#Best Industrial Air Compressor

Explore tagged Tumblr posts

Text

Buy Best Industrial Air Compressors at Best Price in USA at Penry Air

Penry Air is proud to offer an extensive range of top-quality Best Industrial Air Compressors, available in both electric and gas powered models for both home and industrial use. Our competitive prices ensure that you receive reliable products at a fantastic value. Don't hesitate, book with us today!

#Industrial Air Compressors#Best Industrial Air Compressor#Industrial Portable Air Compressor#Best Industrial Air Compressors#Buy Industrial Air Compressor#Industrial Compressor

0 notes

Text

Digoma Enterprise is an experienced leader in manufacturing industrial shafts in India. Knowledge of the highest standards through sophisticated technology enables us to design shafts. Our team of efficient professionals takes great care in providing precision and durability in making these shafts. With insight into the specific demands of industries, we offer customized solutions according to the different types of machines. Digoma Enterprise has years of experience, and that expertise helps us deliver excellent products every time. Our clients trust us for commitment to quality and reliability. If you want expert industrial shaft manufacturers in India, Digoma Enterprise is the right place for you.

#best air compressor spare parts#best supplier#best quality crankshafts#quality products#handcrafted#3d printing#machine learning#best crankshafts#resources#best air compressors#expert industrial shaft manufacturers in India

0 notes

Text

Dasset Engineering: Your Trusted Partner for High-Performance Crankshafts in India

Crankshafts are a critical engine component, serving as the backbone of power transmission and converting linear piston motion into rotational motion. Whether you’re running an automotive engine, stationary machinery, marine engines, or agricultural equipment, the quality of the crankshaft can significantly impact performance, efficiency, and reliability. At Dasset Engineering, we specialize in providing top-tier crankshafts tailored to meet the diverse needs of various industries, making us the best crankshafts manufacturer and supplier in India.

Why Choose High-Quality Crankshafts?

The crankshaft is subjected to immense pressure, high temperatures, and constant motion. Therefore, it must be designed with the utmost precision and constructed from high-quality materials to withstand these stresses. A well-engineered crankshaft minimizes vibrations, reduces engine wear, and ensures optimal performance. That’s where Dasset Engineering comes in, offering a wide range of forged and cast crankshafts to suit every requirement.

Our Crankshaft Solutions: Forged and Cast Crankshafts

At Dasset Engineering, we pride ourselves on delivering high-performance crankshafts that cater to a broad spectrum of applications:

Forged Crankshafts: Forged crankshafts are manufactured through a process that compresses and molds the metal, resulting in a denser, more durable component. These crankshafts are ideal for high-performance engines, such as those in race cars, heavy-duty trucks, and industrial machinery, where strength and resistance to fatigue are paramount. The forging process ensures minimal internal defects, offering excellent structural integrity and superior tensile strength.

Cast Crankshafts: Cast crankshafts are produced by pouring molten metal into a mold, allowing it to cool and solidify into shape. They are suitable for applications where moderate performance and cost-effectiveness are essential. Our advanced casting techniques produce crankshafts with uniformity, precision, and a smooth surface finish. Cast crankshafts are often used in standard automotive engines, air compressors, and other moderate-duty applications.

Both types of crankshafts are available in fully finished or semi-finished conditions. This flexibility allows us to cater to your specific needs, whether you require a crankshaft ready for installation or one that can be customized further to fit unique engine requirements.

Applications of Dasset Engineering Crankshafts

Our crankshafts are designed to deliver optimal performance across various industries and applications:

Automotive Engines: Our crankshafts provide the strength and balance necessary for passenger cars, commercial vehicles, and racing engines, ensuring smooth operation and longevity.

Stationary Engines: For generators, pumps, and industrial equipment, we supply crankshafts that deliver consistent power and reliability.

Marine Engines: In harsh marine environments, our crankshafts offer superior corrosion resistance and durability.

Agricultural and Industrial Engines: Used in tractors, earthmovers, and heavy machinery, our crankshafts are built to handle tough conditions with ease.

Air and Refrigeration Compressors: We provide crankshafts for compressors that demand high precision and balance to maintain performance and reduce vibration.

Why Dasset Engineering Stands Out

Dasset Engineering has earned a reputation as the best crankshaft manufacturer and supplier in India for several reasons:

Commitment to Quality: We use only the finest materials and the latest technologies to produce crankshafts that meet international quality standards.

Expert Engineering: Our team of skilled engineers ensures each crankshaft is meticulously designed and manufactured to deliver peak performance.

Customization Options: We provide both standard and custom solutions to fit the specific needs of our clients, offering flexibility in terms of design, materials, and finishes.

Stringent Testing: Every crankshaft undergoes rigorous quality control tests to ensure it meets our high standards for durability, performance, and reliability.

Conclusion

Dasset Engineering is your trusted partner for high-performance crankshafts in India. Whether you need forged crankshafts for a high-power application or cast crankshafts for cost-effective solutions, we provide products that promise quality, performance, and longevity. Our crankshafts are designed to drive efficiency and reliability, making us the preferred choice for automotive, marine, industrial, and agricultural applications.

Choose Dasset Engineering for all your crankshaft needs and experience unmatched quality and service. Contact us today to learn more about our offerings and how we can support your business!

#Best crankshaft manufacturer in India#High-performance crankshafts for automotive engines#Forged crankshafts supplier for industrial engines#Cast crankshafts for marine and agricultural applications#Crankshaft manufacturer for air compressors in India#Top crankshaft suppliers for tractors and earthmovers#Buy high-quality forged crankshafts in India#Custom crankshafts for industrial and stationary engines#Durable crankshafts for refrigeration compressors#Crankshafts for heavy machinery engines in India#High-strength crankshafts for race cars and heavy-duty trucks#Fully finished and semi-finished crankshafts suppliers#Affordable cast crankshafts for automotive applications#Leading supplier of crankshafts for agricultural equipment#Customized crankshaft manufacturing services in India

0 notes

Text

Hydraulic oil, a critical component in hydraulic systems, works by transmitting power through a hydraulic pump. It's a non-compressible fluid that transfers force within the system, enabling machinery and equipment to perform various tasks with precision and efficiency. As the oil is pushed through hydraulic lines, it creates pressure, allowing for the controlled movement of pistons, cylinders, and other components. To know more about high temperature grease, visit here: https://bit.ly/how-does-hydraulic-oil-work

#engine oil#industrial lubricants#lubricants#oil lubricated air compressor#best engine oil for bike#bike engine oil

0 notes

Text

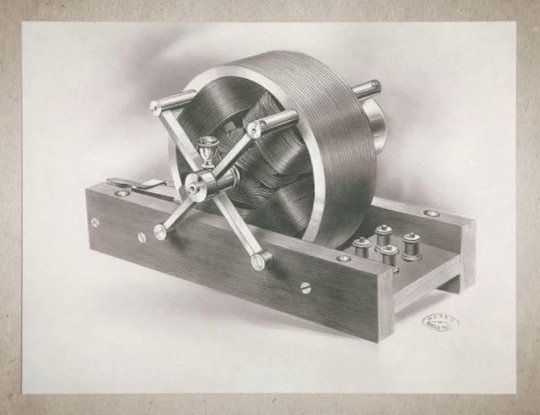

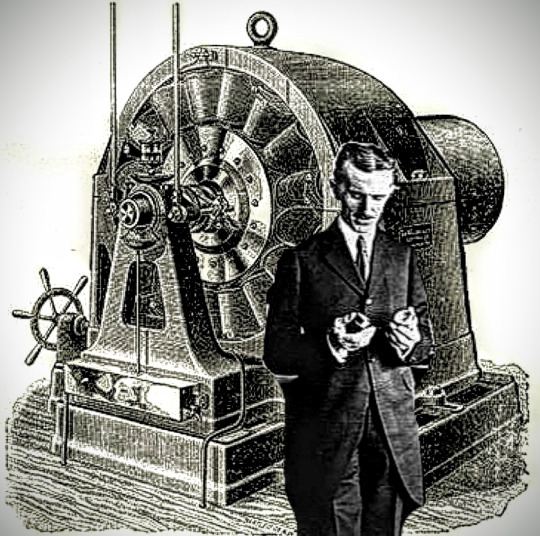

One of the Greatest Inventions of All Time

Nikola Tesla has many revolutionary inventions to his credit, but he is best known for his pioneering work in the development and promotion of alternating current (AC) electrical systems. Tesla's innovations in AC technology revolutionized the generation, transmission, and distribution of electrical power, becoming the foundation for the modern electrical power systems that we use today.

There is a common misconception made that Tesla was the first to invent, or discover, AC, but this is not true. It is well-known that Hippolyte Pixii was the first to discover AC in 1832. Pixii was an instrument maker from Paris who built an early form of an alternating current electrical generator (based on the principle of electromagnetic induction discovered by Michael Faraday), and thus started a new industry in power transmission. Tesla was not the first to discover or invent an AC motor, but he was the first to invent a practical AC induction motor with commercial value that could outperform all other motors. It must be noted that Italian inventor Galileo Ferraris also invented an induction motor similar to Tesla's, but it had no commercial value, and he even admitted himself that it was useless. Tesla's induction motor operates on the principle of electromagnetic induction, properly utilizing a rotating magnetic field that induces a current in a stationary conductor, resulting in rotational motion. The utilization of the rotating magnetic field makes the motor more simple, robust, versatile, efficient, and cost effective in that it has less moving parts reducing the likelihood of mechanical failure (as was common in other motors).

Tesla's induction motor became a fundamental component in the field of electrical engineering and is used today in various applications, being one of the most widely used devices in the world. The motors play a crucial role in transmitting electrical power to homes and businesses. They are commonly used in power generation plants to convert mechanical energy into electrical energy, which is then transmitted through the power grid for distribution to various locations. Induction motors are also widely employed in appliances and machinery within homes and businesses for various applications. These applications include conveyor systems, hoists, cranes, lifts, pumps, fans, ventilation systems, compressors, manufacturing machinery, wind turbines, washing machines, refrigerators, garbage disposals, microwaves, dishwashers, vacuums, air conditioners, robotics, electric vehicles, trains, power tools, printers, etc. Basically, anything that requires a spinning action for power.

The induction motor is widely considered one of the most important inventions in the history of electrical engineering. Its importance lies in its transformative impact on industries, its efficiency and reliability, and its role in the broader electrification of society.

#nikola tesla#science#history#invention#discovery#induction motor#electricity#power#goat#ahead of his time#ahead of our time

152 notes

·

View notes

Text

The Benefits of Partnering with a Trusted Industrial Air Compressor Manufacturer

Industrial air compressors play a vital role in various industries, such as manufacturing, automotive, construction, and more. They are used to power various pneumatic tools and machines, including sanders, drills, and grinders. With so much reliance on these machines, it’s crucial to partner with a trusted industrial air compressor manufacturer. Here are some of the benefits of doing so:

Reliable Quality Products:

Partnering with a reputable industrial air compressor manufacturer means you’ll receive high-quality products that meet industry standards. These manufacturers use the latest technologies and materials to produce top-of-the-line compressors that deliver maximum performance and efficiency. Additionally, these manufacturers provide rigorous quality control processes to ensure that their products meet or exceed customer expectations.

Customized Solutions:

Trusted industrial air compressor manufacturers understand that each business has unique requirements. Therefore, they offer customized solutions to meet specific customer needs. These manufacturers work with their clients to design and develop bespoke compressors that cater to their individual applications. This personalized approach ensures that the compressor is optimized for the client’s operations, enhancing efficiency and productivity.

Expert Advice and Technical Support:

Partnering with a trusted industrial air compressor manufacturer provides access to expert advice and technical support. These manufacturers have knowledgeable and experienced personnel who can help clients choose the right compressor for their applications. Additionally, they provide after-sales services such as installation, maintenance, and repair services. These services ensure that the compressor operates at maximum efficiency and reduces downtime, enhancing productivity and profitability.

Cost Effective Solutions:

Partnering with a trusted industrial air compressor manufacturer is a cost-effective solution for businesses. These manufacturers offer competitive pricing and ensure that their products provide long-term value. Additionally, they offer customized solutions that cater to the client’s needs, reducing unnecessary expenses associated with buying an off-the-shelf compressor. Furthermore, they provide maintenance and repair services that prolong the compressor’s lifespan, reducing the need for costly replacements.

Reliable Delivery and Customer Service:

Trusted industrial air compressor manufacturers understand the importance of timely delivery and excellent customer service. They work closely with their clients to ensure that the compressor is delivered on time and installed correctly. Additionally, they provide ongoing support to ensure that the client’s operations run smoothly. This level of service ensures that the client is satisfied and helps build a long-term relationship with the manufacturer.

Gajjar Compressor is partnering with a trusted industrial air compressor manufacturer provides numerous benefits to businesses. From high-quality products to customized solutions, expert advice, cost-effective solutions, and reliable delivery and customer service, these manufacturers ensure that their clients receive the best value for their investment. Therefore, businesses should prioritize working with reputable industrial air compressor manufacturers to optimize their operations and enhance their productivity and profitability.

2 notes

·

View notes

Text

Invictus provides the best service for equipment rental in the UAE for the oil and gas, marine, power, and construction industries. Our rental fleet covers a wide range of light and heavy equipment, catering to your needs and requirements. With over a decade of experience, we have established ourselves as a reliable partner for our clients’ energy needs, providing top-quality equipment and services.

The main backbone of any energy project are generators and power plants, and we offer a wide range of options to suit your specific needs. Whether you require a small generator for backup power or a large power plant for your operations, we’ve got you covered. Our generators are efficient, reliable, and easy to operate, ensuring an uninterrupted power supply for your operations.

Diesel tanks are essential for storing and transporting fuel, and we offer a range of options to suit your needs. Our diesel tanks are built to last, ensuring the safe and efficient storage of fuel for your operations.

Load banks and transformers are critical components for the testing and commissioning of electrical systems. We offer a range of load banks and transformers that are built to the highest standards, ensuring accurate and reliable testing of your electrical systems.

Portable air compressors are essential for a range of applications, from powering pneumatic tools to providing compressed air for equipment. Our air compressors are built to last, ensuring reliable and efficient operation for your operations.

Mobile tower lights are essential for providing illumination in remote locations, and we offer a range of options to suit your needs. Our tower lights are portable, easy to operate, and built to withstand harsh environments, ensuring reliable lighting for your operations.

High-pressure triplex pumps are essential for a range of applications, from well drilling to pressure testing. Our triplex pumps are built to the highest standards, ensuring reliable and efficient operation for your operations.

Cementing units are essential for the oil and gas industry, and we offer a range of truck and skid-mounted options to suit your needs. Centrifugal pumps are essential for a range of applications, from water transfer to chemical processing. Our centrifugal pumps are available in engine and motor-driven options, ensuring reliable and efficient operation for your operations.

Reverse osmosis plants and storage tanks are essential for the oil and gas industry, and we offer a range of options to suit your needs. Our reverse osmosis plants are built to the highest standards, ensuring reliable and efficient water treatment for your operations.

At Invictus Oil Field, we are committed to providing the best possible service and support to our clients. We offer a range of services, from equipment installation and commissioning to maintenance and repair. Our team of experts is always on hand to provide technical support and advice, ensuring that your operations run efficiently.

In conclusion, Invictus Oil Field is your one-stop destination for all your energy needs. With our extensive range of products and services, we are committed to providing reliable, efficient, and cost-effective solutions for the oil and gas industry. If you are looking for industrial equipment rental in the UAE or across the world, contact us for the best deal.

Generators

Power Plants

Diesel Tanks

Load Banks & Transformers

Portable Air Compressors

Mobile Tower Lights

High Pressure Triplex Pumps

Cementing Units (Truck and Skid Mounted)

Centrifugal Pumps (Engine and Motor driven)

Reverse Osmosis Plant, Storage Tanks (Water and Acid)

2 notes

·

View notes

Text

Receive the Benefits From Preventative Maintenance

Air Solutions Canada believes in preventative maintenance programs.

Neglecting to maintain equipment can lead to it breaking down. The most expensive repairs are usually caused by neglect. It doesn't even take into consideration the costs of your plant going down, or the rental equipment needed during repairs.

We encourage clients to think about preventative maintenance as they do vehicle maintenance.

Do you change your tires when they start to wear or wait until you have an accident on the highway to do so? Do you change your oil every 5,000 kilometers or wait until you have a car that is leaking blue smoke?

However, nobody enjoys having to pay for something they don't really need. This is what we understand. Sometimes maintenance plans can seem expensive and unneeded. Even if your machine is running well, why invest in it?

Air Solutions Canada is a provider of turnkey industrial compressed-air solutions since 1997. Since 1997, we have provided turnkey industrial compressed air solutions to thousands of customers in the GTA as well as throughout Southwestern Ontario. Regular preventative maintenance has many benefits. Neglecting to maintain your system can lead to serious problems.

How can I save money on my company's preventative maintenance program?

You can save money when preventative maintenance is done on time and by qualified staff using quality parts, lubricants, or air tools in Canada. While you may need to spend some money on labour and parts, this is a reasonable investment that will reduce downtime, which can often be exponentially more costly.

Here are some specific results from an air compressor break down:

Lost production

Compressor rental fees (including hook up)

Inconvenience

Refuelling

Rush shipping

Emergency repair costs

Fast decision making

Catastrophic failure that goes beyond economic repair

Unplanned or unbudgeted replacement costs

Panic and Stress

Although it is difficult to place a dollar value on them, you are well aware of the toll they can take.

Is there technology to predict maintenance issues?

We are authorized to sell and install Kaeser's Sigma Air Manager 4.0 system (SAM) as a Kaeser dealer. SAM integrates all the components of your compressed gas system, monitors and analyzes performance in real time and provides alarms and warnings.

Remote diagnostics combined with need-based preventative management ensures maximum reliability in compressed air supply. Permanent availability of compressed system process data and the resulting analysis makes it possible to determine the best time for your compressed air system to be maintained and serviced.

What specific businesses preventative maintenance plans work well for?

Preventative maintenance plans are available for any customer, no matter how large or small. No matter how small the company is, it doesn't really matter whether they are a 1-person operation with a 3HP piston compressor, or a 1,000 person plant with a 5k HP compressor.

Our customers include all industries that use compressed air, including food, beverage, dairy, pharmaceuticals, automotive, paper, electronic, etc.

Air Solutions Canada 29 Innovation Dr, Dundas, ON L9H 7L8 +1-647-691-5694 https://airsolcan.com/

3 notes

·

View notes

Text

Car Garage: The Key to Keeping Your Vehicle in Top Condition

A car is more than just a mode of transportation; it’s an investment that needs proper care and attention. Regular maintenance and timely repairs are crucial to ensure that your vehicle runs smoothly for years to come. One of the best places to get your car taken care of is a reliable car garage. In this article, we’ll discuss the importance of a car garage, the services they offer, and how to choose the right one for your vehicle.

Why Choosing the Right Car Garage Matters

When you choose the right car garage, you’re ensuring that your vehicle receives the best care possible. Your car relies on many complex systems—engine, brakes, transmission, and suspension—each of which requires professional attention at various times. Without proper care, small issues can become major problems, leading to expensive repairs and unexpected breakdowns.

A trustworthy car garage provides the expertise needed to keep your car in good condition. Whether it’s routine maintenance or more serious repairs, an experienced garage can help identify problems early and fix them before they get worse. Moreover, a professional garage will use quality parts and follow industry standards, ensuring that your vehicle is in the best possible hands.

Services Offered by a Car Garage

A car garage offers a wide range of services to keep your vehicle running smoothly. Here are some of the most common services you can expect:

Routine Maintenance: Regular maintenance is essential to extend the life of your car. A good car garage will provide services like oil changes, tire rotations, brake inspections, and air filter replacements. These simple services can prevent costly repairs down the road and keep your car operating efficiently.

Engine Diagnostics and Repair: The engine is the heart of your vehicle. If your car is making unusual sounds, not starting properly, or losing power, an engine diagnostic test at a car garage can help pinpoint the problem. Whether it’s a small issue like a spark plug or a major problem like a faulty timing belt, the garage’s experienced mechanics will find and fix the issue.

Brake Services: Your car’s braking system is crucial for safety. A car garage will inspect the brake pads, rotors, and fluid levels to ensure that everything is functioning properly. If the brakes are worn out or malfunctioning, they can be repaired or replaced promptly to ensure your safety.

Suspension and Steering Repairs: A smooth ride and proper handling are essential for a safe driving experience. If your car feels bumpy, drifts to one side, or makes strange noises while turning, your suspension or steering may need attention. A car garage can inspect and repair these systems, ensuring that your vehicle’s handling is precise and comfortable.

Air Conditioning Services: In hot climates, a working air conditioning system is a must. If your car’s AC isn’t cooling properly, a car garage can check the refrigerant levels, fix leaks, or repair the compressor to ensure you stay comfortable in your vehicle.

A car is more than just a mode of transportation; it’s an investment that needs proper care and attention. Regular maintenance and timely repairs are crucial to ensure that your vehicle runs smoothly for years to come. One of the best places to get your car taken care of is a reliable car garage. In this article, we’ll discuss the importance of a car garage, the services they offer, and how to choose the right one for your vehicle.

Why Choosing the Right Car Garage Matters

When you choose the right car garage, you’re ensuring that your vehicle receives the best care possible. Your car relies on many complex systems—engine, brakes, transmission, and suspension—each of which requires professional attention at various times. Without proper care, small issues can become major problems, leading to expensive repairs and unexpected breakdowns.

A trustworthy car garage provides the expertise needed to keep your car in good condition. Whether it’s routine maintenance or more serious repairs, an experienced garage can help identify problems early and fix them before they get worse. Moreover, a professional garage will use quality parts and follow industry standards, ensuring that your vehicle is in the best possible hands.

Services Offered by a Car Garage

A car garage offers a wide range of services to keep your vehicle running smoothly. Here are some of the most common services you can expect:

Routine Maintenance: Regular maintenance is essential to extend the life of your car. A good car garage will provide services like oil changes, tire rotations, brake inspections, and air filter replacements. These simple services can prevent costly repairs down the road and keep your car operating efficiently.

Engine Diagnostics and Repair: The engine is the heart of your vehicle. If your car is making unusual sounds, not starting properly, or losing power, an engine diagnostic test at a car garage can help pinpoint the problem. Whether it’s a small issue like a spark plug or a major problem like a faulty timing belt, the garage’s experienced mechanics will find and fix the issue.

Brake Services: Your car’s braking system is crucial for safety. A car garage will inspect the brake pads, rotors, and fluid levels to ensure that everything is functioning properly. If the brakes are worn out or malfunctioning, they can be repaired or replaced promptly to ensure your safety.

Suspension and Steering Repairs: A smooth ride and proper handling are essential for a safe driving experience. If your car feels bumpy, drifts to one side, or makes strange noises while turning, your suspension or steering may need attention. A car garage can inspect and repair these systems, ensuring that your vehicle’s handling is precise and comfortable.

Air Conditioning Services: In hot climates, a working air conditioning system is a must. If your car’s AC isn’t cooling properly, a car garage can check the refrigerant levels, fix leaks, or repair the compressor to ensure you stay comfortable in your vehicle.

Transmission Repairs: The transmission is a complex part of your car’s drivetrain. If you’re experiencing difficulty shifting gears, slipping gears, or strange noises, it’s time to visit a car garage. Transmission issues can be costly, but prompt repairs can save you from more expensive replacements later.

Bodywork and Painting: Accidents happen, and when they do, your car might need bodywork. Whether it’s fixing dents, scratches, or more severe damage, a car garage offers services to restore your car’s appearance. They will also provide painting services to make your vehicle look as good as new.

How to Choose the Right Car Garage

With so many car garages to choose from, how do you pick the right one? Here are a few tips to help you make an informed decision:

Reputation: Look for a car garage with a strong reputation for quality service. Check online reviews, ask friends or family for recommendations, and find a garage that has a history of satisfied customers.

Qualified Mechanics: The skill of the mechanics is crucial. Make sure that the car garage employs certified and experienced technicians who are knowledgeable about your car’s make and model.

Pricing Transparency: A trustworthy car garage will provide clear, upfront pricing. Ask for an estimate before any work begins and make sure you understand the cost of parts and labor. Avoid garages that are vague about pricing or try to upsell unnecessary services.

Warranty on Work: A good car garage will offer a warranty on both parts and labor. This shows that they stand behind the quality of their work and give you peace of mind in case something goes wrong after the repair.

Convenience: Consider the location and hours of operation. A car garage that is close to your home or workplace can save you time. Some garages even offer pick-up and drop-off services, making the repair process more convenient for you.

Conclusion

A car garage is an essential part of vehicle ownership, offering both regular maintenance and emergency repairs. Choosing the right garage can help extend the life of your vehicle, keep it running safely, and prevent costly breakdowns. Whether you need an oil change, engine repair, or bodywork, a trusted car garage can provide the expertise and quality service your car deserves. By considering factors like reputation, qualified mechanics, transparent pricing, and warranty, you can find the perfect garage to keep your vehicle in excellent condition for years to come.

0 notes

Text

Buy Best Industrial Air Compressor | Penry Air

Penry Air is your go-to source for Best Industrial Air Compressor online at an affordable price. We carry a wide range of compressors, from 5hp to 10hp, offered by various top manufacturers in the industry. Whether you need to find suppliers or learn more about exporters and traders of industrial air compressors in the USA, we have got you covered. Trust Penry Air for all your industrial compressor needs.

#Air Compressor Online#Industrial Compressor#Buy Industrial Air Compressor#Best Industrial Air Compressors#Industrial Portable Air Compressor#Best Industrial Air Compressor#Industrial Air Compressors

0 notes

Text

Digoma Enterprise is recognized as an industrial shaft manufacturing expert in Ahmedabad. Their staff is well-versed with expertise in making strong and reliable shafts. The manufacturing process goes into minute details for the best output. Digoma Enterprise attracts customers due to their professional approach and quality products. They have advanced technology for making shafts, which functions effectively for a long time. Their expertise and dedication have made them a favorite among industries. Digoma Enterprise is a name to be trusted for quality and service when searching for expert industrial shaft manufacturers in Ahmedabad.

#best crankshafts#best supplier#quality products#best quality crankshafts#3d printing#best air compressor spare parts#best air compressors#handcrafted#resources#machine learning#expert industrial shaft manufacturers in Ahmedabad

0 notes

Text

Why Evaporative Air Cooling is the Best Energy-Efficient Solution for Hot Climates

As temperatures continue to rise, finding an effective and energy-efficient cooling solution is essential. Evaporative air cooling has gained popularity as an eco-friendly and cost-effective alternative to traditional air conditioning. Unlike conventional AC units that rely on refrigerants and compressors, evaporative coolers use water to cool the air, making them ideal for hot and dry climates.

The Benefits of Industrial Air Coolers

For large spaces such as warehouses, factories, and workshops, industrial air coolers offer powerful cooling while significantly reducing energy consumption. These systems: ✅ Consume up to 80% less electricity than traditional air conditioners ✅ Improve indoor air quality with continuous fresh air circulation ✅ Require minimal maintenance and have a longer lifespan ✅ Provide natural and eco-friendly cooling

Why Kitchen AC is Essential for Commercial Kitchens

Commercial kitchens generate excessive heat from cooking equipment, making it crucial to have a reliable cooling system. A Kitchen AC helps in: 🔥 Maintaining a comfortable working environment for staff 🔥 Reducing humidity and improving ventilation 🔥 Preventing food spoilage due to high temperatures

Choose the Right Cooling Solution

Whether you need a cost-effective industrial air cooler or a specialized Kitchen AC, evaporative air cooling stands out as an energy-efficient and sustainable choice. Upgrade your cooling system today and experience better performance with lower operating costs!

Looking for the best cooling solutions? Explore advanced evaporative air cooling options today

0 notes

Text

Best Air Compressors in Faridabad

Advance Equipment, being one of the most promising industrial best air compressor in Faridabad, offers top-of-the-line brands, reliable maintenance, and expert service. We provide energy-efficient compressors for manufacturing, automotive, or commercial applications, ensuring superior performance and durability. Contact us for the best air compressor solutions tailored to your needs.

0 notes

Text

What Is Reefer Repair? A Complete Guide

If you’re in the trucking or logistics industry, you’ve probably heard the term “reefer” before. But if you’re new to the game, you might be wondering: What exactly is reefer repair, and why is it so important?

Let’s break it down in simple terms and discuss why GoGo Logistics and Transport Services in Lanham, MD, is the best choice for reefer repair services.

What Is a Reefer?

A reefer is short for refrigerated trailer—a specially designed truck trailer equipped with a cooling system that keeps perishable goods at a consistent temperature during transportation. These trailers are essential for industries like food distribution, pharmaceuticals, and floral delivery, where temperature-sensitive products must stay fresh.

Since reefers run almost non-stop, their cooling units can wear out or malfunction over time. This is where reefer repair comes into play.

Why Is Reefer Repair Important?

Reefer trailers are the backbone of cold chain logistics. If they break down, it can lead to:

✅ Spoiled Products – A faulty reefer can cause perishable items to go bad, leading to massive financial losses.

✅ Regulatory Issues – The FDA and USDA have strict guidelines on transporting perishable goods. A malfunctioning reefer could mean failing compliance checks.

✅ Delayed Deliveries – A reefer breakdown can disrupt schedules, causing delays and unhappy customers.

That’s why regular maintenance and timely repairs are crucial to keeping these units running smoothly.

Common Reefer Problems and Repairs

Like any machinery, reefer trailers face wear and tear. Here are some common reefer issues and their fixes:

1. Temperature Fluctuations

Problem: The reefer isn’t cooling properly, leading to temperature inconsistencies.

Solution: This could be due to a faulty thermostat, refrigerant leaks, or sensor malfunctions. A reefer technician can diagnose and fix the issue.

2. Compressor Failure

Problem: The compressor is the heart of the refrigeration system. If it fails, the reefer won’t cool at all.

Solution: This often requires a compressor repair or replacement, ensuring the system runs efficiently.

3. Electrical Issues

Problem: Faulty wiring, battery problems, or sensor malfunctions can lead to reefer failure.

Solution: A professional reefer repair technician can troubleshoot electrical problems and ensure all connections are secure.

4. Refrigerant Leaks

Problem: If the refrigerant leaks, the reefer won’t cool properly, and energy consumption increases.

Solution: A certified technician will locate and seal the leak and recharge the refrigerant.

5. Door Seal Damage

Problem: Damaged door seals allow warm air to enter, causing temperature fluctuations.

Solution: Replacing the door seals ensures a tight, efficient cooling system.

Why Choose GoGo Logistics and Transport Services for Reefer Repair?

When it comes to reefer repair, you need a service provider that understands the urgency of keeping your fleet running. That’s why GoGo Logistics and Transport Services in Lanham, MD, is the best choice.

✅ Expert Technicians – Their highly skilled mechanics specialize in diagnosing and fixing reefer issues efficiently.

✅ Fast Turnaround – Time is money in the logistics business. They offer quick repair services to get your reefer back on the road ASAP.

✅ Preventative Maintenance – They don’t just fix problems—they prevent them! Routine maintenance services help avoid costly breakdowns.

✅ 24/7 Emergency Services – Breakdowns don’t always happen during business hours. They offer round-the-clock assistance to keep your reefer running.

Final Thoughts

Reefer repair is essential for any business relying on temperature-controlled transportation. Regular maintenance and timely fixes can prevent major losses, ensure compliance, and keep deliveries on schedule.

If you’re looking for the best reefer repair service in Lanham, MD, GoGo Logistics and Transport Services is your go-to solution. Their expert team, quick turnaround, and 24/7 service make them the ideal choice for keeping your fleet in top shape.

Need reefer repair? Contact GoGo Logistics and Transport Services today and keep your business moving!

0 notes

Text

5 Essential Steps for a Best oil free air compressor installation

Installing an oil free air compressor is crucial for businesses that require clean, contaminant-free compressed air for their operations. Whether you’re using it in the medical, food processing, or electronics industry, a proper installation ensures optimal performance, efficiency, and longevity. Once a compressor is purchased, the next step is installation. Following the manufacturer’s guidelines is essential to ensure durability, optimal performance, and energy efficiency. Unlike traditional compressors, an oil free high pressure air compressor eliminates the risk of oil contamination, making it ideal for sensitive applications. In this guide, we’ll explore five essential steps to install an oil free air compressor efficiently and effectively.

Step-by-step guide to installing oil free air compressor:

Choose the right location

Selecting the perfect place for an oil free air compressor is the first and most essential step in the installation process. A well-chosen location enhances the unit’s efficiency and lifespan while reducing maintenance requirements.

Factors to consider:

Ventilation: Ensure the area is well-ventilated to prevent overheating and allow proper airflow around the compressor.

Temperature control: Keep the compressor in an area with stable temperatures to avoid performance fluctuations.

Accessibility: Allow enough space for maintenance and repairs, ensuring technicians can easily access key components.

Noise reduction: Place the compressor in a soundproofed or less-occupied area to minimize noise disruptions.

Proximity to application: Install the unit closer to the point of use to minimize pressure drops and energy loss.

Prepare a solid foundation:

A stable foundation is important to avoid vibrations, noise, and potential damage to an oil free air compressor. An improper base can lead to misalignment and wear over time.

Key preparations:

Level surface: Ensure the foundation is flat and even to avoid unnecessary pressure on the compressor.

Vibration pads: Install anti-vibration support or pads to absorb shock and reduce operational noise.

Load-bearing capacity: Ensure that the surface can support the compressor’s weight, preventing potential structural damage.

Clear surroundings: Remove obstacles around the unit to allow for free movement of air and personnel.

Electrical and piping connections:

Proper electrical and piping installations are important to ensure an oil free high pressure air compressor runs smoothly without disruptions.

Electrical setup:

Voltage requirements: Confirm that the power supply matches the compressor’s voltage and phase requirements.

Dedicated circuit: Use a separate circuit to prevent power fluctuations and ensure stable operation.

Grounding: Proper grounding is essential to avoid electrical hazards and equipment damage.

Circuit breakers: Install the correct size breakers to handle power surges without tripping.

Piping considerations:

Pipe material: Choose corrosion-resistant materials such as aluminum or stainless steel.

Correct sizing: Use pipes of proper diameter to minimize pressure loss.

Air dryers and filters: Install necessary filtration systems to remove moisture and contaminants from the air supply.

Leak inspection: Regularly check for leaks to avoid energy wastage and maintain efficiency.

Conduct initial testing and calibration:

Before setting an oil free air compressor into full operation, thorough testing and calibration are necessary to ensure optimal performance.

Steps to follow:

Pressure testing: Run the compressor and monitor pressure levels to ensure they meet operational needs.

Noise levels: Check for abnormal noises that might indicate issues, such as loose fittings or misalignments.

Temperature monitoring: Watch the unit’s temperature to confirm it works within the recommended range.

Adjust settings: Calibrate pressure controls, timers, and auto-shutdown features according to your application.

Load testing: Simulate real-world usage to confirm the system can handle demand effectively.

Specify a maintenance routine:

Regular maintenance is key to keeping an oil free air compressor in top condition and avoiding unexpected breakdowns.

Maintenance tips:

Routine inspections: Schedule weekly and monthly checks for wear and tear.

Filter replacements: Replace air filters and separators periodically to maintain air purity.

Lubrication: Even though it’s oil-free, some components might require periodic lubrication to prevent wear.

Drain condensate: Ensure proper drainage of moisture to avoid internal damage.

Professional servicing: Engage with certified technicians for periodic thorough inspections.

Summary:

Installing an oil free air compressor is essential for ensuring efficient performance, energy savings, and long-term reliability. Following these five essential steps—choosing the right location, preparing a solid foundation, ensuring proper electrical and piping connections, conducting initial testing, and specifying a maintenance routine can optimize oil free high pressure air compressor’s performance and extend its lifespan. Investing time in a careful installation process will ultimately pay off in improved efficiency and reduced downtime for your operations. By following these guidelines, businesses can ensure they get the most out of an oil free air compressor, providing a clean and efficient air supply for years to come.

0 notes

Text

What Can You Do With A Jack Hammer?

The tool itself can serve as a guide and aid for a jack-hammer operator in a variety of construction-related applications. The building industry looked significantly different before the invention of instruments like these. How concrete floors, roads, rock points, and other hard surfaces were broken up was completely changed by the development of air compressors and electric and pneumatic jack-hammer equipment.

Nothing compares to the sound of jack-hammers pounding concrete and asphalt, despite the fact that they can be used for a variety of tasks. It is the only method to complete a building project safely and effectively.

To Rent a Jack Hammer, consult with a recognized equipment rental firm that will assess if this equipment meets your needs. Before you start, remember these safety precautions: Knowing How to Use Jack-hammers Often used to break down boulders, blacktop, and pavement, jack-hammers are also known as pneumatic drills. Construction, mining, excavation, and foundation building are among their frequent uses. Jack-hammers are operated by two handles on the top end and shatter hard surfaces with a powered chisel. Electric jack-hammers are typically used for small home repairs. Taking Safety Measures Being able to operate a jack-hammer safely requires knowing how to use and regulate it. Ask the rental tool professional about safe practices and appropriate techniques when you rent the equipment. Make sure that your jack-hammer's electrical cord and all other pieces are securely fastened and in good working order before connecting it. When you're prepared to start, use your legs rather than your back to lift and move the jack-hammer to prevent damage. Measures for Safety Keep yourself safe from electrocution while maintaining the electrical cord condition by wearing it across your shoulder during task operation. Protective equipment consists of strong gloves together with a long-sleeved shirt and long pants, steel-toe boots, and eye protection when operating the jackhammer. To improve control and avoid the chisel jamming, keep the tool at an angle while drilling. Additionally, always disconnect the small jack hammer rental while not in use. Wrapping Up Investing in this equipment may not be the best course of action for your business if you don't anticipate utilizing it frequently or if you prefer to delegate maintenance to someone else. Protecting your bottom line by renting it now will allow you to benefit from the productivity that comes with high-functioning, reasonably priced services with Rent a Jack Hammer without having to wait.

0 notes