#Brazing Furnace Services

Explore tagged Tumblr posts

Text

Tungsten Carbide Inserts for Tunnel Boring Machine

Our tungsten Carbide Inserts for Tunnel Boring machines have good abrasion resistance, impact toughness, and versatility Good, applicable to various complex working conditions.

As a China Tungsten Carbide Inserts for Tunnel Boring Machine Manufacturers and OEM/ODM Tungsten Carbide Inserts for Tunnel Boring Machine suppliers, established in 1990, the company is located in the southern suburb of Changzhou CityJiangsu Province, with the Yancheng historical site in its east, Xitaihu Lake in its west, No. 312 National Highway in its north and Yanjiang Highway in its south. Early this century, the company expanded its product line and started its cemented carbide road through the introduction of technical personnel and purchasing a batch of advanced production equipment from The origin of cemented carbide. After these years' accumulation, the products have covered ball teeth, brazing sheets, all kinds of blades, molds, and other special-shaped products to offer high-quality products and services to national and foreign customers. in 2009, the company purchased advanced low-pressure sintering furnaces, advanced TPA presses, and other equipment to improve our product's quantity and quality and start a new round of struggle.

CONTACT DETAILS Address:North hubin Rood 61# WuJinChangZhou,Jiangsu Phone: +86-13601505006 Fax: +86-0519-86355586

0 notes

Text

Website design companies in Mumbai

Maa Industrial: Your One-Stop Shop for Industrial Furnace Solutions in India

In the world of metalworking and heat treatment, industrial furnaces play a vital role. They are essential for processes like annealing, normalizing, tempering, carburizing, and more. Choosing the right furnace manufacturer is crucial for ensuring the quality, efficiency, and safety of your operations. Maa Industrial emerges as a leading manufacturer of industrial furnaces in India, offering a comprehensive range of solutions to cater to diverse industrial needs.

Why Choose Maa Industrial?

Extensive Furnace Portfolio: Maa Industrial boasts a vast portfolio of industrial furnaces, encompassing:

Annealing and Normalizing Furnaces: Uniformly heat treat your metals for improved machinability and stress relief with Maa Industrial's annealing and normalizing furnaces. Choose from bell, bogie hearth, or car bottom furnace designs to suit your specific requirements.

High-Temperature Furnaces: Process metals at exceptionally high temperatures with Maa Industrial's high-temperature furnaces. These furnaces are ideal for applications like forging, melting, and heat treating specialty alloys.

Pit Furnaces: Maa Industrial offers a variety of pit furnaces, including gas nitriding, annealing, stress relief, and carburizing furnaces. Their pit furnace designs ensure efficient heat distribution and temperature uniformity.

Salt Bath Furnaces: For precise heat treatment processes requiring a molten salt bath, Maa Industrial manufactures high-quality salt bath furnaces. These furnaces are ideal for applications like tempering, annealing, and brazing.

Aluminum Heat Treatment Furnaces: Treat aluminum components effectively with Maa Industrial's aluminum heat treatment furnaces. They offer solutions for T6 hardening, aging, solution heat treatment, and precipitation treatment.

Unwavering Commitment to Quality: Maa Industrial prioritizes quality in every aspect of their operations. They utilize high-grade materials, cutting-edge technology, and stringent quality control procedures to ensure their furnaces are built to last and deliver exceptional performance.

Customized Furnace Solutions: Maa Industrial understands that every industry has unique heat treatment requirements. They offer customized furnace solutions to meet your specific needs, including size, capacity, temperature range, and fuel source.

Expert Furnace Installation Services: In addition to manufacturing furnaces, Maa Industrial provides comprehensive furnace installation services. Their experienced technicians ensure your furnace is installed correctly and commissioned for optimal performance.

More Than Just Furnaces: A Range of Industrial Solutions

Maa Industrial goes beyond just manufacturing furnaces. They offer a variety of additional services to support your industrial operations:

Heat Treatment Furnace Installations: Benefit from Maa Industrial's expert furnace installation services for a seamless and efficient setup process.

Powder Coating Plant Manufacturing: Maa Industrial manufactures high-quality powder coating plants, including booths, curing ovens, and conveyor systems, for a complete powder coating solution.

Hot Air Generator Manufacturing: Explore Maa Industrial's range of hot air generators, available in wood-fired, electric, and gas-fired options, to meet your industrial drying and heating needs.

Benefits of Choosing Maa Industrial

Improved Product Quality: Maa Industrial's furnaces ensure consistent and precise heat treatment, leading to enhanced product quality and performance.

Enhanced Efficiency: Their energy-efficient furnace designs help you save on operational costs.

Increased Productivity: Maa Industrial's furnaces minimize downtime and maximize production output.

Safety and Reliability: Their furnaces prioritize safety with advanced safety features and reliable operation.

One-Stop Shop for Industrial Needs: From furnace selection to installation, Maa Industrial provides a comprehensive solution for all your industrial furnace requirements.

Maa Industrial: Your Partner in Industrial Success

Visit Maa Industrial's website today to explore their comprehensive range of industrial furnaces and other solutions. Contact their experienced team to discuss your specific needs and find the perfect furnace solution for your operations.

Let Maa Industrial Help You Achieve Optimal Heat Treatment Results! https://maanglobalindustries.com/

Looking for a Specific Industrial Furnace?

Maa Industrial's user-friendly website allows you to browse their furnace categories easily. Whether you need an annealing furnace, a high-temperature furnace, or a customized solution, Maa Industrial has the expertise and experience to deliver the right furnace for your application.

0 notes

Text

Supplier of Industrial Induction Heating Systems: AB Induction

AB Induction is a global leader in the design, manufacturing, and supply of advanced industrial induction heating systems. With decades of expertise and a commitment to innovation, AB Induction provides cutting-edge solutions tailored to meet the needs of diverse industries, including automotive, aerospace, metallurgy, and energy.

Key Offerings:

Induction Hardening Machines: Designed for precision surface hardening of gears, shafts, and other components, ensuring durability and wear resistance.

Induction Brazing Systems: Provides efficient and clean bonding of metal parts for applications in HVAC, electrical, and automotive sectors.

Induction Melting Furnaces: High-performance systems for melting ferrous and non-ferrous metals, ideal for foundries and casting applications.

Custom Induction Heating Solutions: Tailored systems for specialized industrial processes, including annealing, forging, and shrink fitting.

Energy-Efficient IGBT Technology: Leveraging advanced solid-state inverters for precise temperature control and reduced energy consumption.

Why Choose AB Induction?

Advanced Technology: Cutting-edge solutions integrating automation, PLC controls, and real-time monitoring for superior performance.

Customization: Systems designed to meet specific requirements, ensuring maximum efficiency and reliability.

Global Presence: A trusted partner serving industries worldwide with local support and service.

Sustainability: Focus on energy efficiency and environmentally friendly heating solutions.

Comprehensive Support: End-to-end services including design, installation, training, and maintenance.

Applications Across Industries:

Automotive: Induction hardening of crankshafts, camshafts, and gears for enhanced durability.

Aerospace: Heat treatment and brazing of critical turbine and structural components.

Foundries: Efficient melting and forging systems for rapid production cycles.

Electronics: Soldering and brazing of electrical connectors and components.

AB Induction’s commitment to quality, innovation, and customer satisfaction has established it as a preferred supplier of industrial induction heating systems worldwide. Whether you need a standard solution or a customized system, AB Induction delivers reliable performance and unmatched precision for all your heating requirements.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Plot No. 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/induction-heating-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

1 note

·

View note

Text

How to Choose the Right CVD Furnace for Your Manufacturing Needs

Choosing the right CVD furnace (Chemical Vapor Deposition furnace) is crucial for manufacturers involved in advanced materials processing. These furnaces are integral to producing high-performance materials like carbon composites, ceramics, and semiconductors, which are essential in industries such as aerospace, automotive, and electronics. To ensure the success of your manufacturing process, it's essential to consider various factors when selecting the right CVD furnace for your needs.

Understand Your Material Requirements

The type of material you plan to process will significantly influence the choice of furnace. For example, carbon and ceramic composites require specialized CVD furnaces designed to handle high temperatures and precise chemical reactions. HHV Thermal Technologies offers a range of customized high vacuum and high-temperature CVD, CVI, and Graphitization furnaces that are engineered to produce these advanced materials with exceptional quality. The ability to control temperature, pressure, and chemical environment in the furnace is vital to achieving the desired properties in your materials.

Consider Furnace Size and Capacity

When choosing a CVD furnace, consider the scale of production and the size of the materials to be processed. Furnaces come in various sizes, from laboratory-scale models to large-scale production units. HHV Thermal Technologies provides customized CVD furnaces that can be tailored to meet specific production requirements, whether you are working with small batches or large volumes of material.

Evaluate Furnace Temperature and Pressure Control

Temperature and pressure control are key factors in the success of CVD processes. Furnaces that operate at high temperatures must maintain consistent heat distribution, while pressure control is critical for producing high-quality coatings or composites. Look for CVD furnaces that offer precise control over these variables. HHV Thermal Technologies furnaces are equipped with user-friendly features that ensure stable temperature and pressure control, which is crucial for producing consistent, high-performance materials.

Consider Automation Features

Automation can greatly enhance efficiency, reduce the risk of human error, and ensure consistent results. When choosing a CVD furnace, consider options that feature automated processes, such as temperature control, gas flow regulation, and system monitoring. HHV Thermal Technologies specializes in premium vacuum brazing furnaces that are built to operate automatically, ensuring high consistency and low contamination for superior brazing. Automated systems also minimize downtime and reduce the need for manual intervention, making them ideal for high-volume production environments.

Examine Furnace Material Compatibility

It's essential to select a CVD furnace that is compatible with the materials you plan to process. Some furnaces are designed specifically for ceramics or carbon-based materials, while others may be more versatile. HHV Thermal Technologies offers CVD, CVI, and Graphitization furnaces specifically designed to process carbon and ceramic composites, ensuring optimal performance and material integrity throughout the process.

Look for After-Sales Support and Service

After-sales support is an important consideration when purchasing a furnace. Look for manufacturers who offer comprehensive service packages, including installation, maintenance, and troubleshooting. HHV Thermal Technologies provides excellent customer support to ensure the longevity and efficiency of your CVD furnace. Their experienced technicians are available to assist with installation, maintenance, and any issues that may arise during operation.

Conclusion

Selecting the right CVD furnace is an essential step in ensuring the success of your manufacturing process. By considering factors such as material compatibility, furnace size, temperature control, and automation features, you can make an informed decision that meets your specific manufacturing needs. HHV Thermal Technologies offers a range of advanced, customizable CVD furnaces and Vacuum Furnace Manufacturers, engineered to deliver superior performance and reliability for carbon, ceramic, and composite material processing. With their user-friendly features and tailored solutions, HHV Thermal Technologies stands out as a top choice for manufacturers seeking high-quality furnaces for their production processes.

For more information, visit the website: https://hhvthermaltech.com/

Contact Us

Site No. 17, Phase 1, Peenya Industrial Area, Bengaluru – 560058, India

Phone: +91-80-41931000

Fax: +91-80-41931100

Email: [email protected]

0 notes

Text

0 notes

Text

Illustration By Antoine Maillard

AN EMPIRE DIVIDED! The Inside Story of How GE CEO Larry Culp Dismantled a 131-Year-Old American Giant.

— By Brooke Sutherland and Ryan Beene | March 20, 2024 | Businessweek | The Big Take

Big sheets of white paper line the perimeter of a meeting room at the General Electric Co. factory in Beavercreek, Ohio. Each sheet is scribbled on with markers and covered with neon Post-it notes outlining the steps needed to produce the tubes and ducts that will eventually be assembled into a jet engine.

The vibe is more elementary school science fair than American industrial icon. But the simplicity is the point. Determining the layout for the Beavercreek facility was tricky: The revamped plant opened last year, combining components of production that had previously been spread out across eight different sites. To figure out the best setup, plant leaders built a replica of furnaces, tube benders and welding booths out of cardboard boxes. That visual, along with the Post-it notes describing production steps such as “brazing,” “bending” and “trimming,” makes it easier to identify and root out manufacturing inefficiencies. The exercise also helps show visiting GE executives how the whole thing works.

Featured in Bloomberg Businessweek, March 25, 2024. Photo illustration: Todd St. John for Bloomberg Businessweek

About 250 managers from around the world have gathered here in the Cincinnati area, which will be the headquarters of GE Aerospace once the conglomerate completes its slow-moving breakup in early April. One stated goal of the executive retreat is to set a culture for the soon-to-be-standalone company. “Culture can’t be declared,” says Farah Borges, who oversees GE Aerospace’s assembly, test and maintenance operations. “You have to build it.��� Some declaring is still apparently necessary, because the team spent the previous day at an event space a few miles away doing just that.

But under Chief Executive Officer Larry Culp, no leadership confab is complete without a gemba walk. Gemba in Japanese means “actual place,” as in the actual place where a product is made. It’s essentially a tour of operations with a heavy emphasis on Q&A with the factory staff. The practice is central to lean manufacturing, an influential operations philosophy developed by Toyota Motor Corp. that Culp has championed at GE.

Culp at the Beavercreek factory in February. Courtesy: General Electric

Factory floor visits aren’t a radical idea for an industrial company, but GE didn’t always do them this way. The company used to place more emphasis on polishing a PowerPoint presentation than on drilling into the details of manufacturing workflows, says Russell Stokes, the head of commercial jet engines and services, who’s been at GE for more than 25 years. Somewhere between the wrong-way financial bets that blew up in the 2008 economic crisis and a huge, disastrous acquisition of energy assets from Alstom SA in 2015, GE, with its persistent mindset that anyone with an MBA could run any business, forgot that it’s a manufacturer at heart.

When Culp became CEO in 2018, GE was far too big and complicated for its own good, and the company’s businesses weren’t bringing in enough money to support its sky-high debts. “We were at risk of not making payroll, in a manner of speaking,” he says. He managed to pay down more than $100 billion of the debt through a series of well-timed divestitures. He dismantled GE Capital, its investment arm, largely untangling the company from a financial albatross. And then, in 2021, he announced that GE—the quintessential American conglomerate, which at one point or another sold washing machines, credit cards, plastic resins and TV advertising slots for NBC’s Super Bowl broadcasts—was breaking up. None of those efforts would’ve been as successful, and perhaps wouldn’t have even been possible, if Culp hadn’t tightened up GE’s operations and turned key businesses into stable, cash-generating entities that could stand on their own.

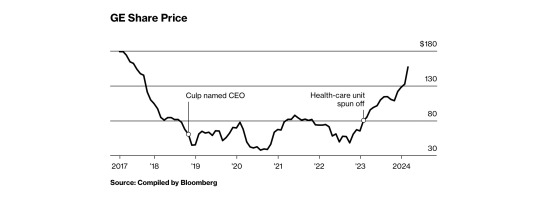

Today, GE’s stock is near a seven-year high. GE HealthCare Technologies Inc., which split off in 2023, is up about 50% from its debut. The final piece is the electric-grid, gas-power and wind-turbine business, which will become its own standalone company called GE Vernova on April 2.

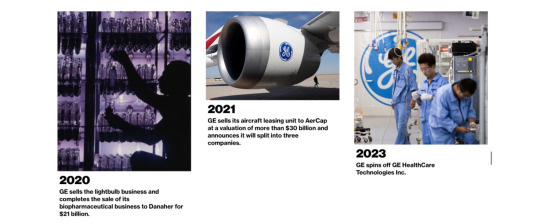

In one sense, Culp is restoring GE to its original identity as a maker of stuff. But he’s also the guy dismantling a monument to American capitalism. From its inception as an outlet for Thomas Edison to commercialize the lightbulb through the era of rapid globalization embodied by Jack Welch, GE practically swallowed entire industries. It loaned planes to companies and money to real estate developers; for a time it even owned a large chunk of Dreyer’s Grand Ice Cream. Most of that is gone now. Culp divested the aircraft leasing arm, biopharmaceutical assets and the remnants of GE’s oil and gas operations and saw through sales of its locomotive and lightbulb units. Even the GE name is on loan. GE appliances are made and sold by China’s Haier Smart Home Co. The new GE will just be a manufacturer of jet engines, essentially, with a few random money pits left over from the old conglomerate, like insurance for elder care and a Polish mortgage business. “We constantly debated what the right structure was,” says Ed Garden, a GE board member since 2017. “But the first order of business was fixing the underlying businesses.”

On the gemba walk, Culp and his aerospace deputies stop to meet with the plant’s lean manufacturing leader, Cem Salahifar, who launches into an overview of the factory’s operations. He describes the facility’s transition from a single, giant furnace—known in manufacturing parlance as a monument—to a bunch of smaller ones spread out around the factory floor. This eliminates the need for employees to shuttle components back and forth and stand around waiting for the heating process to complete. Turnaround times for this part of the production process dropped to 30 minutes from four hours. Culp interjects: The team should appreciate how meaningful this change was, he says, for improving efficiency. He then asks them to find ways to rethink the monuments in their own factories. “We like to tear down monuments,” Culp says.

General Electric Through the Years

The historic American company amassed a sprawling portfolio that at one time or another included locomotives, washing machines, insurance, lightbulbs, MRI machines, credit cards, real estate and the television network NBC.

To be CEO of GE is to be compared with the late Jack Welch. For most of his two-decade reign, Welch made the company bigger, more valuable and more profitable. But the sun began to set on the age of the conglomerate by the time he retired in 2001, and soon other industrial giants were breaking up. Post-Welch CEOs at GE found themselves trying to explain why it made sense to be big for the sake of being big. Jeff Immelt, Welch’s handpicked successor, talked up the benefits of the “GE Store,” a shared repository of technological tools that the whole company could pull off the shelf. In reality, there was no good reason why one company needed to sell MRI machines, jet engines and wind turbines. Even worse, GE’s voluminous sprawl left too many places for problems to hide.

Left: A Leap engine at the Lafayette Engine Facility in Indiana. Photographer: Christopher Payne/Esto/Redux Right: A jet engine test operation. Photographer: Christopher Payne/Esto/Redux

One of the biggest problems was GE Capital, which helped fuel stock growth during the Welch years but proved to be a time bomb. GE had loaded up on debt to support its ventures in corporate lending, real estate, credit cards, mortgages and insurance. When the economic crisis arrived in 2008, GE Capital had more than $500 billion in assets and almost as much debt, which made it the largest financial company in the US that wasn’t technically a bank. As customers worldwide defaulted on loan payments and investors lost their appetite for risk, GE turned to Warren Buffett and the federal government for financial support. Immelt cut GE’s dividend for the first time since the Great Depression. He later sold off huge chunks of GE Capital, but it continued to haunt his successor, John Flannery, who in 2018 disclosed a $15 billion hole in a long-term-care insurance business Immelt had been unable to fully get rid of. The timing couldn’t have been worse: Flannery had cut the dividend two months earlier, to some shareholders’ dismay, and with the gas-power business in a slump and fewer GE Capital assets, there just wasn’t enough money from its operations to keep handing out such generous payments to investors.

GE’s stock was in free fall in 2018, and Flannery overhauled the board. One of the new directors was Culp. A graduate of and former senior lecturer at Harvard Business School, he’d previously been the CEO of Danaher Corp., a onetime industrial conglomerate in its own right that’s idolized by investors for its operational rigor. (Danaher eventually broke up, starting in 2016 with the spinoff of the industrial products company Fortive Corp., shortly after Culp left.)

Culp’s Message: “Everybody Around The Boardroom, Don’t Panic”

Flannery announced a plan to spin off GE’s health-care business in June 2018, but such a wholesale breakup quickly became untenable. The company couldn’t afford it: The remaining operations wouldn’t have generated enough cash to allow GE to pay off its mountain of debt. “We could not spin health care without putting everything fundamentally at risk,” Culp says.

GE’s directors asked Culp if he wanted to run the company. He turned them down—twice, he says—but an August 2018 visit to GE’s gas-power operations in Atlanta began to change his mind. The place was a mess, he tells Bloomberg Businessweek. “We were managing the business in a way that was probably 180 degrees from the way we ran things at Danaher,” he says. But Culp saw a path to fix GE’s operations. His message: “Everybody around the boardroom, don’t panic.”

GE directors offer a bingo card’s worth of MBA-speak to describe how rough the situation was. Tom Horton, former CEO of American Airlines, says he and Culp were both “eyes wide open” when they joined the board together in 2018: “Once we got under the hood, the challenges were more substantial than maybe we anticipated.”

Two months after his visit to Atlanta, Culp was named CEO. In short order, he slashed the dividend to $0.01 a share and killed the plan to spin off health care. Instead, Culp brokered a deal to sell GE’s biopharmaceutical unit to his former employer Danaher. GE received $21 billion in cash for the business, which makes equipment and materials used to manufacture drugs, and offloaded $400 million in pension obligations to Danaher. The transaction was completed in March 2020, about three weeks after the onset of the Covid-19 pandemic brought air travel to a halt, creating an existential challenge for the company’s jet engine business. “I don’t know what would have happened if we hadn’t closed that deal,” Culp says.

GE directors thought the pandemic had made Culp’s job harder, and they wanted to give their CEO another reason to stick with it. In August 2020, the board altered the terms of Culp’s compensation package to give him more time to reach performance targets for a one-time stock bonus and make it meaningfully easier for him to have access to the top payout of about $230 million. Shareholders representing a majority of voting stock opposed the pay deal, but their vote was nonbinding, and the board had already approved the changes anyway. Culp accessed the top tier of the equity grant in July 2023, and the shares will vest next year unless he retires before then. (GE later curbed other aspects of Culp’s compensation.) “We were securing Larry’s leadership for a longer period of time, and that’s proven to be certainly in shareholders’ interest,” Horton says.

There are parallels between Culp and Welch, a company legend who was also legendarily well-compensated. The underlying principles of the lean manufacturing philosophy Culp preaches aren’t all that different from Welch’s cult of Six Sigma, another corporate dogma focused on measuring the rate of operational defects and eliminating inefficiencies. But the two are otherwise very different. Welch’s habit of ranking employees by performance and summarily firing the bottom 10% created a culture of mistrust. Employees who survived layoffs started to think they were the smartest people in the industry, a mentality that persisted after Welch retired and GE began to fade.

Culp has been programming a new mantra into his subordinates, adapted from his time at Danaher: We’re not perfect. “You’ll have some home runs, but you don’t need them every day,” says Jim Lico, who worked for Culp at Danaher and is now president and CEO of Fortive. “No one is perfect.” That kind of talk might’ve gotten a Welch-era executive fired, but it’s part of Culp’s belief in continuous improvement that his team routinely parrots.

This often manifests with seemingly small changes that can make a big impact on productivity over time. In one instance, GE reduced the distance a part must travel around its plant in Greenville, South Carolina, by about 3 miles, says Scott Strazik, the CEO of the soon-to-be-spun-out energy business GE Vernova. Even something as small as reorganizing the toolboxes used by turbine repair technicians can make a big difference. “There’s a long way to go,” Strazik says. GE Aerospace is trying to get its many factories to coordinate more with one another and with the teams that handle contract reviews and other back-office tasks. That process isn’t “perfect,” even if it has improved, says Kayla Ciotti, materials and planning leader at GE Aerospace. “Ten years ago, we had brick walls. Five years ago, we had screen doors,” she says. “The door is open now. There’s no door.”

In contrast with the cutthroat culture at Welch’s GE, Culp’s employees will get some leeway if they do walk into walls. “That doesn’t mean that if you screw something up and you do it repeatedly, there isn’t responsibility to bear,” Culp says. “But a problem-solving culture is far more effective operationally than a finger-pointing culture.”

Brian Carlson remembers his first gemba walk with Culp. Carlson, who runs the 1.2-million-square-foot GE factory in Schenectady, New York, that makes power plant generators, watched Culp stop at one production line in 2019 to inspect a reel of copper wire, which workers fashion into long, braided slabs bent like hockey sticks at both ends. Known as stator bars, these parts are installed inside the guts of enormous generators, which can weigh more than 400 tons. Culp was checking the manufacturing date on a reel of wire. Dozens of reels were stacked on shelves and pallets at the station, burning cash as long as they sat unused. “Others had visited Schenectady before, but it wasn’t into that level of detail,” Carlson says. “When Larry Culp shows up and wants to see how long your material’s been sitting on the factory floor, that simple gesture really sets a tone.”

The foam model at the Schenectady factory. Courtesy: General Electric

After that visit, workers cleared out a large room that once housed office space near the factory’s entrance and spent months building a scale model of the entire factory from hand-cut pieces of white and green foam, which they carefully laid out on rows of folding tables. Placards hang overhead marking each section of the factory, the largest of which declares the purpose of this enormous diorama: “Take it to the model before you take it to the floor.”

The foam factory is now a hub of Schenectady’s operations. Factory staff simulate projects first in the room before testing them on the factory floor. This is part of what’s known inside GE as a kaizen event. Culp loves a good kaizen. The Japanese term means continuous improvement and is another tenet of lean manufacturing. It’s a method for problem-solving that Culp has pushed throughout the company, in which executives and hourly workers dedicate a week to improve a production process, such as the stator bars that caught his attention during his visit in 2019. The goal is to come up with a solution by Friday and have the new process in motion on Monday.

The old way of making stator bars involved moving parts by crane through a 26-step process that took about three months to complete. Each bar now moves on rollers through an eight-step process in as little as three weeks. And now there’s only enough copper wire on hand to sustain a single shift.

On an unusually warm day in late February, Carlson motions to an area on the stator bar line where more improvement is needed. They still use a crane to hoist bars over an active walkway that crosses through the assembly line. A fix is in the works. “See,” he says, “we’re not perfect yet.”

“We Do Not Intend, Let Me Be Clear, To Be All Things To All People”

By early 2021, Culp’s turnaround of GE was starting to take hold, but the company was still sitting on too much debt. A solution arrived that March, when AerCap Holdings NV agreed to acquire GE’s aircraft leasing unit. The deal would allow GE to pay off $30 billion it had borrowed, reducing its debt to the point where the company could realistically think about establishing three separate businesses—in aerospace, health care and energy—that investors would actually want to own.

Culp started mapping out a breakup plan and gave it a code name: Project Revere, inspired by a monument to American patriot Paul Revere near Culp’s home in Boston. He liked the history motif. As GE’s board deliberated a split-up, a defining moment came in a PowerPoint presentation. A slide illustrated the degree to which investors were avoiding the stock simply because it was a conglomerate. “When you just looked at the companies that folks who really wanted to bet on the energy transition or on commercial aerospace were invested in, it was not with us,” Culp says.

In November, a week after the AerCap deal closed, GE announced the spinoff plan. “Everyone felt the weight of that decision,” Culp says at GE Aerospace’s Learning Center in Evendale, Ohio, where visitors can tour a museum of the company’s aerospace achievements, starting with the first American jet engine.

A breakup was never the only option, but it was the best one. Although modern conglomerates do exist (Alphabet, Amazon, Microsoft), GE’s ye olde smokestack model wasn’t working anymore. Investors were getting burned by its bigness more often than they were getting rewarded. The conglomerate structure is especially limiting when it comes to spending money, says David Giroux, a portfolio manager and chief investment officer of T. Rowe Price Investment Management. Massive companies tend to make the wrong acquisitions and overpay for them.

One deal Culp didn’t do was to pay an acquirer to make GE’s insurance problem go away. “There were checks back in the dark days that we could have written that would have been akin to having people tear our eyeballs out,” Culp says. “But you never want to be on the other side of that sort of trade.” Although GE hasn’t done any new business in long-term-care insurance in almost two decades, it’s still paying off claims it agreed to back for other providers. It’s now closed the $15 billion insurance funding shortfall, and investors treat the appendage as more of a quirk than the crisis it was in 2018. Culp says he might get rid of the business someday. But he’s not in any rush.

After the breakup, GE Aerospace will have $25 billion of cash to spend on dividends, share buybacks and acquisitions—with the first two taking priority. Culp won’t say what kinds of deals GE Aerospace might do, only that he’ll look for complementary and easily digestible assets. “We do not intend, let me be clear, to be all things to all people,” he told investors in early March.

All of GE’s gemba walks and kaizens and the intense scrutiny of its manufacturing operations look especially prudent after a series of high-profile quality-control failures among its peers. RTX Corp. is recalling thousands of jet engines because of a manufacturing glitch; Siemens Energy AG sought help from the German government after defects in its wind turbines resulted in massive losses; and Boeing Co. can’t even deliver its 737 Max with all the bolts properly installed.

When there are three GEs, Culp hopes the old name still means something to investors. He says that’s one reason he took the job in the first place: “It’s GE.”

At the company’s off-site in Ohio, executives gathered at Carillon Historical Park in Dayton. It’s home to the Wright Brothers’ Wright Flyer III, the first practical airplane. This piece of aviation history sits next to Culp’s Cafe, which serves an All-American egg sandwich and coffee for $13. The cafe has nothing to do with GE’s CEO. It’s named after Charlotte Gilbert Culp, who founded a baked-goods business in 1902 as a young widow in Dayton. At that time, GE was still just an electrical company.

#Bloomberg#Businessweek#The Big Take#General Electric#GE | CEO | Larry Culp#Dismantling of GE#An Empire Divided

0 notes

Text

Vacuum Oven Manufacturers: A Comprehensive Guide to Industry Leaders

Whether you are a scientist, researcher or industry professional, understanding the leading manufacturers in the field of vacuum oven manufacturers is crucial for making informed decisions. We will introduce you to HHV, renowned for their expertise and high-quality products. With their commitment to innovation and customer satisfaction, HHV has emerged as a trusted name in the industry. Join us as we explore HHV's range of vacuum ovens, their unique features and the advantages they offer to various sectors. Prepare to dive into a world of advanced technology and discover how HHV stands out among other Vacuum Oven Manufacturers.

HHV, a leading manufacturer in vacuum oven technology, has established itself as one of the most reputable and innovative companies in the industry. With a strong commitment to excellence and a dedication to meeting the needs of their customers, HHV stands out as a trusted name in vacuum oven manufacturing. They offer a comprehensive range of high-quality vacuum ovens that cater to various industries such as research and development, pharmaceutical and manufacturing.

By integrating advanced technology and superior craftsmanship, HHV ensures that their vacuum ovens provide precise temperature control and fast heating capabilities, making them ideal for delicate processes such as drying, curing and sintering. Additionally, HHV's vacuum ovens are designed with efficiency in mind, featuring energy-saving features that not only reduce operating costs but also contribute to a more sustainable manufacturing process. With their extensive experience and commitment to delivering exceptional products, HHV continues to be at the forefront of the vacuum oven industry, setting the standards for reliability and performance.

HHV is one of the leading vacuum oven manufacturers in the industry. With years of experience and expertise, HHV has established itself as a reliable and trusted name among professionals and businesses alike. The company specializes in the production of vacuum ovens that cater to a wide range of industries, including aerospace, automotive and medical. In addition to their exceptional vacuum ovens, HHV also offers a comprehensive range of accessories and services to ensure optimal performance and efficiency. Of particular note is their vacuum brazing furnace, which is designed to handle the most demanding brazing applications with precision and accuracy. This high-quality furnace is engineered to provide uniform heating and cooling cycles, allowing for superior brazing results and minimizing stress on the components. With HHV's vacuum brazing furnace, manufacturers can achieve excellent joints and precise temperature control, making it an indispensable tool for industry leaders.

In conclusion, HHV stands out as an industry leader in the field of vacuum oven manufacturing. With their dedication to utilizing state-of-the-art technology and top-notch materials, they ensure reliable and efficient operation, ultimately leading to superior performance and increased productivity for their customers. Moreover, their commitment to customer satisfaction is truly commendable, as demonstrated through their exceptional after-sales service and technical support. When choosing a vacuum oven manufacturer, HHV's benchmark in terms of quality, reliability and customer-centric approach makes them the preferred choice among professionals in the industry. Their unwavering commitment to excellence sets them apart and solidifies their position as leaders in the field.

For more information, visit the website https://hhv.in/

Contact Us

Site No. 17, Phase 1, Peenya Industrial Area, Bengaluru – 560058, India

Phone: +91-80-41931000

Fax: +91-80-28394874

Email: [email protected]

1 note

·

View note

Text

0 notes

Text

Vacuum Brazing Furnace | Changheng

Aluminum Vacuum Brazing Furnace for Sell

A vacuum brazing furnace is a specialized furnace used in the process of vacuum brazing, which is a method of joining metal parts together using a filler metal that is heated in a vacuum environment.

Vacuum brazing furnaces are commonly used in industries that require high-quality and high-performance products, such as aerospace, automotive, and medical industries.

1 note

·

View note

Text

Latest Study Report on Global Furnace Brazing Services Market by Market Intellix

Market Intellix Provides report on 'Global Furnace Brazing Services Market' is a professional and in-depth study on the current state Industry. The Market research report provides an overview, development status and future outlook of the market.

0 notes

Text

Tungsten Carbide Rock Drilling Tools

As a traditional mining drilling tool,tungsten carbide rock drilling tools are subject to complex effects such as impact and wear, and the working conditions are harsh.Our tungsten carbide rock drilling tools are harder, stronger and more ductile than general rock drilling tools. Tungsten carbide rock drilling tools can better adapt to varied drilling conditions, and the wear resistance of the alloy is further improved under the condition that the toughness is not reduced.

As a private enterprise established in 1990, the company is located in the southern suburb of Changzhou CityJiangsu Province, with the Yancheng historical site in its east, Xitaihu Lake in its west, No. 312 National Highway in its north and Yanjiang Highway in its south. Early this century, the company expanded its product line and started its cemented carbide road through the introduction of technical personnel and purchasing a batch of advanced production equipment from The origin of cemented carbide. After these years' accumulation, the products have covered ball teeth, brazing sheets, all kinds of blades, molds, and other special-shaped products to offer high-quality products and services to national and foreign customers. in 2009, the company purchased advanced low-pressure sintering furnaces, advanced TPA presses, and other equipment to improve our product's quantity and quality and start a new round of struggle.

Address:North hubin Rood 61# WuJinChangZhou,Jiangsu

Phone: +86-13601505006

Fax: +86-0519-86355586

1 note

·

View note

Text

table type shot blasting machine manufacturer India

Maa Industrial: Your One-Stop Shop for Industrial Furnace Solutions in India

In the world of metalworking and heat treatment, industrial furnaces play a vital role. They are essential for processes like annealing, normalizing, tempering, carburizing, and more. Choosing the right furnace manufacturer is crucial for ensuring the quality, efficiency, and safety of your operations. Maa Industrial emerges as a leading manufacturer of industrial furnaces in India, offering a comprehensive range of solutions to cater to diverse industrial needs.

Why Choose Maa Industrial?

Extensive Furnace Portfolio: Maa Industrial boasts a vast portfolio of industrial furnaces, encompassing:

Annealing and Normalizing Furnaces: Uniformly heat treat your metals for improved machinability and stress relief with Maa Industrial's annealing and normalizing furnaces. Choose from bell, bogie hearth, or car bottom furnace designs to suit your specific requirements.

High-Temperature Furnaces: Process metals at exceptionally high temperatures with Maa Industrial's high-temperature furnaces. These furnaces are ideal for applications like forging, melting, and heat treating specialty alloys.

Pit Furnaces: Maa Industrial offers a variety of pit furnaces, including gas nitriding, annealing, stress relief, and carburizing furnaces. Their pit furnace designs ensure efficient heat distribution and temperature uniformity.

Salt Bath Furnaces: For precise heat treatment processes requiring a molten salt bath, Maa Industrial manufactures high-quality salt bath furnaces. These furnaces are ideal for applications like tempering, annealing, and brazing.

Aluminum Heat Treatment Furnaces: Treat aluminum components effectively with Maa Industrial's aluminum heat treatment furnaces. They offer solutions for T6 hardening, aging, solution heat treatment, and precipitation treatment.

Unwavering Commitment to Quality: Maa Industrial prioritizes quality in every aspect of their operations. They utilize high-grade materials, cutting-edge technology, and stringent quality control procedures to ensure their furnaces are built to last and deliver exceptional performance.

Customized Furnace Solutions: Maa Industrial understands that every industry has unique heat treatment requirements. They offer customized furnace solutions to meet your specific needs, including size, capacity, temperature range, and fuel source.

Expert Furnace Installation Services: In addition to manufacturing furnaces, Maa Industrial provides comprehensive furnace installation services. Their experienced technicians ensure your furnace is installed correctly and commissioned for optimal performance.

More Than Just Furnaces: A Range of Industrial Solutions

Maa Industrial goes beyond just manufacturing furnaces. They offer a variety of additional services to support your industrial operations:

Heat Treatment Furnace Installations: Benefit from Maa Industrial's expert furnace installation services for a seamless and efficient setup process.

Powder Coating Plant Manufacturing: Maa Industrial manufactures high-quality powder coating plants, including booths, curing ovens, and conveyor systems, for a complete powder coating solution.

Hot Air Generator Manufacturing: Explore Maa Industrial's range of hot air generators, available in wood-fired, electric, and gas-fired options, to meet your industrial drying and heating needs.

Benefits of Choosing Maa Industrial

Improved Product Quality: Maa Industrial's furnaces ensure consistent and precise heat treatment, leading to enhanced product quality and performance.

Enhanced Efficiency: Their energy-efficient furnace designs help you save on operational costs.

Increased Productivity: Maa Industrial's furnaces minimize downtime and maximize production output.

Safety and Reliability: Their furnaces prioritize safety with advanced safety features and reliable operation.

One-Stop Shop for Industrial Needs: From furnace selection to installation, Maa Industrial provides a comprehensive solution for all your industrial furnace requirements.

Maa Industrial: Your Partner in Industrial Success

Visit Maa Industrial's website today to explore their comprehensive range of industrial furnaces and other solutions. Contact their experienced team to discuss your specific needs and find the perfect furnace solution for your operations.

Let Maa Industrial Help You Achieve Optimal Heat Treatment Results! https://maanglobalindustries.com/

Looking for a Specific Industrial Furnace?

Maa Industrial's user-friendly website allows you to browse their furnace categories easily. Whether you need an annealing furnace, a high-temperature furnace, or a customized solution, Maa Industrial has the expertise and experience to deliver the right furnace for your application.

0 notes

Text

A Comprehensive Guide to Choosing the Right Vacuum Furnace Manufacturer

When it comes to Vacuum Furnace Manufacturers, selecting the right partner is crucial for ensuring optimal performance and reliability in industrial applications. Vacuum furnaces play a vital role in various industries, from aerospace to electronics, where precise heat treatment and controlled atmosphere are essential. Here’s a comprehensive guide to help you navigate the process of choosing the ideal industrial furnace manufacturer for your needs.

Understanding Your Requirements

Before diving into the selection process, it's essential to define your specific requirements. Consider factors such as furnace size, temperature range, heating elements, cooling systems, and automation capabilities. Each application may demand unique specifications, so clarity on your operational needs is paramount.

Evaluating Manufacturer Expertise

Look for vacuum furnace manufacturers with a proven track record and expertise in producing reliable equipment. HHV Thermal Technologies stands out in this regard, offering a range of high-quality vacuum brazing furnaces designed for precision and durability. Their commitment to advanced technology and extensive industry experience ensures that their products meet stringent quality standards.

Quality and Reliability

Reliability is non-negotiable when selecting a vacuum furnace manufacturer. Products from reputable manufacturers like HHV Thermal Technologies are known for their robust construction and dependable performance. Whether you need a furnace for annealing, brazing, or sintering, their solutions are designed to deliver consistent results under varying conditions.

Customization Options

Flexibility in customization can significantly impact your operational efficiency. HHV Thermal Technologies offers customizable Vacuum Brazing Furnaces that can be tailored to meet specific application requirements. Whether you require special chamber sizes, advanced control systems, or integration with existing automation, their engineering capabilities ensure a tailored solution.

Support and Service

Choosing a manufacturer that provides comprehensive support and service is vital for long-term satisfaction. HHV Thermal Technologies not only delivers state-of-the-art equipment but also offers expert technical support, maintenance services, and training programs to optimize furnace performance and longevity.

Compliance and Standards

Ensure that the vacuum furnace manufacturer adheres to industry standards and regulations relevant to your sector. HHV Thermal Technologies prioritizes compliance with international quality and safety standards, giving you peace of mind regarding product reliability and regulatory compliance.

Customer Feedback and Reputation

Research customer reviews, testimonials, and industry reputation to gauge the manufacturer’s standing in the market. HHV Thermal Technologies has garnered positive feedback for their innovative solutions and customer-centric approach, making them a trusted choice among vacuum furnace manufacturers globally.

Conclusion

Choosing the right vacuum furnace manufacturer requires careful consideration of factors such as expertise, quality, customization options, support services, and compliance. HHV Thermal Technologies exemplifies these qualities with their range of vacuum brazing furnaces, designed to meet the diverse needs of modern industrial applications. By partnering with a reputable manufacturer like HHV Thermal Technologies, you can ensure enhanced operational efficiency, reliability, and longevity of your furnace investment.

In conclusion, investing in a vacuum furnace from a trusted manufacturer not only enhances operational efficiency but also contributes to the overall success and competitiveness of your business in today’s demanding industrial landscape.

For more information, visit the website: https://hhvthermaltech.com/

0 notes

Text

0 notes

Text

Furnace Brazing Services Market Analysis, Companies Profiles, Size, Share, Growth, Trends and Forecast to 2027

Furnace Brazing Services Market Analysis, Companies Profiles, Size, Share, Growth, Trends and Forecast to 2027

Market Overview The report captures the basic information pertaining to the Furnace Brazing Services market along with the critical analysis of the core market factors. The overview highlights the definition of the industry offerings and their application in varying end-user industries. A thorough analysis of the manufacturing and management technology has been presented as well. The integrated…

View On WordPress

#Furnace Brazing Services#Furnace Brazing Services industry#Furnace Brazing Services industry Analysis#Furnace Brazing Services industry Growth#Furnace Brazing Services industry Growth Size#Furnace Brazing Services market#Furnace Brazing Services market Analysis#Furnace Brazing Services market Growth#Furnace Brazing Services market Share#Furnace Brazing Services market Size#Furnace Brazing Services market Trends

0 notes

Text

Commercial Reverse Osmosis Systems & Water Softeners

Boiling hard water will dissolve minerals and affect the style and texture of meals. Chlorine and chloramine can outcome in a ‘bleaching’ effect making vegetables look uninteresting and less colorful. Metals, minerals or micro organism could trigger your ice to be discolored and cloudy. This is a sign of hard water which might also have an result on the taste. The primary causes for selecting bottled water embody bad odors, humorous tastes or orange or cloudy water.

In 1944 Bradt was deployed to Europe for energetic responsibility with the 38th Infantry Regiment of the 2nd Infantry Division underneath General Hodges, and instantly noticed action in The Battle of the Bulge. On March 31, 1945, Bradt was driving on the turret of a Sherman tank through Warburg, Germany, when the tank was hit by a German Panzerfaust rifle grenade. Bradt acquired multiple shrapnel wounds leaving him permanently disabled. Conversion of inlet water to product-ready water is 50% greater when blending is used, says Cuno. So use this resource kinetico cc series as a place to begin for model new water-related methods and then verify in with the professionals for advice in your particular water needs. Stack Exchange community consists of 182 Q&A communities including Stack Overflow, the largest, most trusted on-line community for builders to study, share their knowledge, and construct their careers.

In 1980, Bradt designed the Six Man Clock, the premise for the clocks that Bradt and Kinetico created for the following 40 years. The identical motor, supplies and techniques had been used. The gear practice from the motor was manufactured from coiled brass wire, engaging with pinion gears and detents. Six brass, brazed, bent and soldered "little men" worked off of a drive gear to look like making the clock move.

The changing of those is a pair hundred dollars. It can be cool for the guy that put in it to get alerts from the system versus from me. Because my furnace and air conditioner have that. If Kinetico could go to that next leap and monitor that for me or for itself, that kinetico cc series may be cool. Kinetico's customer service is very nice and they’re proper on the ball. I actually have to drink an terrible lot of water as a result of I really have kidney issues.

I always had a water filtration system growing up. When we lived in residences, we could not have them so my laundry and my body have been simply yucky. The water filtration system was one of the very first issues we did when we purchased our home. Not quite a year after we moved in, we got the reverse osmosis as a result of we had been doing a Britta thing and it was so dumb as a result of it was like pour-it-and-fill-her thing then the following day, it was empty. With multiple locations throughout the United States, we discovered numerous Yelp evaluations on-line, with most of them being in the 3.5 to 4.5 out of 5 range. From what we did analysis on a couple of Yelp pages, folks appeared to love the data of the representatives, the customer support , and the difference in style as soon as the system was installed.

Kinetico softeners can use 70% less salt than other manufacturers. The company companions with local specialists, which may make it tough to discover out the price of the softener and installation kinetico cc series. If you’re in search of a high-quality, low-maintenance water softener or filtration system, nonetheless, Kinetico is a robust possibility. PuroTwist four Stage 50 GPD TFC Quick Change Water Filtration Retro Fit System.

Water excessive in minerals will have an result on the taste of coffee inflicting it to taste more bitter, since the minerals scale back the coffee’s taste. It’s also possible that some contaminants could “slip in” by way of aging pipes en path to your house.

0 notes