#Automated Optical Inspection segment

Explore tagged Tumblr posts

Text

#Automated Optical Inspection Market#Automated Optical Inspection Size#Automated Optical Inspection Growth#Automated Optical Inspection Trend#Automated Optical Inspection segment#Automated Optical Inspection Opportunity#Automated Optical Inspection Analysis 2024#Automated Optical Inspection Forecast

0 notes

Text

Machine Vision Systems Market: A Comprehensive Analysis

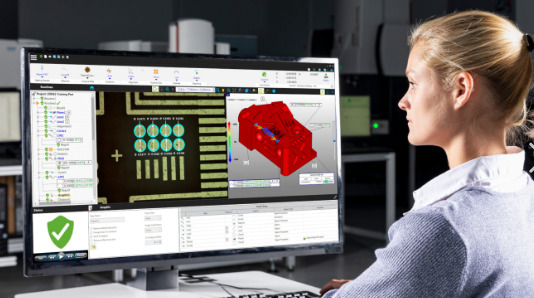

The Machine Vision Systems Market has witnessed substantial growth in recent years, driven by the increasing demand for automation across industries, the rise of advanced technologies such as artificial intelligence (AI) and machine learning (ML), and the need for high precision in production and quality control processes. Machine vision systems play a pivotal role in various applications such as inspection, identification, measurement, and visual guidance in industries ranging from manufacturing to healthcare. This blog delves into the current state of the machine vision systems market, highlighting key trends, market segmentation, major players, and future growth prospects.

What is a Machine Vision System?

Machine vision, also known as computer vision, refers to the technology and methods used to provide imaging-based automatic inspection, process control, and robot guidance. A typical machine vision system includes a camera (or multiple cameras), lighting, software, and a computer or processing unit. These components work together to capture, process, and analyze visual data, enabling machines to interpret their environment in ways that resemble human vision. Unlike traditional systems that require human intervention, machine vision systems can automate tasks such as quality inspection, object detection, and pattern recognition with higher speed, accuracy, and consistency.

Market Drivers

Several factors are driving the growth of the machine vision systems market, with the following being the most prominent:

Automation and Industry 4.0: The trend toward automation and the adoption of Industry 4.0 technologies are major catalysts for the machine vision systems market. Manufacturing industries are increasingly using automation to enhance productivity, reduce human error, and ensure consistent quality. Machine vision systems play a critical role in automating tasks such as assembly line inspections, product verification, and robotic guidance.

Quality Control and Inspection: Quality control is a major application area for machine vision systems, particularly in industries like automotive, electronics, pharmaceuticals, and packaging. With consumers demanding higher quality standards and regulations becoming more stringent, manufacturers are turning to machine vision for precise and efficient inspection processes. These systems are capable of detecting even the smallest defects or deviations from standards, thus ensuring product quality and compliance.

AI and Deep Learning Integration: The integration of AI, deep learning, and machine learning algorithms with machine vision systems is revolutionizing the market. These technologies enable systems to learn from data, improve over time, and make more sophisticated decisions. AI-powered machine vision systems can recognize complex patterns, enhance image processing capabilities, and deliver more accurate results in areas such as facial recognition, object classification, and predictive maintenance.

Rising Demand in Healthcare and Pharmaceuticals: The healthcare and pharmaceutical sectors are also increasingly adopting machine vision systems, particularly in areas like drug manufacturing, diagnostic imaging, and medical device inspection. Machine vision is being used for tasks such as counting tablets, inspecting vials, ensuring proper labeling, and detecting anomalies in medical images. As precision and accuracy are critical in healthcare, machine vision systems are proving to be indispensable tools.

Market Segmentation

The machine vision systems market is typically segmented by component, product type, application, and region.

1. By Component:

Hardware: Cameras, frame grabbers, optics, lighting equipment, and processors.

Software: Vision software used for image processing, pattern recognition, and data analysis.

Services: Installation, integration, training, and maintenance services.

2. By Product Type:

PC-based systems: These systems rely on standard personal computers for processing and analyzing images. They offer flexibility and scalability and are used in applications requiring high processing power.

Smart cameras: Smart cameras are all-in-one systems that include a camera, processor, and software in a single device. They are compact, easy to deploy, and ideal for simpler applications.

3. By Application:

Industrial: Machine vision systems are extensively used in manufacturing industries for inspection, identification, quality control, robotic guidance, and measurement tasks.

Healthcare and Medical Devices: In healthcare, machine vision is used for medical imaging, diagnostic procedures, and monitoring applications.

Automotive: The automotive industry uses machine vision for defect detection, assembly verification, and autonomous vehicle navigation.

Consumer Electronics: Machine vision helps in the inspection and testing of electronic components, circuit boards, and displays.

Others: Other applications include food and beverage, packaging, logistics, and transportation.

4. By Region:

North America: The North American market is a leading region in terms of innovation and adoption of machine vision technologies, especially in the U.S. and Canada. The presence of key players and advanced industries fuels the demand for machine vision systems.

Europe: Europe is another major market, with Germany, the UK, and France being prominent contributors. The region's strong manufacturing sector and focus on quality standards drive the adoption of machine vision technologies.

Asia Pacific: The Asia Pacific region is expected to see the highest growth in the machine vision systems market. The rapid industrialization of countries like China, Japan, South Korea, and India, coupled with the growing demand for automation in manufacturing, is driving market expansion in the region.

Rest of the World: Regions like Latin America, the Middle East, and Africa are also witnessing increasing adoption of machine vision systems, particularly in industries such as oil and gas, food processing, and pharmaceuticals.

Key Players

The machine vision systems market is highly competitive, with a mix of established players and new entrants driving innovation. Some of the key players in the market include:

Cognex Corporation: A leading player in machine vision systems, Cognex provides hardware and software solutions for automated inspection, identification, and guidance tasks.

Basler AG: Known for its high-quality cameras and vision components, Basler serves industries such as manufacturing, logistics, and healthcare.

Teledyne Technologies Incorporated: Teledyne offers a wide range of vision systems and components, including cameras, image sensors, and vision processors.

Keyence Corporation: Keyence provides machine vision systems, sensors, and measurement devices for various industrial applications.

OMRON Corporation: A key player in automation and machine vision, OMRON offers solutions for manufacturing, healthcare, and consumer electronics industries.

National Instruments (NI): National Instruments provides vision systems and software for a broad range of industries, including automotive, aerospace, and defense.

Future Outlook and Trends

The machine vision systems market is poised for continued growth, with several trends shaping its future trajectory:

Advancements in AI and Deep Learning: As AI and deep learning technologies become more sophisticated, machine vision systems will continue to improve in terms of accuracy, speed, and decision-making capabilities. AI-driven machine vision will expand into more complex applications such as autonomous vehicles, facial recognition, and predictive maintenance.

Emergence of 3D Vision Systems: 3D machine vision is gaining traction as industries require more detailed and accurate imaging capabilities. 3D vision systems offer enhanced depth perception, enabling applications such as robotic guidance, bin picking, and quality inspection in manufacturing processes.

Miniaturization and Integration: The trend toward smaller, more compact systems is expected to continue. Smart cameras, in particular, are becoming more powerful while maintaining a compact size. This makes them ideal for space-constrained environments and applications requiring easy deployment.

Growth in Non-Industrial Applications: While machine vision has traditionally been associated with manufacturing, non-industrial applications such as healthcare, retail, and agriculture are expected to drive future growth. In healthcare, for example, machine vision can assist in tasks like surgery, diagnostics, and patient monitoring.

Increased Adoption in Emerging Markets: Emerging markets, particularly in Asia Pacific, Latin America, and Africa, are expected to see increased adoption of machine vision technologies as industries in these regions invest in automation and quality control.

Conclusion

The machine vision systems market is evolving rapidly, driven by the growing need for automation, the integration of AI and deep learning, and the demand for high precision across industries. With applications spanning from manufacturing to healthcare, the future of machine vision looks promising, offering new opportunities for innovation and growth. As industries continue to embrace the benefits of machine vision, the market is expected to see robust expansion in the coming years, with a growing focus on smart technologies, 3D vision, and AI-powered systems.

Browse More

Managed Services Market Overview

Medical Device Technologies Market Trends And Growth

Myopia and Presbyopia Treatment Market Size

0 notes

Text

3D Laser Scanner Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

"Global 3D Laser Scanner Market' - Industry Trends and Forecasts to 2028

Global 3D Laser Scanner Market, By Range (Short Range, Medium Range and Long Range), Product (Tripod Mounted, Fixed CMM Based, Portable CMM Based and Desktop), Type (Optical Scanner, Laser Scanner and Structured Light Scanner), Offering (Hardware and Software and After- Sales Services), Application (Reverse Engineering, Quality Control and Inspection and Virtual Simulation), End Users (Automotive, Healthcare, Aerospace and Defence, Architecture and Construction, Energy and Power, Tunnel and Mining and Artefact and Heritage Preservation Department), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

**Segments**

- By Type: The 3D laser scanner market can be segmented by type into handheld, tripod mounted, and automated & CMM-based. Handheld scanners are portable and can be easily moved around the object to capture the data. Tripod-mounted scanners are stationary devices that provide high accuracy for scanning large objects. Automated & CMM-based scanners are integrated with Coordinate Measuring Machines (CMMs) for precise measurement capabilities. - By Range: The market can also be segmented by range into short range, medium range, and long range scanners. Short-range scanners are suitable for capturing small objects with high precision, medium-range scanners are versatile and can be used for a wide range of applications, while long-range scanners are ideal for scanning large structures or terrains. - By Application: The 3D laser scanner market can be segmented by application into reverse engineering, quality control & inspection, virtual simulation, and others. Reverse engineering applications involve creating digital models of existing objects for redesign or analysis. Quality control & inspection applications ensure that manufactured products meet specifications. Virtual simulation applications are used in industries like architecture and entertainment for creating immersive digital experiences.

**Market Players**

- Leica Geosystems: A well-known player in the 3D laser scanner market, Leica offers a range of high-precision scanners for various applications. - Faro Technologies: Faro is another key player that provides 3D measurement, imaging, and realization technology solutions for a wide range of industries. - Trimble Inc.: Trimble offers advanced positioning solutions that include 3D laser scanning technologies for improved productivity and efficiency. - Hexagon AB: Hexagon provides comprehensive solutions for digital reality capture using 3D laser scanners for industries such as construction, manufacturing, and safety & infrastructure. - Creaform: Creaform specializes in portable 3D measurement technologies, including handheld 3D scanners for various applications across industries.

https://www.databridgemarketresearch.com/reports/globalThe global 3D laser scanner market is poised for significant growth in the coming years due to the increasing adoption of advanced technologies across industries. One of the key trends shaping the market is the growing demand for handheld and portable scanners, as they offer flexibility and ease of use in capturing data from objects of various sizes and shapes. Handheld scanners are particularly popular in industries such as manufacturing, automotive, and aerospace, where precise measurements and quick data capture are essential for operational efficiency and quality control. Additionally, the tripod-mounted scanners segment is witnessing steady growth, driven by the need for high-accuracy scanning of large objects and structures in sectors like architecture, heritage preservation, and construction.

In terms of range segmentation, the market is witnessing a shift towards the adoption of medium and long-range scanners, driven by the demand for scanning larger objects and terrains with high precision and efficiency. Long-range scanners are becoming increasingly popular in applications such as civil engineering, mining, and forestry, where capturing detailed 3D data over expansive areas is critical for planning and analysis. The versatility of medium-range scanners is also driving their adoption across a wide range of industries for tasks such as reverse engineering, quality control, and virtual simulation.

The application segmentation of the 3D laser scanner market highlights the diverse range of uses for this technology across industries. Reverse engineering applications continue to be a major driver of market growth, as industries seek to digitize physical objects for design, analysis, and prototyping purposes. Quality control and inspection applications are also driving the market, as companies focus on ensuring the accuracy and consistency of their manufacturing processes through precise 3D measurements. Virtual simulation applications are another key growth area, with industries like architecture, gaming, and virtual reality leveraging 3D laser scanners to create immersive digital experiences and simulations.

Key players in the global 3D laser scanner market, such as Leica Geosystems, Faro Technologies, Trimble Inc., Hexagon AB, and Creaform, are continuously innovating**Segments**

- By Type: The 3D laser scanner market is segmented by type into handheld, tripod mounted, and automated & CMM-based. Handheld scanners offer portability and flexibility in capturing data, while tripod-mounted scanners provide high accuracy for scanning large objects. Automated & CMM-based scanners are integrated with Coordinate Measuring Machines for precise measurements. - By Range: The market can be segmented by range into short range, medium range, and long range scanners. Short-range scanners are suitable for small objects, medium-range scanners are versatile, and long-range scanners excel at scanning large structures or terrains. - By Application: The market can be segmented by application into reverse engineering, quality control & inspection, virtual simulation, and others. Reverse engineering involves creating digital models of existing objects, quality control ensures products meet specifications, and virtual simulation is used in industries like architecture and entertainment.

**Market Players**

Leica Geosystems, Faro Technologies, Trimble Inc, Hexagon AB, and Creaform are key players in the 3D laser scanner market, offering a range of high-precision scanners for various applications. These companies are continuously innovating to meet the evolving needs of industries that rely on 3D laser scanning technology. The market is driven by the increasing adoption of advanced technologies across industries, with a particular emphasis on handheld and portable scanners for their flexibility and ease of use.

The market is witnessing a trend towards the adoption of medium and long-range scanners, as industries

Key points covered in the report: -

The pivotal aspect considered in the global 3D Laser Scanner Market report consists of the major competitors functioning in the global market.

The report includes profiles of companies with prominent positions in the global market.

The sales, corporate strategies and technical capabilities of key manufacturers are also mentioned in the report.

The driving factors for the growth of the global 3D Laser Scanner Market are thoroughly explained along with in-depth descriptions of the industry end users.

The report also elucidates important application segments of the global market to readers/users.

This report performs a SWOT analysis of the market. In the final section, the report recalls the sentiments and perspectives of industry-prepared and trained experts.

The experts also evaluate the export/import policies that might propel the growth of the Global 3D Laser Scanner Market.

The Global 3D Laser Scanner Market report provides valuable information for policymakers, investors, stakeholders, service providers, producers, suppliers, and organizations operating in the industry and looking to purchase this research document.

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global 3D Laser Scanner Market Landscape

Part 04: Global 3D Laser Scanner Market Sizing

Part 05: Global 3D Laser Scanner Market Segmentation by Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

The investment made in the study would provide you access to information such as:

3D Laser Scanner Market [Global – Broken-down into regions]

Regional level split [North America, Europe, Asia Pacific, South America, Middle East & Africa]

Country-wise Market Size Split [of important countries with major market share]

Market Share and Revenue/Sales by leading players

Market Trends – Emerging Technologies/products/start-ups, PESTEL Analysis, SWOT Analysis, Porter’s Five Forces, etc.

Market Size

Market Size by application/industry verticals

Market Projections/Forecast

Browse Trending Reports:

14g Substrate Materials Market Cloud Application Programming Interface Api And Management Platforms And Middleware Market Abscisic Acid Aba Market Benign Mesonephroma Market Cancer Supportive Care Products Market Data Center Interconnect Market Potash Fertilizers Market Private Label Food And Beverage Market Relational Database Market Commercial Lighting Market Ethoxylates Market Eclinical Solutions Market Vaccines Market Spark Plug Market High Visibility Clothing Market Gas Turbine Services Market Dessert Mix Market Lipid Nutrition Market Barrier Films Flexible Electronics Market Nasal Polyposis Drugs Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

3d Machine Vision Market - Forecast(2024 - 2030)

3D Machine Vision System Market Overview

3D Machine Vision System Market Size is forecast to reach $5.9 billion by 2027, at a CAGR of 11.9% during forecast period 2022-2027. The need for inspection of flaws and controlling a specific task of industrial operations is motivating the utilization of 3D Machine Vision Systems in process control and quality control applications. Additionally, the growing penetration of automation and robotics across various industries and rapid advancements in industrial technologies along with the need for higher productivity are boosting the deployment of 3D Machine Vision Systems. These systems encounter wide range of applications in various industry verticals including oil& gas, aerospace, transportation, automotive among others and are able to serve their inspection needs with the available types such as PC-based and smart camera based 3D Machine Vision Systems. 3D Machine vision systems have been utilized for a number of growing applications including object recognition, automatic inspection, Optical sorting as a real time information for robot controllers. This will drive the market significantly.

Report Coverage

The report: “3D Machine Vision System Market Report– Forecast (2022-2027)”, by IndustryARC covers an in-depth analysis of the following segments of the Brushless DC Motor market

By Product Type: PC Based, Smart Camera Based By Component: Hardware (Camera, Frame Grabber, Lighting, Processor, Optics), Software (Application Specific, Deep Learning) By Application: Quality Assurance and Inspection, Position Guidance, Measurement, Identification, Pattern Recognition and Others By End Users: Automotive, Electrical and Electronics, Healthcare, Consumer Electronics, Aerospace and Defense, Logistics, Security and Surveillance, Printing, ITS, Machinery, Packaging, Food and Beverage and Others By Geography: North America (U.S, Canada, Mexico), South America (Brazil, Argentina, Chile, Colombia and Others), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC (China, Japan India, Australia and Others), and RoW (Middle East and Africa)

Request Sample

Key Takeaways

The rising need for advanced manufacturing in the U.S have increasingly demanded the use of 3D Machine Vision Systems.

The market players are majorly opting for various strategies such as product launch, partnership and agreements and collaborations to gain market traction and further penetration to explore the hidden opportunities in upcoming trends including Industry4.0

Recognizing trends and irregularities in production processes early on machine vision paves the way for realizing the smart factory of the future. Machine vision ensures safety in production process as well as quality in the end product.

3D Machine Vision System Market Segment Analysis - By Component

3D Machine Vision System and components market is led by cameras which are estimated to surpass $3.2 billion by 2027 majorly driven by the advancements in imaging technology. The 3D Machine Vision System industry is expected to grow during the forecast period due to continued evolution of CMOS image sensors, rise in demand for automation in industrial applications and increased investments in R&D of smart camera and software by key players, such as Cognex Corporation, Teledyne Technologies, Inc., Keyence Corporation, and others. The global 3D Machine Vision Systems and components market has increased due to the rapid penetration of automation across several industry verticals. Moreover, the development of advanced sensors and software algorithms capable of offering precise and microscopic inspection in high speed production lines is escalating the growth rate of the market. Machine Vision market is estimated to witness significant growth in the coming years, on account of increased adoption in various industries for automatic inspection and control of machines or processes by capturing and interpreting and analyzing an image.

Inquiry Before Buying

3D Machine Vision System Market Segment Analysis - By End Use Industry

Automotive industry is expected to witness a highest CAGR of 14.1% the forecast period, owing to increasing investments, and funds for semiconductors has been providing opportunities for adoption of automation technology which further set to drive the demand of connectors in semiconductor industry. These systems encounter wide range of applications in various industry verticals including oil& gas, aerospace, transportation, automotive among others and are able to serve their inspection needs with the available types such as PC-based and smart camera based 3D Machine Vision Systems. Investments by the U.S automakers for strengthening of the manufacturing of automobiles with increasing integration of recent robotic vision technologies in vehicles is accompanying the growth of the robotic vision market in the U.S. Industry revenue is projected to continue grow due to this development.

3D Machine Vision System Market Segment Analysis - By Geography

3D Machine Vision System market in Europe region held significant market share of 38% in 2021. The investments are rising for electric, connected and autonomous vehicles and this in turn The U.S. accounted a huge market base for Machine Vision due to the growing adoption of 3D Machine Vision System technology by vision companies continues to witness exploration for new applications in a variety of industries. which are driving the machine vision market driven by a push from companies such as Google and Verizon. The rising initiatives in Middle East and Africa for the increasing need of automation is set to propel the machine vision market. The growth of manufacturing industry in Africa and Middle East (AME) is expected to grow at a rate of 14.2% between 2021 and 2025 thereby significantly driving the market

Schedule a Call

3D Machine Vision System Market Drivers

Growing Demand for Smart Cameras

Smart cameras often support a 3D Machine Vision System by digitizing and transferring frames for computer analysis. A smart camera has a single embedded image sensor. They are usually tailored-built for specialized applications where space constraints require a compact footprint. Smart cameras are employed for a number of automated functions, whether complementing a multipart 3D Machine Vision System, or as standalone image-processing units. Smart cameras are considered to be an effective option for streamlining automation methods or integrating vision systems into manufacturing operations as they are cost-efficient and relatively easy to use. There is a huge demand for smart cameras in industrial production as manufacturers often use them for inspection and quality assurance purposes. Smart cameras are growing at a 9.7% CAGR with Machine vision being a premier use case. Thus, increasing demand for smart cameras will drive the 3D Machine Vision Systems market growth in various industrial applications.

Increasing need for quality products, high manufacturing capacity

3D Machine Vision Systems perform quality tests, guide machines, control processes, identify components, read codes and deliver valuable data for optimizing production. Modern production line are advanced and automated. Machine vision enables manufacturing companies to remain competitive and prevent an exodus of key technologies. Recognizing trends and irregularities in production processes early on machine vision paves the way for realizing the smart factory of the future. Machine vision ensures safety in production process as well as quality in the end product. As a result of this, according to an IDG survey by Insight, 96% of Companies surveyed think computer vision has the capability to boost revenue, with 97% saying this technology will save their organization time and money across the board.

3D Machine Vision System Market Challenges

Lack of awareness among users and inadequate expertise

The robotic vision technology is rapidly changing, with new technologies emerging constantly, and new tools coming to market incredibly fast to make tackling automation problems easier. In the past decade alone, the robotic vision market has seen the introduction of more advanced sensors in terms of both smaller pixels and larger sensors, software platforms that continues to be more accurate, and lighting which is growing brighter and becoming more efficient. The high cost of the research and development in robotic vision and the lack of awareness among users about the rapidly advancing robotic vision technology are key factors likely to hinder the market to an extent.

Buy Now

3D Machine Vision System Industry Outlook

Product launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the market. 3D Machine Vision System top companies include

Cognex

Omron Corp

Sony Corp.

Panasonic Corp.

Microscan

Basler AG

Keyence Corp.

National Instruments

Sick AG

Teledyne Technologies

FLIR

Recent Developments

In July, 2021 Cognex launched its new series of vision software “VisionPro” for industrial machine vision enabling customers to combine deep learning and traditional vision tools in the same application.

In March 2021, Omron launched FH-SMD Series 3D Vision sensors for robotic arms enabling space-saving assembly, inspection, and pick & place and other applications.

#3d Machine Vision Market#3d Machine Vision Market size#3d Machine Vision industry#3d Machine Vision Market share#3d Machine Vision top 10 companies#3d Machine Vision Market report#3d Machine Vision industry outlook

0 notes

Text

Automated Optical Inspection System Market News 2024-2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Automated Optical Inspection System Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Automated Optical Inspection System Market Growth share, size, trends, and forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Automated Optical Inspection System Market?

The global automated optical inspection system market size reached US$ 956.7 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 4,275.9 million in 2032, exhibiting a growth rate (CAGR) of 18.1% during 2024-2032.

What are Automated Optical Inspection System?

An Automated Optical Inspection (AOI) System is a technology employed in manufacturing to examine printed circuit boards (PCBs) and other electronic elements for defects or quality problems. This system utilizes cameras and lighting to capture detailed images of the PCB, which are subsequently analyzed by specialized software to identify issues like missing components, misaligned parts, or soldering defects. By swiftly detecting and addressing these problems, AOI systems enhance production efficiency and ensure the quality of electronic devices.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2039

What are the growth prospects and trends in the Automated Optical Inspection System industry?

The automated optical inspection (AOI) market growth is driven by various factors. The automated optical inspection (AOI) systems market is on the rise, driven by increasing requirements for top-notch electronic components across industries like electronics manufacturing and automotive. These systems are pivotal in guaranteeing the quality and dependability of printed circuit boards (PCBs) by spotting defects such as soldering problems, absent components, and misalignments. Market expansion is also steered by technological progress in AOI systems, resulting in enhanced inspection precision and effectiveness. Furthermore, stringent quality criteria and regulations in diverse industries are boosting the uptake of AOI systems for quality assurance needs. Hence, all these factors contribute to automated optical inspection (AOI) market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type

2D AOI Systems

3D AOI Systems

By Component

Software

System

By Technology

Inline AOI

Offline AOI

By Application

Fabrication Phase

Assembly Phase

By End User

Automotive

Aerospace Defense

Others

By Region

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

Benelux

Nordic

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

ASEAN

Australia New Zealand

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Koh Young Technology

Omron

Viscom

Saki Corporation

Nordson

Kla

Camtek

Cyberoptics

Goepel Electronic

Irtec

Marantz Electronics

Machine Vision Products

Mycronic Ab (Vi Technology)

Dcb Automation

Pemtron

View Full Report: https://www.reportsandinsights.com/report/Automated Optical Inspection System-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Automated Optical Inspection System Market share#Automated Optical Inspection System Market size#Automated Optical Inspection System Market trends

0 notes

Text

Gluten Free Food Market 2024: Emerging Trends, Major Driving Factors, Business Growth Opportunities

Gluten Free Food Market provides in-depth analysis of the market state of Gluten Free Food manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Gluten Free Food in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Gluten Free Food Market Report:

The report offers a comprehensive and broad perspective on the global Gluten Free Food Market.

The market statistics represented in different Gluten Free Food segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Gluten Free Food are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Gluten Free Food.

Major stakeholders, key companies Gluten Free Food, investment feasibility and new market entrants study is offered.

Development scope of Gluten Free Food in each market segment is covered in this report. The macro and micro-economic factors affecting the Gluten Free Food Market

Advancement is elaborated in this report. The upstream and downstream components of Gluten Free Food and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/gluten-free-food-market-100550

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Waste to Energy (WTE) MarketMarket

Recruitment MarketMarket Share

Marketing Automation Software MarketMarket Growth Rate

Devops Tool MarketMarket Forecast

Global 3PL MarketMarket Size

X-Ray Security Screening Systems MarketMarket Growth

Aircraft and Aerospace Aluminum Casting Components MarketMarket Analysis

Web to Print Software MarketMarket Size

Global Identity Management Solutions MarketMarket Share

Global Biometric-as-a-Service MarketMarket Growth

Collision Avoidance Sensors MarketMarket

Network Copyright MarketMarket Share

IoT Fleet Management MarketMarket Growth Rate

Social Media Analytics MarketMarket Forecast

Global Infant Incubator MarketMarket Size

Bone Conduction Headphones MarketMarket Growth

Wood Based Panel MarketMarket Analysis

Cloud Content Delivery Network (CDN) MarketMarket Size

Global Prostate Cancer Nuclear Medicine Diagnostics MarketMarket Share

Global Air Disc Brakes (ADB) MarketMarket Growth

Automated Optical Inspection Systems MarketMarket

Memristors MarketMarket Share

Virtualized Radio Access Network (vRAN) MarketMarket Growth Rate

Cryogen Free Dilution Refrigerators MarketMarket Forecast

Global Chafing Fuel MarketMarket Size

Cotton Picker MarketMarket Growth

Returnable Transport Packaging (RTP) MarketMarket Analysis

Shower Cap MarketMarket Size

Global Dimethyl Carbonate (DMC) MarketMarket Share

Global Aqua Feed MarketMarket Growth

Barcode Verifiers MarketMarket

Mask Blank MarketMarket Share

Cheese Powder MarketMarket Growth Rate

Three Dimensional Fabric MarketMarket Forecast

Global PFAS Remediation Services MarketMarket Size

Channel Gate Market Market Growth

Global Mycelium Leather MarketMarket Analysis

Plethysmometer MarketMarket Size

Global Conductive Die Attach Film MarketMarket Share

0 notes

Text

Understanding Market Segmentation in Automated Optical Inspection: Market Insights and Trends

The automated optical inspection (AOI) market is witnessing rapid growth driven by advancements in technology and the increasing demand for high-quality inspection solutions across various industries. This market is segmented based on type, technology, industry, application, and elements, each playing a crucial role in shaping the landscape of AOI solutions.

Type

AOI systems can be categorized into different types based on their functionality and application:

2D AOI: These systems use cameras and image processing algorithms to inspect components and printed circuit boards (PCBs) for defects such as missing components, misalignment, and soldering issues.

3D AOI: Utilizing advanced imaging techniques such as structured light or laser triangulation, 3D AOI systems offer more detailed inspection capabilities, allowing for the detection of defects on complex surfaces and components with greater accuracy.

Inline AOI: Integrated directly into the production line, inline AOI systems provide real-time inspection of PCBs and components during the manufacturing process, enabling immediate feedback and correction of defects.

Offline AOI: These standalone systems are used for post-production inspection, providing comprehensive analysis and reporting of defects identified during the manufacturing process.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=179056156

Technology

AOI systems leverage various technologies to capture and analyze images for defect detection:

Machine Vision: Utilizes cameras, lenses, and image processing algorithms to capture and analyze images of components and PCBs, enabling rapid and accurate defect detection.

Artificial Intelligence (AI) and Deep Learning: AI-powered AOI systems can learn from large datasets of images to improve defect detection accuracy and adapt to changing inspection requirements over time.

Advanced Imaging Techniques: 3D AOI systems use techniques such as structured light, laser triangulation, and phase-shift profilometry to capture detailed surface profiles and detect defects with high precision.

Industry

AOI solutions find applications across various industries, including:

Electronics and Semiconductor: AOI systems are widely used in electronics manufacturing for inspecting PCBs, components, and semiconductor devices for defects such as soldering defects, component misalignment, and foreign object debris (FOD).

Automotive: In the automotive industry, AOI systems are used for inspecting critical components such as engine parts, electronic control units (ECUs), and safety systems to ensure quality and reliability.

Medical Devices: AOI solutions play a crucial role in the manufacturing of medical devices, ensuring compliance with regulatory standards and detecting defects in components and assemblies.

Aerospace and Defense: AOI systems are utilized in the aerospace and defense industry for inspecting complex components, assemblies, and electronic systems to meet stringent quality and safety requirements.

Application

AOI systems are deployed for various inspection applications, including:

Component Inspection: Detecting defects such as missing components, misalignment, and soldering issues on PCBs and electronic components.

Surface Inspection: Analyzing surface defects such as scratches, dents, and contamination on materials and components.

Assembly Inspection: Verifying the correct assembly of components and detecting assembly errors or inconsistencies.

Quality Control: Ensuring compliance with quality standards and regulatory requirements through comprehensive inspection and defect analysis.

Elements

AOI systems consist of several key elements, including:

Cameras and Optics: Capture high-resolution images of components and surfaces for analysis.

Image Processing Software: Analyzes captured images to detect and classify defects based on predefined criteria.

Lighting Systems: Provide uniform illumination of inspection areas to enhance image quality and defect detection accuracy.

Conveyors and Handling Systems: Transport components and assemblies through the inspection process efficiently and reliably.

Control and Interface Systems: Manage AOI system operation, data acquisition, and integration with production line equipment.

0 notes

Text

Automated Test Equipment Market

Automated Test Equipment market size is forecast to reach USD 9.6 billion by 2030, after growing at a CAGR of 4.1% during the forecast period 2024-2030. All major electronic equipment manufacturers and suppliers need testing mechanism to make systems fool proof before deployment. Automated Test Equipment (ATE) is basically employed to check for defects in the Devices under Test (DUT) and to ensure their quality. The adoption of Automated Test Equipment plays a very significant role in lowering the costs incurred for manufacturing and in the elimination of defective devices.

In the Automated Test Equipment (ATE) Market, there is a persistent drive for technological innovation to augment testing capabilities. Notably, the integration of Artificial Intelligence (AI) and advanced analytics takes center stage, enabling more efficient and precise testing processes. This strategic incorporation of cutting-edge technologies enhances the overall performance of ATE systems, offering businesses the benefits of increased accuracy and efficiency in their testing operations, reflecting the industry's commitment to staying at the forefront of technological advancements.

Request Sample

Report Coverage

The report “Automated Test Equipment Market – Forecast (2024-2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Automated Test Equipment market. By Type: Memory Chip Based Testing, Non-Memory Chip Based Testing, Mixed Signal Based Testing, Discrete Testing, Digital Testing, and Others. By Technology: WCDMA and RF Technology Based Testing, LTE Technology Based Testing, Optical Inspection Technology Testing, Machine Vision Technology Testing, X-Ray Inspection Technology, and Others. By Application: Automotive Electronics, Aerospace and Defence, Consumer Electronics, IT & Telecommunications, Manufacturing, Medical, and Others. By Geography: North America, South America, Europe, APAC, and RoW.

Buy Now

Key Takeaways

• APAC held the largest market share with 65% in 2023. The Asia-Pacific region The Asian market poses the highest potential for growth as India and China are becoming global economies with their focus on the electronics and manufacturing sectors.

By Application - Segment AnalysisIT & Telecommunications dominated the Automated Test Equipment market in 2023. his is primarily driven by the increasing demand for testing complex integrated circuits (ICs) used in telecommunications equipment and information technology devices. Factors contributing to this dominance include the rapid evolution of communication technologies, the surge in demand for high-performance electronic components, and the need for stringent quality assurance in telecommunications infrastructure. As the industry embraces advanced communication standards, automated test equipment plays a pivotal role in ensuring the reliability and functionality of critical components, solidifying the IT & Telecommunications segment's stronghold in the automated test equipment market. According to the International Data Corporation, worldwide spending on telecommunication and pay TV services reached $1.55 trillion in 2023, an increase of 3.0% over 2022.

Drivers – Automated Test Equipment Market

• Increasing Demand for Consumer Electronics Is Expected to Propel the MarketThe Automated Test Equipment Market is poised for growth, primarily driven by the escalating demand for consumer electronics. As technology continues to advance, the consumer electronics industry experiences a surge in demand for cutting-edge products. According to International Telecommunication Union, the global consumer electronics market will reach USD 1.787 billion by 2024. Automated test equipment plays a crucial role in ensuring the quality, reliability, and functionality of electronic components, contributing to the efficiency of manufacturing processes. The need for rigorous testing protocols to meet the high standards of consumer electronics propels the adoption of automated test equipment solutions. This trend is further fueled by reduced manufacturing time, enhanced throughput, and the constant pursuit of innovation within the consumer electronics sector, positioning the automated test equipment market for significant expansion in response to the burgeoning consumer demand. • Increase in the design complexity due to adoption of System-on-a-chip (SoC) has given rise to the need for effective testing operations, which is expected to drive the growth of Automated Test Equipment marketThe proliferation of System-on-a-Chip (SoC) technology, marked by increased design complexity, has necessitated robust testing operations. As electronic systems become more intricate, the demand for comprehensive and efficient testing processes has surged. SoC, integrating multiple functions onto a single chip, brings about challenges in ensuring each component's functionality and reliability. This complexity underscores the critical role of Automated Test Equipment in validating SoC designs. Automated Test Equipment facilitates rapid, accurate, and thorough testing, addressing the intricate requirements of SoC-based devices. The escalating need for effective testing operations to validate SoC functionalities is anticipated to be a key driver for the growth of the automated test equipment market. Manufacturers, in response to the rising complexities associated with SoC, are increasingly relying on advanced automated test equipment solutions to ensure the quality and reliability of their electronic products, positioning the market for substantial expansion.

Challenges – Automated Test Equipment Market

Cost Constraints and Capital IntensityThe Automated Test Equipment (ATE) market faces a significant hurdle in the form of cost constraints and capital intensity. The initial investment required for implementing advanced ATE solutions, including high-end testing equipment and software, can be substantial. This poses a challenge for smaller enterprises and start-ups with limited financial resources. Moreover, the continuous need for upgrades and maintenance further adds to the overall cost. The capital-intensive nature of adopting ATE solutions becomes a barrier, hindering the widespread integration of these technologies across various industries. Striking a balance between cost-effectiveness and cutting-edge testing capabilities is crucial for addressing this challenge and fostering broader market adoption.

Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Automated Test Equipment market. in 2023, The major players in the Automated Test Equipment market are Anritsu Co., SPEA S.p.A, Advantest Corporation, Agilent Technologies Inc., Aeroflex Inc., Teradyne Inc., Chroma Systems Solutions, Inc., Cohu, Inc., Astronics Corporation, Roos Instruments, and Others.

0 notes

Text

Metrology Software, Global Market Size Forecast, Top 10 Players Rank and Market Share

Metrology Software Market Summary

Metrology Software is a type of geometries measuring, evaluation, inspection and management software that can increase the performance and production of measuring operations.

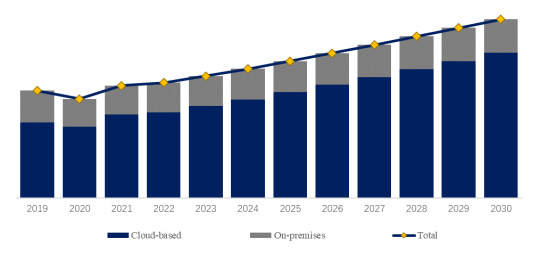

According to the new market research report “Global Metrology Software Market Report 2024-2030”, published by QYResearch, the global Metrology Software market size is projected to reach USD 1.11 billion by 2030, at a CAGR of 5.6% during the forecast period.

Figure. Global Metrology Software Market Size (US$ Million), 2019-2030

Above data is based on report from QYResearch: Global Metrology Software Market Report 2024-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

Figure. Global Metrology Software Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

Above data is based on report from QYResearch: Global Metrology Software Market Report 2024-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Metrology Software include Hexagon, Carl Zeiss, InnovMetric, Renishaw, Metrologic Group, FARO Technologies, Ametek, 3D Systems, Quality Vision International (QVI), Perceptron, etc.

In 2023, the global top 10 players had a share approximately 85.0% in terms of revenue.

Figure. Metrology Software, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Metrology Software Market Report 2024-2030.

In terms of product type, currently Cloud-based is the largest segment, hold a share of 75.5%.

Figure. Metrology Software, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Metrology Software Market Report 2024-2030.

In terms of product application, currently Power and Energy is the largest segment, hold a share of 22.5%.

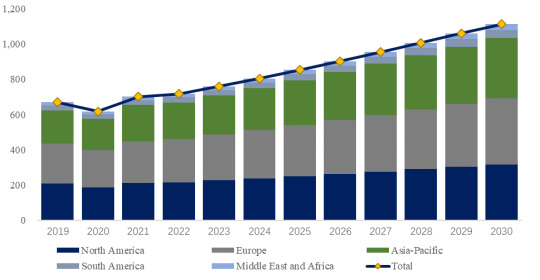

Figure. Metrology Software, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Metrology Software Market Report 2024-2030.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

#Automated Optical Inspection Market#Automated Optical Inspection Size#Automated Optical Inspection Growth#Automated Optical Inspection Trend#Automated Optical Inspection segment#Automated Optical Inspection Opportunity#Automated Optical Inspection Analysis 2024#Automated Optical Inspection Forecast

0 notes

Text

Video Inspection Systems Market Expected to Exceed USD 2.6 Billion by 2032

In 2022, the video inspection systems market reached a value of USD 1.6 Billion, with expectations to soar to USD 2.6 Billion by 2032, marking a projected Compound Annual Growth Rate (CAGR) of 5.3%. This remarkable expansion is primarily propelled by escalating demand across diverse sectors including automotive, aerospace, electronics, and healthcare. These systems play a pivotal role in these industries, offering advanced visual inspection capabilities crucial for maintaining stringent quality control and enhancing production efficiency. Notably, the market's growth is underpinned by continuous technological advancements, particularly the integration of artificial intelligence and machine learning for automated defect detection. Additionally, there is a growing emphasis on precision manufacturing and adherence to rigorous quality standards, further amplifying the adoption of video inspection systems across various industrial domains.

Several factors contribute to the growth of the video inspection systems market:

· Technological Advancements: Continuous innovations in imaging technology, such as high-definition cameras, 3D imaging, and advanced optics, enhance the capabilities and accuracy of video inspection systems, driving market growth.

· Industry 4.0 Adoption: The increasing adoption of Industry 4.0 principles, including automation, data exchange, and smart manufacturing, boosts the demand for video inspection systems to ensure quality control, process optimization, and efficiency in production lines.

· Quality Assurance Requirements: Stringent quality standards across industries such as automotive, aerospace, electronics, and pharmaceuticals necessitate the implementation of reliable inspection systems to detect defects, ensuring compliance and reducing the risk of product recalls or rework.

· Rising Demand for Non-Destructive Testing (NDT): Video inspection systems play a crucial role in non-destructive testing processes, enabling thorough examination of components and materials without causing damage, thus addressing the increasing demand for NDT solutions in various industries.

· Cost Reduction and Efficiency Improvement: Video inspection systems help companies reduce production costs by minimizing waste, optimizing processes, and detecting defects early in the manufacturing cycle, leading to improved overall efficiency and profitability.

· Increasing Focus on Preventive Maintenance: The shift towards predictive and preventive maintenance strategies in industries like manufacturing and energy drives the adoption of video inspection systems for condition monitoring, enabling early detection of equipment failures and reducing downtime.

Top Companies are:

· AM Industrial

· Canon

· Envirosight LLC

· Hikvison

· Uniview

· Agent Video Intelligence

· NICE Systems

· Rausch USA

· Insight Vision

· ARIES INDUSTRIES INC

· Rapidview LLC, CUES

Market Segmentations:

By Component (2023–2032)-

Hardware, Software

By Application (2023–2032)-

Sewer/Drain Inspection, Electrical Conduit, Duct Pipeline Inspection

By End-user (2023–2032)-

Oil &Gas, Food & Beverages, Construction, Manufacturing,Pharmaceuticals

For Further Information Regarding this Report: Ask For Discount:

Regional Analysis

The North American market holds a dominant position in market share, primarily due to the widespread digitization across various industries. Within North America, the United States leads the market, closely followed by Canada. The region’s increasing appetite for advanced video inspection systems is a significant driver of its market growth. Meanwhile, the Asia Pacific region is anticipated to experience the highest growth rate. Notably, the prevalence of natural gas pipelines in this region stands out as a key factor contributing to its rapid expansion in the video inspection systems market.

Competitive Landscape:

The competitive landscape of the video inspection systems market is characterized by the presence of several key players competing to gain market share and maintain their position. Major companies in the market include [insert names of leading companies], which are known for their technological expertise, product innovation, and strong distribution networks. These companies often engage in strategies such as mergers and acquisitions, product launches, partnerships, and collaborations to enhance their market presence and expand their product portfolios. Additionally, there is a significant presence of smaller players and startups that focus on niche segments or innovative technologies, contributing to the overall competitiveness of the market. As the demand for video inspection systems continues to grow across various industries, competition among market players is expected to intensify, leading to further advancements and innovations in the field.

Key highlights of the report include:

1. The report delivers thorough Market analysis, furnishing valuable insights to guide strategic decision-making.

2. The comprehensive research outlined in the study enhances the depth of your presentations and marketing strategies.

3. By offering crucial insights into key market competitors, the study empowers businesses with a strategic edge.

4. It delivers a precise assessment of evolving market dynamics, ensuring readers stay abreast of the latest industry trends.

5. With meticulous breakdowns of various market niches, the report facilitates informed decision-making processes.

Check Out More Related Reports:

Video Analytics Market

Video Conferencing Market

0 notes

Text

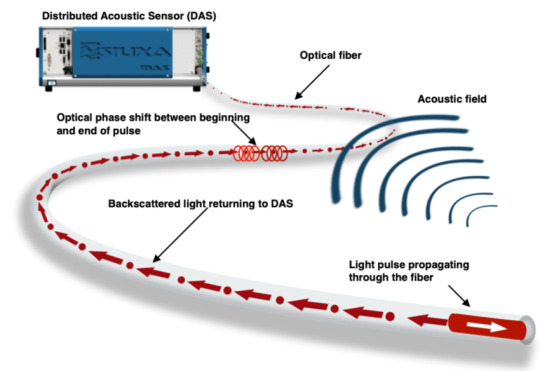

Distributed Fiber Optic Sensor Market: Driving Innovations in Remote Sensing and Structural Health Monitoring

The global distributed fiber optic sensor market size is expected to reach USD 2.53 billion by 2030, registering a CAGR of 6.8% from 2023 to 2030, according to a new report by Grand View Research, Inc. The global industry is expected to grow exponentially over the forecast period. Factors, such as significant demand from the civil engineering vertical and rising adoption in the oil & gas sector, substantially boost the adoption of distributed fiber optic sensor (DFOS). Fiber optics can withstand rough handling, such as in pipes, streams, and reactors, where manual inspection is not feasible. Furthermore, they help in structural health monitoring at dangerous workplaces and can also be used for border security purposes to prevent intrusion.

Distributed Fiber Optic Sensor Market Report Highlights

The temperature sensing application segment dominated the industry in 2022. Temperature sensors find solicitations in the oil & gas and civil engineering segments

Suppliers and manufacturers of fiber optic equipment are looking forward to achieving higher bandwidth, 100 GBPS, by undertaking intense research activities

North America dominated the global industry and accounted for the largest revenue share in 2022

The growing demand for DFOS equipment can be attributed to the ever-growing demand for efficient and optimized processes, across enterprises and manufacturing sectors

For More Details or Sample Copy please visit link @: Distributed Fiber Optic Sensor Market Report

Thus, its capability to work in a challenging environment is another factor propelling the industry's growth. Increasing demand for sophisticated infrastructure and rising per capita income is predicted to lead to industrial automation, urban mobility, and growth in high-end residential projects. Various governments are focusing on conserving their prevailing infrastructure and developing new ones. They are under constant pressure to provide the necessary infrastructure, amenities, and connectivity to people. This has resulted in increased spending on projects, such as roads, railways, and dams. This rapid growth in the advanced civil engineering vertical is expected to boost the DFOS market

The growing acceptance of DFOS has promoted manufacturers and suppliers to increase R&D expenditure to offer better products to their customers. Service providers are trying to regulate efficiencies and optimize their production process to capture maximum market share and eliminate all other substitutes of the fiber optics technology. The high production & installation price of DFOS products is promoting manufacturers to develop more competitively priced and reliable optic inspection products. Technological complexities, along with other challenges, raise the price of deploying fiber optics, which further hamper industry growth.

#DistributedFiberOpticSensor#MarketAnalysis#MonitoringSystems#SurveillanceTechnology#SensingTechnology#IndustrialApplications#InfrastructureMonitoring#RealTimeMonitoring#Innovation#SecuritySolutions

0 notes

Text

The global automated optical inspection system market value is expected to total US$ 777.16 million in 2023. Over the assessment period, demand for automated optical inspection systems is set to rise at 9.1% CAGR. By 2033, the total market valuation is predicted to reach US$ 1,955.71 million.

Growing demand for high-quality electronic components in the automotive, consumer electronics, and aerospace industries is expected to drive demand for automated optical inspection systems. Similarly, the miniaturization of electronic components will likely create growth prospects for the market.

0 notes

Text

Automated Optical Inspection System Market News 2024-2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Automated Optical Inspection System Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Automated Optical Inspection System Market Analysis share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Automated Optical Inspection System Market?

The global automated optical inspection system market size reached US$ 956.7 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 4,275.9 million in 2032, exhibiting a growth rate (CAGR) of 18.1% during 2024-2032.

What are Automated Optical Inspection System?

An Automated Optical Inspection (AOI) System is a technology employed in manufacturing to examine printed circuit boards (PCBs) and other electronic elements for defects or quality problems. This system utilizes cameras and lighting to capture detailed images of the PCB, which are subsequently analyzed by specialized software to identify issues like missing components, misaligned parts, or soldering defects. By swiftly detecting and addressing these problems, AOI systems enhance production efficiency and ensure the quality of electronic devices.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2039

What are the growth prospects and trends in the Automated Optical Inspection System industry?

The automated optical inspection (AOI) market growth is driven by various factors. The automated optical inspection (AOI) systems market is on the rise, driven by increasing requirements for top-notch electronic components across industries like electronics manufacturing and automotive. These systems are pivotal in guaranteeing the quality and dependability of printed circuit boards (PCBs) by spotting defects such as soldering problems, absent components, and misalignments. Market expansion is also steered by technological progress in AOI systems, resulting in enhanced inspection precision and effectiveness. Furthermore, stringent quality criteria and regulations in diverse industries are boosting the uptake of AOI systems for quality assurance needs. Hence, all these factors contribute to automated optical inspection (AOI) market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type

2D AOI Systems

3D AOI Systems

By Component

Software

System

By Technology

Inline AOI

Offline AOI

By Application

Fabrication Phase

Assembly Phase

By End User

Automotive

Aerospace Defense

Others

By Region

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

Benelux

Nordic

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

ASEAN

Australia New Zealand

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Koh Young Technology

Omron

Viscom

Saki Corporation

Nordson

Kla

Camtek

Cyberoptics

Goepel Electronic

Irtec

Marantz Electronics

Machine Vision Products

Mycronic Ab (Vi Technology)

Dcb Automation

Pemtron

View Full Report: https://www.reportsandinsights.com/report/Automated Optical Inspection System-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Automated Optical Inspection System Market share#Automated Optical Inspection System Market size#Automated Optical Inspection System Market trends

0 notes

Text

Automated Optical Inspection Systems Market Size, Share, Demand, Growth and Forecast 2024-2032

Automated Optical Inspection Systems Market provides in-depth analysis of the market state of Automated Optical Inspection Systems manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Automated Optical Inspection Systems in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Automated Optical Inspection Systems Market Report:

The report offers a comprehensive and broad perspective on the global Automated Optical Inspection Systems Market.

The market statistics represented in different Automated Optical Inspection Systems segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Automated Optical Inspection Systems are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Automated Optical Inspection Systems.

Major stakeholders, key companies Automated Optical Inspection Systems, investment feasibility and new market entrants study is offered.

Development scope of Automated Optical Inspection Systems in each market segment is covered in this report. The macro and micro-economic factors affecting the Automated Optical Inspection Systems Market

Advancement is elaborated in this report. The upstream and downstream components of Automated Optical Inspection Systems and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/automated-optical-inspection-systems-market-100572

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Car Rack MarketMarket Analysis

Sexual Wellness MarketMarket Size

Global Shale Gas Processing Equipment MarketMarket Share

Global Protein Hydrolysate MarketMarket Growth

Workflow Automation and Optimization Software MarketMarket

Sulforaphane MarketMarket Share

Silver Powders And Flakes MarketMarket Growth Rate

Carbon-Carbon Composite Material MarketMarket Forecast

Global Organic Rice Protein MarketMarket Size

Polyhydroxyalkanoates (Pha) MarketMarket Growth

Residential Generators MarketMarket Analysis

Information Technology Consulting Services MarketMarket Size

Global Intracranial Stents MarketMarket Share

Global White Box Servers MarketMarket Growth

Non-Grain Oriented Electrical Steel MarketMarket

Laser Communications Terminals (LCTs) MarketMarket Share

Selective Laser Sintering Equipment MarketMarket Growth Rate

Adaptive Optics MarketMarket Forecast

Global 3D Printing Metal MarketMarket Size

Iot Platforms MarketMarket Growth

Proton Exchange Membrane Fuel Cell (PEMFC) MarketMarket Analysis

Transplant Diagnostics MarketMarket Size

Global Sucrose Monolaurate (CAS 25339-99-5) MarketMarket Share

Global Common Mode Choke Coils (CMCC) MarketMarket Growth

Fluid Viscous Dampers (FVD) MarketMarket

Electrophysiology MarketMarket Share

Skinner Blade MarketMarket Growth Rate

Isolator Gloves MarketMarket Forecast

Global Inkjet Paper MarketMarket Size

Cavitated BOPP Film MarketMarket Growth

In-App Advertising MarketMarket Analysis

Tact Switch MarketMarket Size

Global 5G Wireless Base Station MarketMarket Share

Global Healthcare Staffing MarketMarket Growth

Electronically Controlled Air Suspension in Commercial Vehicles(ECAS) MarketMarket

2-Hema Phosphate MarketMarket Share

Electric Massage Sofa Chair MarketMarket Growth Rate

Low Voltage Direct Current (LVDC) MarketMarket Forecast

Global USB Charger Tester MarketMarket Size

Endometrial Biopsy Catheter MarketMarket Growth

0 notes

Text

Machine Vision And Inspection System Market Share and Demand Analysis with Size, Growth Drivers and Forecast to 2030

The latest market report published by Credence Research, Inc. “Global Machine Vision And Inspection System Market: Growth, Future Prospects, and Competitive Analysis, 2022 – 2030. Machine vision and inspection solutions have become crucial components in industrial automation. There’s a growing global demand for these systems, driven by heightened awareness of their benefits and further bolstered by ongoing technological advancements and decreasing costs.

Machine Vision and Inspection System Market is a dynamic and rapidly evolving segment of the technology and manufacturing industry. This market revolves around the development and implementation of advanced machine vision systems and inspection technologies that enable automated quality control, defect detection, and precision measurements in various industrial processes. Machine vision systems rely on cameras, sensors, artificial intelligence, and computer vision algorithms to analyze and interpret visual data, ensuring product quality and consistency across sectors such as manufacturing, automotive, electronics, healthcare, and food and beverage.

Key components of this market include 2D and 3D vision systems, smart cameras, optical character recognition (OCR), and robotic inspection systems. The adoption of machine vision and inspection systems is driven by the need for improved product quality, reduced production errors, increased efficiency, and compliance with regulatory standards. These systems find applications in tasks ranging from surface inspection, part identification, and assembly verification to barcode reading, packaging inspection, and defect sorting.

As technology continues to advance, machine vision systems are becoming more accessible, cost-effective, and capable of handling complex inspection tasks. The market's growth is propelled by Industry 4.0 and the integration of machine vision into smart factories and automation processes. Furthermore, the expanding scope of machine vision applications in areas like healthcare diagnostics, autonomous vehicles, and robotics underscores its versatility and potential for transformative impact across industries.

The dynamics of the Machine Vision and Inspection System Market are shaped by a multitude of factors that influence its growth, innovation, and adoption across various industries. These dynamics encompass trends, challenges, opportunities, and market drivers, all of which contribute to the evolving landscape of machine vision and inspection systems.

Here are the key dynamics at play: