#Ammonium Hydroxide Market

Explore tagged Tumblr posts

Text

Ammonium Hydroxide Market: Key Growth Analysis and Regional Market Trends, Forecast to 2033

Ammonium Hydroxide Industry Outlook 2025:

A report was released freshly that sheds lots of light on the Ammonium Hydroxide Industry. The report covers an summary of the industry along with a exhaustive description that offers a lot of insight. The report also studies the production as well as management technology in numerous end-user industries. An in-depth study in some new and noticeable industry key trends, analysis of the rivalry and regional analysis that is very detailed have been encompassed in the report of the Ammonium Hydroxide market for the assessment period of 2025–2033.

According to Straits Research, the global ammonium hydroxide market size was valued at USD 1.40 billion in 2023. It is projected to reach from USD 1.48 billion in 2024 to USD 2.15 billion by 2032, growing at a CAGR of 5.8% during the forecast period (2024–2032).

Ammonium Hydroxide market research report has been prepared with most up-to-date insight and analysis to give maximum key benefits to the Ammonium Hydroxide industry. Besides, this professional report also contains historic data, present and future market key trends, environment, global technological innovation, upcoming trends and technologies and the technical progress in the associated industry.

Get Exclusive Sample of Report on Ammonium Hydroxide Market is Available Here @ https://straitsresearch.com/report/ammonium-hydroxide-market/request-sample

Covid-19 Pandemic Impact on the Market:

The Covid-19 outbreak negatively affected the market. The strict guidelines of lockdown compulsory by numerous governments and ban on state and international travel to curb the spread of the virus occasioned in a sudden collapse in demand for Ammonium Hydroxide market in 2024.

Moreover, the demand for business analytics is projected to upsurge post-pandemic.

The Top Companies in this Report Include:

Sigma-Aldrich Co. LLC.

KMG Chemicals, Inc.

Tanner Industries, Inc.

Thermo Fisher Scientific Inc.

BASF SE

Mitsubishi Gas Chemical Company

TAIWAN FERTILIZER CO., LTD

Spectrum Chemical Manufacturing Corp

Vijay Gas Industry Pvt. Ltd.

Yara International ASA

MGC Pure Chemicals America, Inc.

Pride-Chem Industries Pte Ltd.

Tritech Catalyst Intermediate Pvt. Ltd.

GFS Chemicals, Inc.

StraitsResearch offers in-depth insights into the market. It presents the study in a comprehensible chapter-wise format, interspersed with data and applicable infographics. The report accepts an analytical approach to help our clients get better considerate about the market. Our expert market research analysts in the various industry domain carries out an widespread primary and secondary research with the benefit of digital intelligence for enhanced decision making.

Ammonium Hydroxide Market 2025-2033: Key Highlights

CAGR of the market during the estimate period 2025-2033

Detailed information on key factors that will assist Ammonium Hydroxide market development during the next five years

Estimation of the Ammonium Hydroxide market size, share and its influence to the parent market

Calculations on upcoming industry trends and changes in consumer behaviour

The evolution of the Ammonium Hydroxide market

Analysis of the market's reasonable landscape and detailed information on key vendors

Comprehensive details of key factors that will challenge the growth of Ammonium Hydroxide market key players

Detailed Segmentation:

By Nature Type

Natural

Synthetic

Chemical

By Application

Cleaning Agent

Acid Neutralizer

Flavor enhancer

Water Treatment

Leaving agent

Others

By End-User

Residential

Commercial

Industrial

Get Detailed Market Segmentation: https://straitsresearch.com/report/ammonium-hydroxide-market/segmentation

Finally, researchers throw light on the identify analysis of Global Ammonium Hydroxide Market dynamics. It also measures the maintainable key trends and industry platforms which are the basic origins behind the industry growth. The degree of rivalry is also measured in the updated research report. With the benefit of SWOT and Porter’s five analysis, the market has been tremendously analysed. It also helps to address the risk and challenges in front of the industries. Furthermore, it provides widespread research on sales approaches.

Geographic analysis:

The global Ammonium Hydroxide market has been spread across North America, Europe, Asia-Pacific, the Middle East and Africa, and the Rest of the World.

Note: All the reports that we list have been tracing the impact of COVID-19. Mutually upstream and downstream of the whole supply chain has been accounted for while doing this. Also, where likely, we will offer an additional COVID-19 update report to the report in Q3, please check for with the sales team.

What Does the Ammonium Hydroxide Market Report Provides?

The report for Ammonium Hydroxide market qualifies an communicative and proficient glance into this market. It examines the market’s present environment in order to have a full grasp of the market’s future ambitions. It gives a inclusive assessment of the universal market sector by leading an in-depth analysis of diverse elements of the industry, including recent industry trends, current conditions, and future prospects.

Have Any Query? Ask Our Experts: https://straitsresearch.com/buy-now/ammonium-hydroxide-market

About Us:

StraitsResearch.com is a leading market research and market intelligence organization, specializing in research, analytics, and advisory services along with providing business insights & market research reports.

Contact Us:

Email: [email protected] Tel: +1 646 905 0080 (U.S.), +44 203 695 0070 (U.K.) Website: https://straitsresearch.com/

#Ammonium Hydroxide Market#Ammonium Hydroxide Market Share#Ammonium Hydroxide Market Size#Ammonium Hydroxide Market Research#Industry

0 notes

Text

https://github.com/Sona75310/gitdev/blob/main/North America Semiconductor Grade Ammonium Hydroxide (NH4OH) Market Drivers And Trends.md

0 notes

Text

Demand for Inorganic Salts To Remain Highest in Asia-Pacific (APAC)

To most people, ‘salt’ simply means table salt, or sodium chloride. However, the word has a specific meaning in chemistry, hence denotes a wide array of compounds, almost all of them powders. In technical terms, any compound that has a cation (positively charged atom) bonded to an anion (negatively charged atom), such that the net charge of the molecule is 0, is a salt. In the simplest form, a salt can be produced by reacting an acid with a base (alkali).

According to P&S Intelligence, the inorganic salts market is expected to display a 6.5% CAGR during 2024–2030, to reach USD 290.8 billion by 2030 from an estimated USD 188.6 billion in 2023. Inorganic salts are those that do not contain a carbon–hydrogen bond. In fact, the majority of the industrially used salts are inorganic. They are used as raw materials, intermediates, and final products in a variety of applications, such as fertilizers, food and beverage products, construction chemicals, healthcare, cosmetics, and personal care and homecare products. Hence, due to such a wide application area of such compounds, their consumption keeps on growing.

Such chemicals can be classified both on the basis of their cation and anion. For instance, sodium chloride can be classified both as a sodium salt and a chloride salt. This makes the segregation of these compounds based on their application a little easier. For instance, phosphate salts, specifically diammonium phosphate and ammonium dihydrogen phosphate (also known as monoammonium phosphate), are majorly used in fertilizers. Similarly, silicate salts are widely consumed in the glass industry; silica being the major raw material that goes into the production of glass.

Moreover, sodium chloride finds application in several cosmetic products, such as oral hygiene products, fragrance, shampoos, skin, nail, hair, cleansing, makeup and bath products, and suntans. Further, two of the major ingredients of shampoos are sodium lauryl sulphate and sodium laureth sulphate. Similarly, the key ingredients of toothpastes are calcium carbonate, calcium hydrogen phosphates, and sodium fluoride. Additionally, calcium carbonate is used in dietary calcium supplements, antacids, and medicinal tablets.

In the same way, titanium dioxide is a major component of paints and coatings as it gives them their white color. Hence, as construction activities burgeon around the world, the demand for paints and coatings will grow, which will drive the consumption of titanium dioxide. Another key material that is witnessing a booming demand with the growing construction sector is steel. It is used widely as a structural element in buildings, bridges, and towers. Its burgeoning consumption is propelling the demand for aluminum oxide, or alumina, which is used as a refractory, the bricks that line the furnaces.

Moreover, a large volume of inorganic salts isn’t used itself, but to extract their base mineral. Many important metals do not exist in the elemental stage, but as oxides and sulphides. For instance, iron exists as ferrous oxide and ferric oxide, while copper, which is also available in its native (elemental) state, is usually extracted from cuprite (cupric oxide) and chalcolite (copper [I] sulphide). Similarly, bauxite contains aluminum in the form of hydroxide salts. In the same way, calcium is usually mined from calcium carbonate (marble), while silver is found in the form of silver sulphide.

Currently, Asia-Pacific (APAC) is the largest inorganic salts market because of its massive chemical industry. The demand for pharmaceuticals, paints and coatings, personal care products, food and beverage products, and fertilizers is booming in the region, which is propelling the demand for a variety of inorganic salts. For instance, the growing automotive sales and construction activities are propelling the demand for paints and coatings, while the rising prevalence of several diseases is driving the consumption of pharmaceuticals. As all these products contain some or the other inorganic salts, their increasing demand is driving that of the latter.

Therefore, with the widening industrial production, the demand for inorganic salts will rise.

Source: P&S Intelligence

#Inorganic Salts Market Share#Inorganic Salts Market Size#Inorganic Salts Market Growth#Inorganic Salts Market Applications#Inorganic Salts Market Trends

1 note

·

View note

Text

0 notes

Text

0 notes

Text

0 notes

Text

Aluminium Sulfide Production Cost

The latest report titled “Aluminium Sulfide Production” by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of Aluminium Sulfide.

Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, production cost details, economics for another plant location, dynamic cost model). In addition, the report incorporates the production process with detailed process and material flow, capital investment, operating costs along with financial expenses and depreciation charges.

Procurement Resource’s detailed report describes the stepwise consumption of material and utilities along with a detailed process flow diagram. Furthermore, the study assesses the latest developments within the industry that might influence Aluminium Sulfide production cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Procurement Resource Assessment of Aluminium Sulfide Production Process:

From Chemical Reaction Between Aluminium Powder and Sulfur: This report presents the detailed production methodology and cost analysis of Aluminium Sulfide industrial production across Aluminium Sulfide manufacturing plants. The manufacturing process commences with the high-temperature reaction between aluminium powder and sulfur. This exothermic reaction leads to the formation of aluminium sulfide as the final product.

Request Free Sample – https://www.procurementresource.com/production-cost-report-store/aluminium-sulfide/request-sample

Aluminum Sulfide Production Methods

Aluminum sulfide can be produced through several methods, each with its unique set of costs and considerations. The primary methods include:

Direct Combination of Aluminum and Sulfur: One of the traditional methods for aluminum sulfide production involves the direct combination of aluminum metal with sulfur. This process typically requires finely powdered aluminum and sulfur, which are heated under controlled conditions to form aluminum sulfide. The cost factors include the price of raw materials, energy consumption for heating, and equipment maintenance.

Chemical Reaction of Aluminum Hydroxide and Ammonium Sulfide: Another route for aluminum sulfide production involves the chemical reaction between aluminum hydroxide (Al(OH)3) and ammonium sulfide ((NH4)2S). This process produces aluminum sulfide along with ammonium hydroxide (NH4OH) as a by-product. The cost factors include the price of aluminum hydroxide, ammonium sulfide, energy for mixing and heating, and separation of aluminum sulfide from the reaction mixture.

Metallurgical Processes: Metallurgical processes, such as the carbothermal reduction of aluminum oxide (alumina) with carbon and sulfur, can also be used to produce aluminum sulfide. This process involves the reaction of alumina with carbon and sulfur at high temperatures to form aluminum sulfide and carbon monoxide gas. The cost factors include the price of alumina, carbon, sulfur, energy consumption for heating, and separation of aluminum sulfide from the reaction products.

Factors Influencing Production Costs

Several factors influence the production costs of aluminum sulfide, ranging from raw material prices and energy costs to process efficiency and environmental regulations. Here are some key factors to consider:

Raw Material Prices: The cost of raw materials, including aluminum, sulfur, aluminum hydroxide, ammonium sulfide, and carbon, significantly impacts aluminum sulfide production costs. Fluctuations in raw material prices due to market demand, supply disruptions, geopolitical factors, and regulatory changes can affect production economics and profitability.

Energy Costs: Energy-intensive processes, such as heating, mixing, and reaction heating, contribute to a significant portion of aluminum sulfide production costs. Energy prices, including electricity, natural gas, and fuel, influence overall operating expenses. Optimizing energy efficiency and exploring alternative energy sources can mitigate the impact of rising energy costs.

Capital Investment: The capital investment required for equipment, infrastructure, and facilities plays a crucial role in determining production costs. Upfront costs for plant construction, process equipment, instrumentation, and control systems constitute a significant portion of total investment. The choice of production technology and scale of operation affect capital expenditure and project economics.

Process Efficiency: The efficiency of aluminum sulfide production processes, including reaction kinetics, heat transfer, mixing, and separation, directly impacts production costs. Improving process efficiency through technological advancements, reactor design optimization, and operational optimization can reduce raw material consumption, energy usage, and waste generation, thereby enhancing cost-effectiveness and competitiveness.

Environmental Compliance: Compliance with environmental regulations and emissions standards adds to production costs through investments in pollution control equipment, emissions monitoring, and regulatory compliance measures. Aluminum sulfide production facilities must adhere to air quality regulations governing emissions of sulfur dioxide (SO2) and other pollutants. Implementing cleaner production technologies and sustainable practices can mitigate environmental risks and regulatory compliance costs.

Market Dynamics: Market dynamics, including supply and demand dynamics, price volatility, competition, and trade policies, influence the profitability of aluminum sulfide production. Changes in market conditions, such as shifts in demand for downstream products or emergence of new technologies, can affect product pricing and market competitiveness. Proactive market analysis and risk management strategies are essential for optimizing production planning and resource allocation.

Product Definition:

Aluminium sulfide (Al2S3) is a chemical compound composed of aluminium and sulfur atoms. It forms a white to grayish crystalline solid. Aluminium sulfide is primarily used in the production of aluminium metal through a process called the Hall-Héroult process, where it serves as a flux to lower the melting point of alumina. It is also employed as a catalyst in various organic reactions. However, it should be handled with care, as it can release toxic hydrogen sulfide gas when exposed to moisture. Aluminium sulfide plays a crucial role in both the aluminium industry and organic synthesis.

Market Drivers:

The market for aluminium sulfide (Al2S3) is primarily driven by its essential role in the aluminium industry, where it serves as a flux in the Hall-Héroult process for aluminium extraction from alumina. This process is particularly critical as global demand for aluminium products, especially in emerging economies, continues to grow. Additionally, aluminium sulfide finds application as a catalyst in various organic reactions, which sustains demand from the chemical and pharmaceutical sectors. Research and development, evolving environmental regulations, and technological advancements further impact the market dynamics for aluminium sulfide, making it a crucial compound in multiple industries.

Looking for an exhaustive and personalised report that could significantly substantiate your business?

Although Procurement Resource leaves no page unfurled in terms of the rigorous research for the commodities that make the heftiest base of your business, we incline more towards tailoring the reports per your specificities. All you need is one-to-one consulting with our seasoned consultants to comprehend the prime parameters you are looking to pin your research on.

Some of the common requests we receive from our clients include:

Adapting the report to the country/region where you intend to establish your plant.

Adjusting the manufacturing capacity of the plant according to your needs.

Customizing machinery suppliers and costs to meet your requirements.

Providing additional information to the existing scope based on your needs.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertakes extensive research to provide our customers with the latest and up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele.

Procurement Resource work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. As a team of experts, we also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with updated and reliable data.

We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate so that they can form strategies that ensure their optimum growth.

Contact Us:

Company Name: Procurement Resource Contact Person: Leo Frank Email: [email protected] Toll Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500 Address: 30 North Gould Street, Sheridan, WY 82801, USA

0 notes

Text

Electronic Grade Ammonium Hydroxide, Global Market Size Forecast, Top 5 Players Rank and Market Share

Electronic Grade Ammonium Hydroxide Market Summary

Electronic-grade ammonia hydroxide is a kind of high purity wet electronic chemical. It can be used in semiconductor industries as an important material in wafer cleaning and etching processes.

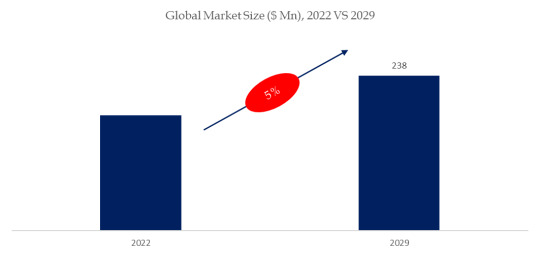

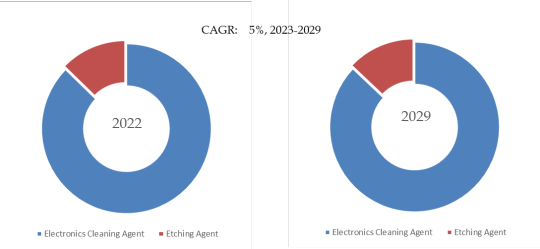

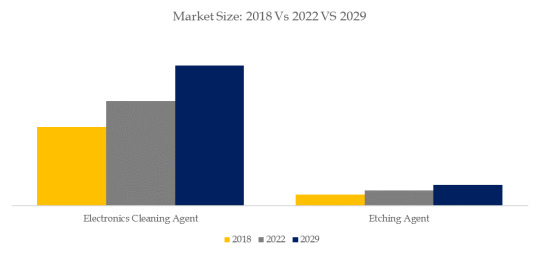

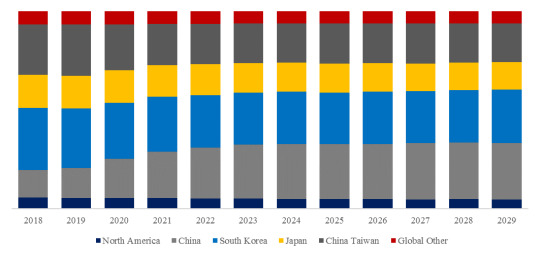

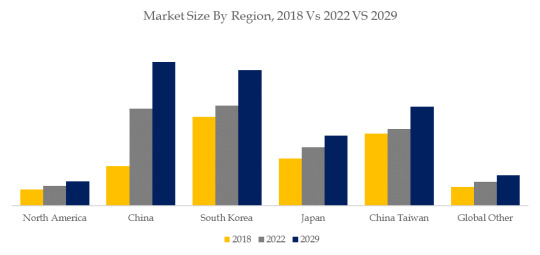

According to the new market research report “Global Electronic Grade Ammonium Hydroxide Market Report 2023-2029”, published by QYResearch, the global Electronic Grade Ammonium Hydroxide market size is projected to reach USD 238.5 million by 2029, at a CAGR of 5.0% during the forecast period.

Figure. Global Electronic Grade Ammonium Hydroxide Market Size (US$ Million), 2022-2029

Based on or includes research from QYResearch: Global Electronic Grade Ammonium Hydroxide Market Report 2023-2029.

Market Drivers:

Semiconductor Industry Growth: The increasing demand for electronic devices and semiconductors is a major driver for the electronic grade ammonium hydroxide market. It is used in the semiconductor manufacturing process for cleaning and etching silicon wafers.

Miniaturization of Electronics: As electronic devices continue to shrink in size, there is a growing need for precise and high-purity chemicals like electronic grade ammonium hydroxide to maintain the quality and performance of microelectronics.

Advancements in Nanotechnology: The development of nanoscale technologies in various industries, including electronics, relies on chemicals like electronic grade ammonium hydroxide for precision fabrication and processing.

Increasing Demand for High-Quality Displays: The production of high-quality displays for smartphones, televisions, and other electronic devices requires chemicals that can provide the necessary level of purity and precision.

Environmental Regulations: Stricter environmental regulations are pushing manufacturers to use environmentally friendly chemicals in their production processes. Electronic grade ammonium hydroxide is preferred for its relatively low environmental impact compared to some alternatives.

Restraint:

Price Volatility: The cost of electronic grade ammonium hydroxide can be subject to fluctuations, depending on the availability of raw materials and market dynamics. This can pose challenges for manufacturers and users in terms of cost management.

Handling and Safety Concerns: Ammonium hydroxide is a corrosive and potentially hazardous chemical. Proper handling and safety measures are essential, which can add complexity and cost to its use in manufacturing processes.

Competitive Alternatives: There are alternative chemicals and processes available for semiconductor cleaning and fabrication, which may compete with electronic grade ammonium hydroxide, especially if they offer cost advantages or superior performance in specific applications.

Opportunity:

Emerging Technologies: The rise of emerging technologies such as 5G, artificial intelligence, and the Internet of Things (IoT) is expected to drive the demand for electronic components, which will in turn boost the market for electronic grade ammonium hydroxide.

Green Manufacturing: There is an opportunity for electronic grade ammonium hydroxide manufacturers to innovate and develop more environmentally friendly formulations to meet the increasing demand for green and sustainable manufacturing practices.

Global Expansion: As the electronics industry continues to expand globally, there is an opportunity for electronic grade ammonium hydroxide suppliers to enter new markets and form partnerships with manufacturers in emerging economies.

Customized Solutions: Offering tailored formulations and services to meet the specific needs of semiconductor and electronics manufacturers can be a competitive advantage, as it can lead to long-term partnerships and customer loyalty.

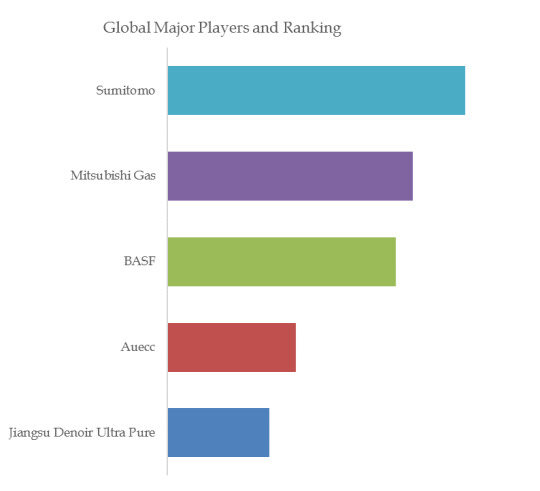

Figure. Electronic Grade Ammonium Hydroxide, Global Market Size, The Top Five Players Hold 70% of Overall Market

Based on or includes research from QYResearch: Global Electronic Grade Ammonium Hydroxide Market Report 2023-2029.

This report profiles key players of Electronic Grade Ammonium Hydroxide such as Sumitomo, Mitsubishi Gas, BASF, Auecc, Jiangsu Denoir Ultra Pure.

In 2022, the global top five Electronic Grade Ammonium Hydroxide players account for 70.2% of market share in terms of revenue. Above figure shows the key players ranked by revenue in Electronic Grade Ammonium Hydroxide.

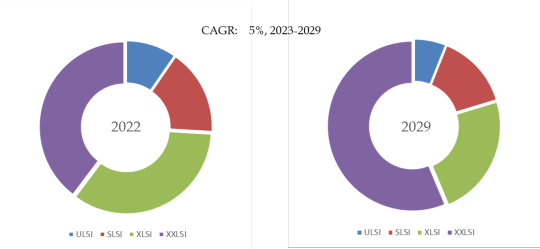

Figure. Electronic Grade Ammonium Hydroxide, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Electronic Grade Ammonium Hydroxide Market Report 2023-2029.

In terms of product type, XXLSI is the largest segment, hold a share of 39.7%,

Figure. Electronic Grade Ammonium Hydroxide, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Electronic Grade Ammonium Hydroxide Market Report 2023-2029.

In terms of product application, Electronics Cleaning Agent is the largest application, hold a share of 87.3%.

Figure. Electronic Grade Ammonium Hydroxide, Global Market Size, Split by Region (Production)

Based on or includes research from QYResearch: Global Electronic Grade Ammonium Hydroxide Market Report 2023-2029.

About The Authors

Lu Jing - Lead Author

Email: [email protected]

Lu Jing is a technology & market senior analyst specializing in chemical, advanced material, and component. Lu has 9 years’ experience in chemical and focuses on catalyst and additive, metal and plastic materials, waste recycling, daily chemicals. She is engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

HAIR STRAIGHTENING

HAIR STRAIGHTENING

In the world of beauty and personal grooming, hair styling plays a pivotal role in defining one's appearance. Among the myriad of styling options available, hair straightening has gained immense popularity for its transformative effects. This article explores the art and science behind hair straightening, encompassing its history, techniques, types, benefits, risks, and emerging trends.

Historical Evolution of Hair Straightening Here's a brief overview of the historical evolution of hair salon for straightening:

1. Ancient Civilizations:

● Egyptian Civilization: Ancient Egyptians used a variety of methods to straighten their hair. They often applied a mixture of oils and fats to their hair, which not only served as a moisturizer but also helped in straightening.

2. Greco-Roman Period:

● Ancient Greece and Rome: During this period, wealthy individuals, particularly women, were known to use heated metal implements to straighten their hair.

3. Renaissance Period:

● 16th and 17th Centuries: In Europe during the Renaissance, women often pursued straight hair, and methods included the use of hot combs and tongs.

4. 19th Century:

● Metal Combs and Heated Rods: The 19th century saw the introduction of metal combs and heated rods, which were heated on stoves and used to straighten hair.

5. Early 20th Century:

● Chemical Relaxers: The early 20th century saw the development of chemical relaxers, which used substances like sodium hydroxide to break down the protein

structure of the hair, allowing it to be reshaped. This marked a significant shift from mechanical methods to chemical treatments.

6. Mid to Late 20th Century:

● Hot Combs and Flat Irons: In the mid-20th century, hot combs and flat irons became popular tools for straightening hair. These tools were heated and then applied to the hair salon to achieve a straightened look.

7. Late 20th Century to Present:

● Chemical Straightening and Hair Straightening Products: The latter half of the 20th century saw the widespread use of chemical straightening treatments, such as relaxers and perms. These treatments became more sophisticated over time, offering different formulations for various hair types. Additionally, the market saw the rise of various hair straightening products, including heat-activated straightening creams and serums.

8. 21st Century:

● Advancements in Technology: The 21st century has brought about further advancements in hair stylist and straightening technology, with the introduction of ceramic and tourmaline flat irons that provide more even heat distribution and reduce damage to the hair.

9. Natural Hair Movement:

● Embracing Natural Texture: In recent years, there has been a growing movement promoting the acceptance of natural hair textures. Many people are now choosing to embrace their natural curls and waves rather than straightening their hair.

The historical evolution of hair straightening reflects changing beauty standards, technological advancements, and cultural preferences over the centuries. Today, individuals have a variety of options, ranging from traditional methods to modern tools and products, to achieve the desired look for their hair.

Understanding the Basics:

A. Natural vs. Chemical Straightening:

Natural Straightening Techniques:

Natural hair straightening methods involve using heat-free techniques to achieve straightened locks. Examples include:

1. Blow Drying: Using a hairdryer and a round brush to straighten hair temporarily.

2. Wrapping: Securing wet hair around the head to promote a straighter appearance as it dries.

Chemical Straightening:

Chemical straightening, also known as relaxing, involves the use of chemical treatments to alter the structure of the hair. Common ingredients include sodium hydroxide, ammonium thioglycolate, and guanidine hydroxide.

B. Popular Hair Straightening Methods:

1.Flat Irons:

Flat irons, or hair straighteners, are versatile tools that use heat to straighten hair. It's crucial to use a quality flat iron and follow proper techniques to prevent damage.

2.Brazilian Keratin Treatment:

This semi-permanent treatment involves applying a keratin solution to the hair, which is then sealed in with heat. The result is smoother, straighter hair that can last for several months.

3.Japanese Hair Straightening:

Also known as thermal reconditioning, this method uses a combination of chemicals and heat to alter the hair's structure, resulting in permanently straightened hair.

Risks and Considerations:

1. Heat Damage:

Excessive use of heat styling tools, such as flat irons, can lead to heat damage, causing dryness, breakage, and split ends. It's essential to use heat protectant products and limit heat exposure.

2. Chemical Damage:

Chemical straightening treatments can lead to damage if not applied correctly or if the hair is not properly maintained afterward. Potential issues include hair breakage, dryness, and scalp irritation.

3. Loss of Natural Curl Pattern:

Permanently straightening hair, especially through chemical treatments, can result in the loss of the natural curl pattern. Individuals should carefully consider the long-term effects and potential regrets before opting for permanent straightening methods.

Tips for Healthy, Straightened Hair:

1. Preparation:

Healthy Hair Foundation:

Start with a foundation of healthy hair by maintaining a proper hair care routine, including regular trims, deep conditioning, and a balanced diet.

2.Consultation:

Before undergoing any chemical straightening treatment, consult with a professional stylist to assess your hair's condition and determine the most suitable method.

3. During the Straightening Process:

Temperature Control:

When using flat irons, set the temperature according to your hair type. Lower temperatures are suitable for fine or damaged hair, while higher temperatures may be needed for thicker, coarser hair.

4.Sectioning:

Divide your hair into sections before straightening to ensure even coverage and optimal results.

5. Aftercare:

Moisturize:

Moisturize your hair regularly using hydrating shampoos, conditioners, and leave-in treatments to combat dryness and maintain smoothness.

Avoid Excessive Heat:

Limit the use of heat styling tools to prevent further damage. Embrace natural hairstyles or opt for no-heat styling options when possible.

Protective Styles:

Consider protective styles like braids or updos to minimize exposure to environmental factors and reduce the need for daily styling.

The Ever-Evolving World of Hair Trends: 1. Embracing Natural Texture:

With the growing movement towards embracing natural beauty, many individuals are opting to showcase their natural hair texture rather than conforming to traditional beauty standards.

2. Temporary vs. Permanent Options:

Consider temporary straightening methods for individuals who enjoy the versatility of switching between straight and curly styles. Permanent options may be suitable for those seeking a long-term solution.

Conclusion:

Hair straightening has evolved significantly over the years, offering a range of techniques catering to diverse preferences and needs. Whether opting for a temporary straightening method for occasional styling or choosing a permanent solution for long-lasting results, individuals should weigh the benefits against the potential risks and invest in proper care to maintain healthy, beautiful hair. As trends continue to evolve, it's essential to stay informed about the latest developments in the world of makeup and hair stylist straightening for a well-informed and confident approach to personal styling.

0 notes

Text

Tetramethyl Ammonium Hydroxide Market Latest Innovative Growing Trends and Forecasts from 2023-2030 - Benzinga

Tetramethyl Ammonium Hydroxide Market Latest Innovative Growing Trends and Forecasts from 2023-2030 Benzinga http://dlvr.it/SwWvTf

0 notes

Text

Inorganic Chemicals Market: Exploring Global Trends and Growth Prospects

The inorganic chemicals market is a crucial segment of the global chemical industry, encompassing a diverse range of chemical compounds that do not contain carbon-hydrogen (C-H) bonds. These chemicals play a pivotal role in various industrial applications, including manufacturing, construction, agriculture, electronics, and more. Inorganic chemicals are typically derived from minerals, ores, and other naturally occurring sources, as well as through various chemical synthesis processes.

Key Types of Inorganic Chemicals:

Acids and Bases: Inorganic acids (e.g., sulfuric acid, hydrochloric acid) and bases (e.g., sodium hydroxide, potassium hydroxide) are fundamental chemicals used in numerous industrial processes, including pH regulation, chemical synthesis, and metal processing.

Salts: Inorganic salts, such as sodium chloride (table salt), calcium carbonate, and ammonium nitrate, are utilized in applications ranging from food preservation to fertilizers and water treatment.

Metals and Metal Compounds: Inorganic chemicals encompass a wide array of metals and their compounds, including aluminum, copper, iron, titanium, and various metal oxides, sulfides, and nitrides. These substances are crucial for industries like electronics, automotive manufacturing, and construction.

Catalysts: Inorganic compounds often serve as catalysts in chemical reactions, accelerating reaction rates without being consumed in the process. These catalysts are widely used in the production of fuels, chemicals, and plastics.

Pigments and Dyes: Inorganic pigments, such as titanium dioxide and iron oxide, are used for coloring various materials, including paints, ceramics, and plastics.

Glass and Ceramics: Inorganic materials like silica, alumina, and various oxides are essential components in the production of glass, ceramics, and refractory materials used in high-temperature applications.

Market Drivers:

Several factors contribute to the growth and demand for inorganic chemicals:

Industrialization and Infrastructure Development: The expanding industrial and construction sectors require inorganic chemicals for manufacturing, building materials, and infrastructure development.

Agricultural Demand: Fertilizers and agrochemicals, which often rely on inorganic compounds, are essential for increasing agricultural productivity to meet global food demands.

Technological Advancements: Industries such as electronics, photovoltaics, and automotive manufacturing rely on inorganic chemicals for advanced materials, components, and devices.

Environmental Concerns: Inorganic chemicals play a vital role in water treatment, air pollution control, and waste management, supporting environmental sustainability efforts.

Challenges:

The inorganic chemicals market also faces challenges, including:

Regulatory Compliance: Inorganic chemicals often have strict regulatory guidelines due to their potential environmental and health impacts.

Competitive Landscape: The market is highly competitive, with numerous global and regional players vying for market share.

Raw Material Availability: Dependence on certain minerals and ores for production can be affected by geopolitical factors and supply chain disruptions.

Sustainability Concerns: The industry is under pressure to develop more sustainable production processes and materials due to increasing environmental awareness.

Regional Trends:

The inorganic chemicals market is global, with production and consumption spread across regions like Asia-Pacific, North America, Europe, and Latin America. The Asia-Pacific region, particularly China and India, is a significant player due to its industrial growth and demand for infrastructure and consumer goods.

Future Outlook:

The inorganic chemicals market is poised for continued growth driven by urbanization, industrialization, and technological advancements. As industries evolve and consumer demands change, the market will likely witness a shift towards sustainable and environmentally friendly practices.

In conclusion, the inorganic chemicals market is a diverse and dynamic sector that underpins various industries. Its role in shaping modern manufacturing, infrastructure, and technological advancements underscores its significance in the global economy.

#Inorganic Chemicals Market Share#Inorganic Chemicals Market Growth#Inorganic Chemicals Market Demand#Inorganic Chemicals Market Trend#Inorganic Chemicals Market Analysis

0 notes

Text

0 notes

Text

Electronic Grade Ammonium Hydroxide Market Size, Share, Growth and Analysis

The Global Electronic Grade Ammonium Hydroxide Market report presents insightful data for clients improving their simple management skills identifying with the global market along with market dynamics, segmentation, competition and local growth. The report describes the market size, market characteristics and market growth for the Electronic Grade Ammonium Hydroxide industry categorized by type, application and consumption sector.

It provides a comprehensive analysis of the aspects related to the pre and post covid market development 19 pandemic.

Prominent Players Covered in the Global Electronic Grade Ammonium Hydroxide Market Are:

BASF

Mitsubishi Gas

Auecc

Donowoo Fine-Chem

Jiangsu Denoir Ultra Pure

Suzhou Crystal Clear Chemical

Jianghua Microelectronics Materials

Electronic Grade Ammonium Hydroxide Market -Regional Analysis:

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth rate of the Electronic Grade Ammonium Hydroxide market in these regions, down to the forecast coverage.

North America (United States, Canada, and Mexico)

Europe (Germany, United Kingdom, France, Italy, Russia, and Turkey, etc.)

Asia Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Colombia, etc.)

Some of the key questions answered in this report:

What is global? Sales Value, Production Value, Consumption Value, Import and Export of the Electronic Grade Ammonium Hydroxide Market?

What application/end user or product type can look for incremental growth prospects?

What are the different sales, Marketing and sales channels in the global industry?

What are the key market trends influencing the growth of the Electronic Grade Ammonium Hydroxide market?

Economic impact on the Electronic Grade Ammonium Hydroxide market industry and trend development of the Electronic Grade Ammonium Hydroxide market industry.

What are the market opportunities, market risk and market overview of the Electronic Grade Ammonium Hydroxide market?

What are the key drivers, restraints, opportunities and challenges of the Electronic Grade Ammonium Hydroxide market and how are they expected to be affect the market?

How big is the market for Electronic Grade Ammonium Hydroxide at regional and country level?

Browse More Details On This Report at - https://www.businessresearchinsights.com/enquiry/request-sample-pdf/electronic-grade-ammonium-hydroxide-market-100863

Contact Us:

Business Research Insights

Phone:

US: (+1) 424 253 0807

UK: (+44) 203 239 8187

0 notes

Text

Global Tetramethyl Ammonium Hydroxide Market Growth by Geographical Region Application Driver Trends Top Company and Forecast To 2027

0 notes

Text

Global Electronic Grade Ammonium Hydroxide Market Factors, Consumption, Current Scenario 2021-2026

The latest research report on ‘Electronic Grade Ammonium Hydroxide market’ added by Futuristic Reports, presents a detailed analysis concerning the market industry, market valuations, revenue assessment, SWOT analysis, and regional range of the business. The report further features key difficulties and development possibilities of the market, while analyzing the business outlook comprising expansion strategies implemented by market leaders.

Electronic Grade Ammonium Hydroxide Market Insights give a deep analysis of the Global Electronic Grade Ammonium Hydroxide Market which evaluates business arrangements, assesses, research and development, application, benefits, advantage, scope, and activities. This report offers an in-depth analysis and advancement of industry significant manufacturers, key drivers, opportunity, challenge, international suppliers also deep study on risks and entry barriers. It additionally offers competitive analysis on the most recent technology, pattern, advancement, future scope, Industry Share, sales, revenue generation, investment analysis, and overall business scenario.

The most recent Electronic Grade Ammonium Hydroxide market report covers all significant perspectives like development driving components, opportunities, and challenges that will govern the business elements in the upcoming years. Additionally, it offers an inside and out an analysis of various industry segmentations to convey a reasonable image of the top revenue prospects in this business sphere.

Get Free Sample PDF (including Complete TOC, Tables and Statistics) of Electronic Grade Ammonium Hydroxide Market @ https://www.futuristicreports.com/request-sample/104448

The Electronic Grade Ammonium Hydroxide Report Assesses the Spectral Range of Business perpendicular. The Major Players Covered in this Report:

(BASFChuandong ChemicalJuhua Group CorporationMitsubishi GasJianghua Microelectronics MaterialsDenoir Ultra PureSuzhou Crystal Clear ChemicalInotecVijay Gas IndustryTaiwan Fertilizer)

By Type, the Segment is Split as:

By Type

ULSI

SLSI

XLSI

By the End-Users/Application, Sub-Segments are:

Electronics Cleaning Agent

Etching Agent

Regional Analysis for COVID-19 Impact on Electronic Grade Ammonium Hydroxide Market:

North America (The United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Spain etc.)

Asia-Pacific (China, Japan, Korea, India, Australia and Southeast Asia etc.)

South America (Brazil, Argentina, Colombia and Chile etc.)

Middle East & Africa (South Africa, Egypt, Nigeria and Saudi Arabia etc.)

Grab Exclusive Discpunt on the Report: https://www.futuristicreports.com/check-discount/104448

Why Choose Futuristic Reports?

Regional Forecast and Demand Requirement;

Pre-Commodity Pricing Volatility;

Technological Upgrades Analysis ;

Location Quotients Scrutiny;

Raw Material Sourcing Strategy;

Competitive Analysis;

Type Mix Matrix;

Vendor Management;

Cost-Benefit Analysis;

Supply Chain Optimization Reasoning;

Patent Analysis;

Carbon Footprint Reasoning;

R & D Analysis;

Mergers and Acquisitions;

Strategic Analysis Covered in TOC: - Key Topics

The report provides a summary of this Electronic Grade Ammonium Hydroxide market with a review of product types and drivers, restraints, challenges, traits using the companies data through our analysis methods. The report analyzes Electronic Grade Ammonium Hydroxide Industry capacity with forecast opportunities. The evaluation with a focus on leading regions of interest niches is presented. The company profiles with revenue plans and proportion estimation, Electronic Grade Ammonium Hydroxide market size, services and products, and different facets are all added.

Introduction

Research Methodology

Executive Summary

Premium Insights

Economy Summary

Electronic Grade Ammonium Hydroxide Market, By Types

Electronic Grade Ammonium Hydroxide Market, By Applications

Electronic Grade Ammonium Hydroxide Market, By Technology

Electronic Grade Ammonium Hydroxide Market, By Regions

Electronic Grade Ammonium Hydroxide Market, By Attributes

Competitive Landscape

Company Profiles

Set Inquiry for Before Buying or Customization of Report at: https://www.futuristicreports.com/send-an-enquiry/104448

Contact:

Futuristic Reports Tel: +1-408-520-9037 Email: [email protected] Media Release: https://www.futuristicreports.com/press-releases

Follow us on Blogger @ https://futuristicreports.blogspot.com/

0 notes