#Capsule Filling Machine:

Explore tagged Tumblr posts

Text

Tablet Capsule Filling & Compression Machine manufacturer

IRM Enterprise Pvt. Ltd., the leading pharma machine manufacturer.

Tablet Compression MachineWe are manufacturer of Tablet Compression Machine. Our tablet compression machines are designed to produce high-quality tablets efficiently and accurately.

Capsule Filling Machine:We are manufacturer of Capsule Filling Machine. Our capsule filling machines are designed to streamline the capsule filling process, providing accurate and efficient operations.

Granulation MachineWe are manufacturer of Granulation Machine. Granulation plays a crucial role in the pharmaceutical manufacturing process. Our granulation machines are designed to efficiently transform raw materials into granules of uniform size and density.

Tablet ToolingWe are manufacturer of Tablet Tooling. Tablet Machine Punches & Dies Tooling and discover the perfect tablet tooling solution for your tablet press machine.

Kalweka Multi-Purpose EquipmentThis equipment integrates various functions, such as mixing, blending, granulation, and drying, into a single system.

For More Details Click here : https://www.karnavatiengineering.com/

0 notes

Text

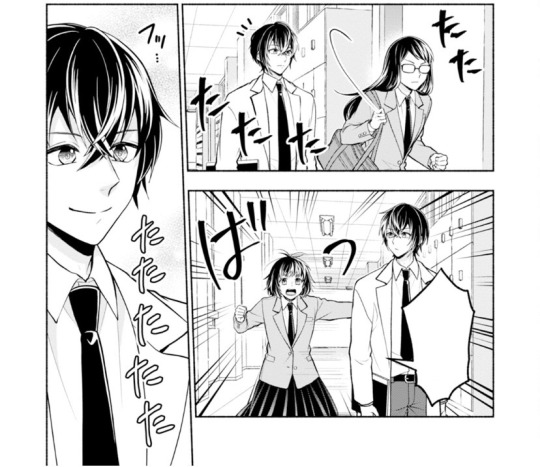

help nooooo i just realised that they butchered akechi’s character too

#i mean… would mr ‘don’t run in the halls’ really *really* smile as two of his students play tag in said halls?#who is he and which ‘verse is he from? the m*t* s**t* ‘verse????#reliving the [redacted] anime is oddly therapeutic in a way. it gives me an appropriate channel for anger venting#so thanks [redacted] anime for being the anger management course that you are </3 i still hate you though </3#man it’s almost 2 am and i need to be up in 4 hours but i stayed up late to read pksp anyway whoops#binge reading the su-mo chapter was quite the experience. i’m glad the bookstore had all 6 vols when i dropped by#and now i finally understand the moon berlitz references. hell yeaaaaaaaaaaaaa#i lost it when the faba faba-d off though. sorry (not sorry) faba dude kinda deserved it#but man. freakin’ moon and her ‘is ok i studied pharm sci i know how to make all medicines :))’#girl pls what kind of magical pharm sci school did you go to? i never learned anythingggg but placebo pills :(( (former pharm sci student)#reminds me that the capsules we used for class were old af and expired so the capsule filling task didn’t go well at all#making suppositories was weird though. shapin’ the thing and pressing it into the mold and all…#but the expensive tablet making machine was very cute. the temptation to smash it to bits was even cuter though~~

8 notes

·

View notes

Text

How Capsule Filling Machines Are Enhancing Pharmaceutical and Nutraceutical Production

The pharmaceutical and nutraceutical industries have experienced remarkable growth over the past few decades, driven by increasing consumer demand for health supplements, medications, and vitamins. To meet this demand efficiently, manufacturers rely on advanced technology, with capsule filling machines standing at the forefront. These machines are transforming production processes, enhancing both the quality and scalability of products.

#Capsule Filling Machines#Capsule Filling Machine Manufacturers#Capsule Filling Machine Suppliers#capsule filling#capsule machine#filling machine

0 notes

Text

Semi Automatic Capsule Counter Machine

Semi-automatic capsule counter machine counts and fills pre-measured capsules into bottles, jars, and pouches. It also has a semi-automatic capsule counter. Various counts for varying capsule sizes can be provided based on the specific needs of each user. It’s interesting to note that this capsule counting machine can fill and count tablets with an extra disc in the same machine. This machine is also known as a semi-automatic tablet counter machine for this reason.

The capsule counter and filling machine is a disc-based device that conforms with cGMP regulations because the disk is made of food-grade materials. The likelihood of contamination is quite low. A specially made vibrator assembly is available in a dish to fully settle capsules into the disc’s holes. It’s interesting that the machine has both an auto and a foot pedal-operated manual mode for multitasking. With its cutting-edge technology, robust construction, and affordable costs, Adinath is among the top producers of capsule counter machines in India.

0 notes

Text

How Do Vegan Capsule Filling Machines Differ from Traditional Options?

In the world of dietary supplements and pharmaceuticals, capsule filling machines are essential for efficient production. However, as the demand for vegan products grows, the need for specialized vegan capsule filling machines has emerged. Here’s a closer look at how vegan capsule filling machines differ from traditional options that primarily handle gelatin capsules.

1. Material Compatibility

Vegan Capsules vs. Gelatin Capsules

The most significant difference lies in the materials used. Traditional capsule filling machines are designed for gelatin capsules, which are derived from animal products. In contrast, vegan capsule filling machines are specifically designed to handle plant-based materials, such as hydroxypropyl methylcellulose (HPMC) or pullulan. These materials require different handling and processing conditions.

2. Design and Mechanisms

Adaptations for Vegan Capsules

Vegan capsule filling machines may incorporate design features tailored to the unique properties of plant-based capsules. For instance, these machines often have adjustments for lower moisture absorption, as vegan capsules can be more sensitive to humidity and temperature changes. Additionally, the filling mechanisms may be modified to accommodate the viscosity and density of the powders used in vegan formulations.

3. Temperature Control

Stability and Quality

Plant-based capsules can be more susceptible to heat than gelatin capsules. Vegan capsule filling machines often include enhanced temperature control systems to prevent capsule deformation during the filling process. This is crucial to maintaining the integrity and effectiveness of the product.

4. Cleanliness and Allergen Considerations

Ensuring Safety

Vegan capsules are often marketed as allergen-free and suitable for various dietary restrictions. Vegan capsule filling machines are designed with strict hygiene protocols to prevent cross-contamination with animal-derived products. This is particularly important for manufacturers looking to appeal to consumers with specific dietary needs.

5. Versatility and Customization

Handling Diverse Formulations

While traditional machines may be limited to specific capsule types, many vegan capsule filling machines offer greater versatility. They can accommodate a range of formulations, including powders, granules, and even liquid fills. This flexibility allows manufacturers to produce a wider variety of products, catering to the growing demand for vegan options.

6. Production Speed and Efficiency

Performance Metrics

Although both vegan and traditional capsule filling machines aim for high efficiency, the production speed can vary based on the machine’s design and capabilities. Some vegan capsule machines may be optimized for slower filling rates to ensure accuracy and minimize waste, especially with sensitive ingredients.

7. Cost Considerations

Investment and ROI

Vegan capsule filling machines may have a different price point compared to traditional machines. While they can be more expensive due to specialized features, the return on investment (ROI) can be significant, given the increasing market demand for vegan products. Evaluating long-term benefits is essential when considering costs.

Conclusion

Vegan capsule filling machines are specifically designed to meet the unique requirements of plant-based capsules, offering advantages in material compatibility, design, and hygiene. As the demand for vegan products continues to grow, investing in the right machinery becomes crucial for manufacturers looking to thrive in this evolving market. By understanding these differences, businesses can make informed decisions that align with their production goals and consumer preferences.

0 notes

Text

Semi-automatic Capsule Filling Machine NCFM-101

Labnics semi-automatic capsule filling machine offers a maximum output of 20,000 pieces/hr with precise dosages. It operates at 0.4–0.6 Mpa air pressure and 0.1 m³/min air supply and offers high productivity, simple operation, and reliable performance.

#laboratory Capsule Filling Machine price#Capsule Filling Machine supplier#Capsule Filling Machine online

0 notes

Text

Tablet Compression Machine, Capsule Filling Machine Manufacturer in India, Europe

At IRM Enterprises Pvt. Ltd., we are committed to being a comprehensive solution provider for all your tablet press machine and capsule filling machine needs to across various industries, including all industirs like Pharmaceuticals, Ayurveda, Food & Confectionary (Polo), Ceramic, Nutraceutical, Veterinary, Camphor, Chlorine, Fresheners, Pesticides, Chemical, and Aquaculture.

Capsule Filling Machine

We understand the importance of precise and efficient capsule filling processes and that is why we bring you a diverse selection of advanced automatic capsule filling machines that cater to various production requirements.

Tablet Compression Machine

As a trusted name in the pharmaceutical machinery sector, we offer top-of-the-line solutions for all your tablet compression needs. We are leading manufacturer, supplier and exporter of automatic machines streamline the tablet manufacturing process, saving time and resources while maintaining the highest quality standards. Our automatic tablet press machines can meet the requirements of various tablet sizes, shapes, and production capacities.

Our Products

Tablet Compression Machines,

Capsule Filling Machines,

Granulation line,

Tablet Tooling,

Granulation Machine,

Kalweka Multi-Purpose Equipment’s

For More Details Click here: https://www.karnavatiengineering.com/ Contact Details : 7567876473

0 notes

Text

Lodha Pharma's Capsule Filling Machine is an innovative product intended to fulfill the wide range of pharmaceutical company requirements. This machine, designed for accuracy and efficiency, fills capsules precisely and consistently with a variety of powders, granules, or pellets. It is a dependable option for high-volume production applications because to its sophisticated technology and sturdy design. Check this page at https://www.lodhapharma.com/high-speed-capsule-filling-machine.php for further details.

0 notes

Text

Capsule filling machine are essential equipment in the pharmaceutical and nutraceutical industries for filling empty capsule with powdered ingredients. These machines come in various sizes and configurations, ranging from manual to fully automatic, and can fill many capsules per hour. They help ensure precise and consistent dosing while also streamlining the production process.

0 notes

Text

Tablet Punch & Dies manufacturer in India Manufacturer

Rimek is a Leading Manufacturer of Tablet Punch and Dies in India.

Pharmacists do not decide pill sizes. Pill size, shape, color, etc. are decided by the Product Development & Research (PDR) team of the pharmaceutical company manufacturing the pills. If the quality of Tablet Tooling machine or Tablet Punch and Dies is compromised it results in hairline crack, corrosion,low productivity of tablets.

Pharma machine Products

Tablet Compression machine Capsule Filling machineGranulation machine Tablet Tooling machineKalweka Multi-Purpose Equipment’s

For More Details Click here : https://www.karnavatiengineering.com/

0 notes

Text

Lodha Machines is the largest manufacturer and exporter of pharmaceutical machinery in Gujarat, India. Offers the best solutions for medicine filling and packaging machines in the pharmaceutical industry. We take pride in providing the highest quality pharma machines, ensuring efficiency, reliability, and compliance with industry standards. We are committed to providing the best quality pharmaceutical machinery, which is designed with precision and meets strong quality control demands. We are also manufacturers of various types of pharmaceutical machinery like Washing & Air jet Cleaning Machines, Autoclaves and Sterilizers, Ampoule Filler Sealer, Liquid Filling Machine, Powder Filling Machine. If you require visit our site: https://www.lodhamachines.com/ or Contact us: +919687731331

#pharmaceutical machinery#capsule filling machine price#pharmaceutical machinery manufacturer#capsule filling machine manufacturer#tablet making machine manufacturer#pharma machine Manufacturer#Washing & Air jet Cleaning Machines#Autoclaves and Sterilizers#Ampoule Filler Sealer#Liquid Filling Machine#Powder Filling Machine

0 notes

Text

Shrink Sleeve Machine – Efficient Packaging Solutions for Labeling and Product Security

Discover state-of-the-art shrink sleeve machines designed for precise and efficient labeling. These machines apply shrinkable plastic sleeves to various container shapes and sizes, offering 360-degree coverage for branding, tamper evidence, and product security. Ideal for industries such as pharmaceuticals, food & beverage, and cosmetics, shrink sleeve machines ensure superior packaging performance with high-speed, automated solutions. For more information about our machine contact us 0493 067 150

0 notes

Text

How to maintain the automatic liquid capsule filling machine daily?

In the fast-paced pharmaceutical manufacturing process, the maintenance and upkeep of the machine are paramount. In this blog post, WECAPS will share with you the daily maintenance methods of the fully automatic liquid capsule filling machine for sale. This maintenance method for the filling machine extends the life of the machine, improves the production efficiency and guarantees the product quality.

Routine maintenance of automatic liquid capsule filling machine

1. Cleaning and Sanitization:

Proper cleaning and disinfection to prevent cross-contamination and ensure product quality.

- Start by disconnecting the machine from the power source and removing any remaining capsules or liquid.

- Use a soft brush or vacuum cleaner to remove dust, debris, and residue from the machine's exterior and interior components.

- Prepare a cleaning solution by diluting a suitable detergent in warm water. Wipe down all surfaces, including the hopper, filling nozzles, and conveyor belts, using a clean cloth or sponge.

- Rinse all components thoroughly with clean water to remove any detergent residue.

- Allow the machine to dry completely before reassembling and reconnecting it.

2.Increased Lubrication

Proper lubrication ensures smooth operation and reduces friction between moving parts.

- Refer to the manufacturer's instructions to identify the specific lubrication points on the machine.

- Use a high-quality food-grade lubricant recommended by the manufacturer.

- Apply the lubricant sparingly to the designated points, ensuring that it reaches all necessary areas.

- Wipe off any excess lubricant to prevent contamination of the capsules or liquid.

3. Inspection and Replacement of Wear Parts:

Inspect worn parts regularly to identify any signs of damage or wear.

- Filling nozzles: Check for any clogs, cracks, or signs of wear. Replace damaged nozzles immediately.

- Conveyor belts: Inspect for any tears, fraying, or misalignment. Replace worn-out belts to maintain smooth capsule transportation.

- Seals and gaskets: Examine for leaks, cracks, or deterioration. Replace damaged seals and gaskets to prevent liquid leakage and ensure proper sealing.

4. Calibration and Adjustment:

Regularly calibrate and adjust machine settings to maintain accurate fill levels and capsule weights.

- Use a calibrated weighing scale to verify the accuracy of the machine's filling volumes.

- Adjust the machine's settings as per the desired specifications, ensuring precise filling volumes and weights.

- Consult the machine's manual or contact the manufacturer for detailed instructions on calibration and adjustment procedures.

5. Operator Training and Systematic Documentation:

Provide staff with appropriate training to ensure safe and efficient operations. Additionally, updated maintenance of detailed documentation is important for traceability and compliance.

- Provide comprehensive training to operators on machine operation, maintenance procedures, and safety protocols.

- Maintain a logbook to record all maintenance activities, including cleaning, lubrication, inspections, and replacements.

- Document any issues or abnormalities encountered during operation and the corresponding actions taken to address them.

Regular and proper maintenance of your automatic liquid capsule filling machine will ensure your machine runs smoothly, minimizes downtime, and consistently delivers accurate and reliable filled capsules. Remember to always refer to the manufacturer's instructions and seek professional help if needed. WECAPS specializes in supplying high-quality pharmaceutical machinery such as automatic capsule filling machines. At the same time, we can also provide customized capsule services. Welcome to come for consultation, we are worthy of your trust!

Related Products

NJP-1200C Fully Automatic Hard Capsule Filling Machine

Features of NJP-1200C

1.Output: 72,000pcs /hour.

2.Function for filling powder, pellet, granule, pellet and pill into capsules.

3.Easy to maintain and easy to operate.

4.Easy and simple size change with short changeover and cleaning times.

5.China-made quality provides an excellent cost-performance ratio.

Machine Advantages of NJP-1200C

1.Closed turret and dosing station, preventing powder come into the turret. Easy to operate, clean and change over the mould.

2.New turret design, adopt 90 linear bearings from Japan, to guarantee machine precision and use life.

3.Adopt bigger cam & dosing disk design, enhance the stability of the machine and extend the use life of the machine.

4.Equippedwith oil pump forsupply lubricate oil to the cam channel, reduce abrasion and extend use life of the parts.

5.Automatic capsule switch, controlled by touch screen via PLC.

6.Touch screenwith used-friendly graphic operator panel.

#automatic liquid capsule filling machine#capsule filling machine#liquid capsule filling machine#maintain liquid capsule filling machine

0 notes

Text

Semi Automatic Capsule Counting Machine

Semi-automatic capsule counting machine counts and fills pre-measured capsules into bottles, jars, and pouches. It also has a semi-automatic capsule counter. Various counts for varying capsule sizes can be provided based on the specific needs of each user. It’s interesting to note that this capsule counting machine can fill and count tablets with an extra disc in the same machine. This machine is also known as a semi-automatic tablet counting machine for this reason.

The capsule counting and filling machine is a disc-based device that conforms with cGMP regulations because the disk is made of food-grade materials. The likelihood of contamination is quite low. A specially made vibrator assembly is available in a dish to fully settle capsules into the disc’s holes. It’s interesting that the machine has both an auto and a foot pedal-operated manual mode for multitasking. With its cutting-edge technology, robust construction, and affordable costs, Adinath is among the top producers of capsule counting machines in India.

0 notes

Text

Manual Capsule Filling Machine

Looking for the perfect solution to your capsule filling needs? Our range of manual capsule filling machines offers versatility and efficiency for all your vitamin and supplement formulations. Whether you're a nootropic enthusiast or a biohacker, our machines cater to various capsule sizes, from 000 to 3.

The 100 Holes Capsule Filling Machine is ideal for small to medium batches, allowing you to fill up to 100 capsules at once with precision. If you need a larger capacity, our 400 Holes Capsule Filling Machine can handle up to 400 capsules and includes a spill guard to keep your workspace clean. For the highest volume, our 600 Holes Capsule Filling Machine fills up to 600 capsules simultaneously, making it perfect for larger operations. All of our machines are designed for ease of use, allowing you to efficiently fill capsules with your chosen ingredients. Visit our website to explore the full range of options, and discover how our manual capsule filling machines can streamline your supplement production process. Join the community of health enthusiasts who trust Lead Life Health for their capsule filling needs!

0 notes

Text

Tablet Tooling, Capsule Filling, Tablet Compression Machine Manufacturer and Supplier

IRM Enterprises Pvt. Ltd offer a wide range of punches and dies that are crafted from durable materials to withstand the demanding requirements of tablet compression. IRM Enterprises Pvt. Ltd we are committed to being a comprehensive solution provider manufacturer and supplier of cutting-edge pharmaceutical machinery, specializing in tablet compression, capsule filling, granulation, and tooling solutions. These machines compress powdered or granular materials into tablets of specific shapes and sizes.

Our Manufacturerd Tablet Machine Punches and Dies Tooling and KAD Kare Kit, you can enhance your tablet production efficiency and maintain the longevity of your tablet press machines, Tablet Compression Machines, Capsule Filling Machines, Granulation line, Tablet Tooling, Granulation Machine, Kalweka Multi-Purpose Equipment’s

For More Details Click here: https://www.karnavatiengineering.com/ Contact Details : 7567876473

0 notes