#Cartridge Heater Suppliers

Explore tagged Tumblr posts

Text

Our recent blog post on cartridge heater contains useful information about its working principle. Also read the applications of cartridge heater in this informative blog. Reach out to us for more details.

#cartridge heater#cartridge heater suppliers#cartridge heater manufacturers#cartridge heater exporters#electrical equipments

0 notes

Text

Find an interesting blog about Cartridge Heater, which contains their helpful information such as the working principle, features, applications, & uses. Explore us, as we are the best Cartridge Heater Manufacturers in India.

#Cartridge Heater#Cartridge Heater Manufacturers#Cartridge Heater Suppliers#Cartridge Heater Exporters

0 notes

Text

Choosing the Ideal Tubular Heater: A Detailed Guide

Selecting the right tubular heater ensures optimal performance, energy efficiency, and durability. Consider factors like material, wattage, and application-specific requirements. For industrial use, stainless steel options offer corrosion resistance, while copper suits water heating needs. Look for adjustable thermostats and safety features for added reliability. Whether for HVAC, ovens, or immersion heating, the right tubular heater enhances efficiency and reduces costs. Explore Sanvi Heat's high-quality solutions for tailored heating needs backed by expertise and support.

0 notes

Text

High & Low Watt Density Ceramic Cartridge Heater Manufacturers & Suppliers

Alfa Heaters offer Cartridge Heating elements expertise both in High density Cartridge Heaters and Low watt Cartridge Heaters density. Call Now +97165461606

0 notes

Text

China supplier MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B power plant spare parts

China supplier MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B power plant spare parts Sold by YOYIK. Deyang YOYIK is a professional production, development, sale of power plant dedicated spare parts and accessories processing company. Through more than 20 years of efforts, the majority of customers have been fully recognized. Limited space, and look forward to your calls for consultation, we will sincerely for your service, your satisfaction is our greatest comfort! Yoyik can offer many spare parts for power plants as below: #DF-MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B-DF Signal Converter ADAM4520 Magnetic Proximity Sensors DF2018 Analog Linear Displacement Sensor ZDET-20B Shaft Speed Sensors CS-1-G-100-05-00 Digital display AC ammeter PA194I-3X1 rpm sensor indicator G-065-05-01 Magnetic Pick-up Speed Sensor DF2012 angular displacement sensor B151.36.09G09 displacement sensor FRD.WJA2.301H lvdt linear position sensor TDZ-1E-31 temperature measurement sensor pt100 WZP2-014s PT100 2M lvdt transducer displacement LVDT-400-6 rtd cable WZPK-646 displacement transducer TDZ-1E-32 rotation sensor D-100-02-01 lvdt transducer displacement HL-3-100-15 LVDT Displacement Transducer Sensors B151.36.09.04.15 thermocouple machine WRN-332NM rtd probe WZPM2 lvdt full form B151.36.09G32 Platinum Thermocouple Wire WRN2-630 LX1=225*76 rpm speed meter DF9011-B dc speed control sensor G-090-02-01 replace thermocouple WRN2-239 0-600℃ linear variable displacement transducer B151.36.09G08 full form of lvdt ZDET1000B pressure switch black 396725-LKTS16 speed meter sensor HZSP-475-50-10-HL celsius thermometer WSS-461 0~350℃ non-contact displacement sensor ZD-7000TDB oil pressure sensor SPB424BXCC RPM Sensor magnetic GSH5 RPM Sensor magnetic CS-1 L=100 Thermocouple Type-K TE-109 tachometer price DF9011-B Type K Thermocouple Cartridge WRNKB-446S/TG MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B rtd cable WZP-201 LVDT Position Sensors K156.36.06.004 vacuum pressure gauge 1201901 lvdt 20mm sensor LVDT-35-3 furnace thermocouple TE-305 Rotary Torque Sensor ZS-02 L=65 element cartridge heaters ZJ-14.5-180 rpm sensor generator DF2018 Surface Thermocouple TC03A2-KY-2B/S13 lvdt-sensor ZDET-25B thermocouples extension lead wires TE-303 linear displacement sensor FRD.WJA2.308 LVDT Position Sensors A191.36.09.03 lvdt 0-300 TDZ-1G-32 pt100 rtd probe thermowell WRNK2 pt100 rtd WZP-221 rotational speed sensor CS-1-G-100-02-01 lvdt displacement transducer B151.36.06(1)G02 thermal resistance tester WZP2M-201 thermocouple k-type WRNK2-294 non-contact displacement sensor TDZ-1E-12 lvdt working principle 400TD non-contact displacement sensor TDZ-1E-22 BENTLY Cable 330130-040-12-00 Tacho RPM sensor CS-3 M16-L60 cartridge heater electric heating heater DJ-22-2/ZBK54019-88 liquid level gauge UTG2005C Displacement sensor 5000TDG 0-250mm LVDT Position Sensors TDZ-1-21 lvdt full form TDZ-1-33 pt100 thermocouple machine WRNK2-292 lvdt displacement sensor inductive sensor HL-6-20-15 thermowell flange TC03A2-KY-2B/S3 Gear speed sensor CS-3-M16-L120 Shaft Rotation Speed Sensors DF6202-005-050-04-00-10-000 lvdt 20mm sensor B151.36.09G42 MAGNETIC LIQUID LEVEL INDICATOR UHZ-10007B DFYLSYC-2024-6-17-A

0 notes

Text

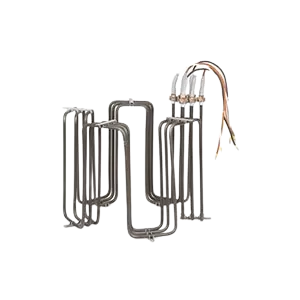

Cartridge Heater Manufacturer and Supplier In India

High-Density Cartridge Heaters play a crucial role in numerous industries, particularly where space constraints and precise temperature regulation are paramount. Crafted with meticulous attention to detail, our Electric Cartridge Heaters boast top-notch materials including premium metals like stainless steel (S.S.) and Lincoln sheathing. They come in standard as well as “D” configurations to suit various setups.

Our cartridge heaters are incredibly adaptable, offering both low and high-density wattage options, catering to a wide spectrum of heating requirements. Renowned for their superior quality, Raghway Tech’s Cartridge Heaters guarantee dependable and efficient performance, even in confined spaces where heating needs can be challenging.

As a leading manufacturer and supplier, we take pride in offering a diverse array of Cartridge Heaters that consistently earn high praise from our clientele. With competitive pricing, our Electric Cartridge Heaters present a cost-effective yet premium solution for applications demanding precise and controlled heat within limited spaces.

FEATURES

Strong construction

Long functional life

High performance

Extremely flexible

Less maintenance

Low-Density & High Density

Excellent heat transfer

Call us on +91–9899466981 OR write to us @ [email protected]

#raaghawaytech

#Cartridgeheater

#industrialheater

0 notes

Text

Keeping Your Appliances Safe: How Magnetic Strainer Filters Prevent Damage

Appliances play a crucial role in our daily lives, making household tasks more efficient and convenient. However, they are susceptible to damage caused by foreign particles and debris that find their way into the system. One effective solution to protect appliances from such damage is the use of magnetic strainer filters. In this blog, we will explore the importance of magnetic strainer filters, how they work, and the benefits they offer in preventing damage to your valuable appliances.

Understanding Magnetic Strainer Filters

Magnetic strainer filters are ingenious devices designed to capture and remove ferrous (magnetic) particles from fluids or gases passing through them. These filters consist of a mesh screen or cartridge that incorporates powerful magnets. As the fluid flows through the filter, the magnetic field attracts and retains any ferrous contaminants, preventing them from entering the appliance and causing potential damage.

Preventing Appliance Damage

Foreign particles like rust, metal shavings, or other debris pose a significant threat to appliances. When they enter the system, they can clog pipes, damage sensitive components, or hinder the proper functioning of moving parts. This can lead to reduced performance, increased energy consumption, and even complete appliance failure.

By installing a magnetic strainer filter in the appliance's inlet or supply line, these damaging particles are effectively trapped and separated from the fluid before it reaches the appliance. This proactive approach helps maintain optimal performance, extends the lifespan of appliances, and saves you from costly repairs or replacements.

Versatility and Application

Magnetic strainer filters find applications in various household appliances, including washing machines, dishwashers, HVAC systems, water heaters, and irrigation systems. They are also widely used in industrial settings, such as manufacturing plants and oil refineries, where the presence of metal contaminants can cause severe damage to expensive equipment.

Easy Installation and Maintenance

Installing a magnetic strainer filter is a straightforward process. They are usually designed to fit in-line with existing plumbing connections, allowing for hassle-free integration into your appliance's system. Maintenance typically involves periodic cleaning or replacing the filter cartridge, depending on the level of contamination.

Environmental Benefits

Apart from protecting appliances, magnetic strainer filters contribute to environmental sustainability. By preventing damage and improving the longevity of appliances, these filters help reduce the overall waste generated from discarded and replaced units. Moreover, they minimize the need for chemical cleaning agents and reduce energy consumption by ensuring appliances operate at peak efficiency.

Conclusion

In a world where appliances play a vital role in our daily lives, protecting them from potential damage is essential. Magnetic filters offer a reliable and cost-effective solution to safeguard appliances from harmful debris and contaminants. By incorporating these filters into your appliance systems, you can prolong their lifespan, reduce the risk of breakdowns, and save on repair or replacement costs. Moreover, by preventing appliance damage, magnetic strainer filters contribute to a greener and more sustainable environment. So, don't wait any longer—take the necessary steps to keep your appliances safe with magnetic strainer filters today.

PERMAG is a leading supplier of plate magnet, and we are committed to providing our customers with the highest quality products available on the market. Thanks to our state-of-the-art manufacturing process, we can produce magnetic rods that meet the most stringent quality standard.

0 notes

Text

About the Use of Thermocouples in Cold Storages

Thermocouples are temperature sensors that are commonly used in a variety of industries, including warehousing. What more?

Read our article to know more.

Looking to purchase sensors for the specific applications?

Call Heatcon Sensors on 098442 33244 to start a discussion and place your order. Heatcon Sensors have been manufacturing quality temperature sensors and accessories for more than 30 years.

#heatconsensorspvtltd#manufacturer#Thermocouple#specialsensors#MedicalApplications#warehouse#coldstorage#clinicaluse#monitoring#bangalore

0 notes

Text

Looking for a reliable and efficient Cartridge Heater Manufacturer in India? Radiant Heating Technologies, leading manufacturer, supplier, and exporter of a wide range of industrial heaters, thermocouples, controllers, and lab equipment, including high-density cartridge heaters.

1 note

·

View note

Link

0 notes

Text

Invest in High Density Cartridge Heaters

With a commitment to precision, reliability, and customer satisfaction, Patel Heaters and Control Pvt Ltd stands as a leading manufacturer and supplier of cartridge heaters in India. Our extensive range of cartridge heater caters to various industrial applications, ensuring efficient and consistent heating solutions.

#cartridge heater#cartridge heater manufacturers#cartridge heater suppliers#cartridge heater exporters#electrical equipments#industrial heaters

0 notes

Text

Learn All About Cartridge Heater - Patel Heaters

Patel Heaters & Control Pvt Ltd provides premium quality Cartridge Heater. These Cartridge Heaters are specially made for mold dyeing, sealing bars, and platen heating purposes in various industries such as packaging machinery, plastic processing machinery, labeling machinery, etc.

#Cartridge Heater#Cartridge Heater Manufacturers#Cartridge Heater Suppliers#Cartridge Heater Exporters

0 notes

Text

Why Tubular Heater Elements Are Perfect for Harsh Environments

In industries that operate in extreme conditions, reliable heating solutions are critical. Tubular heater elements stand out as the ideal choice for these environments. These versatile heaters are designed to withstand high temperatures, corrosive conditions, and heavy-duty usage, making them perfect for industries such as petrochemical, manufacturing, and food processing.

Key Features of Tubular Heater Elements

Durability in Extreme Conditions: Tubular heater elements are built to resist wear and tear caused by extreme heat, moisture, and chemical exposure. Their rugged construction ensures a longer lifespan, reducing the need for frequent replacements.

Customizable Designs: These heaters can be tailored to fit specific industrial requirements, whether it’s in shape, size, or wattage. This makes them adaptable to various applications, such as heating tanks, ovens, or even air ducts.

Energy Efficiency: Tubular heater elements are designed to provide efficient heating with minimal energy wastage. This feature is vital in reducing operational costs for businesses.

Tubular Heater Elements in Qatar

In Qatar, where industries like oil and gas dominate, the demand for resilient heating solutions is high. According to a report by Mordor Intelligence, the oil and gas market in Qatar is expected to grow at a CAGR of 3.1% from 2023 to 2028. Tubular heater elements are integral in maintaining optimal operations in these industries, especially in applications like tank heating and pipeline temperature regulation.

Tubular Heater Elements for Other Regions

Globally, tubular heaters are extensively used in regions with harsh climates or demanding industrial processes. They are critical in industries like pharmaceuticals, automotive, and metalworking, ensuring consistent performance under challenging conditions.

Why Choose Sanvi Heat?

At Sanvi Heat, we specialize in providing top-quality tubular heater elements tailored for harsh environments. Our products combine durability, efficiency, and innovation to meet the unique demands of industries in Qatar and beyond. With a commitment to excellence, we ensure timely delivery and unmatched customer support.

Contact Sanvi Heat today for durable and energy-efficient tubular heater elements. Let us help you power your operations seamlessly, even in the toughest environments.

0 notes

Text

Industrial Heaters Suppliers in Oman – Indian Heat Corporation

Oman's industrial sector is growing rapidly, demanding reliable, high-performance heating solutions. Industrial heaters play a crucial role in diverse industries such as oil and gas, food processing, manufacturing, and construction. Indian Heat Corporation, a leading supplier of industrial heaters, meets this demand with innovative and durable heating solutions.

Why Choose Indian Heat Corporation?

With over a decade of expertise, Indian Heat Corporation offers tailored solutions to meet Oman’s industrial requirements. Our heaters are designed for efficiency, durability, and high performance, making them ideal for Oman’s challenging industrial environments.

Wide Range of Industrial Heaters

Immersion Heaters: Efficient heating for liquids in tanks and vessels.

Cartridge Heaters: Compact, reliable heating for dies and molds.

Infrared Heaters: Perfect for drying and curing processes.

Band Heaters: Designed for precise heating in extrusion and injection molding.

Industries We Serve in Oman

Oil & Gas: High-temperature heaters for pipelines and refineries.

Food Processing: Hygienic heating solutions for cooking and sterilization.

Manufacturing: Energy-efficient heaters for production lines.

Why Oman Prefers Indian Heat Corporation

Customized Solutions: Heaters designed for specific applications.

Premium Quality: ISO-certified materials ensure long-lasting performance.

Technical Support: Expert guidance and after-sales service.

Partner with Indian Heat Corporation

Indian Heat Corporation is committed to supporting Oman's industrial growth by providing advanced heating solutions. For reliable and efficient industrial heaters, contact us today!

Visit Indian Heat Corporation to explore our product range.

#Indian Heat Corporation: Leading Industrial Heaters Manufacturer in Oman#Website: https://indianheatcorporation.com#Contact: 7982533957#About Indian Heat Corporation#Indian Heat Corporation is a leading manufacturer of industrial heaters in Oman#renowned for delivering high-quality and innovative heating solutions tailored to diverse industrial needs. The company is recognized for i#providing advanced heating technologies designed to meet the rigorous demands of various sectors across Oman.#Product Range#Indian Heat Corporation offers a comprehensive range of industrial heaters#including:#Electric Heaters: Versatile and efficient solutions suitable for numerous industrial applications#including process and environmental heating.#Immersion Heaters: Designed for direct heating of liquids in tanks and containers#ensuring precise temperature control and effective heating.#Circulation Heaters: Engineered for continuous heating of fluids in flow systems#enhancing process efficiency and stability.#Infrared Heaters: Provide targeted#energy-efficient heating through infrared radiation for applications requiring focused heat.#Tubular Heaters: Customizable for both direct and indirect heating needs#adaptable to various industrial environments.#Quality and Innovation#Indian Heat Corporation is dedicated to upholding the highest standards of quality in its manufacturing processes. Their industrial heaters#efficiency#and superior performance. The company invests significantly in research and development to incorporate the latest advancements in heating t#Customer-Centric Solutions#The company emphasizes a customer-centric approach#offering customized heating solutions to address specific industrial requirements. Their experienced team works closely with clients to des#reliability#and performance#catering to unique needs across different sectors.

0 notes

Text

High & Low Watt Density Ceramic Cartridge Heater Manufacturers & Suppliers

Alfa Heaters offer Cartridge Heating elements expertise both in High density Cartridge Heaters and Low watt Cartridge Heaters density. Call Now +97165461606

0 notes

Text

China supplier Armoured Thermocouple TC03A2-KY-2B/S19 power plant spare parts

China supplier Armoured Thermocouple TC03A2-KY-2B/S19 power plant spare parts Main: hydraulic machinery and components, hydroelectric generating units; coal-fired generating units; generating units; electrical and electronic products processing; mechanical parts processing. Mainly engaged in the power industry host (steam turbine, water machine, boiler, turbine) accessories, spare parts, spare parts, auxiliary equipment and environmental protection equipment. Deyang YOYIK supply power plant, steel accessories are as follows: Yoyik can offer many spare parts for power plants as below: #DF-Armoured Thermocouple TC03A2-KY-2B/S19-DF lvdt transducer displacement 181.36.06G03 angular displacement sensor 4000TDGN-30-01-01 thermistor TE-302 flexible heating element HY-GYY-1.2-380V/3 sensor de rpm ZCS-03 Hall Effect RPM/Speed Sensor ZS-03 L=65 stainless steel electric tubular heater RJ-14.5-450 liquid level switch BNA15/16-M566 turbine speed sensor CS-1 G-110-03-00 thermal resistance WZRK-135 Φ5 5000 rpm torque sensor CS-1-G-100-03-01 pt100 rtd WZPK2-1716 lvdt transducer displacement TD-1-0150-10-01-01 linear displacement sensor 268.33.01.06 transmission speed sensor CS-2 M6 thread WRNR2-12 Hall Effect Speed/Proximity Sensor PR9376/010-011 pt100 sensor WZP Thermocouple Control WRNK2-292 Shaft Rpm Indicator D521.02 Shaft Vibration Gauge (Preamplifier) TM301-A02-B01-C00-D00-E00-F00-G00 LVDT Measurement 500TDGN lvdt transducer ZD-5000TDA LVDT Displacement Sensors HL-6-400-15 Precision transient speed instrument / rotational speed sensor DF9011 lvdt displacement sensor inductive sensor B151.36.09G24 cable pt100 WZPM2-08-75-M18-S high density cartridge heater ZJ-20-8B Analog Linear Displacement Sensor DET250A Shaft Rotation Speed Sensors G-100-02-01 speed meter sensor CS-1(G-075-02-01) 3 Wire RTD Sensor WZPK2-336 displacement sensor sany TDZ-1-44 lvdt transducer displacement LVDT-25-3 displacement sensor sany ZD-10000TDB industrial heating element JHG03-18B Armoured Thermocouple TC03A2-KY-2B/S19 non-contact displacement sensor TDZ-1E-21 industrial displacement sensor TD-1 300S thermocouple thermometer WRNKB-446S/TG LVDT Displacement Sensors TD-1G thermocouple wire WRN2-4312 output speed sensor HZSP-475-50-10-HR LVDT Measurement 191.36.09.18 sensor de rpm NE6103-005-130-01-05-00-00 rpm sensor generator G-065-02-01 Shaft (Rpm) Indicator-Tachometer WZ-3C-A Resistance thermometer WZPM2-08-040-M18-S temperature sensors WZRM2-001 full form of lvdt 191.36.09.15 Thermocouple Type-K TC03A2-KY-2B/S11 Pt100 Temperature Sensor WZPM-201 5000MM lvdt transducer HL-6-800-15 thermocouple cable WRN2-4312 thermometer gauge WSS-481 φ6 dc heating element 05B35A lvdt linear position sensor TD7000 sensor pt100 WZPM-225 φ25mm Thermocouple Assemblies WRNK2-332 Resistance thermometer WZPM2-08-120-M18-S thermocouple cable WRN-332NM Pt100 Temperature Rtd Sensor WZP2-441-B/A3(Pt100 Thermometer Water-proof WSS-581 rtd thermal resistance WZPK-24 φ6 angular displacement sensor 10000TDZ-AG non-contact displacement sensor B151.36.09G47 displacement sensor sany HTD-1000-6 linear displacement sensor K156.36.06.003 RPM Sensor magnetic GSH5 3 Wire RTD Sensor WZPM2-001 Φ6 rtd temperature sensor WZP2-24SA sensor lvdt 7000TD lvdt transducer displacement TD-1 200S Armoured Thermocouple TC03A2-KY-2B/S19 DFYLSYC-2024-5-8-A

0 notes