#Carbide Inserts

Text

CBN Inserts Suppliers

CBN (Cubic Boron Nitride) inserts are cutting tools used in the machining industry. They are made of a very hard and durable material that is second only to diamond in hardness. CBN inserts are commonly used for machining hard materials such as hardened steel, cast iron, and superalloys.

CBN inserts are designed to provide superior cutting performance, with high speed, high efficiency, and long tool life. They are often used in high-precision machining applications, where high accuracy and surface finish are critical.

CBN inserts come in a variety of shapes and sizes, including square, round, triangular, and diamond-shaped. They can be mounted on various types of cutting tools, including turning and milling tools, boring bars, and grooving tools.

CBN inserts are typically more expensive than other cutting tools, but they can provide significant cost savings in the long run by reducing tool changeover times and increasing machining productivity.

Inserts Suppliers

#CBN#Inserts#Machenzzo#Carbide Inserts#cutting#ceramic#carbide#metalwork#tool#drill bits#grinder#2023#metal#distributor#cnctools#removals#deburring#grinding#shaping#automotive#aerospace#foundary#engineering#suppliers

0 notes

Text

The Ultimate Guide To Carbide Inserts

Carbide inserts are used for creating holes on different surfaces. They can also be used for shaping wood as well as creating a smooth cutting edge. It is the most preferred material when it comes to manufacturing carbide inserts.

0 notes

Text

#CNC spoilboard cutter#cnc insert router tooling#cnc insert v groove bit#cnc helical planing cutter#solid carbide router bit for wood#ball nose solid carbide bit#compression solid carbide bit#upcut solid carbide bit#down cut solid carbide bit#solid carbide router bit for plastics#dowel drill bits#v point drill bits for wood#hinge drill bits#solid carbide dowel bit#solid carbide through point bit#panel saw blade

2 notes

·

View notes

Text

Jaibros offers a range of high-quality carbide bit drills, designed for precise and efficient drilling applications. Crafted from premium carbide materials, Jaibros drills provide exceptional hardness, wear resistance, and heat resistance, ensuring long tool life and optimal performance.

0 notes

Text

2 component carbide insert storage mold

China bi mold maker, offer 2k carbide insert storage mold, multi shot turning insert box, two color milling cutter container, pp tpe cutting tools collection box

#two color carbide insert storage mold#2k turning insert box mold#rotary mold milling cutter container#double cutting tools collection box mold#china mold#2 component mold#bi material mold#multi shot mold

0 notes

Text

Solid Carbide Rod: The Foundation of Precision Engineering!

Introducing the Solid Carbide Rod, the cornerstone of precision engineering. Crafted from high-quality carbide material, this rod serves as the foundation for a wide range of cutting tools and wear-resistant components. With its exceptional hardness, strength, and heat resistance, the Solid Carbide Rod delivers unparalleled performance in demanding applications. From end mills to drills and reamers, this versatile rod ensures precise machining and extended tool life. The Solid Carbide Rod empowers engineers and manufacturers to push the boundaries of precision, reliability, and efficiency. Embrace the power of the Solid Carbide Rod and elevate your engineering endeavors to new heights.

1 note

·

View note

Text

#cnc insert v groove bit#cnc helical planing cutter#solid carbide router bit for wood#ball nose solid carbide bit

0 notes

Text

1 note

·

View note

Video

youtube

Cnc Lathe Cutting Indexable ToolsTurningTool Holders Carbide Inserts for...

#youtube#All inserts and holders are also available. Best prices Best quality +86 19158283975 mailto:[email protected] cnctools carbide endmill

0 notes

Text

The tool is also designed to be used with minimal maintenance

Fine Boring Cartridge: The Ultimate Solution for Precision Boring Fine Boring Cartridge is a cutting-edge tool that is used for precision boring in the field of manufacturing and machining. The tool is designed to provide high accuracy and precision in bore size and shape, making it an indispensable tool for many industrial applications.

In this article, we will discuss the features, benefits, and applications of the Fine Boring Cartridge. Features of Fine Boring Cartridge High Accuracy: The Fine Boring Cartridge is designed to provide high accuracy in bore size and shape.

The tool uses advanced technology to achieve this accuracy, which makes it ideal for applications where precise bore size and shape are critical. Versatility: The Fine Boring Cartridge is versatile and can be used for a wide range of materials, including cast iron, steel, and aluminum.

The tool is also designed to indexable Carbide Inserts for drilling be used on both horizontal and vertical boring machines. Easy to Use: The Fine Boring Cartridge is easy to use and can be quickly installed and removed from the machine, reducing downtime and increasing productivity. The tool is also designed to be used with minimal maintenance, which further increases its ease of use.

Benefits of Fine Boring Cartridge Increased Productivity: The Fine Boring Cartridge is designed to increase productivity by reducing downtime and increasing accuracy and precision.

The tool is also designed to be used with minimal maintenance, which further increases productivity. Improved Quality: The Fine Boring Cartridge provides high accuracy and precision, which results in improved quality in the final product.

1 note

·

View note

Text

Cubic Boron Nitride (CBN) inserts are cutting tools made from a synthetic material that is second only to diamond in hardness. They are widely used in machining applications due to their exceptional properties. Here are the key benefits of using CBN inserts in machining processes:

**1. High Hardness and Wear Resistance:

Exceptional Hardness: CBN is one of the hardest known materials, providing excellent wear resistance during cutting operations.

Long Tool Life: CBN inserts have a longer tool life compared to traditional carbide inserts, reducing the frequency of tool changes and increasing productivity.

**2. High Thermal Stability:

Heat Resistance: CBN inserts can withstand high cutting temperatures without losing their hardness or shape. This makes them suitable for high-speed machining and applications involving heat-resistant materials like hardened steels and superalloys.

Reduced Thermal Stress: CBN inserts generate less heat during cutting, leading to reduced thermal stress on both the tool and the workpiece.

**3. High Chemical Stability:

Chemical Inertness: CBN is chemically inert, making it resistant to chemical wear. This property allows CBN inserts to perform well in applications involving abrasive and corrosive materials.

**4. Superior Surface Finish:

Excellent Surface Finish: CBN inserts produce superior surface finishes on machined parts due to their sharp cutting edges and wear-resistant properties. This is especially important in applications where surface quality is critical, such as in the aerospace and automotive industries.

**5. Versatility and Adaptability:

Wide Range of Applications: CBN inserts are versatile and can be used for various machining operations, including turning, milling, boring, and threading.

Suitable for Hard Materials: CBN inserts are highly effective for machining hard materials such as hardened steels, cast iron, and heat-resistant alloys.

**6. Increased Productivity:

Higher Cutting Speeds: CBN inserts allow for significantly higher cutting speeds compared to conventional carbide inserts. This leads to increased machining efficiency and productivity.

Reduced Downtime: Due to their extended tool life, CBN inserts reduce downtime associated with tool changes and replacements.

**7. Cost Savings:

Longer Tool Life: CBN inserts have a longer operational lifespan, reducing the frequency of tool replacements and overall tooling costs.

Improved Efficiency: Higher cutting speeds and superior surface finishes contribute to improved efficiency, leading to potential cost savings in manufacturing processes.

**8. Environmental Benefits:

Reduced Material Waste: Longer tool life results in reduced material waste from used inserts, contributing to environmental sustainability.

In summary, CBN inserts offer significant advantages in terms of durability, performance, and cost-effectiveness in machining operations. Their ability to withstand high temperatures, maintain sharp cutting edges, and produce excellent surface finishes makes them invaluable tools for manufacturers across various industries.

#cbn#CBN Inserts#CBN#Cutting Tools#Machine Tools#Ceramic Inserts#cutting#ceramic#carbide#metalwork#tool#drill bits#grinder#2023#metal#distributor#cnctools#removals#deburring#grinding#shaping#automotive#aerospace#engineering

0 notes

Text

machining is a fun industry to be in because you see how much plastic waste is generated from overengineered packaging and u remember that individual consumption is basically meaningless. u can extrapolate so much ab the late-capital edifice just from this jpeg

do we really need to transport and store carbide inserts in nifty pez dispensers with dedicated modular sliding joints to connect the containers? no. you could just as easily wrap these pimps in paper with some extra padding inbetween to prevent chipping or marring in transit.

did the engineer behind it need to do it or else she'd lose her job and risk not making rent? probably.

were there upwards of 5 meetings-that-could-have-been-emails about whether to begin including this element on future kennametal packaging? of course.

are these things ever reused?

no .

369 notes

·

View notes

Text

0 notes

Text

Jaibros is renowned for producing high-quality carbide inserts, essential components in various metalworking applications. These inserts are crafted from premium carbide materials, known for their exceptional hardness,

0 notes

Text

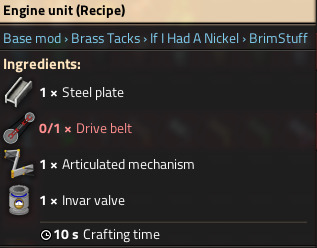

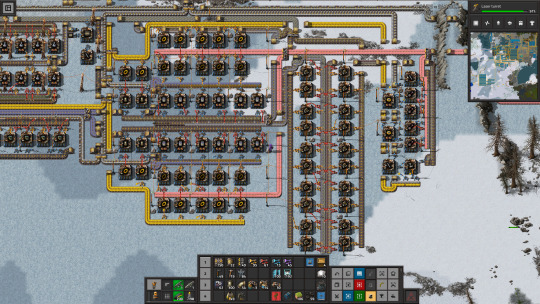

As I push through my final world in factorio 1.1 I realize that I fucking hate this recipe I made.

This sucks. It just sucks. It casts my annoyances with the game into sharp relief.

Big problem with factorio: clever builds where you consolidate multiple steps are intrinsically less effective than boring builds where you just input The Literal Ingredients Of The Recipe to a line of machines, because more processed items are almost always denser.

Here's a reworked vanilla recipe that I'm extremely happy with how it turned out:

The reason I like it so much is the valve is the most complex ingredient here, and the other ingredients can be made from some subset of its raw materials (even the steel if you have fuel on site, or electric smelters.) So if you're paying attention, you get engine units set up for minimal additional time investment or routing difficulty once you have a good valve production setup.

The keen-eyed among you might notice that this setup doesn't fucking scale. This is clever, but it's clever because you are building it in an early omni-spaghetti base that doesn't segregate mall, intermediate, and science production, and everything needs a variety of plates so you're sending the plates around anyway, so building multiple low-volume intermediates out of the same materials is useful because it saves space and time.

But suppose in the end/postgame you need scaled-up train-fed production of engine units for blue science for infinite research. You can make your production block have four input stations for steel, articulated mechanisms, drive belts, and valves, and build the most boring setup ever, or you could be clever and import the raw materials and have... four input stations, for iron, brass, invar, and rubber. Which transport by train way less densely. Even this very good recipe falls victim to the emergent properties of the basic game mechanics.

The only way to make this stay interesting in the postgame is to take the efficiency hit for the aesthetics - and if you are building a base that does infinite research, nobody ever fucking talks about anything except the vaunted SPM number - or to make every intermediate fluffy, i.e. less valuable per item or stack than its precursors. This sucks for plausibility/realism reasons, it messes with the balance of inserters, it feels weird for "more valuable" items to be more numerous, and you shouldn't be encouraged to do every step everywhere and never centralize anything. But okay. I've said before that the postgame is pretty boring and I'm here for the spaghetti. I can tolerate some inefficiencies in my final engine unit build for style points and the ability to allegedly sleep at night under ideal conditions.

Why does the gyroscope suck? Because it's the opposite of the engine unit. Their ingredients' precursors overlap in uninteresting ways. There are nonzero clever things you can do with them once you're fully scaled up, but at that point you will be eating the throughput downsides of being clever at scale. The things that need gyroscopes do not sufficiently overlap with the ingredients of gyroscopes to make making them where they're used not an ingredient explosion.

I think gyroscopes are probably salvageable in future updates of my mods simply by replacing the red circuit with 2-3 green circuits and perhaps some tweaking of the recipes that consume them, but some items I feel do not really make the cut. HV power regulators and both tiers of machining tools, in particular, feel like they need to be majorly reworked or removed entirely. (The biggest step I could take in this direction is drop BZ compatibility, which is a sort of "nuclear option" that makes me hesitate, but several items were added specifically to consolidate the ludicrous number of plates BZ adds to seemingly every machine's recipe. Like, the advanced machining tool and industrial drill head are both to consolidate together diamonds and tungsten carbide.)

A side benefit of doing this is that, if Space Age doesn't permanently put me off the game and I have enough energy to maintain mods going forward, I would then be able to implement my own version of several of the BZ resources that I have some vague ideas for how I would do them slightly differently. Most of my ideas involve adding alternate recipes for things, which conflicts with the hardcoded abomination that is Quality, which is excuse enough for my mods to obliterate that mistake of a mechanic from any pack containing them forever and ever Amen.

3 notes

·

View notes

Text

Tungsten Carbide Burr: Unleash the Power of Precision Grinding!

Experience the pinnacle of precision grinding with the Tungsten Carbide Burr. This exceptional tool is crafted from high-quality tungsten carbide, renowned for its superior hardness and wear resistance. With its sharp cutting edges and versatile shapes, it effortlessly removes material with surgical precision, leaving behind smooth surfaces and intricate details. From deburring to shaping and finishing, the Tungsten Carbide Burr is the go-to choice for professionals in industries like metalworking, woodworking, and automotive. Say goodbye to manual labor and hello to efficient material removal.

1 note

·

View note