#Automotive Bumpers Market Analysis

Explore tagged Tumblr posts

Link

0 notes

Text

Thermoplastic Elastomer Market Overview: Key Drivers and Challenges

The global thermoplastic elastomer market size was USD 26,856.8 million in 2019 and is projected to reach USD 39,424.6 million by 2027, exhibiting a CAGR of 5.7% during the forecast period. The rising demand for lightweight, durable, and recyclable materials is fueling market expansion, with innovations in material development further driving adoption.

The report offers?

The report on the thermoplastic polyurethane market uncovers excellent insights into the market, systematic data with detailed analysis, market dynamics & aspects demonstrating development and growth, meticulous information about vital players in the market, and procured statistics about dominant regions.

Get a Free Sample Report - https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/thermoplastic-elastomer-tpe-market-104515

Key Market Drivers

Growth in Automotive Industry

Increasing use of TPEs in automotive applications such as seals, gaskets, interior components, and bumpers to enhance fuel efficiency by reducing vehicle weight.

Rising Demand for Eco-Friendly Materials

Growing awareness of sustainability is pushing manufacturers to develop recyclable and bio-based TPEs.

Expansion in Medical Applications

TPEs are widely used in medical devices, tubing, and wearable devices due to their flexibility, biocompatibility, and ease of sterilization.

Versatility Across Industries

TPEs’ ability to replace traditional materials in footwear, construction, and consumer goods applications is driving market growth.

Advancements in Material Technology

Development of high-performance TPE grades with enhanced thermal, mechanical, and chemical properties is opening new application areas.

Thermoplastic Polyurethane Market Segmentation

By Type of TPE

Styrenic Block Copolymers (SBCs)

Widely used in adhesives, sealants, and coatings.

Thermoplastic Polyolefins (TPOs)

Primarily used in automotive applications for impact resistance and durability.

Thermoplastic Polyurethanes (TPUs)

Preferred in footwear, medical devices, and consumer electronics for their abrasion resistance and flexibility.

Thermoplastic Vulcanizates (TPVs)

Used in automotive and industrial applications due to their high heat resistance.

Copolyester Elastomers (COPEs)

Known for their high strength and chemical resistance, ideal for engineering applications.

Others (Nylon-based, Bio-based TPEs)

Emerging materials with niche applications in sustainable and specialty markets.

By End-Use Industry

Automotive

The largest application segment, driven by the need for lightweight and durable materials.

Building & Construction

TPEs are used in roofing membranes, sealants, and insulation materials.

Medical

Includes applications in tubing, catheters, and wearable devices.

Footwear

Growing demand for lightweight and comfortable shoes is boosting TPE use in soles and uppers.

Consumer Goods

Includes applications in electronics, toys, and household items.

Others

Includes industrial and agricultural applications.

By Region

North America

Strong demand from the automotive and medical sectors.

Europe

Focus on sustainability and high-quality materials drives market growth.

Asia-Pacific

The largest and fastest-growing region due to rapid industrialization and a booming automotive industry.

Rest of the World

Moderate growth, with opportunities in emerging markets.

Regional Insights:

Expanding Infrastructure to Fuel Growth in APAC

High rates of growth and development and population growth and industry consolidations have resulted in innovation and development, establishing APAC as a global industrial powerhouse. In addition, the expanding infrastructure and increasing product demand in the construction industry will improve the prospects of the market in the forthcoming years. The growing need for high-performance materials is propelling the TPU market in Asia Pacific to new heights. Moreover, the high demand for polyester-based thermoplastic polyurethane from the electronics sector is driving the rise in North America. Furthermore, increased demand for footwear due to increased disposable income would drive market expansion in this region. The fast-developing automobile sector in nations like Germany, France, and the United Kingdom will boost market expansion in Europe.

Emerging Trends

Sustainability and Bio-Based TPEs

Increasing development and adoption of bio-based and recyclable TPEs to reduce environmental impact.

Growing Adoption in 3D Printing

Use of TPE filaments in additive manufacturing is opening new avenues for customization and rapid prototyping.

Advancements in Automotive Applications

Increasing use of TPEs in electric vehicles (EVs) for weight reduction and energy efficiency.

Miniaturization in Medical Devices

Demand for TPEs is growing in wearable and minimally invasive medical devices.

Increased Focus on Customization

Development of tailor-made TPE grades for specific applications across industries.

Source- https://www.fortunebusinessinsights.com/thermoplastic-elastomer-tpe-market-104515

Competitive Landscape

The thermoplastic elastomer market is highly competitive, with key players focusing on R&D and strategic collaborations to expand their market presence. Leading companies include:

BASF SE

SABIC

Dow Inc.

Kraton Corporation

LG Chem Ltd.

Covestro AG

Asahi Kasei Corporation

Mitsubishi Chemical Corporation

Arkema S.A.

Teknor Apex Company

These companies are driving innovation in bio-based and high-performance TPEs to meet the evolving demands of various industries.

Future Outlook

The thermoplastic elastomer market is poised for steady growth, driven by advancements in material science, increasing demand for lightweight and durable materials, and expanding applications in emerging markets. The Asia-Pacific region is expected to lead in growth, while North America and Europe will remain key innovation hubs.

Conclusion

The thermoplastic elastomer market is transforming industries with its unique combination of flexibility, durability, and sustainability. As industries move toward lightweight, high-performance, and eco-friendly solutions, TPEs will play a pivotal role in shaping the future of manufacturing and product design.

0 notes

Text

Maleic Anhydride Market Analysis: Key Drivers, Challenges, and Opportunities

The global maleic anhydride market was valued at USD 4,386.1 million in 2023 and is anticipated to grow at a compound annual growth rate (CAGR) of 4.2% from 2024 to 2030. This growth is largely driven by the rising demand for unsaturated polyester resins (UPR), which is the primary component in the production of fiberglass-reinforced resins. These resins are essential in a variety of applications, including automotive, marine, and construction sectors. In construction, UPRs are commonly used in products like sinks, countertops, and bathtubs, contributing to the growing demand for maleic anhydride.

One of the key drivers behind the growth of the maleic anhydride market is the rising demand for unsaturated polyester resins (UPR). UPRs are essential in the production of fiberglass-reinforced resins, which offer a combination of lightweight, high strength, and resistance to corrosion. These characteristics make them ideal for a wide variety of applications, especially in industries where durability and performance are critical.

In automotive applications, UPRs are used in the manufacture of parts like body panels, bumpers, and other components that benefit from fiberglass’s lightweight and durable nature. Similarly, in the marine industry, fiberglass-reinforced materials are commonly used in boat hulls, decking, and other marine components that require high strength and resistance to environmental factors such as water and corrosion.

The construction industry also benefits from UPRs in the production of durable and aesthetically pleasing products such as bathtubs, countertops, and sinks. As the demand for such products increases in residential, commercial, and industrial construction, the demand for maleic anhydride, which is used to produce UPRs, is expected to grow correspondingly.

Gather more insights about the market drivers, restrains and growth of the Maleic Anhydride Market

Regional Insights

Asia Pacific

Asia Pacific is a major consumer of maleic anhydride globally, holding a significant 52.1% revenue share in 2023. The region's growth in the maleic anhydride market is expected to continue over the forecast period, driven by advancements in key sectors, such as pharmaceuticals, construction, and personal care & cosmetics. In the construction and pharmaceutical industries, maleic anhydride is primarily used in the production of unsaturated polymer resins, which are key materials for various applications. In personal care and cosmetics, maleic anhydride is used in hair fixatives and styling formulas, adding to its versatile demand across industries.

India

The pharmaceutical industry in India is a significant contributor to the growing demand for maleic anhydride. India is a global leader in pharmaceutical production and supplies over 50% of the world’s demand for vaccines. The Indian pharmaceutical sector is the third-largest in terms of global production, according to the India Brand Equity Foundation. As the pharmaceutical industry continues to grow, so does the demand for unsaturated polyester resins derived from maleic anhydride, further boosting market prospects in India.

North America

The North American maleic anhydride market is expected to experience the fastest growth during the forecast period, primarily due to the region’s expanding agricultural, automotive, and construction industries. Maleic anhydride plays a vital role in manufacturing unsaturated polymer resins, which are extensively used in these key sectors. With increasing demand for resins in the automotive and construction industries, the market for maleic anhydride in North America is poised to grow. The U.S. is a primary driver of this growth, given its strong industrial base and significant consumption of maleic anhydride-based resins.

U.S.

The U.S. maleic anhydride market is influenced by various factors, including the fluctuating prices of butane, the raw material used in its production, and ongoing trade dynamics. The market is also impacted by trade tensions, particularly the trade war with China, which has affected supply chains and pricing strategies. Despite these challenges, the U.S. remains a leading consumer of maleic anhydride, driven by demand from its large automotive, construction, and agricultural sectors.

Europe

In Europe, the demand for maleic anhydride is driven by the expanding automotive and construction industries, where it is used extensively in the production of unsaturated polyester resins. These resins are utilized in a wide range of applications, from automobile parts to building materials, making maleic anhydride an essential component. As Europe continues to prioritize sustainability and green construction methods, the demand for high-performance materials like maleic anhydride is expected to rise.

Germany

Germany plays a central role in the global maleic anhydride market, not only as a significant consumer but also as a leading exporter. The country’s market for maleic anhydride is influenced by the growth in the automotive and construction industries, both of which require large amounts of maleic anhydride-based resins. Germany is a key manufacturing hub for automobile production, and its strong industrial output supports a robust demand for maleic anhydride.

Central & South America

In Central and South America, the demand for maleic anhydride is expected to expand, driven by the region’s growing automotive, construction, and food & beverage sectors, along with ongoing industrialization and population growth. The rise of manufacturing activities and increasing infrastructure projects are expected to fuel demand for maleic anhydride in the region, especially for use in resins that are critical for construction and automotive applications.

Argentina

In Argentina, the maleic anhydride market is seeing positive growth, primarily driven by the automotive sector, as well as the wind energy and construction industries. As Argentina continues to expand its infrastructure and energy sectors, including the growing wind energy industry, demand for maleic anhydride is expected to rise. The automotive sector's demand for fiberglass-reinforced composites also contributes to the market’s growth, supporting the use of maleic anhydride-based resins.

Middle East & Africa

The Middle East & Africa (MEA) region is witnessing rising demand for maleic anhydride due to its wide array of applications in agriculture, construction, personal care, cosmetics, and pharmaceuticals. The automotive and wind energy industries in the region are also driving the demand for maleic anhydride, as fiberglass-based resins are used in vehicle parts, wind turbine blades, and other critical components. Furthermore, the ongoing industrialization in the MEA region is expected to further boost the demand for maleic anhydride across several sectors.

Saudi Arabia

Saudi Arabia faces challenges in its maleic anhydride market due to fluctuations in crude oil prices, which impact raw material costs and production dynamics. Despite these challenges, the country continues to be a significant player in the global maleic anhydride market, driven by its diversification efforts away from oil reliance. The government’s focus on expanding non-oil sectors, such as automotive, construction, and renewable energy, is expected to positively influence the demand for maleic anhydride in the region.

Browse through Grand View Research's Organic Chemicals Industry Research Reports.

• The global chlorinated polyethylene market size was valued at USD 641.7 million in 2023 and is projected to grow at a CAGR of 8.3% from 2024 to 2030.

• The global chemical tanker shipping market size was valued at USD 34.65 million in 2023 and is projected to grow at a CAGR of 4.2% from 2024 to 2030.

Key Maleic Anhydride Company Insights

Several key players dominate the maleic anhydride market, with some of the most prominent ones being Huntsman International LLC, Mitsubishi Chemical Corporation, LANXESS A.G., INEOS, and Nippon Shokubai Co., Ltd. These companies have established themselves as significant contributors to the maleic anhydride sector, each employing distinct strategies to strengthen their market position and expand their product offerings.

Mitsubishi Chemical Corporation

Mitsubishi Chemical Corporation is a global leader in performance products and industrial materials, and it operates as a subsidiary of Mitsubishi Chemical Holdings Corporation (MCHC), a prominent investment holding group based in Japan. The company is organized into three major business segments: performance products, industrial materials, and other businesses. Mitsubishi Chemical plays a vital role in the production of maleic anhydride, which is an important raw material in several applications, including the production of unsaturated polyester resins. The company has a significant international presence, with regional offices and subsidiaries in key markets such as the U.S., Germany, Hong Kong, Singapore, and China, allowing it to cater to a diverse range of industries globally.

LANXESS A.G.

LANXESS A.G. is a leading German specialty chemicals company that was formed as a spin-off from Bayer A.G.'s chemical operations and polymer activities. LANXESS is deeply involved in the manufacturing and distribution of a broad array of products, including additives, chemical intermediates, plastics, and other specialty chemicals. As one of the major players in the maleic anhydride market, LANXESS focuses on producing chemicals that serve a variety of industries such as automotive, construction, electronics, and agriculture. The company’s strategic emphasis on innovation and sustainability has positioned it as a strong competitor in the global chemical market.

Key Maleic Anhydride Companies:

The following are the leading companies in the maleic anhydride market. These companies collectively hold the largest market share and dictate industry trends.

• Cepsa

• INEOS

• Huntsman International LLC

• Lanxess A.G.

• Mitsubishi Chemical Corporation

• MOL Hungarian Oil & Gas Plc

• Nippon Shokubai Co., Ltd.

• Polynt Group

• Thirumalai Chemicals Ltd.

• Jiangyin Shunfei

• Tianjin Bohai Chemicals.

Order a free sample PDF of the Maleic Anhydride Market Intelligence Study, published by Grand View Research.

#Maleic Anhydride Market#Maleic Anhydride Market Analysis#Maleic Anhydride Market Report#Maleic Anhydride Market Regional Insights

0 notes

Text

Low Temperature Coatings Market — Forecast(2024–2030)

Low temperature coating is widely used to apply coatings to valves, pipes, fittings and welds. They are mostly used in cold temperature conditions as they have the ability to cure down to 0°C. The increase in energy savings due to reduction in cure temperatures is boosting the growth of the market. The Low Temperature Coatings Market is experiencing a significant uptick due to the increasing demand for energy-efficient coatings. As sustainability becomes a focal point across industries, there’s a surge in the adoption of low-temperature cure coatings. These coatings not only reduce energy consumption during the curing process but also contribute to lowering greenhouse gas emissions.

Industries such as construction, automotive, and aerospace are embracing this trend, driven by both environmental concerns and the need for cost-effective, energy-efficient coating solutions. A notable trend in the Low Temperature Coatings Market is the continuous evolution of low-temperature curing techniques. Manufacturers are investing in research and development to innovate coating processes that can cure effectively at lower temperatures, reducing energy requirements and enhancing application flexibility. Advanced formulations, such as UV-curable low-temperature coatings, are gaining traction for their ability to cure rapidly with minimal heat, opening new possibilities in coating sensitive substrates and expanding the range of applications in various industries.

Request Sample

Report Coverage

The report: “Low Temperature Coatings Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the low temperature coatings industry.

By Coating: Powder Based, Liquid Based.

By Chemistry: Polyester, Epoxy, Polyurethane, Acrylic resin, and Others.

By Application: Concrete, Portable water storage tanks, Fittings, Steel, Pipes, Valves, Wood, wheels, Grills, Bumpers, Roof racks, Exterior and Interior trims, Construction and Others.

By End Use: Automotive, Appliances, Furniture, Industrial, Heavy-Duty Equipment’s, and Others

By Geography: North America, South America, Europe, APAC, and RoW.

Inquiry Before Buying

Key Takeaways

Asia-Pacific dominates the low temperature coatings Market owing to increasing demand from growing automotive industry in the region.

The use of environment friendly coating is driving the growth of the low temperature coatings market.

The longer and costlier drying and curing for large parts is hindering the growth of the low temperature coatings market.

By Chemistry — Segment Analysis

Acrylic segment held the largest share in the low temperature coatings market in 2023 as it is widely used in automotive industry. Acrylic formulations provide an ideal solution combining balanced performance, good weather resistance, and advantageous processing. Acrylic based coatings are tremendously versatile. They have low-cost and a broad performance range, from ultra-removable to ultra-high durability depending on the formulation. Due to this benefit, the application of low temperature coatings based on acrylics is increasing greatly in heavy-duty equipment’s. Epoxy segment is the second largest segment in low temperature coating market. Epoxy coatings are widely used due to their exceptional chemical resistance, low porosity, durability, and bond strength. Epoxy coating films are strongly resistant to most chemicals and make excellent anticorrosion coatings. They are one of the principal materials used to control corrosion in the cold environment.

Buy Now

About IndustryARC™: IndustryARC primarily focuses on Cutting Edge Technologies and Newer Applications of the Market. Our Custom Research Services are designed to provide insights on the constant flux in the global demand-supply gap of markets. Our strong analyst team enables us to meet the client research needs at a very quick speed with a variety of options for your business. We look forward to support the client to be able to better address customer needs; stay ahead in the market; become the top competitor and get real-time recommendations on business strategies and deals. Contact Us: https://tinyurl.com/yk8khvpa Website URL: https://www.industryarc.com/

0 notes

Text

Automotive Fascia Market: Impact Growth, Forecast, Research 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Automotive Fascia Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2031.” The study provides a detailed analysis of the industry, including the global Automotive Fascia Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Automotive Fascia Market?

The global automotive fascia market size was US$ 22.3 Billion in 2022. The global automotive fascia market is expected to register a revenue CAGR of 6.5% during the forecast period and reach a market size of US$ 39.3 Bn in 2031.

What are Automotive Fascia?

An automotive fascia is the front or rear section of a vehicle designed to enhance its appearance and aerodynamics. It usually incorporates parts like the bumper, grille, headlights, and trim pieces into a cohesive and attractive surface. Constructed from materials such as plastic, metal, or composites, the fascia also serves practical functions, including absorbing impact in minor collisions and housing sensors and other essential technological features found in modern vehicles.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2047

What are the growth prospects and trends in the Automotive Fascia industry?

The automotive fascia market growth is driven by various factors and trends. The automotive fascia market is a dynamic and expanding sector, fueled by advancements in vehicle design, increased demand for visually appealing and aerodynamically efficient vehicles, and the integration of cutting-edge technologies. Market growth is driven by factors such as rising vehicle production, consumer preferences for lightweight and durable materials, and stringent safety regulations. Innovations in materials, like high-performance plastics and composites, are improving the functionality and design potential of automotive fascias. Key industry players are focusing on research and development to provide customized and advanced fascia solutions, meeting the evolving demands of the automotive industry. Hence, all these factors contribute to automotive fascia market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Standard Fascia

Illuminated Fascia

Sports Fascia

Luxury Fascia

Others

Material Type:

Plastic

Metal

Composites

Others

Technology:

Passive Safety Systems

Active Safety Systems

Advanced Driver Assistance Systems (ADAS)

Connectivity and Integrated Electronics

Others

Vehicle Type:

Passenger Cars

Light Commercial Vehicles (LCVs)

Heavy Commercial Vehicles (HCVs)

Electric Vehicles (EVs)

Others

Sales Channel:

Original Equipment Manufacturers (OEMs)

Aftermarket

Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Who are the key players operating in the industry?

The report covers the major market players including:

Magna International Inc.

Samvardhana Motherson Group

Faurecia

Plastic Omnium

Flex-N-Gate Corporation

Montaplast GmbH

Compagnie Plastic Omnium

Hanwha Advanced Materials Corporation

Yanfeng Global Automotive Interiors

SRG Global

Toyoda Gosei Co., Ltd.

View Full Report: https://www.reportsandinsights.com/report/Automotive Fascia-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Thermoplastic Polyolefin Market: Current Analysis and Forecast (2022-2028)

According to a new report published by UnivDatos Markets Insights, the Thermoplastic Polyolefin Market was valued at more than USD 4.5 billion in 2020 and is expected to grow at a CAGR of around 6% from 2022-2028. The analysis has been segmented into Type (In-Situ TPO, Compounded TPO, Others); Application (Automotive, Building & Construction, Medical, Industrial, Footwear, Home Appliances); Region/Country.

The thermoplastic polyolefin market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the thermoplastic polyolefin market. The thermoplastic polyolefin market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the thermoplastic polyolefin market at the global and regional levels.

Market Overview

Thermoplastic Polyolefin (TPO) is defined as a polymer/filler blend that usually consists of some fraction of a thermoplastic, an elastomer, or rubber, and usually a filler. Also, TPO compounds are resin blends of polypropylene (PP) and uncrosslinked EPDM rubber and polyethylene. They are characterized by high impact resistance, low density, and good chemical resistance. Furthermore, TPOs are used for exterior body parts such as bumpers, rocker panels, body seals, automotive gaskets, doors & windows, and other parts. Moreover, many companies are expanding their product portfolio by focusing on launching new products in the market which in turn is also contributing to the growth of the market. For instance, in Dec 2020, SABIC launched a new polyolefin plastomer-based solution for liquid containers with superior leakage resistance.

Some of the major players operating in the market include The Dow Chemical Company, Lyondellbasell Industries Holdings B.V., ExxonMobil Corporation, Mitsui Chemicals, Borealis AG, Mitsubishi Chemical Holdings Corporation, Chevron Phillips Chemical Company LLC, Avient Corporation, A.Schulman, and INEOS Capital Limited.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted many industries and has transformed the way industries work is delivered. The thermoplastic polyolefin market has been significantly affected during these times owing to the delay in construction, manufacturing of vehicles, and others during the pandemic.

The global thermoplastic polyolefin market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on type, the market is segmented into in-situ TPO, compounded TPO, and others. The compound TPO category is to witness a higher CAGR during the forecast period. This is mainly because these are high-performance elastomers designed to improve performance in a wide range of end products and applications. Additionally, properties such as weather resistance and non-degradable to sunlight exposure are also some of the factors due to which they are widely used in the production of roofing and other exterior materials

On the basis of application, the market is categorized into automotive, building & construction, medical, industrial, footwear, and home appliances. Among these, the automotive to hold a significant share of the market in 2020. The growth of this segment can be attributed to the growing usage of TPO in automobiles mainly because it provides lightweight and highly durable auto parts. In addition, rapid economic growth in various countries leading to improvements in the transportation infrastructure and construction of vehicle production plants are also expected to positively influence the market of this segment in the upcoming years

Thermoplastic Polyolefin Market Geographical Segmentation Includes:

North America (U.S., Canada, and Rest of North America)

Europe (Germany, UK, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

Asia-Pacific is anticipated to grow at a substantial CAGR during the forecast period. This is mainly due to the increasing construction and automotive industries. In addition, the growth of the healthcare sector and the development of the renewable energy industry is also driving the growth of the market. Furthermore, increased construction production is contributing to the demand for the thermoplastic polyolefin industry in the Asia-Pacific region as it finds applications in commercial and residential roofing owing to its properties such as weather resistance and cold resistance. Further, the TPO roofing systems offer significant reflectivity and energy efficiency, as well as strong UV resistance. Therefore, the use of the TPO in the roof system reduces the heat gain of the building

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=26877

The major players targeting the market include

The Dow Chemical Company

Lyondellbasell Industries Holdings B.V.

ExxonMobil Corporation

Mitsui Chemicals

Borealis AG

Mitsubishi Chemical Holdings Corporation

Chevron Phillips Chemical Company LLC

Avient Corporation

A.Schulman

INEOS Capital Limited

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Thermoplastic Polyolefin market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the thermoplastic polyolefin market?

• Which factors are influencing the thermoplastic polyolefin market over the forecast period?

• What are the global challenges, threats, and risks in the thermoplastic polyolefin market?

• Which factors are propelling and restraining the thermoplastic polyolefin market?

• What are the demanding global regions of the thermoplastic polyolefin market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

About UnivDatos Market Insights (UMI)

Browse Other Related Research Reports from UnivDatos Market Insights

Flotation Reagent Market

Graphite Market

Ammonium Sulfate Market

Oilfield Chemicals Market

Gear Oil Market

About UnivDatos Market Insights

UnivDatos Market Insights (UMI) is a passionate market research firm and a subsidiary of Universal Data Solutions. We believe in delivering insights through Market Intelligence Reports, Customized Business Research, and Primary Research. Our research studies are spread across topics across the world, we cover markets in over 100 countries using smart research techniques and agile methodologies. We offer in-depth studies, detailed analysis, and customized reports that help shape winning business strategies for our clients.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

Chromium Market - Forecast (2024 - 2030)

The Chromium Market size is forecast to reach US$ 15.7 billion by 2027, after growing at a CAGR of 2.6% during the forecast period 2022-2027. Chromium can be used in a wide range of applications which include metal ceramics, chrome plating, refractory materials, dyes and paints, synthetic rubies, along with alloys such as ferrochromium, stainless steel, and other applications. Ferrochromium alloy is produced from chromite through silicothermic or aluminothermic reactions with chromium metal. According to the International Organization of Motor Vehicle Manufacturers (OICA), the total global automobile production reached 80.2 billion units in 2021, an increase of 3% as compared to 77.7 billion units in 2020. Chromium is commonly used for electroplating and conversion coatings in the exterior and interior of automobile parts such as steering wheel trims, gear shifts, license plate frames, bumpers, headlights, and other similar parts. Likewise, the anticorrosive properties of chromium make it ideal for electroplating electrical and electronic equipment. Thus, an increase in demand from the electronic industry along with an increase in automobile production acts as the major driver for the market. On the other hand, health hazards associated with the use of chromium may act as a constraint for the market.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞

COVID-19 Impact

There is no doubt that the COVID-19 lockdown has significantly reduced manufacturing, and production activities as a result of the country-wise shutdown of manufacturing sites, shortage of labor, and the decline of the supply and demand chain all over the world, thus, affecting the market. Studies show that the outbreak of COVID-19 sharply declined the production of raw materials in 2020 due to a lack of operations across multiple countries around the world. However, a slow recovery in the metallurgy industry has been witnessed across many countries around the world since 2021. Chromium is primarily used in the metallurgy industry during the production of metals in order to provide corrosion resistance and a glossy finish to the metals. For instance, according to the World Steel Association, the annual production volume of steel in Spain reached 14 million metric tons in 2021, an increase of 27.7% in comparison to 2020. Furthermore, in September 2021, Emirates Steel, based in Abu Dhabi, announced its plans for the development of a new steel manufacturing plant in the country. Once completed, the new plant is expected to increase the company’s total steel production capacity to over 5 million tons per year. In this way, a steady increase in the production of steel is expected to increase the demand for chromium as it is crucial for the production of stainless steel, owing to its hardening and corrosion resistance properties. This indicates a steady recovery of the market in the upcoming years.

Report Coverage

The report: “Chromium Market Report– Forecast (2022-2027)”, by IndustryARC covers an in-depth analysis of the following segments of the Chromium Industry.

By Type: Trivalent Chromium, Hexavalent Chromium.

By Application: Metal Ceramics, Chrome Plating, Refractory Materials, Dyes and Paints, Synthetic Rubies, Alloys (Ferrochromium, Stainless Steel, Others), and Others.

By End-Use Industry: Metallurgy, Hydraulics & Heavy Machinery, Aerospace & Aviation, Automotive, Construction, Electronics, Others.

By Geography: North America (USA, Canada, and Mexico), Europe (the UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, and the Rest of Asia-Pacific), South America (Brazil, Argentina, Colombia, Chile and the Rest of South America), the Rest of the World (the Middle East, and Africa).

Key Takeaways

Trivalent Chromium held a significant share in the Chromium market in 2021. Its wide range of characteristics, corrosion resistance, and heat resistance properties made it stand out in comparison to other types of chromium in the market.

Metallurgy industry held the largest share in the Chromium market in 2021, owing to the increasing demand for chromium for the production of metals such as steel, aluminum, and more. According to the World Steel Association, the annual production volume of steel in Belgium reached 7 million tons in 2021, an increase of 13.6% in comparison to 2020. The total steel production in Belgium reached 6.1 million tons in 2020.

Asia-Pacific dominated the Chromium Market in 2021, owing to the increasing demand for chromium from the metallurgy sector of the region. For instance, according to the World Steel Association, Japan is considered to be the third-largest country in steel production with 96.3 million tons of steel produced in 2021.

0 notes

Link

0 notes

Text

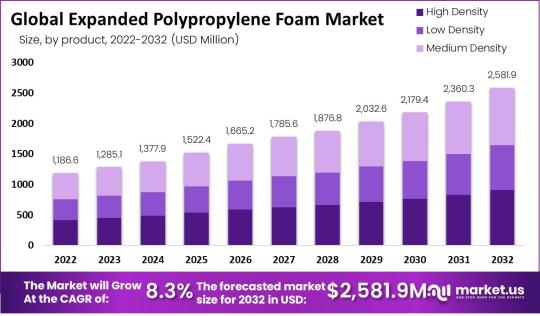

Expanded Polypropylene Foam: High-Density Segment Sees Surge in Automotive and Packaging Uses

Overview :

Expanded Polypropylene Foam Market was valued at USD 1,186.6 million and is expected to reach USD 2581.9 million in 2032. This market is estimated to register a CAGR of 8.3% between 2023 and 2032.

Get a Sample Copy with Graphs & List of Figures @ https://market.us/report/expanded-polypropylene-foam-market/request-sample/

Expanded polypropylene (EPP) foam is a versatile material known for its excellent impact resistance and lightweight properties. It is widely used in various industries due to its durability and cushioning ability. In consumer goods, EPP foam provides protection for sensitive electronics like computer equipment and circuit boards, where its shock-absorbing qualities help prevent damage during transport and use. Additionally, EPP foam's insulating properties make it valuable in packaging, building, and construction, where it contributes to energy efficiency and structural integrity.

Looking ahead, the demand for EPP foam is expected to grow, particularly in the toy and sports equipment sectors. As consumers become more health-conscious and seek products that offer better protection and safety, EPP foam's role in these areas is likely to expand. Its use in toys can provide safer play experiences for children, while in sporting goods, it can enhance comfort and injury prevention. This increasing awareness and preference for quality and safety are driving factors that will likely boost the global market for expanded polypropylene foam.

Key Market Segments

Based on Product

High Density

Low Density

Medium Density

Based on Application

Bumpers

Roof Pillars

Seat Bracing

Armrests

Other Applications

Based on End-User

Automotive

Packaging

Consumer goods

Appliances

Oil & Gas

Other End-Users

By Product Analysis:

The expanded polypropylene (EPP) foam market is segmented into high density, low density, and medium density, with high-density foams leading the market. In 2022, high-density EPP foams commanded over 42.0% of the market share, largely due to their use in automotive safety components and packaging.

By Application Analysis:

In terms of application, bumpers emerged as the leading segment, capturing over 42.0% of the market share in 2022. The increasing need for high-impact-resistant packaging for vehicle components drives this dominance, as EPP foam bumpers provide crucial safety features and impact absorption in automotive interiors and exteriors.

By End-Users Analysis:

The automotive sector is the primary end-user of expanded polypropylene foam, driven by its cost-effectiveness, mechanical strength, and moldability. EPP foam contributes to weight reduction in vehicles, enhancing fuel efficiency by up to 7% and lowering VOC emissions from interior components.

Key Players

JSP

BASF SE

Kaneka Corporation

DS Smith

Furukawa Electric Co., Ltd.

Hanwha Group

Sonoco Products

Knauf Industries

Izoblok

Dongshin Industry Incorporated

Clark Foam Products Corporation

Paracoat Products Ltd.

Molan-Pino South Africa

Signode Industrial Group LLC

Armacel

Furukawa Electric Co., Ltd.

Other Market Players

Drivers:

The expanding automotive industry is a major driver for the expanded polypropylene (EPP) foam market, as its lightweight and impact-resistant properties are ideal for components like bumpers and panels. Additionally, the growth of e-commerce and the increasing demand for sustainable packaging solutions are boosting the use of EPP foam in the packaging sector.

Restraints:

The high cost and price volatility of polypropylene, a key raw material, can impact profitability and increase finished product costs. EPP foam also faces competition from cheaper alternatives like expanded polystyrene (EPS) and may encounter challenges from emerging materials and technologies.

Opportunities:

There is significant growth potential in the automotive and packaging sectors, with emerging applications in building insulation and cushioning. The development of new uses, such as in toys and sports equipment, and advancements in manufacturing technology could reduce costs and broaden the material’s market reach.

Challenges:

Despite its advantages, EPP foam's market growth may be hampered by the development of new materials that could replace it in certain applications. Limited availability and higher costs associated with its recycling could also affect its overall market adoption and sustainability.

0 notes

Text

Ultra High Molecular Weight Polyethelene Market - Forecast(2024 - 2030)

Ultra high molecular weight polyethylene’s industry is affected by its economy and policies, so it is important to focus on economic indexes. With the global recovery in economy, more number of peoples are now paying attention towards environment standards, especially on those region which are still developing and also have large population and fast economic growth. The global ultra-high molecular weight polyethylene market is expected to grow at a CAGR of 9.9% from 2018-2023.

Request Sample

What is UHMWP?

Ultra high molecular weight polyethylene is a part of thermoplastic polyethylene. It has a long chain bonding of about millions of atomic mass unit. Which results as very tough material with its best characteristics of high impact strength, low coefficient of friction, high abrasion resistance and high chemical resistance, one of the best characteristics is that it remains tough even in low temperatures. It is odorless, tasteless and non-toxic type of materials.

What are the applications of UHMWP?

Ultra high molecular weight polyethylene are used in many sectors and industries like, Machined parts, Pulp and paper industry, Food and beverage industry, Porous parts and filters, Waste water treatment, Chemical industry, Sport and Leisure, Textile industry, Automotive industry, Coal and mining industry, Medical devices, Conveyor systems, Marines.

Inquiry Before Buying

Market research and Market Trend of UHMWP

Optimization of the new bonded UHMWPE technology is improving performance and reducing the cost of boats and marines. They are using it as a bumper material to reduce abrasion damage.

UHMWPE material is now widely used in healthcare sector. Due to high number of knee replacement surgeries is boosting the demand of UHMWP. The increasing old age population is expected to drive the market.

UHMWPE material is also getting used in the manufacture of hydraulic seals and bearings, due to good abrasion resistance they are used in medium mechanical duties in water, oil hydraulics, pneumatics and unlubricated applications.

Who are the major players in UHMWP market?

The companies referred in the market research report are Asahi Kasei (Japan), Calanese Corporation (U.S.), Honeywell International (U.S.), Lyondell Basell Industries (Netherlands), Mitsui Chemicals (Japan), Royal DSM (Netherlands) and 10 others.

Schedule a Call

What is our report scope?

The report incorporates in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and its impact during the forecast period 2018-2023.

All our reports are customizable to your company needs to a certain extent, we do provide 20 free consulting hours along with purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

Buy Now

Key Takeaways from this Report

Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level – for product types, end use applications and by different industry verticals.

Understand the different dynamics influencing the market – key driving factors, challenges and hidden opportunities.

Get in-depth insights on your competitor performance – market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

Analyze the sales and distribution channels across key geographies to improve top-line revenues.

Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

Get a quick outlook on the market entropy – M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

#ultra high molecular weight polyethelene market#ultra high molecular weight polyethelene market size#ultra high molecular weight polyethelene market shape#ultra high molecular weight polyethelene market forecast#ultra high molecular weight polyethelene market analysis#ultra high molecular weight polyethelene market report#ultra high molecular weight polyethelene market growth

0 notes

Text

Automotive License Plate Light - Recent Developments Study Analysis by 2033

An automotive license plate light is a lamp attached to the rear of a vehicle that illuminates the license plate. Many vehicles have these lights integrated into the rear bumper, while others have them mounted on the trunk lid or rear deck. The purpose of the license plate light is to ensure that the license plate is visible at night, making it easier for law enforcement to identify the vehicle. In some states, it is also required by law to have a license plate light in order to be legal on the road.

Unlock Growth Potential in Your Industry – Get Your Sample Report Now@https://www.globalinsightservices.com/reports/automotive-license-plate-light-market/?utm_source=PranaliP-organic

Key Trends

The automotive license plate light is a key safety feature on any vehicle. License plate lights help drivers see the license plate number in the dark, and they also make the license plate more visible to other drivers. License plate lights are required by law in many states, and they are typically found on the rear of the vehicle.

There are a few key trends in automotive license plate light technology. One is the use of LED lights. LED lights are more energy-efficient than traditional incandescent bulbs, and they also last longer. LED lights are becoming increasingly common in license plate lights, and many states now require that license plate lights be LED lights.

Another trend is the use of solar-powered license plate lights. Solar-powered license plate lights are powered by the sun, and they do not require batteries. Solar-powered license plate lights are becoming more popular because they are environmentally friendly and they save drivers money on batteries.

A third trend is the use of wireless license plate lights. Wireless license plate lights are battery-powered and they communicate with the vehicle’s computer system wirelessly. Wireless license plate lights are becoming more popular because they are easy to install and they do not require any wires to be run to the vehicle’s battery.

0 notes

Text

Drop Weight Impact Tester: Ensuring Durability and Reliability in Product Testing

Introduction

In the fast-paced world of manufacturing, ensuring the durability and reliability of products is paramount. The Drop Weight Impact Tester, a crucial piece of equipment offered by Pacorr Testing Instruments, is designed to meet these exact needs. This article delves into the features, applications, and benefits of the Drop Weight Impact Tester, highlighting why it is an indispensable tool for industries striving for excellence in product quality.

Introduction to Drop Weight Impact Testing

Drop Weight Impact Testing is a method used to determine the impact resistance of materials. This type of testing simulates real-world conditions where products might be subject to sudden and forceful impacts. The Drop Weight Impact Tester is engineered to replicate these conditions, providing accurate and reliable data on a material's toughness and durability.

Key Features of the Drop Weight Impact Tester

Precision Engineering: The Drop Weight Impact Tester is built with high-quality materials and advanced technology, ensuring precise and consistent results.

Versatility: This tester is capable of evaluating a wide range of materials, including plastics, metals, composites, and ceramics.

User-Friendly Interface: Equipped with an intuitive control panel, the Drop Weight Impact Tester allows for easy operation and data collection.

Adjustable Impact Energy: The device features adjustable impact energy settings, enabling users to customize tests according to specific material requirements.

Safety Measures: Built-in safety features, such as automatic shut-off and secure enclosures, ensure the safety of operators during testing.

Applications of the Drop Weight Impact Tester

The Drop Weight Impact Tester is widely used across various industries, including:

Automotive: Assessing the impact resistance of components such as bumpers, dashboards, and interior panels.

Packaging: Evaluating the durability of packaging materials to ensure they can withstand rough handling and transportation.

Construction: Testing building materials like concrete, steel, and glass for their ability to endure sudden impacts.

Consumer Goods: Ensuring the robustness of products such as smartphones, appliances, and sports equipment.

Benefits of Using the Drop Weight Impact Tester

Enhanced Product Quality: By identifying weak points in materials, manufacturers can make informed decisions to improve product design and quality.

Compliance with Standards: The tester helps companies comply with international quality standards and regulations, fostering trust and credibility in the market.

Cost Efficiency: Early detection of material defects reduces the risk of product failures, saving costs associated with recalls and repairs.

Innovation and Development: Continuoustesting and analysis contribute to the innovation of new materials and products with superior impact resistance.

How to Use the Drop Weight Impact Tester

Using the Drop Weight Impact Tester involves several key steps:

Preparation: Secure the material sample on the testing platform.

Setting Parameters: Adjust the impact energy settings according to the material type and desired test conditions.

Testing: Initiate the test by releasing the drop weight from a predetermined height.

Data Collection: Record and analyze the data to assess the material's impact resistance.

Maintenance and Calibration

To ensure the Drop Weight Impact Tester remains in optimal condition, regular maintenance and calibration are essential. Pacorr Testing Instruments provides comprehensive support and services, including:

Routine Inspections: Regular checks to identify and rectify any wear and tear.

Calibration Services: Ensuring the accuracy and reliability of test results through periodic calibration.

Technical Support: Access to expert guidance and troubleshooting assistance.

Conclusion

The Drop Weight Impact Tester from Pacorr Testing Instruments is a vital tool for any industry committed to producing high-quality, durable products. Its advanced features, wide range of applications, and significant benefits make it an invaluable asset for manufacturers. By investing in this tester, companies can enhance their product development processes, ensure compliance with quality standards, and ultimately deliver superior products to the market.

For more information about the Drop Weight Impact Tester and other testing solutions, visit Pacorr Testing Instruments.

Frequently Asked Questions (FAQ) about the Drop Weight Impact Tester

1. What is a Drop Weight Impact Tester?

A Drop Weight Impact Tester is a device used to measure the impact resistance of materials. It simulates real-world conditions where materials might experience sudden and forceful impacts to determine their toughness and durability.

2. How does the Drop Weight Impact Tester work?

The tester works by dropping a specified weight from a set height onto a material sample. The impact energy and resulting data are used to assess the material's ability to withstand sudden impacts.

3. What types of materials can be tested with the Drop Weight Impact Tester?

The tester is versatile and can evaluate a wide range of materials, including plastics, metals, composites, ceramics, and more.

4. What industries benefit from using the Drop Weight Impact Tester?

Industries such as automotive, packaging, construction, and consumer goods benefit from using this tester to ensure the durability and reliability of their products.

5. What are the key features of the Drop Weight Impact Tester?

Precision engineering for accurate results

Versatility in testing different materials

User-friendly interface for easy operation

Adjustable impact energy settings

Built-in safety measures for operator protection

6. Why is impact testing important?

Impact testing is crucial for identifying the weak points in materials, improving product quality, ensuring compliance with standards, reducing costs associated with product failures, and fostering innovation in material development.

7. How do you set up a test using the Drop Weight Impact Tester?

To set up a test:

Secure the material sample on the testing platform.

Adjust the impact energy settings based on the material and test requirements.

Initiate the test by releasing the drop weight.

Collect and analyze the data to assess the material's impact resistance.

8. How often should the Drop Weight Impact Tester be calibrated?

Regular calibration is essential to maintain the accuracy and reliability of test results. The frequency of calibration depends on the usage and the manufacturer's recommendations. Generally, it should be calibrated at least once a year.

9. What maintenance is required for the Drop Weight Impact Tester?

Routine inspections, cleaning, and lubrication of moving parts are necessary to ensure optimal performance. Additionally, regular calibration and professional servicing by the manufacturer or authorized service providers are recommended.

10. Can the Drop Weight Impact Tester be customized for specific testing needs?

Yes, the Drop Weight Impact Tester can be customized with different impact weights, heights, and additional features to meet specific testing requirements.

11. Is training required to operate the Drop Weight Impact Tester?

While the tester is designed to be user-friendly, it is advisable to undergo training to understand its functionalities fully and ensure accurate testing and data collection.

12. What support services does Pacorr Testing Instruments offer for the Drop Weight Impact Tester?

Pacorr Testing Instruments provides comprehensive support services, including installation, training, routine maintenance, calibration, and technical support to ensure the optimal performance of the tester.

13. Where can I find more information or purchase the Drop Weight Impact Tester?

For more information or to purchase the Drop Weight Impact Tester, visit the official Pacorr Testing Instruments website or contact their sales team directly.

14. What safety features are included in the Drop Weight Impact Tester?

The tester includes automatic shut-off, secure enclosures, and other safety mechanisms to protect operators during testing.

15. How can the data from the Drop Weight Impact Tester be utilized?

The data collected from the tester can be used to enhance product design, improve material selection, ensure compliance with quality standards, and support research and development efforts.

By addressing these frequently asked questions, manufacturers and industry professionals can better understand the importance and utility of the Drop Weight Impact Tester in ensuring product durability and reliability. For further assistance, Pacorr Testing Instruments offers expert guidance and support to help you get the most out of your testing equipment.

About Pacorr Testing Instruments and the Drop Weight Impact Tester

Pacorr Testing Instruments stands at the forefront of providing high-quality and reliable testing equipment designed to meet the diverse needs of industries worldwide. With a commitment to excellence, innovation, and customer satisfaction, Pacorr ensures that manufacturers can maintain stringent quality control, enhance product durability, and comply with international standards.

Pacorr Testing Instruments: A Legacy of Quality

Pacorr Testing Instruments has established itself as a trusted name in the testing equipment industry. Our mission is to deliver top-notch testing solutions that help businesses across various sectors ensure the highest levels of quality and reliability in their products. With a team of experienced professionals and a customer-centric approach, Pacorr continues to innovate and expand its product range to meet the evolving needs of the market.

Drop Weight Impact Tester: A Vital Tool for Quality Assurance

One of Pacorr’s flagship products is the Drop Weight Impact Tester. This advanced testing device is designed to evaluate the impact resistance of materials, making it an essential tool for industries that prioritize product durability and safety. Here’s an in-depth look at what makes the Drop Weight Impact Tester an indispensable asset:

Precision and Reliability

The Drop Weight Impact Tester is engineered with precision and accuracy in mind. It provides consistent and reliable results, ensuring that manufacturers can trust the data to make informed decisions about their materials and products.

Versatility in Testing

This tester is versatile and capable of evaluating a wide range of materials, including plastics, metals, composites, and ceramics. This makes it suitable for various industries such as automotive, packaging, construction, and consumer goods.

User-Friendly Design

The Drop Weight Impact Tester features an intuitive interface that simplifies the testing process. Operators can easily set parameters, conduct tests, and collect data, making it accessible for users of all skill levels.

Customizable Impact Energy

With adjustable impact energy settings, the tester allows for customization according to the specific requirements of different materials. This flexibility ensures accurate testing and meaningful results.

Safety First

Pacorr places a high priority on safety. The Drop Weight Impact Tester is equipped with several safety features, including automatic shut-off and secure enclosures, to protect operators during the testing process.

Applications Across Industries

The Drop Weight Impact Tester is used extensively in various industries to ensure the quality and durability of products:

Automotive Industry: Testing components such as bumpers, dashboards, and interior panels to ensure they can withstand impacts and protect occupants.

Packaging Industry: Evaluating the durability of packaging materials to ensure they can endure rough handling and transportation without compromising the product inside.

Construction Industry: Assessing building materials like concrete, steel, and glass for their ability to endure sudden impacts, ensuring structural integrity.

Consumer Goods Industry: Ensuring the robustness of everyday products such as smartphones, appliances, and sports equipment to enhance customer satisfaction and safety.

Commitment to Customer Satisfaction

At Pacorr, customer satisfaction is paramount. We offer comprehensive support services, including installation, training, maintenance, and technical assistance, to ensure that our clients get the most out of their testing equipment. Our team of experts is always ready to provide guidance and support, helping businesses achieve their quality assurance goals.

Innovating for the Future

Pacorr Testing Instruments is dedicated to continuous innovation. We invest in research and development to improve our products and develop new solutions that address the emerging challenges in quality control and material testing. Our commitment to innovation ensures that our clients always have access to the latest and most effective testing technologies.

Conclusion

The Drop Weight Impact Tester by Pacorr Testing Instruments is more than just a piece of equipment; it is a testament to our commitment to quality, reliability, and innovation. By providing precise, versatile, and safe testing solutions, we empower industries to achieve excellence in product durability and performance. For more information about our products and services, visit Pacorr Testing Instruments and discover how we can help you meet your quality assurance needs.

0 notes

Text

Gum Rosin Prices, Price Trend, Pricing, News, Analysis & Forecast

Gum Rosin Prices have been subject to fluctuations driven by a myriad of factors, ranging from supply and demand dynamics to geopolitical tensions and environmental regulations. This natural resin, derived from pine trees, serves as a crucial raw material in various industries, including adhesives, coatings, inks, and rubber. Historically, gum rosin prices have exhibited volatility due to its susceptibility to weather conditions, pest infestations, and shifts in global trade patterns. Moreover, the market for gum rosin is intricately linked with the performance of end-user industries, such as construction, automotive, and packaging. As a result, any disruptions in these sectors can ripple through the gum rosin supply chain, exerting pressure on prices.

In recent years, environmental concerns have emerged as a significant driver influencing gum rosin prices. Sustainable sourcing practices and eco-friendly manufacturing processes have gained traction, prompting producers to invest in responsible forestry and production methods. Consequently, the adoption of such practices can impact production costs, thereby influencing the pricing dynamics of gum rosin. Additionally, regulatory initiatives aimed at curbing deforestation and promoting biodiversity conservation can introduce compliance costs for producers, further shaping price trends in the market.

Get Real Time Prices of Gum Rosin: https://www.chemanalyst.com/Pricing-data/gum-rosin-1500

Furthermore, the global trade landscape plays a pivotal role in determining gum rosin prices. Tariffs, trade agreements, and currency fluctuations can significantly impact the cost competitiveness of gum rosin exports and imports, leading to price adjustments to maintain market share. Geopolitical events, such as trade disputes and sanctions, can introduce uncertainties, prompting market participants to reassess their sourcing strategies and pricing models. Moreover, shifts in consumer preferences towards locally sourced or sustainably produced gum rosin can alter trade flows and pricing dynamics on a global scale.

Supply chain disruptions, whether caused by natural disasters, transportation bottlenecks, or labor strikes, can also exert short-term pressure on gum rosin prices. These disruptions can lead to inventory shortages or delayed shipments, forcing buyers to compete for available supplies, thereby driving prices upwards. Conversely, periods of oversupply, often resulting from bumper harvests or increased production capacity, can exert downward pressure on gum rosin prices, compelling producers to adjust their pricing strategies to remain competitive.

The interplay between supply and demand dynamics is central to understanding gum rosin price trends. Economic growth, industrial activity, and consumer spending patterns directly influence the demand for products that incorporate gum rosin as a key ingredient. For instance, robust construction activity typically translates to higher demand for adhesives and sealants, which in turn, bolsters the demand for gum rosin. Conversely, economic downturns or slowdowns in specific sectors can dampen demand, leading to price softening as producers seek to offload excess inventory.

On the supply side, factors such as weather conditions, forest management practices, and technological advancements can impact the yield and quality of gum rosin. Adverse weather events, such as storms or droughts, can disrupt resin tapping operations, leading to temporary supply constraints and subsequent price spikes. Conversely, investments in sustainable forestry practices, such as agroforestry and resin tapping optimization, can enhance productivity and supply stability, potentially mitigating price volatility in the long run.

In conclusion, gum rosin prices are influenced by a complex interplay of factors, including supply and demand dynamics, regulatory developments, trade policies, and environmental considerations. Market participants must stay attuned to these multifaceted drivers to navigate the evolving landscape and make informed decisions regarding pricing, sourcing, and risk management strategies. As the global economy continues to evolve and sustainability becomes increasingly paramount, the gum rosin market is likely to witness ongoing shifts in pricing dynamics, presenting both challenges and opportunities for stakeholders across the value chain.

Get Real Time Prices of Gum Rosin: https://www.chemanalyst.com/Pricing-data/gum-rosin-1500

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

ABS Market Trends 2032: Analyzing Growth Drivers and Demand Patterns

The Acrylonitrile Butadiene Styrene (ABS) market has showcased impressive growth, with a valuation of USD 23.2 Billion in 2023 and a projected expansion to USD 35.6 Billion by 2032, reflecting a robust CAGR of 4.9%.

This market offers a comprehensive overview characterized by consistent advancement and diverse applications spanning multiple industries. ABS, renowned for its exceptional strength, durability, and resistance to both heat and chemicals, serves as a key material in sectors such as automotive, electronics, construction, and consumer goods. Its versatility, coupled with its compatibility with various manufacturing processes, contributes significantly to its widespread adoption on a global scale.

Request Sample Report: https://datahorizzonresearch.com/request-sample-pdf/acrylonitrile-butadiene-styrene-market-2782

Recent developments in the ABS market include:

Sustainable Initiatives: With increasing environmental concerns, there’s a growing focus on sustainable ABS production processes and recyclability.

Technological Advancements: Continuous innovations in ABS formulations and manufacturing technologies are enhancing product performance and expanding application possibilities.

Market Expansion in Asia Pacific: The Asia Pacific region, particularly China and India, is witnessing significant growth in the ABS market, driven by rapid industrialization, urbanization, and increasing consumer demand for durable and lightweight products.

Strategic Collaborations and Mergers: Companies in the ABS market are engaging in strategic collaborations, partnerships, and mergers to strengthen their market presence, expand product portfolios, and enhance geographical reach.

Demand from Automotive Sector: The automotive industry remains a key driver of demand for ABS materials, owing to their use in interior and exterior components, such as dashboards, trim panels, and bumpers.

Top Companies are:

· CHIMEI

· BASF SE

· LG Chem

· Asahi Kasei Corporation

· Lotte Chemical Corp

· INEOS

· DuPont

· Formosa Plastics Corporation

· SABIC

· TORAY INDUSTRIES, INC.

· PetroChina Company Limited

· Kumho Petrochemical

Market Segmentations:

By Type (2024 to 2032)

· Opaque

· Transparent

· Colored

By Grade (2024 to 2032)

· High Impact

· Heat Resistant

· Flame Retardant

· Electroplatable

· Blended ABS

By Application (2024 to 2032)

· Appliances

· Electrical and Electronics

· Automotive

· Consumer Goods

· Construction

· Others

Regional Analysis:

Geographically segmented, the Acrylonitrile Butadiene Styrene (ABS) market spans across North America, Latin America, Europe, Asia Pacific, and the Middle East and Africa. Forecasts suggest that Asia Pacific is poised to capture a substantial market share in the coming years, largely driven by burgeoning automotive production in countries such as China and India. According to the International Organization of Motor Vehicle Manufacturers (OICA), Asia’s motor vehicle production surged to approximately 50 million units in 2022. Moreover, the region’s escalating electronics manufacturing sector and rising demand for consumer goods further fuel market expansion.

Key highlights of the report include:

1. The report delivers thorough Market analysis, furnishing valuable insights to guide strategic decision-making.

2. The comprehensive research outlined in the study enhances the depth of your presentations and marketing strategies.

3. By offering crucial insights into key market competitors, the study empowers businesses with a strategic edge.

4. It delivers a precise assessment of evolving market dynamics, ensuring readers stay abreast of the latest industry trends.

5. With meticulous breakdowns of various market niches, the report facilitates informed decision-making processes.

Check Out More Related Reports:

Gas Detection Equipment Market

surface disinfectant market

0 notes

Text

Automotive Fascia Market: Impact Growth, Forecast, Research 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Automotive Fascia Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2031.” The study provides a detailed analysis of the industry, including the global Automotive Fascia Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Automotive Fascia Market?

The global automotive fascia market size was US$ 22.3 Billion in 2022. The global automotive fascia market is expected to register a revenue CAGR of 6.5% during the forecast period and reach a market size of US$ 39.3 Bn in 2031.

What are Automotive Fascia?

An automotive fascia is the front or rear section of a vehicle designed to enhance its appearance and aerodynamics. It usually incorporates parts like the bumper, grille, headlights, and trim pieces into a cohesive and attractive surface. Constructed from materials such as plastic, metal, or composites, the fascia also serves practical functions, including absorbing impact in minor collisions and housing sensors and other essential technological features found in modern vehicles.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2047

What are the growth prospects and trends in the Automotive Fascia industry?

The automotive fascia market growth is driven by various factors and trends. The automotive fascia market is a dynamic and expanding sector, fueled by advancements in vehicle design, increased demand for visually appealing and aerodynamically efficient vehicles, and the integration of cutting-edge technologies. Market growth is driven by factors such as rising vehicle production, consumer preferences for lightweight and durable materials, and stringent safety regulations. Innovations in materials, like high-performance plastics and composites, are improving the functionality and design potential of automotive fascias. Key industry players are focusing on research and development to provide customized and advanced fascia solutions, meeting the evolving demands of the automotive industry. Hence, all these factors contribute to automotive fascia market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Standard Fascia

Illuminated Fascia

Sports Fascia

Luxury Fascia

Others

Material Type:

Plastic

Metal

Composites

Others

Technology:

Passive Safety Systems

Active Safety Systems

Advanced Driver Assistance Systems (ADAS)

Connectivity and Integrated Electronics

Others

Vehicle Type:

Passenger Cars

Light Commercial Vehicles (LCVs)

Heavy Commercial Vehicles (HCVs)

Electric Vehicles (EVs)

Others

Sales Channel:

Original Equipment Manufacturers (OEMs)

Aftermarket

Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Who are the key players operating in the industry?

The report covers the major market players including:

Magna International Inc.

Samvardhana Motherson Group

Faurecia

Plastic Omnium

Flex-N-Gate Corporation

Montaplast GmbH

Compagnie Plastic Omnium

Hanwha Advanced Materials Corporation