#Best Garment Manufacturers In Germany

Explore tagged Tumblr posts

Text

Leading Clothing & Custom Manufacturers in Germany

Discover top-tier clothing and custom clothing manufacturers in Germany. Tailored fashion, quality craftsmanship, and your unique style, all in one place.

#clothing manufacturers in Germany#small order clothing manufacturers in Germany#clothing manufacturers for startups in Germany#custom clothing manufacturer in Germany#best garment manufacturers in Germany#Germany Clothing Manufacturing Company

0 notes

Photo

Hand-washing Apparel In The Sink: How To Do It In The Right Way

It’s a very easy method. Just remember these points mentioned in this blog, Read now.

#Hand-washing Apparel In The Sink#clothing manufacturers in Germany#Wholesale Clothing Suppliers Canada#Best Garment Manufacturers In Germany#Canadian Wholesale Clothing Suppliers

0 notes

Text

Alanic Global: Top Wholesale Clothing Vendors in Germany

Alanic Global offers wholesale clothing and accessories in Germany, Europe, catering to the diverse fashion needs of retailers and businesses.

#custom clothing manufacturers in germany#private label clothing manufacturers in germany#private label clothing suppliers in germany#best garment manufacturers in germany

0 notes

Text

For the hand sewing portions:

- where your needles were manufactured matters VERY MUCH. You need needles made in England, Germany, or Japan. They are made strong, smooth, and very uniform from one another. Needles that were manufactured in China or the USA have a different standard for mass production and are riddled with imperfections that act like tiny little barbs that snag on everything and make sewing more difficult.

- your thimble is meant to be on the finger that anchors the back of your needle while you push it through fabric. It's not supposed to sit on any fingers receiving the needle. If you keep a steady pace, you will not be likely to prick yourself anyway.

- the type of thread you use for a job matters. Silk thread is strong and lays down smoother so you want to use it for button holes or other finishes that could be larger and therefore bulky with thicker threads. Cotton thread is good for hemming and other edge finishes because it doesn't fray easily.

- BEESWAX! There are beeswax items you can buy to run thread over to make it stronger and less likely to tangle.

For machine sewing:

- Iron. IRON! IRON!!! Half of good-quality sewing is pressing and ironing your work as you go. It is tedious, it is constant. DO IT. It will turn out 100 times better 100% of the time.

-with ironing, there are items that are helpful to have and worth investing in if you want to dedicate more time to sewing. First off, an ironing cloth. Just a simple, medium-weight 100% cotton cloth to place over lighter, more sensitive fabrics to keep them from burning, discoloring, or warping under the heat. Especially silks. You can use a scrap of cotton fabric or deconstruct an old t-shirt.

-tailors ham is your best friend when you are getting started in garment making. This little dude helps with pressing curved seams into the shape you want to get the best out of your hard work. PLEASE invest in one filled with sawdust, sawdust reacts to moister from the steam of pressing your fabric that works better with relaxing the fibers than poly-fill.

Things I wish I had read in “beginner” sewing tutorials/people had told me before I started getting into sewing

You have to hem *everything* eventually. Hemming isn’t optional. (If you don’t hem your cloth, it will start to thread. There are exceptions to this, like felt, but most cloth will.)

The type of cloth you choose for your project matters very much. Your clothing won’t “fall right” if it’s not the kind of stretchy/heavy/stiff as the one the tutorial assumes you will use.

Some types of cloth are very chill about threading, some are very much not. Linen doesn’t really give a fuck as long as you don’t, like, throw it into the washing machine unhemmed (see below), whereas brocade yearns for entropy so, so much.

On that note: if you get new cloth: 1. hem its borders (or use a ripple stitch) 2. throw it in the washing machine on the setting that you plan to wash it going forward 3. iron it. You’ll regret it, if you don’t do it. If you don’t hem, it’ll thread. If you don’t wash beforehand, the finished piece might warp in the first wash. If you don’t iron it, it won’t be nice and flat and all of your measuring and sewing will be off.

Sewing’s first virtue is diligence, followed closely by patience. Measure three times before cutting. Check the symmetry every once in a while. If you can’t concentrate anymore, stop. Yes, even if you’re almost done.

The order in which you sew your garment’s parts matters very much. Stick to the plan, but think ahead.

You’ll probably be fine if you sew something on wrong - you can undo it with a seam ripper (get a seam ripper, they’re cheap!)

You can use chalk to draw and write on the cloth.

Pick something made out of rectangles for your first project.

I recommend making something out of linen as a beginner project. It’s nearly indestructible, barely threads and folds very neatly.

Collars are going to suck.

The sewing machine can’t hurt you (probably). There is a guard for a reason and while the needle is very scary at first, if you do it right, your hands will be away from it at least 5 cm at any given time. Also the spoils of learning machine sewing are not to be underestimated. You will be SO fast.

I believe that’s all - feel free to add unto it.

37K notes

·

View notes

Text

Why D-Cut Plastic Bags Are the Go-To Option for Retailers Worldwide

In the bustling world of retail, efficiency and convenience are paramount. One underrated hero in the retail landscape is the D-cut plastic bag. These versatile, handy bags are becoming the go-to option for retailers worldwide. But what exactly makes them so special? Let's explore why D-cut plastic bags are revolutionizing the retail industry.

The Rising Popularity of D-Cut Plastic Bags

Retailers across the globe are constantly seeking ways to improve customer experience while balancing cost-effectiveness. Enter the D-cut plastic bag—a perfect blend of practicality and durability. With a design that caters to a variety of retail needs, these bags have soared in popularity.

What Are D-Cut Plastic Bags?

Simply put, D-cut plastic bags are lightweight, durable bags featuring a cut-out handle in the shape of a 'D'. This design not only makes them easy to carry but also ensures that they can handle heavy items without tearing. Used extensively in grocery stores, clothing shops, and many other retail environments, D-cut plastic bags provide a seamless shopping experience for customers.

Benefits of Using D-Cut Plastic Bags

Durability and Strength

One of the standout features of D-cut plastic bags is their strength. Made from high-quality plastic materials, these bags are designed to withstand significant weight without breaking. This durability ensures that customers can trust these bags to hold their purchases securely.

Cost-Effectiveness

For retailers, managing costs is crucial. D-cut plastic bags are an economical choice, offering a balance between quality and affordability. Their reusability means fewer bags are needed overall, reducing costs in the long run.

Versatility

From groceries to garments, D-cut plastic bags cater to various retail needs. Their multiple sizes and thicknesses make them suitable for different types of products, ensuring that retailers have a go-to solution for all their packaging needs.

The Manufacturing Process at Tilak Polypack

Premium-Grade Materials

At Tilak Polypack, we pride ourselves on using only the best materials. Our D-cut plastic bags start with premium-grade plastic, ensuring longevity and reliability.

Cutting and Shaping

The plastic sheets are meticulously cut into the desired size and shape. This precise cutting process ensures consistency and quality across all our products.

Heat-Sealed Handles

The D-cut handles are heat-sealed to the bag, offering a strong and secure attachment. This technique guarantees that the handles are as durable as the bag itself, providing a comfortable grip for customers.

Why Choose Tilak Polypack?

Quality Assurance

We prioritize quality above all else. Our rigorous quality control measures ensure that every bag meets the highest standards, giving retailers and customers peace of mind.

Customization Options

Understanding the unique needs of retailers, we offer customization options. From logo printing to color choices, our D-cut plastic bags can be tailored to match your brand perfectly.

Global Presence

With a presence in countries like the US, Singapore, Australia, Germany, and more, Tilak Polypack has established itself as a trusted name in the manufacturing of D-cut plastic bags. Our global reach ensures that we cater to retailers worldwide with unmatched reliability.

1 note

·

View note

Text

The Best Garment Manufacturer Knit Composite Factory in Bangladesh

AT A GLANCE Crystal Group consists of Complete Knitting, Dyeing, Dyeing Finishing, Printing, and Garment facilities, intended for Clients who wish to obtain the best quality in their products. In compliance with Int. Standardizations such as Accord, SEDEX, OCS, BCI, GSP certification, AZO free certification, Garments Test, and BSCI, every aspect of operations are maintained at Global Standards. We Specialize in men’s, ladies', children’s, and kids' t-shirts, polo shirts, tank tops, hoodies, jackets, sweatshirts, trousers, leggings, activewear, and undergarments. Crystal Group also hosts a range of companies in various sectors including Aries Corporation (Buying House) Crystal Future Venture Ltd (Telecommunications), C-line (Intercity Luxury Coach Services), Crystal Dairy, Crystal Neerman and Crystal Bricks Company (Construction and Project Development) History Crystal Group was first established in 1991, as a Printing Factory, Operated as a Family Business. Today, Crystal Group Hosts a range of Companies in Multiple Sectors including Telecommunication, Luxury Coach Services, Construction, Dairy Farming, and Buying.

Our Mission Unlike Most Privately Owned Corporations, Crystal Group has never aimed to Maximize Revenue or Profits. Instead, we believe in Giving Back to Society and showing our Nation the Utmost Gratitude for assisting us with our achievements. A company is nothing without its members. We are concerned about everyone’s well-being first; only then can we call ourselves a Successful Organization! We strive to build strong relationships with our clients that outlast the test of time and hope to work hand in hand with them in achieving their Goals! Our Clients and their Requirements are the Top Priority and are handled with the greatest Care and Attention. At Crystal Group, we don’t differentiate ourselves as Employers or Employees. To us, Every Individual Counts and Everyone’s Voices are given a platform to be heard, and each individual’s requirements are considered. We consider ourselves a family where every individual has an important role to play in producing Quality Garments Products for our Clients! . Client List: Buyer Country of Origin Bangladesh Agent Woolworth South Africa Krayons Sourcing LPP Poland Piran Xtex Ireland Dhankora Ravelli Sweden Sisal Apparel New Yorker Germany Sisal Apparel HELM USA Krayons Go Sports France DTO Bel& Bo Belgium DTO London Republic United Kingdom B2Y Grey Wolf United Kingdom B2Y Gemo France Aries Corporation scan wear Denmark Scan wear Falabella Latin America Orient Honeoye La Helle France PDS Asia Star Peacock UK EWM Michael Brandon USA Granville Force Germany Easy Global Orchestra France Vastis Murrin Japan ETO Tex Company Name: CRYSTAL COMPOSITE LTD. (Knit Composite Garments with self-Printing Facilities) Factory Address: Khejur Bagan, Ashulia, Savar, Dhaka.Bangladesh. Year Established: 2006, Advising Bank: Agrani Bank Ltd. UTTARA MODEL TOWN CORPORATE BRANCE HOUSE#09, ROAD#12, SECTOR-6, UTTARA, DHAKA-1230 BANGLADESH SWIFT Code: AGBKBDDH045 Phone No: +88 02 58954590 +88 02 8931220 Department Wise Production Capacity · Knitting - 1,000 kg · Collar Knitting - 25,000 Pcs · Dyeing (Wet Processing) - 12,000 kg · Dyeing (Stentering & Heat Setting) - 15,000 kg · Garments Cutting - 10,000 kg / 32,000 Pcs · Garments Printing - 45,000 Pcs · Garments Sewing - 28,000 Pcs · Garments Finishing - 32,000 Pcs Contact Us: Companies: CRYSTAL COMPOSITE LTD. Email: [email protected] Web: www.crystalgroupbd.com Crystal Knitting dept. Crystal Dyeing dept. Crystal Printing dept. Crystal Garments dept. Factory: 629, Khejur Bagan Ashulia, Savar, Dhaka Bangladesh Mail: [email protected] Managing Director Mr. Sultan Ahmed Mail: [email protected], [email protected] Cell: +880 1714 014214 Director Mr. Shams Bin Sultan Mail: [email protected] Cell:+ 8801315850117, +447940578923 Head of Marketing & Merchandising Md. Mahfuzul Alam Joarder Mail: [email protected] Cell:+ 8801786407784 Crystal Group 629 Khejur Bagan Ashulia, Savar, Dhaka, Bangladesh. E-mail: [email protected] Web: www.crystalgroupbd.com

0 notes

Text

Some Of The Best Sustainable Cyclist Clothing Brands

Sustainable Cyclist Clothing Brands 1. Cadenzia 2. Endura 3. Isadore 4. KOSTÜME 5. Maap 6. Matchy Cycling 7. Rapha 8. TIC CC 9. Universal Colours 10. Velocio 1. Cadenzia

Cadenzia launches in spring 2022 and uses a blend of bamboo viscose and recycled polyester in its cycling jersey. “Bamboo is woven with recycled polyester to create a super soft, high-performance ripstop fabric that is durable and long-lasting,” explains co-founder Rob Stross. “Bamboo is a sustainable fiber, has natural performance benefits and is also one of the fastest growing plants on earth and one of the most sustainable and renewable resources on earth. world." “All of our polyester and nylon fabrics are recycled and Oeko-Tex certified, and we only use YKK Natulon recycled ocean plastic zippers.” The brand will have a line of cycling essentials, with three out-of-season and gender-neutral colors in its range, aiming to eliminate waste.

“Our jersey fabric is made in one color, natural unbleached white and the other colors are then computer printed with eco-friendly dyes directly onto the pattern pieces,” Stross adds. ”. Currently, products verified to contain at least 20% recycled materials can be classified as recycled, and all of its waterproof products are free of PFCs (perfluorinated chemicals used to make fabric is waterproof and very harmful to the environment). Cadenzia products are manufactured in China and shipped to the UK. When the company established its supply chain in Shanghai, it ensured that it was fully localized to the local area so it could track and reduce its carbon footprint, 2. Endura

Endura kit is built to last and be durable, which is why Scottish brand Endura, famous for its durable cycle clothing, was born. Endura incorporates recycled fabrics into its product line in an effort to eliminate waste. “They chose to use recycled fibers on polyester rather than nylon because they have more impact on polyester and solve the problem of plastic bottle waste,” explains Pamela Barclay, product manager at Endura. “This reflects why we don't have more styles with recycled fibers.”

According to the brand, 100% of mountain bike jerseys use recycled fabric compared to 33% of road jerseys. However, the brand hopes to increase this final figure to 100% from 2023. The brand also only markets a product as recycled if it uses more than 50% recycled fibers. In 2020, Endura launched the One Million Trees initiative, in which they pledged to plant one million trees every year for the next 10 years to offset their carbon emissions and aim to become carbon negative by the year 2024. Planting began in Mozambique and has now also begun in Scotland, the brand's country of origin. All Endura products have been PFC-free since 2018, and the company makes all its personalized clothing at its factory in Scotland and the rest in China and Asia. 3. Isadore

The brainchild of ex-pros and brothers Martin and Peter Velits, Isadore releases a sustainability report every year, with details of where its products are produced, progress it has made, as well as new aims and initiatives. The brand is working on core garment traceability and aims to replace all virgin synthetic materials in its products with their recycled counterparts by 2025. Much of Isadore’s kit is made from recycled materials and the brand recently introduced a majority recycled indoor line. ‘The most important part is that there is no performance difference between using virgin synthetics or recycled fabrics,’ explains Martin. ‘Our Alternative line is made entirely from recycled fabrics and we hope to eventually use 90% recycled sources for the synthetic materials.’

Isadore also uses a lot of merino wool in its products. The wool comes from New Zealand and Australia and then gets processed in Germany where the yarns are produced. The fabric is then woven or laminated in the Czech Republic. Isadore only works with Oeko-Tex and Bluesign certified suppliers and manufacturers. Isadore currently doesn’t have the resources to measure and communicate its carbon emissions but is working with its shipping partners to switch to carbon neutral or zero emissions programmes. The brand plans to have an independent audit to go through all its processes in the future. 4. KOSTÜME

KOSTÜME is a very small new brand which has a different business model to others in this guide. Founded by Ed Bartlett, KOSTÜME caps each of its collections to a small number and pre-sells them in advance which it says significantly reduces waste. ‘The fact is that the fashion industry – and that includes cycling apparel – is locked into a business model that creates unfathomable amounts of waste, right throughout the production and retail process,’ explains Bartlett. ‘We are nowhere near a point where so-called sustainable fabrics are going to fix our ecological problems, so the only way to really make an impact is to stop the waste at source, which is where our model comes in. ‘We also do other things like sharing fabric offcuts across multiple products, no hang tags in our packaging, 100% compostable packaging, working with factories with a clear focus on sustainability – but really it’s the limited pre-order model that makes the difference.’

100% of the current range is made from certified recycled materials, and also feature either bluesign, OEKO-TEX or GRS certification. The brand’s main factory is 70% powered by renewable energy, and KOSTÜME donates a percentage of every sale to Stripe Climate, an organisation which is specifically focused on investing in carbon capture and removal solutions. KOSTÜME does not yet track its overall carbon footprint but it has plans to do this in the future, alongside a product repair and takeback scheme. 5. Maap

Australian brand Maap was the first cycling brand to join Bluesign as a full partner. ‘If something is a Bluesign partner, you know that audits have been done and that there will be a certain level of sustainability, which automatically gives you that peace of mind,’ explains Darren Tabone, VP of product at Maap. ‘In our case, Bluesign act like a bit of a big brother, they evaluate your organisation, help review your supply chain and look at all different tiers of the code. Becoming more sustainable is a journey and there’s no real end goal in the sense that you are constantly evolving and learning.’ The brand current uses 95% Bluesign or Oeko-Tex materials and aims to up this to 100% by the end of 2022.

The majority of Maap’s printed fabrics use Green Soul technology which combines sustainable recycled fibres with the environmentally friendly dyeing and finishing processes. It also has had an OffCuts program since 2021 where it makes cycling jerseys out of excess fabric from previous production runs. The bulk of Maap products are made in Europe and it is expanding its Asia source base. The brand is not tracking the carbon emissions yet but this is part of its future plan. It is currently in the process of working out the tonnage of products which are from Bluesign-approved raw materials. 6. Matchy Cycling

Founded in 2016, Matchy Cycling is a French brand based in Annecy. All of its products are made from 30% to 100% recycled materials and the brand is extremely conscious of ensuring local production. ‘We prefer a product made in France using a French fabric that is not recycled than a recycled fabrics made super-far away,’ says Geoffrey Baudoin co-founder of Matchy. ‘All of our bib shorts are made in Italy because the chamois come from Italy so it avoids unnecessary shipping. ‘Some fabrics made by a supplier in France are three times more expensive than usual fabrics but offer a much better durability. It’s a complex topic and we need to look outside of just recycled fabrics even if it’s still an important point for us. ‘All recycled fabrics are not equal, it depends on the supplier and where they come from. The trend has obliged suppliers to invest in these fabrics and we can now say that recycled fibres are almost equal as virgin fibres.’

This year, Matchy begun tracking its footprint and is working with third parties to help understand it. The brand also hopes to become a B Corp by the end of this year. ‘Offering recycled products is one thing but we really try to go deeper as globally we need to reduce our impact which means extending the life cycle of the products, by repairing them, or giving them a second life,’ adds Baudoin. ‘We are working with a local tailor to offer upcycled products this winter.’ All of Matchy’s products are Bluesign-approved and use OekeTex material. The brand does not use any plastic packaging, only recyclable and compostable materials. 7. Rapha

Rapha currently produces 90% virgin materials and 10% environmentally preferred materials (recycled, certified organic or animal welfare versions) by volume but has pledged to flip this on its head by 2025. ‘Some people might be not impressed with 10% today, but it’s all about what we’re trying to get to,’ explains Duncan Money, Rapha’s head of social and environmental impact. ‘It is a journey, and we will be doubling that figure nearly every year to get there.’ Like Endura, Rapha doesn’t publicly market a product as environmentally preferred until this accounts for more than 50% of the product by weight.

Rapha aims to become carbon neutral by 2025, across scope 1, 2 and 3 emissions. - Scope 1 emissions refer to direct GHG emissions that occur from sources that are controlled or owned by an organisation, such as emissions from company vehicles - Scope 2 emissions refer to indirect GHG emissions associated with the purchase of electricity, steam, heat, or cooling, and are a result of an organisation’s energy usage - There are also Scope 3 emissions, which include all other indirect emissions that occur in a company’s value chain It is currently working on its Science-Based Targets and will release these in the middle of the year. Rapha is also one of the founding signatories of the Shift Cycling Culture Climate Commitment. ‘Even if you just looked at it by weight, it’s quite obvious which one we should be addressing first and which one people should be challenging us on,’ says Money. ‘The cycling industry has the potential to be an incredible force for good in the world, but to make the necessary changes we need to take action with urgency, together.’ Rapha is a member of the Sustainable Apparel Coalition and uses Bluesign and Oeko-Tex certified materials 8. TIC CC

In 2019, TIC CC undertook a year-long period of ‘environmental reflection’ which led to 95% of the brand’s SS21 collection being made with recycled fabrics. The brand also reworked its supply chains so that 98% of fabrics and components now come from Europe. For TIC CC co-founder Andrew Monk, taking a holistic approach is an important factor to an evolving sustainability journey. ‘We find that a combination of recycled and virgin fabrics works best,’ says Monk. ‘Of course, this will change as technology improves but you have to take a holistic approach, looking at other impacts including production methodology and distance travelled from source.’

Notably, TIC CC advocates using a Guppyfriend washing bag when washing cycling clothing. Washing cycling kit in this bag prevents microplastic pollution from synthetic micro fibres getting into waterways. TIC CC and all of its key manufacturing partners use 100% renewable energy and the brand uses Bluesign and Oeko-Tex certified materials. TIC CC kit is made in Europe, and its caps are handmade in the UK. The brand has been tracking its emissions internally for the past three years and is considering getting this data accredited in the futu 9. Universal Colours

London-based Universal Colours takes an innovative conscious approach to its products. The brand uses pre-consumer waste and post-consumer waste fabrics and a fluorocarbon-free durable water repellent (DWR), called C0 which is a sustainable, vegetable-based technology. The brand aims to produce considerately sourced cycling clothing but to also educate the consumer on how to care for its garments in order to maximise their longevity. ‘With all our waterproof jackets we give a sample of Nickwax aftercare to reproof it,’ says Will Hurd, a designer at Universal Colours. ‘It’s really important that we communicate to our customers the importance of looking after a product. It’s wrong to assume that customers know what reproofing is.’ But it isn’t straightforward as Hurd explains: ‘We have our own paradox and our own complications because we know our price points are not accessible for everyone. But I think we are very clear and transparent about our fabrics, our costs and have strong ethical policies that we stand by.’

The brand also champions a circular approach, notably in its 100% taste-free biodegradable polyethylene bottle constructed using sugarcane, which can be wholly recycled. At the correct temperature in a landfill or under leaves and soil in a forest, the bio-batch additive activates, and the bottle decomposes into water, humus and gas. The brand says the composting process takes 1-5 years, compared to 450 years for a traditional plastic bottle, and the bottle becomes part of the natural world again. Most of its products are produced at LTP in Lithuania which is a Bluesign-accredited factory, and the brand also works with a factories in China and Taiwan for select products. Universal Colours is currently looking into tracking its emissions and is also a member of 1% for the planet 10. Velocio

The majority of Velocio’s products incorporate recycled or natural fibre, including all of its Spring/Summer jersey line. The brand is aiming to expand the use of these materials into the rest of its collection. Velocio makes its kit in facilities which use renewable energy, primarily solar and produces clothing in small-batch quantities in order to conserve energy, limit overstock and reduce liquidation. ‘It’s ironic given that the bicycle can be such an environmentally friendly mode of transportation, but the industry at large, especially at the aspirational end, has pushed newer/better/faster as their primary marketing language for so long that bikes are essentially disposable,’ says Brad Sheehan, CEO and co-founder of Velocio.

‘That mentality has been absorbed by consumers and it’s the main thing we hope to push back on.’ ‘It’s also not enough to just use recycled fabrics. We’re also looking at the manufacturing partners, fabric suppliers, and end of life phases of our apparel to see how we can improve the entire life cycle.’ Velocio uses Bluesign and Oeko-Tex certified suppliers and is also a member of 1% for the planet. Interested in sustainability and cycling? Check out Read the full article

0 notes

Photo

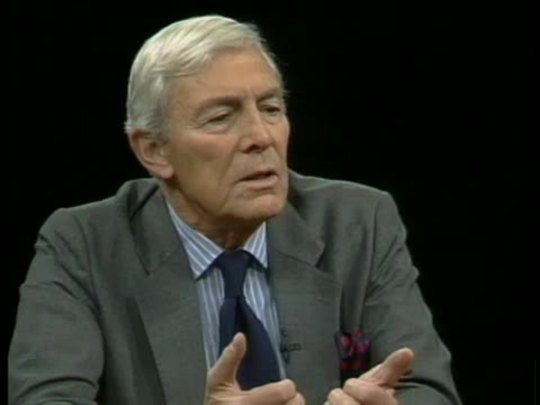

Fashion is an instrument through which you show you belong to a group.

- John Weitz

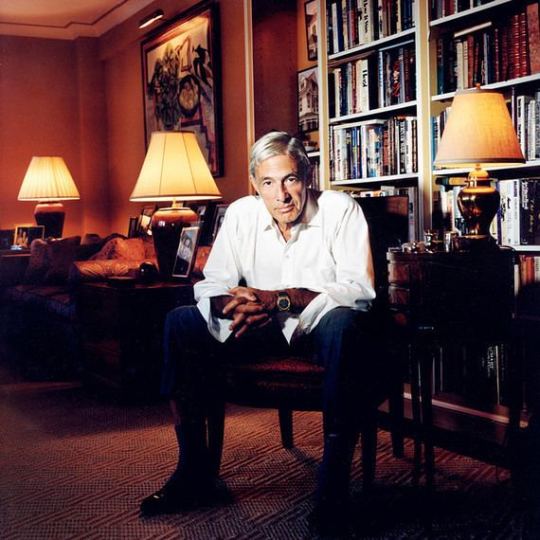

John Weitz was a man for all seasons. Handsome, intelligent, and debonair. He was a novelist, historian, businessman, spy, and above all a renowned mens and ladies fashion designer. James Bond was fiction but he was the real deal.

Born in Berlin in 1923, Hans Werner Weitz was the son of a prosperous clothing manufacturer and German first world war hero, who had won the Iron Cross in the infantry. The family was living well when Christopher Isherwood visited. But they were Jewish, quick to understand what was about to happen, and, in the early 1930s, moved to London, where the young Weitz went to well known private school, St Paul's in London. At St Paul’s he said it was normal to be caned if he didn’t wear morning clothes to class, so he always did with lapels rolled properly. “On weekends we wore blazers…correctly…with the collar up and with a scarf and with brown suede shoes, which were very new then….but never, of course, after six,” he once reminisced.

He was an apt pupil and Oxbridge seemed to be a seamless next stage. However he lasted only a year studying at Oxford University.

Instead he headed off to Paris to begin an apprenticeship with the women's tailor, Captain Edward Molyneaux. In 1938, at the age of 18, Weitz was falsely arrested as an enemy agent while working in the London office of the Paris fashion house Molyneux.

His father was already in America and in 1939, and when France was overuun at the outbreak of the war, Weitz could see he had to get out of Europe. After a tortuous trip through Shanghai, China and later Yokohama, Japan to reach the USA.

In 1943 and now a naturalised American citizen and aged 21, John (as he was now dubbed) was recruited by the Office of Strategic Services (OSS), the forerunner of the CIA, operating in Germany until 1946. He was fluent in both French and German which came in handy in his work during the war in Europe.

He would only ever describe his work in Germany until 1946 as "sensitive," though, much later, his publisher John Fairchild told the New York Times that Weitz "loved all that romantic part of his past. He was a perfect gentleman." What is known about his OSS work was that he was part of a 1944 mission in support of the plan to assassinate Adolf Hitler formulated by German Wehrmacht officers, under the instigation of Claus von Stauffenberg. After the war, Weitz helped to liberate the Dachau concentration camp

Weitz was also a man with connections, as when he confirmed that a former OSS boss had shown him gangster blackmail photos of the longtime FBI director J Edgar Hoover with his boyfriend, Clyde Tolson. In the 1970s, Weitz's friend Albert "Cubby" Broccoli, producer of the James Bond movies, teased him about his resemblance to the character - adding that Weitz was better looking.

Weitz returned to New York in the 1940s, a young garment trader well placed to pick up on American women's new taste for informal sportswear, leather coats and men's shirts.

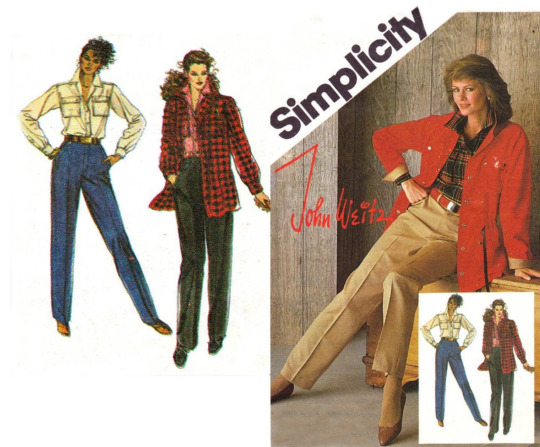

Weitz founded his women’s sportswear business, John Weitz Designs, in 1954, and launched men’s wear a decade later. For his women’s wear, he often tailored the best of men’s designs for the female figure, with looks such as shaped houndstooth checked coats, formal shirts with jet buttons and cuff links, and corduroy pants.

“Whatever happens in women’s pants comes from the men’s pants,” he said in 1965.

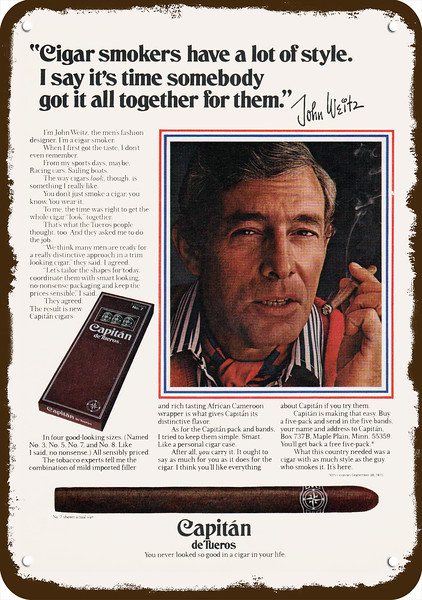

In the Sixties, Weitz began phasing out his women’s and children’s apparel business to concentrate on men’s wear. By 1977, Weitz had 18 licensees and $150 million worldwide retail sales of products bearing his label, including sunglasses, belts, umbrellas and even cigars. That year, he also reentered the licensed women’s apparel category, because, he said, he saw the need for an alternative to coordinated sportswear merchandising.

“I’m rather sick of seeing American working women treated as children with prepackaged clothes,” Weitz said at the time.

In 1964, he launched his menswear range, applying the technical standards of manufacture he had learned from his father. Unusually, in that era of obsolescence, he went for ease and wear - clothes, he said, should be worn "as if they are old and valued friends".

Of course he committed fashion faux pas here and there. This was the 1970s after all. But the previaling zeitgeist had to be understood before we laugh or wince at the designs today. None left a lasting impression quite as strong as the posthumously awarded ‘king of the ‘70s’—the leisure suit.

Once hailed by top designers John Weitz and Calvin Klein as a garment with staying power, the leisure suit was ostracized from the kingdom of en vogue before the 1970s ever came to an end. Just as it had swiftly risen to the top of fashion, it fell into the leagues of comic relief twice as fast. Today we laugh at the cheesy styles, feminine colors, and garish plaids. But what we seem to have forgotten is that the leisure suit did more than just provide us with years of laughs. The leisure suit helped men open themselves up to new ideas in clothing. It allowed them to experiment outside of the style box they’d been locked in for too many years. If the 1970s had passed without the leisure suit, “business casual” for men might never have developed as soon as it did. The leisure suit may have been a fashion catastrophe, but it laid the groundwork for men to strut their fashion stuff for decades to come.

He was his own dream model - "healthy and scrubbed," with a flat stomach - and toured stores showing off his new line of narrow, European-cut shirts, half the width of the standard American style. His navy suit, alphabet-patterned ties and aubergine socks are commonplace now, but were then part of a new, executive self-presentation, more about putting it together than design. By 1974, he had become a household name, with annual earnings of $18m and a Coty Award, fashion's prize for innovation.

Weitz skilfully let his name generate money by itself, using witty advertisements to maintain a high public profile. A poster on the back of New York buses announced, for example, "She ditched him, John Weitz ties and all".

He also used his writing abilities to promote the business image: his book Man In Charge, The Executive's Guide To Grooming, Manners And Travel (1974), became a bestseller, but was really just part of his trade in suavity and martinis. Even his headquarters was above Madison Avenue. There were also two well received novels, Friends In High Places and The Value Of Nothing.

Two other books, however, marked out Weitz as a historian of the Nazi period. He wrote Hitler's Diplomat, a biography of the third reich foreign minister, Joachim von Ribbentrop, and Hitler's Banker, about the president of the Reichsbank, Hjalmar Horace Greeley Schacht.

He was repeatedly asked about reconciling the sale of navy blazers and researching von Ribbentrop, but he saw no clash: "Who else but a fashion designer would understand such a worldly man?" Weitz certainly comprehended the Nazis genius for the projection of personal image, and, though never a major historian, established a sufficiently solid reputation as a researcher that the president of Germany consulted him on the subject.

Meanwhile, he lived the life of his executive book, raced cars at Sebring in the 1950s, and belonged to the New York Yacht Club and the Vintage Sports Car Club. In his Park Avenue apartment, a Chinese chef cooked dinner parties for his friends - among them the novelist Tom Wolfe- and film people.

In 1964, he married the actor Susan Kohner, and their two sons, Christopher and Paul, remembered Ingmar Bergman taking them to the circus, and film directors John Huston and Billy Wilder dropping in for coffee -"just nice old men around the house every once in a while". The boys' chief complaint about their father was that he made them wear blue blazers. Both Chris and Paul would go on to forge their own Hollywood careers as the producers and directors of such movies as American Pie (1999) and About a Boy (2002).

John Weitz had a deep fondness for cats which raised eyebrows amongst his more masculine following. But Weitz was unrepentent. Weitz adored their elegance, and was quoted on them more often than on the Nazis. "Even overweight cats instinctively know the rule: when fat, arrange yourself in slim poses," he wrote.

John Weitz died on 3 October 2002 at the grand old age of 79. He remained a dashing figure and aged well - like the American version of Gianni Agnelli. He had throughout his life the air of adventure, even danger. He was stylish fashion designer who lived up to the executive image of his clothes. It’s no wonder no one balked when he made a name for himself with the nowadays unthinkable ad slogan, “John Weitz designs for the woman who wishes her husband could afford her.” His was a life well lived.

#john weitz#weitz#quote#fashion#spy#history#style#menswear#gentleman#icon#oss#germany#war#america#europe#culture#society

53 notes

·

View notes

Text

Ganz Teddy Bears - A Collectible

The appeal of a Ganz teddy bear is both sincere and tremendous. They have been at the start created in the Fifties, and are nevertheless being made these days. These teddy bears provide you with a shoulder to cry on, and love you unconditionally. Sometimes, if you listen closely, they may let you know "take me domestic." The love affair among us and those Ganz teddy bears shows no signs and symptoms of slowing down.

Often used to calm and reassure kids, that is a long-lasting and conventional filled animal. The fee of those teddy bears has currently improved as they've turn out to be collector's items. It may be very difficult to photo a global that did not have the Ganz teddy bears to provide a listening ear and a heat hug to each young and old.

The teddy undergo has been part of the arena for a long term. The records of the teddy bear started out inside the 12 months 1902. Not best did it make its front into the United states that 12 months, but additionally made its entrance in Germany.

In the US, the teddy bear got its name from a caricature featuring Theodore Roosevelt. In the early 1900s, society female favoured to hold those bears around with them and children had pix excited by their cuddly buddies. U.S. Toy makers were developing bears of all exceptional sizes and styles, such as curler skating teddies and ones with eyes that lit up. However, our companies had to cope with lots of opposition from German bear makers, so quite a few of them went out of enterprise.

The German tradition of toy making is legendary and the advent of pleasant teddy bears was made well-known by businesses like Bing, Schuss, and Herman, combined with Staff. This laid the groundwork for an innovative type of industrially produced bear - the artist-designed manufactured endure. Currently this form of bear is bought with the aid of Ganz and it offers collectors the risk to very own an artist-designed bear this is much less high priced due to the fact it is mass produced.

A lot of clothing and garments for teddy bears are also available. You can examine making non-public teddy bears on-line or via purchasing books supposed for that purpose. Everyone really desires the teddy bear's present of unconditional acceptance, love, and reassurance more than ever.

Teddy bears in karachi had been a favourite toy because the beginnings of the twentieth century. Teddy bears had been evolved at about the equal time in both America and Germany. In America, the toys had been based on a cartoon involving President Theodore Roosevelt, and became a favourite of society women. In Germany, artist designed bears were to be had from numerous manufacturers, and blanketed a high degree of element and customisation.

1 note

·

View note

Photo

We are the manufacturer of Garments like sportwear, fashion wear, workwears, casual and etc. We are offering to our customers best quality in affordable price. Our Offers: 1: Free Mock Up 2: Free R & D 3: Customized Branding(Printing, Embroidery etc) 4: Customized Design 5: Customized Labels 6: Customized Hangtags 7: Free Photoshoot of Product You can contact us without any hesitation. Our Email: [email protected] . #suzarintl #cycling #tshirt #legging #ootd #leggings #fashionstyle #followme #likeforlike #tshirts #modeling #fashionmodel #sportsbra #usa #falloutfits #top #tiedye #videos #socceruniform #feelgood #fashionphotography #instagood #soccerjersey #sportswear #soccer #soccer #soccerjersey #trending (at Germany - Deutschland) https://www.instagram.com/p/CRc2lJcL0bb/?utm_medium=tumblr

#suzarintl#cycling#tshirt#legging#ootd#leggings#fashionstyle#followme#likeforlike#tshirts#modeling#fashionmodel#sportsbra#usa#falloutfits#top#tiedye#videos#socceruniform#feelgood#fashionphotography#instagood#soccerjersey#sportswear#soccer#trending

1 note

·

View note

Photo

choukaath_bd

We Choukaath (BD) is a leading company with over 5 years manufacturing experience in Dhaka, Bangladesh . We deal with all sorts of fashion garments & textiles and support our buyers with utmost sincerity. We are delighted to offer our services to all apparels buyers in the world. We

are exporting both Woven and Knitted garments.We do have qualified work force & maintain a strong liaisons with the production houses to source out the right goods as per buyers demand. Our merchandisers are highly educated, professionally trained people. Basically, our professional expertness, skilled work force an strong connections with the manufactures are our main asset. We always take care of our buyers and put highest degree of attention to the buyers needs.

We are looking for a buyer which is willing to cooperate in long term business. We provide our products with best quality and reasonable price. Our clients range from UK, USA, Canada, Spain, Germany, Denmark, Poland.

1 note

·

View note

Photo

Choosing a Jumpsuit: Remember These 7 Quality Tips

Have you recently discovered your love for jumpsuits? jumpsuits never go out of style? Reading the blog might help!

#Wholesale Womens Jumpsuits Supplier#Wholesale Germany Clothing Manufacturers#Wholesale Womens Jumpsuits#Clothing Manufacturers In Germany#Best Wholesale Clothing Suppliers Canada#Best Garment Manufacturers In Germany

0 notes

Text

Top Footwear Brands in India - Action EVA Flotter

Action EVA Flotter - Daily Use Slippers

If there's one industry that has an evergreen, ever-running market; that's apparel and footwear. The industry of garment and footwear sees the most predominant evolution of all other industries. Count in new styles, trends established by celebrities, or even just plain requirement for comfort, the industry of footwear and fashion goes through the most drastic changes. Along with emerging trends in fashion, footwear is a significant concern for most of the population. Whether they ought to wear formals to work or wear fancy heels to a party; a variety of footwear always comes handy. Irrespective of whether you have the interest or acumen in fashion, it is still essential to wear appropriate footwear based on the occasion. For now, let's concentrate on comfortable flip flops and easy sliders. That being said, the current unpredicted times of COVID has left everyone weary and tired at home. What we all slog for everyday comfort at home. So, whether you wish to jazz up your mood while working at home or want to stay as comfortable as possible, there are these top 5 local footwear brands in India that have defined comfort to another level. With the taste of the customer's changing as quickly as you switch a movie on Netflix, these Indian footwear brands have innovated their products to match our comfort and ease. What are you waiting for? Come on, let's check out the list of the top 5 Indian footwear brands that have changed the way we look at comfort in our shoes.

Top 5 Indian Footwear Brands in India: Proudly Made in India and Local Action Eva (Action Footwear)

Coming first in the list of the most well-known footwear brands in the country is a brand that hails from the capital city of India. A newbie in the list, Action Eva has quickly garnered a lot of appreciation basis the comfort, durability, and variety the brand offers over their stores. Boasting of a commitment to quality and products that showcase higher international standards, the products from Action Footwear speak for themselves. Action Eva has quickly reinvented our standard, traditional flip-flops by designing sandals that carry fashion and comfort, together. Their elegant and stylish array of flip-flops are appropriate to be worn everywhere and anytime. Action Eva is durable and affordable; isn't that the best you can ask for?

Lakhani The "Made-in-India" premium and famous footwear brand in India, Lakhani has made its way into the market ever since 1966. With it's first-ever comfortable to wear creation that became popular in most Indian Households, Lakhani has moved to new heights. While facing a tremendous fall in between, Lakhani is topping the charts again with it's revamped style and fresh designs that are loved. With it's newly initiated concept of manufacturing footwear for people from all walks of life, the company has gained it's lost hold back. Now, Lakhani sells footwear ranging from Rs. 300 to Rs. 1500. This includes a variety of footwear. SKO SKO is the brand that started years ago but was revived by Nishant Kanodia, an investment banker with an attempt to change the aesthetics. The story behind the brand is intriguing as the brand was formerly a boutique footwear space in the country that was run by his parents. It was in a eureka moment that Nishant decided to come back to his roots and give the brand a new definition with Scandinavian aesthetics and styles that are highly inspired by Danish fashion. SKO shoes may pinch your pockets, but the international quality cannot be denied. SKO, with what started as an array of shoes and sandals in a shoe boutique, is now available on most of the online shopping websites. You can easily purchase at Myntra, Flipkart, and Amazon. Liberty Shoes Now, how can one miss counting Liberty Shoes in the list of the top 5 best Indian Footwear brands that made it big? Currently, operating with a turnover that would knock down any other footwear giant, Liberty Shoes is an example of excellent quality and long-lasting commitment. Their shoes range from fancy footwear for women to kids' shoes for over 60 years, now. The brand has grown immensely in appreciation that they now also deliver in destinations like France, Germany, and Italy. Who thought Liberty would become a giant when we were all in school? Liberty currently has more than 150 distributors, 400 independent showrooms, and close to 5000 multi-brand outlets. Relaxo Started as a household name and now a giant headquartered in Delhi, Relaxo might be the last in the list, but it's not the least. Relaxo, the brand which was initiated in the year 1976 by two brothers Ramesh Kumar Dua and Mukund Lal Dua has now become a popular name in Indian households. With its wide variety of beautiful and comfortable footwear, Relaxo manufactures more than six lakhs pairs, every day. With sub-brands like Bahamas, Schoolmate, and Sparx, etc., Relaxo meets quality with fashion and trends. The names present in the list stand synonymous with high-quality, durability, and comfort. Above all, they are all trusted brands that manufacture an excellent mix of affordability, design, and convenience.

#daily use slippers#action#best casual footwear#best slippers for men#Best slippers for women#Best kids slipper#action eva flotters

1 note

·

View note

Video

tumblr

Introduction: We "Romaisa International" are Manufacturer, Importers & Exporters of Leather Garments and Gloves. The major range of our offered products are all kinds of leather jackets, leather vest, leather pant, leather wallets, leather belts, leather ladies purse and handbags and also all range of gloves. That’s the right place for you to choose leather products. We shall be pleased to provide samples and quote on hearing from you about your specific requirement, we can also manufacture gloves according to your designs and pattern. We are eager serve you are esteemed and prestigious organization on the basis of our best quality products, very reasonable prices, just in time delivery and excellent services. Leather Types and Use: A large variety of sheep skins, goat skins, buffalo skins as well as cow skins are selected for producing various types of garments like jacket, coats, trousers, skirts, chaps trousers, vests and ladies & men fashion garments with utmost attention towards quality and selection of finest grades of skins of full aniline and semi-aniline qualities in various colours according to the trends and fashion. Motorbike Suits Leather Types: Motorbike suits are traditional leather clothing. This is because motorcycle suits made of leather are an excellent protection against weather and the cold. Leather is breathable and therefore the ideal compromise between safety, weather protection and comfort. Leather motorcycle suits are clearly superior to those made from textiles in the event of traffic accidents due to their high resistance. Motorcycle leather is usually cow leather. Because of the weather protection requirements, almost always smooth leather is processed. Romaisa International is successfully selling a suit made of cowhide leather and nubuck leather. Motorbike Suits Embroidery: Embroidery on the motorcycle suit and motorbike jackets by Romaisa International. - A water drop on the freshly waterproofed cowhide leather and nubuck leather. Well-worked suits are waterproofed at the seams. For this purpose, cotton-coated synthetic yarns are used. The plastic yarn is weather-resistant and tear-resistant, and the cotton swells in moisture and thereby seals the seam holes. Dark colours are mostly processed. On dark colours, insects that burst on the suits during fast driving are not that visible. On bright colours, everything is more clearly visible and the cleaning effort is then significantly higher. Instead, the garment glided gradually into the business world on the back of a pair of otherwise unrelated trends: the leather jacket’s shift from emblem of rebellion to status symbol, and the casual culture of corporate America. Quality Policy: Quality has always been our focus and, in order to meet international quality requirements accessories are directly imported. The accessories department not only deals in retailing all kinds of leather accessories at its own retail outlets, but also exports these goods to all ports of the world. The garments and the accessories division supplies to leading brands in Germany, UK, Spain, France, Argentina and USA. Certificates & Memberships: We are proud of its following certificates. -- CE Certificates of all our products. -- Member of Sialkot Chamber of Commerce & Industry, Sialkot, Pakistan (SCCI) -- Pakistan Leather Garments & Association, Sialkot, Pakistan (PLGMEA) Price: Pls contact us for updated Final Price Size Specification: From XS-XL, We also provide OEM&ODM Service Delivery Time: Samples / Upon we received the payment, sample will be sent out in 7-10 Days For Small orders, we can ship as customers instruction, DHL, DPD, FEDEX or normal Sea Freight is all available. For Big order, Seaway or Airway is all available as buyers instruction, production time can be negotiated by buyers. We sincerely hope we could offer the best services and competitive price for all the customers as well products quality over 5 years, warmly looking forward to working in cooperation with the worldwide clients. Thanks and Keep in Touch for more Inquires and Thanks to visit our Website, Feel Free to Contact Us. Thanks with Regards Romaisa International C.E.O http://www.romaisaintl.com https://romaisaintl.business.site/ https://www.facebook.com/romaisainl/ https://www.instagram.com/romaisaintl/

#romaisa international#leather garments#Motorbike Gloves#Motorbike Suits#one piece motorbike suit#leather jackets men#leather jacket women#fashion jackets#fashion gloves#welding gloves#working gloves#mechanics gloves#motocross gloves#gym gloves#motorcycle gloves#cycling gloves#leather coats#romaisa leather suppliers#leather supplier uk#leather garments manufacturers#leather shoes#fitness gears#leather belts#leather wallets

3 notes

·

View notes

Text

Some Of The Best Sustainable Cyclist Clothing Brands

Sustainable Cyclist Clothing Brands 1. Cadenzia 2. Endura 3. Isadore 4. KOSTÜME 5. Maap 6. Matchy Cycling 7. Rapha 8. TIC CC 9. Universal Colours 10. Velocio 1. Cadenzia

Cadenzia launches in spring 2022 and uses a blend of bamboo viscose and recycled polyester in its cycling jersey. “Bamboo is woven with recycled polyester to create a super soft, high-performance ripstop fabric that is durable and long-lasting,” explains co-founder Rob Stross. “Bamboo is a sustainable fiber, has natural performance benefits and is also one of the fastest growing plants on earth and one of the most sustainable and renewable resources on earth. world." “All of our polyester and nylon fabrics are recycled and Oeko-Tex certified, and we only use YKK Natulon recycled ocean plastic zippers.” The brand will have a line of cycling essentials, with three out-of-season and gender-neutral colors in its range, aiming to eliminate waste.

“Our jersey fabric is made in one color, natural unbleached white and the other colors are then computer printed with eco-friendly dyes directly onto the pattern pieces,” Stross adds. ”. Currently, products verified to contain at least 20% recycled materials can be classified as recycled, and all of its waterproof products are free of PFCs (perfluorinated chemicals used to make fabric is waterproof and very harmful to the environment). Cadenzia products are manufactured in China and shipped to the UK. When the company established its supply chain in Shanghai, it ensured that it was fully localized to the local area so it could track and reduce its carbon footprint, 2. Endura

Endura kit is built to last and be durable, which is why Scottish brand Endura, famous for its durable cycle clothing, was born. Endura incorporates recycled fabrics into its product line in an effort to eliminate waste. “They chose to use recycled fibers on polyester rather than nylon because they have more impact on polyester and solve the problem of plastic bottle waste,” explains Pamela Barclay, product manager at Endura. “This reflects why we don't have more styles with recycled fibers.”

According to the brand, 100% of mountain bike jerseys use recycled fabric compared to 33% of road jerseys. However, the brand hopes to increase this final figure to 100% from 2023. The brand also only markets a product as recycled if it uses more than 50% recycled fibers. In 2020, Endura launched the One Million Trees initiative, in which they pledged to plant one million trees every year for the next 10 years to offset their carbon emissions and aim to become carbon negative by the year 2024. Planting began in Mozambique and has now also begun in Scotland, the brand's country of origin. All Endura products have been PFC-free since 2018, and the company makes all its personalized clothing at its factory in Scotland and the rest in China and Asia. 3. Isadore

The brainchild of ex-pros and brothers Martin and Peter Velits, Isadore releases a sustainability report every year, with details of where its products are produced, progress it has made, as well as new aims and initiatives. The brand is working on core garment traceability and aims to replace all virgin synthetic materials in its products with their recycled counterparts by 2025. Much of Isadore’s kit is made from recycled materials and the brand recently introduced a majority recycled indoor line. ‘The most important part is that there is no performance difference between using virgin synthetics or recycled fabrics,’ explains Martin. ‘Our Alternative line is made entirely from recycled fabrics and we hope to eventually use 90% recycled sources for the synthetic materials.’

Isadore also uses a lot of merino wool in its products. The wool comes from New Zealand and Australia and then gets processed in Germany where the yarns are produced. The fabric is then woven or laminated in the Czech Republic. Isadore only works with Oeko-Tex and Bluesign certified suppliers and manufacturers. Isadore currently doesn’t have the resources to measure and communicate its carbon emissions but is working with its shipping partners to switch to carbon neutral or zero emissions programmes. The brand plans to have an independent audit to go through all its processes in the future. 4. KOSTÜME

KOSTÜME is a very small new brand which has a different business model to others in this guide. Founded by Ed Bartlett, KOSTÜME caps each of its collections to a small number and pre-sells them in advance which it says significantly reduces waste. ‘The fact is that the fashion industry – and that includes cycling apparel – is locked into a business model that creates unfathomable amounts of waste, right throughout the production and retail process,’ explains Bartlett. ‘We are nowhere near a point where so-called sustainable fabrics are going to fix our ecological problems, so the only way to really make an impact is to stop the waste at source, which is where our model comes in. ‘We also do other things like sharing fabric offcuts across multiple products, no hang tags in our packaging, 100% compostable packaging, working with factories with a clear focus on sustainability – but really it’s the limited pre-order model that makes the difference.’

100% of the current range is made from certified recycled materials, and also feature either bluesign, OEKO-TEX or GRS certification. The brand’s main factory is 70% powered by renewable energy, and KOSTÜME donates a percentage of every sale to Stripe Climate, an organisation which is specifically focused on investing in carbon capture and removal solutions. KOSTÜME does not yet track its overall carbon footprint but it has plans to do this in the future, alongside a product repair and takeback scheme. 5. Maap

Australian brand Maap was the first cycling brand to join Bluesign as a full partner. ‘If something is a Bluesign partner, you know that audits have been done and that there will be a certain level of sustainability, which automatically gives you that peace of mind,’ explains Darren Tabone, VP of product at Maap. ‘In our case, Bluesign act like a bit of a big brother, they evaluate your organisation, help review your supply chain and look at all different tiers of the code. Becoming more sustainable is a journey and there’s no real end goal in the sense that you are constantly evolving and learning.’ The brand current uses 95% Bluesign or Oeko-Tex materials and aims to up this to 100% by the end of 2022.

The majority of Maap’s printed fabrics use Green Soul technology which combines sustainable recycled fibres with the environmentally friendly dyeing and finishing processes. It also has had an OffCuts program since 2021 where it makes cycling jerseys out of excess fabric from previous production runs. The bulk of Maap products are made in Europe and it is expanding its Asia source base. The brand is not tracking the carbon emissions yet but this is part of its future plan. It is currently in the process of working out the tonnage of products which are from Bluesign-approved raw materials. 6. Matchy Cycling

Founded in 2016, Matchy Cycling is a French brand based in Annecy. All of its products are made from 30% to 100% recycled materials and the brand is extremely conscious of ensuring local production. ‘We prefer a product made in France using a French fabric that is not recycled than a recycled fabrics made super-far away,’ says Geoffrey Baudoin co-founder of Matchy. ‘All of our bib shorts are made in Italy because the chamois come from Italy so it avoids unnecessary shipping. ‘Some fabrics made by a supplier in France are three times more expensive than usual fabrics but offer a much better durability. It’s a complex topic and we need to look outside of just recycled fabrics even if it’s still an important point for us. ‘All recycled fabrics are not equal, it depends on the supplier and where they come from. The trend has obliged suppliers to invest in these fabrics and we can now say that recycled fibres are almost equal as virgin fibres.’

This year, Matchy begun tracking its footprint and is working with third parties to help understand it. The brand also hopes to become a B Corp by the end of this year. ‘Offering recycled products is one thing but we really try to go deeper as globally we need to reduce our impact which means extending the life cycle of the products, by repairing them, or giving them a second life,’ adds Baudoin. ‘We are working with a local tailor to offer upcycled products this winter.’ All of Matchy’s products are Bluesign-approved and use OekeTex material. The brand does not use any plastic packaging, only recyclable and compostable materials. 7. Rapha

Rapha currently produces 90% virgin materials and 10% environmentally preferred materials (recycled, certified organic or animal welfare versions) by volume but has pledged to flip this on its head by 2025. ‘Some people might be not impressed with 10% today, but it’s all about what we’re trying to get to,’ explains Duncan Money, Rapha’s head of social and environmental impact. ‘It is a journey, and we will be doubling that figure nearly every year to get there.’ Like Endura, Rapha doesn’t publicly market a product as environmentally preferred until this accounts for more than 50% of the product by weight.

Rapha aims to become carbon neutral by 2025, across scope 1, 2 and 3 emissions. - Scope 1 emissions refer to direct GHG emissions that occur from sources that are controlled or owned by an organisation, such as emissions from company vehicles - Scope 2 emissions refer to indirect GHG emissions associated with the purchase of electricity, steam, heat, or cooling, and are a result of an organisation’s energy usage - There are also Scope 3 emissions, which include all other indirect emissions that occur in a company’s value chain It is currently working on its Science-Based Targets and will release these in the middle of the year. Rapha is also one of the founding signatories of the Shift Cycling Culture Climate Commitment. ‘Even if you just looked at it by weight, it’s quite obvious which one we should be addressing first and which one people should be challenging us on,’ says Money. ‘The cycling industry has the potential to be an incredible force for good in the world, but to make the necessary changes we need to take action with urgency, together.’ Rapha is a member of the Sustainable Apparel Coalition and uses Bluesign and Oeko-Tex certified materials 8. TIC CC

In 2019, TIC CC undertook a year-long period of ‘environmental reflection’ which led to 95% of the brand’s SS21 collection being made with recycled fabrics. The brand also reworked its supply chains so that 98% of fabrics and components now come from Europe. For TIC CC co-founder Andrew Monk, taking a holistic approach is an important factor to an evolving sustainability journey. ‘We find that a combination of recycled and virgin fabrics works best,’ says Monk. ‘Of course, this will change as technology improves but you have to take a holistic approach, looking at other impacts including production methodology and distance travelled from source.’

Notably, TIC CC advocates using a Guppyfriend washing bag when washing cycling clothing. Washing cycling kit in this bag prevents microplastic pollution from synthetic micro fibres getting into waterways. TIC CC and all of its key manufacturing partners use 100% renewable energy and the brand uses Bluesign and Oeko-Tex certified materials. TIC CC kit is made in Europe, and its caps are handmade in the UK. The brand has been tracking its emissions internally for the past three years and is considering getting this data accredited in the futu 9. Universal Colours

London-based Universal Colours takes an innovative conscious approach to its products. The brand uses pre-consumer waste and post-consumer waste fabrics and a fluorocarbon-free durable water repellent (DWR), called C0 which is a sustainable, vegetable-based technology. The brand aims to produce considerately sourced cycling clothing but to also educate the consumer on how to care for its garments in order to maximise their longevity. ‘With all our waterproof jackets we give a sample of Nickwax aftercare to reproof it,’ says Will Hurd, a designer at Universal Colours. ‘It’s really important that we communicate to our customers the importance of looking after a product. It’s wrong to assume that customers know what reproofing is.’ But it isn’t straightforward as Hurd explains: ‘We have our own paradox and our own complications because we know our price points are not accessible for everyone. But I think we are very clear and transparent about our fabrics, our costs and have strong ethical policies that we stand by.’

The brand also champions a circular approach, notably in its 100% taste-free biodegradable polyethylene bottle constructed using sugarcane, which can be wholly recycled. At the correct temperature in a landfill or under leaves and soil in a forest, the bio-batch additive activates, and the bottle decomposes into water, humus and gas. The brand says the composting process takes 1-5 years, compared to 450 years for a traditional plastic bottle, and the bottle becomes part of the natural world again. Most of its products are produced at LTP in Lithuania which is a Bluesign-accredited factory, and the brand also works with a factories in China and Taiwan for select products. Universal Colours is currently looking into tracking its emissions and is also a member of 1% for the planet 10. Velocio

The majority of Velocio’s products incorporate recycled or natural fibre, including all of its Spring/Summer jersey line. The brand is aiming to expand the use of these materials into the rest of its collection. Velocio makes its kit in facilities which use renewable energy, primarily solar and produces clothing in small-batch quantities in order to conserve energy, limit overstock and reduce liquidation. ‘It’s ironic given that the bicycle can be such an environmentally friendly mode of transportation, but the industry at large, especially at the aspirational end, has pushed newer/better/faster as their primary marketing language for so long that bikes are essentially disposable,’ says Brad Sheehan, CEO and co-founder of Velocio.

‘That mentality has been absorbed by consumers and it’s the main thing we hope to push back on.’ ‘It’s also not enough to just use recycled fabrics. We’re also looking at the manufacturing partners, fabric suppliers, and end of life phases of our apparel to see how we can improve the entire life cycle.’ Velocio uses Bluesign and Oeko-Tex certified suppliers and is also a member of 1% for the planet. Interested in sustainability and cycling? Check out Read the full article

0 notes

Text

Your Washing Machine Can Be a Home for Bacteria — What You Should Know

Bacteria were observed on laundry cleaned in customer-grade washing machines at a sanatorium in Germany.

Experts say energy-green domestic washing machines may be a haven for micro organism because they wash garments at lower temperatures. But professionals say maximum of the bacteria concentrations aren’t sufficient to make human beings seriously unwell. They do advocate now and again cleansing the inner of your washing machine and drying garments on strains out of doors. Today’s excessive-efficiency home washing machines may not be casting off bacteria as thoroughly as their older, much less-green counterparts.

This finding comes after a multidrug-resistant pathogen was observed at the apparel of toddlers at a neonatal intensive care unit at a German youngsters’s clinic — despite all ordinary precautions being taken to eliminate exposure to such superbugs.

The eventual perpetrator, investigators determined, became in the sanatorium’s laundry room.

There the investigators determined purchaser-grade washing machines instead of the standard high-temperature commercial washing machines generally used in hospitals, researchers stated in the magazine Applied and Environmental Microbiology.

Fortunately the infants were best exposed to the drug-resistant Klebsiella oxytoca pathogen however now not certainly infected, the researchers said.

What’s to your washer? But the findings boost the question: If the problem is a consumer-grade washing machine, do customers want to be concerned approximately harmful micro organism lingering in their machines at home?

The answer is blended.

“This changed into a washing machine in a health center so it'd be uncovered to bacteria — together with this one — that thrive in medical institution environments,” Dr. Amesh Adalja, a senior scholar at the Johns Hopkins Center for Health Security in Maryland, told Healthline.

“This micro organism is resistant and can reason excessive infections however nonetheless calls for a susceptible host. Many people may be uncovered to drug-resistant micro organism or even colonized with them — like are many healthcare people — but haven't any infections arise,” he said.

But which will shop electricity, these days’s high-performance machines wash clothes at lower temperatures — much less than 140°F.

That means greater bacteria survive the bathing procedure, noted Ricarda M. Schmithausen, PhD, a lead author of the examine and a senior doctor at the Institute for Hygiene and Public Health on the WHO Collaboration Center at the University of Bonn, Germany, in an American Society for Microbiology press release.

In precise, the researchers located bacteria growing within the rubber seals of the washing machine, which then spread throughout the unheated rinse cycle.

Few risks — with a few exceptions However, maximum micro organism are benign or maybe beneficial.

“For those folks who use cold or heat water wash and green short-drying cycles, some hardy germs can be left on our linens and garments, [but] the opportunity of risky, resistant micro organism in our washing machines inflicting disorder could be very far flung,” Dr. Bruce Hirsch, attending infectious disorder doctor at North Shore University Hospital in Manhasset, New York, instructed Healthline.

“We’re all uncovered to bacteria all the time with out contamination. This story suggests that if a family has a family member with a current extended hospitalization, warm water and extended drying have to be considered,” he said.

Dr. Martin Exner, chairman and director of the Institute for Hygiene and Public Health at the WHO Collaboration Center, University Hospital/University of Bonn, wherein the research became carried out, concurred in the have a look at’s press release.

“This is a growing mission for hygienists, because the number of people receiving nursing care from own family contributors is constantly increasing,” he said.

Keeping your washing machine easy If you live with an elderly relative, prone newborn, or surely want to head the more mile, you can take certain measures to keep your garments and washing device freed from the worst bacterial infection.

“Bacteria tends to lurk in the detergent drawer, rubber seals, and washing drum,” Hilary Metcalf, MPH, an contamination preventionist at Mission Hospital in Orange County, California, instructed Healthline.

Consumers have to be specifically cautious of washing machines kept in humid environments including garages or sheds, since those are the correct environments for micro organism to thrive.

And germs which include E. Coli, salmonella, and Klebsiella oxytoca can purpose pneumonia, pores and skin infections, stomach cramps, vomiting, and diarrhea, in particular in humans with compromised immune structures.

Try wiping down seals on your machine with a ten percent bleach answer, some specialists propose.

You can also try washing your washer.

“It might seem counterintuitive, but washing your washing system as soon as a month can extensively lessen you and your family’s publicity to germs and infections,” Metcalf said.

There’s no reason to fret over each wash cycle, however. Instead, pick out your wash settings on a case-by-case foundation relying on how the wash got grimy.

“Normal domestic laundering will competently get rid of ordinary levels of soil. However, if infected with blood or bodily fluids, the laundering system should be stronger with disinfecting answers which include hydrogen peroxide, bleach, or Borax, and in water that’s as a minimum a hundred and sixty°F,” Metcalf stated.

Many washers have a “sanitize” putting as a way to convey it up to those better temperatures outside of its everyday wash cycle.

And there’s a extra effective germkiller people can attempt to hold pathogens far from their garments: drying them out of doors on the road.

“One of the most placing germkillers is the sun,” stated CJ Xia, vice president of marketing and sales at antibody manufacturing company Boster Biological Technology. “Some scientists say to avoid the use of the dryer entirely.”

1 note

·

View note