#CNC Cutting Machines Market Forecast

Explore tagged Tumblr posts

Text

Computer Numerical Control (CNC) Market anticipated growth from USD 69.6 billion in 2023, reaching USD 121.8 billion by 2030.

Computer Numerical Control (CNC) Market Overview

The Computer Numerical Control (CNC) Market is expected to grow from USD 69.6 billion in 2023 at a CAGR of 9.0% to touch USD 121.8 billion by 2030. This growth reflects the increasing adoption of CNC technology across various industries, driven by advancements in automation, precision manufacturing, and the demand for efficient production processes.

Market Drivers

Several factors are propelling the growth of the CNC market:

Increased Automation: The rising need for automation in manufacturing processes is one of the primary drivers. CNC machines significantly reduce human error and production time, leading to enhanced efficiency and productivity.

Diverse Applications: CNC technology is widely used in sectors such as automotive, aerospace, electronics, and medical devices. The versatility of CNC machines allows them to produce complex components with high precision, making them indispensable in modern manufacturing.

Technological Advancements: Innovations in CNC technology, including the integration of artificial intelligence (AI) and the Internet of Things (IoT), are enhancing machine capabilities. These advancements improve real-time monitoring, predictive maintenance, and overall operational efficiency.

Get Sample Copy of this Report @ https://intentmarketresearch.com/request-sample/computer-numerical-control-cnc-market-3058.html

Some of the Major key Players

DMG Mori Seiki

Fanuc

GF Machining Solutions

Haas Automation

Hassay Savage

Mazak

Okuma

Protolabs

Siemens

TRUMPF

Segment Analysis

The CNC market can be segmented based on machine type, end-user industry, and region:

Machine Type: The market includes various types of CNC machines such as milling machines, lathes, laser cutting machines, and more. Among these, milling machines are expected to hold a significant share due to their widespread use in various applications.

End-User Industry: The automotive industry is anticipated to be a major contributor to market growth. As manufacturers seek to optimize production lines and improve quality control, the demand for CNC machines in automotive applications is expected to rise.

Geographical Insights: The Asia-Pacific region is projected to dominate the CNC market during the forecast period, attributed to the presence of major manufacturers and a growing industrial base. Countries like China and Japan are leading in CNC machine production and consumption.

Browse Complete Summary and Table of Content @ https://intentmarketresearch.com/latest-reports/computer-numerical-control-cnc-market-3058.html

Challenges

Despite its promising growth trajectory, the CNC market faces challenges:

High Initial Investment: The cost of acquiring advanced CNC machines can be prohibitive for small and medium-sized enterprises (SMEs). This can limit their adoption in certain sectors.

Skill Gap: There is a growing need for skilled professionals who can operate complex CNC machinery. The shortage of trained personnel may hinder market growth as industries struggle to find qualified workers.

Future Outlook

The future of the CNC market looks promising with continued investment in automation technologies. As industries strive for greater efficiency and precision in manufacturing processes, the demand for CNC machines is expected to rise significantly. Furthermore, the integration of smart technologies will likely revolutionize traditional manufacturing setups, leading to enhanced productivity and reduced operational costs.In conclusion, the Computer Numerical Control (CNC) Market is poised for substantial growth over the coming years. With an expected increase from USD 69.6 billion in 2023 to USD 121.8 billion by 2030 at a CAGR of 9.0%, stakeholders across various sectors should consider leveraging this technology to stay competitive in an increasingly automated world.

Request for Customization @ https://intentmarketresearch.com/ask-for-customization/computer-numerical-control-cnc-market-3058.html

About Us

Intent Market Research (IMR) is designed to offer unique market insights, with a core focus on sustainable and inclusive growth of our clients. We offer comprehensive market research reports and consulting services to help our clients to take data-driven business decisions.

Our market intelligence reports offer fact-based and relevant insights across a range of industries including chemicals & materials, healthcare, food & beverage, automotive & transportation, energy & power, packaging, industrial equipment, building & construction, aerospace & defense, semiconductor & electronics to name a few.

Our approach is deeply collaborative, working closely with clients to drive transformative change that benefits all stakeholders and has positive impacts. With a strong emphasis on innovation, we’re here to help businesses grow, build sustainable advantages, and bring remarkable changes.

Contact Us

1846 E Innovation Park DR Site

100 ORO Valley AZ 85755

Email: [email protected]

Phone: +1 463-583-2713

0 notes

Text

Automation and Smart Technologies: Transforming the Machine Tools Market

Market Overviews

In 2023, the machine tools industry generated income of USD 78.8 billion in 2023, which is projected to experience a CAGR of 4.4% over the forecast period, to attain USD 105.6 billion by the end of the decade. This is primarily attributable to the fact that the precision and proficiency in making are the key indicators for minimum wastage and alteration. Machine tool, which has a very high precision level, can help to avoid material wastages and cost reduction at the time of assembly of the part.

The major reason for the growth of automation and robotics in machining technologies can be identified in the weak workforce in the high-level manufacturing industry of the developed countries and greater use of these techniques in the aerospace, defense, medical device, marine and other sectors.

The progress of Industry 4.0 has conversed multiple innovations like artificial intelligence, big data, robots and automation, allowing more efficacy, productivity and flexibility across major sectors. One of the factors, which increased the use of machine tools in the metal fabrication and industrial manufacturing industries, is the growth of the pressure on manufacturers for good quality products with efficiency, sustainability and acceptable lead time and no possible errors. An example is, automotive industry introduced visual inspection system in their production, this had a great impact in PPM defects.

Key Insights

The metal cutting category held a larger market share of around 70% in 2023 globally.

Metal cutting machine tools is an important part of the industry, which includes automotive, aerospace, defense, mechanical engineering, and medical devices industries for precise shaping of metal and alloys such as iron, steel aluminum, titanium, and copper.

This category contains a huge range of different machinery like crurshers, grinding machines, turning machines, milling machine, electrical discharge machine (EDM) and many other.

Of them, milling machine markets outshine because of their capability to generate accurate cuts of metal, making them primarily engineered by manufacturers.

In contrast, the metal forming machines are used for bending, shaping, and other processes that are associated with metalworking.

The CNC category held a larger market share of around 75% in the global machine tools market in 2023 and is the fastest-growing in the automation segment.

CNC machines reduce manufacturing time and error rates by using CAD and CAM software to receive design instructions from a computer.

They are able to accomplish more tasks in one line prompt then one would be able to give. Therefore, there is a reduction in level of guided instruction.

Numerous types of production equipment like milling, grinding, turning, lathing, drilling and electrical discharge machining can be also merged with CNC technology.

Standard tools like change-handing on the lathe machine or milling with a handheld machine necessitates a higher level of expertise and may not conform to the set shape.

CNC technology is preferred over conventional machine tools for higher precision and more efficient production.

APAC held the largest revenue share in the global machine tools market in 2023 due to increasing industrialization and population growth in countries like China and India.

Competition among emerging economies to become manufacturing powerhouses, coupled with government initiatives like Make in India, Made in China 2025, and Making Indonesia 4.0, has created a favourable investment environment.

Significant growth is also observed in the IT sector of North America.

Source: P&S Intelligence

#Machine Tools Market Share#Machine Tools Market Size#Machine Tools Market Growth#Machine Tools Market Applications#Machine Tools Market Trends

1 note

·

View note

Text

0 notes

Text

The global Metal Cutting Machine Market is projected to grow from USD 5,871.70 million in 2023 to an estimated USD 9,458.15 million by 2032, with a compound annual growth rate (CAGR) of 5.40% from 2024 to 2032.The metal cutting machine market is witnessing significant growth, driven by technological advancements, increasing demand from various industries, and the need for precise and efficient metal cutting solutions. These machines are essential in numerous sectors, including automotive, aerospace, defense, construction, and manufacturing, contributing to the production of complex parts and components with high precision. This article delves into the current state of the metal cutting machine market, highlighting key trends, market drivers, segmentation, and future prospects.

Browse the full report at https://www.credenceresearch.com/report/metal-cutting-machine-market

Market Size and Growth

As of 2023, the global metal cutting machine market is valued at approximately USD 7.2 billion and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. The market's expansion is largely attributed to the rising industrialization and urbanization in developing countries, which has led to increased investments in infrastructure and manufacturing activities. Additionally, the growing adoption of automation in production processes to enhance productivity and reduce labor costs is further propelling the market growth.

Key Market Drivers

1. Technological Advancements: The metal cutting machine industry is undergoing rapid technological advancements, with the introduction of sophisticated and efficient machines. Innovations such as computer numerical control (CNC) machines, laser cutting technology, and plasma cutting machines have revolutionized the market. These technologies offer enhanced precision, speed, and flexibility, making them highly desirable in various industrial applications.

2. Growing Demand from the Automotive Industry: The automotive sector is one of the largest consumers of metal cutting machines. The increasing production of vehicles, coupled with the demand for lightweight and high-strength components, is driving the need for advanced metal cutting solutions. CNC machines and laser cutting technology are extensively used in the automotive industry to manufacture intricate parts with high accuracy.

3. Expansion in the Aerospace and Defense Sector: The aerospace and defense industries require high-precision components for aircraft and defense equipment. The stringent quality standards and the need for complex geometries in aerospace parts necessitate the use of advanced metal cutting machines. The growing defense budgets and the rising production of commercial aircraft are significantly contributing to the market growth.

4. Rise in Construction Activities: The construction industry is experiencing robust growth, particularly in emerging economies. The demand for metal structures, frameworks, and prefabricated components is increasing, leading to a surge in the adoption of metal cutting machines. These machines are essential for cutting and shaping metal parts used in construction projects.

Market Segmentation

The metal cutting machine market can be segmented based on technology, application, and geography.

- By Technology: The market is divided into laser cutting machines, plasma cutting machines, waterjet cutting machines, and others. Laser cutting machines hold the largest market share due to their high precision and efficiency.

- By Application: The key application areas include automotive, aerospace and defense, construction, electronics, and others. The automotive segment dominates the market, driven by the high demand for metal cutting solutions in vehicle manufacturing.

- By Geography: The market is analyzed across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Asia Pacific leads the market, owing to rapid industrialization, a strong manufacturing base, and significant investments in infrastructure development.

Competitive Landscape

The metal cutting machine market is highly competitive, with several key players striving to maintain their market positions through product innovations, strategic partnerships, and mergers and acquisitions. Prominent players in the market include Amada Holdings Co., Ltd., TRUMPF GmbH + Co. KG, Bystronic Laser AG, Coherent, Inc., and BLM Group. These companies are focusing on developing advanced metal cutting solutions to cater to the evolving needs of various industries.

Future Prospects

The future of the metal cutting machine market looks promising, with continuous advancements in technology and increasing demand from end-use industries. The integration of artificial intelligence (AI) and the Internet of Things (IoT) in metal cutting machines is expected to enhance operational efficiency and productivity. Additionally, the growing emphasis on sustainable manufacturing practices is likely to drive the adoption of eco-friendly metal cutting solutions.

Key players

TRUMPF

AMADA Co. Ltd

ESAB Corporation

Bystronic Laser AG

WARDJet

Koike Aronson, Inc.

Nissan Tanaka Corporation

Lincoln Electric Company

Water Jet Sweden AB

Flow International Corporation

Coherent Corp.

Messer Cutting Systems GmbH

Omax Corporation

Boye Laser Applied Technology Co., Ltd.

Han’s Laser Technology Industry Group Co., Ltd.

Segments

Based on Product

Laser Cutting Machine

Waterjet Cutting Machine

Plasma Cutting Machine

Flame Cutting Machine

Others

Based on Application

Automotive

Defense & Aerospace

Electrical & Electronics

Construction

Others

Based on Region

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/metal-cutting-machine-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Machine Tooling Market - Forecast(2024 - 2030)

Machine Tooling Market Overview

The Machine Tooling Market is estimated to surpass $94.42 billion marks by 2026 growing at an estimated CAGR of more than 3.7% during the forecast period 2021 to 2026. Increasing demand for high efficiency in complex machining products is expected to drive the Machine Tooling Market. Rise in demand for low operating cost and high precision, along with technological advancement in production processes, is further resulting in the popularity of CNC machine tools. Moreover, development and launch of next-gen, cutting-edge machine products and solutions are the central focus areas for key players in this market. These players are continuously investing in R&D to create enhanced and sophisticated offerings to strengthen their portfolio and further entrench their position in the market.

Machine Tooling Market Report Coverage

The report: “Machine Tooling Market– Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Machine Tooling Market.

By Type: CNC Machine Tools, Conventional Machine Tools

By Product Type: Metal Cutting Tools (Boring and Drilling, Milling, Finishing, Lathe, Machine Centers and Others), Metal Forming Tools (Rolling, Forging and Press, Extruding and Drawing, Punching and Blanking, Bending, Shearing, Casting and Others) and Special Machine Tools (EDM, EBM, PAM, LBM, USM, ECG, CM and Others)

By Sales Channel: Direct and Indirect

By End User Industry: Automotive, Healthcare, Mining and Metal, Aerospace and Defense, Construction, Electrical and Electronics, Energy and Power, Transportation and Others

By Geography - North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle East and Africa).

Request Sample

Key Takeaways

End users in this market, typically prefer OEMs to provide maintenance support rather than going through a third party. Thus, driving a change in the market model prevalent in this segment.

CNC has various advantages over conventional machines. the various advantages of CNC machines, including high accuracy, safety, time efficiency, flexibility, and low maintenance, is further expected to drive the CNC machine tools market demand.

The core focus areas for leading players in this business are the technical advancement and introduction of next-gen, cutting-edge CNC machine products and solutions. In order to build enhanced and advanced offerings to improve their portfolio and further entrench their position in the industry, these players are actively investing in R&D.

Machine Tooling Market Segment Analysis - By Type

CNC Machine Tools significantly dominate the Machine tool sector accounting for nearly 80% of the market. CNC Machine Tool systems are generally categorised into Milling, Lathe, Drilling, Plasma Cutter, Grinder, Others. The rising demand for high performance in complex machining products is expected to boost the CNC sector. The growth in demand for low running costs and high accuracy, along with technical advances in manufacturing methods, is further contributing to the popularity of CNC machine tools. In addition, the increase in demand across industries particularly in the electronics and automotive sectors contributes positively to the development of the market for CNC machine tools. The core focus areas for leading players in this business are the technical advancement and introduction of next-gen, cutting-edge CNC machine products and solutions. In order to build enhanced and advanced offerings to improve their portfolio and further entrench their position in the industry, these players are actively investing in R&D. Nearly every OEM provides maintenance services to the end users. These end users prefer OEM led maintenance services rather than third parties due to the discounted maintenance services typically offered as well as reliability and improved component procurement policies. This is changing the business model typically utilized in the market.

Inquiry Before Buying

Machine Tooling Market Segment Analysis - By Product Type

The Milling segment held among the highest market share in 2020. Milling machines tools are primarily used in metal grinding processes across a variety of industries. The positive acceleration of the metalworking process industries in the world has ignited the market for milling machines tools. Milling machines tools are extremely flexible and can perform a wide range of functions, such as filling, spinning, chamfering, drilling, gear cutting, and so on. These devices can also render numerous incisions by using multiple cutters.

Moreover, Lathe segment is anticipated to witness significant market growth during the forecast period 2021-2026. Lathe is a tool that rotates every workpiece on its axis in order to execute a wide variety of operations. Automation is the key factor likely to fuel the expansion of the global demand for lathe machines tools. Manufacturers have begun to simplify their manufacturing procedures in order to improve efficiency. The incorporation of the Internet of Things (IoT) into manufacturing (Smart Manufacturing) is one of the latest market trends that will give the business sufficient momentum in the years ahead.

Machine Tooling Market Segment Analysis - By Geography

APAC accounted for the largest share of the Machine tool market. The significant demand from automotive and aerospace sector in China, India and South-East Asia, in particular, is driving market growth. Geographically, RoW (Middle East and Africa) region is anticipated to witness the significant market growth during the forecast period 2021-2026 with a CAGR of 5.22%. The market growth is due to the rising demand of the CNC machine tools from the end-users including automobile, food & beverage, aerospace, construction and others. Growing automotive production primarily in Kuwait, Jordan, and others is projected to boost the market growth. Israel is home to robust mining and manufacturing sector. The country’s manufacturing sector is booming with effective diamond cutting/polishing technologies, aviation and space products, and food processing. These provide promising growth prospects for the machine tool market in the country.

Schedule a Call

Machine Tooling Market Drivers

Rising Adoption of Internet of Things (IoT) Technologies to Fuel Growth

One of the most prominent machine tools market trends is expected to be the increasing uptake of IoT in the manufacturing sector. This will be a result of escalating demand for information and access to information. Furthermore, producers are looking to bring down their production costs, streamline processes, and raise the safety quotient in their units. As a result, there is growing investment in IoT by manufacturers for improved management and control, which is propelling the machine tool market, especially CNC Machine tools. For instance, it is predicted that by 2020, the manufacturing sector will receive an investment of USD 267 billion for IoT integration. Studies have shown that close to 31% of manufacturing operations are already IoT-enabled, which augurs well for this market.

Adoption of CNC Machine Tools in Medical Sector

The medical industry greatly benefits from the efficiency, speed, and accuracy of CNC machining. According to a report by Teton Machine, the number of Americans aged 65 and older is projected to double between 2019 and 2060 95 million. Due to the growth of aging population, the need for precision machining services in the medical industry is growing as well. CNC machines are capable of producing sophisticated surgical instruments, tiny screws and everything in between. In addition medical machined parts for the most complex devices require tight tolerances, which is capable through CNC machine tools. Adding to this, multi-tool and multi-axis machines, such as CNC Swiss turning centers, improve the manufacturing of medical parts with shorter cycle times and owing to the features allowing versatility during production. Moreover several medical equipment manufacturers such as Pulse systems, are focusing on adopting CNC machine tools for advancements in manufacturing. In 2019, Pulse Systems acquired additional CNC (computer numerical control) machine tools to support the company's rapid growth, and has expanded its facilities space to accommodate the newly-added capital equipment. Hence these rising adoption will drive the market growth in the forecast period 2021-2026.

Buy Now

Machine Tooling Market Challenges

High Maintenance Costs and Lack of Training to Hinder Growth of the Market

Generally, CNC machines are costlier than the manually-operated machines. However, with time, the cost is estimated to reduce effectively. Furthermore, to maintain the proper functioning of the machines, regular maintenance of the high-tech pieces is essential by the manufacturers. Apart from this, the focus in the current market is on deploying cheaper machine tools, especially in developing nations. While this saves on initial investment, these machine tools have higher long-term maintenance, parts replacement and other costs, apart from the limited functionality. Besides that appropriate training and machinists need to get acquainted with the professional skills necessary to operate these machines. Hence high maintenance costs and lack of skilled workers will restrict the market growth in the forecast period 2021-2026.

Machine Tooling Market Landscape

Product launches, acquisitions, and R&D activities are key strategies adopted by players in the Machine Tooling Market. Dalian, Amada, JTEKT, Trumpf, Shenyang Machine Tool (SMTCL), Philips Machine Tools, KRC Machine Tool Services, Optimation Technology Inc., Troy Industrial Services, MIC Group and others are considered to be the key players of the Machine Tooling Market.

Acquisitions/Technology Launches/Partnerships

In December 2019, DMG MORI, a leading machine tool manufacturer launched LASERTEC 125 3D hybrid, a new hybrid additive manufacturing system. The LASERTEC 125 is a 5-axis laser deposition welding (LDW) system designed for the maintenance, repair and production of significantly larger parts

IN February 2019, Okuma America Corporation, a world leading builder of CNC machine tools, partnered with Jergens, a superior manufacturer of workholding solutions for machine tools. This partnership was aimed to provide the best possible integrated solutions to the end-user. Such partnerships and Product launches positively impacts the market growth.

#Machine Tooling Market#Machine Tooling Market Share#Machine Tooling Market Size#Machine Tooling Market Forecast#Machine Tooling Market report#Machine Tooling Market Growth

0 notes

Text

Global Top 15 Companies Accounted for 58% of total Electrosurgical Pencil market (QYResearch, 2021)

Electrosurgical pencil is a medical device used to fulgurate, coagulate, cut or dissect biological tissue by the applying electric current. It uses Radio Frequency Alternating Current or RFAC. Electrosurgical pencils are versatile and can suit all operating needs as they come with universal size connector that makes it compatible with most branded electrode tips.

Electrosurgical pencils, also known as cautery pencils used during electrosurgery procedures. They are used to cut biological tissue and control bleeding through Radio Frequency Alternating Current (RFAC).

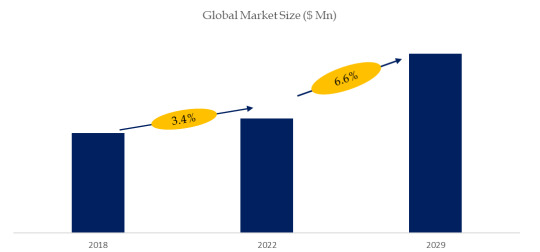

According to the new market research report "Global Electrosurgical Pencil Market Report 2023-2029", published by QYResearch, the global Electrosurgical Pencil market size is projected to grow from USD xx million in 2023 to USD xx million by 2029, at a CAGR of xx% during the forecast period.

Figure. Global Electrosurgical Pencil Market Size (US$ Million), 2018-2029

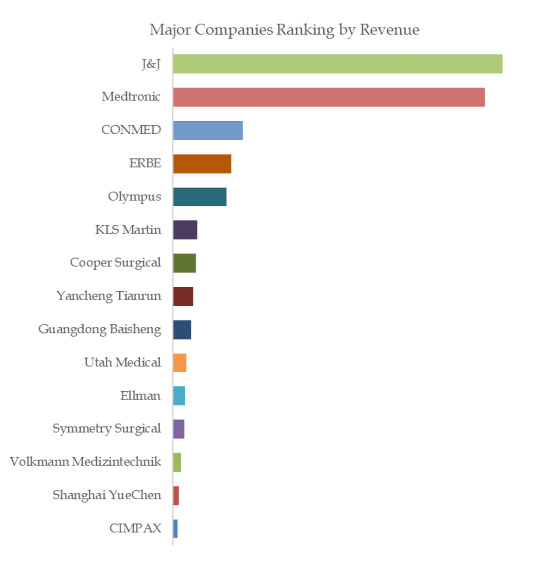

Figure. Global Electrosurgical Pencil Top 15 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Electrosurgical Pencil include J&J, Medtronic, CONMED, ERBE, Olympus, KLS Martin, Cooper Surgical, Yancheng Tianrun, Guangdong Baisheng, Utah Medical, etc. In 2022, the global top five players had a share approximately 58.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

Abrasives Market Outlook Report 2024-2030: Trends, Strategic Insights, and Growth Opportunities | GQ Research

The Abrasives Market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Abrasives Market showcased a significant presence, boasting a valuation of US$ 53.41 billion. This underscores the substantial demand for Acetophenone technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-abrasives-market/

Projected Growth: Projections suggest that the Abrasives Market will continue its upward trajectory, with a projected value of US$ 74.16 billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 4.8%, reflecting a steady and robust growth rate for the Abrasives Market over the coming years.

Technology Adoption:

In the Abrasives market, technology adoption encompasses the development and utilization of advanced abrasive materials, manufacturing processes, and surface finishing techniques. Abrasives are used for grinding, polishing, cutting, and shaping materials such as metals, ceramics, composites, and stones. Various abrasive types include bonded abrasives (e.g., grinding wheels, honing stones), coated abrasives (e.g., sandpaper, abrasive belts), and superabrasives (e.g., diamond, cubic boron nitride). Advanced technologies such as precision grinding, electroplated coatings, and laser machining enhance abrasive performance, precision, and efficiency in diverse applications across industries.

Application Diversity:

The Abrasives market serves diverse applications across industries such as automotive, aerospace, metalworking, construction, electronics, and healthcare. In manufacturing, abrasives are used for surface preparation, deburring, and precision grinding of components in automotive and aerospace production. Additionally, abrasives find applications in metal fabrication for cutting, shaping, and finishing metal parts in construction, machinery, and consumer goods. Moreover, abrasives are utilized in electronics manufacturing for wafer dicing, circuit board fabrication, and precision polishing of semiconductor materials.

Consumer Preferences:

Consumer preferences in the Abrasives market are influenced by factors such as abrasive performance, durability, surface finish quality, and cost-effectiveness. End-users prioritize abrasives that offer high material removal rates, consistent surface finish, and long tool life for efficient machining and finishing operations. Additionally, consumers value abrasives with low clogging tendency, heat resistance, and compatibility with specific materials and machining processes. Moreover, cost considerations, including abrasive price, availability, and overall process economics, play a significant role in consumer purchasing decisions.

Technological Advancements:

Technological advancements in the Abrasives market focus on improving abrasive material properties, manufacturing processes, and tooling technologies to enhance performance, productivity, and sustainability. Research efforts aim to develop new abrasive formulations with enhanced hardness, toughness, and self-sharpening characteristics for improved cutting and grinding efficiency. Additionally, advancements in abrasive coating technologies, such as nanostructured coatings and engineered grain geometries, enhance abrasive adhesion, wear resistance, and tool life in coated abrasive products. Moreover, integration with digital manufacturing technologies, such as CNC machining and robotic automation, enables precise control and optimization of abrasive processes for increased productivity and quality consistency.

Market Competition:

The Abrasives market is characterized by robust competition among abrasive manufacturers, distributors, and end-users, driven by factors such as product performance, quality, pricing, and customer service. Major players leverage their manufacturing scale, R&D capabilities, and global distribution networks to maintain market leadership and gain competitive advantage. Meanwhile, smaller manufacturers and specialty abrasive suppliers differentiate themselves through niche product offerings, customized solutions, and technical expertise in specific applications or industries. Additionally, strategic partnerships, acquisitions, and product innovations are common strategies for companies to expand market presence and enhance competitiveness in the dynamic Abrasives market.

Environmental Considerations:

Environmental considerations are increasingly important in the Abrasives market, with stakeholders focusing on sustainable sourcing, manufacturing processes, and waste management practices. Manufacturers strive to minimize environmental impact by using recycled and eco-friendly abrasive materials, reducing energy consumption, and optimizing water usage in abrasive production processes. Additionally, efforts are made to develop environmentally friendly abrasive coatings and surface treatments that minimize emissions, VOCs (volatile organic compounds), and hazardous waste generation during abrasive machining operations. Moreover, initiatives such as product life cycle assessment (LCA), eco-labeling, and certification programs promote sustainable practices and responsible consumption in the Abrasives market.

Top of Form

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

3M Company

Saint-Gobain Abrasives

Robert Bosch GmbH (Bosch)

Norton Abrasives (A brand of Saint-Gobain Abrasives)

Klingspor AG

Tyrolit Group

Fujimi Incorporated

Deerfos Co., Ltd.

Asahi Diamond Industrial Co., Ltd.

Carborundum Universal Limited

Sia Abrasives Industries AG

Abrasiflex Pty Ltd

Hermes Schleifmittel GmbH

Abrasive Technology

Mirka Ltd.

The research report provides a comprehensive analysis of the Abrasives Market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-abrasives-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

0 notes

Text

Forklift Jack Market Analysis by Size, Share, Key Drivers, Growth Opportunities and Global Trends 2031

The global "Forklift Jack Market Market" report indicates a consistent and robust growth trend in recent times, projecting a positive trajectory expected to persist until 2031. A significant trend observed in the Forklift Jack Market market is the rising consumer inclination towards environmentally sustainable and eco-friendly products. Furthermore, a notable advancement in this market is the increasing incorporation of technology to elevate both product quality and efficiency. Cutting-edge technologies like artificial intelligence, machine learning, and block chain are actively employed to develop innovative products that outperform traditional options in terms of effectiveness and efficiency. The Forklift Jack Market Market Research Report for 2024 highlights emerging trends, growth opportunities, and potential scenarios envisioned up to the year 2031.

By delving into the latest trends, the report keeps businesses abreast of the dynamic market environment, helping them identify emerging opportunities and navigate potential challenges. The meticulous analysis covers various aspects, offering valuable insights into the historical performance of the market and presenting the current (CAGR) status.

Get a Sample Copy of the Report at: https://www.proficientmarketinsights.com/enquiry/request-sample-pdf/1871

Who are the biggest Forklift Jack Market manufacturers worldwide?

Vestil Manufacturing (Indiana)

Global Equipment (U.S.)

Bosch (Germany)

ESCO (U.S.)

GKS Lifting and Moving Solutions (U.S.)

The Forklift Jack Market Market is described briefly as follows:

The global Forklift Jack Market size was USD 3218.9 million in 2024 and the market is projected to touch USD 4438.3 million by 2031, exhibiting a CAGR of 5.50% during the forecast period.

SWOT Analysis of Forklift Jack Market Market:

A SWOT analysis involves evaluating the strengths, weaknesses, opportunities, and threats of a particular market or business. In the case of the keyword market, we'll be looking at the factors that can impact the industry's performance.

Pestle Analysis of Forklift Jack Market Market:

To better comprehend the market environment, a five-force analysis is performed, which takes into account the bargaining power of the customer, the supplier, the threat of substitutes, the threat of new entrants, and the threat of competition.

Get a Sample Copy of Forklift Jack Market Market Report

What are the Types in Forklift Jack Market Market?

Electric Forklift Jack

Hydraulic Forklift Jack

What are Applications in Forklift Jack Market Market?

CNC Machines

Brake Presses

Others

Inquire or Share Your Questions If Any before the Purchasing This Report: https://www.proficientmarketinsights.com/enquiry/queries/1871

Geographical Segmentation:

Geographically, this report is segmented into several key regions, with sales, revenue, market share, and Forklift Jack Market market growth rate in these regions, from 2017 to 2028, covering

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia, and Vietnam)

South America (Brazil etc.)

Middle East and Africa (Egypt and GCC Countries)

Some of the key questions answered in this report:

Who are the worldwide key Players of the Forklift Jack Market Industry?

How the opposition goes in what was in store connected with Forklift Jack Market?

Which is the most driving country in the Forklift Jack Market industry?

What are the Forklift Jack Market market valuable open doors and dangers looked by the manufactures in the worldwide Forklift Jack Market Industry?

Which application/end-client or item type might look for gradual development possibilities? What is the portion of the overall industry of each kind and application?

What centered approach and imperatives are holding the Forklift Jack Market market?

What are the various deals, promoting, and dissemination diverts in the worldwide business?

What are the key market patterns influencing the development of the Forklift Jack Market market?

Financial effect on the Forklift Jack Market business and improvement pattern of the Forklift Jack Market business?

Purchase this Report (Price 3200 USD for A Single-User License) at: https://www.proficientmarketinsights.com/purchase/1871

TOC of Global Forklift Jack Market Market Research Report 2023

1 Forklift Jack Market Market Overview

2 Market Competition by Manufacturers

3 Forklift Jack Market Production by Region

4 Forklift Jack Market Consumption by Region

5 Segment by Type

6 Segment by Application

7 Key Companies Profiled

8 Industry Chain and Sales Channels Analysis

9 Forklift Jack Market Market Dynamics

10 Research Finding and Conclusion

11 Methodology and Data Source

0 notes

Link

#market research future#cnc metal cutting machine tool#metal cutting machine tools#cutting machine tools market#cnc machine tools market

0 notes

Text

Global Top 14 Companies Accounted for76% of total Mounted Reach Mower market (QYResearch, 2021)

Mounted Reach Mower is a machine that cuts grass or other plants that grow on the ground.

In this report, we study Mounted Reach Mower market.

The Mounted Reach Mower market covers Flail Mower and Boom Mower. The typical players include Alamo Group, SaMASZ, Diamond Mowers, FERRI, Seppi M., etc.

According to the new market research report “Global Mounted Reach Mower Market Report 2023-2029”, published by QYResearch, the global Mounted Reach Mower market size is projected to reach USD 0.54 billion by 2029, at a CAGR of 3.6% during the forecast period.

Figure. Global Mounted Reach Mower Market Size (US$ Million), 2018-2029

Figure. Global Mounted Reach Mower Top 14 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Mounted Reach Mower include Alamo Group, SaMASZ, Diamond Mowers, FERRI, Seppi M. Company, Rasco, Atmax Equipment Co, Sanyo Kiki, US Mower, Trackless Vehicles Ltd, etc. In 2021, the global top five players had a share approximately 76.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

https://www.advancemarketanalytics.com/reports/61827-global-flame-cutting-machines-market

Flame Cutting Machines Market Growth Prospect: Is the tide Turning?

Advance Market Analytics released a new market study on Global Flame Cutting Machines Market Research report which presents a complete assessment of the Market and contains a future trend, current growth factors, attentive opinions, facts, and industry validated market data. The research study provides estimates for Global Flame Cutting Machines Forecast till 2029*.

Flame cutting is a thermal cutting process that uses oxygen and a fuel source to create a flame with enough energy to melt and sever material. The process is a thermo-chemical Process requiring a source of intense heat, referred to as “Preheatâ€, and pure oxygen. There are various types of flame cutting machines available for different cutting applications in different industries such as automotive, aerospace, etc. CNC machines are the most widely used machines in advanced countries like China, Japan, Korea, etc. for cutting of the metal sheet for applications ranging from airplane parts to domestic household products.

Key Players included in the Research Coverage of Flame Cutting Machines Market are:

Messer Group (Germany), Koike Group (Japan), Mass Cutting Systems (India), BUG-O SYSTEMS (United States), ARCBRO Ltd. (China), Soitaab Impianti S.r.l. (Italy), SteelTailor (China), Technocrats Plasma Systems Private Limited (India), Th. Wortelboer B.V. (Netherlands), Shanghai Huawei Welding & Cutting Machine (China),

What's Trending in Market: Fully Integrated Oxy-Fuel Cutting System with Cutting Torch, Ignition, Height Sensing and Lifter All in One Package

Challenges: Reduction in Cutting Speed owing to Improper Connections, Bad Hoses, or Leaks Stringent Government Regulation for Safety of Labours

Opportunities: Fast-growing industries like automotive have fuelled the growth opportunities of sheet metalworking in numerous applications in car bodies, airplane wings, medical tables, roofs for buildings and many other things. Automatic and Cost-Effective Machine to Produce High-Quality Products at much Cheaper Rates

Market Growth Drivers: An increasing number of applications in the automotive and aerospace industry owing to high precision, accuracy, and reliability, is the key driving factor for the growth of the market. Growing Number of Manufacturing and Production Activities for High Volume Production in Emerging Economies Low Equipment Cost and No Power Supplies Needed

The Global Flame Cutting Machines Market segments and Market Data Break Down by Type (Manual Flame Cutting Machines, Semi-automatic Flame Cutting Machines, Automatic Flame Cutting Machines, CNC Flame Cutting Machines, Imitation Shape Flame Cutting Machines), Application (Metal Cutting, Glass & Ceramics Cutting, Others), End-User (Automotive, Aerospace & Defence, Construction, Marine, Electronics, Others), Fuel Type (Acetylene, MAPP, Propylene, Propane, Natural Gas)

Get inside Scoop of the report, request for free sample @: https://www.advancemarketanalytics.com/sample-report/61827-global-flame-cutting-machines-market

To comprehend Global Flame Cutting Machines market dynamics in the world mainly, the worldwide Flame Cutting Machines market is analyzed across major global regions. AMA also provides customized specific regional and country-level reports for the following areas.

• North America: United States, Canada, and Mexico.

• South & Central America: Argentina, Chile, Colombia and Brazil.

• Middle East & Africa: Saudi Arabia, United Arab Emirates, Israel, Turkey, Egypt and South Africa.

• Europe: United Kingdom, France, Italy, Germany, Spain, Belgium, Netherlands and Russia.

• Asia-Pacific: India, China, Japan, South Korea, Indonesia, Malaysia, Singapore, and Australia.

0 notes

Text

Metal Cutting Tool Market Industry Development Trends and Strategic Plan for Positive Growth by 2032

The metal cutting tools industry encompasses businesses engaged in the creation, production, and distribution of tools and machinery utilized for cutting, shaping, and molding metal components. These tools vary from handheld instruments like saws, grinders, and shears to highly specialized equipment such as lathes, milling machines, and CNC machines. Serving diverse sectors including automotive, aerospace, construction, and industrial manufacturing, this industry holds a pivotal position in metalworking, given that the precision and caliber of cutting tools directly influence the final product's quality.

Over recent years, the industry has witnessed consistent expansion, propelled by escalating demand for metal products across various sectors. Technological advancements have further spurred the evolution of cutting-edge cutting tools, enhancing efficiency, minimizing waste, and elevating the overall standard of metal products. The burgeoning requisition for metal cutting machinery across multiple industries is fueling market growth.

Request Sample PDF: https://www.alliedmarketresearch.com/request-sample/6584

The metal cutting tool market was valued at $65.5 billion in 2020, and is estimated to reach $107.3 billion by 2032, growing at a CAGR of 4.1% from 2023 to 2032. The global metal cutting tool market size was 2,339 units million in 2020 and is projected to reach 3,237 million units by 2032, registering a CAGR of 2.8% from 2023 to 2032. Major factors such as rise in demand from several industries, such as automation and construction and rise in demand for power tool from household, are expected to boost the metal cutting tool market growth during the forecast period. In addition, rapid expansion in the automotive sector is expected to boost the demand for the metal cutting tools, and positively affect the metal cutting tool market forecast. Moreover, rise in manufacturing of light vehicles is anticipated to develop rapid need for welded automotive components, thus, creating demand for metal cutting tools.

Make Purchase Enquiry Before Buying @ https://www.alliedmarketresearch.com/purchase-enquiry/6584 Metal cutting tool have enabled hassle-free production of components, reducing the time required for manufacturing workpieces. In addition, several large manufacturing facilities are increasingly using these tools. Asia-Pacific is one of the fastest growing regions globally, attributed to its large population and low-cost manufacturing sector. China and Japan are leading manufacturers of automobiles and construction machines. Furthermore, the construction and manufacturing industries in countries such as India, Indonesia, Vietnam, and Bangladesh are experiencing significant growth. These factors boost the demand for metal cutting tool as they are extensively used in construction and automotive industries. In addition, the Asia-Pacific region is home to major metal cutting tool manufacturers, such as Ehwa Diamond, Iscar Ltd, and Makita Corporation.

Request for Customization @ https://www.alliedmarketresearch.com/request-for-customization/6584 Leading Market Players: - • Fanuc America Corporation • Amada Machine Tools Co. Ltd. • BIG Kaiser Precision Tooling Inc. • Sandvik • Komatsu Ltd. • Kennametal • Doosan Machine Tools Co. Ltd. • Ingersoll Cutting Tool Company • Tiangong International Co. • Hitachi Metals About us: Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Wilmington, DE. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of "Market Research Reports" and "Business Intelligence Solutions." AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain. Contact Us: United States 1209 Orange Street, Corporation Trust Center, Wilmington, New Castle, Delaware 19801 USA. Int'l: +1-503-894-6022 Toll Free: +1-800-792-5285 Fax: +1-800-792-5285 [email protected]

0 notes