks like wastewater management, slurry handling, or creating vacuum conditions, these pumps provide essential functionality in various automation setups.

Importance of High-Quality Pumps in Automation

Reliability: Top-quality pumps ensure consistent performance, reducing the risk of system failures and minimizing downtime in automation processes.

Energy Efficiency: Advanced pumps are designed to be energy-efficient, contributing to overall cost savings and sustainable operations.

Adaptability: In automated environments, pumps need to adapt to varying fluid demands and pressure requirements, making flexible design and technology integration vital for effective operation.

Integration with Automation Technology

Sensors and IoT Integration: Modern pumps are often equipped with sensors that monitor flow rate, pressure, and temperature, feeding real-time data to automation control systems. Integration with the Internet of Things (IoT) further enhances predictive maintenance and operational efficiency.

Smart Control Systems: Pumps in automation are increasingly connected to AI-driven control systems, which allow for self-adjustment based on operational needs, optimizing performance while reducing energy consumption.

Applications of Pumps in Industrial and Marine Automation

Industrial Automation: In industries like oil and gas, chemical manufacturing, HVAC, and food processing, pumps maintain critical functions like fluid transfer, chemical dosing, and process cooling.

Marine Automation: In marine systems, pumps manage bilge water removal, ballast operations, fuel transfer, and cooling systems, ensuring vessel safety and operational efficiency.

In summary, pumps are more than just fluid-moving devices; they are essential components that drive automated processes across industries. Their integration with modern control systems and technologies makes them indispensable for achieving efficiency, reliability, and adaptability in automated operations.

0 notes