#Caustic soda lye 32%

Explore tagged Tumblr posts

Text

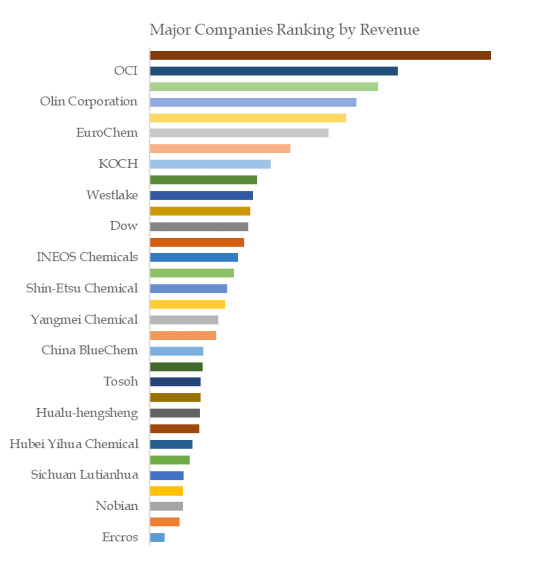

Global Top 32 Companies Accounted for 41% of total Caustic Soda and Urea market (QYResearch, 2021)

Sodium hydroxide is also known as caustic soda, caustic, and lye. Anhydrous (100%, solid) caustic soda has a chemical formula of NaOH and a molecular weight of 40.00.

Urea, also known as carbamide, is an organic compound with chemical formula CO(NH2)2. This amide has two –NH2 groups joined by a carbonyl (C=O) functional group. Urea serves an important role in the metabolism of nitrogen-containing compounds by animals and is the main nitrogen-containing substance in the urine of mammals. It is a colorless, odorless solid, highly soluble in water, and practically non-toxic. Urea is widely used in fertilizers as a source of nitrogen and is an important raw material for the chemical industry.

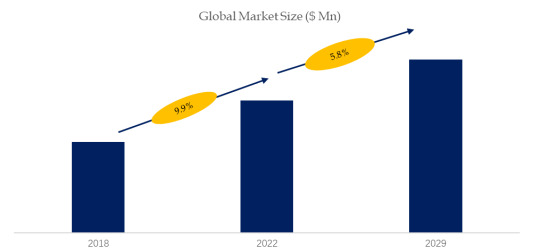

According to the new market research report “Global Caustic Soda and Urea Market Report 2023-2029”, published by QYResearch, the global Caustic Soda and Urea market size is projected to reach USD 156.31 billion by 2029, at a CAGR of 5.8% during the forecast period.

Figure. Global Caustic Soda and Urea Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Caustic Soda and Urea Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch..

Figure. Global Caustic Soda and Urea Top 32 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Caustic Soda and Urea Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

The global key manufacturers of Caustic Soda and Urea include Yara, OCI, CF Industries, Olin Corporation, QAFCO, EuroChem, Nutrien, KOCH, OxyChem, Westlake, etc. In 2021, the global top five players had a share approximately 17.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Case study of Caustic Soda: A Deep Dive into the Technologies and Applications

Caustic soda, also known as sodium hydroxide (NaOH), is a chemical powerhouse with a surprisingly wide range of applications. From its role in manufacturing aluminum to keeping our homes clean, caustic soda's high reactivity and strong base properties make it a vital ingredient in countless processes.

This blog post will delve into the fascinating world of caustic soda, exploring its various forms, production methods, and the key sectors that rely on its unique properties. We'll uncover how caustic soda helps make everything from soap and detergents to textiles and paper products, and even plays a crucial role in water treatment and alumina production.

Introduction

Caustic Soda, or sodium hydroxide, serves as a fundamental ingredient extensively utilized across a broad spectrum of industries, either in its pure form or as a supplementary agent. It is available commercially in two primary forms: firstly, as a diluted solution, commonly referred to as lye, with concentrations typically ranging between 30-32% and 48-50%; secondly, in its solid state, presented as flakes, prills (pearls), or granules.

Caustic soda pearls, also known as sodium hydroxide pearls, beadles, or soda grains, are a type of caustic soda designed specifically for filtration applications. These odorless, spherical beads are about 0.7mm in diameter and can withstand temperatures up to 80 degrees Celsius. Their shape and size make them ideal for use in mash filters and vessels within the filtration process.

Caustic soda flakes, another form of sodium hydroxide, are created by boiling down a caustic soda solution until all the water evaporates. The remaining solid is then crushed into flakes, typically measuring between 0.8mm and 1.2mm in diameter and having a characteristic white color.

These flakes are industrial workhorses, playing a vital role in various sectors.

Textile engineering: Caustic soda flakes help treat fabrics during processing.

Soap and detergent manufacturing: They are a key ingredient in the production of many soaps and detergents.

Paper and pulp industries: Caustic soda flakes contribute to the process of creating paper products.

Alumina refineries: They are essential for extracting alumina from bauxite ore, a critical step in aluminum production.

Caustic Soda Liquid: Unlike its white counterparts, caustic soda liquid is a transparent solution, also known as caustic soda 50%, sodium hydroxide in an aqueous solution, or simply lye solution.

Manufacturing Processes

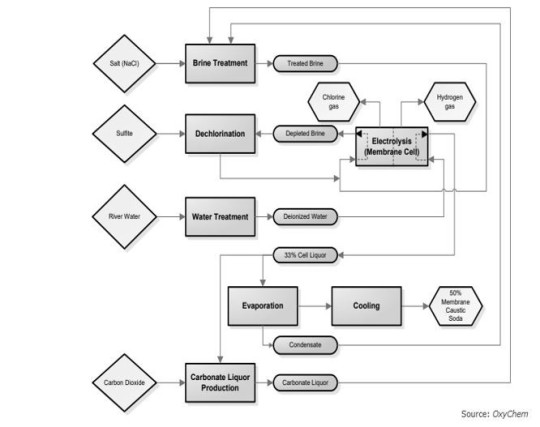

Membrane Cell Process

The membrane cell technique for producing Sodium Hydroxide (NaOH) typically yields approximately 13 percent NaOH. This method employs a specialized membrane to selectively separate Chlorine and Sodium ions. The membrane allows Sodium ions to pass through while retaining Chlorine gas and the salt (brine) solution in a separate compartment. These Sodium ions then react with purified water, akin to the mercury cell method, resulting in the production of Caustic Soda (NaOH). Evaporation is utilized to attain a nominal 50 weight percent solution. The distinctive diffusion properties of the membranes and the decreased evaporation volume in this process lead to less extensive targeting of salt concentrations.

Let’s discuss this process in further detail:

Each chlorine production cell features two electrical contact points: the anode and the cathode, which are divided by an ion-exchange membrane. This membrane selectively permits the passage of sodium ions and a minimal amount of water, guiding them towards the negatively charged cathode.

At the cathode, water undergoes electrolysis, resulting in the formation of hydrogen gas, which is released as bubbles and collected. The remaining caustic solution exits the cell at approximately 30% concentration before often undergoing further concentration to reach a 50% concentration outside the cell.

On the opposite side of the membrane, chlorine gas is produced at the anode, causing the "spent" brine to be replenished with additional solid salt before undergoing purification using an ion exchanger. The chlorine gas typically contains traces of oxygen and often requires purification through liquefaction and evaporation processes.

This method boasts the lowest consumption of electric energy among the three processes, with the steam required for caustic concentration being relatively minimal (less than one tonne per tonne of caustic soda).

Diaphragm Cell Process

The diaphragm cell method employs an asbestos separator to efficiently segregate sodium hydroxide and chlorine, which are the primary outputs of the reactions taking place within the cell. This process generates a liquid referred to as 'Cell liquor,' a diluted alkali solution containing approximately 12 to 14 percent sodium hydroxide by weight, along with a consistent quantity of salt. To attain a 50 percent sodium hydroxide solution, the resulting alkali solution undergoes evaporation to increase the concentration of NaOH. Moreover, this procedure facilitates the extraction of excess salt for recycling back into the cycle.

The sodium hydroxide produced through this technique is recognized under various designations such as Diaphragm cell-grade caustic soda, commercial grade, technical grade, and technical diaphragm. Another grade of caustic soda, known as sublime grade, can be obtained through further concentration of the 50% solution by evaporation, followed by dilution to reduce the salt content in the solution. The process of elevating the alkali concentration from diaphragm cells necessitates considerable heat for water evaporation and concentration enhancement. Despite the substantial heat requirement, diaphragm cells can prove to be more economically viable in comparison to other processes, particularly when steam costs are low, and they involve lower construction expenses.

Major Applications of Caustic Soda

Soaps & Detergents

Caustic soda finds application in the production of soaps and various detergents, many of which are utilized in household and commercial settings, including products like oven cleaners and chlorine bleach.

Aluminium

Caustic soda is employed in the extraction of alumina from bauxite. Alumina, in turn, serves as a key component in the manufacturing of aluminum and a diverse array of items such as foil, cans, and airplane components. Within the realm of building and construction, aluminum finds application in materials utilized for embellishing building exteriors and crafting window frames.

Paper & Pulp

In numerous paper-making procedures, wood undergoes treatment with a solution comprising sodium sulfide and sodium hydroxide. This process yields pure cellulose, which forms the foundation for producing paper sheets. Caustic soda plays a crucial role in the pulp and paper industry by facilitating the removal of impurities such as lignin, oleoresin, and waxes from the raw wood.

Water Treatment

In the procedure of water purification, the addition of caustic soda serves a multifaceted purpose. By adjusting the pH of water, caustic soda plays a pivotal role in mitigating the corrosive nature of water, thereby safeguarding the integrity of infrastructure and plumbing systems through the reduction of corrosive effects on pipes and fittings. Furthermore, this pH adjustment process aids in the precipitation and removal of toxic metals that may be dissolved in the water, contributing to the enhancement of water quality and safety standards.

Market Outlook

The global caustic soda market is poised for significant growth, driven by a substantial demand for alumina across various industries. Caustic soda, also known as sodium hydroxide, plays a pivotal role in the extraction of alumina, a prevalent oxide of aluminum, from naturally occurring mineral deposits. Its application extends across a diverse range of sectors including automotive, construction, and consumer goods like soda cans and food packaging. Alumina, derived through the utilization of caustic soda, finds extensive use in the automotive industry owing to its ability to enhance performance, fuel efficiency, and environmental friendliness without compromising safety or durability in vehicles. Moreover, caustic soda, in its various forms such as lye and flakes, serves as a crucial ingredient in the manufacturing processes of soaps, cleaners, and detergents. Sodium hydroxide flakes exhibit exceptional properties in dissolving oils, grease, and protein-based deposits, making them indispensable in the saponification process for converting vegetable oils into soap. Additionally, they contribute to the production of anionic surfactants, vital components in numerous detergent and cleaning formulations.

Caustic Soda Main Players

Top players operating in the Global Caustic Soda market are Olin Corporation., Formosa Plastics Corporation USA, Dow Chemical, Shintech, Westlake Chemical, Kem One,Covestro AG, Oxychem, Xinjiang Zhongtai Chemical Co., Ltd., INOVYN, Grasim Industries Limited, Tosoh Corporation, Dongying Jingling Chemical, and Others.

Conclusion:

Caustic soda plays a vital role in various sectors, such as in the Bayer's process, where it is utilized for extracting alumina from bauxite ore. In this process, a concentrated solution of caustic soda dissolves alumina to create sodium aluminate, from which alumina is subsequently separated through a reverse reaction. In the chemical industry, caustic soda serves as a crucial raw material, functioning as an intermediate, reactant, pH regulator, and aiding in acidic waste treatment. The escalating demand for caustic soda is attributed to the heightened demand for caustic soda spans various applications including chemicals, alumina, soaps & detergents, and pulp & paper products.

0 notes

Text

Manufacturer and Supplier of CAUSTIC SODA LYE

Meghmani Finechem Limited (MFL) is a leading Manufacturer and Supplier of CAUSTIC SODA LYE 32% & 48% at Dahej, Bharuch, India. The product is produced with the Membrane technology from AKCC, Japan.

CAUSTIC SODA LYE 32% SPECIFICATIONS

CAUSTIC SODA LYE 48% SPECIFICATIONS

APPLICATIONS

Pulp & paperTextilesSoaps and DetergentsChemical ProcessSoda BleachViscose FiberDyes and Dyes IntermediateInorganic chemicals such as Sulphites, Phosphites, etcAgro Chemicals ADVANTAGES

Wide Application of product like cleaning and disinfection, Pahrma and medicine, Energy, Water Treatment and Food ,wood and paper product and alumina ore processing and may industrial usesHaving low impurities of heavy metals like IRON, Lead, copper, nickel, Aluminium and Mercury free productMatching with food grade productManufacturing through world best technology like AKCC – JapanThe Manufacturing Process is environmentally safe , not harm on environment.

CONTACT DETAILS

“Meghmani House”, B/h Safal Profitaire, Corporate Road, Prahladnagar, Ahmedabad – 380015, Gujarat (India). Phone No.: +91 79 29709600 / 71761000 Fax: + 91 79 29709605 Email: [email protected]

0 notes

Link

Aug 23, 2021

Market sources reported that caustic soda lye prices were reduced in Dahej today. According to sources, with effect from August 23, 2021, caustic soda lye prices at Dahej are down by Re.0.50/Kg basic. The new basic price is Rs.32/Kg

0 notes

Text

Global Sodium Hydroxide Market Size, Manufacturers, Supply Chain, Sales Channel and Clients, 2021-2027

Sodium hydroxide is also known as caustic soda, caustic, and lye. Anhydrous (100%, solid) caustic soda has a chemical formula of NaOH and a molecular weight of 40.00.

It is available commercially in the form of liquid, solid, flakes, or particles. Sodium hydroxide has diverse industrial applications due to its strong alkaline nature. It is integral to the manufacture of petroleum products, pulp and paper, alumina, textiles, and soaps and detergents, along with its application in chemical processing, water treatment and petroleum processing.

Download FREE Sample of this Report @ https://www.grandresearchstore.com/report-sample/global-sodium-hydroxide-2021-2027-920

For commercial purposes, caustic soda is used either in a 32%, 45% of 50% etc. aqueous solution or as a solid. Industrially, caustic soda is most commonly manufactured by the electrolysis of a sodium chloride (NaCl) solution. The co-products formed from the electrolytic production of caustic soda are chlorine and hydrogen.

Dow Chemical, Oxychem, Westlake (Axiall), Olin Corporation, and Formosa Plastics Corporation are the leading sodium hydroxide players, the top 5 accounting for approximately 25% of the total market.

China is the largest producer of sodium hydroxide, accounting for about 33% of the total market, followed by North America with 20% market share.

Market Analysis and Insights: Global Sodium Hydroxide Market

In 2020, the global Sodium Hydroxide market size was US$ 34400 million and it is expected to reach US$ 47120 million by the end of 2027, with a CAGR of 4.6% during 2021-2027.

Global Sodium Hydroxide Scope and Market Size

Sodium Hydroxide market is segmented by region, by country, company, type, application and by sales channels. Players, stakeholders, and other participants in the global Sodium Hydroxide market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on sales, revenue and forecast by region, by country, company, type, application and by sales channels for the period 2016-2027.

Segment by Type, the Sodium Hydroxide market is segmented into

Liquid Caustic Soda

Solid Caustic Soda

Caustic Soda Flake

Caustic Soda Particle

Segment by Application, the Sodium Hydroxide market is segmented into

Pulp and Paper

Textiles

Soap and Detergents

Bleach Manufacturing

Petroleum Products

Aluminum Processing

Chemical Processing

Other

Regional and Country-level Analysis:

North America

United States

Canada

Asia-Pacific

China

Japan

South Korea

India

Southeast Asia

Australia

Rest of Asia-Pacific

Europe

Germany

France

U.K.

Italy

Russia

Nordic Countries

Rest of Europe

Latin America

Mexico

Brazil

Rest of Latin America

Middle East & Africa

Turkey

Saudi Arabia

UAE

Rest of MEA

Competitive Landscape and Sodium Hydroxide Market Share Analysis

Sodium Hydroxide market competitive landscape provides details and data information by companies. The report offers comprehensive analysis and accurate statistics on revenue by the player for the period 2016-2021. It also offers detailed analysis supported by reliable statistics on sale and revenue by players for the period 2016-2021. Details included are company description, major business, Sodium Hydroxide product introduction, recent developments, Sodium Hydroxide sales by region, type, application and by sales channel.

The major companies include:

DuPont

OxyChem

Westlake (Axiall)

Olin Corporation

Formosa Plastics Corporation

Tosoh

Ineos Chlor Ltd

Asahi Glass

Covestro

Shin-Etsu Chemical

AkzoNobel

Hanwha Chemical

Solvay

LG Chemical

Tokuyama Corp

SABIC

Kemira

Basf

Aditya Birla Chemicals

GACL

ChemChina

Xinjiang Zhongtai Chemical

Xinjiang Tianye

Beiyuan Group

Shandong Jinling

SP Chemical(Taixing)

Haili Chemical

Huatai Group

Wanhua Chemical (Ningbo)

Tangshan Sanyou Alkali Chloride

Get the Complete Report & TOC @ https://www.grandresearchstore.com/chemicals-and-materials/global-sodium-hydroxide-2021-2027-920

Table of content

1 Study Coverage 1.1 Sodium Hydroxide Product Introduction 1.2 Market by Type 1.2.1 Global Sodium Hydroxide Market Size Growth Rate by Type 1.2.2 Liquid Caustic Soda 1.2.3 Solid Caustic Soda 1.2.4 Caustic Soda Flake 1.2.5 Caustic Soda Particle 1.3 Market by Application 1.3.1 Global Sodium Hydroxide Market Size Growth Rate by Application 1.3.2 Pulp and Paper 1.3.3 Textiles 1.3.4 Soap and Detergents 1.3.5 Bleach Manufacturing 1.3.6 Petroleum Products 1.3.7 Aluminum Processing 1.3.8 Chemical Processing 1.3.9 Other 1.4 Study Objectives 1.5 Years Considered 2 Executive Summary 2.1 Global Sodium Hydroxide Market Size Estimates and Forecasts 2.1.1 Global Sodium Hydroxide Revenue 2016-2027 2.1.2 Global Sodium Hydroxide Sales 2016-2027 2.2 Sodium Hydroxide Market Size by Region: 2021 Versus 2027 2.3 Sodium Hydroxide Sales by Region (2016-2027) 2.3.1 Global Sodium Hydroxide Sales by Region: 2016-2021 2.3.2 Global Sodium Hydroxide Sales Forecast by Region (2022-2027) 2.3.3 Global Sodium Hydroxide Sales Market Share by Region (2016-2027) 2.4 Sodium Hydroxide Market Estimates and Projections by Region (2022-2027) 2.4.1 Global Sodium Hydroxide Revenue by Region: 2016-2021 2.4.2 Global Sodium Hydroxide Revenue Forecast by Region (2022-2027) 2.4.3 Gl

CONTACT US: 276 5th Avenue, New York , NY 10001,United States International: (+1) 646 781 7170 / +91 8087042414 Email: [email protected] Follow Us On linkedin :- https://www.linkedin.com/company/grand-research-store/

0 notes

Text

Caustic soda production process

The caustic soda flake caustic soda is an alias, sodium hydroxide, sodium hydroxide in the industry known as the industrial base, caustic soda, caustic, according to existing forms can be divided into liquid, alkali, alkali protopine, solid particle. The protopine, solid alkali, alkali particles are three forms of solid sodium hydroxide.

image/20170426/1493180762580604

The following chart, followed by caustic soda solid alkali alkali lye particle: 1 from 32% to 61% concentration, this stage in film evaporator. The heating source adopts medium pressure steam and two steam, and is evaporated under vacuum. 2.61% by lye falling film concentrator, using molten salts as heat carrier, will be concentrated into molten alkali lye under atmospheric pressure, and then made the solid caustic soda flake caustic soda machine (molten salt method in the legend). The mass fraction of ionic membrane caustic soda by 32% 1 evaporator (vacuum, two times concentrated to 47% by steam) pump and steam condensate and II evaporator heat exchanger, in the second evaporator further concentrated to 61%, and by 61% in the final of pump alkali concentrator, molten salt heating to concentrate from 98% to 99%, and then made the solid caustic soda flake caustic soda machine. Since the 1 MPa saturated steam power plant to enter the first effect evaporator, condensate and alkali heat I effect after entering the recycling pool, as water supplement, two steam generated II effect and the final concentration of the two steam in the first evaporator as a heat source, 32% alkali evaporation. 415 ~ 430 DEG C molten salt by the molten salt pump into the molten salt furnace into the final concentrator after heating, as heat source alkali evaporation to 98% ~ 99%, and finally back to the molten salt tank, recycling. Molten salt furnace system is a system of closed loop heating by burning furnace, heating coil heating and above the molten salt with the ignition of gas through the pump head, the molten salt cycle in circulation in the system, and because of isolation, minimizing the decomposition of molten salt. In the production of primary heating molten salt should pay attention to the following points. (1) the melting point of molten salt is about 143 DEG C, and the molten salt pipeline should be accompanied by steam. It is better to use the electric heating to prevent the molten salt from freezing in the pipeline. (2) in molten salt gradient heating process, to carefully check valve with hot molten salt, molten salt proceed big circulation in the whole system, especially the small circulation valve is not closed, must rotate in a circle, in order to prevent the molten salt valve die. (3) the molten salt mixture, density is not very uniform, but the initial heating and melting, the moisture content in molten salt is higher, so in the molten salt circulation process, should pay attention to the pump current, if the pump current fluctuation, and lasts for a long time, should immediately stop the pump check, identify the reasons for the problem. Under normal circumstances, the pump current will fluctuate, but the wave

With the increase of molten salt temperature, pump current will gradually decrease and tend to be stable. Caustic soda as a basic chemical raw materials, widely used in papermaking, synthetic detergent and soap, viscose, rayon and cotton and textile industry, pesticides, dyes, rubber and chemical industry, oil drilling, oil refining oil and tar refining oil industry and national defense industry, machinery industry, wood processing and metallurgical industry. Medicine industry and city construction. It is also used in the manufacture of chemicals, paper, soap and detergent, rayon and cellophane.

More info: http://www.navimanufacturer.com

0 notes

Text

CAUSTIC SODA LYE 32% and 48% -MLF Group

Sodium hydroxide in the MFL Group is created during the time spent layer electrolysis and conveyed to the market in a 32% to 48% arrangement. The subsequent item is described by top notch and immaculateness, because of which it has gotten the PZH declaration. The item additionally satisfies the necessities of the most recent version of European Pharmacopeia, which characterizes fundamental quality prerequisites and examination techniques, among which are drug crude materials.

Sodium hydroxide is an inorganic synthetic compound of the hydroxide gathering, having a place with the most grounded antacid. In fluid structure it is a lackluster, unscented and non-combustible item called burning soft drink fluid. It has a place with a gathering of fundamental crude materials, so it is utilized practically in each industry.

In the makeup business, burning soft drink is utilized in the assembling of hard (sodium) cleanser, washing cleansers, shedding cover (stripping and synthetic dermabrasion) and aseptics. In the petrochemical business, the item is utilized for the refining of raw petroleum, mineral oils, pitches, black-top and the extraction of shale gas. In treatment facilities and coking plants, acidic soft drink is utilized to change items from coking coal. In the steel and metallurgical industry, it is utilized for the creation of aluminum from bauxite preparing.

Sodium hydroxide is likewise broadly utilized in the paper-cellulose industry during the time spent pulping wood utilized for the creation of paper or recovered cellulose filaments. Along with sodium sulfate, it is a vital part of the white alcohol arrangement used to isolate lignin from cellulose strands in the Kraft interaction. It likewise assumes a significant part in a few ensuing phases of fading the earthy colored mash coming about because of the pulping cycle. These means incorporate oxygen delignification, oxidative extraction and basic extraction, all of which require a solid basic climate with pH>10.5 toward the finish of the means.

In the development business, burning soft drink is utilized in a few plasticisers for concrete blends. It assists with homogenizing concrete blends, forestalling isolation of sand and concrete and lessening the measure of water required for blending. The lye is additionally utilized in the creation of water glass. It is a significant crude material during the time spent creating shades and colors for paints – e.g., titanium dioxide.

Sodium hydroxide is a significant fixing in the creation of surfactants, washing fluids, and powders, degreasing specialists and water conditioners. In fluid structure it is a segment of different cleansers. It is utilized in the material business in the creation of colors and rayon. In water treatment measures by expanding the pH, water has a less destructive impact on the water establishment and moreover diminishes the substance of lead, copper, and other poisonous metals that can break up in drinking water.

In the drugs business, sodium hydroxide is utilized for instance for the creation of anti-inflamatory medicine, salicylic corrosive, or sulfanilamides.

Both sodium hydroxide strong just as fluid structure are broadly utilized in horticulture. Burning soft drink is utilized in domesticated animals reproducing for the sterilization of homestead premises (pens, cowsheds, poultry houses, sheds, extra spaces), draining hardware and holders for moving and putting away dairy items. It is utilized in natural product cultivating to plant infectious prevention (e.g., contagious plant microbe known as Nectria galligena) and in the insurance of grape plants, while in beekeeping for hives cleaning. For More Details:- http://www.meghmanifinechem.com Phone No.: +91 635 9953661/62/63/64/65 Chlorine Helpline: 1800-11-1735

0 notes

Link

Aug 03, 2021

Caustic soda lye prices have been increased at Dahej. According to sources, with effect from August 3, 2021, caustic soda lye prices at Dahej have been up by Re.1/Kg basic. The new basic price is Rs.32/Kg.

0 notes

Link

Jul 31, 2021

A slight recovery in caustic soda lye prices was noticed at Dahej today. According to sources, with effect from July 31, 2021, caustic soda lye prices at Dahej are up by Re.0.50/Kg basic. The new basic price is Rs.32/Kg.

0 notes