#Antistatic Shoes Market

Explore tagged Tumblr posts

Text

PVC Soles Anti-static Four-hole Shoes

Features:

PU thickened soft sole

Comfortable and non-slip

Antistatic

High quality fabric

Breathable and not stuffy

Company Name:Suzhou Suyu dust-free Technology Co., Ltd. Web:https://www.suyu-cleanroom.com/product/cleanroom-antistatic-shoes/pvc-soles-antistatic-fourhole-shoes.html ADD:1388# Ruyuan road,Xiangcheng economic developing zone,Suzhou,China. Phone:86-13328056777 Email:[email protected] Tip:215133 Profile:The second type of main business: full cotton face towel series, kitchen cloth series, makeup removal cotton series, household disposable mop series, household cleaning series, and other non-woven disposable products production, research and development, sales as one of the enterprise.Also a professional OEM factory.According to customer requirements to design external boxes, external packaging bags, can provide various customer needs. Today's dust-free market comes from the field of dust-free electrostatic resistance of disposable non-woven cloth professional, and customers trust.

0 notes

Text

0 notes

Link

0 notes

Link

Global Antistatic Shoes Market is anticipated to reach US$ 976.3 Mn by 2026 from US$ XX Mn in 2019 at a CAGR of XX % during

0 notes

Text

Antistatic Shoes Market: Structure and Overview of Key Market Forces Propelling Market

The most important property of safety shoes is its ability to resist electric current. Two of the most important things that are to be considered while purchasing such shoes are, how efficient are the shoes at the prevention of electrostatic charging by pushing it out quickly and secondly, if the shoes are shock resistant. It is very important for any person to wear shoes that resist electric current if he works with electricity, because such shoes minimize the level of electricity that enters the body.

Electrical resistance offered by antistatic shoes are between 0.1 and 1000 MegaOhm (MΩ), as measured according to EN 20344: 2011 5 10. Antistatic shoes provide the user with protection against electric shocks and can be worn in various works scenarios.

Electrical resistance offered by electrostatic dissipative shoes are between 0.1 and 100 (MΩ), measured according to BS EN 61340-4-3: 2002 (IEC 61340-4-3:2001). ESD or electrostatic dissipative shoes therefore guarantee a very low electrical resistance.

Antistatic Shoes Market: Drivers and Restraints

Both electrostatic dissipative as well as anti static shoes are safety conducting shoes. They offer a certain degree of isolation while their main function is to provide protection against static electricity. These shoes offer protection by pushing out the static electricity from the shoes to the ground thereby preventing a spark or charge. Conducting safety shoes are used by employees of industries where a static shock could cause serious problems like an explosion.

Brochure for Latest Advancements https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=45720

Industrial equipment manufacturing, semiconductor manufacturing, hospitals, medical industry, computer equipment manufacturing, battery manufacturing, aerospace, electrical engineers, telecommunications equipment manufacturing, are a few examples of the industries where electrostatic dissipative as well as anti static safety shoes are used for protection against electrostatic discharges occurring to sensitive equipment.

One factor that is acting as a hurdle for the growth of the antistatic shoes market is that electrostatic dissipative shoes can cause many dangerous effects on the work locations. The shoes can cause fuel vapor, coal dust, as well as gas explosions, thus making it necessary for people working in such environments to wear electrostatic dissipative safety shoes all the time in order to be safe.

Two major factor that contribute to the efficiency of ESD are humidity as well as the temperature. The safety shoes are classified into class 1, 2 and 3. This classification is done after safety shoes with electrostatic dissipation protection undergo an examination.

Get Report TOC, Figures and Tables https://www.transparencymarketresearch.com/sample/sample.php?flag=T&rep_id=45720

The main variation between class 1, 2 and 3 is the level of humidity, temperature conditions, as well as the time of conditioning.

In order to test the electrostatic characteristics of safety shoes for electrostatic dissipation (ESD) certification, an examination is carried out in laboratory conditions.

The antistatic shoes market is also divided in terms of the product, namely, EVA, SPU, Rubber, PVC, PU.

On the basis of application, the antistatic shoes market is further divided into food factory, laboratory, Pharmaceutical factory, electronics factory, as well as others.

Antistatic Shoes Market: Geographical segmentation

On the basis of geography, the antistatic shoes market is divided into Central and South America, Middle East and Africa, Europe, China, Japan, India, Southeast Asia, as well as North America.

Companies Mentioned

This study also lists the top players, that is, manufacturers as well as exporters of the antistatic shoes market globally. The top players of the antistatic shoes market are Gaston MILLE, JALLATTE, LEMAITRE, SECURITE, Toffeln, ABEBA, AIMONT, Airtox International, ASTRA, COFRA.

0 notes

Text

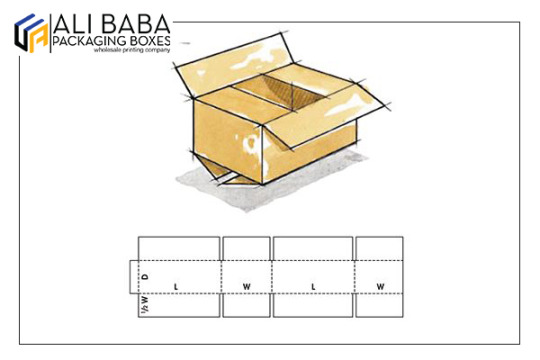

Print your custom cardboard boxes however you want with Alibaba packaging:

if you are thinking as to where to buy cardboard boxes, you ought to be totally aware of the few points of interest offered by these custom cardboard boxes manufactured by Alibaba packaging boxes. The best thing about these custom cardboard boxes is that they are moderate and they can complete various tasks for you. Indisputably, it is the best way to market your products. They are manufactured using eco-friendly material and you can reuse them too. You can get done custom cardboard box printing to improve your home. Just take some inspiration from the Web and start. You can store your sewing kit inside a box to avoid cluttering, you can even make a movie projector out of a cardboard box. It all depends on the quality of the custom printed cardboard boxes to see how long it will stay put.

MEDIUM MATERIAL FOR CARDBOARD BOX PRINTING:

At present, over 80% of items are bundled and stored in various sorts of cardboard boxes, going from paperboard to corrugated small cardboard boxes, comprising of the manufacturing material regularly utilized in the printing industry. Cardboard can be viewed as a sort of paper, and relying upon the cardboard box printing hardware, it tends to be produced in a solitary layer (utilizing a Fourdrinier) or in numerous layers (utilizing a cardboard cylinder machine). For the most part, the materials utilized for the custom printed cardboard boxes are partitioned into three classes: paper, paperboard, and cardboard. For functional purposes, cardboard can be considered as being utilized in the assembling of boxes and barrels. Little boxes are by and large created utilizing paperboard, while bigger boxes are made with folded cardboard. Barrels can be made by twisting layers of Kraft paper until the required strength is gotten, while the base can be made of squeezed cardboard or metal. The best is commonly made of indistinguishable material from the base. The contrast among carton board and paperboard is that the last has experienced a press to accomplish uniform thickness; this task likewise gives the item better brilliance and consistency.

KEEP THE BASIC ELEMENTS IN MIND WHILE ORDERING YOUR BOXES:

In the case that the box is getting ready for graphic imprinting on it, paperboard must be utilized with the goal that the end product is of good quality and visual clarity. The cardboard box printing is structured to make cardboard boxes for moving that meets the business prerequisites of the customer, just as the necessities of the item to be contained in the case, which decide box's style, sort of cardboard, corners, conclusion, joint sorts, and different elements. It must be reviewed that there is a request utilized while determining the size of the custom cardboard boxes, which should consistently be: front, base, and stature (i.e., length, width, and profundity). There is a wide scope of cardboard that can be utilized to make little collapsing boxes, and an assortment of coatings that can improve certain qualities, for example, water opposition, oil obstruction, visual appearance, and so on. Be that as it may, the type of cardboard chosen must meet the essential needs settled, for example, the legitimate bond of inks, sufficient surface region for quality cardboard boxes, appropriate acknowledgment of glues, and simplicity of gathering without causing breaks, wrinkles, or tears when collapsing.

MAKE USE OF CORRUGATED CARDBOARD:

Corrugated cardboard box printing is basically framed utilizing two fundamental components: the 'liner' or spread, and the 'medium' or fluted sheet which is the part which is corrugated. The liner or spread is made of Kraft or semi-Kraft paper and structures a level profile that covers the whole surface region of the ridged cardboard sheet. The corrugated paper (or medium) is joined to this level profile. The diverse assortments of corrugated cardboard have different blends of liner and medium. The medium that is custom cardboard boxes printing is a sort of paper that is ordinarily fabricated utilizing bagasse or straw; its consistency is more springy than the liner and it has a wavy 'fluted' structure. When appended to the liner, it shapes a consistent structure of circular segments that gives more noteworthy opposition, as the load continued is appropriated among the numerous curves the structure the layered cardboard.

TYPES OF CARDBOARD BOX PRINTING:

Cardboard box Printing utilizing the correct strategy by the help of Alibaba packaging boxes. Great printing is fundamental to ensure the correspondence and acknowledgment of your item. Regardless of whether it is a logo, scanner tag or multi-shaded print.

Flexo print:

Flexo custom cardboard boxes printing is the most normally utilized printing technique in the corrugated cardboard industry. It uses water-based inks.

High-quality print (HQP):

HQP is done on unique flexographic printers and accomplishes a higher quality than flexography. A progressively exact, amazing print subsequently, this is the correct procedure for items requiring photograph quality.

OFFSET printing:

Offset custom printed cardboard boxes produce the most splendid result with the keenest value quality proportion. offset printed packaging recounts the tale of your item, builds item refinement, adds to mark understanding, addresses the purchaser, satisfies a need, allures, and affects your image acknowledgment.

Pre-printed liner (PPL):

For large print runs, we frequently use a pre-printed liner (PPL), pre-printing and handling the external layer of paper, before utilizing this to deliver the small cardboard boxes bundling. PPL can be utilized amid occasional highs to guarantee the premium quality result.

Specific coatings (PE):

By adding an additional covering to your bundling, the cardboard boxes for moving will be antistatic, water safe or oxidation safe.

IMPORTANCE OF CARDBOARD SHOE BOXES:

Securing shoes in cardboard shoe boxes has various points of interest. Not solely do shoe boxes shield your shoes from the persevering achieved by changing temperatures and dampness, buildup and bugs- - along these lines dragging out the life of your shoes- - they furthermore extend storage space. Shoes are peculiarly shaped products that can be hard to store in little spaces, and pressing them in corners and sliding them under beds can be perilous to the material and limit of the shoe. Cardboard Shoe boxes empower you to make adequately stackable limit units that can be concealed away in closets, slide under beds or even be stacked impeccably in an open room. With Alibaba packaging boxes service in the market, you don’t have to worry about where to buy cardboard boxes anymore.

#custom cardboard boxes#cardboard packaging boxes#printing cardboard boxes#wholesale cardboard boxes#cardboard boxes for moving#custom size cardboard boxes

1 note

·

View note

Text

What is the difference between a plastic point cloth and a non-slip cloth?

From the perspective of its composition, in fact, there is not much difference between the two. The plastic cloth is composed of plastic and cloth, and the anti-slip cloth is also made of the same material, and the functions are also very similar, non-slip. People in the industry regard them as the same, and the anti-slip cloth is also called a plastic cloth.

1. Point plastic cloth: According to the simple literal meaning, one is point plastic, and the other is cloth; point plastic is a production process, which is simply point plastic on various styles of cloth. Point plastic is to point plastic or silicone with different patterns on the cloth. The purpose is generally to prevent slippage, to provide convenience and safety for consumers' lives; of course, it also has an aesthetic effect, so that the related products meet the aesthetic requirements of consumers.

2.The use of plastic point cloth: PVC, which is what we call polyvinyl chloride, point plastic cloth is made of

PVC

A new coating process is used to form hemispherical plastic particles on the textile base cloth, and make them form a matrix-shaped coating with equal intervals. this

PVC

The new process of point plastic coating, which retains both

PVC

Plastic has the advantages of wear resistance, chemical resistance, noise reduction and shock absorption, high strength, and good electrical insulation, and avoids the shortcomings of the whole layer of plastic or rubber, which causes the fabric to be airtight, poor in water absorption, and stiff in hand. In particular, specially treated fabrics can be made into new types of labor protection products for different purposes. PVC

The plastic point cloth can be made of all kinds of cotton, chemical fiber, blended cloth, canvas and other base materials, and the new point plastic process can be used to produce different textures, different colors and colorful new plastic fabrics, which are suitable for clothing, gloves, shoes, luggage, Interior decoration and many other applications. For example, due to the above advantages of the plastic point cloth, the use of it to make labor insurance gloves is wear-resistant, antistatic, flame retardant, non-slip, breathable and sweat-absorbing, and feels comfortable, etc. Therefore, the domestic labor insurance gloves that have been used for decades are gradually eliminated. It can be seen that the use of plastic-dispensing cloth is very extensive and has potential. Products made from plastic-dispensing cloth will gradually replace some old life products, and can obtain huge market benefits. It is certain that this will be a boon for consumers who are looking for high-quality consumer goods, and a good opportunity to create huge benefits for some experts who want to engage in business operations in this area.

Anti-slip cloth: Changshu Chenshiji Nonwoven Products Co., Ltd. has more than ten years of experience in the production of non-slip cloth and non-slip cloth. We can analyze this aspect. In the industry, the anti-slip cloth is also known as the spot plastic cloth, the drop plastic cloth, the bead cloth, the pearl cloth, and the printed cloth. The craftsmanship is different and the use is not the same. In fact, the plastic cloth and the anti-slip cloth can be called each other, but the names are different, but they are actually the same thing! The plastic point cloth is processed into a non-slip cloth, but the function is added to the head of the point plastic cloth to become a non-slip cloth, and sometimes it can also be called a non-slip cloth. The words are different, but the bottom line is the same.

About CHENSHIJI:

Changshu Chen shi Ji Non-woven Products Co., Ltd. is a manufacturer that specialized in needle-punched or laminated non-woven fabrics. with roll making, and hot shrinking, we produce various products to different customers' standards. which integrates design, development, manufacture, and sales.

0 notes

Link

0 notes

Text

Military and Police Shoes Supplier in Nigeria

Black leather shoes are essential for military and police personnel. They are designed to withstand hard police and military work. Whether you are involved in the battle, working at a crime scene, or standing for an extended amount of time, having the best shoes on duty gives you the advantage to meet any obstacle. Because if your feet are not properly protected and supported, and if your shoes are not comfortable, you will not be able to perform to your fullest ability. We have a big collection of military and police shoes for both men and women that may be used to strengthen any sort of foot and assist in any shift situation. Locating and purchasing the best military and police shoes can be a challenging task. Many factors influence shoe fit, including the type of foot - flat foot - body weight, time spent on patrol, and shifts such as patrol, secret or tactical operations.

Neutron Gear, a military and police shoe supplier in Nigeria is a market leader on a global level. We have a wealth of experience in the field of military and police shoes in Nigeria, and we manufacture a wide variety of high-quality military and police boots for tactical and everyday use in Nigeria. You will benefit from the durability and adaptability of our military and police shoes, which are best suited to the Nigerian operating environment. We manufacture a large volume of military and police shoes in Nigeria that meet high-quality standards for a variety of industries. All of our military and police shoes are durable and comfortable to use daily, with no restrictions on movement. Our military and police shoes have a full leather exterior, are waterproof, breathable, and have an orthopedic insole, as well as an antistatic, antibacterial, and shock-absorbing outsole. Our shoelaces are extremely sturdy and long-lasting. They are suitable for all types of military and police operations. They are stretch well and tighten up very nicely.

0 notes

Text

Tpu Material Market by Deployment, End-user, and Geography - Forecast and Analysis 2020-2027

Overview:

Dynamic features of components are often much acknowledged in end-user industries. Thermoplastic polyurethane (TPU) is a product that offers a vast range of application owing to its features that satisfies several needs generated by the end-user sectors. Among its features, elasticity, transparency, resistance to oil, grease, and abrasion have made it the choicest material for many industries. The automotive industry is one of them that promotes it the most. Due to thermoplastic polyurethane’s wide application in this industry, and the said end-user industry booming at a rapid pace, thermoplastic polyurethanes can reach a valuation of USD 2.96 billion during the forecast period (2016-2023). Market Research Future (MRFR) reveals, in the process, the global thermoplastic polyurethanes market can achieve an impressive CAGR of 6.53%.

On the flip side, the Tpu Material Market is set for a daunting task where it has to go head-to-head with bio-based alternatives. Environmental concerns can pose as a major hurdle for the market and leave a detrimental impact on the market. At the same time, the fluctuating price of the raw materials can also be seen as a rein on the market’s expected growth.

Industry Trend:

BASF has recently announced a new TPU technology where it aggravates the high-performance shoe shank production and makes the entire procedure cost-efficient. Furthermore, it adds excellent mechanical properties such as UV resistance. The production technology can work in tandem with automation.

Callaway, a market giant in golf ball production, is taking its production technology a notch higher by blending TPU with thermoset polyurethane to have a cover for the golf balls which, in turn, would increase its performance.

Access Report @

https://www.marketresearchfuture.com/reports/thermoplastic-polyurethane-market-3269

Segmentation:

The global TPU market can be segmented by grade, types, and application.

Grade-wise, the market includes flame retardant, antistatic, reinforced & others.

Type-based segmentation of the market comprises polyester, polyether, and polycaprolactone.

Based on application, the market can be segmented into automotive, construction, engineering, medical and others.

Regional Analysis:

Geographical segmentation of the market reveals that it spans across North America, Europe, Asia Pacific (APAC), Latin America (LATAM), and the Middle East & Africa (MEA).

Burgeoning industries such as automotive, construction, engineering, medical and others in the APAC are reasons behind the phenomenal growth of TPU market in the region. The booming industry is getting aptly backed by China and India, major emerging economies that are reshaping the commercial setting of the region. Automotive sector of China, India, Taiwan, and South Korea are also playing an essential role in taking the market ahead.

In Europe, the market is mainly getting driven by the construction industry which subsequently, is helping the region to assume the second position. North America, on the other hand, is showing growing consumption of TPU in engineering and medical industry.

Market Dashboard:

The densely packed market is thriving on innovation initiated by various companies to stay afloat. At the same time, multiple collaborations, merger, and acquisitions are leading the market ahead. For instance, Huntsman Corporation acquired Demilec, a formulator of spray polyurethane foam (SPF) insulation based out of North America. Hexpol AB and Wildo Sweden AB collaborated recently to develop bio-based products which can be considered exemplary.

Key players to influence the market significantly are BASF SE, API Plastics, COIM, Headway Polyurethane Co. Ltd., Bayer Material Science AG, Hexpol AB, Wanhua Chemical Group Co. Ltd Huntsman Corporation, Lubrizol Corporation, Miracll Chemical Co. Ltd., and others.

Request For Sample Report Here @

https://www.marketresearchfuture.com/sample_request/3269

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future

Phone: +16468459312

Email: [email protected]

Read More Related Article:

https://www.marketresearchfuture.com/reports/prepreg-market-10580

https://www.marketresearchfuture.com/reports/cosmetic-antioxidants-market-9824

https://www.marketresearchfuture.com/reports/magnetite-nanoparticles-market-10559

https://www.marketresearchfuture.com/reports/glycoprotein-market-10533

0 notes

Text

0 notes

Text

Application of medical boot covers

The medical boot covers produced by Holymed Medical Group are protective boot covers to prevent contact with blood, body fluids and secretions of potentially infected patients, and play a blocking and protective role. This boot cover has obtained Sgs certification and a two-year shelf life. So what are the applications of medical boot covers?

Blue boot covers are one of the important isolation tools. They are mostly made of polypropylene. They are breathable and waterproof. They are not easy to break. They can wrap the socks and trousers of medical staff for isolation, reduce the infection of medical staff and prevent medical staff from wearing shoes. Dirt and dust on the upper and trouser legs are brought into the isolation area, causing pollution.

The medical boot cover not only has good isolation, but also wraps all the socks and trousers of medical staff to achieve the function of sealing and isolation.

It has good waterproof effect, wear resistance, corrosion resistance, tear resistance and peel resistance, is not easy to wear, and has good air permeability. It solves the air-impermeability of plastic film shoe covers.

The lightweight and soft fabric of the medical boot cover provides users with higher comfort. It is antistatic and has passed the EN1149 antistatic standard. Improve comfort and durability, increase protection performance, and provide protection for medical personnel.

Medical boot covers are usually used in conjunction with medical protective clothing, which can achieve a complete isolation effect and can prevent medical personnel from the risk of infecting patients.

The quality of medical boot covers by Holymed Medical Group is guaranteed, and the best products can be bought at the best prices. Medical boot covers also cater to the development of the contemporary market and become an indispensable part of protective equipment.

0 notes

Text

Functional Apparel Market Research Report with forecast year 2020-2027

According to a new market report published by Industry Probe (www.industryprobe.com) titled ‘Functional Apparel Market (Product type: Sportswear: Top wear [T-shirts, Bra, Others (Dress etc.)], Bottom wear [Track Pants, Shorts, Others (Briefs etc.)], Footwear [Shoes, Socks], Activewear: Top wear [T-shirts, Bra, Others (Dress etc.)], Bottom wear [Track Pants, Shorts, Others (Briefs etc.)], Footwear [Shoes, Socks], Protective Wear: Suits, Top wear, Bottom wear, Footwear, [Boots, Toe Guards, Others (Leggings, etc.)], Casual Wear: Top wear [Shirts, T-shirts, Others (Dresses, etc.)], Bottom wear [Jeans, Casual Trouser, Others (Shorts etc.)], Footwear [Shoes, Socks], Formal Wear: Top wear [Shirts, Coat/ Blazers, Others (Tops etc.)], Bottom wear [Trousers, Skirts], Footwear [Shoes, Socks], Others (Vanity Clothing, Outdoor Clothing etc.); Fabric: Conventional Fabric: [Polypropylene, Cotton, Nylon, Wool, Polyester], Specialty Fabric: [Neoprene, Spandex], Others (X-Static, Tencel, Gore-Tex etc.); Finishes: Antimicrobial, Water Resistant, Quick Dry, Moisture Management, Fire Resistant, UV Protection, Others (Stain Repellent, Abrasion Resistant etc.); Consumer Group: Men, Women, Kids; Distribution Channel: Online (Company-owned Website, E-commerce Website), Offline (Hypermarkets & Supermarkets, Specialty Stores, and Brand Stores) – Global Industry Dynamics 2018-19, Trends and Forecast, 2020–2027,’ the global water resistant finish is expected to reach US$ 225.2 Bn by 2027 and expand at a CAGR of 6.3% from 2019 to 2027.

As per the report, the global water resistant finish was valued at US$ 124.8 Bn in 2018 and is expected to expand at a CAGR of 6.3% from 2019 to 2027. In terms of finishes, water resistance segment accounts for the major share of the global functional apparel market. Water resistant apparel offers high resistance to water penetration and allows water vapor to escape at the same time. Growing penetration of water resistant apparel in outdoor sports, owing to its characteristics, such as excellent durability and sturdiness, is anticipated to drive the market growth. Increasing penetration of the product in outdoor sports products, including backpacks, footwear, tents, and other fabric-based gear or garments, owing to its characteristics, such as excellent durability and sturdiness, is anticipated to drive the market growth.

The report states that when it comes to testing fabrics for water-repellent qualities, factors such as permeability and penetration play major parts in these experiments. With the improvement of people’s living standards, functional fabrics such as anti-bacterial, odor-proof, antistatic, waterproof and moisture-permeable, and oil-proof and pollution-proof are becoming increasingly popular with consumers. Growing consumer awareness about health and fitness, increase in disposable income, and adoption of various sports such as snow sports, water sports, and mountaineering are augmenting the demand for sportswear resistant to water.

In terms of finishes, water resistance segment accounts for the major share of the global functional apparel market. Increase in demand for water resistant apparel is driving the production of functional apparel. Rise in the number of snow sports, water sports, and mountaineering are augmenting the demand for sportswear resistant to water. Demand for moisture management, antimicrobial and stain resistant apparel is also expected to drive the market in the near future. Technological advancements and development of fibers and resins that repel water or stains; manage moisture; offer low fabric to skin friction; and allow the material to heat, cool, and breathe are expected to augment market demand over the coming years.

Some of the major players covered under the scope include Adidas AG, Puma SE, Asics Corporation, PVH Corporation, Columbia Sportswear Company, Skechers USA, Inc., Inditex, Under Armour Inc., Nike, Inc., and VF Corporation.

About Us

Industry Probe is a global market intelligence and advisory firm with an unwavering purpose to help businesses achieve strategic objectives through a varied range of offerings. Based on a unique amalgamation of our big data technology and human intelligence, our services are dedicated to serve the businesses operating in the consumer goods and industrial machinery sectors. Our offerings comprises syndicated research, strategic consulting & advisory services, competitive intelligence, and full time engagement to bring true & actionable insights into our clients’ business environment. Combining research & technology adoption, playing the perfect mix of the best data, and centered on consumer goods & industrial machinery sectors, Industry Probe believes in targeting one industry at a time.

Contact

1441 Broadway, 6th Floor – # 6131 New York, NY 10018

Contact: +1-917-985-8551

Email: [email protected]

Website: https://www.industryprobe.com/

0 notes

Text

Thermoplastic Polyurethane Market Size, Share, Growth | Covid -19 Impact Analysis, Demand and Forecast 2023

Thermoplastic Polyurethane Market: Information by Type (Polyester, Polyether and Polycaprolactone), End-Use Industry (Automotive, Construction, Aerospace, Energy & Power, Medical and others), Region (North America, Europe, Asia Pacific, Latin America and the Middle East & Africa) – Forecast till 2025

Thermoplastic Polyurethane Market Overview

Thermoplastic polyurethane market is expected to grow at a rapid phase owing to rising demand from various regions and it vast application in various end-use industries. Thermoplastic Polyurethane has good properties such as elasticity, transparency, and resistance to oil, grease, and abrasion due to this the application of Thermoplastic polyurethane has been expanding.

Globally, the thermoplastic polyurethane market is expected to witness significant growth owing to rising demand from the automotive sector. In addition, thermoplastic polyurethanes applications in medical are also expected to boost the growth of the TPU market in the coming years. However, the growing environmental concerns with the manufacture and usage of thermoplastic polyurethanes are expected to hinder the growth of the market.

In addition, growth of automotive and construction industry are the major industries for consumption of thermoplastic polyurethane especially in APAC region by contributing the major countries such as China, India, Thailand, and South Korea. It is expecting that during 2016-2023 the global thermoplastic polyurethane market will grow with the CAGR of 6.53%.

Thermoplastic Polyurethane Market Revenue is expected to witness a significant growth of USD ~ 2.96 Billion by 2023 with CAGR of ~6.53 % between 2016 and 2023M

Top Key Players Analysis for Thermoplastic Polyurethane Market

API Plastics

BASF SE

Bayer Material Science AG

Headway Polyurethane

Huntsman Corporation

Lubrizol Corporation

Miracll Chemical

Wanhua Chemical Group

Get Full Report Info @ https://www.marketresearchfuture.com/reports/thermoplastic-polyurethane-market-3269

Market Dashboard

The densely packed market is thriving on innovation initiated by various companies to stay afloat. At the same time, multiple collaborations, merger, and acquisitions are leading the market ahead. For instance, Huntsman Corporation acquired Demilec, a formulator of spray polyurethane foam (SPF) insulation based out of North America. Hexpol AB and Wildo Sweden AB collaborated recently to develop bio-based products which can be considered exemplary.

Industry Trend

BASF has recently announced a new TPU technology where it aggravates the high-performance shoe shank production and makes the entire procedure cost-efficient. Furthermore, it adds excellent mechanical properties such as UV resistance. The production technology can work in tandem with automation.

Callaway, a market giant in golf ball production, is taking its production technology a notch higher by blending TPU with thermoset polyurethane to have a cover for the golf balls which, in turn, would increase its performance.

Segmentation

The global TPU market can be segmented by grade, types, and application.

Grade-wise, the market includes flame retardant, antistatic, reinforced & others.

Type-based segmentation of the market comprises polyester, polyether, and polycaprolactone.

Based on application, the market can be segmented into automotive, construction, engineering, medical and others.

Regional Analysis

Geographical segmentation of Thermoplastic Polyurethane Market reveals that it spans across North America, Europe, Asia Pacific (APAC), Latin America (LATAM), and the Middle East & Africa (MEA).

Burgeoning industries such as automotive, construction, engineering, medical and others in the APAC are reasons behind the phenomenal growth of TPU market in the region. The booming industry is getting aptly backed by China and India, major emerging economies that are reshaping the commercial setting of the region. Automotive sector of China, India, Taiwan, and South Korea are also playing an essential role in taking the market ahead.

In Europe, the market is mainly getting driven by the construction industry which subsequently, is helping the region to assume the second position. North America, on the other hand, is showing growing consumption of TPU in engineering and medical industry.

#Thermoplastic Polyurethane Market#Thermoplastic Polyurethane Market Size#Thermoplastic Polyurethane Market Share#Thermoplastic Polyurethane Market 2020#Thermoplastic Polyurethane Market Key Players#Thermoplastic Polyurethane Market Forecast

0 notes

Text

Increasing Applications In Various Industries has Led the Growth of Others Segment of Antistatic Agents Market

The antistatic agents market is projected to grow from USD 437 million to USD 594 million by 2024, at a CAGR of 6.3% from 2019 to 2024. The growth of this market can be attributed to the increasing demand for antistatic agents from the packaging, electronics, and textiles industries. Antistatic agents are added to polymers to remove or reduce the static charge that has accumulated over their surfaces either by reducing the generation of electric charge or increasing the rate of charge dissipation, or both. This static charge accumulation results in processing complexities, attraction and deposition of dust particles, explosions, or fire hazards.

To know about the assumptions considered for the study download the pdf brochure

Key Market Players

BASF SE (Germany), Arkema (France), Clariant (Switzerland), Croda International PLC. (UK), DowDuPont (US), Evonik Industries AG (Germany), Nouryon (Netherlands), Solvay S.A. (Belgium), PolyOne Corporation (US), Riken Vitamin Co., Ltd. (Japan), Mitsubishi Chemical Corporation (Japan), and Kao Group (Japan), among others are the major players operating in the antistatic agents market. These players have been focusing on developmental strategies such as new product launches, expansions, mergers & acquisitions, and partnerships to expand their businesses to untapped and potential markets.

Recent Developments

In October 2017, Clariant launched an amide/amine-free anti-static concentrate for clean-room and Active Pharmaceutical Ingredient (API) films, which are used in the production of pharmaceuticals. This product launch helped the company in increasing its market presence by producing bio-friendly products and enabling manufacturers in the medical and pharmaceutical sectors to control and minimize risks such as attracting dust and mitigating the dissipative charges.

On May 13, 2019, Kao Corporation of Kao Group expanded its production capacity of oleochemicals by completing the joint venture between Kao and PT Apical of Apical Group. This joint venture aimed at increasing the production capacity of fatty acids, which are required to manufacture antistatic agents. This joint venture is also expected to enable Kao Corporation to extend its reach and strengthen its supply chain to produce high-quality products for a wide range of customers.

In October 2017, BASF SE launched a new product, Elastollan with high antistatic properties, increased mechanical strength, excellent abrasion resistance, a broad range of hardness, and good slip resistance that make it appropriate for use as a safety shoe sole, which is manufactured through injection molding. This product launch helped the company in updating its polyurethane and thermoplastic polyurethane product portfolio.

Speak to Analyst: https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=163457499

Contact - Mr. Shelly Singh MarketsandMarkets™ INC. 630 Dundee Road Suite 430 Northbrook, IL 60062 USA : +1-888-600-6441 Email: [email protected]

0 notes