#CNC plasma cutting machine price

Text

Get The Best CNC Plasma Cutting Machine Price

Revolutionize your cutting operations with our CNC plasma cutting machine price at Hilco Industrial! Engineered for precision and efficiency, these machines deliver flawless cuts on a variety of metals. Ideal for fabrication shops, metalworking, and industrial applications. Featuring advanced technology, user-friendly controls, and robust construction, our CNC plasma cutting machines enhance productivity and ensure top-quality results. Upgrade your capabilities with a reliable, cost-effective solution. Contact us today for competitive pricing and expert support! Act now – elevate your cutting precision!

0 notes

Text

#wood cnc machine price#co2 laser machine price in india#Laser Machine Manufacturers in India#CNC Plasma Cutting Machine Price in India#CNC Router Machine Price#CNC Wood Carving Machine Price in India

1 note

·

View note

Text

Benefits of Using CNC Plasma Cutting Tables in Your Workshop

The plasma cutting table is one of the most fine-tuned, broadly used, efficient, and versatile tools for cutting even heavyweight and thick materials quickly. When looking for cutting materials for various types of manufacturing and construction applications you will find that a CNC plasma table is the best alternative. Plasma cutting machines are computer-automated, which allows for an incredibly high level of accuracy for a precise cut every single time. They are successfully used in the metal cutting processes in the manufacturing, agricultural, engineering, and construction industries. Whether you are a small shop owner, a metal artist, or a hobbyist a CNC plasma table can change the way you cut metal, further, it can help save time, material, and money.

The versatile method of plasma cutting is a common technique used by a whole range of industries to cut iron, stainless steel, aluminum, and other metals using a plasma torch. The process of cutting plasma works by sending an electric arc through a gas that is passing through a constricted opening. Gas is blown at high speed from a nozzle while an electrical arc melts the element and compresses air to blow away the molten element. Indeed plasma cutting table is extensively used in pressure vessels, automobiles, locomotives, chemical appliances, engineering machinery, steel buildings, nuclear industry, general machinery, ships, and other resourceful industry areas.

There are ample Benefits of using a plasma cutting table in your workshop. It is found that plasma cutting tables are used on different types of metal depending on the project. With a plasma cutter table, you can cut various kinds of metal in a wide range of thicknesses, such as stainless steel, aluminum, and copper. Moreover, they operate with extreme efficiency and, provide ease of use.

Today with advancements in technology the process of operating a CNC Plasma Table has become simple. They are affordable without the expensive price tags. No complex knowledge or adjustments are necessary to operate our CNC plasma cutting tables. New-age technology advantages of faster cutting and higher productivity offer benefits to smaller shops and to home CNC machine owners. At times plasma tables are so handy that just one person can comfortably handle and operate the whole process.

CNC Plasma tables are used in metal fabrication and manufacturing industries for cutting components from flat metal sheets or plates, including steel, stainless steel, aluminum & other metals.

SUREFIRE CNC is a division of Weldclass Australia, dedicated to providing CNC Plasma & profile-cutting equipment to Australian metal fabricators. SUREFIRE CNC offers Plasma cutting tables for industrial use in XT SERIES. These are durable and suitable for industrial applications. They are cost-effective and easy to operate.

0 notes

Text

Best CNC Plasma Cutting Machines in India | Indian Trade Bird

We are offering our valued customers the lowest prices on CNC Plasma Cutting Machines Indian Trade Birds. Our cnc Plasma Cutting Machine will revolutionize your metal fabrication processes. It is designed with precision and efficiency for a wide range of industrial applications. As a trusted provider, our cutting-edge cnc plasma cutting machines offer superior performance for industries such as manufacturing, construction, and more. These machines deliver high-quality results with adaptability and reliability, ensuring clean and precise cuts. Utilize our cutting-edge cnc Plasma Cutting Machine technology to streamline your metal fabrication processes. We guarantee exceptional quality for your projects and deliver excellence in every cut, all while increasing productivity and cutting down on production time in your industrial operations.

For more details clicks here - https://www.indiantradebird.com/product/cnc-plasma-cutting-machines

0 notes

Text

We’ve bundled 39+ well-made “3 doors in one” CNC vector files for you at a very low price. These are compatible with any CNC-controlled machine. DXF, PDF, SVG, EPS, JPG, and AI files are included. THIS IS NOT A PHYSICAL SIGN. DXF, PDF, SVG, EPS, JPG, and AI files are included. These are compatible with any CNC-controlled machine. For example, a laser cutter. Cutter for Plasma, Vinyl cutters and CNC-controlled routers Laser engravers and plotters are used to create a physical item. Compatible with: Cricut Design Space, Silhouette Studio Basic Edition, Make the Cut!, CorelDraw, and Adobe Illustrator. Sure […] https://tinyurl.com/22r6skwl

0 notes

Text

Precision CNC Machining - Norck

Precision CNC Machining at Norck offers high-precision CNC machined parts in a wide range of metals and plastics, with fast turnaround, competitive pricing, and exceptional quality. Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting, along with advanced CNC machining capabilities including precision turning, milling, grinding, and honing. Additionally, Norck offers CNC milling services for custom parts with tight tolerances and various materials, catering to industries like aerospace, defense, robotics, automotive, and electronics. For CNC-turning services, Norck delivers high-quality CNC-turned parts with tight tolerances and complex geometries, along with diverse material options. The company also specializes in providing precision CNC machining and 3D printing solutions for electronics, offering rapid prototypes, durable parts, and cost-effective manufacturing options.

0 notes

Text

Cutting-Edge CNC Plasma Cutting Software: Arc Professional Automation

Introduction to Arc Professional Automation

Leading software for CNC plasma cutting applications, Arc Professional Automation serves both novice and expert users. Let's examine why it is the leading option in the sector.

User-Friendly Interface

The user-friendly interface of Arc Professional Automation is one of its most important benefits. You will have no issue facing the software's user-friendly layout as soon as you launch it. Regardless of your level of experience, uploading designs, changing settings, and starting cutting operations are all made simple to guarantee an effortless and effective workflow.

Precision Cutting at its Finest

In the field of CNC plasma cutting, accuracy is important and Arc Professional Automation performs well at it. It makes sure that every cut is made as carefully and cleanly as possible thanks to its complex nesting features and strong algorithms. This optimizes material usage and improves the quality of your final products, saving you time and money in the process.

Versatile File Format Support

Arc Professional Automation has broad file format security, supporting DXF, DWG, and SVG among others. You can be confident that this software will adapt to your needs and make the design-to-cutting process smooth, regardless of whether you're importing designs from other programs or starting from scratch.

Compatibility Across CNC Plasma Cutting Machines

No matter what brand or model your CNC plasma cutting machine is, Arc Professional Automation is made to work smoothly with a lot of different kinds of equipment. Regardless of the size of your system—a large industrial-grade system or a small desktop—you can depend on this software to adjust to your particular setup for the best possible connection and performance.

Affordable Excellence

Despite its advanced features and capabilities, Arc Professional Automation remains remarkably affordable. Unlike some competing software solutions that come with hefty price tags, Arc Professional Automation offers exceptional value for money without compromising on quality or performance. This affordability makes it accessible to businesses of all sizes as well as individual users, democratizing access to professional-grade CNC plasma cutting technology.

Conclusion

Elevate Your Cutting Experience with Arc Professional Automation Finally, Arc Professional Automation is the obvious winner when it comes to CNC plasma cutting software. It is the height of superiority in the industry because of to its user-friendly interface, precision cutting capabilities, support for a number of file formats, machine connectivity, and affordability. Arc Professional Automation is the best the tool for helping you accomplish your objectives safely and effectively, whether you're trying to simplify your production process or let your creativity run completely on side projects. Upgrade to Arc Professional Automation today and unlock the full potential of your CNC plasma cutting endeavors!

Source Blog: The Best Software for CNC Plasma Cutting: Arc Professional Automation

0 notes

Text

CNC Flame / CNC Plasma cutting machine available from Pusaan India Automation PVT. LTD.

There are various types of CNC Flame / CNC Plasma cutting machine available from Pusaan India Automation PVT. LTD. We are the best leading manufacturer and supplier of CNC plasma cutting machine in India. We use cutting-edge technology to build high-end machinery. Our CNC plasma cutting machine is reasonably priced because we use high-quality components in it. You can research an Indian CNC plasma cutting machine price and output quality. The quality and cost of our plasma cutting machines in India are higher than those of competitors.

#cncplasma#cncplasmacuttingmachine#plasmacuttingmachine#flamecuttingmachine#machinery#machines#manufacturer#supplier

0 notes

Text

Mastering CNC Machining: Custom CNC Turning Parts for Crafting

CNC machining stands as a pivotal subtractive manufacturing process, employed to craft parts by meticulously eliminating material from a work piece or raw stock. This sophisticated method relies on preprogrammed software and codes to govern the precise movements of the machinery. Embracing an array of equipment like CNC turned parts manufacturers, turning mills, lathes, grinders, and plasma-cutting machines; CNC machining embodies versatility in modern manufacturing.

The genesis of CNC technology predominantly focused on milling, engaging in intricate operations on diverse materials—ranging from metals and glass to plastics and wood. These machines exhibit a diverse spectrum of functionalities, enabling the creation of intricate shapes, intricate cuts, and even intricate engravings on various products. While once exorbitant in the 1970s and ‘80s, contemporary CNC machines have become more accessible, captivating both hobbyists and industry professionals.

Selecting an Apt CNC Machine

Selecting the right CNC machine and Custom CNC turning parts necessitates careful consideration of multiple factors. Here are some guiding tips:

Project Objectives: Align the machine choice with project goals. Opt for a CNC router if woodworking predominates, while a CNC plasma cutter serves as the ideal solution for metal-related projects.

Cost Evaluation: Factor in the comprehensive cost, covering machine price, labor, and maintenance expenses.

Machine Build: Assess the machine's construction. Heavy-duty jobs require robust cast iron structures, while lighter-weight alternatives suffice for less demanding applications.

Power Specifications: Consider the machine's power rating, assuring alignment with your facility’s electrical capacities & evaluating its effect on overall functioning costs.

With extensive proficiency in CNC machining, HSMold has emerged as a premier CNC machining parts manufacturer. Here the professional team is committed to providing top-quality products that always surpass industry benchmarks. Elevate your projects with top-notch CNC machining parts from us today!

0 notes

Text

How CNC Angle Cutting Machines Enhance Production Quality

In the realm of modern manufacturing, the demand for precision, efficiency, and quality has never been higher. CNC angle cutting machine are at the forefront of meeting these demands, revolutionizing how various industries approach production. These Computer Numerical Control or CNC machines offer significant advantages that directly enhance production quality, making them indispensable tools in contemporary manufacturing.

Precision and Accuracy

One of the most significant ways CNC angle cutter machines enhance production quality is through their unmatched precision and accuracy. Traditional cutting methods often rely on manual operation, which can lead to human error and inconsistencies. In contrast, CNC machines are computer-controlled, ensuring that every cut is executed with exact specifications. This precision reduces the margin of error, leading to consistent and high-quality products. Even complex geometries and intricate angles can be cut with unparalleled accuracy, ensuring each piece meets the stringent quality standards required in industries such as aerospace, automotive, and construction.

For businesses looking to acquire top-quality CNC angle cutter machines or CNC plasma cutting machines at a cost-effective price, Hilco Industrial offers a compelling solution. As a reputable seller of used industry equipment, we source its inventory from well-known, closed-down factories. We used to buy all these machines from online machinery auctions.

Consistency and Repeatability

Consistency is key in manufacturing, especially when producing large volumes of parts. CNC machines excel in delivering repeatable results. Once a design is programmed into the machine, it can reproduce identical cuts multiple times with no deviation from the original specifications. This repeatability is crucial for maintaining uniformity across batches, ensuring that every product meets the same quality criteria. This is particularly important in industries where precision parts must fit together perfectly, such as in the assembly of machinery or vehicles.

Efficiency and Speed

A CNC angle cutting machine from Hilco Industrial significantly enhances production efficiency and speed. These machines can operate continuously and at high speeds, far surpassing the capabilities of manual cutting methods. This increased efficiency not only boosts production output but also reduces lead times, allowing manufacturers to meet tight deadlines and respond quickly to market demands. The combination of speed and precision means that high-quality parts can be produced faster, improving overall production timelines and reducing costs.

Reduction of Material Waste

Material waste is a critical concern in manufacturing, both from a cost perspective and an environmental standpoint. CNC machines contribute to quality production by optimizing material usage. The precision of CNC machines ensures that cuts are made accurately, minimizing excess material removal. Additionally, advanced software used in CNC machines can plan cuts to maximize material usage, reducing scrap and saving costs on raw materials. This not only improves the bottom line but also supports sustainable manufacturing practices.

CNC angle cutting machines are instrumental in enhancing production quality across various industries. Invest in quality and innovation with CNC angle cutting and CNC plasma oxy fuel cutting machines from Hilco Industrial, and take your manufacturing processes to the next level.

#cnc angle cutting machine#cnc plasma cutting machine#online machinery auctions#cnc plasma oxy fuel cutting machine

0 notes

Text

How Does A CNC Plasma Cutter Work

A CNC plasma cutter features a few key components, including the table, plasma torch, and CNC software. The table, also known as the bed, is the cutting surface on which the workpiece sits. Above the table, a gantry will hold the plasma torch and move it around. This is the cutting unit, controlled by the computer software.

An electric arc is sent through a gas as it passes through a constricted opening. This increases the temperature of the gas up to 22,000℃ until it converts into plasma and conducts electricity. Then it flows from the torch to the workpiece, melting through the metal. The high-velocity plasma and compressed gas blow the hot melted metal away, cutting straight through and removing the excess.

Advantages Of Plasma Cutting

CNC plasma cutting machines provide several advantages, including precision, affordability, transportability, and more.

Clean And Accurate Cuts: Plasma cutters use air filters to remove any contaminants, ensuring every cut is clean and precise. This ensures a high level of precision, for a faster and smoother cutting experience.

Cost-Effective: CNC plasma cutters are relatively affordable, with our CNC Plasma Table packages starting from $19,900. The initial investment cost is also lower for thicker materials, making it a more accessible option for small to medium-sized businesses. Use our online price configurator to get more accurate pricing.

Portable: Plasma is a more portable option, with no need for gas bottles. This makes it easy to relocate your plasma cutter with little to no transportation concerns.

Can Cut A Wide Range Of Metals: Plasma cutters can cut many materials, including mild steel, stainless steel, steel alloys, aluminium, carbon steel, copper, and brass. The appropriate thickness is determined by the plasma and the CNC table so ask our experts to find the best option for your workshop.

Efficiency: CNC plasma cutters are quick and easy to use, significantly increasing your productivity and efficiency. The software used to control your plasma cutter automates everything, which dramatically speeds up production.

Disadvantages Of Cnc Plasma Cutting

While the team here at Surefire CNC loves plasma cutting, we recognise there are some potential drawbacks. In particular, a cheap CNC machine of poor quality can be prone to inefficiencies with the equipment and software. To avoid this, we recommend opting for a reputable model like the XT Series Plasma Tables.

Additionally, the cut precision on a CNC plasma cutter may be marginally lower than on a waterjet cutter or laser cutting machine. However, these machines are more expensive to purchase and operate.

In summary, plasma cutters offer the perfect combination of accuracy, affordability, and ease of use for most industrial applications.

Best Cutting Machines For Metal Fabrication

For first-time investors and small to medium businesses, CNC plasma cutters are the most cost-effective and practical choice. If you’re wondering which cutting machine is best for your specific application, reach out to our team for tailored advice and product recommendations.

Reference Website Blog Link: https://blog.surefirecnc.com/blogs-and-news/what-is-cnc-plasma-cutting

0 notes

Video

youtube

STV CNC Automation Solution - CNC Plasma Tables

STV CNC provides a variety of plasma-cutting CNC tables, including a CNC Router table, CNC Laser Cutting Machine, Portable Plasma Cutter and Thermal Dynamics Plasma Cutter. STV high-quality CNC plasma cutting tables will make your work more comfortable and less time-consuming. STV CNC provides products at affordable pricing that every small business may afford. To learn more about the additional plasma cutting tables deals. Visit: https://stvcnc.com/product/sparx-cnc4x8-plasma-table/ or contact: (888) 701-7101

0 notes

Text

We’ve bundled 39+ well-made “3 doors in one” CNC vector files for you at a very low price. These are compatible with any CNC-controlled machine. DXF, PDF, SVG, EPS, JPG, and AI files are included. THIS IS NOT A PHYSICAL SIGN. DXF, PDF, SVG, EPS, JPG, and AI files are included. These are compatible with any CNC-controlled machine. For example, a laser cutter. Cutter for Plasma, Vinyl cutters and CNC-controlled routers Laser engravers and plotters are used to create a physical item. Compatible with: Cricut Design Space, Silhouette Studio Basic Edition, Make the Cut!, CorelDraw, and Adobe Illustrator. Sure […] http://tinyurl.com/2yrlr64q

0 notes

Text

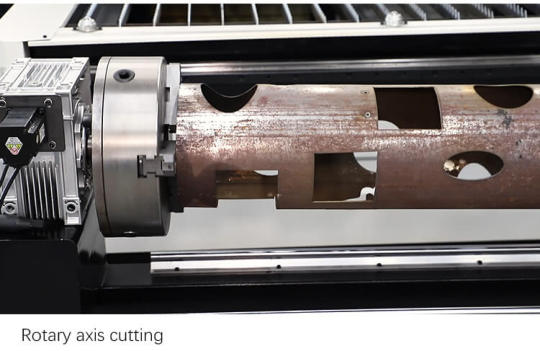

Table Type CNC Plasma Cutting Machine

iGP plasma cutting machine is used for cutting thick metals. The Hypertherm cutting head is a reliable and robust plasma source. Together with the CNC control unit and power source provides precise and high-quality cutting. P-Series plasma cutting machine is designed for precision cutting, High Performance, and High Speed. It can be equipped with Pipe cutting, a 5-Axis beveling head, multi-plasma heads, and Oxy cutting heads.

CNC plasma table machine, including flat plasma cutting machine, plate and tube integrated plasma cutting machine, square tube plasma cutting machine. The reinforced bed makes the equipment more stable during operation, compared with portable plasma cutting machine and gantry plasma cutting machine, desktop plasma cutting machine has the advantages of fast speed and high precision, and is more suitable for batch processing of medium and thin plates.

The CNC plasma cutter machine can not only meet 80% of the needs of large-scale flat cutting, but also 20% of the needs of tube cutting. It is equipped with an advanced tube-sheet dual-use CNC cutting system and a tube-sheet dual-use CNC cutting system.The software realizes the efficient and convenient interchange of cutting methods while cutting the tube and sheet material, which can not only meet the needs of users for cutting round and square tubes but also meet the special-shaped processing of steel plates.

CNC plasma and pipe cutting machine is a precision mechanical transmission device with thermal cutting technology combined with a high efficiency, high precision, high reliability. With inimitable man-machine interface, operation is simple and easy , can cut out various shapes of complex sheet metal quickly and accurately, especially suitable for automatically, thin steel non-ferrous metals, stainless steel and carbon steel plate cutting. It adopts an integrated modular design, quick installation, convenient movement.

Table Type CNC Plasma Cutting Machine Features:

The beam uses light structural design,with good rigidity structure, light deadweight .

The gantry structure, Y axis used dual-motor dual-driven system,X,Y,Z axis all use dual-straight rail that make the machine driving smoothly with high-precision.

Aiming at cutting three dimension LED character, trough metal panels and floor cutting, the accuracy can reach good indicators.If it equipped with United States HYPERTHERM plasma source the machine can reach threshold.

Equipped with other advertise equipment (blister/engraving machine) . Improve the efficiency of several times.

Cutting mouth is small, tidy,and avoid a second dressing processing.

It can apply to iron sheet, the aluminium sheet, the galvanized sheet, hundred steel plates , metal plates.

The numerical control system disposes high, the automatic striking arc, the performance is stable.

Support Wentai, Astronautics Haire, ARTCAM softwares, Type3 produce standard G code way document,also can change software to read AUTO CAD softwares produce DXF form documents.

igoldencnc is professional on CNC cutting machine powered by plasma and oxy-fuel. From basic plate cutting machine, Gantry cnc plasma cutting machine, table cnc plasma cutting machine and portable cnc plasma cutting machine, igoldencnc is also Leading manufacturer in pipe and profile cutting machine, from pipe cutting and beveling, tube cutting and beveling, beam/angle steel/ channel steel/flat buld processing. By developing our own system and software in 3D profiling, igoldencnc become the top brand in metal cutting with competitive price and professional products.We have a comprehensive, made in the USA product line and the engineering expertise to customize our software and controls for your unique application needs. Our CNC plasma tables offer state-of-the-art technology and high-quality components you’d expect to find in machines that cost two to three times as much or sometimes more.

1 note

·

View note

Text

Configuration Instructions of Duct CNC Plasma Cutting Machine

https://www.blkma.com/support/configuration-instructions-of-duct-cnc-plasma-cutting-machine.html

The main configuration of BA-1500*4000 Duct CNC Plasma cutting machine

Bilateral drive, belt cutting torch automatic ignition;

Transverse effective cutting can be 1.5 meters, which can be properly widened.

The longitudinal precision machining can be 18KG, the effective length is 4 meters, and can be lengthened properly.

Standard Configuration: 1 torch of flame, heightened by electricity;

Beijing Start's latest industrial grade CNC system with CCM3, 10.4 inch LCD screen;

Match the homemade nesting software in the expert edition, with the function of common side and bridge.

Can be equipped with automatic and high-pressure arc plasma power to achieve dual purposes: flame and plasma cutting.

Air pipe CNC cutting machine can cut the steel plate's thickness into 0.3-6mm.

The power is the domestic famous brand or the American Haibao power, and the temporary load rate is 100%. The power can work continuously for a long time; the price gap of the power is very large, and the quality of the power directly affects the cutting effect.

BLKMA company can provide non-standard machine customization services according to customer needs, which can meet different processing needs of global customers.

0 notes

Text

CNC Plasma Cutting Machine For Sale in India

There are various types of CNC Flame / CNC Plasma cutting machine available from Pusaan India Automation PVT. LTD. We are the best leading manufacturer and supplier of CNC plasma cutting machine in India. We use cutting-edge technology to build high-end machinery. Our CNC plasma cutting machine is reasonably priced because we use high-quality components in it. You can research an Indian CNC plasma cutting machine price and output quality. The quality and cost of our plasma cutting machines in India are higher than those of competitors.

We often provide our customers a range of choices. Pusaan India Automation PVT. LTD. manufactures a variety of CNC Flame and Plasma Cutting Machine, including Bench Type Plasma Cutting Machine, Portable Gantry Type CNC Plasma Cutting Machine, and CNC flame Cutting Machine manufacturer in india. You can get in touch with us for a lot.

0 notes