#Applications of copper pipe fittings

Explore tagged Tumblr posts

Text

All You Need To Know About Copper Pipe Fittings

What are copper pipe fittings?

Copper pipe fittings are made up of copper tubes that run across your house and an assortment of fixtures attached to these pipes.

These fittings are essential in ensuring water flows smoothly and consistently to various parts of the house. They come in different shapes and sizes, including elbow, tee, reducer, coupling, and cap, among others.

Applications of copper pipe fittings

Copper pipe fittings are entirely versatile and can be used in many different applications. In plumbing, they are primarily used to join two copper pipes or control water flow.

These fittings are also used for air conditioner installation, gas supply, and heating system installation. In addition to these applications, copper pipe fittings are used in industrial processing, refrigeration, natural gas, and much more.

Benefits of using copper pipe fittings

One of the primary benefits of copper pipe fittings is that they are long-lasting and durable. Copper's natural properties prevent the pipework from corroding or decaying, ensuring the materials remain intact for a long time.

Copper pipe fittings are also easy to install, and joining two copper pipes is as simple as soldering them. Unlike plastic, copper fittings are resistant to extreme temperatures, and the material is hygienic, making them ideal for the potable water supply.

#Benefits of using copper pipe fittings#Applications of copper pipe fittings#All You Need To Know About Copper Pipe Fittings#What are copper pipe fittings

0 notes

Text

Discover the exceptional performance of copper nickel pipe fittings, high alloy pipe fittings, Hastalloy pipe fittings, and super duplex fittings in demanding industrial applications. This article highlights the importance of these specialized fittings, ideal for fertilizer service plants and large diameter, heavy-wall pipe fittings. Learn how these advanced materials ensure durability, reliability, and optimal performance for critical systems.

#copper nickel pipe fittings#high alloy pipe fittings#Hastalloy pipe fittings#heavy-wall pipe fittings#japan#fertilizer service plants#super duplex fittings

2 notes

·

View notes

Text

Monel K500 Pipe Fittings Manufacturers in India

-Manilaxmi Industrial

Monel K500 Pipe Fittings are a great option. Because of their increased strength and longevity, the nickel-copper alloy used to make these fittings makes them perfect for a range of demanding applications.

Manilaxmi Industrial is one of the leading exporters of Monel K500 pipe fittings. Customers all over the world are drawn to our products because of their outstanding quality and functionality.

#PipeFittings#IndustrialFittings#PlumbingSupplies#PipingSolutions#PipeConnections#PipeInstallation#PipeAccessories#IndustrialPipes#PlumbingFittings#Pipework#PipeFabrication#PipeSystems#PipeParts#PipeManufacturing#PipingIndustry

2 notes

·

View notes

Text

The Craftsmanship behind Fittings Manufacturing

Fittings like plastic fittings China are connectors that connect pipes, tubes, or hoses. They are intended to form a secure and leak-proof connection, allowing for the uninterrupted passage of liquids, gasses, or even solid objects. Plumbing, HVAC systems, hydraulic and pneumatic machinery, oil and gas pipelines, and other applications all employ fittings. These little components are the unsung heroes of numerous sectors, keeping together contemporary society's complicated architecture.

Fittings: An Art Form Manufacturing

Manufacturing fittings is a complex procedure that necessitates accuracy and attention to detail. Here's a rundown of the stages required in making fittings:

Material Selection: The selection of materials is critical in the manufacture of fittings. diverse materials, such as brass, stainless steel, PVC, or copper, are required for diverse uses. The material used must be corrosion-resistant, long-lasting, and suitable for the contents transported.

Engineers design fittings with accuracy, taking into account parameters such as pressure ratings, temperature, and flow needs. To generate precise and trustworthy products, the design process may use computer-aided design (CAD).

Machining: Machining procedures like as turning, milling, and drilling are commonly used to make fittings from metal fittings manufacturer. These operations shape and refine the material into the correct shape, guaranteeing that the fitting will work properly.

Quality Control: Throughout the production process, stringent quality control methods are employed. Inspections, testing, and monitoring are performed to ensure that the fittings fulfill industry standards and requirements.

Surface Finish: Depending on the application, fittings may be polished, plated, or coated to improve their durability and appearance.

Manufacturing Fittings Innovations

In recent years, the field of fittings production has undergone considerable developments. These advancements seek to boost efficiency, decrease environmental impact, and increase product performance. Among the significant advancements are:

3D Printing: Additive manufacturing, including 3D printing, is becoming more popular for producing complicated, bespoke fits with minimal material waste.

Sustainable Materials: To lessen its environmental imprint, the industry is investigating eco-friendly materials and manufacturing procedures.

Rapid prototype: Computer-aided design and rapid prototype techniques enable the creation and testing of novel fitting designs to be completed more quickly.

IoT technology is being integrated into fittings from plastic fittings manufacturers to monitor and optimize fluid flow, identify leaks, and increase system performance.

Follow our Facebook and Twitter for more information about our product.

#Metal fittings manufacturer#Metal fittings manufacturer China#Professional Metal Manufacturer#Metal Manufacturer China

2 notes

·

View notes

Text

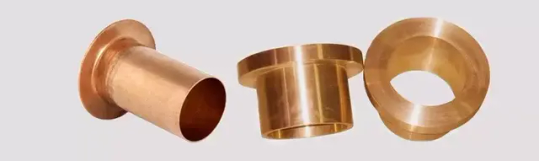

5 Features of Copper Stub Ends.

Copper Stub Ends offers several beneficial features that make them a popular choice for various plumbing and piping applications.

Here are five key features of copper stub ends:

Corrosion Resistance: Copper is naturally corrosion-resistant, making copper stub ends highly durable and suitable for long-term use in various environments. This resistance helps prevent degradation and maintains the integrity of the piping system.

Excellent Thermal Conductivity: Copper is an excellent thermal conductor which means it efficiently transfers heat. This feature is crucial in HVAC systems, where the efficient transfer of hot or cold water is essential for optimal performance.

Soldering/Brazing Compatibility: Copper stub ends, have a plain end that is easily soldered or brazed to copper pipes. Soldering or brazing creates a strong leak-proof joint, ensuring a secure connection between the stub end and the pipe.

Flared End for Easy Attachment: The opposite end of the copper stub end features a flared or raised lip. This design allows straightforward attachment to another component, such as a flange or valve, by bolting or welding.

Versatility: Copper stub ends are versatile fittings used in various applications, including plumbing systems, HVAC installations, and industrial processes. Their adaptability and reliability make them suitable for both residential and commercial projects.

2 notes

·

View notes

Text

Utilising Carbon Steel Pipe Fittings for Reliable Connections in Industrial Projects

Carbon steel pipe fittings are a reliable choice for many industrial projects due to their ability to withstand pressure, temperature changes and corrosion while being easy to connect to joints and valves.

They have excellent shock and vibration resistance, making them ideal for transporting water or other fluids beneath high roadways.

Quality Carbon steel Pipe Fittings for Reliable Connections in Industrial Projects

When selecting pipe fittings for an industrial project, ensure they are made from top-quality materials - especially carbon steel pipes and fittings.

Carbon steel boasts superior strength to other metals and is generally more durable. Furthermore, it has greater rust and corrosion resistance than some steel types.

Selecting the suitable material is essential when selecting a pipe, as each grade has its characteristics and is tailored for specific uses. Knowing what chemicals or temperatures your pipe must withstand will help determine which steel grade works best for your project.

It is wise to select carbon steel pipe fittings treated for durability and resistance to environmental wear and tear. This could include painting, galvanization or other protective coatings, which could significantly extend their lifespan in the long run.

Durability

Carbon steel pipe fittings are highly reliable and long-lasting in industrial projects. They can withstand extreme temperatures, pressures, and vibrations without corroding or cracking.

They make an ideal transport option for liquids and gases in various industries, from construction to electric power generation. Furthermore, their excellent corrosion resistance makes them suitable for corrosive environments.

However, ensuring the carbon steel pipe fittings you select are made from quality materials is essential. Select them based on specific requirements for your application and guarantee they meet an API or ASTM standard rating.

Additionally, ensure your pipe fittings have been tested for reliability in any environment and can withstand the pressures, temperatures and other environmental conditions they will be exposed to. Doing this helps avoid unnecessary disruptions or even complete system failure when needed.

Cost

If your industrial piping system is exposed to harsh weather conditions and water or chemical corrosion, you must create durable connections that resist rusting, corrosion and leaks. Carbon steel pipe fitting solutions offer a cost-effective way to achieve this goal.

These pipes are more cost-effective than stainless steel or copper yet still offer superior resistance to various environmental elements like high temperatures, chemicals and corrosives.

When installing or replacing the pipe, fittings can make the process smoother. There are various types of fittings, such as elbows, tees, reducers and couplings in multiple styles to meet your requirements.

Conclusion

Our carbon steel pipe fittings offer reliable connections to withstand the strain, no matter the application- from industrial plants to high-pressure pipelines. You have your pick of elbows, equal tees, reducer bushings and more.

Our carbon steel pipe fittings are manufactured with up to 2 per cent carbon content for extra strength and resilience in your piping system. They're perfect for transporting air, water, oil, and steam in low-pressure industrial projects.

4 notes

·

View notes

Text

Refrigeration Copper Pipe Fittings Market, Global Outlook and Forecast 2025-2032

Refrigeration Copper Pipe Fittings Market Size, Demand & Supply, Regional and Competitive Analysis 2025-2031

Refrigeration copper pipe fittings are essential components in the HVAC (Heating, Ventilation, and Air Conditioning) and refrigeration industries. They serve as connectors that direct and control the flow of refrigerants through copper pipes. These fittings come in various shapes and sizes, including elbows, tees, couplings, and valves. Designed to handle the high pressures and temperatures that are typical of refrigeration systems, these fittings are integral to ensuring a system’s efficiency and safety.

Copper is the material of choice for these fittings due to its excellent thermal conductivity, corrosion resistance, and ease of fabrication. These properties ensure reliable, leak-free connections, which in turn contribute to the longevity and performance of refrigeration and HVAC systems. Copper’s malleability also makes it easier to manufacture complex fittings that are essential for diverse applications, such as residential, commercial, and industrial refrigeration systems.

Market Size

The global refrigeration copper pipe fittings market was valued at USD 722 million in 2023 and is expected to grow to USD 943.73 million by 2032. This represents a compound annual growth rate (CAGR) of 3.90% over the forecast period. The market’s steady growth can be attributed to the rising demand for refrigeration systems, particularly in developing regions where industrialization and urbanization are on the rise.

Download a free Sample Report PDF

Historically, the refrigeration copper pipe fittings market has seen stable growth due to the increasing global demand for HVAC and refrigeration systems across various sectors, including food processing, pharmaceuticals, and automotive industries. The continued expansion of these industries, along with advancements in refrigeration technologies, is expected to drive the demand for copper pipe fittings in the coming years.

Global Refrigeration Copper Pipe Fittings Market: Market Segmentation Analysis

This report provides a deep insight into the global refrigeration copper pipe fittings market, covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trends, niche markets, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and assessing the position of the business organization. The report structure also focuses on the competitive landscape of the global refrigeration copper pipe fittings market, this report introduces in detail the market share, market performance, product situation, operation situation, etc., of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the refrigeration copper pipe fittings market in any manner.

Market Segmentation (by Application)

Refrigeration Copper Pipe

Heat Exchanger

Others

Market Segmentation (by Type)

90 Degree Elbow

45 Degree Elbow

Key Company

Conex Banninger (IBP)

Mueller Streamline

KME Copper

NIBCO

Viega

TSI Technologies

Parker

MM Kembla

Nippontube

Zhe JIANG HAI Liang

Ningbo Yongxiang Copper Pipeline

Qingdao HONGTAI COPPER

Ningbo Jintian Copper

Zhejiang Jiangxin COPPER Pipeline

Zhejiang Tongbu Pipe Industry

Linhai Hengye Tubing Equipment

Fuzhou Zhenxie PIPE

Access to full report

FAQ

What is the current market size of Refrigeration Copper Pipe Fittings?

➣ The global refrigeration copper pipe fittings market is valued at USD 722 million in 2023 and is expected to reach USD 943.73 million by 2032.

Which are the key companies operating in the Refrigeration Copper Pipe Fittings market?

➣ Key players in the market include Conex Banninger (IBP), Mueller Streamline, KME Copper, NIBCO, Viega, and Parker.

What are the key growth drivers in the Refrigeration Copper Pipe Fittings market?

➣ Key growth drivers include the increasing demand for refrigeration and HVAC systems, advances in refrigeration technology, and growing commercial and industrial applications.

Which regions dominate the Refrigeration Copper Pipe Fittings market?

➣ North America, Europe, and Asia-Pacific are the dominant regions in the refrigeration copper pipe fittings market.

What are the emerging trends in the Refrigeration Copper Pipe Fittings market?

➣ Emerging trends include the demand for eco-friendly and energy-efficient refrigeration systems and the growth of emerging markets such as Asia-Pacific and Latin America.

#RefrigerationCopperFittings#CopperPipeFittings#HVACMarket#MarketForecast#GlobalMarket#RefrigerationIndustry#PlumbingComponents#MarketTrends#IndustrialFittings#CoolingSystems#CopperMarket#MarketGrowth#HVACComponents#PipingSolutions#IndustryAnalysis#EnergyEfficiency

0 notes

Text

Understanding Monel 400’s Strength in Extreme Industrial Conditions

Understanding Monel 400’s Strength in Extreme Industrial Conditions

When it comes to handling tough industrial conditions, Monel 400 stands out as a dependable material. Its strength and resistance to corrosion make it a popular choice for demanding environments. Book A Consultation When it comes to handling tough industrial conditions, Monel 400 stands out as a dependable material. Its strength and resistance to corrosion make it a popular choice for demanding environments. Whether in marine, chemical, or high-temperature applications, Monel 400 consistently provides reliable performance. Let’s explore the standout features of the Monel 400, including its composition, density, and industrial uses. What is Monel 400? Monel 400 is a nickel-copper alloy known for its excellent corrosion resistance and durability. It’s made mostly of nickel (around 63%) and copper (roughly 30%), with small amounts of iron, manganese, carbon, and silicon. This combination of metals makes Monel 400 perfect for industries dealing with seawater, extreme heat, or aggressive chemicals. It’s the material of choice when long-lasting performance and reliability are needed in harsh environments. Monel 400 Chemical Composition The unique chemical makeup of Monel 400 is what gives it its impressive strength and corrosion resistance. The high nickel content provides excellent protection against corrosion, while copper enhances its strength. Iron, manganese, and carbon contribute to its mechanical properties. Here’s a simple breakdown of its composition:Nickel: 63% Copper: 28-34% Iron: 2.5% Manganese: 2% Carbon: 0.3%This mix makes Monel 400 highly resistant to stress corrosion cracking, even in harsh environments like seawater and acidic conditions. Monel 400 Density Monel 400 has a density of around 8.8 to 9.0 g/cm³. It is denser than many metals, but its alloy design makes it still light enough for various applications. This makes it perfect for high-stress situations where strength is important, but weight should be kept to a minimum. Monel 400 in Different Forms Monel 400 comes in several forms, each suited for different industrial applications. Here are some of the key options:Monel 400 Plate:

Ideal for heavy-duty applications like tanks and pressure vessels. It works well in environments with both high temperatures and corrosive chemicals.Monel 400 Round Bar: This form is great for parts like valves and pumps, as it can resist extreme temperatures and corrosion.Monel 400 Pipe: Monel 400 pipes are highly resistant to saltwater corrosion and are commonly used in the marine industry and chemical processing plants.Monel 400 Fittings and Flanges:

These are used to connect pipes and other components, offering the same strength and corrosion resistance as other Monel 400 materials.

Why Choose Monel 400?

Monel 400 is a top choice because of its durability and resistance to corrosion. Here’s why it’s relied on in industries that require these qualities:Exceptional Corrosion Resistance: Monel 400 resists corrosion in harsh environments, including seawater and acidic conditions. It also resists stress corrosion cracking, which makes it ideal for industries that need reliable materials in extreme conditions.High Strength in High Temperatures: It performs well even in high-temperature environments, making it suitable for chemical processing plants and power generation systems where heat is a constant factor.Good Workability: Despite its strength, Monel 400 is easy to fabricate, weld, and machine, making it a popular choice for engineers creating custom parts.Versatile Applications: It’s used in a wide range of applications, from pumps and valves to marine equipment and pressure vessels. Its resistance to oxidation and corrosion makes it perfect for environments that would cause other materials to fail.Longevity and Durability: With proper maintenance, Monel 400 components last a long time, saving businesses from frequent replacements. This makes it a cost-effective solution over time.

Common Applications of Monel 400

Monel 400 is used in many industries because of its strength and ability to withstand tough conditions. Here are some key applications:Marine Industry: Its corrosion resistance makes it a go-to material for shipbuilding, offshore platforms, and other vital marine equipment.Chemical Processing: In chemical plants, it’s used for equipment exposed to harsh chemicals, such as tanks, heat exchangers, piping systems, and valves.Aerospace: Its strength and heat resistance make it ideal for aerospace parts, such as aircraft and engine components, which must endure extreme temperatures and stress.Oil and Gas: Monel 400’s resistance to corrosion in saltwater environments makes it a popular choice for the oil and gas industry. It’s found in valves, pumps, and offshore oil rig components exposed to seawater. Monel Alloy: A Versatile Solution Monel alloys are known for their ability to perform in tough environments. While Monel 400 is the most widely used, other alloys like Monel 500 and Monel 405 also offer strong resistance to corrosion. Depending on the specific needs of a project, these alloys may provide extra benefits while still offering the same level of durability. How Does Monel 400 Perform in Extreme Conditions? Monel 400 excels in environments where most metals would break down quickly. It resists seawater corrosion, high temperatures, and harsh chemicals, making it essential for industrial applications that require long-lasting performance. Whether in marine, chemical, or high-temperature industries, Monel 400 ensures that equipment and components remain reliable over time, even under tough conditions.If your industry requires materials that can withstand extreme environments, Monel 400 is the ideal choice. Its impressive properties and performance make it one of the most trusted materials for demanding applications.For more information about Monel 400, including specifications and availability, check out Steelco Metal to learn how this versatile material can meet your industrial needs. FAQ What is Monel metal used for? Monel metal is widely used in marine, chemical, and aerospace industries due to its excellent resistance to corrosion, high strength, and ability to withstand extreme temperatures. It’s ideal for components exposed to harsh environments. What is the difference between Monel 400 and Monel 500? Monel 400 is a nickel-copper alloy known for its corrosion resistance, while Monel 500 contains aluminum and titanium, offering higher strength and better performance at elevated temperatures. Monel 500 is preferred in high-temperature applications. What are the primary uses of Monel 400? Monel 400 is commonly used in marine environments, chemical processing plants, oil and gas industries, and aerospace for components requiring resistance to corrosion, strength, and durability in harsh conditions. Is Monel 400 resistant to seawater corrosion? Yes, Monel 400 is highly resistant to seawater corrosion, making it ideal for marine applications such as propeller shafts, valves, and pumps exposed to saltwater environments. Read the full article

0 notes

Text

The Hidden Benefits of Using Cupro Nickel Tubes from Dexter Sales Industries

When choosing the right material for piping and tubing, you want something that lasts, performs well, and resists corrosion. One of the best options available today is Cupro Nickel tubes, especially those from Dexter Sales Industries. While many people know about stainless steel or copper tubing, Cupro Nickel often goes unnoticed. However, it offers incredible benefits that make it a top choice in various industries. Let us explore why Cupro Nickel tubes from Dexter Sales Industries might be the perfect fit for your needs.

What Are Cupro Nickel Tubes:

Cupro Nickel is a blend of copper and nickel, often combined with small amounts of iron and manganese to improve strength and corrosion resistance. These tubes are widely used in marine, industrial, and heat exchanger applications.

Why Choose Cupro Nickel Tubes:

Here are some lesser-known benefits of using Cupro Nickel tubes from Dexter Sales Industries:

1. Excellent Corrosion Resistance

Cupro Nickel is highly resistant to corrosion, especially in saltwater environments. This makes it perfect for marine applications like shipbuilding and offshore platforms.

2. Superior Heat Conductivity

One of the standouts features of Cupro Nickel is its ability to conduct heat efficiently. This makes it an ideal choice for heat exchangers, condensers, and cooling systems.

3. Long Lifespan and Durability

Unlike regular copper or stainless-steel tubes, Cupro Nickel tubes have a long lifespan due to their resistance to biofouling and erosion. They can withstand harsh conditions without significant wear and tear.

4. Low Maintenance Costs

Since these tubes are highly resistant to corrosion and fouling, they require minimal maintenance. This means lower operational costs for businesses that rely on these tubes for critical applications.

5. Strong Mechanical Properties

Cupro Nickel tubes have excellent mechanical strength and flexibility, making them ideal for high-pressure systems.

6. High Resistance to Biofouling

Biofouling occurs when microorganisms and algae grow on metal surfaces, leading to reduced efficiency. Cupro Nickel naturally resists biofouling, making it perfect for seawater systems and cooling pipelines.

7. Perfect for Marine Applications

Due to its anti-corrosive properties and durability, Cupro Nickel tubes are widely used in:

Shipbuilding

Desalination plants

Offshore oil and gas platforms

Submarine piping systems

8. Great for Industrial Use

Apart from marine applications, these tubes are also widely used in industries such as:

Power plants (for cooling systems)

Automotive (brake lines)

Aerospace (hydraulic systems)

9. Sustainable and Environmentally Friendly

Cupro Nickel is a recyclable material, making it an eco-friendly option. It reduces waste and helps industries lower their carbon footprint.

10. Reliability and Quality from Dexter Sales Industries

When you buy from Dexter Sales Industries, you are guaranteed high-quality products that meet international standards. Their tubes are tested for durability, efficiency, and performance, ensuring you get the best materials for your needs.

Conclusion:

Cupro Nickel tubes offer a range of benefits, from corrosion resistance and heat conductivity to low maintenance and eco-friendliness. Whether you are in the marine, industrial, or automotive sector, investing in Cupro Nickel tubes from Dexter Sales Industries ensures long-term reliability and performance.

FAQs

1. What makes Cupro Nickel better than stainless steel?

Cupro Nickel is more resistant to seawater corrosion and biofouling, making it ideal for marine applications.

2. Can Cupro Nickel tubes be used for drinking water systems?

Yes! Cupro Nickel is safe for potable water applications due to its anti-microbial properties.

3. How long do Cupro Nickel tubes last?

With proper maintenance, they can last decades, even in harsh environments.

4. Are Cupro Nickel tubes expensive?

While the initial cost may be higher than standard materials, the long lifespan and low maintenance make them cost-effective in the long run.

5. Where can I buy high-quality Cupro Nickel tubes? Dexter Sales Industries is a trusted supplier of premium-quality Cupro Nickel tubes for various applications.

0 notes

Text

The Role of Pipe Fittings in Modern Plumbing Systems

Pipex.ai is one of the high-quality Pipe Fittings Suppliers in India. We suppliers a broad range of Pipe Fittings such as Elbow, Tee, Reducers, Cap, Stub Ends, and so on. Our pipe fittings are well-known for their anti-corrosion qualities. As a Pipe Fittings Manufacturer, we provide different types of coatings and finishes on our products. Our Pipe Fittings Products are utilized for various industrial applications, are long-lasting, and have great strength.

We supply and Manufacture Pipe Fittings at a reasonable price. We also prioritize continuous innovation and advanced manufacturing techniques to enhance the durability and efficiency of our pipe fittings for various industrial applications.We are also leading Pipe Fitting Elbow Suppliers in India.

Types of Pipe Fittings and Their Uses

Pipe Fitting Coupling: Our Pipe Fitting Coupling are crucial for a number of industries, including construction, water treatment, chemical, and oil and gas, because they are made to link pipes securely and seamlessly. Premium materials including alloy steel, carbon steel, stainless steel, and other specific grades are used in the manufacturing of these couplings in order to endure high temperatures and pressures.

Pipe Fitting Cross: A Pipe Fitting Cross, often referred to as a four-way fitting, is a pivotal component in piping systems, designed to connect four pipes at a single junction. This configuration allows for the distribution or collection of fluids or gases, facilitating complex flow pathways in various industrial and commercial uses.

Pipe Fitting Tee: A pipe fitting tee, commonly referred to as a tee fitting, is an essential component in piping systems, designed to combine or split fluid flow. Shaped like the letter 'T', it features three openings: one inlet and two outlets, or vice versa, arranged at 90-degree angles to each other. This configuration allows for the redirection of fluids or gases, making tee fittings indispensable in various industrial and residential applications.

Pipe Fitting Reducer: Pipe fitting reducer is an essential component in piping systems, designed to connect two pipes of differing diameters, thereby ensuring a smooth transition between them. This transition is crucial for maintaining system integrity, controlling fluid dynamics, and accommodating various design requirements. Reducers play a pivotal role in adjusting flow rates, managing pressure changes, and facilitating the integration of different pipe sizes within a network.

Pipe Fitting End Caps: Pipe Fitting End Caps are the components used in plumbing and pipe networks to close off the ends of pipes, valves or other connections. They help to ensure that any pressure created within a system is contained. Different materials can be used for end cap fittings, such as PVC, copper, CPVC and galvanized steel, depending upon the system’s requirements.

Pipe Fitting Bend: A pipe fitting bend is a crucial component in piping systems, designed to alter the direction of fluid flow while maintaining the integrity and efficiency of the system. As a trusted Pipe Fitting Bend Supplier in India, we supply pipe bends in various sizes, bend angles (such as 45°, 90°, and 180°), and materials to meet diverse industrial requirements. Our pipe bends are precision-engineered for easy installation, high-pressure performance, and long-lasting reliability. With strict adherence to global quality standards, we ensure durable and leak-proof solutions for industrial piping applications.

Benefit Of Pipe Fitting in Plumbing system

Pipe fittings are essential components in plumbing and piping systems, offering several key benefits:

Direction and Flow Control: They enable precise direction changes and flow regulation, ensuring efficient fluid transport.

Connection of Different Sizes: Fittings allow for the seamless joining of pipes with varying diameters, accommodating system design requirements.

System Integrity and Safety: By providing secure connections, pipe fittings maintain system integrity, reducing the risk of leaks and enhancing safety.

Maintenance and Repair Efficiency:Pipe Fittings simplify maintenance tasks, allowing for easy isolation and repair of specific sections without disrupting the entire system.

Selecting the Right Pipe Fittings Supplier in India

Choosing a reliable pipe fittings supplier is crucial for ensuring the quality and performance of your piping system. When selecting a supplier in India, consider the following factors:

Quality Assurance: Ensure the supplier adheres to international standards such as ASTM, ASME, and DIN, guaranteeing high-quality products.

Material Selection: A reputable supplier should offer fittings made from various materials, including stainless steel, carbon steel, and alloy steel, to suit different applications.

Customization: The ability to provide customized fittings tailored to specific project requirements is a valuable trait in a supplier.

Industry Experience:Pipe Fittings Suppliers with extensive experience across various industries, such as oil & gas, chemical processing, and construction, are likely to understand diverse project needs.

Customer Support: Responsive customer service and technical support are essential for addressing any issues that may arise during the selection, installation, or maintenance of pipe fittings.

Where to Find the Best Pipe Fitting Supplies?

If you're looking for the best pipe fitting supplies, you can find a wide range of options online. One great resource is Pipex, which offers high-quality pipe fittings to meet your needs. Whether you're working on plumbing, construction, or industrial projects, this website provides a variety of fittings to ensure a perfect fit for your systems.

For those seeking high-quality pipe fittings tailored to diverse industrial applications, Pipex.ai offers a comprehensive range of products. Their offerings are designed to meet stringent national and international standards, ensuring durability and optimal performance across various industries. Pipe Fittings Supplier in India are indispensable components in plumbing and industrial piping systems, enabling the secure connection, direction change, and regulation of fluid flow. Their proper selection and installation are vital for ensuring system efficiency, safety, and longevity.

Check Out To Know More in Details: Pipex.ai

#Pipe Fittings Suppliers in India#Pipe Fittings Supplier in India#Pipe Fitting Elbow Suppliers in India#Pipe Fitting Coupling#Pipe Fitting Cross#pipe fitting tee#Pipe fitting reducer#Pipe Fitting End Caps#Pipe Fitting Bend#Pipe Fittings#Pipe Fittings Suppliers

0 notes

Text

Why Beyond Plumbing Supplies Stands Out for Plumbing Needs in Australia.

A Trusted Source for Quality Plumbing Supplies

Finding the right plumbing supplies Melbourne, plumbing supplies online, or online plumbing supplies Australia can be a challenge when reliability and affordability are top priorities. Whether you are a professional plumber or a DIY enthusiast, selecting a supplier that provides high-quality products with expert guidance makes a difference. Beyond Plumbing Supplies has built a strong reputation by offering a comprehensive range of plumbing products backed by industry expertise and dedicated customer support.

A Comprehensive Selection of Plumbing Products

Sourcing the right materials is crucial for any plumbing project, whether for residential repairs, commercial installations, or industrial applications. Beyond Plumbing Supplies ensures that customers can access a wide selection of essential plumbing products, including plumbing supplies Brisbane, plumbing supplies Sydney, and plumbing supplies Perth. Their inventory includes:

Plumbing fittings and pipes: Options such as PEX pipe, PEX pipe fittings, PEX water pipe, and gas PEX pipe ensure compatibility with different plumbing systems.

Hot water system components: Items such as hot water system parts, gas valve, hot water element, and tempering valve help maintain system efficiency.

Toilet spare parts and tapware: Genuine Caroma cistern parts, toilet spare parts, toilet parts, toilet spares, basin mixer, sink mixer, and plug and waste provide the right fit and function for modern plumbing systems.

Copper pipe and fittings: Essential for robust plumbing installations, including copper pipe, copper pipe fittings, and thermocouple.

Valves and regulators: Components such as hot water tempering valve, pressure limiting valve, water pressure reducing valve, pressure reduction valve, and hot water valves support safe and effective plumbing system operations.

Competitive Pricing Without Compromising Quality

Affordability is a major concern for professionals and homeowners alike. Beyond Plumbing Supplies maintains competitive pricing across its range without sacrificing product quality. This balance ensures that customers receive cost-effective solutions without worrying about subpar materials or unreliable fittings. Whether you are sourcing bathroom tapware, kitchen tapware mixers, or pressure control valves, you get durable products that meet industry standards.

A User-Friendly Online Shopping Experience

For those who prefer the convenience of digital transactions, Beyond Plumbing Supplies provides a seamless online shopping platform that simplifies the purchasing process. Customers can efficiently browse, compare, and order online plumbing parts, fixtures, and accessories with a straightforward interface. The availability of plumbing suppliers Melbourne offering a well-organized e-commerce experience makes procurement faster and hassle-free.

Expert Advice and Reliable Support

One of the standout qualities of Beyond Plumbing Supplies is the expertise of its team. With over 60 years of combined industry experience, the company provides knowledgeable insights and professional advice tailored to each customer's needs. Whether customers require guidance on selecting the right hot water valves or need recommendations on plumbing supplies tapware, Beyond Plumbing Supplies delivers precise and practical solutions.

Supporting the Plumbing and Construction Community

Beyond offering high-quality plumbing supplies across Australia, Beyond Plumbing Supplies actively supports the well-being of those in the construction and plumbing industries. Recognizing the prevalence of mental health challenges within the sector, the company contributes financially to mental health initiatives, helping workers access vital support services. This commitment fosters a positive impact that extends beyond providing essential plumbing products.

Why Choose Beyond Plumbing Supplies Over Other Options?

With multiple plumbing suppliers available, choosing the right one can be overwhelming. Beyond Plumbing Supplies differentiates itself by:

Offering a diverse selection of plumbing supplies Melbourne, plumbing supplies Brisbane, and plumbing supplies Sydney with a focus on quality and longevity.

1. Providing expert guidance from professionals with decades of industry experience.

2. Maintaining competitive pricing without cutting corners on product reliability.

3. Ensuring a seamless online shopping experience with efficient product categorization and fast order processing.

4. Actively supporting mental health initiatives within the construction sector, reinforcing a socially responsible business approach.

A Reliable Choice for Plumbing Professionals and DIY Enthusiasts

Whether you need plumbing supplies Perth, hot water system parts, or pressure limiting valve solutions, Beyond Plumbing Supplies is a dependable provider with a strong reputation. Their commitment to quality, affordability, and community support sets them apart from other suppliers. For those seeking a trusted source of plumbing products, Beyond Plumbing Supplies offers an extensive inventory, industry expertise, and a customer-first approach that ensures long-term satisfaction.

0 notes

Text

Why Monel And Inconel Are The Preferred Alloys For Extreme Environments

Monel is a family of nickel-copper alloys renowned for its excellent resistance to corrosion especially in marine and chemical environments. With a typical composition of 52–67% nickel and 30–40% copper, Monel offers high ductility and ease of fabrication at moderate temperatures, making it ideal for components such as valves, piping systems, and pump shafts used in corrosive settings.

Inconel is a group of nickel-chromium-based superalloys engineered for high-temperature applications. With chromium content between 17–21% and additional alloying elements such as molybdenum, niobium, and titanium, Inconel maintains exceptional mechanical strength and oxidation resistance even at temperatures exceeding 2,200°F (1,204°C). This makes it indispensable in aerospace engine components, gas turbines, and high-pressure reactors.

Technical Advantages in Extreme Environments

1. Corrosion Resistance

Monel: Thanks to its high copper content, Monel exhibits outstanding resistance to seawater, hydrofluoric acid, and other corrosive chemicals. This makes it the preferred choice for marine hardware and chemical processing equipment. However, its performance diminishes at temperatures above 1,000°F (538°C). Inconel: With a robust chromium-induced oxide layer, Inconel retains its corrosion resistance even at elevated temperatures, making it suitable for applications in jet engines, power plants, and chemical reactors.

2. High-Temperature Performance

Monel: Best suited for applications where temperatures remain moderate, Monel’s operational limits are typically below 1,000°F. Its ease of fabrication and lower cost are major benefits when high-temperature resistance is not critical. Inconel: Engineered to maintain mechanical strength and oxidation resistance at temperatures up to 2,200°F (1,204°C) or higher, Inconel is essential for high-stress, high-heat applications in aerospace and energy generation.

3. Mechanical Strength and Durability

Monel: Offers excellent ductility and good strength at room temperature, which is advantageous for forming complex shapes and rapid fabrication processes. Its softer nature, however, limits its use under extreme mechanical loads. Inconel: Exhibits superior tensile and yield strengths even under high thermal stress, making it ideal for critical components such as turbine blades and exhaust systems that must endure continuous high loads.

Quick Comparison Table: Monel V/S Inconel

Monel and Inconel Applications Across Industries

1. Marine & Chemical Processing: Monel’s excellent corrosion resistance makes it ideal for ship components, valves, and chemical plant equipment. Inconel is used in high‑temperature reactors and exchangers handling aggressive chemicals.

2. Oil & Gas: Monel is cost‑effective for tubing and valves in moderately harsh environments, while inconel is chosen for downhole tubulars and high‑pressure components that operate at extreme temperatures.

3. Aerospace & Power Generation: Inconel’s superior high‑temperature strength and oxidation resistance are critical for turbine blades, exhaust systems, and reactor components. Monel is sometimes used for fuel system parts requiring corrosion protection at lower temperatures.

4. Automotive: Monel’s ductility and corrosion resistance benefit components like exhaust systems and fuel tanks.

For businesses operating in extreme environments, the choice of raw materials can be the critical factor between success and failure. When sourcing these specialised fittings online, it is important to verify adherence to international quality standards, such as ASTM and ISO, to ensure product reliability. Therefore, always prioritise quality when buying fittings online to maintain system integrity and safety.

At Online Fittings, we are committed to supplying these high-performance alloys, guaranteeing that our partners have access to the best raw materials tailored to their specific application needs. For further technical insights or to discuss your project requirements, contact our expert team today!

0 notes

Text

Brass Scrap Recycling in Lonsdale: A Sustainable Choice

Introduction

Brass is one of the most valuable and widely used metals in various industries, including plumbing, electrical, and decorative applications. Recycling brass scrap not only conserves natural resources but also significantly reduces environmental impact. If you're in Lonsdale and looking for efficient ways to recycle brass, understanding the process and benefits can help you make informed decisions.

The Importance of Brass Recycling

Brass is an alloy primarily made of copper and zinc, making it highly durable and recyclable. Unlike some materials that degrade after recycling, brass retains its properties, allowing it to be reused repeatedly without loss of quality. Recycling brass scrap:

Conserves natural resources by reducing the need for virgin metal extraction.

Lowers energy consumption compared to producing new brass.

Reduces waste in landfills, contributing to a cleaner environment.

Provides financial incentives for individuals and businesses.

Sources of Brass Scrap

Brass scrap comes from various sources, including:

Plumbing fittings and fixtures – Old taps, pipes, and valves.

Electrical components – Connectors, terminals, and switches.

Industrial machinery – Gears, bearings, and other mechanical parts.

Decorative items – Door handles, chandeliers, and musical instruments.

Spent ammunition – Bullet casings made of brass.

The Brass Recycling Process

The process of recycling brass scrap involves several key steps:

Collection – Brass scrap is collected from different sources, including households, businesses, and industrial sites.

Sorting – The scrap is sorted based on its type and composition to ensure efficient processing.

Cleaning – Any contaminants, such as paint, plastic, or other metals, are removed.

Melting – The cleaned brass scrap is melted at high temperatures in a furnace.

Refining and Alloying – The molten brass is refined and adjusted to achieve the desired alloy composition.

Casting or Rolling – The refined brass is then cast into ingots or rolled into sheets for reuse in manufacturing.

Brass scrap recycling in Lonsdale is a smart and sustainable choice for individuals and businesses alike. By recycling brass, you contribute to environmental conservation, reduce waste, and gain financial benefits. Whether you're a homeowner, contractor, or industrial operator, finding a reliable brass recycling service ensures that your scrap is processed efficiently and responsibly.

0 notes

Text

Premium Copper Fitting Reducing Sleeves for Seamless Connections

Enhance your HVAC systems with our copper fitting reducing sleeves, which are designed for precise pipe diameter transitions. Manufactured with high-quality copper, these fittings ensure durability and optimal performance, minimising potential leaks and maintenance needs. Ideal for various applications, our reducing sleeves are crafted to meet industry standards, providing reliable and efficient solutions for piping requirements.

0 notes

Text

Brass Fasteners from Jamnagar: A Reliable Choice for the USA Market

For businesses in the USA, selecting high-quality fastening solutions is essential for maintaining durability, efficiency, and performance in industries like construction, electrical, marine, and automotive sectors. Brass Fasteners from Jamnagar, India, have become a preferred choice due to their superior quality, corrosion resistance, and affordability.

Jamnagar has established itself as a global hub for Brass Fasteners, exporting to various countries, including the USA. With precision manufacturing, strict quality standards, and cost-effective production, Jamnagar is the go-to source for businesses in the USA looking for reliable Brass Fasteners.

Jamnagar: The Brass Fastener Manufacturing Hub

History of Brass Manufacturing in JamnagarJamnagar has a long-standing history of brass manufacturing, dating back several decades. The city's expertise in brass component production has made it a global leader in the industry. Over time, Jamnagar has developed a strong network of skilled labor, advanced technology, and raw material availability, enabling it to supply Brass Fasteners to the USA market with efficiency and precision.

Why Jamnagar is a Global Leader in Brass FastenersThe success of Jamnagar’s Brass Fastener industry can be attributed to:

Raw Material Availability Easy access to copper and zinc, the key components of brass.

Skilled Workforce A highly experienced workforce ensures quality production.

Advanced Machinery State-of-the-art technology enables precision in manufacturing.

Competitive Pricing Lower production costs allow Jamnagar to offer affordable solutions for USA buyers.

Advantages of Brass Fasteners

Brass Fasteners have gained popularity in the USA due to their exceptional durability, corrosion resistance, and aesthetic appeal. Their unique properties make them suitable for a variety of applications, including construction, marine, electrical, automotive, and industrial manufacturing. Unlike steel, brass does not corrode easily, and unlike plastic, it offers superior strength and longevity.

Below are the key advantages of using Brass Fasteners in various industries:

Corrosion ResistanceOne of the most significant advantages of Brass Fasteners is their high corrosion resistance. Unlike steel, which is prone to rusting when exposed to moisture, brass does not oxidize or deteriorate easily, making it an excellent choice for:

Marine applications Used in boats, docks, and offshore structures due to their resistance to saltwater.

Plumbing systems Ideal for pipes, fittings, and fixtures exposed to constant water flow.

Outdoor constructions Used in bridges, outdoor lighting, and fences, where weather conditions can affect material longevity.

Additionally, brass forms a protective patina over time, enhancing its resistance to harsh environmental conditions. This makes Brass Fasteners an excellent investment for long-term applications in the USA.

Durability and StrengthBrass Fasteners offer a perfect balance of strength and flexibility, making them ideal for high-stress applications. Unlike plastic fasteners that can easily break under pressure or extreme temperatures, brass:

Withstands heavy loads without deforming or cracking.

Maintains structural integrity even in extreme temperature fluctuations, making it suitable for industrial machinery and HVAC systems.

Has excellent wear resistance, which ensures a long service life, reducing the need for frequent replacements.

Industries in the USA, such as automotive, aerospace, and heavy equipment manufacturing, rely on Brass Fasteners for applications where high tensile strength and durability are essential.

Electrical ConductivityBrass is known for its excellent electrical conductivity, making it a preferred choice in electrical and electronic applications. It offers a lower electrical resistance compared to stainless steel, ensuring efficient current flow in wiring and circuit connections.Common electrical applications of Brass Fasteners include:

Power distribution boards: Used in grounding and secure connections.

Electrical switches and outlets: Ensures stable and reliable conductivity.

Automotive electrical systems: Found in battery terminals, wiring harnesses, and control panels.

Because of its non-corrosive properties, brass is widely used in solar panels, wind energy systems, and electric vehicles (EVs) in the USA.

Aesthetic AppealBrass is often chosen for its visually appealing golden hue, making it a preferred material for decorative and architectural applications. The luxurious finish of brass fasteners enhances the overall look of:

Luxury furniture Used in assembling wooden furniture, antique restorations, and high-end decor.

Architectural designs Applied in stair railings, decorative fixtures, and lighting installations.

Jewelry and fashion accessories Used in watchmaking, belt buckles, and ornamental hardware.

Unlike painted or coated steel fasteners, brass retains its shine for a long time, and when exposed to air, it develops a natural patina that adds to its charm.For USA designers, architects, and manufacturers looking to achieve a vintage or high-end aesthetic, brass fasteners are the perfect choice.

Non-Magnetic PropertiesUnlike steel fasteners, Brass Fasteners are non-magnetic, which makes them essential in sensitive industrial and electronic applications. Their non-magnetic nature is highly beneficial for

Medical equipment Used in MRI machines and sensitive diagnostic tools, where magnetic interference must be avoided.

Telecommunications Used in radio equipment, antennas, and satellite communication systems.

Precision instruments Found in navigation tools, compasses, and scientific measuring devices.

In industries where magnetic interference can disrupt operations, such as aerospace, defense, and high-frequency electronics, brass fasteners offer a reliable and interference-free fastening solution.

Types of Brass Fasteners from Jamnagar

Jamnagar is a leading global producer of brass fasteners, supplying high-quality components used in construction, automotive, marine, and electrical industries across the USA market. Brass Fasteners are known for their durability, corrosion resistance, and strength, making them a preferred choice for industrial applications.

Brass NutsBrass nuts are used to secure bolts and screws, providing strong fastening in industrial, mechanical, and structural applications. They offer excellent corrosion resistance, making them ideal for outdoor, marine, and electrical installations.

Brass BoltsBrass bolts provide durable and corrosion-resistant fastening solutions for construction, automotive, and heavy machinery applications. They ensure long-lasting performance in high-moisture environments like plumbing and marine industries.

Brass ScrewsBrass screws are widely used in woodworking, electrical fittings, and decorative applications. Their non-magnetic and rust-resistant properties make them perfect for electronic devices, furniture, and architectural projects.

Brass WashersBrass washers distribute loads evenly, reducing wear and tear on fasteners and connected surfaces. They prevent loosening, absorb vibrations, and enhance fastening stability in industrial and automotive applications.

Brass AnchorsBrass anchors provide strong holding power in masonry, concrete, and drywall applications. They are commonly used in construction, industrial equipment mounting, and structural reinforcements due to their high load-bearing capacity.

Quality Standards for Brass Fasteners

Brass Fasteners from Jamnagar adhere to ISO 9001, ASTM, ANSI, and RoHS standards, ensuring durability, strength, and corrosion resistance for the USA market. They undergo rigorous testing for tensile strength, load capacity, and corrosion resistance, guaranteeing reliability in construction, automotive, marine, and electrical applications. Advanced CNC machining and protective coatings further enhance precision and longevity, making them a trusted choice for industrial use.

ISO Certification and ComplianceJamnagar manufacturers adhere to ISO 9001 and other international certifications, ensuring that Brass Fasteners meet global industry standards for quality, safety, and performance. Compliance with ASTM, ANSI, and RoHS regulations makes them suitable for USA markets.

Material Composition and Durability TestingBrass Fasteners are made from high-quality brass alloys, ensuring optimal copper-zinc balance for strength and corrosion resistance. They undergo rigorous tensile, corrosion, and load-bearing tests to meet the demanding requirements of industrial, construction, and automotive applications.

Precision Engineering and Manufacturing ProcessManufacturers in Jamnagar use advanced CNC machining, automated threading, and heat treatment processes to ensure precision, consistency, and defect-free production. This results in high-performance fasteners that provide secure and long-lasting fastening solutions for USA industries.

Exporting Brass Fasteners to the USA

Jamnagar is a key exporter of brass fasteners to the USA market, supplying industries like construction, automotive, marine, and electronics. Manufacturers comply with ASTM, ANSI, and RoHS standards, ensuring high-quality, corrosion-resistant, and durable fasteners. With cost-effective production and efficient logistics, Jamnagar continues to provide reliable fastening solutions at competitive prices to USA buyers.

Demand for Brass Fasteners in the USA MarketThe USA has a high demand for durable and corrosion-resistant brass fasteners, especially in construction, automotive, marine, and electrical industries. Their non-magnetic and high-conductivity properties make them ideal for electronic and renewable energy applications.

USA Industry Standards and RegulationsJamnagar manufacturers ensure compliance with USA industry standards such as ASTM, ANSI, and RoHS, meeting safety, environmental, and performance regulations. Strict quality checks ensure reliable and defect-free fasteners for industrial use.

Competitive Pricing and Supply Chain EfficiencyWith cost-effective manufacturing processes and bulk production capabilities, Jamnagar offers affordable Brass Fasteners without compromising quality. An efficient logistics network ensures timely exports to the USA, making Jamnagar a preferred sourcing destination for brass fasteners.

Applications of Brass Fasteners in the USA

Brass Fasteners are widely used across various USA industries due to their strength, corrosion resistance, and conductivity. In construction, they secure structural framing, plumbing, and decorative fixtures. The electrical industry relies on them for circuit boards, enclosures, and grounding systems. Their saltwater resistance makes them ideal for marine applications such as ships, docks, and offshore structures. In the automotive sector, Brass Fasteners are essential for engine components, vehicle assembly, and interior fittings, ensuring long-term durability and reliability.

Construction IndustryBrass Fasteners are essential in structural framing, plumbing systems, and decorative architectural designs. Their corrosion resistance and durability make them ideal for bridges, building reinforcements, and HVAC installations.

Electrical and Electronics IndustryWidely used in circuit boards, electrical enclosures, and grounding systems, Brass Fasteners provide high conductivity and resistance to oxidation, ensuring reliable electrical connections in industrial and residential applications.

Marine and Watercraft IndustryDue to their rust and saltwater resistance, Brass Fasteners are extensively used in boats, docks, ship fittings, and offshore structures, offering long-term durability in harsh marine environments.

Automotive and Transportation SectorBrass Fasteners are used in vehicle assembly, engine mounting, and interior components due to their strength, thermal resistance, and non-corrosive properties, ensuring secure and long-lasting automotive applications.

FAQs

Why are Brass Fasteners popular in the USA? Brass fasteners are highly preferred in the USA due to their corrosion resistance, durability, and excellent electrical conductivity. They are widely used in construction, electrical, marine, and automotive industries.

Are Brass Fasteners stronger than steel fasteners? While Brass Fasteners are durable and corrosion-resistant, steel fasteners tend to be stronger in terms of tensile strength. However, brass fasteners are preferred in applications requiring resistance to moisture and non-magnetic properties.

What industries use Brass Fasteners the most in the USA? Brass Fasteners are commonly used in construction, electrical installations, automotive manufacturing, plumbing, marine engineering, and decorative applications.

How do Jamnagar manufacturers ensure quality in brass fasteners? Jamnagar manufacturers follow strict quality control measures, including ISO certifications, material testing, and precision engineering to meet international standards like ASTM and ANSI.

Are Brass Fasteners expensive compared to other materials? Brass Fasteners are slightly more expensive than steel or aluminum fasteners due to the cost of raw materials. However, their longevity, corrosion resistance, and strength make them a cost-effective choice in the long run.

How can USA businesses import Brass Fasteners from Jamnagar? USA businesses can source Brass Fasteners from Jamnagar through online supplier directories, trade fairs, industrial exhibitions, or by directly contacting manufacturers through B2B platforms.

Do Brass Fasteners require maintenance? Brass Fasteners require minimal maintenance due to their corrosion-resistant nature. However, regular cleaning may be needed in high-exposure environments to maintain their appearance and effectiveness.

Can Brass Fasteners be used in high-temperature applications? Yes, Brass Fasteners have good heat resistance and can be used in high-temperature applications. However, extreme heat may cause some softening compared to steel fasteners.

Are Brass Fasteners recyclable? Yes, Brass is a highly recyclable material. Many USA industries prefer brass fasteners due to their sustainability and ability to be reused without losing their properties.

What are the different finishes available for brass fasteners? Brass fasteners can come in various finishes, including polished brass, nickel-plated, chrome-plated, and antique brass, depending on the specific application needs.

0 notes

Text

Understanding Monel 400’s Strength in Extreme Industrial Conditions

Understanding Monel 400’s Strength in Extreme Industrial Conditions

When it comes to handling tough industrial conditions, Monel 400 stands out as a dependable material. Its strength and resistance to corrosion make it a popular choice for demanding environments. Book A Consultation When it comes to handling tough industrial conditions, Monel 400 stands out as a dependable material. Its strength and resistance to corrosion make it a popular choice for demanding environments. Whether in marine, chemical, or high-temperature applications, Monel 400 consistently provides reliable performance. Let’s explore the standout features of the Monel 400, including its composition, density, and industrial uses. What is Monel 400? Monel 400 is a nickel-copper alloy known for its excellent corrosion resistance and durability. It’s made mostly of nickel (around 63%) and copper (roughly 30%), with small amounts of iron, manganese, carbon, and silicon. This combination of metals makes Monel 400 perfect for industries dealing with seawater, extreme heat, or aggressive chemicals. It’s the material of choice when long-lasting performance and reliability are needed in harsh environments. Monel 400 Chemical Composition The unique chemical makeup of Monel 400 is what gives it its impressive strength and corrosion resistance. The high nickel content provides excellent protection against corrosion, while copper enhances its strength. Iron, manganese, and carbon contribute to its mechanical properties. Here’s a simple breakdown of its composition:Nickel: 63% Copper: 28-34% Iron: 2.5% Manganese: 2% Carbon: 0.3%This mix makes Monel 400 highly resistant to stress corrosion cracking, even in harsh environments like seawater and acidic conditions. Monel 400 Density Monel 400 has a density of around 8.8 to 9.0 g/cm³. It is denser than many metals, but its alloy design makes it still light enough for various applications. This makes it perfect for high-stress situations where strength is important, but weight should be kept to a minimum. Monel 400 in Different Forms Monel 400 comes in several forms, each suited for different industrial applications. Here are some of the key options:Monel 400 Plate:

Ideal for heavy-duty applications like tanks and pressure vessels. It works well in environments with both high temperatures and corrosive chemicals.Monel 400 Round Bar: This form is great for parts like valves and pumps, as it can resist extreme temperatures and corrosion.Monel 400 Pipe: Monel 400 pipes are highly resistant to saltwater corrosion and are commonly used in the marine industry and chemical processing plants.Monel 400 Fittings and Flanges:

These are used to connect pipes and other components, offering the same strength and corrosion resistance as other Monel 400 materials.

Why Choose Monel 400?

Monel 400 is a top choice because of its durability and resistance to corrosion. Here’s why it’s relied on in industries that require these qualities:Exceptional Corrosion Resistance: Monel 400 resists corrosion in harsh environments, including seawater and acidic conditions. It also resists stress corrosion cracking, which makes it ideal for industries that need reliable materials in extreme conditions.High Strength in High Temperatures: It performs well even in high-temperature environments, making it suitable for chemical processing plants and power generation systems where heat is a constant factor.Good Workability: Despite its strength, Monel 400 is easy to fabricate, weld, and machine, making it a popular choice for engineers creating custom parts.Versatile Applications: It’s used in a wide range of applications, from pumps and valves to marine equipment and pressure vessels. Its resistance to oxidation and corrosion makes it perfect for environments that would cause other materials to fail.Longevity and Durability: With proper maintenance, Monel 400 components last a long time, saving businesses from frequent replacements. This makes it a cost-effective solution over time.

Common Applications of Monel 400

Monel 400 is used in many industries because of its strength and ability to withstand tough conditions. Here are some key applications:Marine Industry: Its corrosion resistance makes it a go-to material for shipbuilding, offshore platforms, and other vital marine equipment.Chemical Processing: In chemical plants, it’s used for equipment exposed to harsh chemicals, such as tanks, heat exchangers, piping systems, and valves.Aerospace: Its strength and heat resistance make it ideal for aerospace parts, such as aircraft and engine components, which must endure extreme temperatures and stress.Oil and Gas: Monel 400’s resistance to corrosion in saltwater environments makes it a popular choice for the oil and gas industry. It’s found in valves, pumps, and offshore oil rig components exposed to seawater. Monel Alloy: A Versatile Solution Monel alloys are known for their ability to perform in tough environments. While Monel 400 is the most widely used, other alloys like Monel 500 and Monel 405 also offer strong resistance to corrosion. Depending on the specific needs of a project, these alloys may provide extra benefits while still offering the same level of durability. How Does Monel 400 Perform in Extreme Conditions? Monel 400 excels in environments where most metals would break down quickly. It resists seawater corrosion, high temperatures, and harsh chemicals, making it essential for industrial applications that require long-lasting performance. Whether in marine, chemical, or high-temperature industries, Monel 400 ensures that equipment and components remain reliable over time, even under tough conditions.If your industry requires materials that can withstand extreme environments, Monel 400 is the ideal choice. Its impressive properties and performance make it one of the most trusted materials for demanding applications.For more information about Monel 400, including specifications and availability, check out Steelco Metal to learn how this versatile material can meet your industrial needs. FAQ What is Monel metal used for? Monel metal is widely used in marine, chemical, and aerospace industries due to its excellent resistance to corrosion, high strength, and ability to withstand extreme temperatures. It’s ideal for components exposed to harsh environments. What is the difference between Monel 400 and Monel 500? Monel 400 is a nickel-copper alloy known for its corrosion resistance, while Monel 500 contains aluminum and titanium, offering higher strength and better performance at elevated temperatures. Monel 500 is preferred in high-temperature applications. What are the primary uses of Monel 400? Monel 400 is commonly used in marine environments, chemical processing plants, oil and gas industries, and aerospace for components requiring resistance to corrosion, strength, and durability in harsh conditions. Is Monel 400 resistant to seawater corrosion? Yes, Monel 400 is highly resistant to seawater corrosion, making it ideal for marine applications such as propeller shafts, valves, and pumps exposed to saltwater environments. Read the full article

0 notes