#Brazed Plate Heat Exchangers manufacturers

Explore tagged Tumblr posts

Text

Master brazed plate heat exchanger sizing for HVAC systems. Learn brazed plate heat exchanger sizing for HVAC: heat load, flow rates, LMTD. Boost HVAC efficiency.

#brazed plate heat exchanger sizing#brazed plate heat exchanger refrigeration#brazed plate heat exchanger manufacturers

0 notes

Text

Plate-End-Frame Heat Exchangers: A Marvel of Efficiency and Sustainability

Heat exchangers are very important components for numerous sectors, negligible functioning behind the scenes to transfer thermal power between two liquids, whether it is for cooling, heating, or heat recovery aims.

Among the many kinds of heat exchangers, one that has attained substantial popularity because of its effectiveness and environment-friendliness is the plate-end-frame heat exchanger.

The plate-and-frame heat exchanger market will reach USD 8,912.9 million by 2030.

The Basics of Plate-End-Frame Heat Exchangers

Visualize 2 plates squeezing in a heat-conductive material, making a small and effective instrument to transmit heat. This is the core of a plate-end-frame heat exchanger. The machine contains alternating plates, generally created by stainless steel or other strong resources, combined with seals, making a liquid flow channel between them. The end frames are utilized to aid and enfold the plates steadily.

Productivity at Its Best

The main benefit of a plate-end-frame heat exchanger lies in its extremely effective design. The huge surface area of the plates permits an augmented heat transmission rate among the fluids, fortifying it to be extremely effective in several heat exchange applications. If compared to old-style shell-and-tube heat exchangers, plate-end-frame heat exchangers needs less area and material, providing a more lucrative and ecologically friendly solution.

Adaptability and Flexibility

One of the major reasons plate-end-frame heat exchangers have attained extensive appreciation is their adaptability. Such heat exchangers can manage an extensive variety of fluids, such as gases and liquids, making them appropriate for many applications. Whether it is boiling water in residential boilers, cooling chemicals in manufacturing procedures, or improving heat in power plants, plate-end-frame heat exchangers are best suited.

Reduced Ecological Impact

These days, ecological sustainability is an emerging concern. Fortunately, plate-end-frame heat exchangers work flawlessly with such principles. By easing effective heat transfer, such heat exchangers contribute to lesser power usage, decreasing GHG releases and total ecological impact. Their small design and utilization of recyclable materials also reduce waste production, making them an ecological option for heat exchange requirements.

Their compact design and easy maintenance have been driving the demand for them in the chemicals & petrochemicals sector. In addition, the rising global demand for electricity, accelerating industrialization, and burgeoning investments in renewable energy generation in key economies, such as the U.S., Canada, Mexico, Brazil, European countries, India, China, Australia, and New Zealand, are set to boost product sales.

Types of plate heat exchangers

Gasketed plate heat exchangers utilize high-quality gaskets and are made to seal plates together and safeguard against leaks. Plates can effortlessly be detached for cleaning, expansion, or replacing drives, radically decreasing maintenance costs.

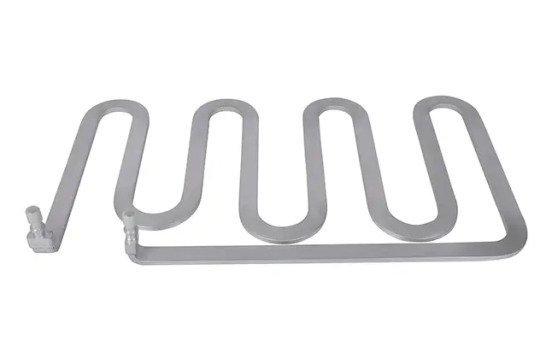

Brazed Plate heat exchangers are utilized in several refrigeration and industrial applications. Because of the stainless-steel plate arrangement with copper brazing, they are extremely resilient to corrosion. Brazed Plate heat exchangers are effective and compact, making them a perfect economic choice.

Hence, plate-end-frame heat exchangers have established themselves as extraordinary manufacturing marvels, offering effective and supportable solutions for heat transfer requirements across industries.

Source: P&S Intelligence

#Plate-and-Frame Heat Exchanger Market Share#Plate-and-Frame Heat Exchanger Market Size#Plate-and-Frame Heat Exchanger Market Growth#Plate-and-Frame Heat Exchanger Market Applications#Plate-and-Frame Heat Exchanger Market Trends

1 note

·

View note

Text

Heat Exchangers Market 2024: Industry Analysis and Opportunity Assessment, Forecast to 2030

Heat Exchangers Industry Overview

The global heat exchangers market size was estimated at USD 18.19 billion in 2023 and is expected to expand at a compounded annual growth rate (CAGR) of 5.4% from 2024 to 2030.

Rising focus on efficient thermal management in various industries, including oil & gas, power generation, chemical & petrochemical, food & beverage, and HVAC & refrigeration, is expected to drive the demand for heat exchangers over the forecast period. Rising demand from chemical industry coupled with increasing technological advancements and a growing focus on improving efficiency standards is expected to drive heat exchangers market growth. Most processes in petrochemical facilities involve high pressure and temperature, thus, necessitating the optimization of heat transfer and enhancement of energy savings, which, in turn, is likely to boost the demand for energy-efficient heat exchangers.

Gather more insights about the market drivers, restrains and growth of the Heat Exchangers Market

U.S. dominated the North America heat exchanger market in 2023, owing to high electricity demand, industrialization, and investments in renewable power generation. Rising investments by oil & gas companies in exploration & production activities in the U.S. are expected to boost the demand for these products in oil & gas industry.

Significant power markets such as China, U.S., India, Russia, and Japan are restructuring their operating models to adopt the structure of renewable energy and efficient utilization of energy by installing heat exchangers and shifting from traditional energy use. This is expected to drive the demand for heat exchangers.

Technological advancements such as tube inserts in heat exchangers are expected to complement the market growth. Furthermore, ongoing technological improvements to improve energy efficiency, total life cycle cost, durability, and compactness of heat exchangers are expected to drive industry growth.

Manufacturers of these products face a long list of difficult supply chain challenges, including increasing demand variability, intense global competition, more environmental compliance regulations, increasing human- and nature-based risks, and inventory proliferation. COVID-19 pandemic has created new challenges, which are compelling manufacturers to innovate their supply chains at a faster speed.

Heat Exchangers Market Segmentation

Grand View Research has segmented the global heat exchangers market report based on product, end-use, material and region:

Product Outlook (Revenue, USD Billion, 2018 - 2030)

Plate & Frame Heat Exchanger

Brazed Plate & Frame Heat Exchanger

Gasketed Plate & Frame Heat Exchanger

Welded Plate & Frame Heat Exchanger

Others

Shell & Tube Heat Exchanger

Air-Cooled Heat Exchanger

Others

End-use Outlook (Revenue, USD Billion, 2018 - 2030)

Chemical & Petrochemical

Oil & Gas

HVAC & Refrigeration

Power GenerationFood & Beverage

Pulp & Paper

Others

Material Outlook (Revenue, USD Billion, 2018 - 2030)

Metals

Alloys

Others

Regional Outlook (Revenue, USD Billion, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

Italy

Spain

UK

Asia Pacific

China

Japan

India

South Korea

Australia

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

South Africa

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The global wood plastic composites market size was estimated at USD 7.15 billion in 2023 and is expected to grow at a CAGR of 11.6% from 2024 to 2030.

The global industrial fasteners market size was estimated at USD 95.57 billion in 2023 and is expected to grow at a CAGR of 4.7% from 2024 to 2030.

Key Companies & Market Share Insights

Global heat exchangers industry is characterized by presence of multinational as well as regional players that are engaged in designing, manufacturing, and distributing these products. Product manufacturers strive to obtain a competitive edge over their competitors by increasing application scope of their products.

Strategies adopted by manufacturers include new product development, diversification, mergers & acquisitions, and geographical expansion. These strategies aid the companies in expanding their market penetration and catering to changing technological demand across various end-use industries.

Key Heat Exchangers Companies:

Alfa Laval

Danfoss

Kelvion Holding GmbH

Güntner Group GmbH

Xylem Inc

API Heat Transfer

Mersen

Hisaka Works, Ltd.

Chart Industries, Inc

Johnson Controls International

HRS Heat Exchangers

SPX FLOW, Inc.

Funke Wärmeaustauscher Apparantebau GmbH

Koch Heat Transfer Company

Southern Heat Exchanger Corporation

Recent Developments:

For instance, in April 2023, Kelvion launched dedicated air cooler series for natural refrigerants. The CDF & CDH ranges are dual discharge air coolers highlighting a similar proficient tube system.

In May 2023, Alfa Laval is enhancing its brazed plate heat exchanger capacity to bolster the global energy transition. The establishment of new facilities in Italy, China, Sweden, and the U.S. signifies significant progress in their initiative to advance manufacturing intelligence and efficiency throughout the entire supply chain.

In January 2021, Alfa Laval, opened a new facility for the production of brazed heat exchangers in San Bonifacio, Italy. The new facility will have more capacity to fulfill the increasing customer demand.

Order a free sample PDF of the Heat Exchanger Market Intelligence Study, published by Grand View Research.

0 notes

Text

Heat Exchangers Market Analysis, Opportunities And Forecast Report 2024-2030

The global heat exchangers market size was estimated at USD 18.19 billion in 2023 and is expected to expand at a compounded annual growth rate (CAGR) of 5.4% from 2024 to 2030.

Rising focus on efficient thermal management in various industries, including oil & gas, power generation, chemical & petrochemical, food & beverage, and HVAC & refrigeration, is expected to drive the demand for heat exchangers over the forecast period. Rising demand from chemical industry coupled with increasing technological advancements and a growing focus on improving efficiency standards is expected to drive heat exchangers market growth. Most processes in petrochemical facilities involve high pressure and temperature, thus, necessitating the optimization of heat transfer and enhancement of energy savings, which, in turn, is likely to boost the demand for energy-efficient heat exchangers.

Gather more insights about the market drivers, restrains and growth of the Heat Exchangers Market

U.S. dominated the North America heat exchanger market in 2023, owing to high electricity demand, industrialization, and investments in renewable power generation. Rising investments by oil & gas companies in exploration & production activities in the U.S. are expected to boost the demand for these products in oil & gas industry.

Significant power markets such as China, U.S., India, Russia, and Japan are restructuring their operating models to adopt the structure of renewable energy and efficient utilization of energy by installing heat exchangers and shifting from traditional energy use. This is expected to drive the demand for heat exchangers.

Technological advancements such as tube inserts in heat exchangers are expected to complement the market growth. Furthermore, ongoing technological improvements to improve energy efficiency, total life cycle cost, durability, and compactness of heat exchangers are expected to drive industry growth.

Manufacturers of these products face a long list of difficult supply chain challenges, including increasing demand variability, intense global competition, more environmental compliance regulations, increasing human- and nature-based risks, and inventory proliferation. COVID-19 pandemic has created new challenges, which are compelling manufacturers to innovate their supply chains at a faster speed.

Heat Exchangers Market Segmentation

Grand View Research has segmented the global heat exchangers market report based on product, end-use, material and region:

Product Outlook (Revenue, USD Billion, 2018 - 2030)

• Plate & Frame Heat Exchanger

• Brazed Plate & Frame Heat Exchanger

• Gasketed Plate & Frame Heat Exchanger

• Welded Plate & Frame Heat Exchanger

• Others

• Shell & Tube Heat Exchanger

• Air-Cooled Heat Exchanger

• Others

End-use Outlook (Revenue, USD Billion, 2018 - 2030)

• Chemical & Petrochemical

• Oil & Gas

• HVAC & Refrigeration

• Power GenerationFood & Beverage

• Pulp & Paper

• Others

Material Outlook (Revenue, USD Billion, 2018 - 2030)

• Metals

• Alloys

• Others

Regional Outlook (Revenue, USD Billion, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o France

o Italy

o Spain

o UK

• Asia Pacific

o China

o Japan

o India

o South Korea

o Australia

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

o Saudi Arabia

o UAE

o South Africa

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The global wood plastic composites market size was estimated at USD 7.15 billion in 2023 and is expected to grow at a CAGR of 11.6% from 2024 to 2030.

• The global industrial fasteners market size was estimated at USD 95.57 billion in 2023 and is expected to grow at a CAGR of 4.7% from 2024 to 2030.

Key Companies & Market Share Insights

Global heat exchangers industry is characterized by presence of multinational as well as regional players that are engaged in designing, manufacturing, and distributing these products. Product manufacturers strive to obtain a competitive edge over their competitors by increasing application scope of their products.

Strategies adopted by manufacturers include new product development, diversification, mergers & acquisitions, and geographical expansion. These strategies aid the companies in expanding their market penetration and catering to changing technological demand across various end-use industries.

Key Heat Exchangers Companies:

• Alfa Laval

• Danfoss

• Kelvion Holding GmbH

• Güntner Group GmbH

• Xylem Inc

• API Heat Transfer

• Mersen

• Hisaka Works, Ltd.

• Chart Industries, Inc

• Johnson Controls International

• HRS Heat Exchangers

• SPX FLOW, Inc.

• Funke Wärmeaustauscher Apparantebau GmbH

• Koch Heat Transfer Company

• Southern Heat Exchanger Corporation

Recent Developments:

• For instance, in April 2023, Kelvion launched dedicated air cooler series for natural refrigerants. The CDF & CDH ranges are dual discharge air coolers highlighting a similar proficient tube system.

• In May 2023, Alfa Laval is enhancing its brazed plate heat exchanger capacity to bolster the global energy transition. The establishment of new facilities in Italy, China, Sweden, and the U.S. signifies significant progress in their initiative to advance manufacturing intelligence and efficiency throughout the entire supply chain.

• In January 2021, Alfa Laval, opened a new facility for the production of brazed heat exchangers in San Bonifacio, Italy. The new facility will have more capacity to fulfill the increasing customer demand.

Order a free sample PDF of the Heat Exchanger Market Intelligence Study, published by Grand View Research.

#Heat Exchanger Market#Heat Exchanger Industry#Heat Exchanger Market size#Heat Exchanger Market share#Heat Exchanger Market analysis

0 notes

Text

Top 10 Heat Exchanger Manufacturers in India

Here’s a list of the top 10 heat exchanger manufacturers in India, along with a brief company description, key highlights (founded, headquarters, major products), and contact information:

Here is Top 10 Heat Exchanger Manufacturers in India

1. GEA India

Description: GEA is a global leader in heat exchangers, providing various solutions across various industries, including food processing, chemicals, and HVAC.

Founded: 1881

Headquarters: Vadodara, Gujarat

Major Products: Plate heat exchangers, shell and tube heat exchangers, air-cooled heat exchangers.

Contact: +91-265-2680723

2. Swastik Hydraulic

Description: Swastik Hydraulic is a leading company with a significant presence in India, specializing in heat transfer, separation, and fluid handling technology.

Founded: 1972

Headquarters: Delhi, India

Major Products: Heat exchangers, Hydraulic Oil Coolers, Lube Oil Coolers, Water Cooled Condensers, Water Cooled Oil Coolers, Water Cooled Heat Exchanger, Shell and Tube Heat Exchangers, Industrial Heat Exchangers, Mild Steel Heat Exchangers...

Contact: +91-9818001293

3. Thermax Limited

Description: Thermax is an Indian multinational company that offers a range of engineering solutions, including energy-efficient heat exchangers for various industrial applications.

Founded: 1966

Headquarters: Pune, Maharashtra

Major Products: Shell and tube heat exchangers, air-cooled heat exchangers, waste heat recovery systems.

Contact: +91-20-66051200

4. HRS Process Systems Ltd.

Description: HRS Process Systems is a leading manufacturer of heat exchangers in India, specializing in innovative heat transfer solutions for the chemical, food, and pharmaceutical industries.

Founded: 1989

Headquarters: Pune, Maharashtra

Major Products: Corrugated tube heat exchangers, plate heat exchangers, scraped surface heat exchangers.

Contact: +91-20-25663441

5. Kirloskar Brothers Limited

Description: Kirloskar Brothers Limited is a prominent engineering company in India, known for its advanced heat exchanger solutions used in power generation, marine, and industrial applications.

Founded: 1888

Headquarters: Pune, Maharashtra

Major Products: Shell and tube heat exchangers, plate heat exchangers, compact heat exchangers.

Contact: +91-20-27214444

6. Bharat Heavy Electricals Limited (BHEL)

Description: BHEL is one of India's largest public sector engineering and manufacturing enterprises, offering a wide range of heavy industrial equipment, including heat exchangers.

Founded: 1964

Headquarters: New Delhi

Major Products: Shell and tube heat exchangers, air preheaters, regenerative heat exchangers.

Contact: +91-11-66337000

7. Danfoss India

Description: Danfoss is a global leader in energy-efficient technologies, including advanced heat exchangers for HVAC, refrigeration, and industrial applications.

Founded: 1933 (Parent company)

Headquarters: Chennai, Tamil Nadu

Major Products: Brazed plate heat exchangers, micro plate heat exchangers, shell and tube heat exchangers.

Contact: +91-44-66501500

8. Swep India

Description: SWEP is a leading manufacturer of compact brazed plate heat exchangers, catering to a diverse range of applications, including HVAC, refrigeration, and industrial processes.

Founded: 1983 (Parent company)

Headquarters: Pune, Maharashtra

Major Products: Brazed plate heat exchangers, compact heat exchangers.

Contact: +91-20-66271100

9. Tranter India Pvt. Ltd.

Description: Tranter is known for its innovative heat exchanger technologies, providing customized solutions for various industries, including oil and gas, power, and chemicals.

Founded: 1932 (Parent company)

Headquarters: Pune, Maharashtra

Major Products: Plate heat exchangers, shell and tube heat exchangers, spiral heat exchangers.

Contact: +91-20-66758000

10. Sondex India

Description: Sondex is a part of Danfoss Group, specializing in high-quality heat exchanger solutions, particularly plate heat exchangers, used in various industrial applications.

Founded: 1984 (Parent company)

Headquarters: Navi Mumbai, Maharashtra

Major Products: Plate heat exchangers, brazed heat exchangers, all-welded heat exchangers.

Contact: +91-22-27837363

These Top 10 List of Heat Exchanger Manufacturers in India are among the top players in the heat exchanger industry, offering a wide range of products and services to meet diverse industrial needs.

This content is generated with AI.

#heatexchangermanufacturerinIndia#heatexchangermanufacturersinindia#TopHeatExchangerManufacturersIndia#BestHeatExchangerCompaniesIndia#HeatExchangerSuppliersDelhiIndia#LeadingHeatExchangerManufacturersinIndia#DelhiNCRHeatExchangerIndustry#HeatExchangerCompaniesinIndia#Top10HeatExchangerSuppliersIndia#HeatExchangerManufacturersListIndia#IndustrialHeatExchangerIndia#TopHeatTransferEquipmentManufacturersIndia

1 note

·

View note

Text

Heat Exchangers Market Likely To Reach Beyond $26.26 Billion By 2030

The global heat exchangers market size is expected to reach USD 26.26 billion by 2030, registering at a CAGR of 5.4% from 2024 to 2030, according to a new report by Grand View Research, Inc. Rising demand from various industries, including chemical & petrochemical, and power generation, along with an increasing focus on improving efficiency standards is expected to drive the market.

The presence of favorable government regulations in the emerging economies of China, India, Brazil, and Mexico about setting up new manufacturing facilities is expected to spur the demand for heat exchangers in various industries. In addition, upcoming nuclear power projects, particularly in the Asia Pacific, are anticipated to drive market growth during the forecast period.

Technological advancements coupled with constant efforts and investments by major market participants in product innovation and research & development are expected to increase the market competitiveness over the coming years. The adoption of novel techniques of additive manufacturing in the production of heat exchangers is likely to complement industrial growth.

The COVID-19 pandemic has severely impacted several economies worldwide. Containment measures, including lockdowns imposed by various countries to curb the spread of COVID-19, have resulted in limiting the operations of manufacturing facilities, thereby negatively impacting the demand for heat exchangers in 2020.

Request a free sample copy or view report summary: Heat Exchangers Market Report

Heat Exchangers Market Report Highlights

The demand for plate & frame heat exchangers is anticipated to witness growth at a CAGR of 6.1% from 2024 to 2030 on account of its simple & compact structure coupled with their ability to increase capacity easily by adding new plates to the system

The shell & tube segment led the market and accounted for 35.6% of the global revenue in 2023

Asia Pacific heat exchanger demand is likely to grow at a CAGR of 6.8% over the forecast period

The demand for heat exchangers in Saudi Arabia is expected to witness a CAGR of 4.5% owing to the presence of a robust oil & gas industry coupled with the growth in the manufacturing sector attributed to the government’s diversification efforts

Heat Exchangers Market Segmentation

Grand View Research has segmented the global heat exchangers market report based on product, end-use, material and region

Heat Exchangers Product Outlook (Revenue, USD Million, 2018 - 2030)

Plate & Frame Heat Exchanger

Brazed Plate & Frame Heat Exchanger

Gasketed Plate & Frame Heat Exchanger

Welded Plate & Frame Heat Exchanger

Others

Shell & Tube Heat Exchanger

Air-Cooled Heat Exchanger

Others

Heat Exchangers End-use Outlook (Revenue, USD Million, 2018 - 2030)

Chemical & Petrochemical

Oil & Gas

HVAC & Refrigeration

Power Generation

Food & Beverage

Pulp & Paper

Others

Heat Exchangers Material Outlook (Revenue, USD Billion, 2018 – 2030)

Metals

Alloys

Others

Heat Exchangers Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

France

Italy

Spain

UK

Asia Pacific

China

Japan

India

Central & South America

Brazil

Middle East & Africa

Saudi Arabia

UAE

List of Key Players of Heat Exchanger Market

Alfa Laval

Danfoss

Kelvion Holding GmbH

Güntner Group GmbH

Xylem Inc.

API Heat Transfer

Mersen

Hisaka Works, Ltd.

Chart Industries, Inc.

Johnson Controls International

HRS Heat Exchangers

SPX FLOW, Inc.

Funke Wärmeaustauscher Apparantebau GmbH

Koch Heat Transfer Company

Southern Heat Exchanger Corporation

#Heat Exchangers Market#Heat Exchangers Market Analysis#Heat Exchangers Market Forecast#Heat Exchangers Market Share#Heat Exchangers Market Growth#Heat Exchangers Market Research#Heat Exchangers Market Trends#Heat Exchangers Market Size#Heat Exchangers Market Outlook

0 notes

Text

Brazing Heat Sink

Brazing heat sink is one of the most effective heat transfer methods. It is composed of a set of corrugated pipe plates between the front and rear baffles. The baffle plate assembly is composed of a sealing plate, a sealing ring and a baffle plate. The interface type can be customized according to the specific requirements of the market and application fields. During the vacuum brazing process, a solder joint is formed at each contact point between the plate and the filler material (brazing material). Using this design method, a heat exchanger composed of two different channels or loops can be manufactured. The design purpose of the brazed fin heat sink is to provide unparalleled performance and the lowest life cycle cost. If brazing technology can be used in your next cooling project, it will surely bring you many benefits, including saving space, energy and maintenance costs.

1 note

·

View note

Text

Brazing Heat Sink: Revolutionizing Heat Transfer Efficiency

In the realm of heat transfer technology, brazing heat sinks stand out as one of the most effective methods, offering unparalleled performance and cost efficiency. Comprising a series of corrugated pipe plates sandwiched between front and rear baffles, these heat sinks are engineered to optimize heat dissipation in various applications.

The assembly of a brazing heat sink consists of a sealing plate, a sealing ring, and the crucial baffle plates. These components come together seamlessly during the vacuum brazing process, wherein solder joints are formed at each contact point between the plates and the filler material, also known as the brazing material. This meticulous design approach allows for the creation of a heat exchanger with distinct channels or loops, catering to diverse market requirements and application fields.

What sets brazed fin heat sinks apart is their ability to deliver exceptional performance while minimizing life cycle costs. By harnessing brazing technology, these heat sinks not only excel in heat dissipation but also offer numerous benefits to users. Among these advantages are space optimization, energy savings, and reduced maintenance expenses.

The compact design of brazing heat sinks enables them to effectively dissipate heat in confined spaces, making them ideal for applications where spatial constraints are a concern. Furthermore, their efficiency in transferring heat translates into significant energy savings, contributing to overall operational cost reduction. Moreover, the robust construction of brazed fin heat sinks minimizes the need for frequent maintenance, thereby further lowering the total cost of ownership over their lifespan.

For industries and projects seeking superior heat transfer solutions, brazing technology presents an enticing proposition. Whether it’s for electronics cooling, automotive applications, or industrial processes, brazed fin heat sinks offer a reliable and efficient means of managing thermal loads. Embracing brazing technology in cooling projects not only ensures optimal performance but also promises long-term benefits in terms of space utilization, energy conservation, and operational cost efficiency.

In conclusion, brazing heat sinks represent a paradigm shift in heat transfer technology, offering unmatched performance and cost-effectiveness. With their innovative design and advanced manufacturing processes, these heat sinks have become indispensable assets across various industries. By incorporating brazing technology into cooling projects, businesses can unlock a multitude of benefits, paving the way for enhanced efficiency and sustainability in thermal management solutions.

0 notes

Text

Brazed Plate Heat Exchangers

Brazed plate heat exchangers are constructed with a series of thin, corrugated stainless steel plates. These plates are carefully stacked and brazed together using a high-temperature process, creating a sealed unit with alternating hot and cold fluid channels.

Features of Brazed Plate Heat Exchangers

High Thermal Efficiency: Brazed plate heat exchangers (BPHE) offer excellent heat transfer efficiency, ensuring optimal energy utilization.

Quick Response Time: BPHEs have low internal volume, allowing for rapid temperature response and efficient heat exchange.

Versatile Application: These heat exchangers are suitable for various fluids, including refrigerants

0 notes

Text

Monel 400 Sheets & Plates Manufacturers In India

Padmavati Steel & Engg.Co. offers an epic dimension of Monel Alloy 400 Sheets Plates and Coils, where it is the commitment of our party individuals to look at these things for a completing defect all things considered accomplishing most amazing quietness of the customers.

Monel 400 Sheets is utilized for hydrocarbon and compound overseeing gear, marine structure, shafts, fittings, valves, siphons, gets, and warmth exchangers. These Monel 400 Plates is utilized in made plant contraption, for the reason that of its bewildering use restraint.

Monel 400 Coils shows first – rate use check and taking off quality in a blend of fundamental and acidic circumstances and it's especially fitting for diminishing conditions. The machinability of these Monel 400 Slatting Coils (UNS N04400) is hard as it works-toughens all through machining. At that point, Monel 400 Perforated Coils are other than being offered in various sizes and shapes to our clients. While these Alloy 400 Sheets has varying phenomenal conditions, it is a long way from the ideal metal.

The machinability of Alloy 400 Plates is poor in setting on their tendency to rapidly work – set. These Alloy 400 Coils could in like way be potentially welded, bound, and brazed, which other than has shocking mechanical properties at underneath zero temperatures. Quality and hardness Alloy 400 Slatting Coils gets stretched out with basically slight devastating of versatility or effect check.

MONEL 400 SHEET, PLATE SPECIFICATIONS

Grade: Monel Alloy 400 / UNS N04400

Size: 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mmetc

Finish: Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Form: Sheets, Plates, Coils, Slatting Coils, Perforated Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange)

Specifications: ASTM B168 / ASME SB168

Form: Shim Sheet, Foils, Rolls, Chequered Plate, Flats, Designer Sheet, Blank (Circle), Strip, Plain Sheet, Coils, Ring (Flange) etc.

Hardness: Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

Applications: Gas Processing, Specialty Chemicals, Pulp, Paper Off-Shore Oil Drilling Companies, Power Generation, Petrochemicals, Pharmaceuticals, Pharmaceutical Equipment, Chemical Equipment, Sea Water Equipment, Heat Exchangers, Condensers, Industry

#Monel 400 Sheets & Plates Manufacturers#Monel 400 Sheets & Plates Exporters#Monel 400 Sheets & Plates Suppliers

0 notes

Text

Discover the efficiency of brazed plate heat exchangers for your Canadian operation. Learn how they transform thermal management in various applications.

#brazed plate heat exchanger in Canada#brazed plate heat exchanger manufacturers#brazed plate heat exchanger refrigeration

0 notes

Text

Unlocking Efficiency and Savings with Brazed Plate Heat Exchangers: Your Path to Cost-Efficiency

The cornerstones of success in the current corporate environment are cost reductions and efficiency. Brazed Plate Heat Exchangers (BPHEs) are revolutionizing the way organizations in a variety of sectors manage heat transfer operations. This essay tries to persuade you to integrate them into your operations if you haven't already.

What's a Brazed Plate Heat Exchanger?

Before we dive into the benefits of BPHEs, let's break down the concept in simple terms. Think of a BPHE as a super-efficient, eco-friendly, and compact device that transfers heat from one fluid to another. It's like having a secret weapon in your battle to cut costs and boost productivity.

Energy Efficiency Redefined

Energy bills can be a significant expense for businesses, and any reduction in energy consumption can lead to substantial savings. Here's where BPHEs shine. They are designed to minimize heat loss and maximize heat transfer. In practical terms, this means lower energy consumption, which translates to reduced operating costs.

For instance, in the chemical industry, where temperature control is paramount, BPHEs help maintain precise temperatures without the energy-wasting inefficiencies of traditional heating and cooling systems. That not only reduces costs but also lessens your carbon footprint, appealing to both your wallet and eco-conscious consumers.

Space-Saving Marvels

Space is a precious commodity in any business, and BPHEs are masters of space utilization. These compact exchangers are a fraction of the size of conventional heat exchangers, allowing you to optimize your available real estate. Whether you're running a sprawling manufacturing facility or a modest commercial kitchen, the space you save with BPHEs can be repurposed for other productive uses.

Unrivaled Durability

BPHEs are designed to withstand the rigors of continuous operation. Made from corrosion-resistant materials, these heat exchangers are built to last, even in the most demanding industrial environments. This longevity is not just cost-effective; it also reduces downtime and maintenance hassles, ensuring that your operations run smoothly.

ost-Effective Installation

Taking on new technology can be intimidating, particularly if it requires a significant financial investment. BPHEs, however, provide an affordable option. They minimize disturbance to your current activities and save upfront expenditures due to their lower size and ease of installation. They show to be an astute long-term investment for your company because of their accelerated return time. In a world where every penny counts and sustainability is a growing concern, Brazed Plate Heat Exchangers are more than just a piece of equipment. They are your partners in achieving cost savings, energy efficiency, and environmental responsibility.

If you haven't yet explored the potential of BPHEs in your industry, now is the perfect time to do so. These compact, durable, and versatile devices have the potential to transform the way your business manages heat transfer, making you more competitive and eco-friendly. With Brazed Plate Heat Exchangers, you can embrace the next wave of heat exchange technology and watch your business grow while saving money and the environment. Not only is it a sensible decision, but it's also a responsible one.

0 notes

Link

According to the new market research report “Brazed Plate Heat Exchangers Market by Application (Evaporator, Condenser, And Economizer), End-use Industry (HVACR, chemical, food & beverage, power, heavy industries, and others), and Region – Global Forecast to 2024″, published by MarketsandMarkets™, the BPHEs Market is expected to grow from USD 799 million in 2019 to USD 1,120 million by 2024, at a CAGR of 7.0%.

#brazed plate heat exchangers#Brazed Plate Heat Exchangers market#Brazed Plate Heat Exchangers industry#Brazed Plate Heat Exchangers manufacturers#Brazed Plate Heat Exchangers applications

1 note

·

View note

Video

tumblr

Water to water heat exchangers are responsible for exchanging heat between waste water and freshwater. The heat transfer process between the liquids does not involve direct contact or mixing of the two. If you are looking for the best quality Water Heat Exchanger then you should contact AIC Heat Exchanger - which offers Complete Heat Transfer Solutions.

#aicheatexchangers#DoubleWall#heat exchanger#water to water heat exchanger#Double Wall Heat Exchanger#shell and tube heat exchangers#brazed plate heat exchangers#Shell and Tube Heat Exchanger#Heat Exchanger Manufacturer#heat exchangers market#USA

0 notes

Link

Alfa Laval copper-brazed plate heat exchangers are a compact, efficient and maintenance-free solution for heating, cooling, evaporation and condensing in numerous applications. Each unit is designed for duty optimization, with a range of unique features that ensure both superior thermal performance and maximum reliability. This enables the longest possible service life – even under conditions with extremely high design pressures.

Brazed plate heat exchangers have no headers, tie bars or sealing gaskets because the plates are furnace brazed at temperatures of 1100°C. During the assembly phase, a sheet of brazing material (generally copper but also nickel) is placed between the plates, the pack is pressed and subsequently baked for some hours.

#brazed plate heat exchanger#brazed heat exchanger#brazed heat exchanger manufacturers#brazed plate heat exchanger manufacturers

0 notes

Text

The global construction sector is growing rapidly, owing to the increasing focus and investments in the sector. This growth of the sector is expected to increase the demand of HVACR systems. Brazed Plate Heat Exchangers are used in HVACR systems, and hence, the BPHEs market in HVACR industry is expected to witness the highest growth rate.

#Brazed Plate Heat Exchangers Market#Brazed Plate Heat Exchanger Market#Brazed Plate Heat Exchangers Manufacture#Brazed Plate Heat Exchangers Industry#heat exchanger market#heat exchangers#heat exchanger#heat#Brazed Plate Heat Exchangers Industry Trends#Brazed Plate Heat Exchangers Trends#Brazed Plate Heat Exchangers Type#Brazed Plate Heat Exchangers Market Forecast#Brazed Plate Heat Exchangers Market Insights

0 notes