#Brick Making Machine in india

Explore tagged Tumblr posts

Text

Advanced Fly Ash Brick Making Machines for Durable Bricks

Brick Machine is stand out as a trusted name in the industry. We are providing modern fly ash brick making machines designed to deliver durable and high-quality bricks. Our advance machinery incorporate the latest technology to make sure that superior brick strength and efficiency making it a perfect solution for sustainable construction projects. These machines are designed to minimize manual effort while you maximizing production capacity and we are providing an perfect balance between innovation and practicality for brick manufacturers.

Brick Machine is make strong commitment to quality and performance or we can delivered unparalleled reliability in the field of fly ash brick production. Our machine are built to meet various small scale manufacturer or a large industrial setup production requirement. Our machine are compete to help business succeed in the competitive construction sector with their energy efficiency and robust construction. Choose Brick Machine for your fly ash brick making needs and experience unmatched excellence.

Brick Machine is perfect solution for your brick manufacturing needs with advance fly ash brick making machines. Our machines are designed for durability and efficiency or we can make sure that our machine are superior quality and high production capacity for sustainable construction. Visit Our Website brickmachinery.in to learn more about our innovative product and how they can improve your business operations.

#fly ash brick making machine#brick making machine#hydraulic brick making machine#paver block making machine#brickmakingmachine#fly ash brick making machine in gujarat#brick making machine in india#brickmachine#fly ash brick plant#block making machine

0 notes

Text

Fully automatic Brick making machine, BMM310 dispatched to Uttar Pradesh, India

SnPC Machines: Factory of bricks on wheel

SnPC Machines is providing heavy brick making truck that can produce brick with a speed of more than 25K brick per hours with a minimum labor and resources. BMM manufactured by SnPC Machines are making it possible for kiln owner to fulfill their brick requirements in a limited time and investments.

#BMM310#BMM410#SnPC Machines#brick making machine India#brick making machine Delhi#Top quality bricks#brick machine UP#Team SnPC

7 notes

·

View notes

Text

Durable Clay brick making machine

SnPC Machines: Clay brick making machine manufacturers in India

SnPC Machines India Is A Leading Manufacturer Of Brick Making Machines Specially The Mobile Brick Making Machines Bmm160, Bmm310, Bmm400, Bmm404 And Sbm180 All The Models Can Be Tailored As Per The Customers Requirements For Both Indian And Overseas Customers.

#SnPC Machines#clay brick making machine#machine for making brick#red clay brick machine#BMM310#best clay brick machine in India#innovation in brick machine#red soil brick machine#brick machine India#brick machine Gujarat

2 notes

·

View notes

Text

High-Quality Paver Block Making Machine for Durable Construction

In the ever-evolving world of construction, efficiency and quality are paramount. BTM Product understands this need and offers cutting-edge solutions to meet the demands of modern construction

projects. Our high-quality paver block making machine stands at the forefront of innovative technology, designed to produce durable and aesthetically pleasing paver blocks for various applications.

The Importance of Quality Paver Blocks

Paver blocks have become an integral part of urban landscaping and construction projects. They offer numerous benefits, including:

1. Enhanced aesthetics 2. Improved water drainage 3. Easy installation and maintenance 4. Durability in various weather conditions 5. Versatility in design and patterns

To achieve these benefits, it's crucial to have a reliable and efficient paver block making machine that can consistently produce high-quality blocks.

BTM Product's Paver Block Making Machine: A Cut Above the Rest

At BTM Product, we pride ourselves on offering the best paver block making machine in the industry. Our state-of-the-art equipment is designed with precision and built to last, ensuring that you can meet the demands of your construction projects with ease.

Advanced Technology

Our paver block making machine incorporates the latest advancements in manufacturing technology. With computerized controls and automated processes, you can achieve consistent quality and high production rates.

Versatility in Block Production

Whether you need standard pavers, interlocking blocks, or custom designs, our machine can handle it all. The versatile mold system allows for quick changes, enabling you to produce a wide range of block sizes and shapes to suit various project requirements.

Energy Efficiency

We understand the importance of reducing operational costs. That's why our paver block making machine is designed with energy efficiency in mind. The optimized hydraulic system and intelligent power management ensure that you get maximum output with minimal energy consumption.

Key Features of Our Paver Block Making Machine

1. High production capacity 2. Precise vibration control for optimal compaction 3. User-friendly interface for easy operation 4. Quick mold change system 5. Robust construction for long-term reliability 6. Low maintenance requirements 7. Customizable settings for different mix designs

The BTM Product Advantage

When you choose a paver block making machine from BTM Product, you're not just getting equipment; you're investing in a complete solution. Our team of experts provides comprehensive support, from initial setup to ongoing maintenance and troubleshooting.

Training and Support

We offer thorough training programs to ensure that your staff can operate the machine efficiently and safely. Our technical support team is always available to address any questions or concerns you may have.

Quality Assurance

Every paver block making machine that leaves our facility undergoes rigorous quality checks. We stand behind our products with a solid warranty and after-sales service to give you peace of mind.

Expanding Your Product Line: Fly Ash Brick Making Machine

In addition to our paver block making machine, BTM Product also offers a high-quality fly ash brick making machine. This eco-friendly option allows you to produce durable bricks using industrial waste products, contributing to sustainable construction practices.

Benefits of Fly Ash Bricks

1. Environmentally friendly 2. Cost-effective production 3. High strength and durability 4. Excellent thermal insulation properties 5. Uniform size and shape

Our fly ash brick making machine is designed to deliver the same level of quality and efficiency as our paver block equipment, ensuring that you can diversify your product offerings without compromising on standards.

Choosing the Right Machine for Your Needs

Selecting the best paver block making machine or fly ash brick making machine for your business depends on various factors, including:

1. Production capacity requirements 2. Available space 3. Budget considerations 4. Types of blocks or bricks needed 5. Local market demand

BTM Product offers a range of models to suit different needs, from small-scale operations to large industrial setups. Our experienced sales team can help you assess your requirements and recommend the perfect machine for your business.

Success Stories

Many of our clients have seen significant improvements in their operations after incorporating our paver block making machine into their production line. For instance, a mid-sized construction company in the Midwest reported a 40% increase in production efficiency and a 25% reduction in material waste within the first six months of using our equipment.

Another client, a landscaping firm on the East Coast, was able to expand their product offerings and secure larger contracts thanks to the versatility and quality of blocks produced by our machine.

The Future of Construction: Embracing Innovation

As the construction industry continues to evolve, staying ahead of the curve is crucial. BTM Product is committed to ongoing research and development, ensuring that our paver block making machine and fly ash brick making machine remain at the cutting edge of technology.

We're exploring advancements in materials science, automation, and sustainable practices to bring you even more innovative solutions in the future. By choosing BTM Product, you're not just investing in today's technology but also positioning your business for tomorrow's opportunities.

Conclusion

In the competitive world of construction and landscaping, having the right equipment can make all the difference. BTM Product's high-quality paver block making machine offers the perfect blend of efficiency, versatility, and durability to help your business thrive.

Whether you're looking to start a new venture or upgrade your existing production line, our paver block making machine and fly ash brick making machine are designed to meet your needs and exceed your expectations. With BTM Product as your partner, you'll have the tools and support necessary to deliver outstanding results in all your construction projects.

Contact BTM Product today to learn more about our innovative solutions and how we can help take your business to the next level. Experience the difference that comes with choosing the best paver block making machine in the industry.

0 notes

Text

The Ultimate Startup Guide for Fly Ash Brick Manufacturing

🔥 Wanna be your own boss? Start by mastering the art of Fly Ash Brick Manufacturing! 🧱💼 Let's unlock your entrepreneurial potential! 💥 #SmallBusinessTips #flyashbrickmachine #manufacturingbusiness #flyashbricksmakingmachine

With India’s construction industry adopting sustainable practices, the popularity of eco-friendly fly ash bricks is rising. Previously, clay bricks dominated the market; however, cement bricks have gradually become favoured, and now fly ash bricks are gaining traction. Fly ash is a coal combustion byproduct, and India has it in abundance, making it ideal for brick production. Launching a fly ash…

View On WordPress

#automatic fly ash bricks machine#best business ideas#business ideas#fly ash brick machine#fly ash brick making#fly ash bricks#fly ash bricks business#fly ash bricks business plan#fly ash bricks machine#fly ash bricks making business#fly ash bricks making machine#fly ash bricks manufacturing process#how to start a fly ash brick manufacturing business#how to start fly ash brick business#manufacturing business ideas 2024#manufacturing business ideas in india#mini manufacturing business ideas#new business ideas#new business ideas 2024#small business ideas

0 notes

Text

youtube

Full Automatic Rotary Egg Tray Making Machine- Paper Tray

Waste paper use make so many difrent types of products . One of those products is egg tray. And today we are going to tell you and show you its entire process. We will explain all the processes one by one, give complete information about the machine, how much it costs and how many types there are. Best Egg Trays Making Machine Factory Using Waste Paper | Fully Auto Egg Cartoon Making , EGG Trays Making Machine with Waste Paper ,

#Fully Automatic#Laxmi Enterprises#egg tray packing machine#egg tray manufacture#egg tray manufactures#Paper Pulp egg tray manufactures#Manufacturer#Fully Automatic Egg Tray Machine Metal Multilayer Dryer#Eggs Trays Brick Dryer System#Semi Automatic Egg Tray Machine (Without Dryer)#Paper Pulp Egg Tray Making Machine#Rotary Egg Tray Making Machine#Egg Tray Forming Machine#Egg Tray machine with Brick Dryer#Automatic Egg Tray Plant Video how to make#egg tray making machine price in india#egg tray making machine price in south africa#egg tray making machine price in kolkata#egg tray making machine companies#egg carton making machine#paper egg tray making machine#small egg tray making machine#manual egg tray making machine#egg carton manufacturing machine#pulp egg tray making machine in india#egg tray making machine fully automatic#cheap egg tray making machine#egg tray making machine italy#egg tray making machine manufacturer#egg crate manufacturing machine

1 note

·

View note

Text

Auto Pallet Stacker System manufacturer in coimbatore

Introducing the Auto Pallet Stacker System - 15 Bricks, a highly efficient solution for automating the pallet stacking process. Designed and manufactured by a leading Auto Pallet Stacker System manufacturer in Coimbatore, this advanced system is engineered to improve the productivity and accuracy of stacking operations. With a range of powerful features, it is an ideal choice for industries looking to enhance their material handling.

Equipped with a 15 H.P/11.25 KW hydraulic motor, the Auto Pallet Stacker System ensures smooth operation, while the 3 H.P/2.25 KW conveyor system optimizes material flow. The system also includes a high-performance pan mixer machine and a hopper vibrator for greater efficiency. The stacker is powered by a robust 3 H.P/2.25 KW hydraulic motor and features a travel motor of the same power for reliable movement and positioning. It has a pallet chain conveyor and hydraulic-free fill system to simplify stacking tasks, cutting down on labor requirements significantly.

The machine's control is managed through a PLC system, providing precise control over its operations. With a stacker cycle time of 15 seconds and a robust hydraulic pump, the Auto Pallet Stacker System Coimbatore ensures high output with minimal downtime. The system is designed with durable components, including grained hard chromed sliding rods and steel casting sliding bushes, ensuring longevity and optimal performance.

As trusted Auto Pallet Stacker System exporters in Coimbatore, India, we take pride in offering a high-quality product designed to meet the demanding needs of modern industries. With a land requirement of 1.5 acres and a production capacity of 12 laborers per shift, the Auto Pallet Stacker System is an investment that improves operational efficiency and productivity. Experience the benefits of automation with our advanced system, tailor-made for the evolving industrial landscape.

For more details on the Auto Pallet Stacker System, feel free to contact us today!

Website Link : -http://www.bennyenterprises.net/

Contact no : - 9360623765

Mail id : - [email protected]

Address :- Site No:13, Thadagam Road,K.N.G.Pudur Pirivu,

Opp: Indian Oil Petrol Pump, Next to Agarwal School, Somayampalayam (PO), Coimbatore - 641 108,Tamil Nadu, India

Socail media link

facebook link :- https://www.facebook.com/Bennyindustries

short describiton :- Benny Enterprises specializes in manufacturing innovative block-making machines and construction equipment. With a commitment to quality and precision, the company provides cutting-edge solutions for the construction industry, including automatic block-making machines, tile-making machines, and custom-designed equipment to meet various industrial needs.

#Auto Pallet Stacker System#Auto Pallet Stacker#Auto Pallet Stacker System manufacturer in Coimbatore#Benny Enterprises

0 notes

Text

wholesale electrical distributors in India

In today’s fast-paced industrial landscape, precision and accuracy are paramount. One tool that has become indispensable for various applications is the industrial digital counter. Whether you are in manufacturing, logistics, or quality control, having reliable counters can streamline operations and enhance productivity. If you’re considering upgrading or purchasing new equipment, this guide will walk you through the benefits and considerations of buying industrial digital counters online.

What Are Industrial Digital Counters?

Industrial digital counters are devices used to count events, products, or operations within a given timeframe. They display numerical values in a clear, easy-to-read format, making it simple to monitor processes such as production rates, machine cycles, and inventory levels. Unlike traditional mechanical counters, digital counters offer enhanced features such as programmable settings, multiple display options, and connectivity capabilities.

Why Buy Industrial Digital Counters Online?

Wide SelectionOne of the biggest advantages of buying industrial digital counters online is the sheer variety available. Online platforms offer an extensive range of products from different manufacturers, allowing you to compare features, specifications, and prices all in one place. This accessibility ensures that you can find the perfect counter that meets your specific needs.

ConveniencePurchasing online eliminates the need to travel to physical stores. You can browse products at your own pace, read reviews, and make informed decisions from the comfort of your office or home. This convenience is particularly beneficial for busy professionals who may not have the time to visit multiple suppliers.

Competitive PricingOnline retailers often offer competitive pricing due to lower overhead costs compared to brick-and-mortar stores. You can easily find deals, discounts, or promotional offers that may not be available in physical locations. Additionally, many online platforms provide price matching, ensuring you get the best deal.

Detailed Product InformationWhen you buy industrial digital counters online, you can access comprehensive product descriptions, specifications, and user manuals. Many platforms also include customer reviews and ratings, giving you valuable insights into the performance and reliability of the counters.

Key Considerations When Buying Industrial Digital Counters

Application RequirementsBefore making a purchase, clearly define the application for which you need the digital counter. Consider factors such as the environment (e.g., indoor vs. outdoor), the type of data to be measured, and the required accuracy. Different counters are designed for specific tasks, so choosing the right one is crucial.

Features and FunctionalityIndustrial digital counters come with various features, including programmable settings, multiple counting modes, and connectivity options like USB or Bluetooth. Assess your needs to determine which features are essential for your operations. For instance, if you need to track multiple parameters, look for counters that offer advanced functions.

Durability and ReliabilityIn industrial settings, equipment must withstand harsh conditions. Check the specifications for durability, such as temperature resistance, moisture protection, and impact resistance. Investing in a reliable counter ensures long-term performance and minimizes the risk of equipment failure.

Supplier ReputationResearch the online retailers you consider purchasing from. Look for established suppliers with positive customer reviews and a solid track record in the industry. A reputable supplier is more likely to provide quality products and reliable customer support.

How to Buy Industrial Digital Counters Online

Research and CompareStart by researching different models and manufacturers. Use comparison tools available on many websites to evaluate features, specifications, and prices side by side.

Read ReviewsCustomer reviews can provide invaluable insights into the performance and reliability of the counters you’re considering. Look for feedback from users in similar industries to gauge the product's effectiveness.

Check Return Policies and WarrantiesBefore finalizing your purchase, review the return policies and warranty information. A good warranty can provide peace of mind, ensuring that you are covered in case of any defects or issues.

Place Your OrderOnce you’ve found the right industrial digital counter, proceed to checkout. Ensure you enter all necessary information accurately to avoid any delays in shipping.

Conclusion

Buying industrial digital counters online can significantly enhance your operational efficiency and accuracy. With a wide selection, competitive pricing, and the convenience of online shopping, it’s easier than ever to find the perfect counter for your needs. By considering your application requirements, desired features, and supplier reputation, you can make an informed decision that supports your business goals. Embrace the power of digital counters and take your industrial processes to the next level!

#Buy Industrial Digital Counters Online#electronic timers for industrial automation in India#digital temperature controllers in India#contactor suppliers in India#overload relay price list in India

0 notes

Text

Your One-Stop Destination for Tools and Building Materials

Hardware shops are essential businesses for homeowners, contractors, DIY enthusiasts, and professionals in the construction and engineering fields. These stores offer a vast array of products, from basic tools to advanced equipment, as well as building materials for every project imaginable. Whether you're fixing a leaky pipe, building a piece of furniture, or constructing a house, a well-stocked hardware shop is your go-to resource.

This article will provide an in-depth look at the various aspects of hardware shops, including the types of products they offer, their role in different industries, and how they serve as crucial hubs for both professionals and amateurs alike.Looking for the top 10 hardware shops in Chennai. Find the best stores offering quality tools, building materials, and supplies for all your construction needs.

The Role of Hardware Shops in Everyday Life

Hardware shops have long been an integral part of communities, serving both individual customers and businesses. They are typically smaller, neighborhood stores that cater to local needs, but large-scale hardware superstores like Home Depot, Lowe’s, and Ace Hardware also dominate the market in many countries. In India, particularly in cities like Chennai, hardware shops are widespread, offering everything from small tools to large-scale industrial supplies.

Key Products and Services Offered by Hardware Shops

1. Hand Tools

At the heart of every hardware store is an extensive selection of hand tools. These include everything from hammers, wrenches, and pliers to screwdrivers, saws, and measuring tapes. Hand tools are the backbone of most DIY and professional jobs, used in a wide variety of settings.

2. Power Tools

In addition to traditional hand tools, most hardware shops also stock a range of power tools. These include drills, grinders, sanders, saws, and other machines that are powered either by electricity or batteries. Power tools significantly reduce the effort required for many tasks, making them indispensable for professionals in construction and engineering, as well as for serious hobbyists.

3. Building Materials

A key section of any hardware store is dedicated to building materials. These materials include cement, bricks, timber, steel rods, tiles, and pipes. Hardware shops offer everything you need for construction, whether you're building a small extension to your home or working on a large-scale construction project.

4. Plumbing and Electrical Supplies

Hardware shops typically carry a variety of plumbing supplies such as pipes, faucets, fittings, and valves. These items are essential for both new installations and repairs. Similarly, a well-stocked hardware shop will offer electrical supplies including wires, switches, light fixtures, and fuses. Both plumbing and electrical sections cater to household repairs and professional installations.

5. Paints and Painting Accessories

A trip to the hardware store wouldn’t be complete without exploring the paint section. Hardware shops carry paints in various types (emulsions, oil-based, latex, etc.) and a spectrum of colors, alongside accessories like brushes, rollers, and drop cloths. Whether it's for a full-scale home makeover or a quick touch-up, this section is indispensable.

6. Fasteners and Fittings

Nuts, bolts, screws, nails, hinges, and brackets are just a few of the fasteners and fittings available in hardware stores. These seemingly small components are essential to construction, furniture assembly, and even artwork installation.

7. Gardening and Outdoor Equipment

Many hardware shops also stock tools and materials for gardening and outdoor maintenance. Items such as shovels, rakes, lawnmowers, and seeds can be found in this section. Some shops may even sell fertilizers, pesticides, and other products necessary for garden upkeep.

8. Safety Equipment

Safety is a priority in any construction or repair job, and hardware shops provide essential protective gear such as helmets, gloves, goggles, ear protection, and boots. Whether you're a professional contractor or a DIY enthusiast, having the right safety equipment is crucial.

Specialty Hardware Shops vs. General Hardware Stores

While many hardware stores offer a broad range of products, some specialize in specific niches. For example:

Plumbing and Sanitary Stores: Focus primarily on plumbing fixtures, pipes, bathroom fittings, and related products.

Electrical Hardware Shops: Specialize in lighting, wiring, and electrical components.

Timber and Carpentry Stores: Cater mainly to woodworkers and carpenters, offering timber, plywood, and related materials.

These specialty stores are often frequented by professionals who need specific products for their trade.

Hardware Superstores: Convenience and Variety

In recent years, hardware superstores have gained popularity due to the convenience they offer. These large retail outlets, like the aforementioned Home Depot or Lowe’s, offer a wide selection of products under one roof. Customers can find virtually everything they need for home improvement, building, or repair projects in these mega stores.

The Importance of Knowledgeable Staff

One of the key advantages of hardware shops is the expertise and knowledge of their staff. Whether you're shopping at a small neighborhood store or a large retail chain, the ability to get advice on tools, materials, and techniques is invaluable. Experienced staff can help you choose the right products for your project, suggest alternatives, and provide guidance on how to use the tools safely and effectively.

The Rise of Online Hardware Stores

While brick-and-mortar hardware stores remain popular, the rise of online shopping has transformed the industry. Today, many hardware stores have an online presence, allowing customers to browse products, read reviews, and make purchases from the comfort of their homes. This is especially convenient for customers who are looking for specific items that may not be readily available in their local store.

Conclusion

Hardware shops, whether large or small, are vital to the functioning of many industries and the day-to-day lives of individuals. From the most basic home repair to complex construction projects, these stores provide the tools and materials needed to get the job done. Their extensive range of products, personalized service, and essential role in both local economies and global industries make them an indispensable part of modern life. Whether you're a professional contractor or a weekend DIY enthusiast, a visit to a well-stocked hardware store is always the first step in bringing your project to life.Searching for a reliable hardware shop in Chennai. Discover stores offering a wide range of tools, building materials, and supplies for all your project needs.

0 notes

Text

The Best Brand of Brick Making Machine in India

Purchasing a brick making machine in India is a good strategy for builders and developers who want to enhance productivity, quality, and profitability of construction ventures. The common practices for making bricks have drawbacks involving performing labour for many hours while still producing bricks of imprecise extent and strength. Unlike brick making machines where high-quality uniform bricks are produced by machines with little or no human interferences thus improving the construction processes.

A major revolution has been recorded in the automation of the construction of brick machines which enhance highly increased production. These machines can generate a considerable number of bricks in a short time, minimizing time off and delivering great-measure schedules in a shorter time. Moreover, the automated processes in these machines help avoid human interventions or accidents and cuts expensive material wastage in the construction projects.

The new models developed by Brick Machinery Company are ideally suited to produce high-quality and long-lasting bricks in a relatively shorter duration. A reputed company in manufacturing construction equipment, Brick Machinery has developed machines which boosts production rates and accuracy for each brick it manufactures to make construction businesses in India competitive. Brick making machine importer in India is aimed to get a product that is sturdy, consistent, and efficient since using a brick making machine for modern construction requires high output.

Features to Look for in a Brick Making Machine

Automation Level

The machines help in the making of bricks with minimal effort from human beings and also increase the productivity of the bricks. Search for models that have different automation options that will enable high production with limited manpower.

Production Capacity

It is also important to assess the machines production capabilities in order to determine if it fits your project’s demand. Brick Machinery has equipment for both small and big requirements which makes it easier for any business to use them.

Durability

A good feed system must have long term durability to support the overall performance. Brick Machinery designs and constructs its machines from high quality materials to enable them endure rigorous use and harsh environments which are characteristic of the construction industry in India.

Ease of Operation

Easy to use design allows the operators to control the machine without much training to prevent mistakes. Easy to use controls are integrated into each brick making machine that is marketed in India to include even those who may not have advanced skills.

Why Brick Machinery Stands Out as the Best Brand in India

Quality Assurance

Brick Machinery has given commitment to maintaining high standard in all its practices. Every machine is tested and checked for its quality before it is supplied and each machine supplied to India exceeds the international standards of performance for brick-making machines. These qualities have placed Brick Machinery as a reputable organization in its fields of operation.

Innovative Technology

The key driver at Brick Machinery is innovation. They incorporate state of the art technology to produce very efficient, energy-saving machines that are also durable. This is because Brick Machinery is improving the capabilities of the products to suit the ever-changing market requirements making it among the best brick making machine in India.

Customer Satisfaction

There are so many good reviews left behind by happy customers and with this, Brick Machinery Has built a good reputation in the market. Their machines have revolutionized the production of bricks for a number of firms and the testimonials from the clients show that they are durable and work well. Speaking to users from brick kilns across India, Brick Machinery has lived up to expectations and has established itself as one of the premier companies dealing in brick making machines in India.

Choose the Best Brick Making Machine for Your Needs

For those interested in advanced technologies in brick making, visit the Brick Machinery which includes a wide option. Check out our website today to know more about how much these machines can enhance your construction career. For more information on your specific requirements or to purchase a solidly constructed machine, call Brick Machinery today!

#fly ash brick making machine#brick making machine#hydraulic brick making machine#paver block making machine#brickmakingmachine#fly ash brick making machine in gujarat#brick making machine in india#brickmachine#fly ash brick plant#block making machine

0 notes

Text

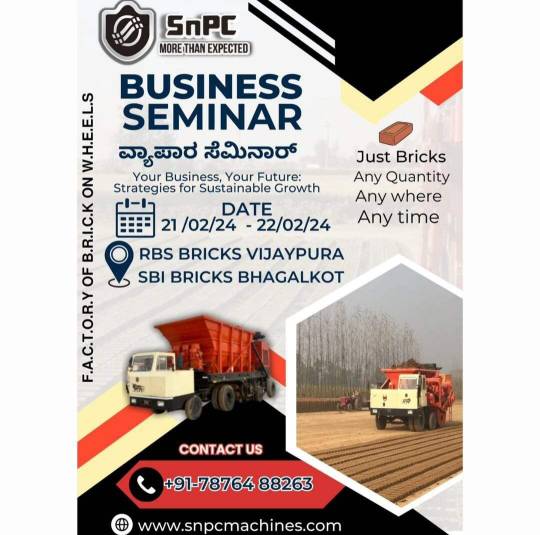

Business Seminar by SnPC Machines

SnPC Machines: Factory of bricks on wheel

Your business, your future strategies for sustainable Growth Just bricks: Any where, any time, any quantity SnPC Machines is organizing business seminar in BhaghalKot and Vijayapur Karnataka, we request the presence of your honor. Date: 21/2/24, 22/02/24 +917876488263 +917015732792

#SnPC Machines#brick making machine#clay brick making machine#BMM410#BMM310#Top quality bricks#Business seminar#event in India#upcoming event 2024#Team SnPC#Mobile brick making machine

7 notes

·

View notes

Text

The bricks, the better foundation!

Snpc Clay Brick making machine

Red Brick Making Machine: There Are Many Players In The Brick Making Machines Around The Globe But SnPC Machines India Is The Only Team/Group Of Kiln Owners Whose Focus Is Not Only In The Selling Of Brick Making Machines But To Introduce The New Age Technology For The Brick Production Process And The Mobile Brick Making Machine Model Bmm400, Bmm404 Is The Latest Example Of That YouTube Link Given, Whereas Other Machines Are Even Stationary Or Fixed That Can Produce Up To 6000-8000 Bricks Even In 01 Hour Or A Day Here Bmm404 Can Produce Up To 25000. Bricks In Just 01 Hour. It Is An Achievement Itself Of Team SnPC That A Single Mobile Brick Making Machine Can Produce Up To 25000 Bricks In Just 01 Hour With The Help Of Only 02 Manpowers Or Technicians And Available For Both Indian And Overseas Customers.

#Snpc Clay brick making machine#machine for making brick#brick machine India#brick machine Delhi#brick machine Odisha#clay brick machine#red clay brick#top quality bricks#brick press#off road construction machinery#off road brick making machine

1 note

·

View note

Text

From Blueprint to Reality: How AI is Transforming the Construction Process

In recent years, Artificial Intelligence (AI) has revolutionized industries across the globe, and the construction sector is no exception. What was once a slow and labor-intensive process is now becoming more efficient, precise, and innovative, thanks to AI. From the initial blueprint to the final structure, AI is transforming how buildings are designed, constructed, and maintained. Many colleges for architecture in India are also incorporating AI-driven tools in their curriculum to prepare the next generation of architects for this shift. Let’s explore how AI is streamlining the construction process, making it faster, safer, and more cost-effective.

AI in Design and Planning

At the start of every construction project, there’s a design and planning phase. This crucial step determines the project’s structure, layout, and cost. Traditionally, it’s a time-consuming process, requiring multiple revisions and intense collaboration. AI, however, is speeding things up. With AI-driven design tools, architects can input constraints such as budget, materials, and environmental factors, and the software generates optimized blueprints almost instantly. These tools offer creative solutions that might not be obvious to human designers, allowing for innovative building designs that maximize space and efficiency.

Automation on the Job Site

When it comes to construction, AI isn’t just behind a computer screen—it’s on-site, too. Automated machinery, powered by AI, is taking over repetitive and labor-intensive tasks. For example, bricklaying robots can place thousands of bricks per day with incredible precision, reducing human error and increasing speed. These AI-powered machines can work longer hours without tiring, helping to complete projects faster and with fewer workers. This doesn’t mean humans are out of the picture, but it allows skilled workers to focus on more complex tasks, improving overall site productivity.

Smarter Project Management

Managing a construction project involves juggling a lot of moving parts—schedules, materials, workers, and budgets. AI is helping project managers stay on top of these details by using predictive analytics to foresee potential delays or cost overruns. By analyzing historical data, AI can make informed predictions about project timelines and resource needs, ensuring projects stay on track. If problems arise, AI can automatically adjust schedules or recommend solutions, minimizing disruptions and keeping everything running smoothly.

Enhancing Safety on Construction Sites

Construction sites can be dangerous, with risks ranging from machinery accidents to falling debris. AI is making these environments safer. Drones equipped with AI can monitor job sites in real-time, checking for safety violations and hazards. AI systems can analyze data from past accidents and predict future risks, allowing site managers to take preventive action before problems occur. This proactive approach is reducing accidents and improving overall safety for workers.

Predictive Maintenance and Building Management

Even after a building is completed, AI continues to play a vital role. Smart buildings equipped with AI systems can monitor their own condition, flagging any potential issues such as structural weaknesses or faulty systems. This predictive maintenance allows building owners to address problems before they become major repairs, saving time and money in the long run. Additionally, AI can help manage a building’s energy usage, automatically adjusting heating, lighting, and ventilation based on occupancy, further reducing operational costs.

Promoting Sustainability in Construction

Sustainability is a growing priority in construction, and AI is helping the industry go green. By analyzing data on materials and construction methods, AI can suggest environmentally friendly alternatives that reduce waste and carbon emissions. AI also helps architects design energy-efficient buildings that use resources more sustainably, creating structures that have a lower environmental impact from start to finish.

The Future of AI in Construction

As AI continues to advance, its role in construction will only grow. In the near future, we might see fully automated construction sites where robots and AI-driven machines handle most of the physical labor, supervised by humans who manage the more complex decision-making tasks. AI will also enhance collaboration, providing real-time updates and insights to all stakeholders involved, improving transparency and communication throughout the project lifecycle.

Conclusion

AI is changing the construction industry in profound ways, from speeding up design processes to making job sites safer and more efficient. By automating repetitive tasks, optimizing project management, and promoting sustainability, AI is helping to bring construction into the future. While the industry will always need the human touch, AI is playing an essential role in turning blueprints into reality faster and smarter than ever before. As technology continues to evolve, the possibilities for innovation in construction are endless, paving the way for smarter, safer, and more sustainable building practices. Educational institutions like Anna University affiliated colleges in Chennai are preparing future professionals by integrating AI and cutting-edge technologies into their architecture programs, ensuring students are equipped for the evolving industry

MIDAS MARG Swarnabhoomi, Velur Village, Cheyyur Post, Chengalpattu District, Tamil Nadu – 603 302, India. Phone : 044-27538010

#colleges for architecture in india#architecture colleges in chennai#best architecture colleges in chennai under anna university

0 notes

Text

Are you using Concrete Block? Things You Need to Know

A concrete block, also known as a building block, is entirely formed of concrete from Brick Contractors near Brisbane and then bonded together to form a large, long-lasting structure. These blocks used in building projects can be’solid’ or ‘hollow’, made of lightweight or standard concrete, and come in a variety of sizes, depending on the exact needs.

Concrete blocks are available in a variety of forms and dimensions. These blocks are made using water, cement, and aggregate.

Solid concrete blocks are extremely hefty and made of aggregate. They are commonly utilized in building projects. They are strong and contribute to the stability of buildings. These strong concrete blocks are ideal for large-scale applications, such as force-bearing walls. They are smaller than other bricks; therefore concrete masonry takes less time than brick masonry.

Masonry building uses hollow concrete blocks. Aside from conserving steel and cement, labor costs on the project site are decreased and the building process is accelerated. These blocks reduce the weight of masonry structures while improving wall properties such as thermal and sound insulation. Standard hollow concrete blocks come in two sizes: full and half size. These concrete blocks come in a variety of sizes, patterns, and forms to suit your needs and preferences.

Concrete blocks for Block Wall Construction in Brisbane are an ideal alternative for partition walls since they are simple and quick to install. The inclusion of steel reinforcement increases the structure’s strength. Hollow concrete blocks are commonly used on both exterior and interior walls, including load bearing, partition, panel, and boundary walls. Solid concrete blocks are perfect for chimneys and fireplaces, but they also work well with non-load-bearing walls and garden walls.

Concrete blocks are used in minor landscape schemes. Many outdoor furniture and patio concepts are created with their assistance. These blocks may be utilized as storage facilities since they protect commodities from changing weather conditions, and engineers employ them to build material bins. The use of concrete blocks has increased widely due to their advantages over conventional red bricks.

Offering adaptability, durability, and strength, Concrete blocks are a vital building element in the construction industry. Concrete blocks are often referred to as concrete bricks, cement blocks, or bricks. In Karnataka, India, where development is flourishing, cement blocks are becoming more popular due to their versatility in meeting a variety of structural demands, low cost, and simplicity of installation.

Why are Concrete Blocks preferred over Red Bricks?

Strength: Concrete blocks have more compressive and tensile strength than red bricks. This makes them better suited for high-rise structures that require higher load-bearing capability.

Concrete blocks require less cement and plaster than red bricks, resulting in substantial cost savings during construction.

Concrete blocks are more resistant to weathering and shattering during transit, making them a more reliable and long-lasting option.

Ease of Use: Concrete blocks by Brick Contractors near Brisbane are machine-made, which reduces the possibility of faulty goods and allows for more exact size and shaping than red bricks.

#Brick Contractors near Brisbane#brick exterior#brick pavers#brick manufacturer in brisbane#home renovation brisbane#bricklayer brisbane#all types of brick and block walls in gold coast

0 notes

Text

youtube

Full Automatic Hydraulic Egg Tray Making Machine

Semi Automatic Paper Egg Tray Making Machine Electric 42 KW 440 Waste Paper Egg Tray Making Machine Automatic Paper Egg Tray Manufacturing Plant & Machines Waste Paper Automatic Egg Tray Machine Recycle Paper Egg Tray Machine Waste Paper Egg TRAY AND APPLE Tray Machine, Best Egg Trays Making Machine Factory Using Waste Paper Waste Paper Egg Tray Making Machine, 440 KW, Production EGG Trays Making Machine with Waste Paper Paper Egg Tray Making Machine, 91 KW, Production Capacity Automatic Rotary Egg Tray / Egg Carton Making Machine Egg Tray Machine With Affordable Prices Semi Automatic Egg Tray Machine _ Laxmi Enterprises Egg Tray Pulping System Semi Automatic Hydraulic Paper Egg Tray Making Machine बेकार कागज का उपयोग करके अंडे की ट्रे बनाने की सर्वोत्तम मशीन फैक्टरी पेपर एग ट्रे मशीन बेकार कागज अंडा ट्रे बनाने की मशीन, 440 किलोवाट, उत्पादन बेकार कागज/छोटे पैमाने के साथ ईजीजी ट्रे बनाने की मशीन पेपर एग ट्रे बनाने की मशीन, 91 किलोवाट, उत्पादन क्षमता स्वचालित रोटरी अंडा ट्रे / अंडा कार्टन बनाने की मशीन

#All Machines are Available#Fully Automatic Egg Tray Machine#EGG TRAY Machine#Fully Automatic#Laxmi Enterprises#egg tray packing machine#egg tray manufacture#egg tray manufactures#Paper Pulp egg tray manufactures#Manufacturer#Fully Automatic Egg Tray Machine Metal Multilayer Dryer#Eggs Trays Brick Dryer System#Semi Automatic Egg Tray Machine (Without Dryer)#Paper Pulp Egg Tray Making Machine#Rotary Egg Tray Making Machine#Egg Tray Forming Machine#Egg Tray machine with Brick Dryer#Automatic Egg Tray Plant Video how to make#egg tray making machine price in india#egg tray making machine for sale#egg tray making machine price in south africa#egg tray making machine south africa#egg tray making machine price in kolkata#egg tray making machine companies#egg carton making machine#paper egg tray making machine#small egg tray making machine#manual egg tray making machine#egg carton manufacturing machine#pulp egg tray making machine in india

0 notes

Text

Automatic Flyash Brick Making Machine Belt Type – 15 Bricks

The Automatic Flyash Brick Making Machine Belt Type – 15 Bricks is an advanced solution designed to meet the growing demand for sustainable and efficient brick manufacturing. As a leading automatic fly ash brick machine manufacturer in Coimbatore, we focus on delivering precision-engineered equipment that ensures quality and durability.

This state-of-the-art model, ABMH 8SP Ultra DX 15 Bricks System, is powered by a 15 H.P hydraulic motor and features a brick eject system supported by a 2 H.P motor. The machine is built to perform under high pressure with a maximum of 440 BAR, utilizing a turbo twin vane hydraulic pump for seamless operations. Its efficient conveyor system, driven by a 3 H.P motor, ensures smooth material handling. Complementing the process is a 20 H.P pan mixer that guarantees uniform mixing of fly ash, cement, and other materials.

Engineered for reliability, the machine’s robust build includes 63 EN8 grained hard-chromed sliding rods and steel casting sliding bushes. The ejector conveyor, made from tough polymer, ensures quick and easy mold changes, reducing downtime. With a cyclic time of just 15 seconds, this automatic fly ash brick making machine can produce up to 15 bricks per cycle, maximizing productivity while minimizing labor costs.

Ideal for industries requiring high-quality fly ash bricks, this system is backed by PLC control for precision and automation. It requires a 1.5-acre land area and a shed of 60’x120’ feet for operation, along with a water capacity of 15,000 liters per shift.

Recognized as a trusted automatic fly ash brick machine exporter in Coimbatore, India, we provide machines that cater to both domestic and international markets. This model’s durability, ease of maintenance, and high efficiency make it a top choice for businesses seeking reliable brick manufacturing solutions.

Website Link : -http://www.bennyenterprises.net/

Contact no : - 9360623765

Mail id : - [email protected]

Address :- Site No:13, Thadagam Road,K.N.G.Pudur Pirivu,Opp: Indian Oil Petrol Pump, Next to Agarwal School, Somayampalayam (PO), Coimbatore - 641 108,Tamil Nadu, India

Socail media link

facebook link :- https://www.facebook.com/Bennyindustries

short describiton :- Benny Enterprises specializes in manufacturing innovative block-making machines and construction equipment. With a commitment to quality and precision, the company provides cutting-edge solutions for the construction industry, including automatic block-making machines, tile-making machines, and custom-designed equipment to meet various industrial needs.

#brick manufacturing#Automatic Flyash brick making machine belt type#Automatic Flyash brick making machine#Automatic Flyash brick making

0 notes