#Applications of Hot and Cold Rolled Steel

Explore tagged Tumblr posts

Text

Hot Rolled vs. Cold Rolled Steel: Unveiling the Key Differences for Optimal Performance

In the world of steel manufacturing, understanding the differences between hot rolled and cold rolled steel is crucial for selecting the right material for your projects. Each type offers unique properties and benefits that cater to different applications and performance requirements. This article will delve into the key differences between hot rolled and cold rolled steel, helping you make informed decisions for your needs.

For high-quality steel products and more information, visit Stainless Steel Strip Coil.

What is Hot Rolled Steel?

Hot rolled steel is produced by rolling the steel at high temperatures, typically over 1700°F (926°C). This process makes the steel easier to shape and form, resulting in a product that is ideal for structural components and other applications where precise shapes and tolerances are less critical.

Characteristics of Hot Rolled Steel

Surface Finish: Hot rolled steel has a rough, scaly surface that is a result of the cooling process after being rolled.

Tolerances: It generally has looser tolerances compared to cold rolled steel, making it suitable for applications where exact dimensions are not crucial.

Cost-Effective: The production process is simpler, making hot rolled steel more cost-effective for large-scale manufacturing.

Ductility: It has excellent ductility, allowing it to be easily welded and formed into various shapes.

What is Cold Rolled Steel?

Cold rolled steel is produced by rolling the steel at room temperature after it has cooled from the hot rolling process. This additional processing step enhances the steel's strength, surface finish, and dimensional accuracy, making it suitable for more precise and high-performance applications.

Characteristics of Cold Rolled Steel

Surface Finish: Cold rolled steel has a smooth, polished surface that is aesthetically pleasing and ideal for visible components.

Tolerances: It has tighter tolerances and greater dimensional accuracy, making it perfect for applications that require exact specifications.

Strength: The cold rolling process increases the steel's strength and hardness, providing better performance in demanding environments.

Cost: Due to the additional processing steps, cold rolled steel is typically more expensive than hot rolled steel.

Key Differences Between Hot Rolled and Cold Rolled Steel

Manufacturing Process

Hot Rolled Steel: Rolled at high temperatures, which allows for easier shaping but results in a rougher finish.

Cold Rolled Steel: Rolled at room temperature, providing a smooth finish and greater strength due to the additional processing.

Surface Quality

Hot Rolled Steel: Rough, scaly surface that is suitable for structural applications where the finish is not a primary concern.

Cold Rolled Steel: Smooth, polished surface that is ideal for applications requiring a high-quality finish.

Dimensional Accuracy

Hot Rolled Steel: Looser tolerances, making it suitable for projects where exact dimensions are not critical.

Cold Rolled Steel: Tighter tolerances and greater precision, ideal for high-performance applications.

Cost

Hot Rolled Steel: More cost-effective due to the simpler manufacturing process.

Cold Rolled Steel: More expensive due to the additional processing and improved properties.

Applications of Hot Rolled and Cold Rolled Steel

Hot Rolled Steel

Construction: Used for structural components like I-beams, angle iron, and other infrastructure.

Automotive Frames: Suitable for parts that do not require precise dimensions.

Heavy Equipment: Ideal for manufacturing components that will undergo further machining or fabrication.

Cold Rolled Steel

Precision Parts: Used in manufacturing parts that require tight tolerances and high strength.

Appliances: Suitable for making components that need a high-quality finish and precise dimensions.

Automotive: Used for manufacturing critical components that require greater strength and accuracy.

Conclusion

Choosing between hot rolled and cold rolled steel depends on your project's specific requirements. Understanding the key differences in their manufacturing processes, surface qualities, dimensional accuracies, and costs can help you make an informed decision.

For high-quality steel products and expert guidance, visit Stainless Steel Strip Coil. Our extensive range of steel solutions ensures you find the right material for your application, delivering optimal performance and reliability.

#Hot Rolled Steel Properties#Cold Rolled Steel Advantages#Hot vs. Cold Rolled Steel Comparison#Steel Manufacturing Processes#Surface Finish of Rolled Steel#Dimensional Accuracy in Rolled Steel#Applications of Hot and Cold Rolled Steel

0 notes

Text

What is the stamping process?

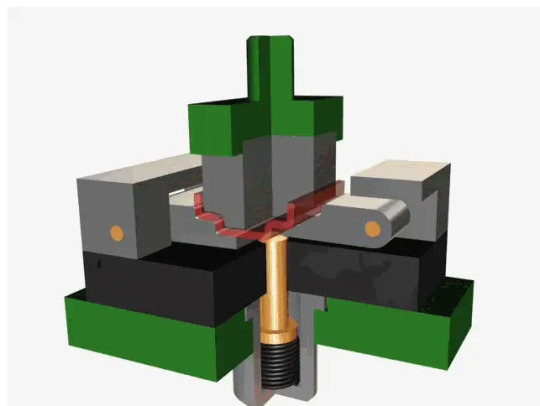

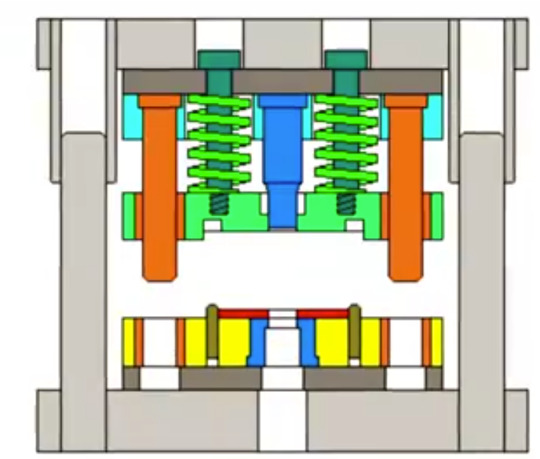

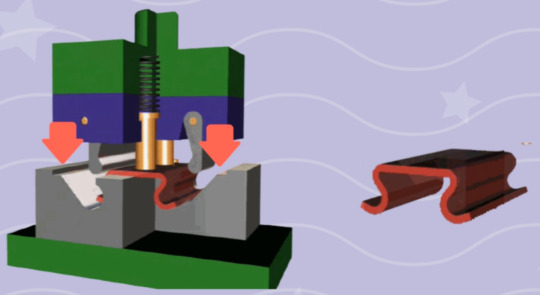

1.Stamping is a forming method that uses a press and a die to apply external force to plates, strips, pipes and profiles to cause plastic deformation or separation, thereby obtaining a workpiece (stamping part) of the desired shape and size. Stamping and forging belong to plastic processing (or pressure processing), collectively known as forging. The blanks for stamping are mainly hot-rolled and cold-rolled steel plates and strips. 60-70% of the steel in the world is sheet material, most of which is stamped into finished products. The body, chassis, fuel tank, radiator fins of automobiles, the steam drum of boilers, the shell of containers, the iron core silicon steel sheets of motors and electrical appliances are all stamped. There are also a large number of stamped parts in products such as instruments and meters, household appliances, bicycles, office machinery, and daily utensils.

2.Stamping is a production technology that uses the power of conventional or special stamping equipment to directly subject sheet metal to deformation force in the die and deform it, thereby obtaining product parts with certain shapes, sizes and performances. Sheet metal, die and equipment are the three elements of stamping. According to the stamping temperature, it is divided into hot stamping and cold stamping. The former is suitable for sheet metal processing with high deformation resistance and poor plasticity; the latter is carried out at room temperature and is a commonly used stamping method for thin plates. It is one of the main methods of metal plastic processing (or pressure processing) and also belongs to material forming engineering technology.

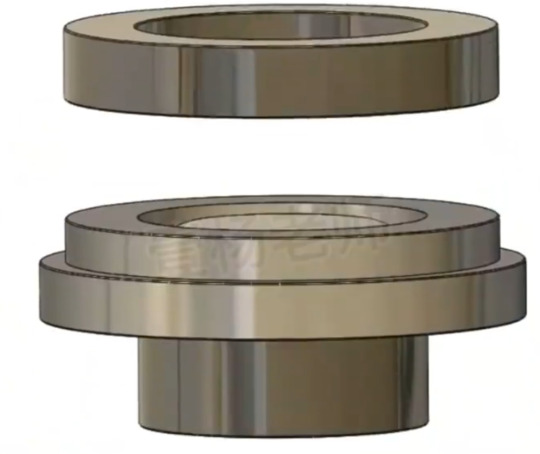

3.The die used for stamping is called a stamping die, or simply a die. A stamping die is a special tool for batch processing materials (metal or non-metal) into the required stamping parts. The die is crucial in stamping. Without a die that meets the requirements, batch stamping production will be difficult to carry out; without advanced dies, advanced stamping technology cannot be achieved. The stamping process, die, stamping equipment and stamping materials constitute the three elements of stamping processing. Only when they are combined with each other can stamping parts be obtained.

Sheet metal, die and stamping equipment are the three essential elements of stamping processing:

Characteristics and application of stamping processing Stamping production relies on dies and presses to complete the processing process. Compared with other processing methods, it has the following characteristics in terms of technology and economy:

(1) The dimensional accuracy of stamped parts is guaranteed by the die, and they have exactly the same characteristics, so the quality is stable and the interchangeability is good.

(2) Due to the use of die processing, parts with thin walls, light weight, good rigidity, high surface quality and complex shapes that cannot be or are difficult to manufacture by other processing methods can be obtained.

(3) Stamping processing generally does not require heating of the blank, nor does it require large amounts of metal cutting like cutting processing, so it is not only energy-saving, but also metal-saving.

(4) For ordinary presses, dozens of pieces can be produced per minute, while high-speed presses can produce hundreds or thousands of pieces per minute. Therefore, it is a highly efficient processing method. Due to the above-mentioned outstanding characteristics of stamping technology, it is widely used in various fields of the national economy. For example, industries such as aerospace, machinery, electronic information, transportation, weapons, daily electrical appliances and light industry all have stamping processing. Not only is it widely used in the industry, but everyone comes into direct contact with stamping products every day. Stamping can produce small precision parts in watches and instruments, as well as large covers for cars and tractors. Stamping materials can use ferrous metals, non-ferrous metals and some non-metallic materials.

3 notes

·

View notes

Text

Songshun Steel Rod Supplier: Provides Various High Quality Steel Rods

Steel rod is a common rod-shaped steel material made of metal materials, it is widely used in machinery, ships, construction, engineering, manufacturing and other fields. Steel rods are one of the indispensable materials in the steel market and are in high demand, so steel rod suppliers play a pivotal role in the steel market. Songshun Steel, as a high-quality steel rod supplier in China, can provide various high-quality steel rod materials to the world. It not only has rich varieties and sufficient inventory, but also ensures that the quality, service, price, etc. can satisfy you. This article will introduce the steel rods and advantages provided by Songshun steel rod supplier.

Steel Rod Types Songshun Steel, as a steel rod supplier with a wide range of steel materials, provides steel bar materials of various materials. Our steel rod types are as follows:

(1) Classified by process, it can be divided into hot-rolled, forged and cold-drawn steel bars; (2) Classified by material, steel rods can be divided into alloy steel rods, Ordinary carbon steel rods, stainless steel rods, tool steel rods, high-speed steel rods, aluminum alloy rods, synthetic fiber steel rods, etc.; (3)Classified by shape, it can be divided into solid steel rods, round steel rods, square steel rods, hexagonal steel rods, wire rods, etc.

Steel Rod Properties High quality steel rod supplier, offering a wide range of high performance steel rods. As a reliable steel rod supplier in China, Songshun Steel provides steel rods with the following properties:

Excellent wear resistance, corrosion resistance and high temperature resistance Better electrical and thermal conductivity High strength and rigidity Good solderability and stability Good plasticity and toughness

Uses Of Steel Rods As a professional steel rod supplier, we have an in-depth understanding of steel rods and clearly understand the purposes for which our customers purchase steel rods. Below are some of our customers’ applications for steel rods in various fields.

Construction field: Steel rods are often used to reinforce concrete structures, and are also used to support structures such as beams, columns, bridges, and columns.

Automobile manufacturing field: Steel rods are used to manufacture various engine parts, rods, brake calipers, exhaust pipes, connectors, support columns, door beams, roof frames, etc.

In the manufacturing of electronic and electrical equipment, steel rods are often used to make wires for electromagnetic coils, transformers and generators. They are also used as heat-conducting elements in air conditioners, refrigerators, and other appliances, among other things.

In the manufacturing field, it is often used to manufacture various mechanical parts, tools, cutters, drill bits, planers, etc.

In addition to the above fields, steel rods are also used in aerospace, energy and power transmission, oil and gas industry, shipbuilding, chemical and heavy industry, home furnishing and decoration, etc.

Steel Rod Supplier In addition to the above points, as a high-quality and reliable steel rod supplier, Songshun can not only provide a variety of high-performance, multi-purpose and types of steel rods, but also has advantages in quality, professionalism, service, price, etc.

We ensure the quality of steel rods, provide various testing services, provide products in strict accordance with international production standards and customer requirements, and provide steel rods with the best performance and quality to customers.

Songshun has an experienced team that studies various steel rod materials and provides customers with one-stop solutions and technical support.

Whether it is processing, pre-sales or after-sales service, we are professional and can ensure that your project is completed smoothly and perfectly.

Competitive prices, abundant inventory, and ability to deliver on time.

Understand industry policies, market demand, international trade, etc., and be able to make reasonable strategies to adjust industrial structure, optimize product quality, improve operational efficiency, and promote innovative development according to market changes in a timely manner.

Adhere to the path of sustainable development, adhere to the goal of achieving win-win development with customers, adhere to treating every customer with sincerity, adhere to customer-centeredness, and meet customer needs.

In summary, Songshun Steel can become a reliable steel rod supplier, not only providing high-quality steel rod materials, but also having other advantages. In the future, we are committed to becoming your preferred steel rod supplier, constantly moving forward, and providing you with better steel products.

2 notes

·

View notes

Text

Did you know about the Steel Facts? Steel is one of the most widely used materials in the world, found in everything from buildings and bridges to cars and household appliances. Steel is 100% recyclable without any loss of quality.

But what happens when steel products reach the end of their life cycle in all these applications?

Actually, it’s not the end. Indeed, for steel there is no end, as steel is 100% and infinitely recyclable without any loss of quality. The steel in end-of-life products can be melted down to be reused in the production of new steel.

This involves several stages:

Collection:

Sorting:

Shredding:

Melting and refining:

Casting and rolling:

The study delves into the value of reestablishing compositional information for steel recycling and sheds light on the dynamic nature of steel grades.

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA, Your Trusted Partner in Special Steels. Explore a vast inventory of Die Blocks and Tool Steels sourced from renowned manufacturers worldwide…

Our Steel Yards boast a comprehensive inventory, including:

DIE STEEL ( HH 370 – 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

COLD WORK STEELS – HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Learn more : https://www.viratsteels.com/

Any further queries feel free to contact us : 📩[email protected] 📲+91-98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#SteelFacts#ToolSteel#DieSteels#MetalIndustry#HCHCr

2 notes

·

View notes

Text

Samrat Header Machine: Revolutionizing Thread Rolling and Cold Forge Technology in India

India's industrial machinery sector has been witnessing remarkable advancements, with cutting-edge innovations redefining the standards of productivity and efficiency. Among these innovations, the Samrat Header Machine and Fully Automatic Thread Rolling Machines have emerged as game-changers. These machines, designed with precision engineering, are essential for manufacturing processes that require high accuracy, durability, and scalability. This article delves into the features, benefits, and applications of the Cold Forge Header Machine and Thread Rolling Machine, emphasizing their critical role in India's manufacturing landscape.

Overview of Samrat Header Machine

The Samrat Header Machine is a robust, high-performance industrial tool designed for forming fasteners and components with complex shapes. This machine is specifically crafted to meet the demands of industries such as automotive, aerospace, construction, and electronics. Its cutting-edge technology allows manufacturers to achieve superior quality outputs with minimal waste, making it a preferred choice for small and large-scale production units.

Some of the standout features of the Samrat Header Machine include:

Precision Engineering: Ensures consistency in output and minimizes errors.

High Speed and Efficiency: Increases production rates without compromising on quality.

Durability: Built with premium-grade materials, ensuring long-term performance even under challenging conditions.

Fully Automatic Thread Rolling Machine: Efficiency at Its Best

Thread rolling is a crucial process in manufacturing screws, bolts, and other fasteners. The Fully Automatic Thread Rolling Machine in India has taken this process to the next level by eliminating manual interventions and ensuring precision. This machine is ideal for producing high-strength threaded components used in critical applications.

Key Advantages:

Automation: Drastically reduces human error and increases consistency.

Versatility: Capable of handling a wide range of materials, including steel, brass, and aluminum.

Cost-Effective: Lowers production costs by minimizing material wastage and labor requirements.

Eco-Friendly: Ensures energy-efficient operation with reduced carbon emissions.

By automating the threading process, manufacturers can achieve unparalleled accuracy, making the machine indispensable for industries requiring uniform and reliable threading.

Cold Forge Header Machine: Revolutionizing Forging Processes

The Cold Forge Header Machine is a powerhouse in the forging industry. Unlike traditional hot forging, cold forging maintains the material's structural integrity while enhancing its strength. This machine is primarily used for producing parts such as bolts, rivets, and studs with exceptional precision.

Key Features:

Energy Efficiency: Requires less energy compared to hot forging methods.

Improved Surface Finish: Results in smooth and precise components.

Increased Material Strength: Enhances the mechanical properties of the finished product.

Cold forging with this machine also ensures reduced waste, making it an environmentally sustainable choice.

Applications Across Industries

Both Thread Rolling Machines and Cold Forge Header Machines are indispensable in sectors like:

Automotive: For producing high-strength bolts, nuts, and engine components.

Construction: Manufacturing durable fasteners for heavy-duty applications.

Aerospace: Ensuring precision and reliability in critical components.

Electrical: Creating components that demand high levels of accuracy.

Conclusion

The Samrat Header Machine, Fully Automatic Thread Rolling Machine, and Cold Forge Header Machine represent the pinnacle of modern manufacturing technology in India. These machines are not just tools; they are solutions that empower industries to meet growing demands with precision and efficiency. As India continues its journey toward becoming a global manufacturing hub, these machines will undoubtedly play a pivotal role in driving progress, innovation, and sustainability.

1 note

·

View note

Text

An Overview of HR Coils and Their Applications in Industries

Hot rolled coils are considered the building blocks for many industries and have acted as a catalyst for industrial growth owing to their versatility and dependability. These are products of steel manufactured through thermal and mechanical processing with great accuracy, hence finding their application across various industries, from automobile parts to the construction business.

Understanding HR Coils: The Marvel of Manufacturing

Hot rolling refers to the process of making thick steel slabs into thinner, more usable coils through a complex series of heating above their recrystallization temperature—usually around 1,700°F or 926°C—in order to allow the metal to be at its most malleable. This enables the metal to be rolled down to desired thicknesses without loss in structural integrity.

Salient Features Define Quality HR Coils

The remarkable properties of the HR coils result from their processing:

Surface Finish: Mill scale finish.

Dimensional Tolerance: Exact tolerance thickness.

Mechanical Properties: Strength and ductility enhanced.

Material Homogeneity: Homogeneous material in the coil.

Conclusion

The features discussed above have enhanced the properties of HR coil, thus highly commendable for use in areas where good mechanical properties and less cost of manufacture are vital.

Industrial Uses of the Coils in Different Sectors

Automotive Sector

HR coils have a number of major applications in the automotive industry, which are as follows:

Chassis Components: Frame rails, cross members.

Structural Elements: Body panels, reinforcements.

Wheel Rims: Strong, solid components.

Excellent formability and strength-to-weight ratio make the material quite ideal for meeting high automotive safety standards without compromising productivity.

Construction and Infrastructure

HR coils play a vital role in building strong infrastructure. Some of their applications are as follows:

Structural Steel: Beams, columns, and support structures.

Roofing Systems: Metal roofing panels and components.

Bridge Components: Deck plates and supporting elements.

The material's durability and load-bearing capacity make it indispensable in construction projects of all scales.

Heavy Equipment Manufacturing

The heavy machinery sector utilizes HR coils for:

Equipment Frames: Robust structural components.

Buckets and Attachments: High-wear applications.

Storage Tanks: Large-volume containment solutions.

Quality Considerations and Selection Criteria

Material Grade Selection

Choosing the appropriate HR coil grade depends on several factors:

End-use requirements.

Environmental exposure conditions.

Processing capabilities.

Cost considerations.

Regulatory requirements.

Surface Quality Requirement

Applications require surfaces of different qualities:

Commercial Quality (CQ): Applications of a general nature.

Drawing Quality: Improved surface.

Structural Quality (SQ): Applications that bear loads.

Economy and Financial Advantages

There are some significant economic advantages of using HR coils:

Lower Production Cost: Fewer processes are required for them than cold-rolled ones.

Less Energy Consumption: Less energy spent to produce the material.

Less Material Waste: The materials will be used most efficiently.

Longer Service Life: Durability in demanding applications.

Environmental Impact and Sustainability

State-of-the-art production methods for HR coils are heading towards sustainability by:

Energy-Efficient Processing: By using state-of-the-art heating and cooling systems.

Integration of Recycling: Steel products can be highly recycled.

Waste Reduction: Waste generation can be reduced through optimized production planning.

Environmental Compliance: Globally accepted standards are followed.

Future Trends and Innovations

Evolution in the HR coil industry continues with:

Development of AHSS.

Advanced surface technologies.

Improved process control systems.

Integration of smart manufacturing.

Informed Decision-Making

While choosing HR coils for specific purposes, one should consider:

Technical Requirements: Mechanical properties, dimensional specifications, and surface finish requirements.

Consultation with metallurgical expertise and experienced suppliers regarding optimum results in certain applications will also be useful to select the correct specification for the HR coil. The right choice of material, processing requirement, and quality control can be advised accordingly to successfully apply in specific industrial projects.

#HR coils#hot rolled steel#industrial steel applications#steel coils#construction materials#automotive steel

1 note

·

View note

Text

Stainless Steel 316L Sheet is the main type of SS 316L sheets are perforated sheets, Strips, Coils, Chequered plate, shim sheet, Foils, Flats, and Circles. Jindal and POSCO are the leading manufacturers in India that produce 316L cold rolled sheets and SS 316L HR Coils. Steels have an association with Jindal and buy stainless steel sheets and plates in large quantities. A240 Grade 316L material from many manufacturers of stainless steel sheets in India and South Korea in different thicknesses from 0.2 mm to 120mm. SA 240 Grade 316L material to more than 30 countries since 2008.

Steels is an approved supplier of Stainless steel sheets and coils in very large scale organizations in India, Kuwait, Oman, South Africa, Qatar. Steels supply SS 316L Plate in all common thickness is cut to size so our customers save money and don't pay for wastage. Stainless Steel 316 plates are produced by two manufacturing processes Hot rolled and cold worked. If you are looking for SS 316L Plate or strips for the acidic or high-temperature application so you should check the documents like MTR, Invoice, proof of origin. Steels stock are genuine and certified material of all reputed and well-known manufacturers of uns s31603 stainless steel plate.

Specification Schedule of Stainless Steel 316L Sheets & Plates

SS ASTM Standard SpecificationASTM A240 / ASME SA240International Standard

ASTM A 480

ASTM A 959

ASME IID

EN ISO 9445

EN ISO 18286

EN 10051

EN 10088-1

ISO 15510

Size Range

Cold rolled ASME SA240 Stainless Steel Sheet 0.5-6.4 mm

Hot rolled ASME SA240 Stainless Steel Sheet 3.0–10.0 mm

Thickness0.1 to 100 mm ThkWidth10-2500mmLength2m, 2.44m, 3m, or as requiredFinish2B, 2D, BA NO (8), Cold rolled sheet (CR), Hot rolled plate (HR), SATIN (Met with Plastic Coated), No.1 finish hot rolled, 1D, 2B, No.4, BA, 8K, satin, hairline, brush, mirror etc.HardnessHalf Hard, Soft, Hard, Quarter Hard, Spring HardFormSheet, Plate, Strip, Flats, Clad Plate, Coils, Foils, Plain Sheet, Flat Shim, Flat Sheet, Shim Sheet, Rolling Sheet, Rolling Plate, Rolls, Blank (Circle), soft annealed, descaled, tread plate, sheared, annealed, Checker Plate manufacturer and Supplier

7 notes

·

View notes

Text

Stainless Steel 304 Coils Stockists In India

Title: Exploring the Versatility of Stainless Steel 304 Coils: A Comprehensive Guide

Introduction: Stainless steel is a ubiquitous material known for its durability, corrosion resistance, and versatility in various applications. Among the numerous grades available, Stainless Steel 304 stands out as a popular choice for its excellent properties. This article delves into the world of Stainless Steel 304 Coils, examining their composition, characteristics, and diverse applications.

Section 1: Composition and Properties 1.1 Chemical Composition:

Breakdown of key elements in Stainless Steel 304 Coils.

Impact of chromium and nickel on corrosion resistance.

Other alloying elements and their contributions.

1.2 Mechanical Properties:

Tensile strength, yield strength, and elongation.

High-temperature performance.

Comparison with other stainless steel grades.

Section 2: Manufacturing Process 2.1 Hot vs. Cold Rolling:

Explanation of hot rolling and cold rolling processes.

Effects on coil thickness, surface finish, and mechanical properties.

2.2 Annealing Process:

Importance of annealing in enhancing corrosion resistance.

Annealing temperature and duration.

Section 3: Applications 3.1 Automotive Industry:

Use of Stainless Steel 304 Coils in exhaust systems and automotive components.

Corrosion resistance in harsh environmental conditions.

3.2 Construction Sector:

Applications in structural elements, facades, and roofing.

Aesthetics and durability in architectural designs.

3.3 Food and Beverage Industry:

Hygienic properties of Stainless Steel 304 Coils.

Common applications in food processing and storage.

3.4 Chemical and Petrochemical:

Resistance to corrosive chemicals and harsh environments.

Use in pipelines, tanks, and chemical processing equipment.

Section 4: Advantages and Challenges 4.1 Advantages:

Excellent corrosion resistance.

High strength and durability.

Ease of fabrication and maintenance.

4.2 Challenges:

Susceptibility to chloride-induced corrosion.

Cost considerations compared to other stainless steel grades.

Section 5: Maintenance and Care

Best practices for maintaining the integrity of Stainless Steel 304 Coils.

Cleaning methods and corrosion prevention.

Conclusion: In conclusion, Stainless Steel 304 Coils offer a compelling combination of corrosion resistance, mechanical strength, and versatility. Whether in automotive, construction, or food industries, these coils continue to play a crucial role in various applications. Understanding their composition, manufacturing process, and proper maintenance is key to unlocking their full potential in diverse settings.

2 notes

·

View notes

Text

Stainless Steel 304L Sheets & Plates Exporters In Mumbai

It is verified to express that you are seeking after down impeccable sheets plates and don't think about which grade is bona fide for you? In the event that your answer is extremely, by then Stainless Steel 304L Sheets and Plates is the correct decision for you. The tempered steel of examination 304L offers assorted basic highlights like great, high bore, and long connection life. These sheets and plates unavoidable consequence of SS are made by top quality grungy material and are supply wherever all through the globe. The Ss 304 L plates and sheets are proposed to meet the particular necessities of the clients. These SSs things are made particularly for high risky and high warmth catch applications.

The Stainless Steel 304L Sheets and Plates are enduring and can fit into any length with no burden and it is open in various shapes and sizes. The Padmavati Steel & Engg.Co. is a standard, exporter and provider of SS sheets and plates and this thing is utilized in different relationship for various applications. It is dealt with by national in like way as expansive standards.

The SS sheets and plates of appraisal 304L come in ASTM A240/ASME SA240 standard. The thickness of SS Plates/Sheets is extending from 3mm to 20mm. It comes in different fulfillments, for example, hot moved, cold rolled and others. These are given in different structures, for example, plain sheet, shim sheet, Designer sheet, checkered plate, and so on. It comes in another inside and out that truly matters ambiguous standard, for example, UNS 30403, JIS 304L, BS 304S11 and others. Before dispatch last result to the customer, it is familiar with different tests to guarantee its quality.

STAINLESS STEEL 304L SHEET AND PLATE SPECIFICATION

Standard : ASTM / ASME A240 / SA240 Size : 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm Thickness :0.01 mm to 250 mmThk Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) Finish : Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) Hardness : Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

For more information Visit our website: https://www.padmavatisteel.com/stainless-steel-304l-sheet-plate-manufacturers-suppliers-importers-exporters-stockists.html Contact Us: +91-9930388308 Email: [email protected]

4 notes

·

View notes

Text

The Versatility of ASTM A105 Carbon Steel Round Bars: An Overview

Introduction:

ASTM A105 carbon steel round bars are considered one of the most commonly used materials in various industries worldwide. They are known for their versatility, strength, and durability, making them an ideal material for a wide range of applications where strength and reliability are paramount. This blog post will provide an in-depth overview of ASTM A105 carbon steel round bars, including their properties, characteristics, applications, and more.

Properties of Carbon Steel Round Bars:

ASTM A105 carbon steel round bars are made from low-carbon steel and are known for their unique properties. They are cold drawn, turned, and polished, which gives them a smooth surface finish and excellent dimensional accuracy. These bars have a minimum yield strength of 36,000 psi and a minimum tensile strength of 70,000 psi, making them strong and durable.

Characteristics of Carbon Steel Round Bars:

ASTM A105 carbon steel round bars have several characteristics that make them perfect for various applications. They are highly corrosion-resistant, making them an ideal choice for harsh environments. Additionally, these bars are easy to machine, weld, and form, allowing for greater flexibility in design and manufacturing. They can also withstand high temperatures without losing their strength, making them suitable for applications that require heat resistance.

Applications of Carbon Steel Round Bars:

ASTM A105 carbon steel bars are used in various applications across various industries, from construction and manufacturing to automotive and aerospace. They are commonly used in the fabrication of pressure vessels, piping, and fittings, as well as in the production of pump shafts and other mechanical components. These bars are also used to construct buildings, bridges, and other structures that require strength and durability.

Advantages of Using Carbon Steel Round Bars:

There are several advantages to using CS round bars in manufacturing and construction applications. For one, these bars are highly versatile, making them suitable for a wide range of applications. They are also strong and durable, making them a good choice for harsh environments. Additionally, these bars are easy to weld, machine, and form, so they can be easily used in complex designs. Finally, ASTM A105 carbon steel round bars are cost-effective, making them an ideal choice for large-scale industrial applications.

Manufacturing Carbon Steel Round Bars:

ASTM A105 carbon steel round bars are manufactured using hot-rolled or cold-drawn processes. The hot-rolled process involves heating the steel to a high temperature and then rolling it into a round bar shape. In contrast, the cold-drawn process involves drawing the steel through a die at room temperature to produce a round bar. The cold-drawn process produces round bars with better dimensional accuracy and surface finish than the hot-rolled process.

Conclusion:

In conclusion, ASTM A105 CS round bars are an excellent choice for various industry applications. They are versatile, strong, and durable, ideal for harsh environments. Additionally, these bars are easy to machine, weld, and form, allowing for greater flexibility in design and manufacturing. If you are looking for a cost-effective, reliable material, ASTM A105 carbon steel bars are an excellent choice.

2 notes

·

View notes

Text

What Should You Look for in a Reliable Steel Coils Manufacturer?

When sourcing materials for construction, fabrication, or industrial processes, one of the most crucial decisions a business makes is choosing the right steel coils manufacturer. Steel coils are vital in numerous industries—from automotive and construction to shipbuilding and general manufacturing. But how can you ensure that you're getting top-quality products and trustworthy service? This blog will answer the most essential questions you should ask before selecting a supplier and why Saba Steel stands out in Nigeria’s competitive steel market.

Why Are Steel Coils So Important in Industrial Applications?

Steel coils are rolled steel products used in a wide variety of manufacturing applications. They can be either hot-rolled or cold-rolled, depending on their intended use. Hot-rolled coils, like those offered by Saba Steel, are particularly favored for structural applications because of their strength and malleability.

They are commonly used in:

Construction of bridges, buildings, and ships

Automotive body parts

Tubes and pipes manufacturing

Home appliances and electrical equipment

Since steel coils form the base of many critical components, their quality can significantly influence the safety and efficiency of the final product. This makes the choice of a steel coil manufacturer a strategic decision rather than just a procurement task.

What Factors Define a Trustworthy Steel Coils Manufacturer?

With so many options available, what should you look for in a steel coils supplier? Below are some of the most important aspects to consider:

1. Product Quality and Material Standards

A reputable steel coil manufacturer will strictly adhere to international material standards such as ASTM, ISO, or EN certifications. These standards ensure that the steel coils are durable, corrosion-resistant, and capable of withstanding various industrial pressures. At Saba Steel, all products are manufactured using premium-grade raw materials and undergo rigorous quality checks.

2. Production Capacity and Timely Delivery

Can the manufacturer meet your bulk order requirements on time? A delay in delivery can derail your entire production schedule. A good supplier must offer consistent stock levels, flexibility in order quantities, and a reliable logistics network. Saba Steel ensures that production and delivery are streamlined to meet the specific needs of clients across Nigeria and beyond.

3. Range of Products and Customization Options

Do they offer both hot-rolled and cold-rolled coils? Can they accommodate custom thickness, width, and weight? A top-tier steel coils manufacturer like Saba Steel provides customizable solutions that align with project-specific requirements, eliminating the need for additional modifications on-site.

4. Competitive Pricing Without Compromising Quality

Price is always a critical factor, but it shouldn’t come at the cost of quality. Saba Steel offers some of the most competitive rates in the Nigerian steel industry without compromising on durability or performance. Their transparent pricing and long-term contracts provide excellent value for money.

5. Reputation and Customer Support

Word-of-mouth, client reviews, and case studies can speak volumes about a company’s reliability. Does the supplier respond to queries promptly? Do they offer post-sale support? At Saba Steel, customer satisfaction is a top priority, with dedicated professionals ensuring every client receives personal attention and after-sales assistance.

Why Choose Saba Steel as Your Steel Coils Manufacturer?

Based in Nigeria, Saba Steel is a leading supplier of hot-rolled coils and other steel products. Here are a few reasons why they are trusted by businesses across multiple industries:

Decades of Experience: Their long-standing presence in the steel manufacturing sector gives them unmatched industry insight.

Quality Assurance: Every batch is tested for strength, thickness, and chemical composition.

Sustainability Practices: Saba Steel emphasizes environmentally friendly manufacturing processes.

Nationwide Delivery: Whether you’re in Lagos, Abuja, or Port Harcourt, you can expect timely and secure deliveries.

Client-Focused Solutions: They work closely with customers to ensure the steel coils meet all functional and structural needs.

Final Thoughts

Choosing the right steel coil manufacturer isn't just about price—it’s about long-term reliability, consistent quality, and superior service. Businesses that partner with a trusted supplier like Saba Steel enjoy peace of mind, knowing that their core materials meet the highest standards of performance and compliance.

SABA STEEL INDUSTRIAL NIGERIA LIMITED

14- 16 Mission St, Apapa 102103, Lagos, Nigeria

234 8032254136

0 notes

Text

Steel Processing Market Trends Shaping Modern Manufacturing

The Steel Processing Market is a critical enabler of the global industrial and construction ecosystem. From automotive and aerospace to infrastructure and heavy machinery, processed steel plays a vital role in manufacturing strong, durable, and customized components. The demand for precision-engineered steel products is surging, driven by technological advancements, infrastructure development, and increased investments in high-performance applications.

As economies move toward cleaner and smarter manufacturing, steel processors are transforming traditional techniques with automation, digitization, and sustainability-focused processes.

Market Overview

Steel processing involves cutting, shaping, bending, welding, and coating steel to meet specific design requirements across sectors. The two main types of steel processed are flat steel and long steel, which are transformed into sheets, coils, bars, wires, and other components through a variety of techniques, including cold rolling, hot rolling, annealing, and galvanizing.

Key Market Trends

Growing Demand for Customized Steel Solutions

OEMs and end-users are seeking pre-fabricated steel components to reduce turnaround time and increase precision in production.

Automation and Digitalization in Steel Plants

Smart steel processing using CNC machines, robotics, and real-time analytics is reducing human error and enhancing operational efficiency.

Rise in Demand from Automotive and Aerospace Industries

With the push toward lightweight, high-strength materials, processed steel is crucial in manufacturing vehicle frames, panels, and structural parts.

Surge in Green Steel and Low-Carbon Processing

Steel processors are adopting eco-friendly practices like hydrogen-based processing and recycled scrap steel usage to cut emissions.

Growth Drivers

Infrastructure Development Across the Globe

Bridges, highways, metros, and industrial zones all depend on precisely processed steel components.

Rising Construction Activity in Emerging Markets

Rapid urbanization in Asia-Pacific, Latin America, and Africa is fueling demand for processed structural steel.

Renewable Energy Sector Expansion

Wind turbines, transmission towers, and solar panel frames require high-quality processed steel for safe and long-lasting deployment.

Advancements in Metallurgy

Innovations in alloy development and treatment processes are creating stronger and more corrosion-resistant steel variants.

Challenges in the Steel Processing Market

High Capital Investment

Setting up modern processing facilities involves heavy investment in machinery, automation, and quality control systems.

Supply Chain Volatility

Disruptions in raw material supply or fluctuating iron ore and scrap prices impact profit margins.

Skilled Labor Shortage

Despite automation, a shortage of experienced technicians and engineers in developing regions can slow down expansion.

Environmental Compliance Pressures

Processors must comply with increasingly stringent global emissions and waste disposal regulations.

Future Outlook

AI-Integrated Steel Processing

Predictive maintenance, real-time quality monitoring, and automated workflows will dominate future steel service centers.

Growth in Pre-Engineered Buildings (PEBs)

Processed steel will be a key material in modular construction and prefabricated structures.

Surge in Steel Recycling Initiatives

The circular economy trend is pushing processors to adopt scrap steel melting and reprocessing technologies.

Regional Expansion in Asia-Pacific

Countries like India, Vietnam, and Indonesia are becoming steel processing hubs due to low labor costs and rising domestic demand.

Conclusion

The Steel Processing Market is evolving into a high-tech, sustainable, and demand-driven industry. As industries continue to demand faster, stronger, and more eco-friendly materials, steel processors will play a central role in building the modern world—bridging innovation with resilience.

0 notes

Text

Electrical Steel Laminations Manufacturers: Powering the Electrical World

Electrical steel laminations are the unsung heroes in the world of electrical engineering. These thin sheets of specialized steel play a pivotal role in transformers, electric motors, and generators, making electrical energy conversion and distribution more efficient. Manufacturers of electrical steel laminations are at the heart of this crucial component production. The manufacturing process of electrical steel laminations is intricate. It starts with carefully selected steel alloys, often containing silicon to enhance magnetic properties. The raw steel is first hot – rolled to reduce its thickness and improve its initial structure. Subsequently, it undergoes cold – rolling, a process that further refines the thickness and texture of the steel, making it suitable for lamination production. Precision punching or laser – cutting techniques are then employed to shape the steel into the desired lamination patterns. These patterns vary depending on the application, whether it’s for a large – scale power transformer or a small – sized electric motor in household appliances. In the global market, there are several leading electrical steel laminations manufacturers. For instance, companies like Nippon Steel & Sumitomo Metal in Japan have a long – standing reputation for high – quality products. They leverage advanced manufacturing technologies and strict quality control measures to ensure that their laminations meet the exacting standards of the electrical industry. In China, Baowu Steel Group has significantly expanded its presence in the electrical steel market, and Jiangyin Centersky Electrical Appliance Co., Ltd has also emerged as a competitive player. With its focus on technological innovation and quality – oriented production, Jiangyin Centersky Electrical Appliance Co., Ltd’s state – of – the – art production facilities enable it to produce a wide range of electrical steel laminations, catering to both domestic and international demands. The demand for electrical steel laminations is closely tied to the growth of the electrical and electronics industries. With the increasing adoption of renewable energy sources such as wind and solar power, there is a greater need for efficient transformers and generators. These rely on high – quality electrical steel laminations to minimize energy losses during the conversion and transmission of electrical energy. In the automotive sector, the rise of electric vehicles (EVs) has also spurred demand. The electric motors in EVs require precisely designed laminations to optimize performance and extend battery life. As technology continues to evolve, electrical steel laminations manufacturers are constantly innovating. They are researching new alloy compositions to further improve magnetic properties and reduce energy losses. Additionally, advancements in manufacturing processes aim to increase production efficiency while maintaining the highest quality standards. This combination of product innovation and process improvement positions these manufacturers as key enablers in the transition towards a more energy – efficient and sustainable future.

0 notes

Text

Top Bright Steel Bar Suppliers in Sonipat

Bright Steel Bar Suppliers in Sonipat – Trusted Quality from SS Engineering Work

When it comes to sourcing premium-grade steel for construction, manufacturing, or industrial use, choosing the right supplier is crucial. For businesses and fabricators in Haryana, finding trustworthy Bright Steel Bar Suppliers in Sonipat ensures durability, precision, and long-term performance. This is where SS Engineering Work stands out as a reliable name in the steel industry.

What Are Bright Steel Bars?

Bright steel bars are steel products that are cold finished—meaning they are drawn, peeled, or turned after being hot rolled. The result is a product with a smooth surface, tighter dimensional tolerance, and improved mechanical properties. These bars are commonly used in the production of fasteners, automotive components, machinery parts, shafts, tools, and furniture fittings.

Their aesthetic appeal, along with strength and machinability, makes bright steel bars a go-to material across various industries.

Why Choose Bright Steel Bar Suppliers in Sonipat?

Sonipat, located in the industrial heart of Haryana, is a growing hub for manufacturing and engineering. With many fabrication units and industrial facilities operating in the region, demand for high-quality steel materials is steadily rising. Working with local Bright Steel Bar Suppliers in Sonipat offers multiple advantages:

Faster Delivery: Proximity ensures quick dispatch and delivery for urgent requirements.

Cost Efficiency: Lower transportation costs result in better pricing.

Local Support: Easy access to customer service, product consultations, and after-sales support.

SS Engineering Work – Your Trusted Steel Partner

Among the leading Bright Steel Bar Suppliers in Sonipat, SS Engineering Work has carved a niche with its commitment to quality, consistency, and customer satisfaction. Here's what makes them a top choice:

High-Quality Material: All steel bars undergo stringent quality checks to meet industry standards for strength, surface finish, and dimensional accuracy.

Wide Product Range: SS Engineering Work supplies bright bars in various grades, diameters, and finishes to suit different applications.

Custom Orders: Whether you need specific lengths, cutting, or machining, the company can handle custom requirements with ease.

Industrial Expertise: With years of experience in steel fabrication and supply, the team understands industry demands and delivers accordingly.

Competitive Pricing: Despite offering premium quality, the pricing remains competitive, making it a win-win for clients.

Applications Across Industries

Bright steel bars from SS Engineering Work are used in:

Automotive and aerospace parts

Construction and infrastructure

Agricultural machinery

Electrical components

Furniture and fixtures

Whether you're running a small workshop or managing a large manufacturing facility, quality raw materials like bright steel bars can make a significant difference in the final product. Trusting a reputed supplier ensures long-term value and reliability.

Final Thoughts For anyone seeking dependable Bright Steel Bar Suppliers in Sonipat, SS Engineering Work is a name you can count on. With a strong focus on product excellence and customer satisfaction, they are the preferred supplier for many industries in Haryana and beyond. Contact them today to explore their product offerings and place your next order with confidence.

#bright bar manufacturer in delhi#bright bar manufacturers in delhi#bright bar manufacturer in punjab#bright bar manufacturers in haryana#bright bar manufacturer#bright bar manufacturers in punjab

0 notes

Text

Hot Rolled Steel: Benefits, Applications, and Advantages ?

Steel is perhaps the most highly versatile and critical material to utilize in contemporary industry. Steel’s strength and durability make it an indispensable commodity from construction and infrastructure through to automobiles and heavy equipment. Perhaps the most widely used type of steel throughout these industries is hot rolled steel.

At Parco Engineers, we provide premium TATA Astrum Super HR Sheets, which are highly relied upon by industries for consistent performance and unmatched quality. Throughout this blog post, we shall cover all that you need to know about hot rolled steel sheets — starting with the manufacturing process up to the main advantages, uses, and benefits.

What Are Hot Rolled Steel Sheets?

Hot rolled steel sheets are steel rolls that are rolled while hot — usually over 1700°F (926°C). Steel is malleable and soft at this temperature, making it easy to form. The hot rolled sheet is then rolled through sets of rollers to give it the desired thickness and size.

Unlike cold rolled sheets, which are rolled at room temperature to create a smoother and more accurate finish, hot rolled steel sheets are typically utilized in applications where precise dimensions aren’t essential. Still, they have many advantages that make them the perfect choice for structural purposes and projects that need strong, tough, steel.

TATA Astrum HR sheets, which can be found at Parco Engineers, are among the most trusted HR sheet products to be found in the market, renowned for their strength, affordability, and versatility.

How Are Hot Rolled Steel Sheets Formed?

The process of manufacturing hot rolled steel plates starts from a big billet of steel that is heated to a temperature above its recrystallization temperature. After getting heated enough, it is rolled through a number of rolling mills that thin it out but lengthen it.

Here’s a step-by-step process:

Heating: The steel slab is heated at high temperatures (above 1700°F).

Rolling: It is rolled over rollers to create sheets, plates, or coils.

Cooling: The steel sheets in the hot rolled condition are left to cool to room temperature, producing a scaled finish.

Cutting: The steel is cut to desired lengths or rolled into coils and processed further.

The finished hot rolled sheet or plate can have minor thickness and surface finish variations, which is not a problem for most of its structural uses.

Advantages of Hot Rolled Steel

Let’s consider the most important advantages of the hot rolled steel usage:

1. Cost-Effective Production

One of the key benefits of hot rolled steel plates is that they are inexpensive. Hot rolling takes less time and is cheaper than cold rolling. Since hot rolled sheet does not involve the additional steps of pickling and annealing, it can be made more quickly at a lower price point — making it suitable for mass use.

2. Enhanced Workability

Because hot rolled steel is rolled hot, it heats the steel up and makes it soft and ductile when it’s being manufactured. This makes it easy to shape into various sizes and shapes, and as such, it is ideal for where welding, forming, and machining are involved.

3. High Strength and Durability

Although coarser in texture than cold rolled sheet, hot rolled steel sheets possess high strength and strength-to-weight ratio despite their weight. Therefore, they are best suited for load-bearing purposes as well as structures where tensile strength is to be high.

4. Larger Sizes Available

Hot rolled steel plate can be fabricated in much larger sizes than cold rolled steel. This makes it ideal for heavy-duty jobs like ship construction, bridges, and large construction projects.

Common Applications of Hot Rolled Steel

Due to its mechanical characteristics and cost-effective manufacturing, hot rolled steel sheets find application in a diverse array of industries. Some of the most popular applications are:

1. Construction and Infrastructure

Hot rolled steel plates find common usage in building frames, beams, and columns. They are a major material in bridges, industrial sheds, and highway construction due to their strength and durability.

2. Automotive and Transportation

In automobiles, hot rolled sheets are utilized to produce pieces such as chassis, frames, and wheel rims. They are ideal for such uses due to their weldability and formability.

3. Agricultural Machinery

Ranging from tractors and ploughs to harrows and trailers, HR sheets find widespread usage in the production of rugged and robust agricultural machinery.

4. Heavy Machinery and Equipment

Because of its wear and tear resistance, hot rolled steel is perfect for the production of heavy machinery, pressure vessels, tanks for storage, and earthmoving machines.

5. Shipbuilding and Offshore Structures

Hot rolled steel plates possess high corrosion resistance when treated and find extensive application in ship hulls, decks, and bulkheads of ships and offshore structures.

Advantages of Hot Rolled Sheet

The following are some of the salient benefits of applying hot rolled sheet in different applications:

1. High Mechanical Strength

Hot rolled steel sheets possess high tensile strength due to which they are ideal for structural parts where mechanical strength is the primary consideration.

2. Improved Formability

In comparison to cold rolled sheets, HR sheets are quite easy to bend, cut, or form into different configurations, providing more flexibility in terms of fabrication.

3. Weldability

The hot rolled steel plates’ surface simplifies welding, which is necessary for structural component construction, machinery, and frameworks.

4. Flexibility in Different Grades and Thicknesses

Hot rolled steel comes in many different thicknesses and sizes to suit various industry requirements — from light use to heavy building.

5. Eco-Friendly and Recyclable

Steel is 100% recyclable, and using HR sheet contributes to sustainable manufacturing practices. TATA Astrum HR sheets, offered by Parco Engineers, comply with environmental standards and provide eco-friendly solutions.

Why Choose TATA Astrum Super HR Sheets from Parco Engineers?

As an authorized distributor of TATA Astrum Super HR Sheets, Parco Engineers ensures you get premium-grade hot rolled steel sheets with:

Consistent quality

Dimensional accuracy

Competitive pricing

Reliable delivery and technical support

Whether you’re constructing infrastructure, producing machinery, or processing automobile components, our series of HR sheets can address your requirements with the highest performance and reliability.

Final Thoughts

The selection of a suitable steel product determines the success and extent of any project. Although cold rolled sheets are most suitable for precision projects, hot rolled steel sheets have the strength, economy, and flexibility to be used for large-scale and structural projects.

With demonstrated performance in stressful conditions, hot rolled steel plates are a first preference among engineers, fabricators, and constructors. At Parco Engineers, we introduce you to the finest of TATA HR sheet solutions — engineered for quality, reliability, and long-term value.

0 notes

Text

Best Quality Round Bar Manufacturer in India

Nippon Alloy Inc is a trusted Round Bar Manufacturer in India, offering high-performance Round Bars crafted from premium stainless steel, alloy steel, and carbon steel. Built for strength, precision, and durability, our round bars are widely used in construction, oil & gas, marine, and automotive industries. With excellent surface finish, corrosion resistance, and dimensional accuracy, our bars deliver unmatched reliability in every application.

As a reliable Round Bar Supplier in India, we provide a wide range of sizes, grades, and finishes to meet diverse industrial needs. From hot-rolled to cold-drawn and polished bars, our products are designed for both strength and appearance. We proudly export our round bars to countries like the USA, Saudi Arabia, Egypt, Brazil and many more countries, where our name is recognized for consistent quality and fast service.

We are also known as a leading Sheets & Plates Manufacturer in India, we offer additional products including stainless steel pipes, tubes, flanges, and fittings. Counted among the top Round Bar Manufacturers, we ensure every product is tested for strength, durability, and performance. Choose Nippon Alloy Inc for metal solutions that are engineered to last and trusted worldwide.

Our Website : https://nipponalloys.com/

Product : Round Bar

0 notes