#Automatic Flour Mill Plant

Explore tagged Tumblr posts

Text

https://www.authortalking.com/the-benefits-of-partnering-with-experienced-flour-mill-plant-manufacturers/

Discover the top 10 benefits of partnering with renowned flour mill plant manufacturers. Maximize efficiency, quality, and profitability with expert guidance.

0 notes

Text

Why Choose an Automatic Flour Mill Plant

Shree Viratra Engineering is the leading Flour Mill Plant Manufacturer and Exporter in India. A flour mill plant is an industrial facility that is used to process wheat grains into flour. Flour is a staple food that is widely used in various cuisines worldwide. Flour Mill Plant also known as Atta Mill Plant.

Benefits of Flour Mill Plant:

1) Consistent Quality: Flour mill plants use advanced technology and machinery to ensure that the milling process is efficient and consistent. This results in high-quality flour that is nutritious and safe for consumption. 2) Versatility: Flour mill plants can process various types of grains, such as wheat, maize, and rice, into different types of flour, such as whole wheat flour, all-purpose flour, and bread flour, making it a versatile facility for the food processing industry. 3) Increased Efficiency: A flour mill plant can produce a large quantity of flour in a relatively short time compared to manual processing. This leads to increased efficiency in the processing and packaging of flour, saving both time and labor costs. 4) Customization: Flour mill plants can be customized to produce different types of flour, including whole wheat flour, all-purpose flour, and specialty flour. This enables businesses to cater to specific customer needs and preferences.

Process of Flour Mill Plant:Intake and Cleaning: The first step in the process is to clean the grain. This involves removing any impurities such as stones, and dust. Conditioning: Once the grain has been cleaned, it is conditioned to optimize the milling process. This involves adding moisture to the grain to ensure that it is at the right level for milling. Milling: The next step is the milling process itself. The grain is fed into a milling machine that grinds it into flour. Grinding – This is the real action; here the raw material is ground to make a powder out of the wheat grains. First of all, all types of grains are blended well to form a batch of raw material. Packing: Finally, the flour is packed into bags or other containers for distribution. The packaging process may involve weighing and measuring the flour, as well as labeling and sealing the bags.

What Type of Machinery Used in Flour Mill Plant: Pre-Cleaner, Grader, Scoller, Conveyor, Planshifter, Centrifugal, Chakki, Packaging Machine, and a lot more as per the requirement.

Flour Mill Plant Features:

Easy to Operate and Maintain

Simple with Design with Sturdy Construction

High Efficiency

Lower Energy Consumption

Low Noise

Pollution-Free Operation

The grinding temperature is controlled below 15°

Conclusion:Flour Mill Plants are an essential part of the food industry. They play a crucial role in the production of high-quality flour. The use of modern technology has made the process more efficient, reliable, continued operation performance, low noise, and long-life service resulting in the production of high-quality flour at a faster rate.

0 notes

Text

Effortless Flour Grinding with Natrajaatachakki's Automatic Atta Chakki Machines

Make flour grinding easy with Natrajaatachakki's automatic atta chakki machines. Forget the pain of manual grinding—these machines do the work for you, giving you fresh, homemade flour in no time. Perfect for all types of grains, it's the easiest way to upgrade your kitchen routine!

0 notes

Text

What is a Dust Collector System and How it is works ?

AKJ Industries is a leading manufacturer and supplier of Dust Collector Systems in India, specializing in delivering high-performance solutions for industries requiring air purification and dust control. Their dust collector systems are designed to capture airborne dust particles, providing a cleaner and safer environment for industrial operations.

Uses:

AKJ Industries’ dust collector systems are widely used in industries such as cement, metalworking, pharmaceuticals, woodworking, mining, and food processing. These systems play a crucial role in maintaining workplace safety and air quality by effectively removing dust particles from the air. Dust collectors are essential in areas with heavy dust emissions like manufacturing plants, construction sites, and processing facilities, ensuring compliance with environmental and safety regulations.

Working:

Dust collector systems by AKJ Industries work by pulling in contaminated air through a series of filters. The system is equipped with fans that create airflow, drawing dust-laden air into the collection unit. Once inside, the dust particles are trapped by filters (such as bag filters or cartridge filters), and clean air is then expelled back into the environment. The accumulated dust is either collected in a hopper or disposed of periodically to maintain system efficiency. Advanced systems come with automatic cleaning mechanisms that prevent filter clogging and ensure continuous operation.

Benefits:

1. Improved Air Quality: The primary benefit of AKJ Industries' dust collector systems is cleaner air, reducing the risk of respiratory issues and improving overall working conditions.

2. Increased Productivity: By keeping the workspace free from dust, these systems ensure that machines and equipment run smoothly, preventing breakdowns and reducing maintenance costs.

3. Compliance: Dust collectors help industries meet regulatory standards for air quality, avoiding legal penalties and enhancing workplace safety.

4. Energy Efficient: AKJ's dust collectors are designed for minimal energy consumption, providing effective dust control without excessive power usage.

These benefits make AKJ Industries a trusted partner for businesses seeking reliable dust collection solutions.

Our Related Products:

Horizontal Cartridge Dust Collectors

Portable Dust Collectors

Wood Dust Collector

Bag House Dust Collectors

Cement Silo Dust Collector

Silo Dust Collector

Flour Mill Dust Collector

Cyclone Dust Collector

For more Information:- Contact us:- +91–9868621620 , +91–0120–4941514 Email:- [email protected], Address:- Khasra No-164, Pawan Puri Industrial Area, Abupur Muradnagar, Ghaziabad, U.P-201206

0 notes

Text

Fabric Filters: Keeping Your Air Clean and Your Operation Running Smoothly

In many industrial processes, dust and particulate control is essential. This is where fabric filters, also known as bag filters or pulse jet bag filters, come in. These workhorses of the air filtration world offer a reliable and efficient solution for capturing dust particles from air streams.

How Fabric Filters Work

Fabric filters utilize a series of woven or felted filter bags housed within a containment structure. Dust-laden air enters the filter and passes through these bags. The fabric acts as a barrier, trapping dust particles on its surface while allowing clean air to permeate through to the other side.

Cleaning the Fabric Bags

To maintain efficiency, fabric filters incorporate a cleaning mechanism. This typically involves a controlled burst of compressed air that travels through the bags at timed intervals. This dislodges dust particles from the fabric, allowing them to fall into a collection hopper for disposal.

Benefits of Fabric Filters

High Efficiency: Fabric filters can capture a wide range of dust particle sizes, even those incredibly fine.

Versatility: They can be used in a variety of applications across numerous industries, handling various dust types and concentrations.

Durability: Fabric filters are constructed with rugged materials to withstand harsh industrial environments.

Cost-Effective: They offer a cost-effective solution for dust collection, with low maintenance requirements and long filter bag lifespans.

Energy Efficient: The cleaning mechanism in fabric filters is designed for minimal compressed air usage, resulting in energy savings.

Applications for Fabric Filters

Fabric filters have a wide range of applications, including:

Cement production: Capturing dust from grinding mills, kilns, and clinker coolers.

Chemical processing: Removing dust from various chemical manufacturing processes.

Food and beverage production: Controlling dust in flour mills, grain processing facilities, and food packaging operations.

Woodworking: Filtering dust from sanding, sawing, and other woodworking processes.

Metalworking: Removing dust from grinding, polishing, and other metalworking operations.

Power generation: Capturing fly ash and other particulate matter from power plants.

Choosing the Right Fabric Filter

When selecting a fabric filter, several factors need to be considered, including:

The type and size of dust particles being filtered

The required air flow rate

The operating temperature of the air stream

The desired level of filtration efficiency

Himenviro - Your Partner in Fabric Filter Solutions

At Intensiv-Filter Himenviro, we offer a comprehensive range of fabric filter solutions to meet your specific needs. Our team of experts can help you select the right filter, design a customized system, and ensure optimal performance.

Contact us today to learn more about how fabric filters can benefit your operation!

0 notes

Text

Investing in high-quality machinery is crucial for businesses in the food processing industry, particularly for those involved in flour milling. Fully automatic atta chakki plants equipped with pulverizer machines represent the pinnacle of efficiency and product quality. Lucknow, a hub of industrial innovation, is home to some of the leading manufacturers of these advanced machines. This article explores the benefits, pricing, and key manufacturers of fully automatic atta chakki plants and pulverizer machines, highlighting Creature Industry as a prominent supplier in Lucknow.

#InvestInQuality#FoodProcessingMachinery#FlourMilling#AttaChakkiPlant#PulverizerMachine#IndustrialEfficiency#ProductQuality#LucknowManufacturers#CreatureIndustry#FoodProcessingInnovation#HighQualityMachinery#AutomatedMilling#IndustrialInnovation#LeadingManufacturers#EfficientProduction#BusinessInvestment#FoodIndustry#MachinerySupplier#AdvancedTechnology#ManufacturingExcellence#ProductConsistency#HygieneStandards#CostEffectiveSolutions#IndustrialMachinery

1 note

·

View note

Text

Fully Automatic Turnkey Plant Setup — Sona Machinery

Key Components of Sona Machinery’s Turnkey Plant Setup:

· Customized Design and Engineering

· State-of-the-Art Machinery

· Efficient Workflow Integration

· Precision Control Systems

· Comprehensive Training and Support

Benefits of Sona Machinery’s Turnkey Solutions:

· Enhanced Productivity

· Quality Assurance

· Operational Efficiency

· Scalability and Flexibility

Industries We Serve:

Rice Milling

Grain Processing

Seed Cleaning and Sorting

Pulses Processing

Flour Milling

Sona Machinery’s Fully Automatic Turnkey Plant Setup is the cornerstone of modern agricultural processing, delivering unparalleled efficiency, reliability, and precision to elevate your production capabilities. Experience the transformation in agricultural processing with our innovative turnkey solutions.

0 notes

Text

Truck Loading Conveyors manufacturers

Truck Loading Conveyors manufacturers

Raj Conveyors are the leading Truck Loading/Unloading Conveyors manufacturers. Our offered Loading Conveyors System is very cost effective, easy to maintain and saves considerable floor space. These are used to load carton boxes & Bags into trucks and containers. Were the loading deck is not available. Can be used in different industries were bags and boxes are used extecively for packing.

Movable

Easy to handle

Can achieve different heights for stacking of bags

Please Contact Us for Our Technical Broucher

Dock less Loading Conveyors

Dockless loading conveyors is quite welcome to automatiCally load or unload goods in and out of trailers/vans/truck/containers in warehouse,harbor,airport,dock,etc.it solves the problems of no shipping docks when loading or unloading.the mechanized operation largely increases work efficiency,relieves labor intensity and also reduces cost for modern enterprises in a side range of applications.it facilitates goods handing work and also provides advantages to advanced production,modernized mangement and safe operation.

Bags Loading & Unloading Conveyors

These types of conveyors are used for loading and unloading of 50, 100kg bags both jutte and carton boxes. This conveyors is having huge demand in soya plants, sugar mills & flour mills for storing activities.

#Warehouse Conveyor manufacturers#Flexible Gravity Conveyor manufacturers#Spiral Chutes conveyors manufacturers#Spiral gravity Roller Conveyors manufacturers#Truck Loading Conveyors manufacturers#Telescopic Belt Conveyors manufacturers

0 notes

Photo

"MEN ARE OUTMODED BY MODERN MACHINES,” North Bay Nugget. December 28, 1932. Page 2. ---- Technocracy Leaders Aims to Convince with Scientific Data ---- MACHINE-AGE PROGRESS ---- Industrial Creed on Defensive Against Its Persistent Opponents ---- New York, Dec. 28— Under the casual title of "An Energy Survey of North America" are being compiled some 3000 complicated graph and chart which some scientists believe will change the whole future course of this continent's life. These chart are the substance of Technocracy and by them the organization and its senstlonal promises of prosperity, leisure, and progress must stand or fail.

Technocracy is now on the defensive against critics who condemn the scheme as contrary to all established American principle and as dangerous to American morale at a time when it already is precariously balanced. Technocracy has only half-facts, reinforced by speculative theory, with which to fight back. "But just wait," says the Technocrat “until we have all our data ready.”

Many physical scientists as well as economists politician and industrialists now are among the doubters of the new philosophy of national technical control. But Howard Scott, chief Technocrat, is confident that once his fact-finding project is finished and the complete functioning of our "social mechanism has been pictured in blue-prints, the world can do nothing other than believe.

"Engineers may differ in political and social beliefs," Scott said, "but not as scientist. Engineers as such can be neither radical nor conservative given facts, they cannot disagree. If we provide them with all the data on what is happening industrially to this country, they will ell reach the same conclusion." Likened to Power Plan But why did Technocracy begin it work? Was it not necessary to make an unscientific assumption that there was something wrong with our present system before starting out to discover scientifically what was the matter with it?

Let Professor Walter Rautenstrauch, head of the Industrial engineering department of Columbia University, and host to the Technocrats answer this one:

“No,” he said, "We started on perfectly valid observations. If we had a power plant, for instance, that failed to respond automatically to increased or lightened load, we would know it was out of adjustment.

"We have seen our social mechanism get farther and farther out of adjustment. Industrial employment goes down; production goes up. Consumption doesn't keep pace with production; but debt goes skyrocketing. Depressions follow booms; but each succeeding period of prosperity is shorter and each depression is lower and of longer duration. It is like a huge machine shaking itself to pieces."

Here are some other observations of the Technocrats:

For 7,000 years mankind had to depend on the human body for energy and no change was effected in the rate of doing work. Then, James Watt and his steam engine started a revolution in the last 100 years; with steam and electricity, we have multiplied our energy resource 9,000,000 times.Scott says that of this acceleration 8,766,000 has occurred since 1900.

Machine-Age Progress. At for production increases, there are almost as many significant examples as there are machines: Five days once were required to make a pair of shoes; today, one workman can make 68 pairs in that time. Old-time brick-makers produced about 450 per day per man; a modern straight-line plant can make as many as 400,000 per day per man. A glass-blowing machine operated by one man can do the work of 19 using the handicraft method. A miller of old could make a barrel and a half of flour a day; a modern mill can produce 30,000 barrel a day per man— with a shorter day and better flour.

More up-to-date comparisons are furnished by statements that: An automobile could be made in 1929 with one-third as many man hours as were required in 1919— and one-twelfth as many as in 1909 .... Freight car unloading machinery is 218 times rapid as hand labor. Seventy men operating a digging machine can do the work of 7,000 with pick and shovel. With the same number of men, three times as much pig iron can be produced now as in 1904.... American power stations employing a total of about 240,000 men can produce energy equaling the work of 1,350,000,000 men ... A rayon plant is being built in New Jersey which will require no human labor except for one man pushing buttons Electric light bulb production has been speeded up 9000 times, per men hour, since 1914.

What are some other aspects of the picture as the Technocrats see it? While production increased at a fairly steady pace, employment in the manufacturing industries also increased— until 1918. Then, Scott says, the charts of every industry so far studied show that man-hours began to decrease while production continued to increase. These trends continued until 1929 when both fell off sharply.

Course of Depression They dropped as everyone knows into the present depreeelon And about depressions Technocracy has this to say:

That each succeeding one has been greater than the last and that each furnished the impetus for greater mechanizations of industry. Production efficiency was increased 9 per cent in 1905, 8 per cent In 1909, 11 per cent in 1912, 9 per cent in 1915, and 20 per cent in 1922. Today, says Technocracy, industry is so efficient that if our peak production of 1929 were to be resumed, less than half of our unemployed workers could be re-employed. And at the rate of decline now anticipated another ten years would bring the unemployment total to 25.000.000.

Now about debts which do not concern Technocracy except insofar as they are considered to be helping shake to pieces our present system: "We lift ourselves out of depressions by the creation of new debt,” Scott declares. "Our debt totals continue to rise when every other Index like production employment and consumption is decreasing. We now owe 16 times as much as in 1915 and more than four times as much per capita. Our total Industrial debt today is about $218,000,000,000 and it is increasing at a geometric rate. Taxes and obsolescence included the fixed charges on this debt now are $34,000,000,000 a year— nearly half the national Income in 1928. These obligations, which must be supported by the sale of goods, are growing faster than the goods are being produced."

Say Era Has Ended The old argument that has been advanced against the menace of technology— that the displacement of workers in Industry releases them for the building up of new industries— no longer holds good the Technocrats believe. They admit that that has happened before but declare that a limit has been reached. They claim to have discovered that technological advances now are bounding upward in geometric progression, where before they proceeded arithmetically. They say that the creation of new industries cannot possibly check the decline of employment because old Industries are constantly being further mechanized and the few new ones are made mechanically efficient as soon as they appear.

If there were no other restraining factor, Technocracy believes our present rates of growth would be curbed by scarcity of raw materials. Since 1900, they announce the United States has mined more iron than has been produced by all the world since the dawn of history. And if coal production were to increase at the rate it has in the past, we would need a ball of coal as large as the earth to supply our needs for the next 50 years.

Those are some of the reported findings of Technocracy. Most of them have bean criticized as inaccurate by reputable authorities in each field.

Photo caption: Labor looms in heroic proportions in the commonly accepted picture of mechanistic America. But Technocracy poses the question of whether man has become a mere adjunct to the machine. For Instance, 100 times more work is done when man lays aside a shovel to guide a giant coal-digging machine like one shown here. This is part of the argument concerning the machine age and its effects.

#new york#technocracy#technocratic government#the great depression#planned economy#economic crisis#capitalism in crisis#planisme#government by engineers#useless hands#mechanization#man machine#birth of the technocratic state#politics of chaos

0 notes

Photo

Domestic Combined Rice Mill With Pulverizer Hammer Mill 3HP Electric Motor - Krishitool.com

Book Now : https://www.krishitool.com/product-details.php?item_id=1917

Contact us : 9641377575

#combined rice mill machine#Combined Domestic Rice Machine#Automatic Mini Rice Machine#Combined flour and rice mill#Rice Mill Combine#combined rice and flour mill#rice mill machinery price list in india#combined rice mill price in india#mini rice mill price in kolkata#mini rice mill machine price in india#modern rice mill machinery price#mini rice mill 3hp#Mini Rice Mill#Rice Mill Plant#Flour Mill-Rice MIll Plant#Rice Mill Machinery#Combined Mini Rice Mill#Rice Mill#rice milling machinery#rice milling machine#top 10 rice mill in india#rice mill price in india#rice mill plant#rice mill price in assam#rice mill machine price list#rice mill machinery list#commercial rice mill machine price

1 note

·

View note

Text

https://handyclassified.com/safety-features-in-fully-automatic-flour-mill-plants

Discover how advanced safety features in fully automatic flour mill plants improve operational security and efficiency.

0 notes

Text

Benefits of Installing Dal Mill Plants in Food Processing Facility

Shree Viratra Engineering is the leading Manufacturer and Exporter of Dal Mill Plant in India. We also offer Multi-Pupose Dal Mill Plant like Toor Dal Mill Plant, Moong Dal Mill Plant, Udad Dal Mill Plant, Matar Dal Mill Plant, Chana Dal Mill Plant, Masoor Dal Mill Plat, Masoor Malka Dal Mill Plant, Black Dal Mill Plant, and Moth Dal Mill Plant. In this article, we will explore the benefits of the Dal Mill Plant and how we can help you to maximize your dal production. Dal is a staple food that is consumed by millions of people all over the world. As the world’s population grows, the demand for dal is increasing day by day. This makes it necessary for farmers to increase their daily production to meet the demand. Dal Mill Plant are one of the most effective ways to increase dal production. We offer several advantages over traditional methods of dal production, such as Increase efficiency, consistent quality, continue operation performance, low noise, pollution-free operation, low power consumption, long life, less manpower required, and less maintenance required.

Benefits of using Dal Mill Plant: Dal Mill Plant has several benefits that make them a popular choice among Dal farmers. Increased Production Efficiency: Dal Mill Plant uses advanced technology and equipment to process pulses into dal, which increases the production efficiency. With the installation of a dal mill plant in a food processing facility, the entire production process can be streamlined, resulting in higher productivity and faster output. Consistent Quality: Dal mill plants ensure consistent quality of output by using modern machinery and equipment. The use of automated systems for grading and sorting ensures that the dal is of high quality and meets the required standards. Health Benefits: Dal is a rich source of protein, fiber, and essential nutrients. With the installation of a dal mill plant, a food processing facility can offer healthy food options to consumers, contributing to their overall health and well-being. Versatility: Our Multi-Purpose Dal Mill Plant is versatile like Toor Dal Mill Plant, Moong Dal Mill Plant, Udad Dal Mill Plant, Matar Dal Mill Plant, Chana Dal Mill Plant, Masoor Dal Mill Plat, Masoor Malka Dal Mill Plant, Black Dal Mill Plant and more. Government Support: The Indian government provides various subsidies and incentives for the food processing industry, including the installation of a dal mill plant. As a leading Dal Mill Plant Manufacturer and Supplier in India, Shree Viratra Engineering provides installation of the Dal Mill Plant and offers various benefits like, Increase efficiency, consistent quality, continue operation performance, low noise, pollution-free operation, low power consumption, long life, less manpower required, and less maintenance required.

Dal Milling Plant Components:A Dal Milling Plant consists of several components that work together to process Dal. These components include Cleaning and Grading Machines, Dehusking Machines, Splitting Machines, Polishing Machines, Packaging Machines, Electrical Control Panels, separators, etc.

Factors to consider in choosing the Dal Mill Plant:When choosing a Dal Mill Plant, there are several factors that you should consider. Like Capacity, Automation, and Technology, Quality of Output, Maintenance and After-Sales Support, Energy Efficiency, Reputation of the Manufacturer, etc. Shree Viratra Engineering as a leading Manufacturer of Toor Dal Mill Plant in Jodhpur considers all these factors and provides a top-performance Dal Mill Plant.

Conclusion:Dal Mill Plants are an effective way to increase dal production. We offer several advantages over traditional methods of dal production, including increased efficiency, better quality control, and reduced labor costs. When choosing a Dal Mill Plant, it is important to consider factors such as the size of your farm, your budget, and the level of automation you require. As a Leading Supplier of Dal Mill Plant in India, Shree Viratra Engineering provides high-quality, long-life, durable, Dal Mill Plant.

0 notes

Text

High-Quality Automatic Atta Chakki Machines | Natrajaatachakki Manufacturer

Need a reliable automatic atta chakki machine manufacturer? 🌾✨ Natrajaatachakki offers top-quality, lasting, and easy-to-operate flour milling machines to meet all your needs. These machines work great whether you're using them for your house or your business. They promise freshly milled flour every time. 🏡🥖 Count on Natrajaatachakki for original, efficient, and excellent flour grinding solutions! 🌟

#AtaChakki#AutomaticMachines#FlourMill#natrajaatachakki#AttachakkiManufacturer#AutomaticAttachakkiMachine

0 notes

Link

We are bringing forth a wide range of Automatic Flour Mill as per the customer s requirements and demands. This Atta Chakki Plant is easy to install and has high working capacity that raises its demand rapidly. Further, our Atta Chakki Plant is made up of latest technology and finest quality components. Our Mailing Address:[email protected] | Toll Free Number :- 1800 258 8168 Mobile Number:– +91-98100-41919, +91-81999-70507 | Bansal Engineers

#flour mill plant#flour mill machinery#flour mill machine#automatic flour mill plant price#flour mill price

0 notes

Text

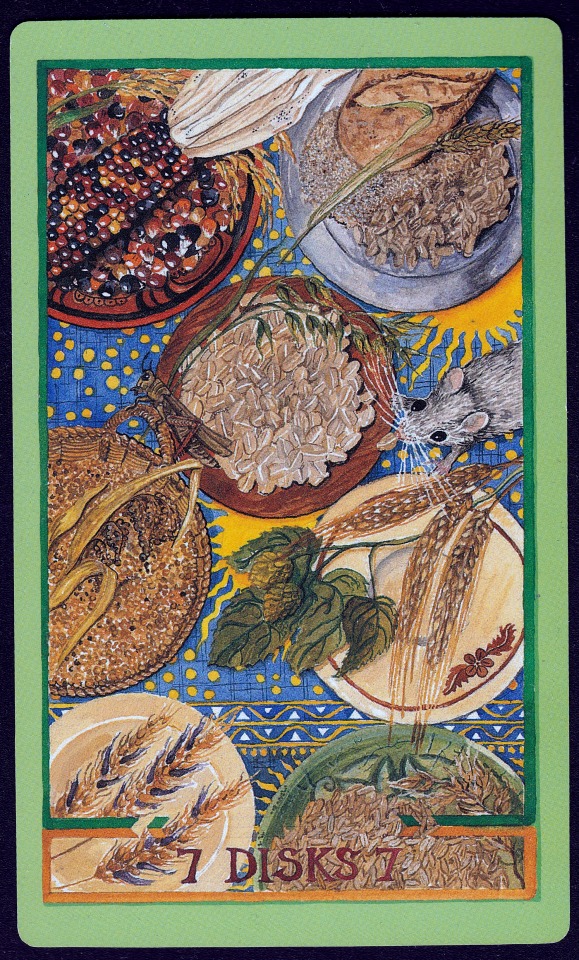

7 of Pentacles ~ Wheel Of Change Tarot

Grains from Around the World Seven is the product of three and four, and it therefore symbolizes the combination of the solar four with the lunar three. Seven is the number of synthesis and the number of the macrocosm because of its relation to the seven ancient planetary bodies for whom the days of the week are named. Seven was the number of Athena, the virgin goddess of practical woman’s knowledge, and in the Pythagorean system it was considered the number of wisdom. The heavenly sphere in which the seven planetary bodies moved was often thought of by the ancients as the heavenly corn mill. In Greek and Norse mythology there was a great goddess at the center of the cosmic millstone turning this cosmic wheel. Its continual turning was like the action of the mill; as it revolved again and again the Great Wheel created time while the earthly grain mill turned the grain to flour for bread. Grain is symbolic of the total life of the plant. It embodies all forms of the Triple Goddess within it, for it is the death of the plant and embodies the crone, it is the edible fruit of the the nurturing mother, and it is the new seed and is symbolic of the virgin, not yet planted. Grain was a child of the Great Goddess and embodied her son as the universal grain god, who was sacrificed yearly and returned in the form of nourishing food and sacred beer. In Native American myth, Corn Woman was killed and dragged around a field, and where her blood spilled the first corn plants grew. The grain embodies the soul of a people because life is dependent on it as the staple food of all. The sacrifice of the corn god symbolizes the cutting and harvest of something valued and sacred. The harvest is made with ceremony so as not to offend the spirit of the corn and to insure that the next harvest will be bountiful. In every culture the grain is honored; it is planted, reaped, milled, and used with respect for the spirit that lives within it. In cultures where alcohol is made from the grain—beer and whiskey from barley, sake from rice, and vodka from rye—the potent spirit of the god lived within the alcohol and entered you when you drank of his resurrected body. In the Seven of Disks both the grain itself and the plate or basket are apt symbols for the disk. Any foodstuff may represent the suit of Disks, for food nourishes us and helps the physical body grow. The plate offers the food to us, frames the food, and keeps it from the ground; it is a way of distinguishing the food as sacred. These seven grains from around the world—corn, wheat, oats, millet, barley, rye, and rice—show that although we all come from different cultures we are, in essence, the same. We all need grain to survive, and we all cultivate and honor the food we grow, investing it with symbolic value so that its nourishment is complete. This is a mirror of our unique qualities within the framework of humanity. People have such a strong relationship to their cultural grain that we automatically associate rice with China, oatcakes with Scotland, and corn with the native people of the Western Hemisphere. The addition of the mouse and grasshopper is a reminder of the smaller creatures of the earth and their needs. The grasshopper is a summer pest and sometimes arrives in great swarms as the locust and destroys the grain crop. He is a symbol of chance and of the unpredictable nature of the world. He is the reminder that we are not the only species here and that nature is beyond our control. The grasshopper’s ownership of the land and its grasses is supreme, and we borrow the land from him. The grain-loving mouse is a representative of the god Apollo, who originally had oracular shrines of mouse priestesses under the title Apollo Smin the us (“Mouse Apollo”). The mouse, bringer of disease, in sympathetic magic also brought its cure, and Apollo was credited as the god of medicine. Apollo was the god of the most famous oracular shrine at Delphi, which he got by challenging and defeating the goddess Python. To this day the snake perpetually chases the mouse, hoping for the return of her oracular shrine. By classical times the little mouse god who ate the summer grain grew in importance and was associated with the sun as his twin sister Artemis was with the moon. Apollo was the lord of all that was bright: art, music, poetry, and the dance, and he was called Phoebus Apollo (“Shining Apollo”). Apollo was associated also with the Egyptian Horns (the son of the sun), and through these associations, in later classical times, Apollo was the personification of the sun. Apollo’s sun shines on the tablecloth beneath the plates as a symbol of the yearly course of the sun in the planting and harvesting of the grain. The sun is also like the grain in that its representative hero undergoes the sacrifice symbolized in the harvest of the grain. The life of the sun and the life of the grain are analogous, for many grains are planted in the dark of the year—buried in the darkness of the earth near the solstice—grow while the sun’s power grows, and are cut down as the sun reaches its peak in summer. The potent energy of the shining sun lives within the grain. Δ When this card is a part of your reading, be aware of people’s unique qualities; just as rice is different from millet, so you are different from others. In doing this, see the golden sun within them and be sure to discover it within yourself as well. Recognize the little creatures and do them honor by seeing them as part of the web of life. When others need what you have, help them to provide for themselves by teaching them and showing the way. This is also a card of personal nourishment, reminding you that you need nurturance both on the simple level of the physical and on the more complex levels as well. This is the macrocosmic view demanded by the seven. Find what feeds your soul: read, dance, write poetry, paint, eat well. Remember to honor that which feeds you, by ritual or with simple respect, treating whatever you use well: the paper you draw and write on, the instrument you play—and respect yourself. Live in the Apollonian mode of rational creativity. Like those who planted the grain and could see the yearly cycle, remember the cycles of time and honor them. Alexandra Genetti. The Wheel of Change Tarot.

6 notes

·

View notes

Text

Azad Machinery Works

Azad Machinery Works- We are a manufacturer of Industrial Flour Mill, Dal Besan Mill, Mirch, Haldi Dhania & Dalya, Sattu Plant, Ayurvedic Medicine Plant & also deals in Machine parts.

http://azadmachineryworks.com

India’s best flour mill maker. The high qualities Flour Mill product Manufacture. Azad Machinery works Private Limited uses the latest Technique in flour mill making. That’s our customer has believed in our products. Company has provided the satisfaction of work. The Technique & Designing we have used the latest and modern. We have manufactured Automatic Mini Flour Mill, Dal and Besan Plant and many more plants. We have Change in our machine with change technique and develop a fully automatic plant. Since 1930 The Azad Machinery works Private Limited has Success running.

#flour mill manufacturer#flour mill business#atta chakki machine#single phase atta chakki price#wheat flour mill#automatic flour mill machine price#wheat grinding machine#commercial atta chakki price#mini flour mill machine#atta mill machine#flour making machine

1 note

·

View note