#BlowerParts

Explore tagged Tumblr posts

Text

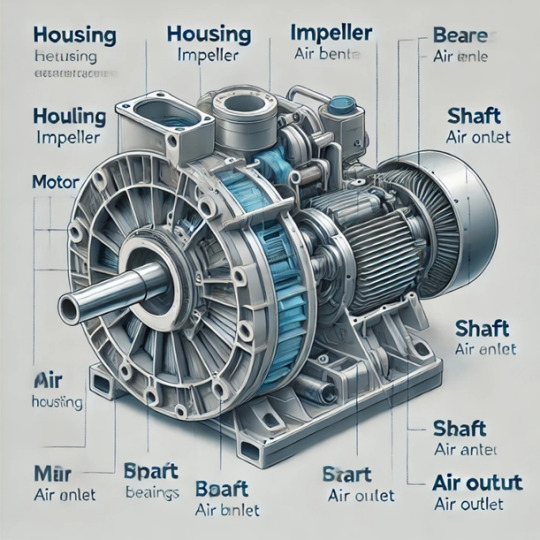

Blower Assembly Replacement Kit HVAC _ PartsHnC

The HVAC blower assembly is responsible for circulating air throughout the building by drawing in outside air, filtering it, heating or cooling it as necessary, and then distributing it through the ductwork. The blower assembly typically consists of a fan, a motor, and a housing.The thermostat sends signals to the blower assembly to adjust the fan speed and temperature of the air as needed.

For an efficient and reliable HVAC system, the Blower Assembly HVAC is a great choice for optimal system performance.

0 notes

Text

Top 10 Maintenance Practices to Extend Blower Lifespan

For industries relying on blowers for crucial operations, regular maintenance is essential to ensure efficiency and avoid costly downtime. At Central Blower Pomona, we provide high-quality blower parts that enhance performance and extend equipment lifespan. Here are ten best practices to keep your blower in optimal condition:

1. Schedule Regular Inspections

Check for wear and tear on blower components, such as impellers, belts, and bearings.

Inspect for unusual noises, vibrations, or overheating.

2. Keep It Clean

Regularly clean the blower to prevent debris build-up, which can affect performance.

Use compressed air to remove dust from internal components.

3. Lubricate Moving Parts

Apply the recommended lubricants to bearings and other moving parts to minimize friction.

Follow the manufacturer’s guidelines for frequency and type of lubrication.

4. Monitor Alignment

Ensure proper alignment between the blower and its motor to avoid undue stress on the system.

Use alignment tools to check periodically.

5. Replace Worn-Out Parts

Replace aging or damaged blower parts promptly to prevent further damage.

Stock up on key components like seals, impellers, and filters to avoid delays.

6. Check Filters Regularly

Inspect and clean air intake filters to ensure proper airflow.

Replace filters as needed to avoid clogging and reduced efficiency.

7. Maintain Proper Tension in Belts

Check belt tension and adjust as necessary to prevent slipping or over-tightening.

Replace cracked or frayed belts immediately.

8. Monitor System Parameters

Regularly check pressure, temperature, and airflow to detect anomalies.

Install monitoring sensors for real-time data and alerts.

9. Avoid Overloading

Operate the blower within its design specifications to prevent undue strain.

Ensure the system is not subjected to excessive pressures or loads.

10. Train Personnel

Provide proper training to operators and maintenance teams on blower operation and care.

Share guidelines on recognizing early signs of problems.

By implementing these practices and using high-quality blower parts from Central Blower Pomona, you can maximize the lifespan and efficiency of your equipment.

Blower Parts

Case Studies and Testimonials

Case Study: Boosting Efficiency in a Food Processing Plant

Challenge: A food processing plant experienced frequent blower breakdowns, leading to production delays.

Solution: By replacing worn-out impellers and filters with high-quality blower parts from Central Blower Pomona, the plant improved the reliability of its system.

Result:

30% reduction in downtime.

Improved airflow efficiency, saving energy costs.

Testimonial: "Central Blower Pomona’s parts made a noticeable difference. Our blowers run smoother and require less frequent repairs." – Plant Maintenance Manager, XYZ Foods

Case Study: Enhancing Air Quality in a Manufacturing Facility

Challenge: A manufacturing facility struggled with inadequate ventilation, causing employee discomfort.

Solution: The facility upgraded its blowers with custom impellers and energy-efficient components from Central Blower Pomona.

Result:

Enhanced air circulation.

20% reduction in energy consumption.

Testimonial: "We���re thrilled with the performance. Central Blower Pomona’s parts were exactly what we needed." – Facility Manager, ABC Manufacturing

Customer Support Content

At Central Blower Pomona, we’re committed to providing top-notch support for all your blower needs. Here’s how we help:

Installation Guides

Step-by-step video tutorials for replacing parts like impellers, bearings, and filters.

Printable PDF guides available for every product.

Warranty Assistance

Hassle-free warranty claims for defective or damaged parts.

Dedicated support team to guide you through the process.

Troubleshooting Resources

Quick tips for diagnosing common blower issues.

Live chat support for immediate assistance.

FAQs

1. What is the warranty period for your blower parts?

Our blower parts come with a standard 12-month warranty. Extended warranties are available for select components.

2. How do I know which part to order?

Refer to your blower’s manual or contact our support team with your blower’s model number for assistance.

3. Are your parts compatible with all blower brands?

We offer a wide range of parts compatible with most major blower brands. Contact us for specific compatibility inquiries.

4. Can I install the parts myself?

Yes, our parts come with detailed installation instructions. For complex installations, we recommend professional assistance.

5. Do you provide bulk discounts?

Yes, we offer competitive pricing for bulk orders. Reach out to our sales team for a quote.

6. How soon can I get my order?

We provide fast shipping with most orders delivered within 3-5 business days. Expedited options are available.

0 notes

Text

Rajlaxmi Machine Tools offers HMP | Ramato | Roent Make Hand Blowers, Electric Blowers, Motorised Air Blower, Motorized Air Blowers, Ring Blowers, Turbo Blowers, Centrifugal Blowers, MS Fabricated Air Blowers, Suction Blowers, Pressure Blowers Manufacturer From Rajkot Gujarat Bharat (INDIA).

#RajlaxmiMachineTools#HMPBlowers#RamatoBlowers#RoentBlowers#HandBlowers#ElectricBlowers#MotorisedAirBlower#MotorizedAirBlowers#RingBlowers#TurboBlowers#CentrifugalBlowers#MSFabricatedAirBlowers#SuctionBlowers#PressureBlowers#BlowerManufacturer#RajkotBlowers#GujaratBlowers#IndiaBlowers#AirBlowers#IndustrialBlowers#BlowerSystems#BlowerSolutions#HighPerformanceBlowers#EnergyEfficientBlowers#BlowerParts#BlowerAccessories#BlowerProducts#RajlaxmiBlowers#BlowerCompany#BlowerFactory

0 notes