#Bond Paper Slitting Rewinding

Link

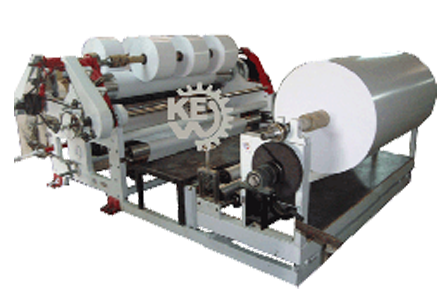

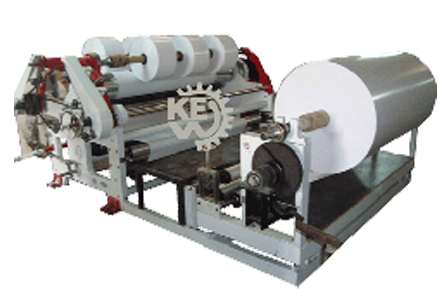

Bond Paper Slitting Rewinding Machine, Paper Slitter Rewinder Machine Manufacturer, Slitting Rewinding Machine for all types of Paper Roll. Our Bond Paper Slitting Rewinding Machine required for its accurate slitting and rewinding premium qualities with meeting International Standarad. It ensures perfect slitting of material with consistent, flawless results and constant line speed.

#Bond Paper Slitting Rewinding#Paper Slitter Rewinder Machine Manufacture#Paper Sliter Rewinder Machine#Sliter Rewinder Machine#Sliter Rewinder

0 notes

Link

We have been successfully Manufacturing, Exporting & Supplying all types of high quality performance Filter Paper Slitter Rewinder Machine Manufacturer, High Performance Slitting Rewinding Machine, Slitter Rewinder Machine, Bond Paper Slitting Rewinding Machine, Kraft Paper Slitting Rewinding Machine, Butter Paper Slitter Rewinder Machine. Our Filter Paper Slitter Rewinder Machine comes in use for Slitting of all types of Filter Paper Materials. Nowadays Filter Paper is used like Air Filter, Coffee Filter, Air Conditioner, Fuel Filters, Laboratory Filters, Oil Filters, Tea Filters, etc.

#Filter Paper Slitter Rewinder Machine#Filter Paper Slitter Rewinder Machine Manufacturer#Filter Paper Slitter Rewinder#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitting Rewinding#Bond Paper Slitting Rewinding#Kraft Paper Slitting Rewinding#Butter Paper Slitter Rewinder Machine#Butter Paper Slitter Rewinder

0 notes

Link

We are Manufacturer, Exporter & supplier High speed Thermal Paper Slitting Rewinding Machine Manufacturer with high quality equipment and suitable for international standard and company specific. Slitting of all types of Paper Slitter Rewinder Machine, Heavy Duty Paper Slitting Rewinding Machine, Paper and Board Mill Slitter Rewinder Machine, Ice Cream Cup Paper Slitter Rewinder Machine, Fax Roll Paper Slitter Rewinder Machine , Coated Paper Slitter Rewinder, Filter Paper Slitter Rewinder Machine, Bond Paper Slitting Rewinding Machine, Kraft Paper Slitting Rewinding Machine.

#Thermal Paper Slitting Rewinding Machine#Thermal Paper Slitting Rewinding Machine Manufacturer#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitting Rewinding#Slitter Rewinder#Bond Paper Slitting Rewinding Machine#Paper and Board Mill Slitter Rewinder Machine#Fax Roll Paper Slitter Rewinder Machine

2 notes

·

View notes

Text

What Is The All-in-one Web Guiding System

Once there is not an alignment of the coils, it will cause errors in the subsequent steps and the material wasting or the downtime of the machine. Therefore, when processing the web, the web guiding is necessary for the offset and it is widely used in a bonding machine, a printing machine, a coater, a paper machine, a dyeing machine, etc, which has various requirements for the winding and rewinding processes. An all-in-one web guiding system refers to the technical operation of the coils to keep the edge of the coil neat and consistent during spraying, printing, die-cutting, lamination, slitting, or other coil winding processes. Its wide applications have brought huge benefits to the coil industries. The all-in-one system has automated industries such as corrugated paper, textile, printing, labels, papermaking, plastic film, building materials, tires, and non-woven corrugated paper processing.

The Work Principle Of All-in-one Web Guiding System

The high-precision, high-speed, and high-efficiency coil automatic processing has high requirements for the lateral position of the controlled coil. Equipped with a high-performance automatic web guide system is the key to improving coil production capacity and output. The coil will shift laterally during moving, unwinding and rewinding. Therefore, the web guiding system can be installed in the above three positions for controlling the coil to pass through the designated position accurately.

All-in-one web guide machine adopts high-speed microprocessor, digital, modular and intelligent circuit design. The advanced programming, user-friendly interface, high-performance components and complete circuit protection design, make the system run continuously and stably. The response time of the control system is less than 0.01 seconds and the accuracy of the system itself can reach 0.01mm. During the coil winding process, the web guide sensor detects the position of the edge or line to pick up the deviation signal of the edge or line position.

Then the position deviation signal of the web guiding machine is sent to the web guide controller for logical operation. After the judges and processes of the control unit, it will control the drive motor to skew the web to the correct position.

The Functions & Advantages Of All-in-one Web Guiding System

The high-performance web guide system has a fast response time, high-speed CPU calculation and can support ultrasonic sensors, photoelectric sensors, CCD sensors for the different response of coils. It has the advantages of simple and practical operation, ball screw, high precision, low noise, maintenance-free, long service life, flexible installation.

Center compensation deviation web guiding can quickly guide the high-frequency feed errors. It integrates operation and control technology with a highly compact web guide. The guiding system has an innovative sensor detection real-time display and a real-time feedback system for system detection information.

The all-in-one system is driven by a brushless DC servo motor and precision ball screw, with compact structure, good mechanical rigidity, low inertia, high precision, suitable for high-speed and high-precision web guide in coil processing.

Three Detection Methods Provided By All-in-one Web Guiding System

The All-in-one web guiding system provides three different detection methods, which include edge detection, line tracking, or alignment detection. The drive system is driven by a brushless motor and the drive stroke is strictly proportional to the coil offset. The system can also be used in conjunction with different sensors to meet the needs of different coils, such as ultrasonic sensors, photoelectric sensors, CCD sensors, etc. The microcomputer digital controller provides precise control for the various functions of the guide system.

Daily Maintenance Of All-in-one Web Guiding System

1.Alignment: Tools, workpieces and accessories should be placed neatly. The web guiding system should be equipped with thorough protection equipment.

2. Cleaning: Cleaning inside and outside including all sliding surfaces, guidelines, gears, racks, etc, ensuring all parts will not leak oil, water, air, or electricity.

3. Lubricating: Refuel and change oil timely. The oil quality meets the requirements. Oil tanks, oil guns, oil cups, lumps, tubes should clean and keep complete.

4.Safety: The operation personnel should be familiar with the maintenance structure of the web guide system, complying with the operating procedures and reasonably use the all-in-one system with daily maintenance, carefully maintenance tools to prevent accidents.

For more information, please visit the page of why choose all-in-one web guide system.

0 notes

Link

Our Butter Paper Slitter Rewinder Machine comes in use for Slitting of all types of Butter Paper Material like Coated, Ice Cream Cup, Photograph, Stationery, Paper Slitter Rewinder Machine, Thermal Sensitive Paper Slitter Rewinder Machine, Bond Paper Slitting Rewinding Machine, Kraft Paper Slitting Rewinding Machine, Paper and Board Mill Slitter Rewinder Machine, Slitter Rewinder Machine, Slitting Rewinding Machine. All types of Paper Mills & Paper Converters require Slitting of Butter Paper for different type of applications.

#Butter Paper Slitter Rewinder Machine#Butter Paper Slitter Rewinder Machine Manufacturer#Butter Paper Slitter Rewinder#Paper Slitter Rewinder#Paper Slitter Rewinder Machine#Slitter Rewinder Machine#Slitter Rewinder Machines#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Slitting Rewinding Machine#Slitting Rewinding Machine Manufacturer#Slitting Rewinding

0 notes

Text

Air-laid Paper Market : Present Scenario and the Growth Prospects 2017 – 2025

Air-laid paper is a nonwoven fabric, textile-like material made from fluff pulp. It is made from 85% wood pulp and 15% binder. Air-laid paper is very bulky, porous, and soft. It has good water absorption properties. The raw paper pulp material is treated with extra softness and absorbency. Therefore, air-laid paper holds as much as six times its own weight in fluids and simultaneously has a greater wet strength compared to traditional paper tissue. Under the manufacturing process of air-laid paper, fibers are brought into an air flow and from there to a moving belt or perforated drum, where they shape a randomly leaning web. Air-laid webs possess lower density and higher softness contrast to carded webs. Air-laid webs also possess immense adaptability in terms of fibers and fiber blends. Manufacturing of air-laid paper takes place in three major steps: fiber opening, web formation, and web bonding. The physical characteristics of air-laid nonwovens make them suitable for various disposable absorbent applications in consumer, industrial, and institutional markets.

Planning to lay down strategy for the next few years? Our report can help shape your plan better.

Air-laid paper offers the following advantages: easy disposal after use – no laundry, textile-like surface and drape, very low linting, no dust, no static, strong even when wet, and clean and hygienic. It can also be sterilized.

Based on product, the air-laid paper market can be segmented into multi bond, thermal bond, latex bond, and hydrogen bond. Under latex bond, two different methods can be used to apply latex binder to the web, depending on the design of the production line. Under thermal bond, the web must contain synthetic bonding fibers (generally bi-components with polyethylene and polypropylene). After compaction, the web is transported into an oven, which softens and melts the sheaths of the fibers to the point where they fuse together, bonding the various components of the web. The web is then calendered to the correct thickness, cooled, and transported to the slitting/rewinding system. Hydrogen bonding utilizes the ability of cellulose fibers to bond together when naturally occurring moisture contained in the fibers is removed while the fibers are in close contact. Generally, bonding is accomplished under conditions of high temperature and pressure. This process eliminates the need for synthetic binders to be added to the air-laid web. Multi bond is a combination of latex and thermal bond. The web is thermally bonded and a light application of latex is sprayed on both sides of the web to reduce the lint that is often released in high-speed converting operations.

To obtain all-inclusive information on forecast analysis of global market, request a PDF brochure here.

In terms of application, the air-laid paper can be divided into Disposable Wiping- Household Cleaning Wipes, and Hand Wipes, Table-Top and Food Handling, Personal Care Products- Feminine Napkins, and Adult Incontinence. Air-laid paper is primarily used in feminine hygiene products and wipes. Wipes can be used in many applications such as body wash, hand wash, baby wipes, industrial wipes, and household cleaning wipes.

Based on region, the global air-laid market can be segregated into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Europe is the dominant region of the Air-laid paper market, followed by North America. This can be ascribed to the increase in usage of wipes in Europe for personal care and food handling processes.

For more actionable insights into the competitive landscape of global market, get a customized report here.

Key players operating in the air-laid paper market are Glatfelter, MAIN S.p.A., M&J Airlaid Products A/S, Georgia-Pacific, EAM Corporation, DELT papir, C-Airlaid, Lucart S.p.A, DENI, McAirlaid’s Vliesstoffe GmbH, Fitesa, Oji Kinocloth, Jiangmen Renfull Papermaking Co., Ltd., and Nanning Qiaohong New Materials Co.

0 notes

Text

Strategic Overview of the Air-laid Paper Market

Air-laid paper is a nonwoven fabric, textile-like material made from fluff pulp. It is made from 85% wood pulp and 15% binder. Air-laid paper is very bulky, porous, and soft. It has good water absorption properties. The raw paper pulp material is treated with extra softness and absorbency. Therefore, air-laid paper holds as much as six times its own weight in fluids and simultaneously has a greater wet strength compared to traditional paper tissue. Under the manufacturing process of air-laid paper, fibers are brought into an air flow and from there to a moving belt or perforated drum, where they shape a randomly leaning web. Air-laid webs possess lower density and higher softness contrast to carded webs. Air-laid webs also possess immense adaptability in terms of fibers and fiber blends. Manufacturing of air-laid paper takes place in three major steps: fiber opening, web formation, and web bonding. The physical characteristics of air-laid nonwovens make them suitable for various disposable absorbent applications in consumer, industrial, and institutional markets.

Read report overview at: https://www.transparencymarketresearch.com/air-laid-paper-market.html

Air-laid paper offers the following advantages: easy disposal after use – no laundry, textile-like surface and drape, very low linting, no dust, no static, strong even when wet, and clean and hygienic. It can also be sterilized.

Based on product, the air-laid paper market can be segmented into multi bond, thermal bond, latex bond, and hydrogen bond. Under latex bond, two different methods can be used to apply latex binder to the web, depending on the design of the production line. Under thermal bond, the web must contain synthetic bonding fibers (generally bi-components with polyethylene and polypropylene). After compaction, the web is transported into an oven, which softens and melts the sheaths of the fibers to the point where they fuse together, bonding the various components of the web. The web is then calendered to the correct thickness, cooled, and transported to the slitting/rewinding system. Hydrogen bonding utilizes the ability of cellulose fibers to bond together when naturally occurring moisture contained in the fibers is removed while the fibers are in close contact. Generally, bonding is accomplished under conditions of high temperature and pressure. This process eliminates the need for synthetic binders to be added to the air-laid web. Multi bond is a combination of latex and thermal bond. The web is thermally bonded and a light application of latex is sprayed on both sides of the web to reduce the lint that is often released in high-speed converting operations.

Request to view sample of this report at: https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=42449

In terms of application, the air-laid paper can be divided into Disposable Wiping- Household Cleaning Wipes, and Hand Wipes, Table-Top and Food Handling, Personal Care Products- Feminine Napkins, and Adult Incontinence. Air-laid paper is primarily used in feminine hygiene products and wipes. Wipes can be used in many applications such as body wash, hand wash, baby wipes, industrial wipes, and household cleaning wipes.

Based on region, the global air-laid market can be segregated into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Europe is the dominant region of the Air-laid paper market, followed by North America. This can be ascribed to the increase in usage of wipes in Europe for personal care and food handling processes.

Key players operating in the air-laid paper market are Glatfelter, MAIN S.p.A., M&J Airlaid Products A/S, Georgia-Pacific, EAM Corporation, DELT papir, C-Airlaid, Lucart S.p.A, DENI, McAirlaid’s Vliesstoffe GmbH, Fitesa, Oji Kinocloth, Jiangmen Renfull Papermaking Co., Ltd., and Nanning Qiaohong New Materials Co.

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

About Us:Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with your aims. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information we offer customized solutions through adhoc reports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.TMR believes that unison of solutions for clients-specific problems with right methodology of research is the key to help enterprises reach right decision.ContactTransparency Market Research

90 State Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Email:

Website:

https://www.transparencymarketresearch.com

0 notes

Link

We Are Leading Manufacturer, Supplier and Exporter from Ahmedabad. Different Types Of Slitter Rewinder Machine, Paper Slitter Machines, Heavy Duty Slitting Rewinding Machine, Jumbo Paper Roll Slitter Rewinder Machine, Bond, Butter, Thermal Paper Slitting Rewinding Machine Manufacturer, Coated Paper Slitter Rewinder Machine, Filter Paper Slitter Rewinder Machine and Butter Paper Slitter Rewinder Machine.

#Paper Slitter Machines#Slitter Rewinder Machine#stretch film rewinding machine#fabric slitter machine#slitting rewinding machine#slitter rewinder machines#paper slitting rewinding machine

1 note

·

View note

Link

We are Specialized manufacturer of Kraft Paper Slitting Rewinding Machine, high quality equipment Doctoring Rewinding Machine Manufacturer, Slitter Rewinder Machine manufacturer, Slitter Rewinder, Paper Slitter Rewinder Machine, Bond Paper Slitting Rewinding Machine, Butter Paper Slitter Rewinder Machine, Thermal Sensitive Paper Slitter Rewinder Machine. Our Kraft Paper Slitting Rewinding Machine comes in use for Slitting of all types of Kraft Paper Material like and then further processed for making different envelopes, sacks etc.

#Kraft Paper Slitting Rewinding#Kraft Paper Slitting Rewinding Machine#Paper Slitting Rewinding#Paper Slitting Rewinding Machine#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder#Slitting Rewinder Machine#Slitting Rewinder Machine Manufacturer#Slitting Rewinder#Slitter Rewinding Machine#Slitter Rewinding Machine Manufacturer

0 notes

Link

Engaged in manufacturing process of Butter Paper Slitter Rewinder Machine with technical professionals to fulfill industry specific requirement and material. Different types of Paper Slitter Rewinder Machine, Kraft Paper Slitting Rewinding Machine, Bond Paper Slitting Rewinding Machine, Thermal Paper Slitting Rewinding Machine, Paper and Board Mill Slitter Rewinder Machine, Heavy Duty Paper Slitting Rewinding Machine. Slitting of all types of material like Plastic, Paper, Flexible Packaging, PVC, Aluminum Foil, Stretch Film, LDPE Film, BOPP Film, BOPP Tape.

#Butter Paper Slitter Rewinder Machine#Butter Paper Slitter Rewinder Machine Manufacturer#Paper Slitter Rewinder Machine#Paper Slitter Rewinder#Slitter Rewinder Machine#Slitter Rewinder Machine Manufacturer#Slitter Rewinder

0 notes