#BatteryResearch

Explore tagged Tumblr posts

Text

Introducing the Semco SI-B CT 5V 60A 16CH, a cutting-edge battery testing system for prismatic and pouch cells. With 16 independent channels, it ensures accurate formation, grading, and performance testing—perfect for EV battery manufacturers, energy storage, and R&D labs.

Learn more at Semco Infratech.

#BatteryTesting#LithiumIonBattery#EVBattery#EnergyStorage#BatteryTechnology#ElectricVehicles#BatteryManufacturing#RenewableEnergy#TechInnovation#SustainableEnergy#SmartEnergy#PowerSolutions#CleanTech#GreenEnergy#FutureEnergy#BatteryResearch#EnergyEfficiency#Electrification#BatterySafety#SemcoInfratech

0 notes

Text

The Future of Lithium-Ion Batteries: Innovations Ahead

Lithium-ion batteries have revolutionized the way we power our devices, from smartphones to electric vehicles. But what does the future hold for this incredible technology?

Exciting innovations are on the horizon! Researchers are exploring solid-state lithium-ion batteries, which promise greater safety and higher energy density. Additionally, advancements in fast-charging capabilities could reduce charging times significantly, making EVs even more practical.

Another breakthrough is the development of lithium-sulfur batteries, which could store up to five times more energy than traditional lithium-ion cells. These innovations could reshape industries, creating a more sustainable and efficient energy future.

Speaking of batteries, if you're looking for smaller cells, like a reliable SR626SW battery, don't forget to explore options that meet your needs. Keep an eye on these tech advancements—they’re set to power tomorrow!

What do you think about the future of lithium-ion technology? Let’s chat! 🚀🔋

#LithiumIonBatteries#BatteryInnovation#FutureOfEnergy#EnergyStorage#BatteryTechnology#SustainableEnergy#GreenTechnology#ElectricVehicles#CleanEnergy#TechInnovation#BatteryResearch#LithiumBatteries#BatteryRevolution#SmartEnergy#PoweringTheFuture

0 notes

Text

Lithium-ion Battery Binders Market worth $3.7 billion by 2027

The report "Lithium-ion Battery Binders Market by Type (Anode and Cathode), Material (PVDF, CMC, PMMA, SBR), Battery Chemistry, End Use (Automotive, Consumer Electronics, Energy Storage, Industrial), and Region - Global Forecast to 2027", is projected to grow from USD 1.6 billion in 2022 to USD 3.7 billion by 2027, at a CAGR of 18.7% from 2022 to 2027. Growing demand of various applications such as automotive, consumer electronics and industrial is expected to drive the global lithium-ion battery binders market.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=143858620

The lithium iron phosphate segment, by battery chemistry is estimated is estimated to grow at the highest rate in 2021.

By battery chemistry, the lithium iron phosphate segment is estimated is expected to grow at the highest CAGR during the forecast period in 2021. Lithium iron phosphate batteries suitable for use in high-power applications such as electric vehicles and power tools due to their high charge and discharge rates. These batteries have longer life spans, require lower maintenance, and are cost-effective and lightweight. These batteries have high use for end users in automotive and power generation, among other industries.

The polyvinylidene fluoride segment is estimated to account for the largest share of the lithium-ion battery binders market by material in 2021.

By material, the polyvinylidene fluoride segment accounted for the largest share of the lithium-ion battery binders market in 2021. It is a specialty plastic material in the fluoropolymer family widely used in applications such as chemical processing, construction, oil & gas. PVDF is widely used in lithium-ion batteries as a binder due to its high level of electrochemical and thermal stability and its excellent adhesion between electrode films and collectors.

The industrial segment is estimated to account for the largest share of the lithium-ion battery binders market by end-use in 2021.

By end-use, the industrial segment accounted for the largest share of the lithium-ion battery binders market in 2021. Lithium-ion batteries are used as the power source in off-the-road vehicles such as golf carts, data centers, forklift trucks, mining vehicles, and construction and industrial equipment. There is a continuous requirement for power supply for telecom data centers. Over the past few years, there has been a significant increase in the number of data centers, leading to an increase in demand for power. Thus, companies are shifting toward lithium-ion batteries as a power source for data centers. This is expected to drive the market for industrial segment during the forecast period.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=143858620

Europe is estimated to account for the second largest share of the global lithium-ion battery binders market in 2021

The Europe region accounted for the second largest share of the lithium-ion battery binders market in 2021. European region is hub to various growing manufacturing industries such as automotive, consumer electronics and others. Lithium-ion batteries are widely used in these industries and its growth helps to contribute the larger demand for lithium-ion battery binders in the region.

Arkema (US), Solvay (Belgium), LG Chem (South Korea), ENEOS Corporation (Japan), and Zeon Corporation (Japan) are some of the leading players operating in the lithium-ion battery binders market. These players have adopted the strategies of expansions, new product development, partnership, and joint ventures to enhance their position in the market are some of the leading players operating in the lithium-ion battery binders market.

#LithiumIonBatteries#BatteryTechnology#EnergyStorage#BatteryBinders#LithiumIonMarket#SustainableEnergy#EVBatteries#CleanEnergy#BatteryMaterials#ElectrodeBinders#GreenEnergy#BatteryManufacturing#EnergyInnovation#RenewableEnergy#BatteryResearch

0 notes

Photo

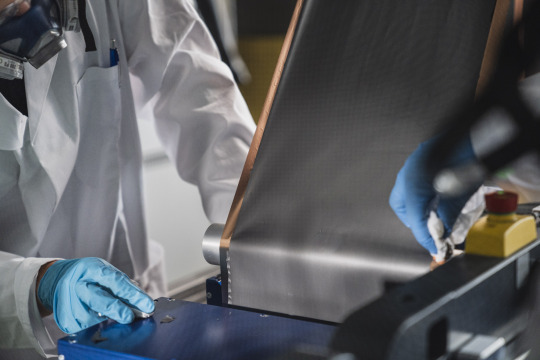

Doku Fraunhofer IWS - Dresden

#fraunhofer#fraunhoferiws#fraunhoferdresden#science#forschung#batterie#batterietechnologie#research#scientific research#battery#batteryresearch#batteryscience#siegfriedmichaelwagner#dresden#sachsen#germany#silliconsaxony#sogehtsaechsich#tech industry

0 notes

Photo

With the increasing demand and supply of 𝐋𝐢𝐭𝐡𝐢𝐮𝐦 𝐁𝐚𝐭𝐭𝐞𝐫𝐢𝐞𝐬, it has become one of the 𝒎𝒐𝒔𝒕 𝒕𝒓𝒂𝒅𝒆𝒅 𝒑𝒓𝒐𝒅𝒖𝒄𝒕 on our portal. 🤗 What are you waiting for join us today and avail 𝟏𝟎𝟎% 𝐅𝐫𝐞𝐞 𝐌𝐞𝐦𝐛𝐞𝐫𝐬𝐡𝐢𝐩💯 🌐Visit- www.go2bng.com 📩E-mail us - [email protected] 📲Call us - 1800 57205 58 #buyandsell #b2b #b2bmarketplace #batterycompany #energysolutions #sustainableenergy #battery #batterystorage #batteryresearch #batterymanufacturer #liionbatteries #batterytechnology #batterymanufacturing #homeappliances #electricvehicles #batteryelectric #bms #batterymanagement #evehicles #india #trade #exportimport7m

1 note

·

View note

Text

Asia-Pacific Flexible Battery Industry estimate to 2018-2024

Asia-Pacific Flexible Battery Industry estimate to 2018-2024

Asia-Pacific Flexible Battery Industry Report 2018 is an expert and top to bottom examination on the present condition of the Flexible Battery business Asia-Pacific Flexible Battery statistical surveying report gives an essential review of the business including definitions, characterizations, applications and industry chain structure. The Flexible Battery advertise investigation is accommodated…

View On WordPress

#Asia-PacificFlexible Battery Flexible BatteryResearch Report#Asia-PacificFlexible Battery Industry#Asia-PacificFlexible Battery sector#Flexible Battery Flexible Battery Industry#Flexible Battery 2018 Report#Flexible Battery market analysis#Flexible BatteryMarket

0 notes

Text

The Prismatic Cell Tester 5V 60A 64CH offers accurate voltage and current measurements with independent 64-channel control. Designed for prismatic cell testing, it ensures reliable performance for R&D and manufacturing. Features include modular design, comprehensive software integration, and precise battery evaluation.

#BatteryTesting#PrismaticCellTester#BatteryAnalyzer#EVBatteryTesting#LithiumBattery#BatteryTechnology#EnergyStorage#BatteryResearch#LabEquipment#BatteryTestingEquipment#RDBatteryTesting#ElectricVehicleBattery#HighPrecisionTesting#BatteryManufacturing#TechInnovation

0 notes

Text

Explore the Semco SI BCDS 34V 30A 8CH, a high-performance Battery Charge Discharge Tester designed for Lead-Acid and Lithium Batteries. With 8 independent channels, it ensures precise testing, making it ideal for battery manufacturers, research labs, and testing facilities.

🔹 Learn More: www.semcoinfratech.com 📞 Call: +91-8920681227

📢 Subscribe for the latest insights on battery technology!

0 notes

Text

youtube

Explore the Semco SI BCDS 34V 30A 8CH, a high-performance Battery Charge Discharge Tester for Lead-Acid & Lithium Batteries. With 8 channels, it ensures precise testing for battery manufacturers, labs, and testing facilities.

Call: +91-8920681227 | 🌐 Visit: www.semcoinfratech.com

📢 Subscribe for More! 🔔

#BatteryTesting#ChargeDischargeTester#LithiumBattery#LeadAcidBattery#BatteryResearch#SemcoInfratech#Youtube

0 notes

Text

The SEMCO SI BCDS 60V 20A 40CH Battery Aging Machine offers precise lifecycle testing for lithium-ion batteries, ensuring accurate performance assessments for R&D and manufacturing applications.

#BatteryTesting#BatteryAging#LithiumIon#BatteryLife#BatteryPerformance#BatteryResearch#BatteryTechnology#BatteryTestingEquipment#BatteryTest#BatteryAnalyzer#BatteryTesters#BatteryTestingSystem#BatteryTestingMachine#BatteryTestingLab#BatteryTestingSolutions

0 notes

Text

Optimize battery performance with the Semco SI-Y BCDS 50V (5A/10A)35CH, designed for accurate aging and reliability testing of lithium-ion batteries.

#BatteryTesting#BatteryAgingMachine#LithiumIonBatteries#SemcoInfratech#BatteryPerformance#BatteryTechnology#EVBatteries#BatteryResearch#BatteryLifeCycle#EnergyStorage

0 notes

Text

Explore the critical role of aging tests in battery development and manufacturing. These tests uncover degradation mechanisms, optimize materials, enhance performance, and ensure the reliability, safety, and longevity of batteries for applications like EVs and energy storage.

#BatteryAgingTests#BatteryManufacturing#BatteryDevelopment#BatteryQuality#EnergyStorageSolutions#LithiumIonBatteries#BatteryTechnology#BatteryReliability#BatteryPerformance#SustainableEnergy#BatterySafety#EVBatteries#BatteryTesting#BatteryLifeOptimization#BatteryDegradation#BatteryInnovation#EnergyEfficiency#RenewableEnergyStorage#AdvancedBatteries#BatteryResearch

0 notes

Text

Working of a Battery: How Is the Energy Created?

Batteries are integral to modern life, powering everything from smartphones and laptops to electric vehicles and renewable energy storage systems. But have you ever wondered how a battery works? In this blog, we will demystify the process behind battery energy creation and explore their fundamental components and chemical reactions.

What Is a Battery?

A battery is an electrochemical device that converts stored chemical energy into electrical energy. It operates based on the principles of electrochemistry, specifically oxidation-reduction (redox) reactions, where electrons are transferred between substances.

Key Components of a Battery

Every battery consists of three primary components:

Anode (Negative Electrode):

The anode undergoes oxidation, releasing electrons during the discharge process.

Common materials like lithium (in lithium-ion batteries), and zinc (in alkaline batteries).

Cathode (Positive Electrode):

The cathode undergoes reduction, accepting electrons during the discharge process.

Lithium cobalt oxide, nickel manganese cobalt (NMC), and manganese dioxide are common materials.

Electrolyte:

A medium that facilitates the movement of ions between the anode and cathode.

Common electrolytes like liquid solutions, gels, or solid-state materials containing salts like lithium hexafluorophosphate (LiPF6).

Separator:

A porous barrier that prevents direct contact between the anode and cathode, avoiding short circuits while allowing ion flow.

How Does a Battery Create Energy?

The energy creation process in a battery involves three main stages:

1. Charge Phase:

During charging, an external power source applies voltage to the battery.

Electrons are forced from the cathode to the anode through an external circuit, while ions migrate through the electrolyte to maintain charge balance.

This process stores chemical energy in the battery.

2. Discharge Phase:

When the battery powers a device, the stored chemical energy is converted back into electrical energy.

The anode releases electrons, which flow through the external circuit to the cathode, generating an electric current.

Simultaneously, ions travel through the electrolyte to complete the internal circuit.

3. Redox Reactions:

The energy generation hinges on redox reactions:

Oxidation at the Anode: The anode loses electrons (e.g., Li → Li+ + e⁻).

Reduction at the Cathode: The cathode gains electrons (e.g., CoO2 + Li+ + e⁻ → LiCoO2).

These reactions create a flow of electrons, producing electrical energy.

Types of Batteries and Their Working Principles

Different types of batteries use unique chemistries to create energy:

Primary Batteries:

Non-rechargeable and designed for single use.

Examples: alkaline batteries, and zinc-carbon batteries.

Secondary Batteries:

Rechargeable and suitable for multiple cycles of use.

Examples: lithium-ion, lead-acid, nickel-metal hydride (NiMH) batteries.

Flow Batteries:

Use liquid electrolytes stored in external tanks.

Ideal for large-scale energy storage applications.

Factors Influencing Battery Efficiency

Energy Density: Determines how much energy the battery can store per unit weight or volume.

Charge and Discharge Rates: Measured in C-rates, indicating how quickly the battery can be charged or discharged.

Temperature: Extreme temperatures can reduce battery efficiency and lifespan.

Cycle Life: Refers to the number of charge-discharge cycles a battery can undergo before its capacity significantly diminishes.

Innovations in Battery Technology

Recent advancements aim to improve battery performance, sustainability, and safety:

Solid-State Batteries: Replace liquid electrolytes with solid materials for higher energy density and safety.

Lithium-Sulfur Batteries: Offer higher energy capacity compared to traditional lithium-ion batteries.

Recycling Technologies: Protect valuable materials like lithium, cobalt, and nickel to reduce environmental impact.

Conclusion

The working of a battery is a fascinating interplay of chemistry and physics. By understanding the basic principles behind energy creation, we can appreciate the importance of batteries in driving technological progress and supporting a sustainable future. As innovations continue to enhance battery technology, the potential applications and benefits will only expand.

If you’re intrigued by the science behind batteries or have questions about their applications, please leave a comment or explore our other blogs for more insights.

#BatteryTechnology#EnergyStorage#RenewableEnergy#CleanEnergy#Sustainability#GreenEnergy#ElectricVehicles#Innovation#BatteryTech#BatteryScience#LithiumIon#BatteryLife#BatteryStorage#BatteryPower#BatteryResearch

0 notes

Text

Ensure the safety and performance of your #lithiumionbatteries with a #BCDS. Discover the key benefits and why it's essential for both research and production.

Discover how a BCDS ensures:

Optimal performance

Enhanced safety

Extended lifespan

Quality assurance

Accelerated research

You can learn more about how a BCDS can benefit your business.

#BCDS#batterytesting#batterylife#batteryperformance#batteryresearch#batterymanufacturing#batterychargingdischarging#testingmachine#neware#semcoinfratech

0 notes