#CNC Graphite Processing

Explore tagged Tumblr posts

Text

Achieve remarkable precision and efficiency in your projects with our advanced CNC Graphite Processing solutions, tailored to meet the demands of modern manufacturing.

#CNC Graphite Processing#Graphite Milling Machines#CNC precision engraving machine#Graphite Lathe#Graphite Milling

0 notes

Text

How to save your brain from being eaten by AI (maybe): keep a sketchbook

At the beginning of May I started bookmarking photographers who are using AI in interesting ways, to add to my Instagram collection of digital art references (#artdirectionneversleeps). Later that month I did my own first experiments using NightCafe to visualise ideas for a client. It was entertaining and frustrating, partly because of my lack of prompt skills, and partly because the "styles" you could apply to your "artwork" looked exactly like bad fantasy art from the 1980s.

However, by June, photographers I was working with were using Midjourney to conceptualise setups – still with a bit of that tacky SciFi book cover feel, but it was proving genuinely useful to talk about how sets might be designed, for instance. By July, I was seeing film directors use AI for pitching storyboards, and my lovely students at Condé Nast College of Fashion and Design using it for presentation mock-ups.

That's just three months. From AI being a "what?" to becoming a completely logical, natural part of the image-making process, for at least some parts of the creative industries. The speed of change is head-spinning. And this is just the beginning.

Meanwhile, also in May, I was teaching at CNC on a really fun module about Brand Identity Design. Part of this involved the students keeping a sketchbook, to explore and develop their ideas. One of my lectures was about WHY people keep sketchbooks, and I illustrated several points with quotes from designers, architects and artists, and pages from my own sketchbooks from waaaaay back in the day.

Because WBITD, when I was an art student, I kept sketchbooks constantly. Not only was it a course requirement, for me it was also a way to stave off boredom and depression: it's hard to think negative thoughts when your brain is absorbed in analysing the curves of a hand or a coffee cup or a flower. When my best friend and I used to Interrail around Italy, I would draw our cafe tables and the local streets, and we'd get rewarded with extra drinks and desserts by kindly waiters.

Somewhere around the mid 90s I gave up sketching, partly because life got more hectic, and partly because smartphones got invented. When Emma and I started the BID course this summer, it had been a very long time indeed since I cracked open a sketchbook. And, erm, even though I did buy one – a lovely, spiral-bound, hard covered book with wonderful heavyweight paper, from Seawhite of Brighton – it took me another few months to start using it.

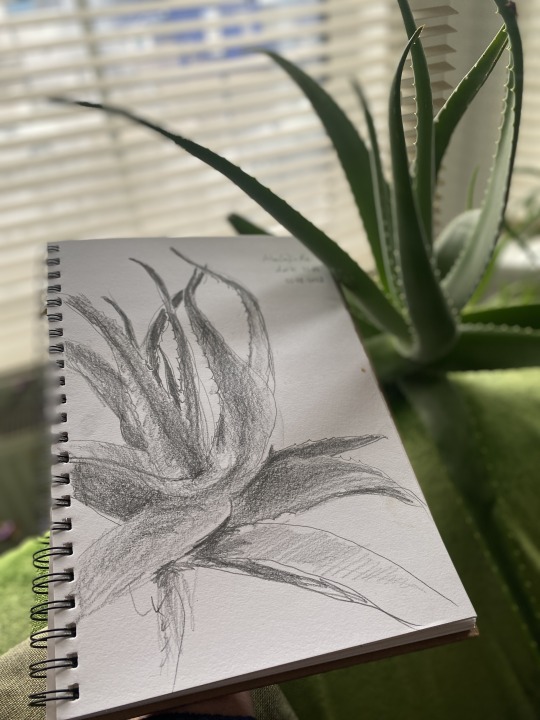

Two things pushed me into finally starting: firstly, it's #drawugst and I thought I should try a drawing a day, every day, during August. I started on Tuesday, August 1st, with a graphite pencil sketch of my aloe plant. I did it in semi-darkness, around 9pm, and my hand-eye coordination felt a but rusty, but following the heavy curves of the plant was satisfying.

On Wednesday I drew fallen agapanthus blossoms, playing with coloured marker pens (of which I have a ridiculously huge collection, almost never used). This was a reminder of the importance of not trying to control the end result while you're sketching. Because you just can't.

Yesterday evening I scribbled our messy after-dinner table. I used the graphite pencil, a Koh-I-Noor Hardtmuth charcoal pencil, and an Edding 1225 calligraphy pen – and blackberries. The fruit, not the redundant communication device. Blackberry juice is a fabulous art material – it gives this beautiful purple inky result, and it's such a pleasure to smear all over the paper. I'd picked the berries earlier this evening on Wormwood Scrubs, just to add to the satisfaction of the whole experience. (And this morning I made almond milk smoothies with the rest of them.)

The other thing which made me finally restart a sketchbook after all this time is AI. I can see that it is just going to get bigger, more powerful, and more indispensable in my industry. I'm not going to worry about losing my job to a bot (I don't have "a job", anyhow), but I am concerned about what it will do to our creativity.

When you use one tool extensively it starts to train your brain, you develop habits and shortcuts. It's one thing to have tricks for making the most of Photoshop, or to have routines when you set up an InDesign document. But when you're trying to generate ideas you need to keep an open mind. To look at things from different angles. To look again, look harder. Try wacky ideas. Draw with your food. Stick things onto the pages. Doodle. Take a line for a walk. Write notes to self. Be creative. Be messy. Be human.

5 notes

·

View notes

Text

The Evolution of PTFE Gaskets: Advancements in Material and Technology

PTFE (Polytetrafluoroethylene) gaskets have become a critical component in industries ranging from oil and gas to pharmaceuticals, evolving to meet the demands of increasingly complex industrial applications. In this article, we will dive into the history, technological advancements, and future potential of PTFE gaskets, exploring why they are a go-to choice for businesses around the world.

1. Introduction to PTFE Gaskets: An Industry Staple

Brief Overview of PTFE and Gaskets Polytetrafluoroethylene, more commonly known as PTFE, is a synthetic polymer renowned for its high chemical resistance, temperature tolerance, and low friction properties. Used extensively across industries, PTFE gaskets serve as critical sealing solutions, preventing leaks and preserving operational safety.

Why PTFE Gaskets Are EssentialThe material properties of PTFE make it highly versatile and ideal for environments requiring excellent thermal, chemical, and mechanical resistance. For B2B businesses, especially in chemical processing, food manufacturing, and petrochemicals, PTFE gaskets offer reliability, durability, and cost efficiency.

2. The Early Days: The Discovery and Initial Applications of PTFE

The Discovery of PTFEPTFE was discovered accidentally in 1938 by Dr. Roy Plunkett, a chemist at DuPont. Initially, PTFE's high chemical inertness and thermal stability caught the interest of various industries.

Initial Industrial ApplicationsIn the early days, PTFE was mainly used in military and aerospace applications, especially during World War II. Its unique properties, such as high-temperature resistance and non-reactive nature, made it ideal for sealing applications in extreme conditions.

3. PTFE in the Sealing Industry: Adoption of PTFE Gaskets

Why PTFE Became a Preferred Gasket MaterialWith its robustness, PTFE quickly became the material of choice for gaskets in aggressive chemical environments. Its flexibility allowed it to adapt to a range of temperatures, pressures, and chemicals.

Industries That First Adopted PTFE GasketsIndustries including chemical processing, oil and gas, and pharmaceutical manufacturing adopted PTFE gaskets early due to their reliability and compatibility with aggressive fluids and gases.

4. Key Properties of PTFE That Revolutionized the Gasket Industry

Thermal ResistanceOne of the standout properties of PTFE is its ability to withstand temperatures up to 260°C, making it suitable for high-temperature applications without degrading.

Chemical CompatibilityPTFE's resistance to nearly all chemicals (with the exception of a few) sets it apart from other gasket materials, making it valuable for industries where corrosion and contamination are concerns.

Low Friction and Non-Stick PropertiesPTFE’s low coefficient of friction minimizes wear, making it suitable for dynamic applications with moving parts, ensuring longevity and minimal maintenance.

5. Advancements in PTFE Gasket Technology: Meeting Modern Demands

Improved Manufacturing TechniquesManufacturing methods for PTFE gaskets have evolved, including precision molding, CNC machining, and advanced cutting techniques. This has allowed manufacturers to produce gaskets with tighter tolerances and more complex shapes.

Material Enhancements: Blended and Filled PTFEIn recent years, PTFE gaskets have been enhanced by blending PTFE with other materials, such as glass or graphite. These filled PTFE gaskets provide increased mechanical strength, abrasion resistance, and dimensional stability while retaining the chemical inertness of pure PTFE.

Expanded PTFE (ePTFE)A major advancement in the PTFE gasket industry is expanded PTFE (ePTFE), which offers enhanced flexibility and compressibility, making it suitable for irregular or damaged flange surfaces. This development has significantly improved the performance of PTFE gaskets in challenging sealing environments.

6. Specialized PTFE Gaskets for Industry-Specific Requirements

Food and Pharmaceutical-Grade PTFE GasketsFor food and pharmaceutical industries, PTFE gaskets now come in FDA-approved grades, ensuring compliance with health and safety regulations. These gaskets are non-toxic and have anti-microbial properties.

High-Pressure PTFE GasketsCertain PTFE gaskets are designed to withstand high pressures, making them suitable for heavy-duty applications, such as high-pressure steam and oil pipelines. These gaskets often feature reinforced or metal-encased designs to handle intense conditions.

Cryogenic-Grade PTFE GasketsFor industries dealing with extremely low temperatures, such as liquefied natural gas (LNG), PTFE gaskets have been modified to maintain flexibility and sealing capabilities even at cryogenic temperatures.

7. Innovations in PTFE Gasket Manufacturing: New Technologies

Laser Cutting and 3D PrintingLaser cutting has enabled high-precision PTFE gaskets that fit seamlessly in complex applications. 3D printing is also emerging, allowing for the creation of customized gasket shapes that were previously difficult to achieve.

Nanotechnology and CoatingsAdvances in nanotechnology have allowed for PTFE gaskets with enhanced surface coatings that improve chemical resistance and lower permeability. This helps in reducing the absorption of certain chemicals, enhancing the lifespan of the gasket.

Digital Design and SimulationToday, PTFE gaskets are designed using digital modeling tools that allow engineers to simulate gasket performance under specific conditions. This reduces the need for trial and error, streamlining the design process and ensuring optimal gasket performance.

8. Commercial Advantages of PTFE Gaskets for B2B Applications

Reduced Maintenance CostsPTFE gaskets require minimal maintenance due to their durability and chemical resistance, reducing downtime and repair costs for B2B industries.

Improved Operational EfficiencyPTFE gaskets ensure reliable sealing, which is critical for maintaining pressure and temperature control in systems. This directly enhances efficiency and productivity.

Compliance with Regulatory StandardsFor industries regulated by safety and environmental standards, PTFE gaskets offer compliance due to their non-reactive and durable nature, helping businesses avoid costly compliance issues.

Customization for Specific ApplicationsModern PTFE gaskets are highly customizable, allowing businesses to tailor gasket specifications to their exact needs, leading to better performance and cost-effectiveness.

9. The Future of PTFE Gaskets: Trends and Predictions

Sustainability in ManufacturingWith growing emphasis on sustainable practices, manufacturers are focusing on eco-friendly production methods for PTFE gaskets, including recycling and reducing waste.

Increasing Demand in Emerging MarketsAs industries in emerging markets grow, the demand for durable and reliable sealing solutions like PTFE gaskets is expected to increase, opening new avenues for manufacturers.

Smart Gaskets with Embedded SensorsFuture PTFE gaskets may feature embedded sensors that monitor temperature, pressure, and leakage in real-time, alerting maintenance teams to potential issues before they escalate.

Integration with Industry 4.0The evolution of digital technologies will likely bring PTFE gaskets into the fold of Industry 4.0, enabling data collection and analysis for predictive maintenance and operational optimization.

10. Selecting the Right PTFE Gasket Supplier: Key Considerations

Experience and ExpertiseWhen selecting a PTFE gasket supplier, it’s essential to choose a provider with a proven track record in producing high-quality gaskets for your specific industry.

Customization and FlexibilityA supplier capable of providing custom solutions will help ensure that the PTFE gaskets meet your exact requirements, optimizing performance and cost-effectiveness.

Quality Assurance and CertificationsLook for suppliers with strong quality assurance practices, such as ISO certification, to ensure that their PTFE gaskets meet stringent industry standards.

After-Sales Support and Technical AssistanceFor B2B businesses, reliable technical support is crucial for troubleshooting issues and ensuring the gaskets perform as expected in challenging environments.

11. Conclusion: PTFE Gaskets as a Core Component in Modern Industries

PTFE gaskets have come a long way since their inception, transforming from a basic sealing solution into a highly specialized component essential for modern industry operations. As technology advances and industrial demands grow, PTFE gaskets will continue to evolve, providing businesses with reliable, efficient, and customizable sealing solutions. For B2B decision-makers, choosing PTFE gaskets is more than a functional decision; it’s a strategic investment in operational resilience and efficiency.

0 notes

Text

Digital Light Processing DLP Projector Market Size, Share, Growth, Trends [2032]

Digital Light Processing DLP Projector Market provides in-depth analysis of the market state of Digital Light Processing DLP Projector manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Digital Light Processing DLP Projector in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Digital Light Processing DLP Projector Market Report:

The report offers a comprehensive and broad perspective on the global Digital Light Processing DLP Projector Market.

The market statistics represented in different Digital Light Processing DLP Projector segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Digital Light Processing DLP Projector are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Digital Light Processing DLP Projector.

Major stakeholders, key companies Digital Light Processing DLP Projector, investment feasibility and new market entrants study is offered.

Development scope of Digital Light Processing DLP Projector in each market segment is covered in this report. The macro and micro-economic factors affecting the Digital Light Processing DLP Projector Market

Advancement is elaborated in this report. The upstream and downstream components of Digital Light Processing DLP Projector and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/digital-light-processing-dlp-projector-market-100556

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Global Early Phase Clinical Trial Outsourcings MarketMarket Share

Global Paraformaldehyde MarketMarket Growth

Spa Software MarketMarket

Desktop CNC Machines MarketMarket Share

Programmable DC Power Supplies MarketMarket Growth Rate

Dyes and Pigments MarketMarket Forecast

Global Data Labeling Solution And Services MarketMarket Size

Online Betting MarketMarket Growth

Auction House MarketMarket Analysis

Electronic Grade Hydrofluoric Acid MarketMarket Size

Global Security Orchestration Automation and Response (SOAR) MarketMarket Share

Global Usb Portable Battery MarketMarket Growth

Indoor Location By Positioning Systems MarketMarket

Concentrated Solar Power (CSP) MarketMarket Share

Exome Sequencing MarketMarket Growth Rate

Industrial Electric Vehicle MarketMarket Forecast

Global Basketball Equipment MarketMarket Size

Apps for Kids MarketMarket Growth

Connected Street Lights MarketMarket Analysis

Paste PVC Resin MarketMarket Size

Global Privacy Management Software MarketMarket Share

Global Herpes Treatment MarketMarket Growth

T-cell Therapy MarketMarket

General Purpose Polystyrene (GPPS) MarketMarket Share

Water Hardness Removal MarketMarket Growth Rate

Beta Cyfluthrin MarketMarket Forecast

Global Minimally Invasive Surgery Video Columns MarketMarket Size

Computerized Maintenance Management System (CMMS) Software MarketMarket Growth

Distributed Denial-Of-Service (DDoS) MarketMarket Analysis

Bio-Based 1,3-Butanediol MarketMarket Size

Global Civil Engineering Design Software MarketMarket Share

Global Glycerol Monooleate MarketMarket Growth

Travel and Expense Management Software MarketMarket

Ureteroscopy MarketMarket Share

Flexible Graphite Sheet MarketMarket Growth Rate

Blast Suppression Damper Market Market Forecast

Global FRP Prefab Bathroom MarketMarket Size

OLED Coater and Developer MarketMarket Growth

Plant based Hemostat Powder Market Market Analysis

0 notes

Text

The Ultimate Guide to Gasket Kits: Insights for Manufacturers and Suppliers

Gasket kits are essential components in numerous industries, from automotive and aerospace to plumbing and manufacturing. They play a critical role in ensuring the integrity and performance of machinery and systems by preventing leaks and maintaining pressure. As manufacturers and suppliers of gasket kits, understanding the nuances of the market, the latest innovations, and the needs of your customers can set you apart in this competitive industry.

Understanding Gasket Kits

1. What Are Gasket Kits? Gasket kits typically include various types of gaskets made from different materials designed to fit specific applications. These kits are crucial in creating a seal between two surfaces, preventing leakage of fluids or gases. Common materials used include rubber, silicone, metal, and composite materials, each suited for specific conditions and requirements.

2. Types of Gaskets

Rubber Gaskets: Ideal for low-pressure applications, providing flexibility and resilience.

Metal Gaskets: Used in high-pressure and high-temperature environments, offering durability and strength.

Silicone Gaskets: Known for their excellent temperature resistance and flexibility.

Composite Gaskets: Combine multiple materials to offer enhanced performance in specialized applications.

Market Trends and Innovations

1. Advanced Materials The development of new materials has significantly improved gasket performance. For example, the use of expanded PTFE (ePTFE) provides superior sealing capabilities, while graphite gaskets offer excellent thermal conductivity and resistance to chemical attacks.

2. Customization and Precision Engineering Customers increasingly demand gaskets tailored to their specific needs. Advances in CNC machining and 3D printing have enabled manufacturers to produce highly precise and custom gaskets, reducing lead times and improving performance.

3. Environmental Considerations Sustainability is a growing concern in the gasket industry. Manufacturers are exploring eco-friendly materials and production processes to minimize environmental impact. Biodegradable and recyclable gasket materials are gaining popularity, aligning with global efforts to reduce waste.

Challenges and Solutions

1. Quality Control Ensuring the quality of gasket kits is paramount. Implementing rigorous testing protocols, such as pressure testing and material analysis, can help maintain high standards. Investing in advanced quality control equipment and training for staff is essential.

2. Supply Chain Management Supply chain disruptions can affect the availability of raw materials and the timely delivery of gasket kits. Building strong relationships with reliable suppliers and diversifying sources can mitigate these risks. Implementing inventory management systems can also enhance supply chain resilience.

3. Customer Education and Support Providing customers with comprehensive information and support is crucial. Offering detailed product specifications, installation guides, and technical support can enhance customer satisfaction and loyalty. Regularly updating customers on new products and industry trends can position your company as a trusted partner.

Future Outlook

The gasket kit industry is poised for continued growth, driven by advancements in materials science, increasing demand for customized solutions, and the ongoing push for sustainability. Manufacturers and suppliers who stay ahead of these trends and invest in innovation will be well-positioned to capitalize on new opportunities.

Conclusion

As a manufacturer or supplier of gasket kits, understanding the evolving landscape of the industry is vital. By embracing new technologies, maintaining rigorous quality standards, and prioritizing customer needs, you can ensure your products stand out in a competitive market. Stay informed, stay innovative, and continue to deliver exceptional value to your customers.

Whether you’re looking to enhance your product offerings or streamline your supply chain, keeping abreast of the latest trends and challenges in the gasket industry is essential. With the right strategies and a commitment to excellence, you can achieve sustained success in this dynamic field.

0 notes

Text

Precision and Velocity of Graphite Cutting Band Saw Machine Technology

In the realm of industrial manufacturing, precision, and speed are paramount, especially when it comes to cutting materials with unique properties such as graphite. The Graphite Cutting Band Saw Machine, a specialized piece of equipment designed to handle the complexities of cutting graphite and other similar materials, has become an indispensable tool in various industries. This article delves into the intricacies of the Graphite Cutting Band Saw Machine's cutting precision and speed, examining how this technology has evolved to meet the demands of modern industry.

The Graphite Cutting Band Saw Machine is engineered to provide high levels of precision in its cutting operations. The precision of a Graphite Cutting Band Saw Machine is determined by several factors, including the quality of the blade, the machine's alignment, and the control systems that guide the cutting process. The blades used in these machines are made from high-quality, durable materials that can withstand the abrasive nature of graphite. These blades are designed with a specific tooth configuration that allows for clean, accurate cuts with material displacement.

The alignment of the Graphite Cutting Band Saw Machine is another critical factor in achieving precision. The machine's frame must be rigid and stable to ensure that the blade remains true to its path during the cutting process. This alignment is maintained through regular maintenance and calibration, which ensures that the machine operates with efficiency and accuracy.

The control systems of the Graphite Cutting Band Saw Machine play a vital role in managing the precision of the cuts. Modern machines are equipped with advanced computer numerical control (CNC) systems that allow for precise programming of the cutting path. These systems can be programmed to make complex cuts with a high degree of accuracy, making the Graphite Cutting Band Saw Machine an ideal choice for intricate workpieces.

In addition to precision, the speed at which the Graphite Cutting Band Saw Machine operates is also of great importance. The speed of the blade is a critical parameter that can affect both the quality of the cut and the overall productivity of the machine. The blade speed is carefully calibrated to match the properties of the material being cut. For graphite, which is a relatively soft and brittle material, a lower blade speed is typically used to prevent damage to the material.

The Graphite Cutting Band Saw Machine also features variable speed control, allowing operators to adjust the blade speed according to the specific requirements of the job. This flexibility enables the machine to handle a wide range of materials and cutting tasks, further enhancing its versatility and efficiency.

Moreover, the Graphite Cutting Band Saw Machine is designed with a focus on reducing vibration and noise during operation. These factors can negatively impact the cutting process, leading to inaccuracies and potential damage to the workpiece. By reducing vibration and noise, the machine can operate at higher speeds without compromising the quality of the cut.

The use of cutting fluids in the Graphite Cutting Band Saw Machine is another aspect that contributes to both the precision and speed of the cutting process. These fluids help to cool the blade and lubricate the cut, reducing friction and heat generation. This, in turn, allows for faster cutting speeds and helps to maintain the integrity of the workpiece.

In conclusion, the Graphite Cutting Band Saw Machine is a highly specialized piece of equipment that offers cutting precision and speed. Through the use of high-quality blades, precise machine alignment, advanced control systems, and careful management of blade speed and cutting conditions, these machines can deliver consistent, high-quality results. As industries continue to demand more from their cutting equipment, the Graphite Cutting Band Saw Machine stands as a testament to the ongoing innovation and development in the field of material processing technology.

0 notes

Text

Global Top 7 Companies Accounted for 72% of total Mesocarbon Microbeads market (QYResearch, 2021)

MCMB (mesocarbon microbeads) synthetic graphite is prepared from petroleum pitch or coal tar. MCMB is one of the promising carbon anode materials for Li-ion batteries. MCMB has high specific capacity and a spherical morphology, which is beneficial for high packing density of the anode. The low surface area of MCMB can minimize the unfavorable side reactions during the charge-discharge process.

According to the new market research report “Global Mesocarbon Microbeads Market Report 2023-2029”, published by QYResearch, the global Mesocarbon Microbeads market size is projected to reach USD 0.38 billion by 2029, at a CAGR of 10.5% during the forecast period.

Figure. Global Mesocarbon Microbeads Market Size (US$ Million), 2018-2029

Figure. Global Mesocarbon Microbeads Top 7 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Mesocarbon Microbeads include BTR New Material Group, China Steel Chemical, Baotailong New Materials, Shanshan Group, Nippon Carbon Co., Ltd., etc. In 2021, the global top four players had a share approximately 72.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

CERAKOTE LIGHTWEIGHT AR-15 80% RECEIVER SET

All machining processes for our LightWeight AR15 80% Lower are completed other than drilling/milling the FCG (Fire Control Group) pocket and trigger slot, and drilling the Selector switch, Trigger and Hammer pin holes.

Cerakote LightWeight AR-15 80% Receiver Set Includes: – Ltd lifetime warranty against manufacturer defects

Lower Receiver: – CNC Machined from 6061-T6 Billet Aluminum – Rear lug pocket already machined – ‘Pictogram’ style Fire-Safe Engravings – Added overall strength from integral trigger guard – Machined (not broached) Mag Well with wide flare

Upper Receiver: – CNC Machined from 6061-T6 Billet Aluminum – Sleek and low-weight No-FA slick-side design – Accepts standard ejection port cover, pin and spring – Close in slim-line case deflector – Built to mil-spec dimensional standards

Optional:

– Bolt release pin hole Drilled and Tapped 6-32 – Cerakote Burnt Bronze (Pictured) – Cerakote FDE (Flat Dark Earth) – Cerakote Graphite Black – Cerakote Tungsten Grey – Cerakote Custom Color [View Here]

Availability:

Although not generally restricted, you should refer questions regarding manufacture, NFA Regulations, and individual state regulations to the BATFE, your local law enforcement or obtain legal guidance prior to manufacturing.

No FFL Required! This cerakote AR15 80% receiver set can be securely purchased from our website, and shipped direct to your home or business. (See the Shipping/Returns webpage for updated Shipping Restrictions)

0 notes

Text

Resin Bond Grinding Wheels

Resin Bond grinding wheels are generally divided into resin bond diamond grinding wheels and resin bond CBN grinding wheels according to abrasives. Henan E-Grind Abrasives Co., Ltd's Resin Bond grinding wheels have long service life, excellent self-sharpening ability and good shape retention, high grinding efficiency.

Resin Bond Grinding Wheels For Sale

Cut Off Wheels

High-speed steel, mold steel, hardened steel, tool steel, stainless steel, and other ferrous metals can all be cut with the E-Grind CBN cut off wheel.

Grinding Wheels For Woodworking Tools

Diamond and CBN grinding wheels for woodworking tools with good self-sharpness, high grinding efficiency, and long use life.

Tool & Cutter Grinding Wheels

We have a full series of grinding wheels for the whole manufacturing process of tools and cutters, from cutting rods to final CNC grinding.

Grinding Wheels For Die & Tooling

For Die & Tooling grinding, we developed different bonds for grinding steels, carbides, and mixture of steel and carbide, no clogging or glazing.

Centerless Grinding Wheels

Resin bond centerless grinding wheels are widely used for high productivity and mass production of rods, bars and tubes with high precision.

Resin Bond Double Disc Grinding Wheels

Grind Resin bond Double disc wheels are widely used for surface roughing and finishing top and bottom of precision parts, such as compressor cylinder, rotors, automobile parts, spring, semi-conductor parts, etc.

Tissue Paper Knife Grinding Wheel

Tissue Paper Knives need to be resharpened online without coolant, E-Grind developed a special CBN grinding wheel and diamond grinding in the resharpening process, with no sparking.

Economical Grinding Wheels

To meet the demand for low-cost grinding wheels, E-Grind develops economical grinding wheels and helped customers save costs.

How Long Does A Diamond Grinding Wheel Last?

Parameters that affect the life of the grinding wheel:

Since the specifications of the grinding wheel and the grinding conditions are intricately intertwined to create the optimum sharpness and life, you will find the best conditions for actual machining by looking at each combination of work, machining conditions, and grinding wheel specifications.

Factors that affect the life of the diamond grinding wheel:

Specifications of the grinding wheel such as abrasive grains, particle size, coupling, concentration, and bond type, together with grinding conditions such as Cutting depth, feed rate, rotational speed (peripheral speed), and type and amount of grinding fluid are all factors affecting the life of the diamond grinding wheel.

FAQs of Resin Bond Grinding Wheels

What is resin bond grinding wheel?

The resin bond grinding wheel is the type of grinding wheel that uses resin as a bond, one of the three elements that make up a grinding wheel. In the case of resin bond grinding wheels, it only represents the bond, so it is necessary to see the specifications in detail to see what purpose and function the grinding wheel has. It is also called a resinoid grinding wheel.

Why CBN wheel, not diamond wheel, for grinding ferrous materials?

Fe, Cr, Ti, Ni, etc, can’t be machined by diamond, because these metal elements will cause a series of chemical reactions, such as oxidation or graphitization reaction with diamond, the diamond grains will wear off quickly during the grinding process of the above-mentioned materials. CBN(Cubic Boron Nitride), as the second hardest material after diamond and with similar properties to diamond, is used for machining non-diamond-machinable metals.

CBN is the best suitable abrasive for grinding ferrous materials. You will hardly generate a high temperature because CBN has an extremely good conductivity for temperature, so the heat generated is dispersed quickly.

How to choose the suitable resin bond grinding wheel?

Proper grinding wheel selection is critical to get a high grinding efficiency and good workpiece quality. According to the material of the workpiece to be ground, we can roughly choose the resin bond grinding wheels with the below principles.

Diamond grinding wheel: Tungsten Carbide, Cermet, Hard metal/steel combinations, Glass, Quartz, Ceramics, Ferrotitanite Graphite, Magnetic materials

CBN grinding wheel: Stainless steel(SS), HarHardened high-speed steel (HSS), High alloyed steels with at least 55 HRC, Case-hardened steels, Iron-based powder coatings, Soft steels, Chill castings, Stellite.

0 notes

Text

Unlock exceptional machining capabilities with the Longmen Graphite Machine Center, engineered for precision and performance in handling complex graphite components.

#Longmen Graphite Machine Center#Graphite Processing Machines#Graphite cnc#Graphite Processing#Graphite Mould

0 notes

Text

Best Graphite Machining Product Suppliers

For those looking for the best graphite machining product suppliers, there are many considerations to be made. The quality of the graphite and the machining process are both important factors, as is the cost and availability of the product. Additionally, the supplier’s reputation, expertise, and customer service are all important.

The quality of the graphite is paramount. Graphite is used in a variety of industries, and is a strong, lightweight material with excellent electrical and thermal conductivity. It is also a slippery material, making it difficult to work with. Quality graphite should be free of impurities and contaminants and have a high level of thermal and electrical conductivity.

The machining process is also important. Graphite can be machined using a variety of methods, including CNC machining, EDM (electrical discharge machining), and manual machining. CNC machining is the most precise, but requires more time and is more expensive. EDM is faster and less expensive, but produces less precise results. Manual machining is the most affordable option, but is also the least precise.

The cost of the product is a key factor in choosing a supplier. The cost of the graphite itself is an important consideration,

0 notes

Text

What's Electrical Discharge Machining (EDM)?

EDM Machine

Electrical discharge machining (EDM) is a type of machining operation employed for shaping conductive workpieces into geometrically complex parts. Electrical discharge machines are particularly ideal for machining components that have complicated contours or subtle cavities that might be hard to produce with other conventional machining equipment. The process involves supplying electricity to both shaping tool as well as the workpiece and then bringing the tool into closeness with the workpiece, that is completely immersed in a dielectric fluid bath. This proximity causes the electrical field intensity between your tool and workpiece to overcome the strength of the dielectric fluid, and produces a number of electrical discharges together. These electrical discharges remove material from the workpiece, and the pattern or form of material removed relies upon the form of the tooling electrode. Following the machining operation, the dielectric fluid is replaced between the electrodes. Aside from acting as a dielectric between the two electrodes, the fluid also plays a key role in the machining process, as it is used to flush away the removed material and funky the machined area. The nature of the process is such that, while material is being taken off the workpiece; the tooling electrode can also be gradually eroded, making periodic replacement necessary.

EDM Machine Recommendation

The electrical discharge machining process is extremely precise and usually utilized in producing components that are typically complex and need extreme accuracy. In addition, another section of application that EDMs perform above par is in the machining and shaping of hard or exotic materials such as titanium, Hastelloy, Kovar, Inconel, as well as hardened steel. However, the only real caveat using the electrical discharge machining process is that it could be only be combined with conductive materials.

There are essentially two types of electrical discharge machines, which differ within the type of tooling electrode that they're outfitted with. They're sinker EDMs and wire EDMs. The sinker EDM, also referred to as a ram EDM uses a shaped tooling electrode to facilitate the machining process. This tooling electrode is created by conventional machining right into a shape that's specific to the application it is used for as well as an exact reverse of the shape to be machined in to the workpiece. The tooling, typically machined from graphite, can be used with an insulating fluid for example oil or any other dielectric fluids. This shaped tooling is linked to a power supply and made to approach the workpiece electrode, creating electrical discharges together, which cause erosion in the desired shape. This kind of EDM is typically used for precise machining of complex 3D parts, such as injection molding, die tooling, and other components that require exceptional accuracy.

The wire EDM, on the other hand, is an electrical discharge machine that uses an excellent metallic wire, usually produced from brass, which provides a cutting electrode to accurately shape intricate, complex aspects of thick metal plates. The wire and workpiece are both supplied with electricity and when the wire approaches the workpiece, electrical discharges occur together. These discharges remove material in the workpiece inside a shape that is similar to a cutting or slicing action. Because the wire electrode is eroding combined with the workpiece, it's continuously fed into the workpiece from a spool to make sure uninterrupted cutting operation. The wire is fed through two guides, typically produced from diamonds, each placed above and below the workpiece electrode. These guides are movable on a 2-axis x-y plane and are CNC controlled for cutting. The cutting operation occurs on the workpiece that is completely immersed inside a dielectric fluid bath, normally de-ionized water, which is often used like a coolant and also to eliminate the removed material. This machining process can be used to cut complex and intricate 2D shapes on thick metal parts, especially aspects of hard and exotic metals such as Inconel and titanium. Some components commonly machined using wire EDMs are stripper plates, custom gears, and other parts that need to be intricately eliminate. However, the advent of upper guides and multi-axis freedom of motion in the newer wire EDMs, allows these machines to chop intricate tapers and transitional shapes as well.

2 notes

·

View notes

Text

Best Wood Router

A router is a hand device or energy device that routs (hollows out) an area in difficult material, together with wood or plastic. Routers are specifically utilized in woodworking, specifically cabinetry. Usually they are hand held or fastened, with the cutting come to be, in router tables.

The hand device form of router is the real shape. It is a specialized hand plane with a extensive base and a narrow blade that projects properly past its base plate (giving it the nickname antique girl's enamel). The electricity device form of router, with a spindle driven by way of an electric powered powered motor, is now the extra commonplace shape. The hand tool model is now regularly referred to as a router plane; for a few responsibilities, it although has some advantages over the electricity tool. Some employees preserve in mind the electrical router one of the maximum flexible woodworking energy equipment.[1] CNC wood routers put in force the advantages of Computer Numerical Control (CNC). VIsit Here

Related to the router is a smaller, lighter version, designed specially for trimming laminates. It can be used for smaller popular routing artwork. For instance, with the ideal jig it can be used for recessing door hinges and recessing lock faceplates. Even rotary tools can be used as routers even as the right bits and add-ons (at the side of plastic router bases) are related.

Chip formation

Modern plunge router displaying dirt extraction tube Routing and milling are conceptually similar, and surrender mills may be utilized in routers, however routing wood isn't always like milling steel in terms of the mechanics. Chip formation is specific, so the maximum dependable tool geometry is one-of-a-kind. Routing is well applied to pretty susceptible and brittle materials, normally wooden. As the ones substances are inclined in small sections, routers can run at extremely immoderate speeds, so even a small router may also moreover reduce unexpectedly. Owing to inertia at the ones excessive speeds, the everyday timber cutting mechanism of Type I chips cannot take vicinity. The cutter facet angle is blunt, drawing near ninety°, and so a Type III chip bureaucracy, with waste fabric produced as first-rate dust. This dust is a breathing risk, even in benign materials. The forces closer to the cutter are light, so routers may be handheld.

When milling metals, the material is tremendously ductile, despite the fact that remaining sturdy even at a small scale. A Type II chip paperwork, and waste can be produced as non-forestall swarf. Cutter forces are high, so milling machines should be sturdy and rigid, commonly large systems of solid iron.

Intermediate substances, along side plastics and occasionally tender aluminium, can be reduce through way of both technique, although routing aluminium is usually more of an improvised expedient than a production process, and is noisy and hard on gear.

Makita laminate trimmer Routing is typically constrained to tender metals (aluminium and so on.) and rigid non-metals. Specially designed cutters are used for an expansion of styles, cuts, and edging. Both hand managed and system managed/aided routers are not unusual nowadays.

Workpiece geometry Routing is a shaping approach that produces finished edges and shapes. Some substances which might be tough to form with one-of-a-kind methods, which include fiber-glass, Kevlar, and graphite, can be fashioned and completed properly thru diverse routing strategies. Apart from finished edges and shaping, cutaways, holes, and capabilities also can be formed using routers.

The spindle router is positioned on the finer cease of the scale of labor completed by the usage of a moulding spindle. That is to say it can lessen grooves, facet moulding, and chamfer or radius the brink of a piece of timber. It is also feasible to apply it for cutting some joints. The form of cut that is created is decided by way of the scale and shape of the bit (cutter) held within the collet and the intensity via the depth adjustment of the best plate.

Variety of routers There are an expansion of router styles, a few are plunge, a few are D treated, some are double knob dealt with. Different manufacturers produce the routers for one-of-a-kind timber works, as Plunge Routers, Fixed Base Wood Routers, Combo Routers, Variable pace Routers, Laminate Trimmer, CNC Wood Routers.[citation needed] Nowadays, maximum higher exceptional routers have variable velocity controls and could have plunge bases that also may be locked in area so the router can also be used as a hard and fast base router.[citation needed] Some have a gentle-begin feature, which means that they build up velocity progressively. This function is specifically applicable for routers with a large cutter. Holding a 3 horse-strength router and turning it on without a gentle-start might be dangerous, due to the torque of the motor. Holding it with two palms is a ought to. For routers with a toggle kind on / off transfer it's far important to check to affirm the switch is within the off function, previous to plugging it in. For safety, large router cutters can generally only be utilized in a router that is installed in a router table, this makes the tool even greater versatile and stable.[citation needed]

The reason of multiple cope with preparations is relying at the bit, control is much less difficult with different configurations. For instance, when shaping the brink of a first-rate table top, many customers choose a D cope with, with variable pace, as it seems to permit better manage and burning the wood can be minimized.

Routers have many makes use of. With the help of the multitude of jigs and numerous bits, they're able to generating dovetails, mortises, and tenons, moldings of endless sorts, dados, rabbets/rebates, raised panel doorways and frames, reducing circles, and loads more.[citation needed]

Features of the present day spindle router

template manual bushing secured in the base around the router cutter The device usually includes a base housing a vertically installed ordinary electric motor with a collet on the give up of its shaft. The bit is peak-adjustable to allow protrusion thru an opening in a flat sole plate, normally via adjusting the motor-mounting peak (the mechanism of adjustment is widely numerous amongst manufacturers). Control of the router is derived from a deal with or knob on every issue of the tool, or thru the more currently evolved "D-cope with".

There are two wellknown types of router—plunge and glued. When using a plunge-base router, the best of the bottom is located on the face of the art work with the reducing bit raised above the artwork, then the motor is grew to come to be on and the cutter is reduced into the paintings. With a fixed-base router, the lessen depth is about in advance than the device is have become on. The sole plate is then each rested flat on the workpiece overhanging the edge just so the lowering bit isn't always contacting the paintings (after which getting into the artwork from the component as quickly because the motor is have become on), or the sole plate is positioned at an angle with the bit above the paintings and the bit is "rocked" over into the paintings as soon because the motor is grew to become on. In each case, the bit cuts its way in, however the plunge router does it in a greater sensitive way, even though the bit used want to be formed so it bores into the timber while reduced.

The baseplate (sole plate) is normally spherical (though this, too, varies with the resource of individual models) and can be used along with a fence attached to the bottom, which then braces the router towards the edge of the artwork, or thru a straight-element clamped across the work to achieve a at once reduce. Other manner of guiding the gadget encompass the template manual bushing secured inside the base around the router cutter, or router cutters with integrated manual bearings. Both of those run closer to a right away facet or original template. Without this, the various reaction of the wood against the torque of the tool makes it no longer viable to govern with the precision generally required.

Table mounted router

View under a router table displaying plunge router attached. A router can be established upside down in a router table or bench. The router's base plate is installation to the bottom of the table, with a hole allowing the bit to protrude above the desk pinnacle. This allows the paintings to be passed over the router, instead of passing the router over the paintings. This has blessings even as jogging with smaller objects and makes some router operations more secure to execute. A router desk can be equipped with a fence, fingerboards and other paintings-guiding accessories to make the operation more secure and further correct.

A easy router desk includes a inflexible pinnacle with the router bolted or screwed immediately to the lowest. More complex answers may be advanced to allow the router to be without difficulty eliminated from the desk in addition to facilitate adjusting the router's bit height using a boost mechanism; there's a sizable range of commercially to be had systems.

In this mode, the router can carry out obligations similar to a spindle moulder. For smaller, lighter jobs, the router used in this way can be extra convenient than the spindle moulder, with the venture of set up being without a doubt quicker. There is likewise a much wider range of bit profiles available for the router, no matter the fact that the size is constrained.

The router desk is normally orientated just so the router bit is vertical and the table over which the work is exceeded is horizontal. Variations on this encompass the horizontal router desk, in which the table stays horizontal but the router is set up vertically above the desk, in order that the router bit cuts from the aspect. This alternative is for side operations, which consist of panel raising and slot cutting.

Profiles made in timber with the aid of several common router bits.

Two typical router bits: (pinnacle) a ¼-inch shaft Roman Ogee with bearing, (backside) 1/4-inch shaft dovetail bit. Router bits are available hundreds of types to create either decorative results or joinery aids. Generally, they're categorized as both excessive-speed steel (HSS) or carbide-tipped, but a few recent innovations consisting of solid carbide bits offer even extra range for specialized duties.

Aside from the materials they're manufactured from, bits can be labeled as part bits or non-component bits, and whether or not or now not the bit is designed to be anti-kickback. Edge bits have a small wheel bearing to act as a fence against the work in making aspect moldings. These bearings may be changed via using using commercially to be had bearing kits. Changing the bearing, in effect, adjustments the diameter of the lowering place. This is particularly vital with rabbeting/rebating bits. Non-facet bits require using a fence, either on a router desk or attached to the work or router. Anti-kickback bits rent delivered non-reducing bit material across the circumference of the bit's shoulders which serves to restrict feed-rate. This reduces the threat that the workpiece is driven too deeply into the bit (that may result in first rate kickback from the reducing issue being unable to compensate).

Bits additionally range via way of the diameter in their shank, with ½ inch, 12mm, 10mm, ⅜ inch, 8mm and ¼ inch and 6mm shanks (ordered from thickest to thinnest) being the most commonplace. Half-inch bits cost greater however, being stiffer, are a whole lot less at risk of vibration (giving smoother cuts) and are much less probable to interrupt than the smaller sizes. Care need to be taken to ensure the bit shank and router collet sizes match exactly. Failure to do so can motive permanent damage to either or each and might lead to the damaging state of affairs of the bit popping out of the collet for the duration of operation. Many routers encompass removable collets for the well-known shank sizes (within the USA ½-in and ¼-in, in Great Britain ½-in, 8mm and ¼-in, and metric sizes in Europe—no matter the truth that within the United States the ⅜-in and 8mm sizes are regularly most effective available for extra value).

Many cutting-edge routers allow the speed of the bit's rotation to be various. A slower rotation lets in bits of big decreasing diameter for use efficaciously. Typical speeds variety from 8,000 to 30,000 rpm.

Router bits can be made to in shape nearly any possible profile. Custom router bits may be ordered. They are mainly useful for domestic restoration initiatives, in which manufacturing of the specific trim and molding has been discontinued.

Sometimes complementary bits are to be had in devices designed to facilitate the joinery used in body and panel production. One bit is designed to reduce the grove inside the rail and stile quantities at the same time as the other shape the edge of the panel to in form inside the grove.

CNC router

A CNC timber router is a pc controlled device to which the router or spindle mounts. The CNC Machine may be both a transferring gantry fashion, wherein the desk is constant and the router spindle movements over it, or consistent bridge design, in which the desk movements under the router spindle, or hand-held style, in which the operator movements the system to the location to be reduce and the device controls the superb adjustments. CAD/CAM software programming is used to model the component this is to be created in the computer after which create a device direction for the device to comply with to reduce out the part. The CNC moves alongside three axes (X-Y-Z). Most CNC routers have a 3 motor power machine the use of either servo or stepper automobiles. More advanced routers use a four motor gadget for added velocity and accuracy.

Similar tools A tool just like a router, however designed to maintain smaller reducing bits—thereby making it less difficult to deal with for small jobs—is a laminate trimmer.

A related device, referred to as a spindle moulder (UK) or shaper (North America), is used to maintain larger cutter heads and may be used for deeper or large-diameter cuts. Another related device is the pin router, a bigger static version of the hand electric powered powered router but typically with a far extra effective motor and exclusive abilities which includes automatic template copying.

Some profile cutters use a decreasing head reminiscent of a spindle router. These want to now not be stressed with profile cutters used for metallic plate which use a flame because the slicing technique.

We wish this may clear your visions approximately wood routers work, to buy the quality one please visit at: https://bestwoodrouter.Stay/

1 note

·

View note

Text

Powder Metallurgy 粉末冶金

ようぎょうLONG POST INCOMING

Why, you ask? Because apparently you can get paid $65/hr interpreting for a powder metallurgy company.

Updated Aug 2021: bold is words I actually use, bold and large text are words I use often! Italics are notes/corrections.

metallurgy = 冶金(やきん);金属高額(きんぞくこうがく) powder metallurgy = 粉末冶金(ふんまつやきん)

Materials:

alloy = 合金(ごうきん);アロイ;混合体(こんごうたい)

aluminum/aluminium = アルミ・アルミニウム;軽銀(けいぎん)

bronze = 青銅(せいどう);ブロンズ

cemented carbide = 超硬合金 (ちょうこうごうきん) / 超硬質合金 ( ちょうこう しつ ごうきん) [used as a cutting tool] Usually just カーバイド

ceramic = セラミック ; 窯業 (ようぎょう)?

composition (of a material) = 合成(ごうせい)

composition (ingredient) = 成分(せいぶん)

ferrous sulfate = 硫酸鉄(りゅうさんてつ); ferrous hydroxide = 水酸化鉄(すいさんかてつ);ferrous = 第一鉄

filler [for joining to parts] = 充填材・充填剤(じゅうてんざい)

graphite = 黒鉛(こくえん)?;石墨(せきぼく)except I can never quite figure out which one it is, sometimes I say グラファイト、and sometimes it’s just カーボン anyway

non-ferrous = 非鉄(ひてつ);non-ferrous metals = 非鉄金属(ひてつきんぞく)

tempering iron; forging steel; wrought iron = 鍛鉄(たんてつ)

wrought iron = 錬鉄(れんてつ)

wrought steel = 錬鋼(れんこう)

Processes/Tools (separate later)

bonding/welding temperature = 接合温度(せつごうおんど)

blend = ブレンド;混ぜる(まぜる);混ぜ合わす(まぜあわす) this should be 配合

bond = 結合(けつごう)this should be 接合

bonding = 接着(せっちゃく);ボンディング

carburizing/cementation = 浸炭(しんたん) “Decarb” 脱炭 comes up more frequently

casting = 鋳造(ちゅうぞう);鋳物(いもの);鋳金(ちゅうきん);鋳込み(いこみ)

coining = コイニング

compaction/compression = 成形(せいけい);圧縮(あっしゅく)outside of metallurgy also known as “molding”

die forging/contour forging/stamp forging = 型鍛造(かたたんぞう)

electric current sintering = 通電焼結法

erosion = 腐食(ふしょく) this is more like what rust does

forging/tempering = 鍛錬(たんれん);鍛造(たんぞう);鍛え(きたえ)

grinding = 研削加工 (けんさく かこう ) this should be 研磨

heat treatment = 熱処理(ねつしょり)

hone = 研ぐ(とぐ);研ぎ澄ます(とぎすます)

honing = ホーニング

impregnate = 注ぎ込む(つぎこむ);oil impregnation = 含油(がんゆ)

induction heating = 誘導加熱(ゆうどうかねつ)

lathe = 旋盤 (せんばん)

lubrication = 潤滑(じゅんかつ);ルブリケーション;注油(ちゅうゆ);減摩(げんま)

machining = 機械加工 ( きかいかこう) ; 加工(かこう);切削(せっさく) mostly as 加工

mold (cast) = 原板(げんばん);成型(せいけい)

noise = 騒音(そうおん);usually unpleasant - 雑音(ざつおん)

press (machine) = 圧搾機(あっさくき)LMAO we just say ブレス

press (verb) = 圧する(あっする)

quench = 焼入れ(やきいれ)

sintering = 焼結(しょうけつ)

sizing = 寸法修正(すんぽうしゅうせい)again, we just say サイズ or サイジング

soldering/brazing = 鑞付け(ろうづけ) and ロウ材 for “braze (material)”

stamping = プレス加工(ぷれすかこう)

stress (on a mechanical part) = 応力(おうりょく)I get the feeling I should be using this word more often

strip (away) = 剥ぎ取る (はぎとる)

swaging = スエージング

tempering = 鍛錬(たんれん);練り(ねり)?;焼戻し(やきもどし)

torque/torsion = トルク;捩じり(ねじり)

tumbling = タンブラー (lol)

ultra-precision machining/cutting = 超精密加工(ちょうせいみつかこう)

weld/welding = 溶接(ようせつ);溶着(ようちゃく)

vibration = 振動(しんどう);顫動(せんどう)

Products (maybe?):

appliance = 機械(きかい);アプライアンス I mean, we use 機械 to mean “machine” (noun) all the time...

ball bearings = 玉軸受け(たまじくうけ)

bevel gear = 傘歯車(かさはぐるま)

bushing = ブッシング

clutch = クラッチ

components = 部品(ぶひん);構成要素(こうせいようそ);構成分子(こうせいぶんし)

differential gear = 差動歯車(さどうはぐるま)[+装置(そうち)];デフ

gear teeth = サイクロイド歯車(さいくろいどはくるま)

planetary gear = 遊星歯車(ゆうせいはぐるまそうち)[+装置(そうち)] usually just プラネタリーギア

roller bearing = ころ軸受(ころじくうけ);ローラーベアリング

spline = 鎧板(よろいいた);スプライン

sprag (linchpin, wheel stops, sprag clutch, one-way clutch) = 輪留め(わどめ);ワンウェイクラッチ

spring = 発条(ばね)

sprocket = スプロケット

sprocket wheel = 鎖歯車(くさりはぐるま);鎖車(くさりぐるま)

spur gear = 平歯車(ひらはぐるま)I forget but probably スパーギア

Product parts/related words:

automatic transmission = オートマチックトランスミッション;自動変速機 usually “AT”

automation = オートメーション;自動化(じどうか)

burr (on a machined edge) = バリ

capacitor discharge ignition = キャパシター・ディスチャージド・イグニッション [why is it ‘discharged’ in Japanese?]

chain drive = 鎖電動(くさりでんどう)

clean room = 無塵室(むじんしつ) we call it クリーンルーム

CNC = Numerical control (?)

cutting tool (machining) = 切削工具 ( せっさくこうぐ) or usually ツール. The stuff that goes in the presses is ツーリング .n.

die (mold) = 金型(かながた)

diode = ダイオード;二極真空管

failure analysis = 失敗学(しっぱいがく)

feed hole/sprocket hole = 繰出し孔

gear train = ギアトレーン

helical gear = 斜歯歯車(はすばはぐるま);ヘリカルギア

laser = レーザー

load = 負荷(ふか)I think this meant load as in 供給

machine tool (machining) = 工作機械 ( こうさくきかい) I hate so much that they’re “machining machines” - 加工機械

magnetic field = 磁場(じば);磁場(じじょう);磁界(じかい)

milling machine = 製粉機(せいふんき);フライス盤(ばん)

powder = 粉(こな)often referred to as 原料

prototype = 原型(げんけい);祖型(そけい);プロトタイプ also 試作

transmission = 変速機(へんそくき) or often ���ランスミッション

Qualities:

balance = 均衡(きんこう);バランス

bevel (slanting surface) = 斜面(しゃめん);傾斜(けいしゃ);斜角(しゃかく)

brittle (fragile) = 脆い(もろい)

carbon-neutral = カーボンニュートラル

consistency = 一貫性(いっかんせい);つじつま ?;徹底(てってい)

density = 密度(みつど)?;

濃度(のうど)?;比重(ひじゅう)(specific gravity)

dimensions = 大きさ(おおきさ)?; internal dimensions = 内寸(ないすん)? should be 寸法

distortion = こじつけ;歪曲(わいきょく);ディストーション

(metal) fatigue = 金属疲労(きんぞくひろう)

geometry = 幾何学(きかがく)・幾何(きか)I think it’s probably looking for 形状

hardness = 硬度(こうど);剛性(ごうせい);硬質(こうしつ);硬さ(かたさ)

integrity = 整合性(せいごうせい)?

photovoltaic(s) = 太陽光発電(たいようこうはつでん)

proprietary = 私的(してき)?;特許(とっきょ)patented/ I think maybe 独自 as well

pore = 気孔(きこう);細孔(さいこう)

porosity = 多孔性(たこうせい);孔隙率(こうげきりつ)?;気孔(きこう)

purity (of a substance) = 純度(じゅんど)

sharp = 尖った (とがった)

ratio/proportion = 比率(ひりつ)I probably should be using that word

tolerance (electrical) = 裕度(ゆうど)most of the time it’s not electrical, it’s dimensional, and I think it’s 許容

versatility = 多芸(たげい)

Other:

cost saving = コストセービング;コスト削減(さくげん);スケールメリット HA it’s almost always “CR”

factory = 工場(こうじょう)

flange = フランジ

(the) former = 前者 (ぜんしゃ) (vs. the latter)

integrity (trustworthiness) = 誠意(せいい)

(the) latter = 後者 (こうしゃ)

means; way; measure = 手段 ( しゅだん )

operator = 操作者(そうさしゃ)usually 作業者

preeminence (excellence, superiority) = 卓越(たくえつ)

screen = スクリーン

shop floor = 現場(げんば);生産現場(せいさんげんば)

tooling cost = 型代(かただい);型費(かたひ);金型費(かながたひ)(metal)

vendor = 業者(ぎょうしゃ);売り手(うりて)?

Abbreviations

PM = powder metallurgy

HVC = high velocity compaction

CDC = conventional die compaction

#FINISHED#powder metallurgy#Japanese translation#translation#hmmm kinda do kinda don't want this#technical Japanese#long post#updated Feb. 6 2019#powdered metal#metal#powder metal

89 notes

·

View notes

Photo

PXG: “We couldn’t help ourselves”

By ED TRAVIS

Last spring when high-end clubmaker Parsons Xtreme Golf, or as it is better known simply PXG, introduced the 0211 line of irons some thought the company was changing its business strategy. The cast rather than forged 0211s are “priced within reach” falling in the upper end of the traditional price spectrum for irons at $225 per club. This makes a set of 4-iron through pitching wedge $1,575 which though expensive is comparably priced to many iron models sold by the major manufacturers.

However, in August PXG decided a new tour-style blade was appropriate and introduced the 0311 ST with the comment, “We couldn’t help ourselves. We just had to make a pure tour blade.” They did and the pricing at $650 per club ($4,550 for 4-iron through pitching wedge steel or graphite shafts) is reminiscent of the sticker shock golfers had with the first PXG models.

The ST designation stands for Super Tour and the heads are triple forged from 8620 carbon steel for a tighter grain structure and then CNC milled, an expensive finishing process that insures precise shaping of each head. Blade length was shortened somewhat, the blade’s offset is small and the topline thin. Coupled with the nickel chromium (NiCr) plated finish 0311 STs look like what they are, a players-category iron.

PXG’s familiar weight ports, seven of them, are distributed across the lower flange on rear of the head. The three in the middle have light titanium weights and the remaining four, two towards the heel and two the toe, have heavier weights of tungsten. This combination is designed to provide both help with the proper ball launch and trajectory as well as providing added forgiveness.

In keeping with the requirements of the better players targeted by PXG for the 0311 STs, lofts are not as strong as usually found in game improvement irons with the 5-iron 26° and the pitching wedge 47°. They are available now at a limited number of club fitters and on the PXG website.

Images courtesy of PXG

1 note

·

View note

Text

Professional Carbon Graphite Manufacturing Company in China

Graphite block have longer life after special anti-oxidation processing and heating more uniform. We have complete production processing and professional CNC equipment's and advanced tech processes to produce carbon graphite products. We mainly offer graphite crucibles, graphite rotors, graphite block, graphite plate, graphite rod, graphite heating parts, graphite pipes.

0 notes