#Bauxite Price Trend

Explore tagged Tumblr posts

Text

Bauxite Prices Trend | Pricing | News | Database | Chart

Bauxite is the primary ore from which aluminum is extracted, making it one of the most crucial raw materials in the global industrial sector. As a vital component in aluminum production, the price of bauxite can significantly impact a variety of industries, from aerospace to automotive, as aluminum is used extensively in manufacturing these products. The price of bauxite is driven by several factors, including supply-demand dynamics, geopolitical influences, transportation costs, and technological advancements in extraction methods. In recent years, the bauxite market has seen fluctuations in prices, influenced by global economic conditions, regional production capacities, and environmental regulations.

The global demand for aluminum is a key factor in the pricing of bauxite. As industrialization continues to rise, especially in developing nations, the need for aluminum products has surged. Aluminum’s versatility and lightweight properties make it ideal for use in a range of applications, including in the construction of vehicles, aircraft, and electronics. With the global economy becoming increasingly focused on sustainability and energy-efficient products, the demand for aluminum is expected to grow. As a result, the price of bauxite, which is essential for aluminum production, is directly influenced by these market shifts.

Get Real Time Prices for Bauxite : https://www.chemanalyst.com/Pricing-data/bauxite-1471

Geopolitical tensions also play a significant role in determining the price of bauxite. Major bauxite-producing countries, such as Australia, Guinea, Brazil, and Jamaica, influence the global supply chain. Any disruptions in these regions, whether due to political instability, changes in trade policies, or labor strikes, can lead to sudden changes in bauxite prices. For instance, fluctuations in export duties or environmental regulations in producing countries can affect supply, causing the price of bauxite to rise. This volatility is often passed on to consumers and industries that rely on aluminum, making the cost of bauxite a critical factor in their operations.

Transportation and logistics also contribute to the pricing of bauxite. As a bulk commodity, bauxite is often transported over long distances from mines to processing plants or refineries. Shipping costs, fuel prices, and infrastructure challenges can influence the overall cost of bauxite. For instance, changes in global fuel prices or disruptions in major shipping routes due to natural disasters or geopolitical events can lead to increased transportation costs, thereby raising the price of bauxite. In addition, the cost of transporting bauxite to key markets can fluctuate based on global trade patterns and the availability of shipping containers, making logistics an important aspect of bauxite pricing.

Another factor affecting bauxite prices is the technological advancements in mining and refining processes. Over time, improvements in extraction techniques and efficiency have played a role in controlling costs. As miners find more efficient ways to extract and process bauxite, they can reduce the overall cost of production. However, these advancements require significant investment, which can be a challenge for smaller producers. Larger companies with access to advanced technology are able to maintain a competitive edge, but smaller firms may struggle with price fluctuations as they may not be able to achieve the same economies of scale. This has led to market consolidation in some regions, where larger companies dominate bauxite production and pricing.

Environmental regulations are becoming an increasingly important consideration for the bauxite industry. As concerns over environmental sustainability rise, many countries are implementing stricter environmental policies on mining operations. These regulations can include restrictions on land use, emissions controls, and waste management practices. Compliance with these environmental standards often requires additional investment in technology and infrastructure, which can raise the cost of bauxite production. Furthermore, the growing global focus on reducing carbon emissions has pushed many bauxite producers to adopt cleaner, more sustainable mining practices, which can increase operational costs. As these standards become more widespread, it is likely that bauxite prices will reflect the increased cost of production associated with maintaining these environmental practices.

The bauxite market is also influenced by the availability of alternative materials and the development of recycling technologies. As the demand for aluminum rises, there is increasing pressure to find alternative sources of raw materials. While bauxite remains the most economically viable option for aluminum extraction, recycling aluminum products has become an attractive option to meet demand. The recycling of aluminum requires significantly less energy than producing aluminum from bauxite, which reduces environmental impact and production costs. However, the recycling industry still faces challenges in scaling up to meet global demand, which means bauxite remains the primary source for aluminum production. Nonetheless, as recycling technologies improve, it is possible that the demand for bauxite may fluctuate depending on the growth of aluminum recycling.

Supply chain dynamics also significantly affect bauxite prices. While major producers, such as Australia and Guinea, hold substantial reserves of bauxite, their ability to meet global demand is impacted by local mining conditions and logistical constraints. Guinea, for example, is one of the largest exporters of bauxite, but the country’s infrastructure challenges, including road conditions and port capacities, can hinder the efficiency of production and shipping. Similarly, changes in local mining laws, labor conditions, and technological advancements can either increase or reduce bauxite supply, thus influencing prices. As a result, the global bauxite market can experience periods of oversupply or shortages, which can lead to significant price fluctuations.

In conclusion, the price of bauxite is influenced by a complex set of factors that include supply and demand, geopolitical influences, transportation costs, technological advancements, and environmental regulations. These factors often interact in unpredictable ways, causing bauxite prices to fluctuate over time. As global demand for aluminum grows, particularly in emerging economies, the price of bauxite will continue to be an important consideration for industries reliant on aluminum production. Understanding these dynamics is crucial for businesses and stakeholders in the aluminum supply chain, as it allows them to make informed decisions in an ever-changing market. The future of bauxite prices will likely be shaped by a combination of technological advancements, geopolitical stability, and a growing focus on sustainability.

Get Real Time Prices for Bauxite : https://www.chemanalyst.com/Pricing-data/bauxite-1471

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Bauxite#Bauxite Price#Bauxite Prices#Bauxite Pricing#Bauxite News#Bauxite Price Monitor#Bauxite Database#Bauxite Price Chart#Bauxite Price Trend

0 notes

Text

In-Depth Analysis of the Global Caustic Soda Market

The caustic soda market has become an essential component of the global chemical industry, serving as a critical raw material in various industrial applications. Also known as sodium hydroxide (NaOH), caustic soda is a highly versatile chemical with a wide range of uses, including in the production of paper, textiles, detergents, and aluminum. This comprehensive article provides a detailed analysis of the current state of the global caustic soda market, exploring key drivers, challenges, and future trends.

Buy the Full Report for More Insights on Caustic soda Capacity and Capex Forecast Download a Free Report Sample

Market Dynamics

Key Drivers of Market Growth

Several factors are propelling the growth of the global caustic soda market:

Growing Demand in End-Use Industries: Caustic soda is a crucial ingredient in numerous industries, including paper and pulp, textiles, soaps and detergents, and water treatment. The increasing demand for these products, driven by population growth and rising standards of living, directly impacts the caustic soda market.

Expansion of the Aluminum Industry: The production of aluminum is one of the largest consumers of caustic soda. As the demand for aluminum continues to rise, particularly in the automotive and aerospace sectors, the caustic soda market is expected to grow accordingly. Caustic soda is used in the Bayer process to extract aluminum oxide from bauxite, making it an indispensable component of aluminum manufacturing.

Water Treatment Applications: With growing concerns over water scarcity and pollution, the demand for caustic soda in water treatment processes is increasing. Caustic soda is used to adjust the pH levels of water, neutralize acids, and remove heavy metals, making it essential for ensuring clean and safe water supplies.

Challenges Facing the Caustic Soda Market

Despite its robust growth, the caustic soda market faces several challenges:

Environmental Concerns: The production of caustic soda is energy-intensive and can have significant environmental impacts, including the release of chlorine and other pollutants. As environmental regulations become more stringent, manufacturers are under pressure to adopt cleaner and more sustainable production methods, which may increase costs.

Fluctuating Raw Material Prices: The cost of key raw materials used in caustic soda production, such as salt and electricity, can be volatile. These fluctuations can affect the profitability of caustic soda producers and lead to price instability in the market.

Health and Safety Risks: Caustic soda is highly corrosive and poses significant health and safety risks if not handled properly. This necessitates stringent safety measures in its production, storage, and transportation, adding to operational costs and complexity.

Segmentation of the Caustic Soda Market

By Production Process

The caustic soda market is segmented based on the production process, which includes:

Membrane Cell Process: The membrane cell process is the most widely used method for producing caustic soda, accounting for the majority of global production. This process is preferred due to its higher energy efficiency and lower environmental impact compared to other methods.

Diaphragm Cell Process: The diaphragm cell process is another common method for producing caustic soda. Although it is less energy-efficient than the membrane cell process, it is still widely used, particularly in regions with lower electricity costs.

Mercury Cell Process: The mercury cell process is the oldest method of producing caustic soda. However, due to environmental concerns related to mercury emissions, this process is being phased out in many countries in favor of more sustainable alternatives.

By Application

Caustic soda is utilized in a wide range of applications, including:

Paper and Pulp Industry: Caustic soda is extensively used in the paper and pulp industry for processes such as chemical pulping, bleaching, and de-inking. The increasing demand for paper products, particularly in packaging and hygiene applications, drives the consumption of caustic soda in this sector.

Textile Industry: In the textile industry, caustic soda is used in the dyeing and finishing processes, as well as in the production of synthetic fibers. The growth of the global textile industry, fueled by rising consumer demand for clothing and home textiles, contributes to the expansion of the caustic soda market.

Alumina Production: As previously mentioned, caustic soda is a critical component in the production of alumina from bauxite ore. The ongoing growth of the aluminum industry, driven by demand from sectors such as automotive, construction, and electronics, continues to drive the need for caustic soda.

Soap and Detergent Manufacturing: Caustic soda is a key ingredient in the production of soaps and detergents, where it is used to saponify fats and oils. The global demand for cleaning and hygiene products, particularly in light of the COVID-19 pandemic, has bolstered the caustic soda market.

By End-User

The end-users of caustic soda include:

Chemical Manufacturing: The chemical industry is one of the largest consumers of caustic soda, using it as a raw material in the production of various chemicals, including solvents, plastics, and pharmaceuticals.

Water Treatment Facilities: As mentioned earlier, caustic soda is widely used in water treatment facilities to purify water and neutralize acidic waste streams.

Food and Beverage Industry: In the food and beverage industry, caustic soda is used for cleaning and sanitizing equipment, as well as in the processing of certain food products, such as cocoa, chocolate, and beverages.

Regional Analysis

The global caustic soda market is geographically segmented into:

North America

North America is one of the leading regions in the global caustic soda market, driven by strong demand from the paper, chemical, and aluminum industries. The United States, in particular, is a major producer and consumer of caustic soda, with a well-established industrial base and advanced production technologies.

Europe

Europe is another significant market for caustic soda, with countries like Germany, France, and the United Kingdom leading the region. The growth of the market in Europe is supported by the expansion of the chemical and textile industries, as well as the increasing focus on sustainable production methods.

Asia-Pacific

The Asia-Pacific region is expected to witness the fastest growth in the caustic soda market, driven by rapid industrialization, urbanization, and population growth. China and India are the largest markets in the region, with significant demand from the paper, textile, and alumina industries. The increasing investments in infrastructure development and manufacturing activities further contribute to the market's expansion in this region.

Latin America and Middle East & Africa

These regions are also experiencing growth in the caustic soda market, although at a slower pace compared to North America and Asia-Pacific. The demand for caustic soda in Latin America is primarily driven by the chemical and mining industries, while in the Middle East & Africa, the growth is supported by the expansion of the oil and gas sector, which requires caustic soda for various applications.

Future Trends in the Caustic Soda Market

Sustainability and Environmental Considerations

As environmental concerns continue to rise, the caustic soda industry is increasingly focused on sustainability. Manufacturers are investing in cleaner production technologies, such as the membrane cell process, to reduce the environmental impact of caustic soda production. Additionally, there is a growing emphasis on the recycling and reuse of caustic soda in various industrial processes, further contributing to sustainability efforts.

Technological Advancements

Technological advancements in the production and application of caustic soda are expected to shape the future of the market. Innovations such as electrochemical processes and waste-to-chemical technologies are being explored to enhance production efficiency and reduce environmental impact. These advancements are likely to drive the market's growth in the coming years.

Emerging Markets

The caustic soda market is poised for significant growth in emerging markets, particularly in Asia-Pacific, Latin America, and Africa. The rapid industrialization and urbanization in these regions create new opportunities for market expansion, as the demand for caustic soda in various industries continues to rise.

Conclusion

The global caustic soda market is set to continue its growth trajectory, driven by the expanding demand from key end-use industries such as paper, textiles, alumina, and water treatment. While challenges such as environmental concerns and fluctuating raw material prices persist, the market is expected to benefit from technological advancements and increasing focus on sustainability. As emerging markets continue to develop, the caustic soda market presents significant opportunities for growth and innovation.

0 notes

Text

Aluminium Hydroxide Manufacturing Plant Project Report 2024: Setup and Cost

Introduction

Aluminium hydroxide is a versatile and crucial compound used across a variety of industries, including pharmaceuticals, water treatment, and as a fire retardant. It is primarily employed as a precursor in the production of aluminum metal and various aluminum-based compounds. The Aluminium Hydroxide Manufacturing Plant Project Report provides a detailed guide to setting up a facility dedicated to producing this valuable material. This report covers market analysis, plant design, manufacturing processes, and financial considerations, offering a comprehensive roadmap for stakeholders interested in launching a successful aluminium hydroxide production plant.

Market Analysis

1. Demand Assessment

Assessing the demand for aluminium hydroxide is essential for understanding the project's potential. Key applications include:

Pharmaceuticals: Used as an antacid and in various drug formulations.

Water Treatment: Acts as a flocculant to remove impurities from water.

Fire Retardants: Incorporated into materials to enhance fire resistance.

Aluminum Production: Serves as a primary feedstock for producing aluminum metal.

The growth in these sectors drives the demand for aluminium hydroxide. Analyzing market trends and future projections helps in estimating potential market size and revenue.

Get a Free Sample Report with Table of Contents @

https://www.expertmarketresearch.com/prefeasibility-reports/aluminium-hydroxide-manufacturing-plant-project-report/requestsample

2. Competitor Analysis

Understanding the competitive landscape is crucial for positioning your plant effectively. This involves:

Market Share Analysis: Identifying key players in the aluminium hydroxide market and their market share.

Product Differentiation: Examining how competitors differentiate their products, such as through purity, particle size, or specialized applications.

Pricing Strategies: Comparing pricing models to develop a competitive pricing strategy for your product.

Competitor analysis provides insights into market opportunities and helps in formulating strategies to gain a competitive edge.

3. Customer Segmentation

Identifying potential customers is key to targeting and marketing your products. Key segments include:

Pharmaceutical Companies: Require high-quality aluminium hydroxide for drug formulations.

Water Treatment Facilities: Use the compound for purifying water.

Construction and Manufacturing: Utilize it as a fire retardant and in various industrial applications.

Aluminum Producers: Depend on aluminium hydroxide as a primary raw material.

Understanding the needs of these segments helps tailor product offerings and marketing efforts to meet specific requirements.

Plant Design and Layout

1. Facility Design

Designing the plant involves creating an efficient layout that ensures smooth production and operational efficiency. Key components include:

Production Areas: Space for chemical reactors, filtration units, and drying systems.

Raw Material Storage: Areas for storing bauxite ore (the primary source of aluminium hydroxide) and other chemicals.

Quality Control: Dedicated space for testing and quality assurance.

Administrative Offices: Areas for management, finance, and administrative functions.

An efficient layout minimizes production downtime and maximizes operational efficiency.

2. Equipment Selection

Choosing the right equipment is essential for effective aluminium hydroxide production. Key equipment includes:

Chemical Reactors: For carrying out the chemical reactions to produce aluminium hydroxide from bauxite ore.

Filtration Units: To separate aluminium hydroxide from the reaction mixture.

Drying Systems: To remove moisture from the filtered aluminium hydroxide and achieve the desired consistency.

Packaging Machinery: For packaging the finished product into suitable containers for distribution.

Selecting high-quality, reliable equipment ensures consistent production and product quality.

3. Safety and Compliance

Implementing safety measures and complying with regulations are crucial for smooth operations. This includes:

Safety Protocols: Training employees on handling chemicals and operating equipment safely.

Emergency Systems: Installing fire suppression systems, first aid stations, and emergency exits.

Regulatory Compliance: Adhering to industry standards and regulations related to chemical manufacturing, safety, and environmental impact.

Manufacturing Process

1. Raw Material Preparation

The primary raw material for aluminium hydroxide production is bauxite ore. Preparation involves:

Crushing and Grinding: Bauxite ore is crushed and ground to increase its surface area for the extraction process.

Chemical Treatment: Bauxite is treated with a solution of sodium hydroxide to extract aluminium hydroxide.

2. Extraction and Precipitation

The extraction process involves:

Bayer Process: Bauxite ore is mixed with sodium hydroxide in high-pressure reactors. This process dissolves the aluminium oxide, which is then precipitated as aluminium hydroxide.

Separation: The aluminium hydroxide is separated from the remaining impurities through filtration and sedimentation.

3. Drying and Calcination

The precipitated aluminium hydroxide undergoes:

Drying: Removing moisture from the aluminium hydroxide using drying systems.

Calcination: Heating the dried aluminium hydroxide at high temperatures to produce alumina (Al₂O₃), if required, for further processing.

4. Packaging and Storage

The final aluminium hydroxide product is:

Packaged: In suitable containers for distribution, ensuring protection from contamination and degradation.

Stored: In appropriate storage areas to maintain product quality and prevent contamination.

Quality Control

Maintaining high product quality is essential for meeting industry standards and customer expectations. Quality control measures include:

Purity Testing: Ensuring that aluminium hydroxide meets purity specifications and is free from contaminants.

Consistency Checks: Verifying that each batch of aluminium hydroxide is consistent in terms of particle size, moisture content, and other properties.

Compliance Testing: Ensuring that the product meets regulatory requirements and industry standards.

Regular testing and inspections help maintain product reliability and performance.

Financial Planning

1. Capital Investment

Initial capital investment includes:

Facility Construction: Building and setting up the manufacturing plant.

Equipment Purchase: Acquiring reactors, filtration units, drying systems, and packaging machinery.

Raw Materials: Procuring initial stock of bauxite ore and other chemicals.

2. Operating Costs

Ongoing expenses consist of:

Raw Materials: Regular procurement of bauxite ore and chemicals.

Labor Costs: Salaries for production staff, quality control, and administrative personnel.

Utilities: Costs for electricity, water, and other utilities.

Maintenance: Regular upkeep of equipment and facility.

3. Revenue Projections

Estimating potential revenue involves:

Market Pricing: Setting competitive prices based on market analysis and production costs.

Sales Forecasting: Projecting sales volume based on demand and customer needs.

4. Profitability Analysis

Assessing profitability includes:

Cost-Benefit Analysis: Comparing production costs with potential revenue.

Return on Investment (ROI): Evaluating the expected return based on financial projections.

Regulatory Compliance

Compliance with regulations is crucial for legal operation and market acceptance. This includes:

Chemical Manufacturing Regulations: Adhering to standards related to chemical production and safety.

Health and Safety Regulations: Ensuring workplace safety and employee protection.

Environmental Regulations: Complying with laws related to waste management, emissions, and environmental impact.

Frequently Asked Questions (FAQ)

What is aluminium hydroxide used for?

Aluminium hydroxide is used in various applications, including pharmaceuticals (as an antacid), water treatment (as a flocculant), fire retardants, and as a precursor in aluminum production.

What are the primary raw materials for aluminium hydroxide production?

The primary raw material is bauxite ore, which is processed to extract aluminium hydroxide through chemical treatment.

What is the Bayer Process?

The Bayer Process is a method for extracting aluminium hydroxide from bauxite ore using sodium hydroxide. The process involves dissolving aluminium oxide from bauxite and precipitating it as aluminium hydroxide.

What is involved in the drying and calcination of aluminium hydroxide?

Drying involves removing moisture from aluminium hydroxide, while calcination involves heating the dried product at high temperatures to produce alumina (if further processing is required).

What are the key considerations in plant design?

Key considerations include designing an efficient layout, selecting appropriate equipment, implementing safety measures, and ensuring regulatory compliance.

What are the financial considerations for setting up an aluminium hydroxide manufacturing plant?

Financial considerations include capital investment for facility setup and equipment, ongoing operating costs, revenue projections, and profitability analysis.

How important is quality control in aluminium hydroxide manufacturing?

Quality control is crucial for ensuring that aluminium hydroxide meets industry standards, regulatory requirements, and customer expectations. It involves regular testing and inspections to maintain high product quality.

Media Contact:

Company Name: Claight Corporation Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A. Email: [email protected] Toll Free Number: +1–415–325–5166 | +44–702–402–5790 Address: 30 North Gould Street, Sheridan, WY 82801, USA Website: www.expertmarketresearch.com Aus Site: https://www.expertmarketresearch.com.au/

0 notes

Text

Boehmite Market Growth, Share, Global Trends by 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Boehmite Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Boehmite Market Research share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Boehmite Market?

The boehmite market is expected to grow at a CAGR of 8.1% during the forecast period of 2024 to 2032.

What are Boehmite?

Boehmite, also called aluminum oxide hydroxide, is a mineral form of aluminum oxide with the chemical formula AlO (OH). It is typically found in bauxite deposits and serves as a key intermediate in alumina production, which is crucial for manufacturing aluminum metal. With a flat, plate-like crystal structure, boehmite is commonly employed as a filler in diverse industrial applications such as ceramics, catalyst supports, and coatings. It is also utilized as a flame retardant and in the production of abrasives. Its favorable characteristics, including high surface area and thermal stability, render it valuable across various industrial processes.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1681

What are the growth prospects and trends in the Boehmite industry?

The boehmite market growth is driven by various factors. The market for Boehmite is witnessing substantial growth, propelled by its broad applications in ceramics, catalysts, and coatings industries. Boehmite's effectiveness as a filler in these sectors is particularly advantageous due to its high surface area and thermal stability. The market is also benefiting from increasing demand for flame retardants and abrasives, both of which utilize Boehmite. Furthermore, the market is expected to be driven by a growing emphasis on sustainable materials, as Boehmite is considered more environmentally friendly compared to some alternatives. However, challenges such as fluctuating raw material prices and competition from other fillers and additives could potentially hinder market expansion. Hence, all these factors contribute to boehmite market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Monohydrate Boehmite

Trihydrate Boehmite

By Application:

Catalysts

Coatings

Ceramics

Polymers

Adhesives

Others

By End-Use Industry:

Automotive

Electronics

Aerospace

Construction

Pharmaceuticals

Energy

Others

By Particle Size:

Nano Boehmite

Micro Boehmite

Segmentation By Region:

North America:

United States

Canada

Asia Pacific:

China

India

Japan

Australia & New Zealand

Association of Southeast Asian Nations (ASEAN)

Rest of Asia Pacific

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX (Belgium, the Netherlands, Luxembourg)

NORDIC (Norway, Sweden, Finland, Denmark)

Rest of Europe

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

The Middle East & Africa:

Saudi Arabia

United Arab Emirates

South Africa

Egypt

Israel

Rest of MEA (Middle East & Africa)

Who are the key players operating in the industry?

The report covers the major market players including:

Sasol Limited

Nabaltec AG

CHALCO

TOR Minerals International

Showa Denko K.K.

Xuancheng Jingrui New Material Co., Ltd.

Zhengzhou Research Institute of Chalco

TABALUX GmbH

Zibo Xinglu Chemical Co., Ltd.

Kawai Chemicals Corporation

AnHui Estone Materials Technology Co., Ltd.

AluChem, Inc.

View Full Report: https://www.reportsandinsights.com/report/Boehmite-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Dynamics of the Global Caustic Soda Market: Trends, Growth Drivers, and Future Outlook

Caustic soda, also known as sodium hydroxide (NaOH), plays a pivotal role across various industries as a versatile chemical compound. This article delves into the current trends, key growth drivers, challenges, and future prospects shaping the global caustic soda market.

Current Market Overview:

Diverse Industrial Applications:

Caustic soda is a fundamental chemical with applications in pulp and paper production, textiles, chemicals manufacturing, water treatment, alumina refining, soaps and detergents, and various other sectors Caustic soda.

Chemical Industry Dominance:

The chemical industry is the largest consumer of caustic soda, utilizing it in the production of organic and inorganic chemicals, including PVC, detergents, soaps, and petroleum products, driving significant demand.

Water Treatment and Alumina Refining:

The water treatment sector relies on caustic soda for pH regulation, wastewater treatment, and neutralization processes. In alumina refining, it is crucial for extracting alumina from bauxite ore.

Key Market Trends and Growth Drivers:

Pulp and Paper Industry Growth:

The expanding pulp and paper industry, particularly in emerging economies, fuels demand for caustic soda in bleaching processes, pulp treatment, and paper manufacturing, supporting market growth.

Increasing Demand in Chemical Manufacturing:

Caustic soda's role as a key chemical feedstock for various industries, including textiles, detergents, petroleum refining, and food processing, drives consistent demand globally.

Water Treatment and Environmental Regulations:

Stringent environmental regulations mandating water quality standards and wastewater treatment drive the Demand of caustic soda in water treatment plants and industrial effluent treatment processes.

Challenges and Opportunities:

Energy Costs and Production Efficiency:

Fluctuating energy costs impact caustic soda production costs, necessitating efficient production technologies, such as membrane cell electrolysis, to enhance energy efficiency and reduce operational expenses.

Competitive Landscape and Pricing Pressures:

Global market competition, capacity expansions, and pricing pressures from alternative chemicals pose challenges for caustic soda manufacturers, requiring strategic pricing strategies and operational optimizations.

Future Outlook and Market Projections:

Growth in Emerging Economies:

Rapid industrialization, infrastructure development, and urbanization in emerging economies, especially in Asia-Pacific and Latin America, are expected to drive sustained demand for caustic soda across multiple sectors.

Technological Advancements and Sustainability Initiatives:

Continued research in electrolysis technologies, recycling processes for caustic soda, and sustainable production methods align with industry efforts towards environmental sustainability and resource efficiency.

End-User Industry Expansion:

Increasing applications in sectors such as textiles, food processing, pharmaceuticals, and petroleum refining, coupled with evolving consumer preferences and industry regulations, will contribute to market expansion.

Conclusion: The global caustic soda market continues to evolve driven by its indispensable role in diverse industries and applications. Market players need to focus on technological innovation, sustainable practices, strategic collaborations, and market diversification to capitalize on growth opportunities and navigate challenges in this dynamic market landscape.

0 notes

Text

Primary Aluminium Market: Trends and Insights

Introduction

The global primary aluminium market is a vital sector within the broader metals industry, characterized by its extensive applications across various sectors, including automotive, aerospace, construction, packaging, and electronics. Aluminium, renowned for its lightweight properties, durability, and corrosion resistance, has become indispensable in modern manufacturing processes.

According to a study conducted by Next Move Strategy Consulting, the Primary Aluminium Market is projected to witness significant growth, with an anticipated size of USD 141.50 billion and a compound annual growth rate (CAGR) of 3.6% by 2030.

Understanding the Primary Aluminium Market

Historical Overview: The history of aluminium dates back to the 19th century, marked by the development of cost-effective production methods such as the Hall-Héroult process. Over the years, aluminium has emerged as a versatile metal, finding applications in diverse industries due to its favourable properties.

Request for a sample, here: https://www.nextmsc.com/primary-aluminium-market/request-sample

Market Segmentation: The primary aluminium market can be segmented based on product type, end-user industry, and geography. Product types include ingots, billets, and slabs, while end-user industries encompass automotive, aerospace, construction, packaging, and electrical appliances.

Value Chain Analysis: The primary aluminium value chain involves several stages, including bauxite mining, alumina refining, primary aluminium smelting, downstream processing, and distribution. Each stage presents opportunities for value addition and optimization.

Trends Shaping the Primary Aluminium Market

Rising Demand in Automotive and Aerospace Industries: The automotive and aerospace sectors are significant consumers of primary aluminium, driven by the need for lightweight materials to improve fuel efficiency and reduce emissions. With the transition towards electric vehicles (EVs) and the emphasis on sustainable aviation, the demand for aluminium is expected to escalate further.

Focus on Sustainability and Recycling: Sustainability has become a central theme in the primary aluminium market, with stakeholders prioritizing eco-friendly practices and recycling initiatives. Aluminium recycling not only conserves natural resources but also requires significantly less energy compared to primary aluminium production, aligning with global sustainability goals.

Technological Advancements in Production Processes: Technological innovations play a crucial role in enhancing efficiency and reducing environmental impact in primary aluminium production. Advanced smelting technologies, such as inert anode technology and electrolysis optimization, are gaining traction for their potential to lower energy consumption and greenhouse gas emissions.

Geographical Shifts in Production and Consumption: The primary aluminium market is witnessing geographical shifts, with emerging economies in Asia-Pacific, particularly China, emerging as key players. Rapid industrialization, urbanization, and infrastructure development in these regions are driving robust demand for primary aluminium, reshaping the global market landscape.

Impact of Trade Dynamics and Tariffs: Trade dynamics and tariffs significantly influence the primary aluminium market, impacting supply chains and pricing structures. Trade disputes between major aluminium-producing nations can lead to price volatility and market uncertainties, affecting stakeholders across the value chain.

Insights into Market Dynamics

Market Drivers: Several factors drive growth in the primary aluminium market, including increasing urbanization, infrastructure development, technological advancements, and evolving consumer preferences towards lightweight and sustainable materials.

Market Restraints: Despite its promising outlook, the primary aluminium market faces certain challenges, including fluctuating raw material prices, regulatory constraints, geopolitical tensions, and competition from alternative materials.

Opportunities for Market Players: Market players can capitalize on emerging opportunities by investing in research and development (R&D) to innovate new alloys, expanding production capacities, forging strategic partnerships, and leveraging digitalization to optimize operations and supply chain management.

Challenges to Address: Addressing challenges such as energy efficiency improvements, carbon footprint reduction, waste management, and compliance with stringent environmental regulations are imperative for the sustainable growth of the primary aluminium market.

Regional Analysis

North America: North America remains a significant market for primary aluminium, driven by robust demand from the automotive, aerospace, and construction sectors. The region also boasts advanced manufacturing capabilities and a focus on technological innovation.

Europe: Europe is witnessing a transition towards sustainable practices, with stringent environmental regulations driving demand for recycled aluminium. The region's automotive industry is leading the adoption of lightweight materials to meet stringent emissions standards.

Asia-Pacific: Asia-Pacific, led by China, is the largest consumer and producer of primary aluminium globally. Rapid industrialization, urbanization, and infrastructure development in countries like China and India fuel demand for aluminium across various sectors.

Middle East and Africa: The Middle East and Africa region possess significant bauxite reserves, providing a competitive advantage in primary aluminium production. However, the region faces challenges related to infrastructure development and political instability.

Future Outlook and Predictions

Market Growth Prospects: The primary aluminium market is poised for steady growth, driven by expanding applications, technological advancements, and increasing focus on sustainability.

Emerging Trends: Emerging trends such as lightweight, electric mobility, circular economy initiatives, and Industry 4.0 integration are expected to shape the future trajectory of the primary aluminium market.

Key Challenges: Overcoming challenges related to energy efficiency, carbon emissions, regulatory compliance, and geopolitical uncertainties will be critical for sustaining growth in the primary aluminium market.

Strategic Imperatives: Market players need to adopt a proactive approach by investing in R&D, fostering innovation, enhancing operational efficiencies, and strengthening collaborations across the value chain to capitalize on emerging opportunities and mitigate risks effectively. Embrace Digital Transformation: The integration of digital technologies such as artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), and data analytics can revolutionize operations within the primary aluminium market. By harnessing data-driven insights, companies can optimize production processes, improve predictive maintenance, enhance supply chain visibility, and optimize resource utilization, thereby gaining a competitive edge in the market.

Inquire before buying, here: https://www.nextmsc.com/primary-aluminium-market/inquire-before-buying

Prioritize Talent Development and Training: Investing in talent development and training programs is essential for building a skilled workforce equipped to tackle the evolving challenges and opportunities within the primary aluminium industry. By fostering a culture of continuous learning and skill enhancement, companies can ensure that their employees possess the expertise and capabilities required to drive innovation, improve productivity, and adapt to changing market dynamics effectively.

Enhance Stakeholder Engagement and Communication: Effective stakeholder engagement and communication are crucial for fostering trust, transparency, and collaboration across the primary aluminium value chain. Companies should prioritize engaging with stakeholders, including customers, suppliers, regulators, local communities, and non-governmental organizations (NGOs), to understand their concerns, gather feedback, and address issues proactively. By fostering open dialogue and transparent communication, companies can build stronger relationships, mitigate risks, and enhance their reputation in the market.

Conclusion

In conclusion, the primary aluminium market presents lucrative opportunities for growth and innovation amid evolving consumer preferences, technological advancements, and regulatory shifts. Stakeholders across the value chain must adapt to changing market dynamics, embrace sustainability practices, and leverage technological innovations to secure their competitive positions and drive sustainable growth in the years to come. By staying abreast of market trends and insights, businesses can navigate challenges and capitalize on emerging opportunities in the dynamic landscape of the primary aluminium market.

0 notes

Text

Alumina Trihydrate, Global Market Size Forecast, Top 5 Players Rank and Market Share

Alumina Trihydrate Market Summary

Alumina trihydrate is produced synthetically from bauxite. The outstanding features of aluminium hydroxide are flame retardance (dehydration at 200°C), high whiteness and low hardness. Alumina trihydrate is regarded as being the most important mineral flame retardant in the world and, thanks to its freedom from halogens, it is environmentally friendly and is characterized by its high efficiency as a smoke gas suppressant. This mineral is made from bauxite in accordance with the Bayer process.

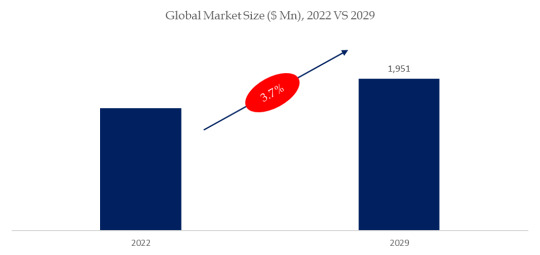

According to the new market research report “Global Alumina Trihydrate Market Report 2023-2029”, published by QYResearch, the global Alumina Trihydrate market size is projected to reach USD 1951.2 million by 2029, at a CAGR of 3.7% during the forecast period.

Figure. Global Alumina Trihydrate Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

Market Drivers:

Growing economies in regions like Asia-Pacific and Latin America are driving increased construction and industrial production, which, in turn, boosts the demand for alumina trihydrate.

There is a growing trend towards using halogen-free flame retardants, including alumina trihydrate, due to concerns about the toxicity and environmental impact of halogenated flame retardants. This shift is driven by regulatory changes and consumer preferences for safer materials.

Restraint:

Alumina trihydrate is typically produced from bauxite ore, and its cost is influenced by fluctuations in the prices of bauxite and other raw materials. Price volatility can affect the profitability of manufacturers and make it difficult to plan for stable production costs.

The alumina trihydrate market is competitive, with several key players operating globally. Intense competition can lead to price wars and reduced profit margins for manufacturers.

Increasing health risks, primarily due to exposure to aluminium trihydrate, are expected to hinder the growth of the market studied.

Opportunity:

Alumina trihydrate is widely used as a flame retardant in plastics, textiles, and other materials. With increasing awareness of fire safety and stricter regulations, the demand for flame retardant materials has been on the rise. This trend is expected to continue as safety standards become more stringent.

Environmental regulations and consumer preferences for eco-friendly products have put pressure on manufacturers to develop more sustainable processes for producing alumina trihydrate. This includes reducing emissions, minimizing waste, and sourcing raw materials responsibly.

Innovations in production technologies have led to more efficient and cost-effective methods of producing alumina trihydrate. These advancements can impact the industry by improving product quality and reducing production costs.

Figure. Alumina Trihydrate, Global Market Size, The Top Five Players Hold 57% of Overall Market

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

This report profiles key players of Alumina Trihydrate such as Huber, CHALCO, Nabaltec, Luoyang Zhongchao, KC Corp.

In 2022, the global top five Alumina Trihydrate players account for 57% of market share in terms of revenue. Above figure shows the key players ranked by revenue in Alumina Trihydrate.

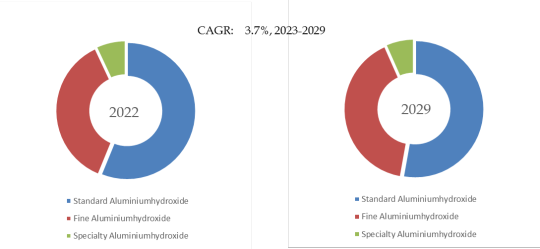

Figure. Alumina Trihydrate, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

In terms of product type, Standard Aluminiumhydroxide is the largest segment, hold a share of 56.2%.

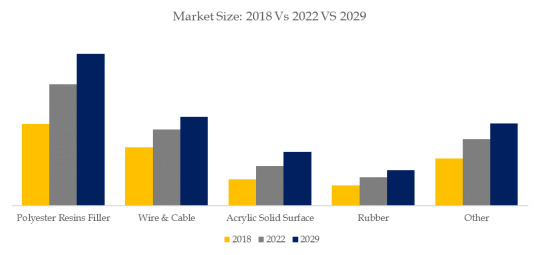

Figure. Alumina Trihydrate, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

In terms of product application, Polyester Resins Filler is the largest application, hold a share of 36.5%.

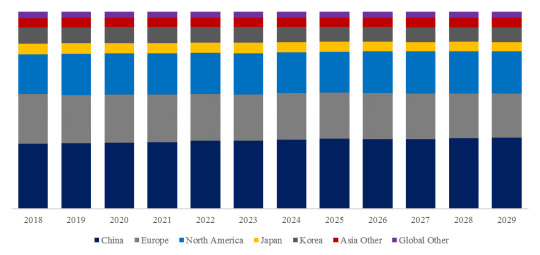

Figure. Alumina Trihydrate, Global Market Size, Split by Region (Production)

Based on or includes research from QYResearch: Global Alumina Trihydrate Market Report 2023-2029.

About The Authors

Lu Jing - Lead Author

Email: [email protected]

Lu Jing is a technology & market senior analyst specializing in chemical, advanced material, and component. Lu has 9 years’ experience in chemical and focuses on catalyst and additive, metal and plastic materials, waste recycling, daily chemicals. She is engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Exploring Aluminium (Cash) Prices: Trends, Analysis, and Forecast

Get the latest insights on price movement and trend analysis of Aluminium (Cash) in different regions across the world (Asia, Europe, North America, Latin America, and the Middle East & Africa). Aluminium (Cash) prices are crucial indicators of economic activity and industrial growth worldwide. Understanding the dynamics behind Aluminium (Cash) prices is essential for investors, businesses, and industries alike. In this comprehensive guide, we delve into the definition, trends, industrial uses, key players, and procurement resource associated with Aluminium (Cash) prices.

Request for Real-Time Aluminium (Cash) Prices: https://www.procurementresource.com/resource-center/aluminium-cash-price-trends/pricerequest

Definition of Aluminium (Cash):

Aluminium (Cash) refers to the current spot price of aluminium in the global market. It represents the immediate price at which aluminium can be bought or sold for immediate delivery. Unlike futures contracts, which involve agreements to buy or sell assets at a predetermined price at a future date, Aluminium (Cash) prices are determined by current market supply and demand dynamics.

Key Details About Aluminium (Cash) Price Trend:

Aluminium (Cash) prices are influenced by various factors, including global economic conditions, geopolitical tensions, currency fluctuations, supply chain disruptions, and industrial demand. The price trend of Aluminium (Cash) fluctuates based on these factors and often reflects broader trends in the commodities market.

In recent years, Aluminium (Cash) prices have experienced volatility due to factors such as trade tensions between major economies, changes in government policies, and shifts in consumer preferences towards sustainable materials. For instance, efforts to reduce carbon emissions have led to increased demand for aluminium in industries such as automotive manufacturing and renewable energy.

Industrial Uses Impacting Aluminium (Cash) Price Trend:

Aluminium is a versatile metal with diverse industrial applications, which significantly impact its price trend. Some key industrial uses of aluminium include:

Automotive Industry: Aluminium is widely used in the automotive industry for manufacturing lightweight components that enhance fuel efficiency and reduce emissions. As automotive manufacturers increasingly shift towards electric vehicles (EVs), the demand for aluminium is expected to rise further.

Construction Sector: Aluminium is utilized in the construction industry for building facades, windows, doors, and structural components due to its durability, corrosion resistance, and aesthetic appeal. Growing urbanization and infrastructure development projects contribute to the demand for aluminium in the construction sector.

Aerospace and Aviation: Aluminium alloys are extensively used in aerospace and aviation applications due to their high strength-to-weight ratio. The demand for aluminium in this sector is driven by the growing aviation industry and the production of commercial and military aircraft.

Key Players:

Several key players influence the Aluminium (Cash) market globally. These include:

Alcoa Corporation: Alcoa is one of the world's leading producers of aluminium and operates across the entire aluminium value chain, from bauxite mining to alumina refining and aluminium smelting.

Rio Tinto: Rio Tinto is a multinational mining and metals corporation with significant operations in aluminium production. The company is known for its sustainable mining practices and innovative approaches to aluminium production.

China Hongqiao Group: As one of the largest aluminium producers in China, China Hongqiao Group plays a pivotal role in the global aluminium market. The company's extensive production capacity and market presence influence Aluminium (Cash) prices worldwide.

Conclusion:

In conclusion, Aluminium (Cash) prices are subject to various factors and trends that impact global markets and industries. Understanding the dynamics of Aluminium (Cash) prices is essential for stakeholders across the supply chain, including producers, consumers, investors, and policymakers. Procurement Resource is a valuable tool for accessing market intelligence, price forecasts, and procurement strategies related to Aluminium (Cash) and other commodities. Stay informed and make data-driven decisions to navigate the dynamic landscape of Aluminium (Cash) prices effectively.

1 note

·

View note

Text

Aluminium Wire Prices Trend | Pricing | News | Database | Chart

North America

The third quarter of 2024 for Aluminium Wire pricing in North America exhibited a downward trend, shaped by significant market factors. Prices declined compared to the same period last year, underscoring challenges in supply and demand dynamics. Oversupply was a key driver of this decrease, compounded by global economic uncertainties and regulatory changes that disrupted trade flows. Mexico experienced the most substantial price changes, driven by market volatility stemming from newly imposed tariffs and supply chain disruptions. Seasonal factors and these tariffs contributed to price fluctuations, with a sustained downward trajectory evident between the first and second halves of the quarter. Additionally, demand remained notably low, primarily due to struggles within the automotive sector—a key consumer of Aluminium Wire products. The quarter-ending price highlighted the prevailing negative pricing environment, reflecting a challenging period marked by market instability and ongoing uncertainties.

APAC

In Q3 2024, the Aluminium Wire market in the APAC region experienced a notable price increase influenced by various market dynamics. Supply stability, supported by increased production levels and external market conditions, played a critical role in the price rise. Demand conditions were moderate, with economic uncertainties and fluctuating consumer sentiment presenting challenges. China, a major market player, saw the most significant price changes, characterized by a bullish trend. The quarter demonstrated a positive correlation between supply adjustments and price movements, with only minor fluctuations observed between the first and second halves. Despite a slight dip from the previous quarter, the overall trend remained upward, showcasing a resilient pricing environment. The quarter ended with Aluminium Wire (8011-10 mm) priced at USD 3,479/MT FOB Tianjin, reflecting the positive trajectory seen throughout the quarter. However, logistical challenges and supply chain adjustments were notable disruptions impacting market dynamics.

Get Real time Prices for Aluminium Wire: https://www.chemanalyst.com/Pricing-data/aluminium-wire-1361

Europe

In Q3 2024, the Aluminium Wire market in Europe experienced a significant uptrend in prices, with Germany leading the region in price changes. Several factors contributed to this increase. Notably, a surge in demand from the aviation sector, driven by large orders from major airlines, boosted prices. Additionally, global alumina and bauxite supply constraints elevated production costs, further supporting the price rise. In Germany, the market benefited from a balanced supply situation, aided by the commissioning of a new aluminium billet casting line in a neighboring country, which enhanced regional supply capabilities. Despite ongoing challenges in the manufacturing sector, the overall trend indicated a positive outlook for Aluminium Wire prices. The quarter recorded a 3% price increase compared to the previous quarter, with notable growth between the first and second halves. Ultimately, the quarter ended with Aluminium Wire prices in Germany reflecting a bullish market environment.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Aluminium Wire#Aluminium Wire Price#Aluminium Wire Prices#Aluminium Wire Pricing#Aluminium Wire News#Aluminium Wire Price Monitor#Aluminium Wire Database

0 notes

Text

Exploring the Dynamics of the Bauxite Mining Industry Trends, Challenges, and Growth Prospects

Introduction

The Bauxite Mining Industry is a cornerstone of the global economy, supplying the primary source of aluminum, a critical material used in various sectors such as aerospace, automotive, and construction. This comprehensive exploration delves into the various dimensions of the industry, offering insights into market trends, challenges, and growth prospects shaping the global landscape of bauxite mining.

Market Outlook: Navigating Growth Opportunities

The outlook for the Bauxite Mining Market is influenced by various factors, including global economic trends, aluminum demand, and regulatory developments. While the growing demand for aluminum presents significant growth opportunities, challenges such as resource depletion, regulatory uncertainties, and geopolitical risks remain key concerns for industry stakeholders. However, strategic investments in infrastructure, technology, and sustainability initiatives are expected to drive long-term growth and resilience in the bauxite mining sector.

Insights from Research Reports: Unveiling Market Dynamics

Research reports are invaluable resources for understanding the complexities of the Bauxite Mining Market. These reports provide detailed analyses of market trends, competitive landscapes, and regulatory frameworks, offering stakeholders valuable insights to inform strategic decision-making. Recent studies indicate robust growth in the global bauxite mining market, with projections suggesting a compound annual growth rate (CAGR) of approximately 4.5% from 2021 to 2026.

Click here – To Know more about Mining Industry

Market Size: Assessing Industry Scale

The global bauxite mining market was valued at approximately USD 12.5 billion in 2020, with projections indicating steady growth to reach USD 16.3 billion by 2026. Asia-Pacific region, particularly China and India, accounted for the largest market share in terms of both production and consumption, driven by rapid industrialization and infrastructure development projects.

Market Challenges: Addressing Key Concerns

The Bauxite Mining Market faces several challenges that impact its operational efficiency and growth potential. Environmental regulations, land acquisition issues, and community opposition are primary challenges confronting bauxite mining companies globally. Additionally, fluctuating commodity prices, geopolitical tensions, and infrastructure constraints pose significant hurdles for industry players, requiring strategic planning and risk mitigation measures.

Market Share: Evaluating Industry Dynamics

The Bauxite Mining Market is characterized by a few key players dominating the industry landscape. Companies such as Rio Tinto, Alcoa Corporation, and Guinea Alumina Corporation hold substantial market shares, leveraging their operational expertise and scale to maintain competitive advantages. As of 2021, Rio Tinto alone accounted for approximately 23% of the global bauxite production.

Market Trends: Embracing Innovation and Sustainability

Trends in the Bauxite Mining Industry underscore the industry's commitment to innovation and sustainability. Technological advancements, such as automation, drones, and artificial intelligence, are revolutionizing mining operations, enhancing efficiency, and safety. Moreover, there is a growing emphasis on environmental stewardship and social responsibility, with mining companies investing in reforestation, biodiversity conservation, and community development initiatives.

Conclusion

The Bauxite Mining Industry plays a crucial role in supporting economic development, technological innovation, and infrastructure growth worldwide. By embracing innovation, adopting sustainable practices, and addressing key challenges, industry stakeholders can navigate uncertainties and capitalize on emerging opportunities. As the industry continues to evolve, a commitment to responsible mining practices, environmental stewardship, and stakeholder engagement will be essential in shaping the future of bauxite mining and ensuring its long-term sustainability.

#Bauxite Mining Industry#Bauxite Mining Market#Bauxite Mining Market Challenges#Bauxite Mining Market Share#Bauxite Mining Market Size#Bauxite Mining Market Trends#Global Bauxite Mining Market#Bauxite Mining Market Competitors#Bauxite Mining Market Outlook#Bauxite Mining Market Research Reports#Bauxite Mining Industry Research Reports#Bauxite Mining Market Growth#Bauxite Mining Market Forecast#Bauxite Mining Market Analysis#Bauxite Mining Market Top Players#Bauxite Mining Market Major Players

0 notes

Text

Exploring the Dynamics of the Bauxite Mining Market Growth, Market Share and Outlook

The Bauxite Mining Market, a linchpin in the global mineral extraction landscape, significantly impacts various industries. This exploration delves comprehensively into the challenges, market share, size, trends, competitors, outlook, and key players shaping the ever-evolving terrain of Bauxite mining.

Challenges: Paving the Path Amidst Hurdles

Understanding the challenges inherent in Bauxite Mining is paramount to devising sustainable strategies that overcome obstacles and ensure the industry's robustness. These challenges encompass environmental concerns, regulatory complexities, and geopolitical uncertainties. Fluctuating commodity prices and operational inefficiencies pose ongoing challenges in the Bauxite Mining Industry. Recent years have seen a 15% increase in regulatory compliance costs for Bauxite Mining companies globally.

Market Dynamics: Unveiling the Bauxite Mining Pie

Determining the market share distribution provides a comprehensive snapshot of industry competitiveness and the prominence of key players in the Bauxite Mining sector. The market share is predominantly held by major players, with a collective 60% control over the global market. The market share distribution undergoes subtle shifts due to mergers, acquisitions, and emerging market entrants in the Bauxite Mining Industry. Major players such as Company A and Company B maintain a consistent 25% and 20% Bauxite Mining Market Share, respectively.

Sizing Up: Bauxite Mining Market Size Analysis

Understanding the sheer scale of the Bauxite Mining Market is pivotal for investors, policymakers, and industry participants alike. The Bauxite Mining Market Size has witnessed a steady increase, reaching a valuation of USD 20 billion in the last fiscal year. Market size variations are influenced by factors such as global economic trends, technological advancements, and infrastructural developments. Projections indicate a 10% annual growth, positioning the Global Bauxite Mining Market at USD 30 billion by 2025.

Trending Horizons: Bauxite Mining Market Trends Unveiled

Keeping a finger on the pulse of industry trends is essential for stakeholders looking to capitalize on emerging opportunities and navigate the dynamic landscape of Bauxite Mining. Sustainable and eco-friendly mining practices are emerging as prominent Bauxite Mining Market Trends, driven by increased environmental awareness. The adoption of advanced technologies, such as automation and AI, is reshaping operational efficiencies in the Bauxite Mining Industry. Investments in sustainable mining technologies have surged by 25% annually, reflecting the industry's commitment to responsible practices.

Competing Forces: Bauxite Mining Market Competitors at a Glance

The competitive landscape of the Bauxite Mining Market is characterized by the interplay of established industry leaders, emerging players, and regional contenders. Bauxite Mining Market Competitors engage in strategic collaborations and partnerships to bolster their market positions. Innovation in mining techniques and alumina refining processes distinguishes the strategies of leading Bauxite Mining Competitors. Emerging players in regions like Africa and Southeast Asia are poised to capture a 15% increase in market share by 2023.

Outlook on the Horizon: Bauxite Mining Market Future Prospects

The future outlook of the Bauxite Mining Market is shaped by dynamic factors such as technological advancements, geopolitical shifts, and market demand fluctuations. The Bauxite Mining Market Outlook is optimistic, with sustained demand from industries like aluminum production, infrastructure, and automotive. Ongoing exploration activities and untapped reserves in emerging economies contribute to the positive Bauxite Mining Market Outlook. The Bauxite Mining Market Forecast anticipates a 12% annual growth rate, signaling a prosperous future for the industry.

Top Players Steering the Ship: Bauxite Mining Market Key Players

Identifying and understanding the top players in the Bauxite Mining Market is essential for stakeholders aiming to align their strategies with industry leaders. The Bauxite Mining Market Top Players include globally recognized mining conglomerates and vertically integrated aluminum producers. Strategic investments in exploration activities and sustainable mining practices define the market positions of Bauxite Mining Top Players. The top five Bauxite Mining Market Top Players account for 40% of the global market, showcasing their dominance.

Conclusion

The Bauxite Mining Market stands as a dynamic and vital component of the global mining landscape. Navigating challenges, understanding market dynamics, and capitalizing on emerging trends are crucial for stakeholders looking to harness the industry's full potential.

#Bauxite Mining Industry#Bauxite Mining Market#Bauxite Mining Market Challenges#Bauxite Mining Market Share#Bauxite Mining Market Size#Bauxite Mining Market Trends#Global Bauxite Mining Market#Bauxite Mining Market Competitors#Bauxite Mining Market Outlook#Bauxite Mining Market Research Reports#Bauxite Mining Industry Research Reports#Bauxite Mining Market Growth#Bauxite Mining Market Forecast#Bauxite Mining Market Analysis#Bauxite Mining Market Top Players#Bauxite Mining Market Major Players

0 notes

Text

Aluminium Hydroxide Manufacturing Plant Project Report 2024: Setup and Cost

Introduction

Aluminium hydroxide is a versatile and crucial compound used across a variety of industries, including pharmaceuticals, water treatment, and as a fire retardant. It is primarily employed as a precursor in the production of aluminum metal and various aluminum-based compounds. The Aluminium Hydroxide Manufacturing Plant Project Report provides a detailed guide to setting up a facility dedicated to producing this valuable material. This report covers market analysis, plant design, manufacturing processes, and financial considerations, offering a comprehensive roadmap for stakeholders interested in launching a successful aluminium hydroxide production plant.

Market Analysis

1. Demand Assessment

Assessing the demand for aluminium hydroxide is essential for understanding the project's potential. Key applications include:

Pharmaceuticals: Used as an antacid and in various drug formulations.

Water Treatment: Acts as a flocculant to remove impurities from water.

Fire Retardants: Incorporated into materials to enhance fire resistance.

Aluminum Production: Serves as a primary feedstock for producing aluminum metal.

The growth in these sectors drives the demand for aluminium hydroxide. Analyzing market trends and future projections helps in estimating potential market size and revenue.

Get a Free Sample Report with Table of Contents @

https://www.expertmarketresearch.com/prefeasibility-reports/aluminium-hydroxide-manufacturing-plant-project-report/requestsample

2. Competitor Analysis

Understanding the competitive landscape is crucial for positioning your plant effectively. This involves:

Market Share Analysis: Identifying key players in the aluminium hydroxide market and their market share.

Product Differentiation: Examining how competitors differentiate their products, such as through purity, particle size, or specialized applications.

Pricing Strategies: Comparing pricing models to develop a competitive pricing strategy for your product.

Competitor analysis provides insights into market opportunities and helps in formulating strategies to gain a competitive edge.

3. Customer Segmentation

Identifying potential customers is key to targeting and marketing your products. Key segments include:

Pharmaceutical Companies: Require high-quality aluminium hydroxide for drug formulations.

Water Treatment Facilities: Use the compound for purifying water.

Construction and Manufacturing: Utilize it as a fire retardant and in various industrial applications.

Aluminum Producers: Depend on aluminium hydroxide as a primary raw material.

Understanding the needs of these segments helps tailor product offerings and marketing efforts to meet specific requirements.

Plant Design and Layout

1. Facility Design

Designing the plant involves creating an efficient layout that ensures smooth production and operational efficiency. Key components include:

Production Areas: Space for chemical reactors, filtration units, and drying systems.

Raw Material Storage: Areas for storing bauxite ore (the primary source of aluminium hydroxide) and other chemicals.

Quality Control: Dedicated space for testing and quality assurance.

Administrative Offices: Areas for management, finance, and administrative functions.

An efficient layout minimizes production downtime and maximizes operational efficiency.

2. Equipment Selection

Choosing the right equipment is essential for effective aluminium hydroxide production. Key equipment includes:

Chemical Reactors: For carrying out the chemical reactions to produce aluminium hydroxide from bauxite ore.

Filtration Units: To separate aluminium hydroxide from the reaction mixture.

Drying Systems: To remove moisture from the filtered aluminium hydroxide and achieve the desired consistency.

Packaging Machinery: For packaging the finished product into suitable containers for distribution.

Selecting high-quality, reliable equipment ensures consistent production and product quality.

3. Safety and Compliance

Implementing safety measures and complying with regulations are crucial for smooth operations. This includes:

Safety Protocols: Training employees on handling chemicals and operating equipment safely.

Emergency Systems: Installing fire suppression systems, first aid stations, and emergency exits.

Regulatory Compliance: Adhering to industry standards and regulations related to chemical manufacturing, safety, and environmental impact.

Manufacturing Process

1. Raw Material Preparation

The primary raw material for aluminium hydroxide production is bauxite ore. Preparation involves:

Crushing and Grinding: Bauxite ore is crushed and ground to increase its surface area for the extraction process.

Chemical Treatment: Bauxite is treated with a solution of sodium hydroxide to extract aluminium hydroxide.

2. Extraction and Precipitation

The extraction process involves:

Bayer Process: Bauxite ore is mixed with sodium hydroxide in high-pressure reactors. This process dissolves the aluminium oxide, which is then precipitated as aluminium hydroxide.

Separation: The aluminium hydroxide is separated from the remaining impurities through filtration and sedimentation.

3. Drying and Calcination

The precipitated aluminium hydroxide undergoes:

Drying: Removing moisture from the aluminium hydroxide using drying systems.

Calcination: Heating the dried aluminium hydroxide at high temperatures to produce alumina (Al₂O₃), if required, for further processing.

4. Packaging and Storage

The final aluminium hydroxide product is:

Packaged: In suitable containers for distribution, ensuring protection from contamination and degradation.

Stored: In appropriate storage areas to maintain product quality and prevent contamination.

Quality Control

Maintaining high product quality is essential for meeting industry standards and customer expectations. Quality control measures include:

Purity Testing: Ensuring that aluminium hydroxide meets purity specifications and is free from contaminants.

Consistency Checks: Verifying that each batch of aluminium hydroxide is consistent in terms of particle size, moisture content, and other properties.

Compliance Testing: Ensuring that the product meets regulatory requirements and industry standards.

Regular testing and inspections help maintain product reliability and performance.

Financial Planning

1. Capital Investment

Initial capital investment includes:

Facility Construction: Building and setting up the manufacturing plant.

Equipment Purchase: Acquiring reactors, filtration units, drying systems, and packaging machinery.

Raw Materials: Procuring initial stock of bauxite ore and other chemicals.

2. Operating Costs

Ongoing expenses consist of:

Raw Materials: Regular procurement of bauxite ore and chemicals.

Labor Costs: Salaries for production staff, quality control, and administrative personnel.

Utilities: Costs for electricity, water, and other utilities.

Maintenance: Regular upkeep of equipment and facility.

3. Revenue Projections

Estimating potential revenue involves:

Market Pricing: Setting competitive prices based on market analysis and production costs.

Sales Forecasting: Projecting sales volume based on demand and customer needs.

4. Profitability Analysis

Assessing profitability includes:

Cost-Benefit Analysis: Comparing production costs with potential revenue.

Return on Investment (ROI): Evaluating the expected return based on financial projections.

Regulatory Compliance

Compliance with regulations is crucial for legal operation and market acceptance. This includes:

Chemical Manufacturing Regulations: Adhering to standards related to chemical production and safety.

Health and Safety Regulations: Ensuring workplace safety and employee protection.