#Calcium Hydroxide Price

Explore tagged Tumblr posts

Text

Calcium Hydroxide Prices: Trend | Pricing | News | Price | Database

Calcium Hydroxide, commonly known as slaked lime, is a critical compound in various industries, and its market price trends are influenced by a multitude of factors. This compound, derived from the hydration of quicklime, serves as a versatile material with applications ranging from construction and water treatment to agriculture and chemical manufacturing. The global market for calcium hydroxide has seen significant developments in recent years, driven by the dynamic interplay of supply and demand, raw material availability, production costs, and evolving regulatory frameworks.

The price of calcium hydroxide is closely tied to the cost of its primary raw material, limestone, and the energy-intensive processes required for its production. Variations in limestone availability, coupled with fluctuations in energy prices, directly impact the cost structure of calcium hydroxide manufacturing. For instance, rising fuel costs can escalate production expenses, leading to higher market prices. Conversely, an abundant supply of raw materials and improved production efficiency can help stabilize or reduce prices. Additionally, advancements in production technologies, such as the adoption of energy-efficient kilns and automation, have played a role in mitigating cost pressures, enabling manufacturers to offer competitive pricing.

Get Real time Prices for Calcium Hydroxide: https://www.chemanalyst.com/Pricing-data/calcium-hydroxide-1204

Demand for calcium hydroxide is driven by its diverse applications across multiple sectors. The construction industry represents a major end-user, utilizing calcium hydroxide in mortar, plaster, and soil stabilization. Growth in construction activities, particularly in emerging economies, has spurred demand, supporting price stability. Similarly, the water treatment sector relies on calcium hydroxide for pH adjustment and contaminant removal, with increasing environmental awareness and stricter water quality regulations driving demand. The agricultural sector also contributes to market growth, using calcium hydroxide as a soil conditioner and pest control agent. However, shifts in sector-specific demand can create short-term price fluctuations, especially when one industry experiences a sudden downturn or surge.

Environmental regulations and sustainability trends have further influenced the calcium hydroxide market. Many governments and regulatory bodies have imposed stringent environmental standards, encouraging industries to adopt eco-friendly materials and processes. Calcium hydroxide’s role in reducing industrial emissions, neutralizing acidic waste, and managing water pollution has enhanced its appeal, leading to sustained demand. However, compliance with environmental regulations can also increase production costs, as manufacturers invest in greener technologies and pollution control measures, which may reflect in higher market prices. At the same time, the growing emphasis on circular economies and waste recycling has created new opportunities for calcium hydroxide applications, potentially offsetting cost pressures.

The competitive landscape of the calcium hydroxide market further influences pricing strategies. Key players in the industry strive to maintain a balance between profitability and market share by adopting dynamic pricing models. Larger manufacturers often leverage economies of scale to offer competitive prices, while smaller producers may focus on niche markets or value-added products to differentiate themselves. Strategic partnerships, mergers, and acquisitions among market participants have also contributed to price stabilization by optimizing resource utilization and enhancing market reach. Additionally, investments in research and development have led to the introduction of high-purity and specialized calcium hydroxide grades, catering to the unique requirements of industries such as pharmaceuticals and food processing.

Global economic trends, including inflation, currency fluctuations, and geopolitical tensions, add another layer of complexity to calcium hydroxide pricing. Inflationary pressures can increase the cost of raw materials, labor, and transportation, indirectly influencing market prices. Currency devaluation in major producing or consuming countries can also affect international trade dynamics, impacting export and import prices. Geopolitical events, such as trade wars or sanctions, can disrupt supply chains and create uncertainties, leading to price volatility. In response to such challenges, market players often adopt hedging strategies or long-term contracts to mitigate risks and ensure price predictability.

Looking ahead, the calcium hydroxide market is expected to witness continued growth, supported by rising demand from key end-use industries and ongoing advancements in production technologies. The global push for sustainable development and environmental stewardship will likely expand the scope of calcium hydroxide applications, reinforcing its market position. However, potential challenges such as raw material scarcity, energy price hikes, and regulatory compliance costs could exert upward pressure on prices. Stakeholders in the calcium hydroxide market will need to navigate these dynamics carefully, balancing cost efficiency with innovation and sustainability to remain competitive in an evolving landscape.

Get Real time Prices for Calcium Hydroxide: https://www.chemanalyst.com/Pricing-data/calcium-hydroxide-1204

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Calcium Hydroxide#Calcium Hydroxide Price#Calcium Hydroxide Prices#Calcium Hydroxide Pricing#Calcium Hydroxide News

0 notes

Note

might be dumb interpretation but after reading this line over and over for a month i have come to this conclusion : she will pay HIM good money aka her fame life, literal money (assuming that this song is about calcium hydroxide i think he only stayed with her for everything that’s attached with taylor as a public figure rather than just a person) she knows how much this stuff matters to him so she will give him everything that she has if only he sees her as her !! like she was so broken in this relationship and dare i say suffocated and trapped that she begged him to see her by extracting something from her like all others !! anything so that she can feel loved and comforted if that makes sense x i think it’s a clever way of expressing how fame effects her whole life while also describing her situation-ship

i totally agree it was about her feeling unseen and alone in that relationship, and being willing to pay a large price if only he would attempt to understand her and love her. my interpretation is that it's not entirely literal but it is about her career, making herself smaller, sacrificing parts of herself or her life, in order to make it work. she's putting in all the tokens in a losing game!! but yes we're all saying the same thing basically!

6 notes

·

View notes

Photo

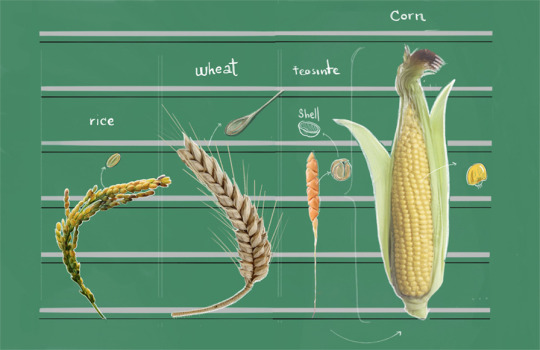

Maize: From Mexico to the world

For Mexicans, the “children of corn,” maize is entwined in life, history and tradition. It is not just a crop; it is central to their identity. By Matthew O'Leary May 20, 2016

EL BATAN, Mexico (CIMMYT) – For Mexicans, the “children of corn,” maize is entwined in life, history and tradition. It is not just a crop; it is central to their identity.

Even today, despite political and economic policies that have led Mexico to import one-third of its maize, maize farming continues to be deeply woven into the traditions and culture of rural communities. Furthermore, maize production and pricing are important to both food security and political stability in Mexico.

One of humanity’s greatest agronomic achievements, maize is the most widely produced crop in the world. According to the head of CIMMYT’s maize germplasm bank, senior scientist Denise Costich, there is broad scientific consensus that maize originated in Mexico, which is home to a rich diversity of varieties that has evolved over thousands of years of domestication.

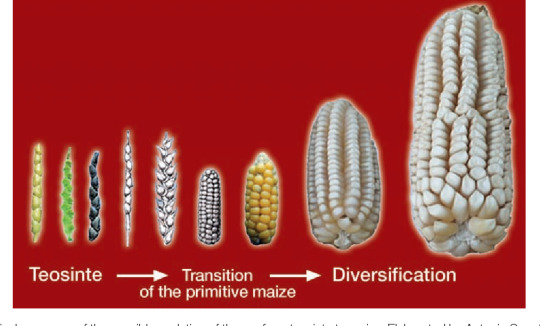

The miracle of maize’s birth is widely debated in science. However, it is agreed that teosinte (a type of grass) is one of its genetic ancestors. What is unique is that maize’s evolution advanced at the hands of farmers. Ancient Mesoamerican farmers realized this genetic mutation of teosinte resembled food and saved seeds from their best cobs to plant the next crop. Through generations of selective breeding based on the varying preferences of farmers and influenced by different climates and geography, maize evolved into a plant species full of diversity.

The term “maize” is derived from the ancient word mahiz from the Taino language (a now extinct Arawakan language) of the indigenous people of pre-Columbian America. Archeological evidence indicates Mexico’s ancient Mayan, Aztec and Olmec civilizations depended on maize as the basis of their diet and was their most revered crop.

As Popol Vuh, the Mayan creation story, goes, the creator deities made the first humans from white maize hidden inside a mountain under an immovable rock. To access this maize seed, a rain deity split open the rock using a bolt of lightning in the form of an axe. This burned some of the maize, creating the other three grain colors, yellow, black and red. The creator deities took the grain and ground it into dough and used it to produce humankind.

Many Mesoamerican legends revolve around maize, and its image appears in the region’s crafts, murals and hieroglyphs. Mayas even prayed to maize gods to ensure lush crops: the tonsured maize god’s head symbolizes a maize cob, with a small crest of hair representing the tassel. The foliated maize god represents a still young, tender, green maize ear.

Maize was the staple food in ancient Mesoamerica and fed both nobles and commoners. They even developed a way of processing it to improve quality. Nixtamalization is the Nahuatl word for steeping and cooking maize in water to which ash or slaked lime (calcium hydroxide) has been added. Nixtamalized maize is more easily ground and has greater nutritional value, for the process makes vitamin B3 more bioavailable and reduces mycotoxins. Nixtamalization is still used today and CIMMYT is currently promoting it in Africa to combat nutrient deficiency.

White hybrid maize (produced through cross pollination) in Mexico has been bred for making tortillas with good industrial quality and taste. However, many Mexicans consider tortillas made from landraces (native maize varieties) to be the gold standard of quality.

“Many farmers, even those growing hybrid maize for sale, still grow small patches of the local maize landrace for home consumption,” noted CIMMYT Landrace Improvement Coordinator Martha Willcox. “However, as people migrate away from farms, and the number of hectares of landraces decrease, the biodiversity of maize suffers.”

Diversity at the heart of Mexican maize

The high level of maize diversity in Mexico is due to its varied geography and culture. As farmers selected the best maize for their specific environments and uses, maize diverged into distinct races, according to Costich. At present there are 59 unique Mexican landraces recorded.

https://www.cimmyt.org/blogs/maize-from-mexico-to-the-world/

5 notes

·

View notes

Text

水酸化カルシウム (Calcium Hydroxide) の価格動向: 詳細なチャート、市場分析、将来の見通し

水酸化カルシウム (Calcium Hydroxide) は消石灰とも呼ばれ、幅広い用途を持つ無臭の白い粉末です。建設、農業、水処理など、さまざまな業界で使用されています。ただし、水酸化カルシウムの価格は、世界的な需要、サプライ チェーンの動向、経済状況など、い��つかの要因によって変動する可能性があります。

水酸化カルシウムの世界的な需要 水酸化カルシウムの世界的な需要は、その多様な用途によって推進されています。

建設: セメント、モルタル、石膏の製造に使用されます。

農業: 土壌 pH の調整や殺虫剤として使用されます。

水処理: 廃水や飲料水の処理に使用されます。

製紙業: 紙や板紙の製造に使用されます。

その他の用途: 次亜塩素酸カルシウムや炭酸カルシウムなど、さまざまな化学物質の製造に使用されます。 水酸化カルシウムの価格に影響を与える要因 水酸化カルシウムの価格には、いくつかの要因が影響します。

リアルタイムで 水酸化カルシウム (Calcium Hydroxide) 価格: https://www.analystjapan.com/Pricing-data/calcium-hydroxide-8

原材料コスト: 水酸化カルシウム生産の主要原材料である石灰のコストは、その価格に大きく影響します。

エネルギーコスト: 水酸化カルシウム生産のエネルギー集約型プロセスは、生産コストに影響を与える可能性があります。

世界的な需要と供給: 世界的な経済状況、産業の成長、および特定の業界動向は、水酸化カルシウムの需要に影響を与える可能性があります。

地政学的要因: 貿易摩擦、地政学的リスク、およびサプライチェーンの混乱は、水酸化カルシウムの入手可能性と価格に影響を与える可能性があります。

競争と市場動向: 水酸化カルシウム生産者間の競争は、価格だけでなく代替材料の入手可能性にも影響を与える可能性があります。

現在の市場動向と価格見通し 現在の水酸化カルシウム市場は、中程度の需要と安定した供給が特徴です。ただし、季節変動、原料コストの変化、および経済的要因により、価格が変動する可能性があります。水酸化カルシウム市場は、いくつかの大手企業が世界中で事業を展開しており、非常に競争が激しいことに留意することが重要です。この競争は、価格を安定させ、過度の価格上昇を防ぐのに役立ちます。

最新の水酸化カルシウムの価格と市場動向を把握するには、業界の専門家に相談し、市場レポートを監視し、信頼できるサプライヤーと連携することをお勧めします。水酸化カルシウムの価格に影響を与える要因を理解し、市場の動向に関する情報を入手することで、企業はこの多用途の化学物質の調達と使用に関して情報に基づいた決定を下すことができます。

ANALYST JAPAN

Call +1 (332) 258- 6602 1-2-3 Manpukuji, Asao-ku, Kawasaki 215-0004 Japan

Website: https://www.analystjapan.com

Email: [email protected]

0 notes

Text

The Ashford Formula: Top Pick for Solidifying and Sealing Concrete

Setting a benchmark in solidifying and sealing concrete, the Ashford Formula is causing a revolution in the industry. Its non-organic mixture soaks into concrete to defend, maintain, and fortify it, which is fantastic for business- and home-focused projects. Know more about Ashford Formula Cost Per Sqm.

Unpacking the Ashford Formula

The Ashford Formula has led the way as a concrete densifier and sealer for more than seven decades. It reacts with concrete's free lime and calcium hydroxide, transforming it into a compact, challenging, and enduring surface. Enquire the Ashford Formula Cost Per Sq Ft.

The Story Behind the Ashford Formula

The Ashford Formula, created in the '40s, is the pioneer product for lasting concrete defense. Loads of tests and real-life uses have shown its success, making it a go-to for the global build-and-design crowd. Find Ashford Formula Price.

How does the Ashford Formula Get the job done?

So here's the scoop on how the Ashford Formula does its thing—it dives deep into the concrete and starts a chemical reaction with the calcium stuff. This turns into a crystal-like web inside the concrete's tiny holes, toughening and making the surface rock-hard. Plus, it slaps a no-entry sign on the concrete to prevent water, oils, and other nasties from entering.

Perks of Going with the Ashford Formula

Boost in Toughness

The Ashford Formula shines by making Concrete Repair much more challenging. When you densify concrete, it can stand up to wear way better, meaning you won't have to fix it as much.

Looks Way Better

Not only does the Ashford Formula Refurbish Old Concrete Floors, but it also makes it look nice. It gives the concrete a slick, shiny surface that brings out its natural good looks and makes it a breeze to keep clean.

Saves You Cash

Going with the Ashford Formula Price can help your wallet out. Thanks to the long-term protection it offers, you'll spend less cash fixing up concrete, and it'll stay in good shape way longer, so you'll see the savings stack up.

Kind to the Planet

The Ashford Formula is a friend to the environment. It's safe, does not catch fire, and has zero VOCs so you can use it anywhere.

Places Where You Go Shopping

Retail spaces get a nice shiny finish with the "Ashford Formula," making stores look better and the floors more straightforward to clean.

Residential Uses

Home spaces like garages, driveways, and cellars can also use the "Ashford Formula." It hooks you up with the harsh and nice-looking perks for your house just like it does for shops.

Choosing on the Ashford Formula

You must make sure the surface is prepped right to nail it with the "Ashford Formula." The concrete must be spotless and can't have any gunk like oil, grease, or grime.

FAQs.

Why does the Ashford Formula stand out among other concrete sealers?

The Ashford Formula stands out due to its unique reactive qualities. It dives deep into the concrete and forges a crystalline structure inside the tiny holes. This action strengthens and solidifies the concrete from within ensuring the protection lasts a long time.

Is it cool to apply the Ashford Formula to old concrete?

You can apply the Ashford Formula to both spanking new and old concrete. But you should give older concrete a good scrub and prep it to make sure you get the best outcome when you spread it on.

0 notes

Text

Find Adaptable Calcium Carbonate for a Variety of Industries

Partnering with a supplier who consistently delivers high-quality products that satisfy industry standards is crucial when looking for a reputable Precipitated calcium carbonate manufacturer. A material that can be used in many different industries, such as paper, plastics, paints, and pharmaceuticals, is precipitated calcium carbonate. It is the perfect choice for a variety of manufacturing processes due to its exceptional qualities, which include high purity, fine particle size, and excellent dispersibility. Businesses can guarantee that their final products maintain the highest standards of quality and performance by selecting the best PCC manufacturer.

A fine white powder is created by the chemical reaction of limestone with an aqueous solution of calcium hydroxide and carbon dioxide to create precipitated calcium carbonate. Because of its special qualities, this powder has a wide range of uses. PCC is used as a filler material in the paper industry to increase opacity and brightness, improving the quality of paper goods. PCC is used as a white pigment and filler in plastics to improve the material's strength, toughness, and smoothness of surface. PCC is also frequently utilized in the manufacturing of paints and coatings, where it enhances the finish's gloss, opacity, and smoothness.

Precipitated calcium carbonate also helps the pharmaceutical industry, where it is utilized as a calcium supplement in food and health products and as an excipient in tablet formulations. PCC is perfect for these applications where safety and consistency are crucial due to its high purity and fine particle size. Because of its advantageous qualities, PCC is also used in other industries, such as the production of rubber, adhesives, and sealants.

Manufacturers of precipitated calcium carbonate are essential in making sure the product satisfies the particular needs of every sector. To ensure consistency in particle size and purity, high-quality PCC needs to be made with sophisticated manufacturing processes. Manufacturers must make sure the PCC is free of contaminants that might compromise its performance and functionality in a range of applications. Therefore, it's critical to pick a manufacturer who uses cutting-edge technology for PCC production and strictly adheres to quality control standards.

The capacity to offer customized products is one of the most important considerations when choosing a precipitated calcium carbonate manufacturer. A manufacturer should be able to modify the product in accordance with the specific requirements of various applications, such as differing particle sizes or surface treatments. A competent PCC manufacturer will collaborate closely with clients to fully comprehend their requirements and offer a solution that will result in the best possible performance in the finished product.

The supply's dependability is yet another crucial factor. Companies that frequently need large amounts of PCC should collaborate with a manufacturer who can guarantee reliable, prompt delivery. Delivery delays can disrupt production, so picking a manufacturer with a solid track record is essential. Furthermore, a major component of overall cost effectiveness, particularly for companies that depend on large amounts of PCC, is a manufacturer's pricing. Profitability can be increased and production costs can be decreased with competitive pricing.

Among producers of precipitated calcium carbonate, Sudarshan Group is a well-known leader, providing a broad selection of superior goods that satisfy the various demands of different industries. Having worked in the industry for many years, Sudarshan Group offers PCC that satisfies the strictest requirements for consistency and purity. They are a trusted partner for companies looking for dependable supply and customized solutions because of their sophisticated manufacturing techniques and dedication to quality. Whether you require PCC for paints, paper, plastics, or any other application, Sudarshan Group has the know-how and resources to guarantee that your goods satisfy industry standards.

In conclusion, it's critical to take into account aspects like product quality, customization possibilities, supply dependability, and competitive pricing when selecting a precipitated calcium carbonate manufacturer. You can guarantee that your company will have access to the greatest products available, supported by first-rate service and industry knowledge, by choosing a trustworthy manufacturer like Sudarshan Group.

0 notes

Text

Hydrated Lime Manufacturer in Jodhpur

Mahalaxmi Chemical Industries: Your Trusted Hydrated Lime Manufacturer in Jodhpur

We are proud to introduce Mahalaxmi Chemical Industries, a leading manufacturer of high-quality hydrated lime in Jodhpur. With years of experience and a commitment to excellence, we have established ourselves as a reliable and trusted supplier of this versatile chemical compound.

Our hydrated lime is produced using state-of-the-art equipment and processes, ensuring the highest standards of purity and quality. We carefully select the finest raw materials and subject them to rigorous quality control measures to guarantee that our products meet the stringent requirements of our customers.

Hydrated lime, also known as slaked lime or calcium hydroxide, is a versatile chemical with a wide range of applications. It is commonly used in the construction industry for soil stabilization, asphalt modification, and masonry applications. It is also used in agriculture to neutralize acidic soils, in water treatment to remove impurities, and in the production of paper, glass, and steel.

At Mahalaxmi Chemical Industries, we are committed to providing our customers with the highest quality products and services at competitive prices. We understand the importance of timely delivery and reliable service, and we work closely with our customers to ensure that their needs are met.

Whether you are a contractor, farmer, water treatment plant operator, or manufacturer, we have the hydrated lime you need. Contact us today to learn more about our products and services.

0 notes

Link

Check out this listing I just added to my Poshmark closet: VBG Cozy Pumpkin Spice Latte Organic Oatmeal & Coffee Soap PRICE FIRM.

0 notes

Text

Understanding Key Chemical Compounds and Their Market Dynamics

In the realm of chemical manufacturing, various compounds play pivotal roles in industries ranging from construction to consumer products. This article delves into several essential chemicals, including Monoethylene glycol (MEG), Diethylene glycol (DEG), Bentonite powder, Caustic soda, and Sodium bicarbonate. We will explore their applications, suppliers, manufacturers, price trends, and market dynamics, providing valuable insights for industry stakeholders.

Monoethylene Glycol (MEG)

What is Monoethylene Glycol?

Monoethylene glycol (MEG) is a colorless, odorless, and sweet-tasting liquid. It is primarily used as a raw material in the production of antifreeze and polyester fibers. MEG is a crucial component in various industrial processes, including the manufacture of plastics, resins, and solvents.

Applications of MEG

Antifreeze Production: MEG is widely used in automotive and industrial antifreeze formulations.

Polyester Fiber Manufacturing: It is a key ingredient in producing PET (polyethylene terephthalate) fibers for textiles.

Chemical Intermediate: MEG serves as a building block for various chemicals, including solvents and plasticizers.

Market Insights

The demand for MEG remains robust, driven by the textile and automotive industries. According to recent market analysis, the price of MEG fluctuates based on raw material costs and global supply dynamics. In 2024, prices averaged around $0.80 to $1.10 per pound. Key suppliers include BASF, LyondellBasell, and Indorama Ventures, known for their extensive production capacities.

Diethylene Glycol (DEG)

What is Diethylene Glycol?

Diethylene glycol (DEG) is another important chemical derived from ethylene glycol. It has similar properties to MEG but features a higher boiling point. DEG is primarily used in the production of resins, plasticizers, and as a solvent in various applications.

Applications of DEG

Plasticizer Production: DEG enhances flexibility and durability in plastic products.

Solvent in Chemical Reactions: It serves as a solvent for dyes, inks, and coatings.

Antifreeze Formulations: DEG is also used in specific antifreeze formulations, complementing MEG.

Market Dynamics

The market for DEG is influenced by the same trends affecting MEG. The average price of DEG in 2024 ranges from $0.90 to $1.20 per pound. Major manufacturers such as Huntsman Corporation and Eastman Chemical Company play significant roles in this market.

Bentonite Powder

What is Bentonite?

Bentonite is a clay derived from volcanic ash, known for its absorbent properties. It comes in two primary types: sodium and calcium bentonite. This versatile material finds applications across various industries.

Applications of Bentonite

Construction Industry: Used as a sealing agent in landfills and ponds.

Pet Care: Commonly utilized in cat litter due to its absorbent nature.

Oil and Gas Industry: Bentonite serves as a drilling mud, enhancing the drilling process.

Current Market Trends

The price of bentonite fluctuates based on demand and raw material availability. In 2024, prices average around $80 to $150 per ton. Key suppliers include American Colloid Company and Minerals Technologies Inc., renowned for their high-quality products.

Caustic Soda (Sodium Hydroxide)

What is Caustic Soda?

Caustic soda, or sodium hydroxide, is a highly corrosive chemical widely used in various industrial processes. It is essential for the production of soaps, detergents, and in the paper manufacturing industry.

Applications of Caustic Soda

Soap and Detergent Manufacturing: It serves as a critical ingredient in saponification.

Pulp and Paper Industry: Caustic soda is used in the pulping process to remove lignin.

Water Treatment: It helps adjust pH levels in water treatment processes.

Price and Supply

In 2024, the average price of caustic soda hovers around $0.20 to $0.50 per pound. Leading manufacturers like Dow Chemical and Olin Corporation dominate the market, ensuring a steady supply chain.

Sodium Bicarbonate

What is Sodium Bicarbonate?

Sodium bicarbonate, commonly known as baking soda, is a versatile compound used in food preparation, cleaning, and various industrial applications.

Applications of Sodium Bicarbonate

Food Industry: Used as a leavening agent in baking.

Cleaning Products: Acts as a gentle abrasive in household cleaners.

pH Regulation: Utilized in swimming pools and aquariums to maintain balanced pH levels.

Market Insights

Sodium bicarbonate's price in 2024 ranges from $0.60 to $1.20 per pound. Suppliers like Arm & Hammer and Solvay are key players in this market.

Soda Ash (Sodium Carbonate)

What is Soda Ash?

Soda ash, or sodium carbonate, is a vital industrial chemical used primarily in glass manufacturing. It also serves various other applications, including detergents and chemicals.

Applications of Soda Ash

Glass Manufacturing: A primary ingredient in producing glass and ceramics.

Detergents: Enhances cleaning efficiency in laundry and dishwashing products.

Water Softening: Used in water treatment processes to remove hardness.

Current Price Trends

In 2024, the price of soda ash averages $200 to $300 per ton. Major manufacturers include OxyChem and Tata Chemicals, which significantly impact market supply.

Conclusion

Understanding these key chemical compounds—Monoethylene glycol, Diethylene glycol, Bentonite powder, Caustic soda, Sodium bicarbonate, and Soda ash—is crucial for businesses across various sectors. Their applications are diverse, spanning textiles, construction, and food production. By staying informed about market trends and pricing, industry stakeholders can make better decisions regarding sourcing and production strategies.

0 notes

Text

Calcium Hydroxide Prices | Pricing | Trend | News | Database | Chart | Forecast

Calcium Hydroxide Prices often referred to as slaked lime, is a widely used chemical compound with applications across various industries such as construction, water treatment, agriculture, and food processing. The price of calcium hydroxide is influenced by several factors, including raw material costs, production processes, supply and demand dynamics, and regional market conditions.

One of the primary determinants of calcium hydroxide prices is the cost of its raw material, calcium carbonate. Calcium hydroxide is produced by hydrating calcium oxide, which is derived from calcium carbonate through a process known as calcination. Any fluctuations in the price of calcium carbonate, driven by factors like mining costs, energy prices, and transportation expenses, can directly impact the cost of producing calcium hydroxide. For instance, a rise in energy prices can increase the cost of calcination, leading to higher prices for calcium hydroxide.

The production process itself also plays a crucial role in determining the price of calcium hydroxide. Efficient production methods, technological advancements, and economies of scale can help manufacturers lower production costs and, consequently, offer more competitive pricing. On the other hand, outdated equipment or processes, coupled with high labor costs, can drive up the cost of production, resulting in higher market prices. Manufacturers that invest in modern production facilities and adopt energy-efficient practices are often better positioned to control costs and stabilize prices.

Get Real Time Prices for Calcium Hydroxide: https://www.chemanalyst.com/Pricing-data/calcium-hydroxide-1204

Supply and demand dynamics are another significant factor affecting calcium hydroxide prices. In regions where demand for calcium hydroxide is high, such as in rapidly growing construction or water treatment sectors, prices tend to be higher due to the increased consumption. Conversely, in areas with limited demand or oversupply, prices may be lower. Seasonal variations can also influence demand; for example, construction activities often peak during certain times of the year, leading to increased demand and potentially higher prices for calcium hydroxide. Additionally, global economic conditions, such as infrastructure development projects, can create spikes in demand, further influencing prices.

Regional market conditions, including regulatory policies, transportation costs, and local production capacities, also impact calcium hydroxide prices. In regions where stringent environmental regulations are in place, the cost of complying with these regulations can be passed on to consumers in the form of higher prices. Transportation costs are another critical factor, particularly for a commodity like calcium hydroxide, which is typically sold in bulk. Proximity to production facilities can significantly affect prices; regions closer to production sites may enjoy lower prices due to reduced transportation costs, while more remote areas might face higher costs.

The international trade of calcium hydroxide can also influence local prices. Countries that rely heavily on imports may experience price fluctuations based on changes in global supply chains, tariffs, and trade policies. For example, any disruption in the supply chain, such as port closures or logistical challenges, can lead to a shortage of calcium hydroxide in the market, driving up prices. Conversely, favorable trade agreements or increased local production can lead to more stable or even lower prices.

Market competition is another important aspect that affects calcium hydroxide prices. In regions with a high number of suppliers, competition can drive prices down as companies strive to offer more attractive pricing to secure market share. However, in markets with limited competition or where a few large companies dominate, prices may be higher due to reduced price competition. Additionally, the presence of substitute products can also influence calcium hydroxide prices. For example, in some applications, other materials like sodium hydroxide or magnesium hydroxide can be used as alternatives. If these substitutes are available at lower prices, it can put downward pressure on calcium hydroxide prices as manufacturers and consumers may opt for more cost-effective options.

The impact of macroeconomic factors such as inflation, currency exchange rates, and global economic trends cannot be overlooked when discussing calcium hydroxide prices. Inflationary pressures can lead to higher prices for raw materials, energy, and labor, all of which contribute to increased production costs. Currency exchange rates can affect the price of imported raw materials and finished products, particularly in markets that rely on international trade. For instance, a stronger local currency may reduce the cost of imports, potentially lowering calcium hydroxide prices, while a weaker currency could have the opposite effect.

Sustainability trends and environmental concerns are increasingly influencing the chemical industry, including the market for calcium hydroxide. As industries move towards greener and more sustainable practices, there is growing demand for eco-friendly production methods. Companies that invest in sustainable production processes may incur higher initial costs, which could be reflected in the prices of their products. However, as these practices become more widespread and as consumers increasingly prioritize sustainability, companies may find that they can command a premium for environmentally friendly calcium hydroxide products.

In conclusion, calcium hydroxide prices are shaped by a complex interplay of factors, including raw material costs, production efficiencies, supply and demand dynamics, regional market conditions, and macroeconomic influences. While fluctuations in any of these areas can lead to changes in pricing, understanding these underlying factors can help businesses and consumers better navigate the market. As the industry continues to evolve, particularly with the increasing emphasis on sustainability and technological advancements, it will be crucial for stakeholders to stay informed about the factors driving calcium hydroxide prices to make strategic decisions that align with market trends.

Get Real Time Prices for Calcium Hydroxide: https://www.chemanalyst.com/Pricing-data/calcium-hydroxide-1204

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Calcium Hydroxide#Calcium Hydroxide Price#Calcium Hydroxide Prices#Calcium Hydroxide Pricing#Calcium Hydroxide News

0 notes

Text

Calcium Thiosulfate Manufacturing Plant Project Report 2024: Setup and Cost

Introduction

Calcium thiosulfate is a key chemical with diverse applications, including in agriculture as a soil amendment, in industry as a reducing agent, and in water treatment as a dechlorinating agent. The Calcium Thiosulfate Manufacturing Plant Project Report provides a comprehensive guide to establishing a facility dedicated to producing this important compound. This report covers every aspect of the project, from assessing market demand and technical feasibility to financial planning and regulatory compliance, ensuring a thorough understanding of what is needed to successfully set up and operate the manufacturing plant.

1. Project Overview

A calcium thiosulfate manufacturing plant focuses on producing calcium thiosulfate through chemical reactions involving calcium salts and thiosulfuric acid. The project report should outline the entire process, from feasibility studies and plant design to financial planning and operational strategies.

2. Market Analysis

Demand and Applications: Calcium thiosulfate has a range of applications across different sectors. In agriculture, it is used as a soil amendment and fertilizer. In industry, it functions as a reducing agent, while in water treatment, it helps in removing chlorine. Understanding market demand involves analyzing these applications, identifying key markets, and estimating potential demand.

Regulatory Environment: The production and use of calcium thiosulfate are subject to regulatory guidelines to ensure safety and environmental protection. Regulations may vary by region, so it is crucial to understand and comply with local, national, and international regulations governing chemical manufacturing and usage.

Competitive Landscape: Assess the competitive environment by identifying existing manufacturers, their market share, and pricing strategies. This analysis helps in positioning your product effectively and developing strategies to differentiate it from competitors.

Get a Free Sample Report with Table of Contents @

https://www.expertmarketresearch.com/prefeasibility-reports/calcium-thiosulfate-manufacturing-plant-project-report/requestsample

3. Technical Feasibility

Production Process: The manufacturing of calcium thiosulfate typically involves the following steps:

Reaction: React calcium hydroxide or calcium carbonate with thiosulfuric acid. This reaction produces calcium thiosulfate and water.

Purification: The product may require purification to remove impurities and ensure high quality.

Formulation: Calcium thiosulfate is then formulated into the desired form, such as a powder or liquid, depending on its intended application.

Plant Design and Layout: Designing an efficient plant layout is essential for smooth operations. The layout should include areas for raw material storage, reaction vessels, purification units, packaging, and quality control. The design should also ensure compliance with safety and environmental regulations.

Technology and Equipment: Invest in reliable technology and equipment to ensure efficient production and high-quality output. Key equipment includes reactors, filtration systems, drying units, and packaging machinery. Selecting the right technology helps in maintaining product quality and optimizing production efficiency.

4. Financial Analysis

Capital Investment: Initial capital expenditure covers costs related to land acquisition, plant construction, equipment procurement, and raw materials. Developing a detailed financial plan helps in securing funding and managing initial investments.

Operational Costs: Regular operational expenses include raw materials, labor, utilities, maintenance, and administrative costs. Accurately estimating these costs is crucial for pricing strategies and ensuring profitability.

Revenue Projections: Forecast potential revenue based on market demand, production capacity, and pricing strategy. A break-even analysis helps determine how long it will take to recover the initial investment and start generating profit.

5. Implementation Strategy

Project Timeline: Develop a detailed timeline for the project, including milestones such as design finalization, construction, equipment installation, and production start-up. A well-structured timeline ensures that the project stays on track and meets deadlines.

Risk Management: Identify potential risks, such as technical issues, regulatory changes, and supply chain disruptions. Develop a risk management plan with strategies to mitigate these risks and handle challenges effectively.

Human Resources: Hire and train skilled personnel for various roles, including chemical engineers, production operators, quality control experts, and administrative staff. Proper training ensures that employees can perform their duties effectively and maintain high standards.

6. Regulatory and Compliance Considerations

Regulatory Approval: Obtain necessary approvals from relevant regulatory bodies by submitting detailed documentation about the manufacturing process, safety data, and environmental impact assessments. Compliance with regulations is essential for legal operation and market acceptance.

Environmental Compliance: Adhere to environmental regulations to minimize the plant’s impact on the environment. Implement practices for waste management, emissions control, and resource conservation to meet regulatory requirements and promote sustainability.

Safety Standards: Ensure compliance with safety standards to protect employees and prevent accidents. Implement safety protocols, provide regular training, and conduct safety audits to maintain a safe working environment.

7. Quality Control and Assurance

Quality Control: Establish robust quality control measures to ensure that calcium thiosulfate meets industry standards. This includes testing raw materials, monitoring production processes, and conducting final product evaluations.

Process Optimization: Continuously monitor and optimize manufacturing processes to improve efficiency, reduce costs, and enhance product quality. Embrace technological advancements and best practices to drive operational improvements.

FAQs

What is calcium thiosulfate used for?

Calcium thiosulfate is used in various applications, including agriculture (as a soil amendment and fertilizer), industry (as a reducing agent), and water treatment (to remove chlorine). Its versatility makes it valuable across different sectors.

What are the main challenges in setting up a calcium thiosulfate manufacturing plant?

Key challenges include navigating regulatory requirements, managing high capital and operational costs, ensuring product quality, and maintaining compliance with safety and environmental standards. Effective planning and risk management are essential for overcoming these challenges.

How can a manufacturing plant ensure regulatory compliance?

Ensuring regulatory compliance involves understanding and adhering to guidelines from relevant authorities. This includes obtaining necessary approvals, following safety and environmental regulations, and maintaining documentation for audits and inspections.

What environmental considerations should be addressed in a calcium thiosulfate manufacturing plant?

Environmental considerations include managing waste, controlling emissions, and conserving resources. Implementing waste management practices, emissions control measures, and sustainable resource use helps minimize the plant’s environmental impact and ensure regulatory compliance.

How can the financial viability of a calcium thiosulfate manufacturing plant be assessed?

Financial viability can be assessed through a comprehensive financial analysis that includes capital investment, operational costs, revenue projections, and break-even analysis. This helps determine profitability and evaluate the return on investment.

Media Contact:

Company Name: Claight Corporation Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A. Email: [email protected] Toll Free Number: +1–415–325–5166 | +44–702–402–5790 Address: 30 North Gould Street, Sheridan, WY 82801, USA Website: www.expertmarketresearch.com Aus Site: https://www.expertmarketresearch.com.au/

0 notes

Text

Looking for high-quality calcium hydroxide? Shaurya Minerals offers top-grade calcium hydroxide at the most competitive prices. Whether for industrial, agricultural, or construction applications, our calcium hydroxide meets the highest standards of purity and performance.

0 notes

Text

水酸化カルシウム (Calcium Hydroxide) 市場概要: 現在の価格、トレンド分析、将来の予測

水酸化カルシウム (Calcium Hydroxide) の価格は、原材料費、製造方法、市場需要など、いくつかの重要な要因によって左右されます。消石灰または水和石灰として一般に知られる水酸化カルシウムは、建設、水処理、農業、化学製造など、さまざまな業界で広く使用されています。水酸化カルシウムを製造するための主な原材料である石灰石のコストは、その市場価格を決定する上で重要な役割を果たします。石灰石の入手可能性や価格の変動は、水酸化カルシウムの価格に直接影響を与える可能性があります。

建設業界は、土壌安定化、モルタル、石膏に使用される水酸化カルシウムの最大の消費者の 1 つです。特に発展途上国では、建設活動が増加すると、水酸化カルシウムの需要が増加し、価格が上昇します。逆に、景気後退時など、建設部門の減速は、需要の減少と価格の安定または低下につながる可能性があります。季節的な傾向も価格に影響します。建設活動は暖かい時期に増加する傾向があり、需要と価格が一時的に急上昇する傾向があります。

水酸化カルシウムの価格に影響を与えるもう 1 つの重要な要因は、水処理と環境管理での使用です。水質汚染と廃棄物管理に関する世界的な意識が高まるにつれて、浄水プロセスにおける水酸化カルシウムの需要が増加しています。この需要の増加は、特に水不足に直面している地域や環境��制が強化されている地域では、価格変動の一因となる可能性があります。さらに、水酸化カルシウムは、工業プロセスからの硫黄排出量を削減するために排ガス脱硫に使用されており、環境規制が厳しくなると需要が高まり、価格に影響を与える可能性があります。

農業は、主に酸性土壌を中和するための土壌改良剤として水酸化カルシウムが使用されるもう 1 つの分野です。この業界における水酸化カルシウムの価格は、季節的な需要、農業の生産性、地域の農業慣行によって左右される可能性があります。植え付けシーズンなど、農業活動が活発な時期には、水酸化カルシウムの需要が増加し、一時的な価格上昇につながる可能性があります。

エネルギー コストは、水酸化カルシウムの価格に影響を与えるもう 1 つの重要な要因です。水酸化カルシウムの生産にはエネルギーが大量に必要であり、石灰石を生石灰に変換するために高温が必要であり、その後、生石灰が水和されて水酸化カルシウムになります。天然ガスや電気などのエネルギーコストの変動は、生産コストに直接影響する可能性があります。エネルギー価格が上昇すると、生産者はこれらの高コストを消費者に転嫁し、水酸化カルシウムの価格上昇につながる可能性があります。

輸送コストも、特に輸入に依存している地域では、水酸化カルシウムの価格設定に影響を与えます。水酸化カルシウムはかさばるため、輸送が総コストのかなりの部分を占めます。燃料価格の上昇、物流の混乱、または輸送規制の変更により、輸送コストが上昇し、水酸化カルシウムの最終市場価格に影響する可能性があります。地元の石灰岩源に簡単にアクセスでき、効率的な輸送ネットワークがある地域では、輸入に依存している地域と比較して、価格がより安定している可能性があります。

リアルタイムで水酸化カルシウム (Calcium Hydroxide)価格: https://www.analystjapan.com/Pricing-data/calcium-hydroxide-8

原材料の入手可能性や国際貿易条件などのグローバルサプライチェーンのダイナミクスも、水酸化カルシウムの価格に影響を与えます。地政学的緊張、自然災害、規制の変更などの要因によるサプライチェーンの混乱により、一時的に水酸化カルシウムが不足し、価格が急騰する可能性があります。逆に、サプライチェーンの効率性の向上と生産能力の向上は、時間の経過とともに価格を安定させるのに役立ちます。

窯の設計の革新やより効率的なエネルギー源の使用など、水酸化カルシウムの生産における技術的進歩は、生産コストを削減し、価格に影響を与える可能性があります。さらに、生産プロセスでのバイオ燃料や炭素回収技術の使用など、持続可能な慣行の開発は、環境への影響を軽減し、長期的なコストを削減するのに役立ちます。

要約すると、水酸化カルシウムの価格は、原材料費、主要産業からの需要、エネルギー価格、輸送ロジスティクスなど、さまざまな要因によって左右されます。これらの影響を理解することは、水酸化カルシウムに依存する企業や業界がコストを効果的に管理し、調達戦略を計画するために不可欠です。

ANALYST JAPAN

Call +1 (332) 258- 6602 1-2-3 Manpukuji, Asao-ku, Kawasaki 215-0004 Japan

Website: https://www.analystjapan.com

Email: [email protected]

0 notes

Text

Improving Concrete Durability in Qatar and the United Arab Emirates with Ashford Formula and Cure Sealers

Maintaining long-lasting, high-performance concrete surfaces is absolutely vital in the fast changing building scene in the UAE and Qatar. Advanced technologies like Ashford Formula and Cure Seal Hardener have become revolutionary as infrastructure expands and the need for durability rises. These particular treatments not only enhance surfaces but also offer necessary defense against dust, environmental stress, and wear.

Why Gulf Region Concrete Densifiers Matter

Architectural wonders and ambitious infrastructural initiatives by the UAE and Qatar are well-known. Still, the hot, dry environment presents special difficulties for building materials—especially concrete. Concrete surfaces could swiftly degrade without appropriate treatment, resulting in expensive repairs and maintenance. Here is where specific densifiers such as the Ashford Formula Data Sheet are quite important.

Describe the Ashford Formula.

Reacting with free lime and calcium hydroxide in concrete, the Ashford Formula Cost Per Sqm in Qataris a liquid concrete densifier. Its persistent, crystalline state within the pores increases surface resistance to abrasion, moisture, and dust. Ideal for high-traffic locations including warehouses, parking garages, and industrial floors, this procedure greatly increases the lifetime and durability of concrete buildings.

Advantages of the Ashford Formula:

By preventing the formation of concrete dust, dust proofing keeps safer and cleaner surroundings.

Reducing wear and tear—even under heavy machinery—helps to improve abrasive resistance.

Once put in use, low maintenance calls for less upkeep, so saving time and expenses over time.

Complementary Solution: Cure Seal Hardener

Although the Ashford Formula emphasizes densification, Cure Seal Hardeners seal the concrete surface, therefore providing additional protection. In one step they cure, seal, and harden the concrete, therefore improving surface strength and stopping water absorption. In the UAE's building industry, where fast curing and protection are crucial to achieving project deadlines, this dual-action technique is especially beneficial.

Budget Issues in Qatar

Project planning and budgeting depend on knowledge of the cost of these therapies. Depending on the provider, project scale, and application requirements, the Ashford Formula cost per square meter usually falls between QAR 40 and 70 in Qatar. The cost per square foot translates for individuals operating in smaller regions to roughly QAR 4 to 7. Although the initial outlay could seem hi`gh, the long-term maintenance and repair savings make this a rather affordable choice.

UAE Uses: Applications

Large-scale infrastructure developments in the United Arab Emirates are fueling a growing need for concrete treatments. From commercial buildings to airport runways, the Ashford Formula and Cure Sealers are starting to be standard solutions. Often searched keywords like "concrete densifier suppliers UAE" and "sustainable building materials UAE" demonstrate the growing curiosity in high-performance building materials.

Finally, confidently build the future.

Maintaining the lifetime and performance of concrete surfaces is non-negotiable in the UAE's construction-intensive areas including Qatar. Reliable and reasonably priced ways to improve durability, lower maintenance, and satisfy sustainability targets are advanced technologies including the Ashford Formula Cost Per Sq Ft in Qatar and Cure Seal Hardeners. Investing in these treatments allows builders and contractors to create long-lasting infrastructure even in the tough Gulf environment.

0 notes

Text

The Best Lime for Soil Stabilization in India: A Comprehensive Guide

Soil stabilization is an essential procedure in civil and construction engineering. It improves the physical properties of soil in order to increase its durability and strength. In India Lime is among the most efficient and widely used substances to lime for soil stabilization in India.

Understanding Soil Stabilization

Soil stabilization refers to the treatment of soil in order to improve its physical properties which makes it more solid and suitable for use in construction. This is vital for increasing the load-bearing capability of soil, while reducing its flexibility, and improving the resistance of soil to. Lime, a mineral that is calcium-rich, reacts with soil to produce these enhancements.

Different types of lime used for Soil Stabilization

There are a variety of lime that are used for soil stabilization. Each has distinct properties and advantages:

Quicklime (Calcium Oxide): Quicklime is extremely reactive and is widely employed for soil stabilization that is quick and fast. It is highly reactive to water, which makes it the ideal choice for projects that require quick outcomes.

Hydrated Lime (Calcium Hydroxide): Hydrated lime is made by introducing water into quicklime. This is less reactive than the quicklime, but nevertheless efficient to stabilize soil for a prolonged time.

Dolomitic Lime: This kind of lime has both magnesium and calcium carbonate, which can provide additional advantages to soil stability, including better soil structure and increased nutrient availability.

The benefits of using lime to Stabilize Soil

Utilizing lime for soil stabilization in India provides numerous advantages:

Better Load-Bearing Capacity Lime treatment greatly increases the load-bearing capacity in soil which makes it ideal for the construction of roads or buildings as well as other infrastructure.

Reduced Plasticity Lime decreases the flexibility of soil and makes it less susceptible to bending under the pressure of. This is crucial in areas that have large structures or a lot of traffic.

Improved Durability Lime-stabilized soil has greater durability, able to withstand extreme conditions of weather as well as resisting the effects of erosion.

Cost-effective: Lime is a cost-effective option for stabilizing soil compared to other options which makes it a desirable alternative for large-scale projects.

Finding the best Lime to Stabilize Soil in India

When choosing the right lime to stabilize soils in India there are a variety of factors to be taken into consideration:

Sort of Soil The different types of soil react differently when treated with lime. Knowing the soil type is essential to select the correct lime.

Project Requirements The particular requirements of the project, like the durability and strength of the soil stabilized, will affect the selection of lime.

Cost and availability: The availability and price of lime can differ across various regions of India. It is important to choose a supplier of lime that can provide quality lime at a reasonable cost.

Top Lime Suppliers for Soil Stabilization India

A number of businesses in India are renowned for providing top-quality soil stabilization lime. They offer a variety of lime products to satisfy the various requirements of engineering and construction projects. Some of the most reputable lime producers of India include:

Rajasthan Lime: known for its high-quality lime products Rajasthan Lime is a leading producer of the best lime for soil stabilization in India. Their products are extensively utilized in construction projects throughout the nation.

Sigma Minerals Limited: Sigma Minerals Limited is another renowned lime producer in India and offers a variety of lime products that are used for soil stabilization and for other purposes.

Universal Lime and Mineral Co.: This company offers a range of lime-based products for soil stabilization that meet the needs of both large and small-scale construction projects.

Best Practices to Use Lime for Soil Stabilization

To get the most effective results from lime used to stabilize soil it is vital to follow the most effective practices:

Test of Soils: Perform thorough soil tests to determine its characteristics and the suitability to be treated with lime. This will aid in choosing the correct type and amount of lime.

Proper mixing: Ensure that the lime is mixed evenly with the soil for the same level of stabilization. This can be accomplished by using equipment that is specifically designed, like spreaders or rotary mixers.

Correct Curing Give the limestone enough time to mix with the soil to achieve the desired stability. A proper curing process is vital to maximizing the benefits of the lime treatment.

Qualitative Control Continuously checks the stability of the soil to ensure that it is meeting the specifications of the project. This means testing the durability, strength, as well as other properties in the soil.

Conclusion

Lime is a diverse and effective substance to stabilize soil, providing many benefits to civil engineering and construction initiatives in India. Through understanding the various varieties of lime that are available and following the most effective techniques for lime treatment project managers can be sure of the effectiveness for their stabilization of soil efforts. With best lime for soil stabilization in India like Rajasthan Lime, Sigma Minerals Limited as well as Universal Lime and Mineral Co. getting high-quality limestone to stabilize soil in India is now easier than ever before.

#best lime for soil stabilization in India#top lime for soil stabilization in India#lime for soil stabilization in India

0 notes

Text

Calcium Stearates Manufacturers and Zinc Stearates Manufacturers: A Comprehensive Guide

In the world of industrial chemistry and materials, calcium stearates and zinc stearates are indispensable components. These chemicals play a pivotal role in various industries, offering exceptional performance in multiple applications. Calcium Stearates Manufacturers This comprehensive guide will delve into the nuances of calcium stearates and zinc stearates, while also shedding light on One Pack Stabilizer Prices and Vietnam Calcium Carbonate Importers. By the end of this article, you'll have a profound understanding of these crucial materials.

Calcium Stearates Manufacturers

Calcium stearate is a vital industrial chemical compound that finds its application across diverse sectors. It is a calcium salt derived from stearic acid, known for its remarkable versatility and utility. The manufacturing of calcium stearates is a complex process that involves the reaction of stearic acid with calcium oxide or hydroxide.

Applications of Calcium Stearates

Plastics Industry: They serve as excellent lubricants and release agents in the plastic molding process, ensuring easy release of molded products from molds.

Rubber Industry: In rubber manufacturing, calcium stearates act as an effective acid scavenger, preventing the formation of harmful acids during processing.

Pharmaceuticals: They are employed as lubricants in the production of tablets and capsules.

Cosmetics: Calcium stearates enhance the texture and consistency of cosmetic products, such as creams and powders.

Food Industry: These compounds are approved food additives used as emulsifiers and anticaking agents.

Leading Calcium Stearates Manufacturers

ABC Chemicals: Renowned for their consistent high-quality calcium stearate production.

XYZ Chemicals: Known for innovative manufacturing processes that lead to superior product quality.

Zinc Stearates Manufacturers

Zinc Stearate Overview

Zinc stearate, like its calcium counterpart, is an essential chemical compound with a wide range of applications. Zinc Stearates Manufacturers It is produced by reacting stearic acid with zinc oxide, resulting in a fine, white powder with remarkable properties.

Applications of Zinc Stearates

Plastics and Rubber Industries: They are used as lubricants and release agents, similar to calcium stearates, ensuring smoother manufacturing processes.

Paints and Coatings: Zinc stearates serve as flatting agents and offer excellent opacity and gloss control in paints and coatings.

Pharmaceuticals: They are employed as lubricants in tablet manufacturing, ensuring efficient drug

Prominent Zinc Stearates Manufacturers

UVW Chemicals: A global leader in the production of high-quality zinc stearates.

LMN Industries: Known for their innovative processes that yield superior zinc stearate products.

One Pack Stabilizer Price

Understanding One Pack Stabilizers

One Pack Stabilizers are a vital component in the plastics industry, playing a critical role in stabilizing and enhancing the performance of polymer products. They are composed of various additives, including calcium stearates and zinc stearates, One Pack Stabilizer Price which work together to improve the quality and durability of plastic materials.

Quality Assurance: These importers adhere to strict quality control standards, guaranteeing the purity and quality of the calcium carbonate they import.

Competitive Prices: Healthy competition among importers results in competitive pricing, benefiting manufacturers and end-users.

In conclusion, calcium stearates and zinc stearates, along with their role in One Pack Stabilizers and the growing market of Vietnam Calcium Carbonate importers, are critical elements in various industries. Their quality and reliability are paramount for the success of businesses relying on them. Understanding the manufacturing process, applications, and the leading manufacturers in this field is essential to make informed decisions.

0 notes