#Carbon Fiber Tape Market

Explore tagged Tumblr posts

Text

1 note

·

View note

Text

Carbon Fiber Tape Market: Global Demand Analysis & Opportunity Outlook 2035

Research Nester’s recent market research analysis on “Carbon Fiber Tape Market: Global Demand Analysis & Opportunity Outlook 2035” delivers a detailed competitors analysis and a detailed overview of the global carbon fiber tape market in terms of market segmentation by type, end user, and by region.

Lightweight and High Strength to Promote Global Market Share of Carbon Fiber Tape

Carbon fiber tapes are used in the construction of wind turbine blades, as they provide enhanced structural integrity and durability. The sports industry utilizes carbon fiber tapes for manufacturing equipment like tennis rackets, golf clubs, bicycles, etc., as they improve performance through reduced weight and increased strength.

Carbon fiber tapes find applications in strengthening and reinforcing structures like bridges and buildings, providing increased longevity and resistance to external forces. With an increasing focus on sustainability, carbon fiber tapes are gaining popularity as they offer a more eco-friendly alternative to traditional materials.

Request Report Sample@

Some of the major growth factors and challenges that are associated with the growth of the global carbon fiber tape market are:

Growth Drivers:

• Rising Automotive Industry

• Growing Lightweight and High Strength

Challenges:

While carbon fiber is known for its lightweight and high strength properties, recycling carbon fiber materials is challenging. The lack of efficient recycling technologies for carbon fiber tapes can raise concerns about their long-term environmental impact and sustainability. The production capacity for carbon fiber tapes is relatively limited compared to other materials. Meeting the growing demand for carbon fiber tapes in various industries can be a challenge if production capacity does not keep up.

The bidirectional segment is to garner a highest revenue by the end of 2035 by growing at a significant CAGR over the forecast period. The sports industry has seen a growing interest in bidirectional carbon fiber tapes for manufacturing sporting goods like tennis rackets, golf clubs, and hockey sticks. The tapes' isotropic properties contribute to enhanced performance in various sports equipment. The aerospace industry has been another major consumer of bidirectional carbon fiber tapes. These tapes are used in aircraft components where load-bearing capabilities in multiple directions are crucial for structural integrity.

By region, the Europe carbon fiber tape market is to generate a notable revenue by the end of 2035. The aerospace and defense sectors in Europe have been significant consumers of carbon fiber tapes. These tapes are used in aircraft components, satellites, and defense equipment due to their lightweight and high-strength properties. The European automotive industry has been actively focusing on light weighting to improve fuel efficiency and reduce emissions. Carbon fiber tapes are used in lightweight automotive components, contributing to overall weight reduction and improved vehicle performance.

This report also provides the existing competitive scenario of some of the key players of the global carbon fiber tape market which includes company profiling of Hexcel Corporation, Toray Industries, Inc., Teijin Limited, SGL Carbon SE, Mitsubishi Chemical Carbon Fiber and Composites, Inc., and others.

Access our detailed report at:

0 notes

Text

Best Tape Ball Bats: Elevate Your Cricket Game

Tape ball cricket is a popular and exciting variation of traditional cricket, often played in streets, parks, and open spaces. One of the essential elements for success in this version of the game is having the best tape ball bat. Unlike standard cricket bats, these are tailored for the lighter tape ball, offering superior control, power, and speed. In this article, we’ll discuss how to choose the right bat and highlight some top options available in the market. For a wide selection of sporting goods, visit Sports World London.

Why Tape Ball Bats Are Different

Tape ball cricket bats are specifically designed to meet the demands of the lighter and less rigid tape ball. These bats prioritize lightweight construction, better balance, and enhanced stroke-making ability. Traditional bats may feel heavy or lack the right response for tape ball cricket.

Key Factors to Consider When Choosing a Tape Ball Bat

1. Material

Poplar Wood: Ideal for beginners due to its lightweight and affordability.

Kashmir Willow: Preferred by seasoned players for its durability and better stroke power.

Carbon Fiber Reinforcement: Some modern bats feature carbon elements to increase strength while keeping weight minimal.

2. Weight

A bat between 900 to 1100 grams is ideal for tape ball cricket. Lighter bats allow for quicker swings and better shot control.

3. Balance and Handle Design

Look for bats with an ergonomic handle and well-balanced structure. This helps in making precise shots and reduces hand fatigue.

4. Grip

A comfortable, non-slip grip is essential for long playing sessions. Some bats come with pre-installed high-quality grips, while others may require customization.

Top Recommendations for Tape Ball Bats

1. SS Gutsy Tape Ball Bat

This bat is crafted from premium wood, offering excellent durability and power for aggressive shots.

Material: Kashmir willow

Weight: Lightweight for effortless handling

Key Feature: Superior sweet spot for maximum stroke power

2. CA Plus 1500 Tape Ball Bat

Known for its robust build and lightweight design, this bat is a favorite among tape ball enthusiasts.

Material: Poplar wood

Weight: Ultra-light for swift swings

Key Feature: Budget-friendly with great performance

3. GM Blaze Tape Ball Bat

This bat provides excellent balance and control, making it perfect for beginners and seasoned players alike.

Material: High-quality wood with carbon reinforcement

Weight: Balanced for controlled shots

Key Feature: Durable and reliable for intense matches

Maintenance Tips for Prolonging Bat Life

Clean After Every Match: Use a damp cloth to remove dirt and tape residue.

Avoid Moisture: Keep your bat dry to prevent wood damage.

Use Protective Covers: Store your bat in a cover to protect it from impact and scratches.

Regrip When Needed: Replace grips periodically to maintain comfort and control.

Conclusion

Choosing the best tape ball cricket bat is essential for maximizing your performance and enjoyment of the game. Focus on factors like material, weight, balance, and grip to find the perfect fit for your playing style. Don't forget proper maintenance to extend the life of your bat. Explore a wide range of high-quality cricket equipment at Sports World London. Happy cricketing!

#BestTapeBallBat#CricketBats#StreetCricket#TapeBallGame#CricketEssentials#CricketTips#SportsWorldLondon

1 note

·

View note

Text

0 notes

Text

All You Need to Know About Narrow Woven Fabric Manufacturers

Narrow fabric is defined as a textile good that is not more than 30 centimeters (12 inches) in width and is sewn or woven. The small width of the fabric makes it exclusive and special. Myriad Narrow Woven Fabric Manufacturers are available in India. You can find them physically and online also. These fabrics are used in different industries such as textile and apparel, the medical sector, automotive, luggage and bags, military and safety gear, sporting and many more. Let us understand various products and industries that use narrow-knitted fabric.

Narrow fabric, including tape and webbing, makes a significant contribution to making any goods and industries that depend on textiles. The various applications of these fabrics are here:-

Military devices and clothing

Parachutes

Seatbelts in cars and other vehicles

Medical: tapes and elastic bands

Belts, straps in undergarments

Airbags

Bags handle, straps

Bookbinding

Packaging stuff

Furniture upholstery straps and many more

The majority of narrow fabrics generally come with a width of 2.5 or less. Jawahar Group is the most credible Narrow Woven Fabric Manufacturer in India. The company is proficient in knitting a broad series of tape and webbing goods. The focus of the organization is to weave high-grade narrow fabrics along with additional services to boost the performance and aesthetic aspects of the end product.

What Are Different Narrow Fabric Types

Tape and narrow fabric goods are generally produced using fabrics such as nylon, cotton tape, and polyester. Other textiles are also utilized based on the demand for the goods. Numerous factors also determine different aspects of weaving products, such as width, weave and type of fabric. In the following section, some usual fabrics and their usage are explained -

Polyester: Polyester is a long-lasting, strong and lightweight fabric. It comes under the synthetic form of the fabric. This fabric doesn't shrink and tangle. Moreover, it has strong protection against outer surroundings. Polyester webbing is generally ideal for its competence to survive substantial masses of objects from sports goods, military applications, and more.

Nylon: Nylon is also a synthetic form of fiber, and it has great protection against abrasion. Moreover, nylon is long-lasting and strong enough to be used in all types of situations. Plenty of narrow woven fabric manufacturers prefer nylon for military usage.

Cotton: cotton is a gentle, breathable and moisture-absorbing fabric, and it is the most preferred and used webbing in many clothing applications. Moreover, this is a natural fiber and has a renewable capacity. Other narrow fabrics that are usually applied in various industries are acetate, carbon fiber etc.

What is The Process of Narrow-Weaving Fabric?

Tape looms, and width looms (needles) help weave narrow-width fabric. At present, traditional and high-tech textiles have evolved the weaving technique for narrow-width fabrics because of the huge requirements of such goods in the market and industries. Now, advanced technology has made it easier to work fast and generate high production of products made by such fabrics.

Computer-aided design (CAD) programming applications and pattern generation technologies have become useful in manufacturing contemporary narrow weaving machines. Aramid, Dyneema cotton, carbo, polyester and nylon are some of the materials used in narrow weaving fabric. The applications of these fabrics can be seen in the form of industrial belts, undergarment straps, waist belts, safety belts, bags, apparel, shoelaces, ribbons, wrist bands and many more.

We apply the same procedure for manufacturing narrow fabrics that competitors use. However, we take care of details, precision, and the requirement for small widths. In our production unit, we look after all types of obstacles that come along while we weave fabrics via feeders and looms to sewing and cutting machines.

How Narrow Fabric is Bringing Positive Changes in Various Industries and Offices

At present, businesses and commercial organizations have only 2 or 3 purposes. One is to provide quality services, products, and assistance to customers. The second is to increase their market share and capitalization, which eventually enhances their revenue. The third one is to enhance the efficiency of their business and working staff. Office atmosphere has a great contribution to productivity, convenience and satisfaction. Fabric usage in the infrastructures, interiors, and furniture helps make your office atmosphere welcoming for every entrant and working staff. Jawahar Group is an honored Narrow woven fabric manufacturer, and we are making efforts to deliver inventive fabric applications that certainly boost office efficiency. Let's know how narrow fabric can change the vibes of an office and bring positivity to the atmosphere: -

Long-Lasting and Cost-Effectiveness: Investment in office furnishing and furniture is indeed a big step, and repetitive repair and replacement can disturb the office atmosphere. It also hampers the productivity of the office and its staff. Jawahar Group's narrow fabrics have long-lasting, comfortable and cost-effective features. They are easy to maintain and don't require repetitive repair and replacement. This durability and cost-effectiveness enable businesses to assign enhanced resources to different efficiency improvement actions.

Highly Comfortable: Our high-grade and versatile fabric provides enhanced comfort. If the sitting arrangement and the furniture in the office are not comfortable, then it can drain workers' productivity and make them exhausted. When you select appropriate upholstery, including gentle and breathable furniture, it can decrease tiredness and enhance concentration. We ensure that pour fabric material-made objects provide optimum comfort to make people work even longer without any inconveniences. It eventually helps in increasing their work efficiency.

Sustainable and Appealing: The look and style of fabric are essential attributes, but sustainability is the most crucial factor that we should pay attention to. Our eco-friendly fabric application facilitated business in making the offices environmentally friendly. A sustainable office atmosphere complements the motivation of youth working in the office.

Employee Confidence and Aesthetics: An attractive and aesthetically sound office can easily raise the confidence of every staff working in it. We have graceful and splendid fabric applications that can bring a contemporary and stylish touch to office space. The accurate color selection and texture can elevate the happy hormone of the staff, and they can contribute passionately with enhanced productivity.

How Jawar Group is Transforming the Narrow Fabric Industry

Multiple contenders are manufacturing narrow woven fabric worldwide, and often, it is tricky for consumers to pick an honest and suitable company. Among many suppliers and makers, Jawahar Group has maintained the standards and ethics in the narrow fabric market. They create goods through robust technology. They have employed competent artisans to complete the job. People can get high-grade fabrics for various industries.

We have found that the scope of narrow fabric application is increasing in various industries, including furniture, footwear, jewelry, aerospace, military, industrial safety, automotive, engineering, packaging, apparel, leather, and many more. But often, it is a big concern how we can select a reliable fabric manufacturer. However, companies like Jawahar Group work with all standard laws, experience, credulity and quality parameters.

If you are keen to select a reliable and authentic narrow woven fabric supplier or producer, then first inspect the experience that the company should have. Moreover, they must have qualified, accomplished, and experienced staff to perform the fabric knotting. They should have accurate knowledge of the right kind of fabric used for different applications. You need to check their credentials, work history, previous work, list of clients, client feedback, and all other factors to validate their claims.

Some manufacturers understand the needs of their customers. Such companies give the foremost importance to customer satisfaction. They even design different fabrics for their different usages. You can review their collections to find the things you need. Many designers in this industry come up with several designs based on the materials used in such fabrics. If you want some trendy narrow fabrics, you can keep in touch with their stuff.

Specific machines are used to design and manufacture narrow woven fabrics. So, ensure that the manufacturer you are hunting for, is using such advanced machines. If they are using these modern and state-of-the-art machines, then there is a reason to work with them. Moreover, you should visit the factory physically to find out whether the machines they are claiming are there or not. You can even ask them to provide a demo of their fabric production.

If you cannot visit the factory, then you must check their website and get ideas. Moreover, you can check their reviews, ratings and feedback online. It will provide you with information about their production process and what actions they implement. Confirm that the information they have provided is genuine on their website.

You also need to speak with workers, customers, and associated people over the phone and on the internet. It is essential to get a response to all your queries and doubts. It will certainly be useful to select a credible fabric manufacturer that provides high-grade products.

Conclusion

When it comes to selecting a responsible, credible and experienced narrow woven fabric manufacturer then, Jawahar Group has got the distinction through their commitment, assurance and excellence in delivering top-quality fabrics and associated products.

1 note

·

View note

Text

Composite Materials Market - Forecast 2024-2030

Composite Materials Market size is forecast to reach $158 Billion by 2030, after growing at a CAGR of 7.9% during 2024-2030. This growth is driven by the automotive industry increasingly adopts polymer composites, leveraging their diverse physical and chemical properties to replace heavier metal components. This shift not only offers weight savings but also maintains crucial features like mechanical strength. Moreover, with global initiatives targeting zero emissions by 2050, there's a heightened demand for composites in the automotive sector. This drive toward sustainability propels the rapid development, innovation, and production of electric vehicles (EVs), where composites play a pivotal role in achieving lighter vehicle weights and enhancing overall efficiency.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞

Additionally, the demand for carbon fiber, an advanced composite material, is surging across diverse sectors including automotive, sports equipment, aerospace, defense, and more. This heightened demand has led to a notable trend of increasing numbers of carbon fiber manufacturers year after year. With its lightweight yet strong properties, carbon fiber continues to be sought after for its versatility and performance capabilities. The proliferation of manufacturers underscores the expanding market for composite materials, reflecting the growing recognition of carbon fiber's value across industries.

By Type: FRP Composites (Fiber Reinforcement Polymers) (Glass Fiber Reinforced Polymers (GFRP), Carbon Fiber Reinforced Polymers (CFRP), Aramid Fiber Reinforced Polymers (AFRP), Others), Matrices (Polymer Matrix Composite (PMC), Metal Matrix Composite (MMC), Ceramic Matrix Composites (CMC)), Resins (Thermoset resins (Epoxy, Vinyl Ester, Polyester, Others), Thermoplastic resins), Others

By Form: Fiber Tow, Unidirectional Tape, Cloth.

By Method: Open molding (Hand Lay-Up, Spray-Up, Filament Winding), Closed molding (Compression molding, Pultrusion, Reinforced Reaction Injection molding (RRIM), Resin Transfer molding (RTM), Vacuum Bag Moulding, Others)

By Application: Aerospace, Wind Energy, Automotive, Construction, Electrical, Sporting Goods, Pipes & Tanks, Others

By Geography: North America, South America, Europe, APAC, and RoW.

COVID-19 / Ukraine Crisis - Impact Analysis:

• The COVID-19 pandemic significantly impacted the composite materials market, disrupting global supply chains, halting manufacturing operations, and dampening demand across industries. Lockdown measures and travel restrictions hindered construction projects, automotive production, and aerospace activities, key sectors for composite materials. Reduced consumer spending and uncertainty led to the postponement or cancellation of projects, affecting demand for composites. However, the pandemic also spurred innovation and adaptation within the industry, with a renewed focus on lightweight materials for sustainable transportation and healthcare applications. Despite initial setbacks, the market is expected to rebound gradually as economies recover and investments in infrastructure and renewable energy resume.

• The Russia-Ukraine crisis has cast a shadow of uncertainty over the composite materials market, impacting the global supply chain and pricing dynamics. With Russia being a significant supplier of raw materials such as glass fiber and resin, disruptions in trade routes due to geopolitical tensions have led to supply shortages and increased costs. Additionally, market instability has caused hesitancy among manufacturers to invest in long-term projects, affecting the overall growth trajectory of the industry. As a result, companies are seeking alternative sourcing strategies and closely monitoring developments to mitigate risks and adapt to the evolving geopolitical landscape, ensuring resilience in the composite materials market.

Key Takeaways:

• Asia Pacific (APAC) stands out as the fastest-growing market in the composite materials sector. The region's robust industrialization, rapid urbanization, and extensive infrastructure development projects are driving the demand for composite materials. Additionally, increasing investments in automotive, aerospace, and construction industries further contribute to APAC's accelerated growth. With a burgeoning economy and expanding manufacturing capabilities, APAC continues to present significant opportunities for market expansion and innovation in the composite materials industry.

• FRP composites (Fiber Reinforced Polymers) emerge as the fastest-growing type of composite materials in the market. Their robustness, lightweight nature, and corrosion resistance make them highly sought-after in industries ranging from construction to automotive. With increasing applications in infrastructure, aerospace, and marine sectors, FRP composites continue to experience rapid adoption, driving their prominence in the composite materials market.

• Aerospace stands out as the fastest-growing application in the composite materials market. The industry's demand for lightweight, high-strength materials to improve fuel efficiency and performance has propelled the use of composites in aircraft manufacturing. With increasing production of commercial and military aircraft, along with the development of next-generation aerospace technologies, the aerospace sector is driving significant growth and innovation in the composite materials market.

0 notes

Text

Thermoplastic Tapes Market worth $4.4 billion by 2028

The report "Thermoplastic Tapes Market by Fiber Type (Glass, Carbon), Resin Type (PAEK, PA, PPS, PP), Application (Aerospace & Defense, Automotive & Transportation, Oil & Gas, Sporting Goods, Medical & Healthcare), and Region - Global Forecasts to 2028", is estimated at USD 2.7 billion in 2023 and is projected to reach USD 4.4 billion by 2028, at a CAGR of 10.5% from 2023 to 2028. Factors such as the superior properties of thermoplastic tapes like corrosion resistance, lightweight and high strength, durability, and improved performance are positively driving the growth of the thermoplastic tapes Market. Thermoplastic composite materials are 50-70% lighter than steel and 25-30% lighter than aluminum. Increment in consumption of thermoplastic tapes is expected to increase owing to changing consumption patterns i.e. from heavy to lightweight composite, fuel efficiency, and cost-effectiveness. Further, the continuous innovation, new product development, and processing applications to create more promising opportunities in aerospace & defense, automotive & transportation, and other industries will bolster demand for the thermoplastic tapes market.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=137180592

Glass fiber held the second largest market for thermoplastic tapes.

Glass fiber are used in various applications due to their low cost compared to traditional materials such as steel and aluminum. Glass fiber-based thermoplastic tapes are preferable over carbon fiber as they provide a quick and affordable way to build parts & molds and make repairs. Glass fibers are easy to process and less expensive but have low tensile strength and performance than carbon fiber. The glass fiber segment of the thermoplastic tapes market is expected to grow significantly in the coming years, driven by the low cost and easy processing of fiberglass that can be used in various applications .

PA segment holds the second-highest market in 2022.

Polyamide (PA)-based compounds are widely used thermoplastic composites worldwide. Thermoplastic composites containing PA resin matrix offer an ideal combination of properties suitable for automotive, aerospace & defense, energy, industrial, and electronics applications. Polyamide is easy to process, has high resistance to heat and chemical attack, good mechanical strength, and stiffness with good dielectric properties, friction, and wear resistance. It enables automotive OEMs to reduce weight without compromising vehicle performance. Polyamide, when used along with long carbon fibers, provides higher strength in automotive applications. In the automotive & transportation industry, PA is used for door modules, bumper stiffeners, and dashboard crossbeams.

Sample Request-https://www.marketsandmarkets.com/requestsampleNew.asp?id=137180592

Middle East & Africa is expected to grow with a significant CAGR during the forecast period.

The thermoplastic tapes market in the Middle East & Africa includes the UAE, South Africa, and Rest of the Middle East & Africa. The market growth is attributed to the developing aerospace & defense, automotive & transportation industries in the region. Thermoplastic tapes are in demand in the Middle East & Africa due to their lightweight and corrosion-resistant properties. The oil & gas industry, aerospace & defense, automotive & transportation, and sporting goods markets are driving up the demand for these tapes in the region. Key aircraft manufacturers, such as Boeing, Airbus, and Bombardier, are targeting Gulf buyers for the business jet market. The demand for repairing existing pipes, tanks, and infrastructure in the oil & gas industry contributes to market growth. The increasing need for sporting goods is also driving the thermoplastic tapes market in the region.

The major players in the thermoplastic tapes market are Toray Industries, Inc. (Japan), SABIC (Saudi Arabia), Mitsui Chemicals, Inc. (Japan), Evonik Industries AG (Germany), Hexcel Corporation (US), Teijin Limited (Japan), Arkema (Netherlands), and Solvay (Belgium), BASF SE (US), and SGL Carbon (Germany), among others.

#ThermoplasticTapes#CompositeMaterials#AdvancedMaterials#Lightweighting#AerospaceMaterials#AutomotiveIndustry#HighPerformanceMaterials#SustainableMaterials#Thermoplastics#ManufacturingInnovation#IndustrialMaterials#EngineeringPlastics#CompositeTapes#PolymerScience#InnovationInMaterials

0 notes

Text

Ginger Market Developments, Trends & Opportunities till 2032

Ginger Market provides in-depth analysis of the market state of Ginger manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Ginger in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Ginger Market Report:

The report offers a comprehensive and broad perspective on the global Ginger Market.

The market statistics represented in different Ginger segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Ginger are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Ginger.

Major stakeholders, key companies Ginger, investment feasibility and new market entrants study is offered.

Development scope of Ginger in each market segment is covered in this report. The macro and micro-economic factors affecting the Ginger Market

Advancement is elaborated in this report. The upstream and downstream components of Ginger and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/ginger-market-100565

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Artificial Meat MarketMarket Growth

Dermo-Cosmetics MarketMarket Analysis

Hand Dryers MarketMarket Size

Global Glass Fiber Reinforced Gypsum (GFRG) Panels MarketMarket Share

Global Mountain Bicycles MarketMarket Growth

Aseptic Packaging For The Pharmaceutical MarketMarket

Automotive Simulation MarketMarket Share

Semiconductor Chip Handler MarketMarket Growth Rate

Transcranial Magnetic Stimulator MarketMarket Forecast

Global Cloud Natural Language Processing MarketMarket Size

Education Technology (EdTech) MarketMarket Growth

Digital English Language Learning MarketMarket Analysis

Macromolecule Hydrogel MarketMarket Size

Global Luxury Vinyl tile (LVT) MarketMarket Share

Global Virtual Power Plant MarketMarket Growth

Digital Diagnostics MarketMarket

LED Lens MarketMarket Share

UAV Propellers MarketMarket Growth Rate

Computer Keyboards MarketMarket Forecast

Global Peanut Allergy Therapeutics MarketMarket Size

Advanced Ceramics MarketMarket Growth

Drone Defense System MarketMarket Analysis

Urea Formaldehyde Concentrate (UFC) MarketMarket Size

Global Bike Tube & Tire MarketMarket Share

Global Rhodiola Rosea P.E. MarketMarket Growth

Aerospace Inconel Blisk MarketMarket

Commercial Airport Baggage Handling System MarketMarket Share

Mica Tape for Insulation MarketMarket Growth Rate

Radio Frequency (RF) Energy Harvesting MarketMarket Forecast

Global Architectural Acoustic Panels MarketMarket Size

Arsenic Removal MarketMarket Growth

Carbon Dioxide MarketMarket Analysis

Air Quality Apps MarketMarket Size

Global Positive Temperature Coefficient (PTC) Thermistors MarketMarket Share

Global X-ray Non-Destructive Testing Equipment MarketMarket Growth

Atorvastatin Calcium MarketMarket

Fermentation Airlock MarketMarket Share

Mica Paper MarketMarket Growth Rate

Baggage Towing Tractor MarketMarket Forecast

Global Foldable IOL Market MarketMarket Size

0 notes

Text

Exploring the Carbon Fiber Prepreg Market: Trends, Advantages, and Future Outlook

Introduction

The Carbon Fiber Prepreg Market is experiencing robust growth, driven by the increasing demand for lightweight, durable, and high-performance materials across various industries. Carbon fiber prepreg, a composite material made from carbon fibers pre-impregnated with a resin system, offers exceptional strength-to-weight ratio, stiffness, and corrosion resistance. This article delves into the current trends, advantages, and future prospects of the carbon fiber prepreg market.

What is Carbon Fiber Prepreg?

Carbon fiber prepreg is a pre-impregnated material where carbon fibers are combined with a thermoset or thermoplastic resin. This combination ensures uniform resin distribution and eliminates the need for additional resin during the manufacturing process. The material is stored in a refrigerated state to prevent premature curing, ensuring optimal performance and ease of use in various applications.

Current Market Trends

1. Growing Demand in Aerospace and Defense: The aerospace and defense sectors are major drivers of the carbon fiber prepreg market. The need for lightweight and high-strength materials to enhance fuel efficiency and performance in aircraft and defense equipment has significantly boosted the adoption of carbon fiber prepreg.

For a comprehensive analysis of the market drivers:- https://univdatos.com/report/carbon-fiber-prepreg-market/

2. Automotive Industry Adoption: The automotive industry is increasingly using carbon fiber prepreg to reduce vehicle weight, improve fuel efficiency, and enhance performance. High-end sports cars and electric vehicles (EVs) particularly benefit from the material's properties, leading to its growing demand.

3. Expansion in Wind Energy Sector: The wind energy sector is another key contributor to the carbon fiber prepreg market growth. Carbon fiber prepreg is used in the manufacturing of wind turbine blades, offering superior strength and reduced weight, which increases the efficiency and lifespan of the turbines.

4. Innovations in Manufacturing Processes: Advancements in manufacturing processes, such as automated fiber placement (AFP) and automated tape laying (ATL), are enhancing the production efficiency and quality of carbon fiber prepreg. These innovations are making the material more accessible and cost-effective for various industries.

5. Sustainability and Recycling: The push for sustainable materials and recycling solutions is influencing the carbon fiber prepreg market. Research and development efforts are focused on creating recyclable prepreg materials and improving recycling processes, aligning with global sustainability goals.

Advantages of Carbon Fiber Prepreg

1. High Strength-to-Weight Ratio: Carbon fiber prepreg offers an exceptional strength-to-weight ratio, making it ideal for applications where reducing weight without compromising strength is crucial. This property is particularly valuable in aerospace, automotive, and sporting goods industries.

2. Durability and Corrosion Resistance: The material's inherent resistance to corrosion and environmental degradation ensures longevity and reliability in harsh conditions. This makes it suitable for marine, infrastructure, and industrial applications.

3. Consistent Quality and Performance: Pre-impregnated with resin, carbon fiber prepreg provides consistent quality and performance. The controlled resin content ensures optimal mechanical properties and reduces the risk of manufacturing defects.

4. Ease of Use: Carbon fiber prepreg simplifies the manufacturing process by eliminating the need for additional resin application. This reduces processing time and labor costs, making it an efficient choice for high-volume production.

For a sample report, visit:- https://univdatos.com/get-a-free-sample-form-php/?product_id=31181

Future Prospects

The future of the carbon fiber prepreg market looks promising, driven by several key factors:

1. Increased Use in Electric Vehicles (EVs): As the EV market expands, the demand for lightweight materials to improve battery efficiency and vehicle range will drive the adoption of carbon fiber prepreg. Manufacturers are increasingly integrating this material into EV components to enhance performance.

2. Advancements in Material Science: Ongoing research and development in material science are expected to yield new formulations and resin systems for carbon fiber prepreg. These advancements will further improve the material's properties and expand its application range.

3. Emerging Markets: The growth of emerging markets in Asia-Pacific, Latin America, and the Middle East presents significant opportunities for the carbon fiber prepreg market. The increasing industrialization and infrastructure development in these regions will boost the demand for high-performance materials.

4. Sustainability Initiatives: The focus on sustainability and environmental regulations will drive innovations in recyclable and eco-friendly carbon fiber prepreg. The development of sustainable manufacturing processes and materials will enhance the market's growth prospects.

Conclusion

The Carbon Fiber Prepreg Market is set for substantial growth, fueled by its exceptional properties and wide-ranging applications across various industries. As technology advances and the demand for lightweight, durable, and high-performance materials increases, carbon fiber prepreg will continue to play a pivotal role in shaping the future of manufacturing and engineering. With a strong focus on sustainability and innovation, the market is poised to meet the evolving needs of modern industries and contribute to a more efficient and sustainable future.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

#Carbon Fiber Prepreg Market#Carbon Fiber Prepreg Market Growth#Carbon Fiber Prepreg Market Share#Carbon Fiber Prepreg Market Forecast

0 notes

Text

Rolling Forward: Insights into the Skateboard Market

Skateboarding, once considered a niche sport, has evolved into a global cultural phenomenon and a thriving industry in its own right. From city streets and skate parks to professional competitions and mainstream media, skateboarding has permeated various aspects of modern culture, influencing fashion, music, art, and lifestyle trends. The skateboard market, driven by a diverse community of enthusiasts, manufacturers, and retailers, offers a fascinating glimpse into the dynamics and trends shaping the world of skateboarding.

At the heart of the skateboard market lies the enduring appeal and versatility of skateboarding as a recreational activity and a form of self-expression. Skateboarding transcends age, gender, and background, attracting individuals from diverse walks of life who share a passion for creativity, freedom, and adrenaline-fueled thrills. Whether it's mastering tricks and maneuvers, cruising through city streets, or simply hanging out with friends at the local skate park, skateboarding offers a unique blend of athleticism, artistry, and camaraderie that resonates with people around the world.

Moreover, the skateboard market is driven by innovation and creativity in skateboard design, construction, and technology. Manufacturers are constantly pushing the boundaries of what's possible in skateboard engineering, experimenting with new materials, shapes, and features to improve performance, durability, and aesthetics. From traditional wooden decks and aluminum trucks to composite materials and carbon fiber reinforcements, skateboard manufacturers are leveraging cutting-edge techniques and technologies to create high-performance boards that meet the evolving needs and preferences of riders.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS10062

Furthermore, the skateboard market is influenced by broader trends in youth culture, fashion, and lifestyle that shape consumer preferences and purchasing behavior. Skateboarding has become more than just a sport—it's a lifestyle, a subculture, and a form of self-expression for many enthusiasts. As a result, skateboard manufacturers are not only focusing on product innovation but also on brand identity, storytelling, and community engagement to connect with consumers on a deeper level. Collaborations with artists, musicians, and influencers, as well as sponsorships of events and competitions, are common strategies used by skateboard brands to build authenticity and loyalty among their target audience.

Additionally, the skateboard market is characterized by a diverse range of products and segments catering to different riding styles, skill levels, and preferences. From classic street skateboards and longboards to cruiser boards and electric skateboards, there is a skateboard for every rider and every occasion. Skateboard decks come in various shapes, sizes, and concaves, allowing riders to customize their boards to suit their individual preferences and riding style. Similarly, wheels, trucks, bearings, and grip tape offer endless options for personalization and performance enhancement, allowing riders to fine-tune their setups for optimal performance and comfort.

Despite the opportunities for growth, the skateboard market also faces challenges, including competition from other action sports, safety concerns, and regulatory issues. Skateboarding competes for attention and resources with other action sports such as surfing, snowboarding, and BMX, which can limit its growth potential and market share. Additionally, safety concerns related to skateboarding injuries, accidents, and liability issues pose challenges for industry stakeholders, requiring education, advocacy, and risk management strategies to address. Furthermore, regulatory issues such as bans on skateboarding in certain areas, restrictions on skate park construction, and zoning regulations can hinder access to skateboarding facilities and limit opportunities for growth and participation in the sport.

In conclusion, the skateboard market is a dynamic and vibrant industry that reflects the passion, creativity, and diversity of the skateboarding community. With its roots in counterculture and rebellion, skateboarding has evolved into a mainstream phenomenon with global appeal and influence. By understanding the dynamics, trends, and challenges of the skateboard market, industry stakeholders can capitalize on opportunities to innovate, connect with consumers, and shape the future of skateboarding for generations to come.

0 notes

Text

Unidirectional Tapes Market Latest Report By Product, Fiber, End-Use, Region And Forecast To 2030: Grand View Research Inc.

San Francisco, 3 April 2024: The Report Unidirectional Tapes Market Size, Share & Trends Analysis Report By Product (Thermoplastic, Thermoset), By Fiber (Carbon, Glass, Other Fiber), By End-use (Aerospace & Defense, Automotive), By Region, And Segment Forecasts, 2024 – 2030 The global unidirectional tapes market size is anticipated to reach USD 793.6 million by 2030 and is anticipated to expand…

View On WordPress

0 notes

Text

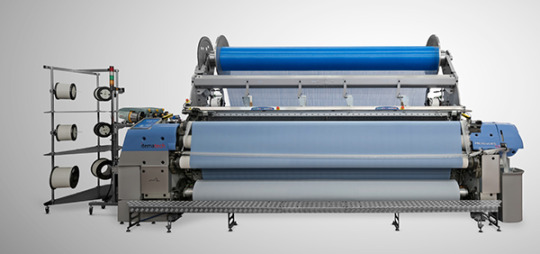

Itema showcases the Itematech weaving solutions at Techtextil 2024

Itema, a leading global provider of advanced weaving solutions, including weaving machines, spare parts, and integrated services, exhibits the most complete product portfolio to weave technical fabrics at Techtextil Frankfurt (Hall 12 – Booth D24) from April, 23rd to April, 26th.

Recognizing the specificity of the technical textile industry, Itematech was established in 2019 with the aim to provide a comprehensive range of weaving solutions tailored to manage complex fabrics in an easy yet efficient way. Today, Itematech stands as the optimal choice for weavers seeking for a unique partner able to offering the most diverse weaving machine portfolio available on the market for producing technical fabrics, including Single Positive Rapier, Negative and Positive Rapier, Airjet, and Projectile weaving machines.

At Techtextil 2024 the Itematech representatives will introduce to visitors the whole Itematech weaving range and the latest advancements to weave technical fabrics, in details:

UniRap: The Itematech Single Positive Rapier Weaving Machine

The absence of the weft exchange, thanks to the positive single rapier weft transfer, enables the Itematech UniRap to weave the widest range of high tenacity yarns, from carbon tape and fibers, to fiberglass, aramid fibers, steel and lead-coated yarns, and many others. Designed as an open platform, the Itematech UniRap comes to the market in a double version specifically developed for technical textiles weaving: the UniRap | P Weft Insertion System enables the effective insertion of carbon tapes and tape shaped yarns with no torsion up to 30mm, while the UniRap | G Weft Insertion System is ideal to weave the widest range of technical yarns. What makes the two versions even more interesting is the possibility to switch the two weft transfers easily and quickly, thus providing weavers with two weft insertion technologies in one.

Hercules: The Itematech Negative and Positive Rapier Weaving Machine

The Hercules reinforced machine structure coupled with its textile flexibility offers weavers the ideal weaving technology to produce the most demanding technical textiles, from extremely high density to finest fabrics. One of a kind on the market, Hercules provides unbeatable textile flexibility thanks to its unique weft transfer system that enables the valuable possibility to switch easily and quickly from positive to negative rapiers, thus leading to superior textile efficiency when handling the widest range of weft yarns counts, from 20 up to 48,000 dtex, in single or multiple weft insertions configurations. Hercules is available in weaving width up to 6200mm and features a modular structure, customizable according to weavers’ textiles needs. In fact, the basic machine structure is reinforced and can be equipped with different devices capable to reach a beating force up to 5.5 tons (depending on the reed width). Hercules textile range includes but is not limited to agrotextiles, medium and heavy coating fabrics, medium and heavy conveyor belts, medium and heavy filter fabrics, fiberglass, geotextile, heavy canvas, geogrid, plain carpet.

P7300HP V8: The Itematech Projectile Weaving Machine

Technical fabrics are the specialty of the legendary P7300HP due to its reliable and versatile weft insertion system, based on the single insertion driven by the projectile which catches the weft and carries it directly with no exchanges, providing unmatched efficiency. The P7300HP continues to represent an unbeaten and unbeatable benchmark for those looking to weave the very widest fabrics (over 6 meters) and high-specialty materials, such as agrotextile, geotextile and primary carpet backing fabrics.

R9500EVO : The Itematech Rapier Weaving Machine

The Itema R9500EVO is the latest version of the Itema best-seller R9500. The continuous roll-out of customized special versions tailored for technical applications, including coating, para-aramid, fiberglass, bolting cloth, fabrics for automotive, light filter fabrics, among others, as well as dedicated devices for each application make the R9500EVO the perfect machine for the manufacturing of the full range of technical textiles, including the ones with the finest monofilament yarns, multifilament yarns with high tenacity, and multiple pick insertion fabrics.

R9500EVO is equippable with the Itema iSAVER tech. The Itema breakthrough device eliminates the waste selvedge on the fabric’s left-hand side, thus significantly reducing the wastage of raw materials and resources leading to cost reduction and contributing to sustainable weaving. iSAVER tech is available to weave a wide range of technical yarns and it is even retrofittable as upgrade kit on all R9500 series machine models.

A9500EVO: the Itematech Airjet Weaving Machine

When it comes to weaving very high-density fabrics, the airjet A9500EVO is customizable with dedicated devices to ensure excellent results while answering to the most demanding weaving needs. In particular, the Itema Airjet A9500 iLENO for Seconday Carpet Backing has recently been launched on the market and rapidly gained popularity among technical weavers. This special airjet machine, indeed, has been designed by Itema to successfully and effectively weaving Secondary Carpet Backing fabrics with the goal to maximize weavers productivity and return on investment.

Techtextil 2024 represents an unmissable opportunity to discover all the Itematech weaving solutions and to discuss with our experts any weaving need.Visit us in Hall 12 – Booth D24.

0 notes

Text

0 notes

Text

Carbon Fiber Tapes Market Size Worth $4.9 Billion By 2027 | CAGR: 13.4%

Carbon Fiber Tapes Market Growth & Trends The global carbon fiber tapes market size is expected to reach USD 4.9 billion by 2027, expanding at a CAGR of 13.4%, according to a new report by Grand View Research Inc. The rapidly rising demand for advanced materials with superior strength to weight ratio in the transportation sector is expected to bolster the market over the forecast period. Carbon…

View On WordPress

0 notes

Text

Carbon Composites Market, Share, Size, Trends, Forecast and Future Outlook

Carbon Composites Market

The market research report provides a comprehensive analysis of the industry, with a specific focus on the Carbon Composites Market. It examines the size, growth rate, and major trends within the Carbon Composites Market, offering valuable insights into its current state and future prospects. The report explores the significance of Carbon Composites in driving market dynamics and shaping business strategies. It investigates the market drivers, such as increasing consumer demand and emerging trends related to Carbon Composites, providing a deep understanding of the factors influencing market growth. Additionally, the report assesses the competitive landscape within the Carbon Composites Market, profiling key players and their market share, strategies, and product offerings. It also addresses market segmentation, identifying different segments within the Carbon Composites Market and their unique characteristics. Overall, the market research report equips businesses operating in the Carbon Composites Market with valuable information and actionable recommendations to capitalize on opportunities and navigate the challenges in the industry.

Request Free Sample Report @ https://www.vertexbusinessinsights.com/request-sample/180/carbon--composites-market

This research covers COVID-19 impacts on the upstream, midstream and downstream industries. Moreover, this research provides an in-depth market evaluation by highlighting information on various aspects covering market dynamics like drivers, barriers, opportunities, threats, and industry news & trends. In the end, this report also provides in-depth analysis and professional advices on how to face the post COIVD-19 period.

The research methodology used to estimate and forecast this market begins by capturing the revenues of the key players and their shares in the market. Various secondary sources such as press releases, annual reports, non-profit organizations, industry associations, governmental agencies and customs data, have been used to identify and collect information useful for this extensive commercial study of the market. Calculations based on this led to the overall market size. After arriving at the overall market size, the total market has been split into several segments and sub segments, which have then been verified through primary research by conducting extensive interviews with industry experts such as CEOs, VPs, directors, and executives. The data triangulation and market breakdown procedures have been employed to complete the overall market engineering process and arrive at the exact statistics for all segments and sub segments.

Carbon Composites Market Segment Analysis

Carbon Composites Market By Product Type

Unidirectional Carbon Fiber Sheet

Prepregs

Fabrics & Tape

Laminates

Molded Components

Carbon Composites Market By Raw Materials

PAN-based Carbon Fibers

Pitch Based Carbon Fibers

Recycled Carbon Fibers

Carbon Composites Market By End User

Aerospace

Automotive

Wind Energy

Sports & Recreation

Construction

Marine

Carbon Composites Market By Region

North America

Europe

Asia Pacific

South America

Middle east & Africa

Ask Queries @ https://www.vertexbusinessinsights.com/enquiry/180/carbon--composites-market

Table of Content

1 Executive Summary

2 Market Introduction

2.1 Definition

2.2 Architecture

2.3 Scope of the Study

2.4 Related Stakeholders

3 Research Methodology

3.1 Introduction

3.2 Primary Research

3.2.1 Key Insights

3.2.2 Breakdown of Primary Interviews

3.3 Secondary Research

3.3.1 Important Sources

3.4 Market Size Estimation Approaches

3.4.1 Top-Down Approach

3.4.2 Bottom-Up Approach

3.4.3 Data Triangulation

3.5 List of Assumptions

4 Market Dynamics

4.1 Introduction

4.2 Drivers

4.3 Restraints

4.4 Opportunities

4.5 Porter's Five Forces Model Analysis

4.6 Value Chain Analysis

4.7 Impact of COVID-19 on Global Carbon Composite Market

5 Global Carbon Composite Market, By Product Type

5.1 Introduction

5.2 Unidirectional Carbon Fibre Sheet

5.3 Prepregs

5.4 Fabrics & Tape

5.5 Laminates

5.6 Moulded Components

6 Global Carbon Composite Market, By Raw Material

6.1 Introduction

6.2 PAN-based Carbon Fibers

6.3 Pitch Based Carbon Fibers

6.4 Recycled Carbon Fibers

7 Global Carbon Composite Market, By End User

7.1 Introduction

7.2 Aerospace

7.3 Automotive

7.4 Wind Energy

��7.5 Sports & Recreation

7.6 Construction

7.7 Marine

8 Global Carbon Composite Market, By Region

8.1 Introduction

8.2 North America

8.2.1 US

8.2.2 Canada

8.2.3 Mexico

8.3 Europe

8.3.1 Germany

8.3.2 UK

8.3.3 France

8.3.4 Italy

8.3.5 Spain

8.3.6 Rest of Europe

8.4 Asia-Pacific

8.4.1 China

8.4.2 India

8.4.3 Japan

8.4.4 South Korea

8.4.5 Rest of Asia-Pacific

8.5 Middle East and Africa

8.6 South America

9 Competitive Landscape

9.1 Introduction

9.2 Vendor Evaluation Criteria

9.3 Vendor Share Analysis, 2021

9.4 Recent Developments, 2019-2021

9.4.1 New End User Launches

9.4.2 Partnerships

9.4.3 Mergers or Acquisitions

9.4.4 Business Expansions

10 Company Profiles

(This section covers the Business Overview, Financial Overview, End User and End User Offerings, Recent Developments, SWOT Analysis, and Key Strategies of the top market vendors. The given sequence does not represent their rankings in the market.

10.1 Toray Industries, Inc.

10.2 Teijin Limited

10.3 Hexcel Corporation

10.4 Mitsubishi Chemical Holdings Corporation

10.5 SGL Carbon

10.6 Zoltek Companies, Inc. (a subsidiary of Toray Industries)

10.7 Cytec Solvay Group (now part of Solvay S.A.)

10.8 Axiom Materials, Inc.

10.9 Park Aerospace Corp.

10.10 PRF Composite Materials

10.11 DowAksa

10.12 SABIC

10.13 Lanxess AG

10.14 Toho Tenax (a subsidiary of Teijin Limited)

10.15 Owens Corning

10.16 Hyosung Corporation

10.17 Gurit Holding AG

10.18 Colbond B.V. (a subsidiary of Low & Bonar)

10.19 Plasan Carbon Composites

10.20 Royal DSM

10.21 Nippon Electric Glass (NEG)

10.22 Gurit Holding AG

10.23 SGL Carbon SE

10.24 TenCate Advanced Composites (a part of Toray Industries)

10.25 Huntsman International LLC

10.26 Others

11 Appendix

11.1 Discussion Guide

11.2 Customization Options

11.3 Related Reports

Continue…

ABOUT US:

Vertex Business Insights is one of the largest collections of market research reports from numerous publishers. We have a team of industry specialists providing unbiased insights on reports to best meet the requirements of our clients. We offer a comprehensive collection of competitive market research reports from a number of global leaders across industry segments.

CONTACT US

Phone: + (210) 775-2636 (USA) + (91) 853 060 7487

0 notes