#Aluminum Sand Casting Companies

Explore tagged Tumblr posts

Text

Sand Casting Aluminum: A Comprehensive Guide

Sand casting, one of the oldest and most versatile metal casting processes, has been a staple in manufacturing for centuries. Regarding aluminum, sand casting offers a unique combination of precision, flexibility, and cost-effectiveness, making it a popular choice for various applications. This blog will delve into the sand casting aluminum, its advantages, the materials involved, and tips for achieving optimal results.

What is Sand Casting?

Sand casting is a metal casting process characterized by the use of sand as the mold material. The process involves creating a sand mold into which molten metal is poured. Once the metal has cooled and solidified, the sand mold is removed to reveal the finished part. This method is suitable for producing complex shapes and large components, making it a go-to technique for automotive and aerospace industries.

The Sand Casting Process for Aluminum

The sand casting process can be broken down into several key steps:

Pattern Creation: The first step involves creating a pattern of the part to be cast. This pattern can be made from various materials, including wood, metal, or plastic. The pattern is usually slightly larger than the final product to account for shrinkage during cooling.

Mold Making: The pattern is then used to create a mold. This is done by packing sand around the pattern, which is typically coated with a releasing agent to ensure it can be removed easily. The sand is often mixed with a binder to help it hold its shape. Once the pattern is removed, the mold consists of two halves, known as the cope and drag.

Melting Aluminum: In parallel with the mold-making process, aluminum is melted in a furnace. The melting temperature for aluminum typically ranges from 1220°F to 1290°F (660°C to 700°C), depending on the alloy used.

Pouring the Molten Metal: Once the aluminum is molten, it is carefully poured into the prepared sand mold. This step requires precision to ensure that the mold fills completely and to minimize the risk of defects.

Cooling and Solidification: After pouring, the aluminum is allowed to cool and solidify within the mold. The cooling time varies based on the size and thickness of the cast part.

Mold Removal: Once the aluminum has solidified, the sand mold is broken apart to remove the cast part. This is often done mechanically, depending on the size and complexity of the casting.

Finishing: The final step involves cleaning and finishing the cast part. This may include sandblasting to remove any remaining sand, machining to achieve precise dimensions, and surface treatments for improved aesthetics and protection.

Advantages of Sand Casting Aluminum

Sand casting aluminum has several advantages that make it an attractive option for manufacturers:

Cost-Effectiveness: Sand casting requires less expensive materials compared to other casting methods, and the molds can be reused multiple times, further reducing costs.

Versatility: This method can accommodate a wide range of shapes, sizes, and alloys. Whether you need small precision components or large structural parts, sand casting can deliver.

Good Surface Finish: Sand casting can achieve a reasonable surface finish, reducing the need for extensive post-processing.

Ease of Modifications: The pattern can be easily modified to make adjustments to the design without the need for complex tooling.

Scalability: Sand casting is suitable for both small batch production and large-scale manufacturing, making it adaptable to various production needs.

Applications of Sand Cast Aluminum

Aluminum sand casting is used across numerous industries. Some common applications include:

Automotive Components: Engine blocks, transmission housings, and other structural components.

Aerospace Parts: Brackets, housings, and structural components for aircraft.

Marine Applications: Boat hulls, engine components, and fittings.

Consumer Products: Cookware, tools, and decorative items.

Tips for Successful Sand Casting

To achieve optimal results in sand casting aluminum, consider the following tips:

Use Quality Materials: Invest in high-quality sand and binders to improve mold integrity and casting quality.

Optimize Pattern Design: Ensure the pattern is designed with appropriate draft angles and fillets to facilitate easy removal from the mold.

Control Pouring Temperature: Monitor the melting temperature of the aluminum and ensure it is poured at the correct temperature to minimize defects.

Manage Cooling Rates: Understand the cooling characteristics of aluminum and adjust the mold design to control cooling rates, reducing the risk of cracking.

Perform Quality Inspections: Regularly inspect the castings for defects such as porosity, shrinkage, and dimensional accuracy. This helps in identifying issues early in the process.

Conclusion

Sand casting aluminum remains a vital technique in modern manufacturing, offering numerous advantages in cost, versatility, and scalability. By understanding the sand casting process, its benefits, and best practices, manufacturers can produce high-quality aluminum parts that meet the demands of various industries. Whether you're looking to create intricate designs or large components, sand casting offers a reliable solution that has stood the test of time.

0 notes

Text

North America Metal Casting Market Size Analysis Report

Business Market Insights recently announced the release of the market research titled North America Metal Casting Market Outlook to 2030 | Share, Size, and Growth. The report is a stop solution for companies operating in the North America Metal Casting market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. North America Metal Casting Market report allows business to reduce their risks by offering a closer picture of consumer behavior, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, Business Market Insights is helping brands unlock revenue opportunities in the North America Metal Casting market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated North America Metal Casting market research has all that you need.

What are Key Offerings Under this North America Metal Casting Market Research?

Global North America Metal Casting market summary, current and future North America Metal Casting market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global North America Metal Casting Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the North America Metal Casting Market?

North America Metal Casting market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. North America Metal Casting market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their North America Metal Casting market share.

Report Attributes

Details

Segmental Coverage

Product Type

Carbon Steel Alloys

Stainless Steel Alloys

Aluminum Alloys

Grey Iron

Ductile Iron

and Others

Process

Sand Casting

Investment Casting

Gravity Die Casting

and Others

Application

Automotive

Aerospace

Marine

Textile

Building and Construction

Oil and Gas

Industrial Machinery

and Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Alcoa Corp

ArcelorMittal SA

Lucchini RS SpA

MEDEKO CAST Sro

Novacast Ltd

Posco Holdings Inc

Tycon Alloy Industries (HongKong) Co Ltd

Other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective North America Metal Casting market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

The Business Market Insights offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The North America Metal Casting market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

About Us:

Business Market Insights is a market research platform that provides subscription services for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductors, Aerospace & Defense, Automotive & Transportation, Energy & Power, Healthcare, Manufacturing & Construction, Food & Beverages, Chemicals & Materials, and Technology, Media & Telecommunications.

Contact Us: : www.businessmarketinsights.com

0 notes

Text

The Impact of New Tech on Aluminum Casting Production and Design

Adding new technologies like automation, modelling software, and advanced sensors has had a big effect on aluminium casting, which is an important part of making things. Automation speeds up output, lowers the cost of labour, and improves consistency. Engineers can use simulation software to make mould designs better and predict problems before they happen. This cuts down on waste and raises the quality of the casting. Advanced sensors keep an eye on important parameters, ensuring exact control over temperature and pressure. This makes the castings stronger. These improvements will have big effects on the business.

Historical Context of Aluminum Casting

Aluminium casting has been around for a long time, and it uses both old-fashioned ways and new technology. At first, methods like sand casting and die casting were done by hand. New techniques, such as investment casting and solid mould casting, have been added to these methods over time to make them better. Technology has changed the business world by making it easier to make things with complicated shapes and patterns.

Impact on Production Efficiency

New technologies in casting, like 3D printing and additive production, have changed the business by making it possible to make prototypes quickly and custom parts. Automation and robotics have sped up output by reducing mistakes made by humans and streamlining processes. Computer-aided design (CAD) and simulation apps are now necessary to make designs better and reduce errors.

Enhancements in Design Capabilities

Improvements in aluminium casting have made production much more efficient by cutting down on wait times and increasing production rates. These technologies cut down on waste, energy use, and labour costs, which makes the business more competitive. They also help make production more sustainable and eco-friendly, which makes it easier for businesses to meet the needs of growing customers.

Quality Control and Assurance

New technologies like computed tomography and ultrasonic testing have completely changed modern checking methods. Real-time tracking and data analytics allow for quick changes, which reduces defects and raises the consistency and dependability of the product, making sure that aluminium castings meet strict performance standards.

Sustainability and Environmental Considerations

Every Aluminium casting production company is now focusing on sustainability and the environment. They are using energy-efficient furnaces, melting metal more efficiently, and reducing waste through process control, closed-loop systems, recycling programs, and circular economy practices. All of these things help make the future more sustainable.

Challenges and Limitations of New Technologies

New technologies come with problems, like high costs and large beginning investments, which can hurt smaller businesses. To get the most out of technology, it's important to fill in skill gaps and train workers, and integrating new technologies into current systems needs careful planning.

Future Trends in Aluminum Casting Technology

New technologies, such as additive manufacturing and advanced simulation tools, are expected to change the aluminium casting industry. These technologies will likely increase automation, improve efficiency, and raise product quality, giving businesses chances to grow and come up with new ideas.

Final Thoughts

New technology has had a big effect on metal casting, making it more efficient, better quality, and cheaper. To stay competitive in a market that is changing quickly, manufacturers must use new technologies. Performance and sustainability will get even better as new ideas are brought to the production and creation of aluminium castings in the future.

0 notes

Text

Intake Manifold Casting: Designed for Powerful and Reliable Engines

An engine is the backbone of a vehicle and its performance is reliant on various parts working together. One of such parts is intake-manifold. It takes care that the proper amount of air and fuel mixture reaches engine cylinders to get optimum performance.

The significance of Intake Manifold Casing

The intake manifold casting has a very important role in an engine. It is used for the supply of air and fuel to every cylinder. The casting of the manifold provides endurance, precision and sturdiness. This eventually adds up to the performance and reliability of the vehicle. Precision casting is required to produce these manifolds, which will improve engine performance and durability.

What Casting Means for Intake Manifolds

Casting is a key component in the shaping of a manifold for specific engine requirements. Why high-quality cast parts are essential

Improved Performance- A well-cast air manifold optimizes the airflow and leads to better combustion.

Durability- The high-quality materials that are used to cast the parts provide durability and resistance to wear.

Improved Heat Resistance- Proper casting makes sure the manifold is able to withstand extreme temperatures.

Precision of Design- A manifold precisely cast ensures uniform air distribution and improves engine performance.

The Benefits of an Intake Manifold Casting that is Well-Designed

The efficiency and durability of an engine are directly affected by the design of a manifold. Following are some of the major advantages.

1. Enhanced fuel economy

This is to make sure that air and fuel are evenly distributed, which enables engines to combust fuel more effectively. This translates into improved mileage and lower emissions.

2. More engine power

Engines get a more efficient combustion with a smooth and continuous airflow. This leads to an improvement in horsepower and performance.

3. Long-Lasting performance

Castings made of durable and strong materials help manifolds to withstand extreme temperatures, thus ensuring their long-term durability.

Casting Materials and Manifold Manufacturing

The material used in casting is important for its durability and performance. Materials commonly used include:

Aluminium: Aluminum is lightweight and has excellent heat resistance properties.

Cast iron: Cast iron is known for its durability and strength, but it is heavier than aluminum.

Composite Material: Provides a balance of weight reduction and durability.

High-quality manifolds are beneficial to industries

Precision-cast manifolds are used by many industries including automotive, heavy equipment, and power generation. These manifolds improve the efficiency of gasoline and diesel engines. They ensure smooth operation across a variety of applications.

How to Choose a Reliable Supplier

It is important to select a manufacturer who has experience in casting manifolds. Companies such as AKP Ferrocast are experts in the production of high-quality manifolds by using advanced casting methods. They are known for their precision and durability.

What to consider when selecting an intake manifold

To ensure the best engine performance, it is important to consider several factors when choosing a manifold:

Engine Type- The manifold must be compatible with engine specifications.

Material quality- High-quality cast materials increase durability and heat resistance.

Design Efficient - A manifold with a well-structured structure improves fuel combustion and air flow.

Performance vs. Cost- It is important to strike a balance between affordability, and efficiency.

Evolution of Manifold Casting Technology

Over the years, casting techniques have evolved significantly. Modern casting techniques include

Sand Casting : is one of the oldest, most reliable ways to create durable manifolds.

Die Casting : Produces lightweight, precise manifolds. Commonly used in aluminum designs.

Casting 3D Printing : A new technology that improves precision and lowers production costs.

Conclusion

A properly designed intake manifold casting is essential to the efficiency, performance and longevity of an engine. Precision casting allows manufacturers to ensure high-quality components, which allow engines to run smoothly and reliably. A high-quality manifold is a great investment for industrial or automotive use. It can improve fuel efficiency and power while reducing costs over time.

0 notes

Text

How Aluminum Foundry Services Can Cut Down Production Costs

In the manufacturing industry, aluminium foundry services are essential because they make it possible to supply a spread of aluminium components using casting, melting, and finishing techniques. These services, which are crucial in sectors including consumer products, automotive, and aerospace, are customized to satisfy certain design specifications. Cutting costs has a significant impact on manufacturing's sustainability and profitability. By streamlining manufacturing procedures, lowering material waste, and improving product quality, using aluminium foundry services will result in considerable cost savings. Complex geometries and lightweight designs could also be produced, which reduces material costs and increases energy efficiency during usage and transit. These services' scalability enables companies to switch production levels in response to plug demands, reducing excess inventory and related expenses.

Understanding Aluminum Foundry Services

The manufacturing of aluminium castings for the buyer goods, automotive, and aerospace sectors is a component of Aluminium foundry service. Aluminium is melted and then poured into moulds to harden into acceptable forms. The scope includes design advice, tooling, and finishing processes, as well as casting. Sand casting, die casting, and investment casting are common methods for casting aluminium. Die casting is quicker and more accurate, while sand casting is cheaper and versatile. Investment casting provides excellent dimensional precision and surface polish. Large manufacturers and specialized foundries that extensively invest in cutting-edge technology to enhance production capabilities define the world. Casting quality has increased, and labour expenses have decreased because of advanced technology and automation. Operations are streamlined by software, which boosts productivity and reduces waste. For material efficiency, premium aluminium alloys are necessary, and efficient machining and recycling techniques facilitate a circular economy.

The Role of Technology in Cost Reduction

Technology is important for cutting costs since it increases accuracy and reduces manual work. Software solutions also make effective planning and resource allocation possible. By boosting throughput and reducing material waste, technology also improves efficiency and waste reduction.

Material Efficiency and Waste Management

Superior aluminium alloys are essential for performance and longevity, which lowers the necessity for replacements and repairs. Just-in-time production and lean manufacturing reduce waste and maximize material use. Reusing scrap and excess materials, as well as recycling and reusing materials in foundry processes, lowers costs and features a positive environmental impact.

Labor Cost Savings

By redistributing workers to skilled jobs, boosting their capacities, and increasing their capacity to adapt to new technology, automation lowers labour costs. Additionally, it reduces redundancies and simplifies processes by fixing effective procedures in place, which lowers labour costs overall. This leads to cost savings in foundry operations.

Economies of Scale

The benefits of large-scale production, including enhanced efficiency, better negotiating power with suppliers, cost advantages, lower costs per unit due to volume discounts, lower transportation and handling costs, and therefore the effect of production volume on unit costs, are mentioned as economies of scale.

Customization and adaptability

Prototyping plays a key role in cost-effective production, early design flaw detection, and client feedback. This text emphasizes the benefits of customization and adaptability in development, emphasizing the power to adapt products to specific needs, improve customer satisfaction, reduce costs through efficient design modifications, streamline change implementation processes, minimize waste, and more.

Quality Control and Assurance

While abiding by industry norms, upholding high standards of quality improves consumer trust and brand reputation. Defects and rework, however, will end in higher costs and even a loss of revenue. Staff training, the implementation of continuous improvement procedures, and continuous improvement processes themselves are all samples of effective quality management techniques.

Case Studies and Real-World Examples

Successful applications of aluminium foundry services are demonstrated through case studies and real-world examples, demonstrating creativity and efficiency. Testimonials from customers attest to the standard of the services provided, and businesses see measurable cost reductions. Pre- and post-implementation cost comparisons offer valuable insights into resolving typical production issues. Best practices and lessons learned from industry leaders are also covered.

Conclusion

Numerous benefits, including cost-effectiveness, design freedom, and improved product performance, are offered by aluminium foundry services. Businesses should consider these services because the manufacturing sector develops to satisfy production demands and keep a competitive advantage. Long-term financial advantages and increased operational efficiency are possible outcomes of those services.

0 notes

Text

How a Company Can Improve Production with an Aluminum casting supplier

Utilized in a sort of sectors, including consumer products, automotive, and aerospace, aluminum casting is an important part of the manufacturing industry. It's perfect for improving product performance and lowering weight due to its lightweight and corrosion-resistant qualities. Its accuracy and adaptability leave the assembly of intricate patterns and forms that satisfy contemporary technical specifications. By offering premium raw materials and cutting-edge casting technology, suppliers of aluminum casting materials increase production efficiency. Working with reliable suppliers shortens lead times, cuts waste, and improves internal control, which results in a more efficient manufacturing process and lower prices.

Understanding Aluminum Casting

Melted metal is poured into a mould during the aluminum casting manufacturing process to supply particular components and shapes. Sand casting, die casting, or permanent mould casting are often used, counting on the value, manufacturing volume, and required qualities. Due to its exceptional strength-to-weight ratio, resistance to corrosion, and thermal conductivity, aluminum could also be utilized in a good range of applications. Additionally, it reduces assembly procedures by enabling complicated geometries and elaborate designs. Because aluminum is so recyclable, it helps to scale back environmental impact and promote sustainability. It's frequently utilized in consumer products, automotive, and aerospace to enhance durability, performance, and fuel economy. Aluminum is a popular material in several industries due to its flexibility.

Selecting the proper Aluminum Casting Supplier

It is essential to carefully consider manufacturing capacity, industry standards, and financial stability when choosing an Aluminum casting supplier. By evaluating a supplier's technological prowess and expertise, you'll confirm they will satisfy project requirements, comprehend the method, and produce high-quality products while also adapting to changing industry expectations.

Establishing Strong Communication Channels

Clear communication, frequent meetings, and real-time feedback are all necessary for productive supplier collaboration. A collaborative atmosphere is promoted by putting tactics like frequent meetings and updates into practice. A simpler collaboration results from using technology to supply real-time information, which improves transparency and expedites problem-solving.

Implementing internal control Measures

Strict internal control procedures are necessary for the aluminum casting industry to ensure product quality and preserve supply chain integrity. Working alongside suppliers to determine precise quality standards and completing frequent audits and inspections strengthens adherence, lowers faults, and improves product dependability. To ensure customer satisfaction and build lasting partnerships with suppliers, this proactive approach is important.

Streamlining the availability Chain

By simplifying its supply chain, the aluminum casting sector will increase operating efficiency. Businesses will save lead times and inventory costs by identifying bottlenecks and inefficiencies through a radical study. Ensuring timely delivery of supplies and components entails streamlining order processing and building a solid logistical structure with suppliers.

Investing in Technology and Innovation

Modernizing aluminum casting procedures requires significant investments in innovation and technology. Cutting-edge tools like CAD and simulation software increase accuracy and hamper waste. Continuous improvement is promoted by supporting suppliers' adoption of creative approaches. Production efficiency is improved by integrating automation and digital technologies, which raises output and lowers operating expenses.

Training and Development

In order to take care of high standards in aluminum casting operations, worker growth and training are essential. It gives workers the know-how to handle cutting-edge equipment and uphold quality standards. A competent workforce is produced by working with suppliers on skill development projects, which benefits the entire supply chain. Innovation and excellence are fostered by continuous improvement for sustained industrial success.

Measuring Performance and Outcomes

Key performance indicators (KPIs) are essential for tracking the results of production improvement. They evaluate output rates, quality, and efficiency statistically. Frequent evaluation of supplier performance guarantees that suppliers fulfil requirements and make valuable contributions to the manufacturing process. Operational effectiveness is improved, and tactics are modified to address production and supplier contribution inadequacies in response to performance data.

Conclusion

There are several advantages to working with an aluminum casting supplier, including having access to top-notch materials and knowledge, which will enhance operational processes and production efficiency. For increased productivity and success in their production processes, companies should evaluate their existing supplier connections and take steps to make or strengthen alliances with suppliers of aluminum casting.

0 notes

Text

Bharat Engineering: Leading the Charge as Premier Automotive Casting Manufacturers

In the world of automotive manufacturing, the need for precision, quality, and reliability is paramount. Whether it's engine components, transmission parts, or chassis elements, every part needs to be expertly crafted to ensure performance and safety. Bharat Engineering, a leading name in the automotive casting industry, has established itself as a trusted manufacturer of high-quality automotive castings that meet the demands of the global automotive market.

Who is Bharat Engineering?

Bharat Engineering is a pioneering company specializing in the design, development, and manufacturing of a wide range of automotive casting products. With decades of experience in the field, Bharat Engineering has positioned itself as one of the top automotive casting manufacturers in the industry, serving a broad spectrum of clients from original equipment manufacturers (OEMs) to suppliers in the aftermarket sector.

The company operates with a strong emphasis on quality, precision, and innovation. They understand the critical role of casting in automotive production, ensuring that every part they manufacture is engineered to withstand the rigorous demands of modern vehicles.

The Importance of Automotive Castings

Automotive castings are essential to a vehicle’s performance, durability, and safety. These castings, typically made from metals like aluminum, steel, and iron, are used in various components such as engine blocks, cylinder heads, transmission housings, and brake components. High-quality castings provide strength, heat resistance, and long-lasting durability, all of which are essential for the efficient and safe operation of a vehicle.

Automotive casting manufacturers like Bharat Engineering play a crucial role in ensuring that these parts meet the highest standards of quality and precision. By using advanced manufacturing techniques and state-of-the-art technology, Bharat Engineering ensures that each automotive casting product meets strict tolerances and is free from defects, ensuring optimal performance.

Why Choose Bharat Engineering for Automotive Castings?

State-of-the-Art Manufacturing FacilitiesBharat Engineering invests heavily in its manufacturing capabilities. The company utilizes advanced casting technologies such as sand casting, die casting, and investment casting, enabling them to produce parts with exceptional accuracy and strength. Their manufacturing facilities are equipped with the latest machinery, ensuring that all castings meet international standards and industry requirements.

Customization and VersatilityOne of the key strengths of Bharat Engineering is its ability to provide customized solutions. Whether it’s a highly complex casting or a mass-produced component, Bharat Engineering can design and manufacture castings tailored to the specific needs of their clients. This flexibility allows them to serve a wide range of automotive sectors, from small car manufacturers to large commercial vehicle producers.

Quality AssuranceAt Bharat Engineering, quality is not just a buzzword; it is embedded in every stage of production. The company follows a stringent quality control process, with multiple checks throughout the manufacturing cycle. Each product undergoes rigorous testing to ensure it meets the highest standards for dimensional accuracy, strength, and durability. This commitment to quality ensures that their customers receive automotive castings that perform optimally, even under the most challenging conditions.

Cost-EffectivenessBharat Engineering’s experience and scale allow them to offer competitive pricing without compromising on quality. The company’s efficient manufacturing processes help reduce wastage and production time, enabling them to pass on cost savings to their clients. This makes Bharat Engineering an attractive partner for OEMs and suppliers looking for high-quality castings at a reasonable price.

Sustainability and Environmental ResponsibilityAs environmental concerns continue to grow, Bharat Engineering is committed to sustainability. The company employs eco-friendly casting processes and practices waste reduction techniques to minimize its environmental footprint. They also use recycled materials whenever possible, helping reduce the demand for raw resources and lowering the overall environmental impact of their operations.

Key Automotive Components Manufactured by Bharat Engineering

Bharat Engineering specializes in a wide array of automotive castings, including:

Engine BlocksEngine blocks are at the heart of every vehicle’s performance. Bharat Engineering manufactures robust and high-strength engine blocks using advanced casting techniques. These blocks are designed for optimal thermal efficiency and strength, ensuring a long lifespan and superior performance.

Transmission PartsTransmission systems require components that can withstand immense torque and stress. Bharat Engineering produces transmission housings, gearboxes, and other transmission parts that are engineered for precision and durability.

Brake ComponentsAutomotive brake systems are critical to vehicle safety. Bharat Engineering’s castings for brake rotors, calipers, and other braking system components are designed to deliver high performance and reliability, even under extreme conditions.

Suspension and Chassis ComponentsBharat Engineering produces a variety of suspension and chassis components such as control arms, knuckles, and crossmembers. These parts are designed to provide strength, durability, and weight reduction, improving overall vehicle handling and safety.

Exhaust and Emission Control PartsWith the automotive industry’s growing focus on sustainability, Bharat Engineering manufactures components for exhaust systems and emission control, including catalytic converter housings and muffler parts, using materials designed to withstand high temperatures and corrosive environments.

Innovation and Future of Automotive Castings

As the automotive industry evolves with advancements in electric vehicles (EVs), autonomous technology, and lightweight materials, Bharat Engineering continues to innovate. The company is actively working on developing new casting techniques to produce lighter, stronger, and more cost-effective components, particularly for the emerging electric vehicle market.

With the shift towards EVs, castings for electric motor housings, battery enclosures, and power electronics have become increasingly important. Bharat Engineering is at the forefront of this shift, exploring new materials and casting methods that meet the unique requirements of the electric vehicle industry.

Conclusion

Bharat Engineering has established itself as a leader in the automotive casting industry, offering a comprehensive range of high-quality components that meet the demands of modern vehicles. With a focus on precision, innovation, and sustainability, Bharat Engineering continues to push the boundaries of what’s possible in automotive casting manufacturing. Whether you are an OEM, a Tier 1 supplier, or a manufacturer in the aftermarket sector, Bharat Engineering is a trusted partner in delivering reliable, high-performance casting solutions.

For businesses looking for reliable automotive casting manufacturers, Bharat Engineering offers the expertise, technology, and commitment to quality needed to drive success in the competitive automotive market.

0 notes

Text

10 Different Types of Casting Process Used in Manufacturing

The article aims to discuss the various kinds of casting processes that are used globally in the manufacturing industry for producing quality products.

There has been a notable increase in the industrial products. That should not be a problem, because there are several kinds of metal casting services. With the help of these services, complex products can be effortlessly manufactured.

In order for the firm or company to choose the right or specific kind of casting manufacturing process, they need to first know the different types of casting processes that are used in the manufacturing industry.

Each of the casting process methods comes with its own benefits and flaws. A brief overview of various types of casting processes has been provided in the article.

What is the casting process?

The casting process is a method where the metal parts are produced according to the specific needs of the clients. It is done by pouring the molten metal into a mould. Then once it has been poured, hardened, and cooled, the desired shapes are designed.

So, casting helps industries achieve their goal of having the metal pieces according to their shapes, ideal for mass production. Besides, there are several kinds of casting that can immensely help to satisfy the user requirements.

What are the different types of Casting Processes?

There are different kinds of casting processes that can be used according to the needs of the user.

Sand Casting Process

The sand casting is a simple process of casting that helps cast ferrous or non-ferrous metal alloys. This method is mostly used for the production of metals that find applications in the automobiles like the engines, cylinders, and crankshafts.

The mould is produced from silica-based substances that can be naturally bonded. Then it is used to produce a mould surface that is smooth. The mould surface consists of two parts namely, cope (the upper half) and drag (the lower half).

Then the molten metal is poured into the desired pattern. Then it is left to harden so that it can form the final shape. The excess metal is removed in the final metal casting product.

Gravity Die Casting

This method is also called permanent mould casting. Here the metal and the metal alloys are fabricated using the moulds that come reusable. They can be steel, graphite, and the like. The metal casting process can be used to make items like gears, pipe fittings, wheels, and so on.

The molten metal is directly poured into the mould cavity. This happens when there is an influence of gravity, where the die is angled to adjust the filling. Then, the molten metal is let to cool down so that it can solidify inside the mould.

This method uses the mould from the bottom up, which enables it to have a greater casting rate than sand casting. But it can be somewhat costly than most methods.

Pressure Die Casting

There are two types of die casting, namely low-pressure die casting and high-pressure die casting. Low-pressure die casting is used for the production of large components. The high-pressure die casting is used in the production of geometrical shapes that need very high precision.

Some examples would be nonferrous metals like zinc, tin, copper, and aluminum.

Investment Casting

This type of casting is also known as lost-wax casting. Here the metals are produced by using the wax pattern of the metal. Then a refractory material and a binding agent are used. This is done so that the exact shape is obtained, and the molten metal can be poured into the mould.

It is a labour-intensive process that is expensive as well. This method is used to produce several products like gears, bicycle trunks, moto discs, and blasting machine replacements.

Plaster Casting

The casting process makes use of the mould that contains ‘Plaster of Paris.’ Here, the plaster is allowed to cool and then the metal is let to dissolve in the contents, due to the limited thermal conductivity.

This helps achieve high precision. The method is used to produce cross-section pieces that are narrow & need to fit in small gaps. It helps in the production of small castings that contain small amounts of castings of 45 kgs.

Centrifugal Casting

This kind of casting is called roto casting where cylindrical objects are produced for industrial applications. It is done with the help of the centrifugal forces. Here the metal is poured into the spinning die of the metal casting.

Then at high pressure with the help of the centrifugal forces, the molten metal is shaped inside the die. Because the spinning happens constantly, the metal that is in molten form takes the shape of the centrifugal casting.

Examples can include bush bearings, clutch plates, piston rings, and cylinder liners.

Lost-Foam Casting

This method is almost the same as the investment casting. However, the pattern is made of foam, and not from wax. When the design of the metal has been produced, the casing is coated with a refractory ceramic.

Then the molten metal is poured into the mould. The method is used to produce alloy steel, carbon steel, alloy cast iron, and ferrous alloys.

Vacuum Casting

This kind of casting method happens under a vacuum pressure of 100 bar. This is done to help the exhaust gas from the mould. Besides, it helps remove the bubbles and air pockets, when the molten metal is poured inside a vacuum chamber.

Then the metal is cured in a heating chamber. The products formed are commonly used in the automotive, aerospace, electronics, marine, and telecommunications.

Squeezing Casting

In this casting method, the high pressure is used for preventing shrinkage. But due to the specialised tooling requirements, it can’t be used for large production. Some products include space frame joints, aluminum front steering knuckles, chassis frames, and brackets.

Continuous Casting

In this type of casting the production of metals profiles comes infused having a constant cross-section. It is mainly used for the production of steel bars. Besides, it can be also used for semi-continuous casting.

The molten metal allows a solid metal surface to form on the liquid metal. The solidification of the metal happens from the outside. Then the remaining strands of the metal can be taken away from the mould.

Conclusion

This is it. These were some of the most popular casting methods that are used in the market. Each method has its own pros & cons. From the above article, it becomes obvious that choosing the appropriate casting method is critical for producing sublime products. With so many different types of casting methods metal components can be produced. It becomes crucial that the right kind of casting method is used to produce quality goods.

0 notes

Text

What are the Machined Castings and Their Benefits

The metal machining and casting processes are often portrayed as a “pick one or the other” comparison for fabricators. But as we hinted in our recent article about casting vs. machining, there are many cases where the most efficient means of production will leverage both casting and machining together.

This article summarizes the benefits of machining castings and how to ensure you can incorporate both of these manufacturing processes into your next design.

A machined casting is a part that was first cast into a semi-finished product, then finished with precision CNC machining.

You can produce the initial castings using one of several casting methods, such as die casting, investment casting, or sand casting. However, each of these casting methods tends to have its own drawbacks, like a rough surface finish or the inability to make certain design features.

CNC machining helps improve product quality and adds missing design elements. You can use one or more machining processes — like CNC milling, turning, drilling, sawing, or a less conventional machining method — to help create premium finished products.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Machining 6061 Aluminum from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.lication: Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect.

The Benefits of Machining Castings

The machining of castings has two primary benefits:

Adding features and removing unwanted as-cast material. Improving precision and surface finish. To better understand why these benefits are so important, let’s explore the applications relevant to each one.

1) Modifying As-Cast Parts Turbine with curved fins Parts that technicians have only just removed from their casting mold are considered “as-cast.” The manufacturer hasn’t subjected them to machining, sandblasting, or another finishing process.

These parts will typically have unwanted excess material from the gating system, parting lines, and any risers or vents your manufacturer included in the casting setup. At a minimum, fabricators must use simple cutting tools to remove unwanted overpour material. And if multiple parts are cast in a shared mold to improve efficiency, technicians must cut them from the gating system individually.

Producers must use more intensive CNC machining for higher quality parts to meet the product design and remove parting lines. Doing so can help hide the most obvious signs of casting and significantly improve finished quality.

Another key factor in modifying as-cast parts is the addition of features that you cannot effectively produce using casting. For example, you can’t produce the curved fins on a turbine (like the one seen above) using a permanent mold because you cannot separate the mold halves after the casting material hardens.

And while you could use a technique like investment casting to address casting designs where you cannot remove the mold halves, many other casting challenges could make machining the preferred solution. For example, holes, grooves, and threads are often much higher quality when produced by CNC machining.

2) Improving Finished Quality Surface roughness meter checking machined casting Even if a casting does not need additional machined features and you can easily remove the overpour material, precision CNC machining is an essential step for top-quality parts.

Casting methods like die casting produce a superior surface finish relative to other casting methods, so they may only need minor machining touchups to remove parting lines. But machining castings becomes essential for parts produced by sand casting and investment casting if they must have a smooth surface finish.

The other essential reason for machining castings is to improve accuracy and precision on parts with strict tolerance limits. Modern CNC machines can achieve a much higher degree of precision than casting.

Fabricators that need to produce a large volume of identical parts can take advantage of casting to save cost, then use CNC machining to meet tolerance requirements. But to do this, designers must account for machining allowances in the casting stage.

Adding Machining Allowances to Your Designs Die cast magnesium gear housing (machined casting) Regarding machined castings, designers must incorporate machining allowances into the mold design so that as-cast parts have enough material for precision machining.

For example, imagine your finished part has a small protrusion with tight tolerances. If the mold design has a feature the same size as the protrusion, any shrinkage or porosity will make the feature smaller than it was supposed to be. If you need any machining to improve the surface finish or refine the shape of the protrusion, machinists would be forced to remove even more material or risk leaving the part rough and unfinished.

Adding machining allowances to your part design slightly increases the size of any as-cast parts or part features that the manufacturer will finish with CNC machining. These allowances help fabricators consistently meet tolerance requirements with fewer rejected parts while significantly reducing machining times.

XTJ is a leading OEM Manufacturer that is dedicated to providing one-stop manufacturing solutions of Machining 6061 Aluminum from prototype to production. We are proud to be an ISO 9001 certified system quality management company and we are determined to create value in every customer relationship. We do that through collaboration, innovation, process improvements, and exceptional workmanship.lication: Automotive industry, Bicycle and motorcycle, Door and windows and furniture, Household appliance, Gas meter, Power tool,LED lighting, Medical instrument parts, ect.

What Are The Machined Castings And Their Benefits? - Online Manufacturing For Metal Parts And Plastic Parts, XTJ Precision Mfg Ltd 2024 May (cncpartsxtj.com)

0 notes

Text

Is Sand Casting Strong? Unveiling the Strength of Sand Cast Components

When it comes to manufacturing metal parts, sand casting has remained one of the most traditional yet highly effective processes in the foundry industry. But one question that frequently arises is, Is sand casting strong? To truly understand the strength of sand-cast components, we must dive into the process, material characteristics, and factors that contribute to the strength of sand casting.

Understanding Sand Casting

Sand casting is a versatile and widely used method for producing metal parts. It involves creating a mold from sand, pouring molten metal into the mold cavity, and allowing it to solidify into the desired shape. The process is highly flexible and cost-effective, making it popular in a wide range of industries such as automotive, aerospace, agriculture, and heavy equipment manufacturing.

The materials used in sand casting molds are usually silica sand mixed with bonding agents like clay or chemical binders. This combination creates a highly heat-resistant mold that can withstand the temperatures required for casting various metals, including iron, aluminum, steel, and bronze.

The Mechanics of Sand Casting: What Influences Strength?

The strength of sand-cast components depends on several factors, including the choice of metal, the design of the casting, the sand used in the mold, and the casting process parameters. To better understand the question, "Is sand casting strong?" let’s examine the key aspects influencing the strength of sand-cast products.

1. Material Selection

The strength of sand-cast parts is significantly influenced by the type of metal being cast. Different metals have inherently different mechanical properties, such as tensile strength, hardness, and durability. For instance:

Aluminum is lightweight but has lower tensile strength compared to other metals like steel or cast iron.

Cast iron provides excellent compressive strength, making it suitable for components subjected to high loads.

Steel offers the best balance between tensile and compressive strength, providing exceptional durability for various applications.

Therefore, the choice of metal depends on the end-use of the component. A sand casting company specializing in high-performance materials can tailor their casting process to maximize the strength properties of the chosen metal.

2. Sand Mold Quality

The quality and composition of the sand used in the casting mold play a crucial role in determining the final strength of the cast product. Factors such as sand grain size, moisture content, and the type of binder affect the surface finish, dimensional accuracy, and structural integrity of the casting.

Fine-grained sand leads to smoother finishes and more intricate detail in castings, but it may be less permeable, which can affect metal flow and cooling.

Coarser sand can improve mold permeability and cooling rates, but may result in a rougher surface finish.

Additionally, the strength of the mold itself is essential for withstanding the thermal and mechanical stresses of casting. Mold failure or deformation can lead to defects in the casting, compromising its strength.

3. Pouring and Cooling Process

The pouring and cooling phase of sand casting is another critical factor influencing the strength of the final product. Rapid or uneven cooling can lead to internal stresses, warping, and even cracks in the metal, all of which weaken the component.

A well-controlled cooling process ensures uniform solidification, preventing the formation of voids, cracks, or unwanted stress concentrations. Sand casting companies use advanced techniques like simulation software and thermal analysis to optimize the cooling phase, ensuring the mechanical strength of cast components.

4. Casting Design

The design of the casting is vital for both functionality and strength. Features such as wall thickness, fillet radii, and draft angles must be considered carefully to prevent weak points and stress concentrations in the final component. For example:

Thicker sections in a casting are more prone to shrinkage defects during cooling, potentially reducing the strength of the part.

Sharp corners can act as stress risers, leading to crack initiation under load.

Therefore, optimizing the casting design for strength is a critical step in producing durable, high-performance components.

Comparing Sand Casting with Other Casting Methods

To put sand casting strength into context, it’s helpful to compare it with other popular casting methods, such as die casting and investment casting.

1. Die Casting

Die casting uses a permanent metal mold and high pressure to force molten metal into the mold cavity. It produces parts with excellent dimensional accuracy and surface finish, and it is often used for high-volume production.

While die-cast parts are typically stronger due to the denser microstructure produced by high-pressure casting, sand casting offers greater flexibility in terms of size, material choice, and design complexity. For large or complex components, sand casting remains a viable option where die casting may be impractical.

2. Investment Casting

Investment casting, also known as lost-wax casting, produces parts with exceptional precision and surface finish. However, it is generally more expensive and time-consuming than sand casting, making it less suitable for producing larger components or those with less stringent dimensional tolerances.

In terms of strength, investment-cast parts can be comparable to sand-cast parts, depending on the metal used and the specific application. However, for heavy-duty industrial components, sand casting remains a popular choice due to its ability to produce robust, large-scale parts at a lower cost.

Common Applications of Sand Casting

Despite advancements in casting technology, sand casting continues to be a preferred choice for various industries due to its unique advantages. Its strength and versatility make it suitable for a wide range of applications, including:

1. Automotive Industry

Sand casting is extensively used in the automotive sector to produce engine blocks, transmission housings, and other critical components. The ability to cast metals like aluminum and cast iron, along with the flexibility of design, allows manufacturers to produce strong, lightweight, and cost-effective parts.

2. Aerospace and Defense

The aerospace and defense industries rely on sand casting to produce complex, high-strength components such as turbine blades, engine parts, and structural components. The ability to work with high-performance alloys ensures that sand-cast parts meet the stringent strength and durability requirements of these industries.

3. Agricultural and Heavy Equipment

For agricultural and heavy machinery, strength and durability are paramount. Sand casting is used to produce components like gears, housings, and brackets that must withstand heavy loads and harsh operating conditions. The versatility of the sand casting process allows manufacturers to create rugged, long-lasting parts that are vital to the performance of these machines.

Enhancing the Strength of Sand-Cast Components

While sand-cast components are inherently strong, various post-casting processes can further enhance their mechanical properties. Techniques such as heat treatment, surface finishing, and machining can improve the strength, hardness, and wear resistance of the cast parts.

Heat treatment can be applied to alter the microstructure of the metal, increasing its strength and toughness.

Surface finishing techniques, such as shot blasting or grinding, can remove surface imperfections and improve the overall durability of the component.

Many sand casting companies offer these value-added services to ensure that their cast components meet the specific strength requirements of their clients.

Conclusion: Is Sand Casting Strong?

The short answer is yes—sand casting is strong. The strength of sand-cast components depends on various factors, including material selection, mold quality, casting design, and casting process control. While it may not always offer the same level of precision as methods like die casting or investment casting, sand casting excels in producing robust, durable components for a wide range of industrial applications.

With the right expertise and equipment, a sand casting company can tailor its processes to produce high-strength components that meet the rigorous demands of industries like automotive, aerospace, and heavy machinery. By understanding and optimizing the factors that influence strength, manufacturers can ensure that sand cast parts perform reliably in even the most demanding applications.

So, if you're considering sand casting for your next project, rest assured—it’s not just a cost-effective method, but a process capable of producing parts with exceptional strength and durability.

0 notes

Text

Global Top 5 Companies Accounted for 74% of total Ceramic Sand (for Casting Use) market (QYResearch, 2021

Ceramic Foundry Sand, technically named as “Fused Ceramic Sand for Foundry”, also named as ceramite, is good spherical grain shape which is made from calcined bauxite. Its main content is aluminum oxide, and it is processed by melting, blowing, sieving and blending. Ceramic sand, has much better properties than that of silica sand to gain a better performance in foundry. It has high refractoriness, stable inert characteristics, excellent flowability, intrinsic hardness and wear resistance.

Ceramic Foundry Sand has the following characteristics:

The thermal expansion coefficient of ceramic sand is very low, which is similar to zircon sand. Using the Ceramic Foundry Sand to make moulds and cores, the veins and other expansion defects of castings are eliminated;

Because of the great spherical shape of the particle, Ceramic Foundry Sand has good flowability and easy to fill in. The moulds and cores are of high permeability and easy to shakeout after casting;

By using Ceramic Foundry Sand, 30-50% of the binder consumption can be saved with the smooth surface and substantial structure;

Ceramic Foundry sand is a neutral and inert material, so it can be used in acid and alkali binders systems, also adapt to various alloys;

Ceramic Foundry Sand has high refractoriness and good stability. It is especially suitable for the production of complexity sand cores and steel castings;

It has wide particle size, which can be combined and mixed arbitrarily to meet specific needs of customers;

Because of the high value of Moh’s Harness and spherical shape, Ceramic Foundry Sand has good recycling performance and low crushing ratio, so it can be easily reclaimed by many methods.

In 2020, the global Ceramic Sand (for Casting Use) market size was US$ 169.10 million and it is expected to reach US$ 251.65 million by the end of 2027, with a CAGR of 5.39% between 2021 and 2027.

The data for 2021 is an estimate, based on the historical data and the integrated view of industrial experts, manufacturers, distributors, and end users, etc.

Top-down and bottom-up approaches are used to validate the global Ceramic Sand (for Casting Use) market size and to estimate the market size for company, regional division, product type and application (end users). In the complete market engineering process, both top-down and bottom-up approaches along with several data triangulation methods have been extensively utilized to perform market estimation and market forecast for the overall market division and subdivision listed in this report. Extensive qualitative and further quantitative analysis has also been done from all the numbers arrived at in the complete market engineering process to list key information throughout the report.

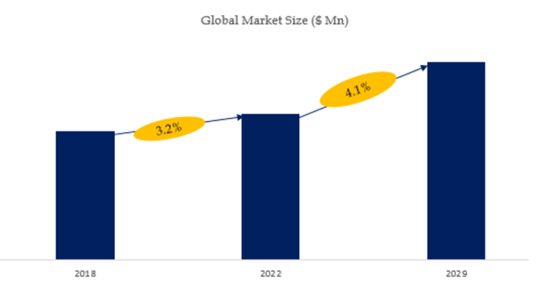

According to the new market research report “Global Ceramic Sand (for Casting Use) Market Report 2023-2029”, published by QYResearch, the global Ceramic Sand (for Casting Use) market size is projected to reach USD 0.27 billion by 2029, at a CAGR of 4.1% during the forecast period.

Figure. Global Ceramic Sand (for Casting Use) Market Size (US$ Million), 2018-2029

Figure. Global Ceramic Sand (for Casting Use) Top 5 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Ceramic Sand (for Casting Use) include CARBO Ceramics, Kailin Foundry, Itochu Ceratech, Sanmenxia Qiangxin, Jingang New Materials, Henan Jinnaiyuan, CMP Group, Company 8, Company 9, Company 10, etc. In 2021, the global top five players had a share approximately 74.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Metal Casting Service: How to Choose the Best Method and Material for Your Project

Metal casting has been a cornerstone of metalworking for art and industrial projects since 3200 BCE, and it has evolved to produce a wide array of objects such as weapons, jewelry, and components for the automotive, electronics, aerospace, machinery, and medical industries. This method is ideal for creating both simple and intricate metal parts more efficiently and cost-effectively than other techniques, including CNC prototyping.

However, for certain projects, blending CNC machining with metal casting delivers the best of both worlds: speed and precision. If you're deciding which method suits your project best, consult with an experienced service providerwho can assist you in choosing the appropriate materials and metal casting techniques.

Which metal casting method and material should you choose?

Your choice depends on factors like your part’s design, shape, size, strength, purpose, and quantity, as well as the desired surface finish, cost, and project timeline. Regardless of your design, take the time to check it against your preferred manufacturing process to determine if you need to make any changes. Here are some of the popular metal casting services:

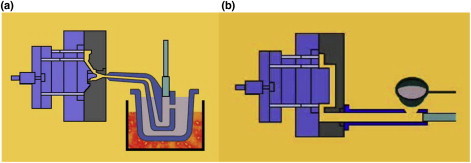

Hot chamber or gooseneck die casting: Hot chamber is the most commonly used die casting process where a chamber of an injection system is immersed in molten metal, while a gooseneck metal feeder delivers the metal into the cavity.

Cold chamber die casting: Where machine corrosion is a concern, cold chamber die casting can be the alternative to the hot chamber method because it doesn’t immerse the injection system into molten material.

Sand casting: A tried-and-true metal casting method that uses hardened sand to make complex parts.

Selecting the best materials

Whether CNC prototyping or metal casting, material selection ultimately depends on what you’re making, the quantity, and the function. Pressure die casting can deliver high-quality parts in high volumes using materials like magnesium, zinc, and aluminum. These materials are versatile for making prototypes and end-use parts. Additionally, consider the environmental factors that can impact your design, the material properties, and the part’s life cycle.

Get expert help

Let HLH Proto take the guesswork out of selecting the best methods and materials for metal casting and CNC prototyping. The company’s seasoned engineers and toolmakers are ready to assist to ensure your project’s success. Send the quote request form today to get started.

0 notes

Text

Care and Protection of Outdoor Furniture

Expert Care and Protection of Outdoor Furniture to Keep Your Outdoor

Imagine sitting in your backyard with the sounds of nature all around you. Your lovely outdoor furniture makes the space feel warm and inviting, expanding your living area and giving you a lot of chances to relax and have fun. But if you want this dream to come true, you need to take the time to take care of your outdoor furniture. Here is a complete guide to making sure it lasts as long as possible and looks great:

Specialized Care for Materials:

Teak Wood: Teak is valued for its fine grain and ability to resist water. Over time, it gets a lovely silver sheen. But cleaning it often with mild soapy water and a soft brush keeps dirt and mold from building up. You might want to use a teak cleaner and brightener once in a while for a better clean.

Powder-Coated Aluminum: Aluminum that has been powder-coated: This low-maintenance material doesn't rust or corrode. Wipe it down with light soapy water and dry it with a soft cloth to clean. Don't use rough cleaners on the surface; they can damage it.

Marine-Grade Plastic: This type of plastic is strong enough to survive rough weather and is great for places that are wet or near the coast. It stays in good shape by cleaning it every so often with mild soapy water and a soft cloth. Using a weak bleach solution and then washing the item well can help get rid of stubborn stains.

Wrought Iron: Even though cast iron is very strong, it can rust in damp places. It is important to clean it regularly with mild soapy water, paying special attention to cracks and joints. If you see rust, sand it off and paint over the spot. You might want to think about powder covering for extra safety in tough settings.

HDPE (High-Density Polyethylene): is an eco-friendly material that doesn't fade, crack, or split. Cleaning it once in a while with light soapy water and a soft cloth works. If necessary, a weak bleach solution can be used to get rid of tough spots.

Tips for Basic Care Being Cleaning

Cover When Not in Use: Buy covers for your outdoor furniture that won't get damaged by the weather, especially during bad weather or long times of not being used. This adds another layer of defense against fading, water damage, and dirt.

Store Cushions Indoors: Cushions that can be taken off add comfort and style, but they can fade and grow mold if they are stored outside. When not in use, keep them inside, ideally in a bag that lets air flow.

Place carefully: Don't leave furniture out in full sunlight for long periods, as this can speed up the fading process. Use shields or places with shade to protect yourself from the sun's strong rays.

Take Care of Spots: Spills and spots should be taken care of right away to keep them from setting. Always follow the cleaning instructions that come with your furniture to get the best results.

Why regular inspection is important:

Inspections at certain times of the year help find small problems before they get worse. Check for cracks, bending, paint that is coming off, broken screws, and rust. Taking care of these early on will keep you from having to make bigger fixes or replacements later on.y on saves you from larger repairs or replacements later.

Maintenance:

If you need to fix something complicated or clean a lot of big pieces of furniture, you might want to get professional help. Professionals have the skills and tools to bring your furniture back to its former beauty.

The Sitoro Advantage:

Sitoro, a top company in Pune, India that makes outdoor furniture, knows how important it is to have furniture that lasts and doesn't get damaged by the weather. Their use of high-quality materials, skilled work, and careful building methods guarantees that your outdoor furniture will last for years to come. They also sell a variety of care and upkeep items that are made to keep your investment looking great and lasting a long time.

By taking these steps to care for and protect your outdoor furniture, you can make sure it lasts for many years. Your backyard retreat becomes an extension of your home and a reminder of how beautiful well-kept furniture can look for a long time. Remember that a little care will go a long way toward protecting your outdoor paradise and making sure that you can enjoy those moments of rest and fun for many years to come.

0 notes

Text

Gamma Foundries is a non-ferrous sand castings company. They produce aluminum casting, copper base alloy casting and stainless-steel sand castings from one-off to thousands for a wide variety of industries. Gamma Foundries also has a no-bake molding op…

0 notes

Text

A Fusion of Craftsmanship and Foundry Mastery

In the realm where raw materials are reborn as works of art, the art of metal casting stands as a testament to human ingenuity. It's a delicate dance between tradition and innovation, craftsmanship and technology. This is the world where custom brass castings, the legacy of gray iron casting foundries, and the allure of non-ferrous metals come to life.

A Symphony of Skill and Creativity: Picture a skilled artisan meticulously crafting a mold, pouring molten metal into its waiting cavity, and watching as it cools and takes on its final form. This is the essence of custom-specified brass castings and metal foundries. Each piece is a unique creation, born from the fusion of an artisan's skill and the malleability of metals.

Casting Foundry: In a world of constant change, the gray iron casting foundry remains a bastion of tradition. With a legacy dating back centuries, these foundries embrace time-tested techniques that have been passed down through generations. Gray iron casting involves pouring molten iron into molds, producing sturdy and versatile components used in various industries.

Unveiling Non-Ferrous Metals: Beyond the realm of iron lies the allure of non-ferrous metals like copper, aluminum, and zinc. These metals possess unique properties that make them sought after for both artistic and industrial applications. From the warm, glowing hues of copper to the lightweight versatility of aluminum, non-ferrous metals offer a canvas for creativity that extends beyond the conventional.

Crafting the Future with Innovation: While tradition forms the backbone of metal casting, innovation propels it into the future. Modern techniques and technology enhance precision and efficiency, allowing artisans and foundries to push the boundaries of what's possible.

Each piece crafted is a testament to the enduring marriage of artistry and foundry expertise, embodying the potential of raw materials to transform into something truly extraordinary. If you are looking for non ferrous metal foundry, you can get in contact with Illini Foundry. For more than eight decades, Illini Foundry Company (IFC) has been catering to clients across the country from our 12,000-square-foot green sand foundry in Central Illinois's Peoria Metro region. Originally Published at- https://melodious-fowl-fb9.notion.site/A-Fusion-of-Craftsmanship-and-Foundry-Mastery-5b7cd3147e814770b4cac94d7f0887bb?pvs=4

0 notes

Text

Aluminum Casting Market: Competitive Landscape and Strategic Insights for Industry Players

The aluminum casting market refers to the global industry involved in the production and supply of aluminum castings. Aluminum casting is a manufacturing process that involves the pouring of molten aluminum into a mold to create various shapes and sizes of solid metal components. These castings are widely used in a wide range of industries, including automotive, aerospace, construction, electrical, and consumer goods.

Here is some comprehensive information about the aluminum casting market:

Market Overview:

The aluminum casting market has experienced significant growth over the years, driven by the increasing demand for lightweight and durable components in various industries. Aluminum castings offer several advantages, including excellent corrosion resistance, high strength-to-weight ratio, good thermal conductivity, and high dimensional stability.

Types of Aluminum Castings:

There are several types of aluminum castings, including die casting, sand casting, permanent mold casting, and investment casting. Die casting is the most common method and involves injecting molten aluminum under high pressure into a steel mold. Sand casting utilizes sand molds, while permanent mold casting uses reusable molds made of steel or iron. Investment casting involves creating wax patterns that are coated with ceramic, and the molten aluminum is poured into the ceramic mold.

Market Drivers:

The aluminum casting market is primarily driven by the growth in industries such as automotive and aerospace. The automotive industry, in particular, demands lightweight components to improve fuel efficiency, reduce emissions, and enhance overall performance. Aluminum castings provide an ideal solution due to their lightweight nature and strength. Additionally, the aerospace industry relies on aluminum castings for various critical components due to their high strength and heat resistance.

Market Trends:

a. Increasing Use of Aluminum in Electric Vehicles: The growing demand for electric vehicles (EVs) has led to an increased use of aluminum castings in their production. Aluminum components, such as motor housings, battery enclosures, and structural parts, help reduce the weight of EVs and improve their range.

b. Adoption of Advanced Casting Technologies: The aluminum casting industry is witnessing the adoption of advanced technologies such as computer-aided design (CAD), computer-aided engineering (CAE), and simulation software. These technologies enable manufacturers to optimize casting designs, reduce defects, and enhance overall product quality and efficiency.

c. Sustainable Practices: The aluminum casting market is also focusing on sustainable practices by implementing recycling programs for aluminum scrap. Recycling aluminum not only reduces waste but also helps conserve energy and natural resources, making it an environmentally friendly choice.