#Aluminum Alloys in Additive Manufacturing trends

Text

Aluminum Alloys in Additive Manufacturing Market Size 2022 Research Report by, Companies, Product Types, End users, Market Dynamics and Forecast to 2027

Aluminum Alloys in Additive Manufacturing Market Size Analysis and Insights 2022:

Aluminum Alloys in Additive ManufacturingMarket Report 2022, the business scene is covered from driving variables to upstream business sectors and the general condition of the market. An inside and out examination of the general development possibilities for the worldwide and regional market was given which depended on a top to bottom investigation of key industry players, essential and auxiliary information.

Global Aluminum Alloys in Additive Manufacturing Scope and Market Size

The global Aluminum Alloys in Additive Manufacturing market is segmented by company, region (country), by Type, and by Application. Players, stakeholders, and other participants in the global Aluminum Alloys in Additive Manufacturing market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on sales, revenue and forecast by region (country), by Type and by Application for the period 2017-2027.

It assists new organizations with playing out a positive evaluation of their strategies since it covers a scope of points market members should know about to stay serious.

Aluminum Alloys in Additive Manufacturing Market Report distinguishes different vital participants on the lookout and reveals insight into their methodologies and coordinated efforts to battle rivalry. The complete report gives a two-layered image of the market. By knowing the worldwide income of makers, the worldwide cost of makers, and the creation by producers during the gauge time of 2022 to 2027, the peruser can distinguish the impressions of producers in the Aluminum Alloys in Additive Manufacturing business.

Aluminum Alloys in Additive Manufacturing Market – Competitive and Segmentation Analysis:

As well as giving an outline of effective promoting systems, market commitments, and ongoing improvements of driving organizations, the report additionally offers a dashboard outline of driving organizations’ at various times execution. A few approaches and examinations are utilized in the exploration report to give inside and out and precise data about the Aluminum Alloys in Additive Manufacturing Market.

The Major players covered in the Aluminum Alloys in Additive Manufacturing market report are:AMC Powders, AP&C, ATI Metals Corp., Aeromet, Alcoa, Carpenter (CarTech), GKN Hoeganaes, H.C. Starck, Heraeus, Hoganas, LPW Technology, Metalysis, Praxair Surface Technologies, Toyal, USMP, and Valimet

Get a Sample Copy of the Aluminum Alloys in Additive Manufacturing Market Report 2022: https://www.lexisbusinessinsights.com/request-sample-226609

The current market dossier provides market growth potential, opportunities, drivers, industry-specific challenges and risks market share along with the growth rate of the global Aluminum Alloys in Additive Manufacturing market. The report also covers monetary and exchange fluctuations, import-export trade, and global market

The SWOT analysis, compiled by industry experts, Industry Concentration Ratio and the latest developments for the global Aluminum Alloys in Additive Manufacturing market share are covered in a statistical way in the form of tables and figures including graphs and charts for easy understanding.

Global Aluminum Alloys in Additive Manufacturing Scope and Segment:

Aluminum Alloys in Additive Manufacturing market is sectioned by Type and by Application. Players, partners, and different members in the worldwide Aluminum Alloys in Additive Manufacturing market will actually want to acquire the advantage as they utilize the report as a strong asset. The segmental investigation centres around deals, income and figure by Type and by Application for the period 2017-2027.

The Global Aluminum Alloys in Additive Manufacturing market is expected to increase at a significant rate during the conjecture time frame, somewhere in the range of 2022 and 2027. The market is developing at a consistent rate and with the increasing reception of techniques by central members, the market is supposed to ascend over the projected horizon.

Final Report will add the analysis of the impact of COVID-19 on this industry.

The momentum market dossier gives market development potential, open doors, drivers, industry-explicit difficulties and dangers piece of the pie alongside the development pace of the worldwide Aluminum Alloys in Additive Manufacturing market. The report additionally covers money related and trade variances, import-send out exchange, and worldwide market

The SWOT investigation, assembled by industry specialists, Industry Concentration Ratio and the most recent improvements for the worldwide Aluminum Alloys in Additive Manufacturing piece of the pie are shrouded in a factual manner as tables and figures including diagrams and outlines for simple comprehension.

On the basis of product type: this report displays the production, revenue, price, market share and growth rate of each type, includes: Read Complete Report.

On the basis of the end users/applications: this report focuses on the status and outlook for major applications, consumption (sales), industry share and growth rate for each application, including: Read Complete Report.

Aluminum Alloys in Additive Manufacturing Market – Regional Analysis:

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Aluminum Alloys in Additive Manufacturing in these regions, from 2017 to 2027, covering

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Columbia etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

Some of the key questions answered in this report:

What is the global (North America, Europe, Asia-Pacific, South America, Middle East and Africa) sales value, production value, consumption value, import and export of Aluminum Alloys in Additive Manufacturing?

Who are the global key manufacturers of the Aluminum Alloys in Additive Manufacturing Industry? How is their operating situation (capacity, production, sales, price, cost, gross, and revenue)?

How the competition goes in the future related to Aluminum Alloys in Additive Manufacturing?

Which is the most leading country in the world?

What are the Aluminum Alloys in Additive Manufacturing market opportunities and threats faced by the vendors in the global Aluminum Alloys in Additive Manufacturing Industry?

Which application/end-user or product type may seek incremental growth prospects? What is the market share of each type and application?

What focused approach and constraints are holding the Aluminum Alloys in Additive Manufacturing market?

What are the different sales, marketing, and distribution channels in the worldwide industry?

What are the upstream raw materials and manufacturing equipment of Aluminum Alloys in Additive Manufacturing?

What are the key market trends impacting the growth of the Aluminum Alloys in Additive Manufacturing market?

Economic impact on the Aluminum Alloys in Additive Manufacturing industry and development trend of the Aluminum Alloys in Additive Manufacturing industry.

What are the market opportunities, market risk, and market overview of the Aluminum Alloys in Additive Manufacturing market?

What are the key drivers, restraints, opportunities, and challenges of the Aluminum Alloys in Additive Manufacturing market, and how they are expected to impact the market?

What is the Aluminum Alloys in Additive Manufacturing market size at the regional and country-level?

How do you find your target audience?

Request Sample and Purchase this report-- https://www.lexisbusinessinsights.com/request-sample-226609

Our research analysts will help you to get customized details for your report, which can be modified in terms of a specific region, application or any statistical details. In addition, we are always willing to comply with the study, which triangulated with your own data to make the market research more comprehensive in your perspective.

With tables and figures helping analyse worldwide Global Aluminum Alloys in Additive Manufacturing market trends, this research provides key statistics on the state of the industry and is a valuable source of guidance and direction for companies and individuals interested in the market.

Detailed TOC of Global Aluminum Alloys in Additive Manufacturing Market Research Report 2022

Aluminum Alloys in Additive Manufacturing Market Overview

Aluminum Alloys in Additive Manufacturing Estimate and Forecast by Region

Global Aluminum Alloys in Additive Manufacturing Competition Landscape by Players

Global Aluminum Alloys in Additive Manufacturing Market Size by Type

Global Aluminum Alloys in Additive Manufacturing Market Size by Application

United States Aluminum Alloys in Additive Manufacturing Market Facts and Figures

Europe Aluminum Alloys in Additive Manufacturing Market Facts and Figures

China Aluminum Alloys in Additive Manufacturing Market Facts and Figures

Japan Aluminum Alloys in Additive Manufacturing Market Facts and Figures

Southeast Asia Aluminum Alloys in Additive Manufacturing Market Facts and Figures

India Aluminum Alloys in Additive Manufacturing Market Facts and Figures

Company Profiles and Key Figures in Aluminum Alloys in Additive Manufacturing Business

Aluminum Alloys in Additive Manufacturing Manufacturing Cost Analysis

Marketing Channel, Distributors and Customers

Market Dynamics

Research Findings and Conclusion

Appendix

17.1 Research Methodology

17.1.1 Methodology/Research Approach

17.1.2 Data Source

17.2 Author List

17.3 Disclaimer

About Us:

Lexis business insights is a market intelligence company specialized in healthcare & pharmaceuticals, chemicals & materials, machinery & equipment, service software, consumer goods, medical devices, electronics & semiconductors, ict, and more. With A categorical and comprehensive focus on these high-growth industries our solutions are effectively capable of streamlining your business strategies.

Note: In case the reports don't match your requirement then we can do a specialized Custom Research for you. Our multifarious capabilities, cross-sector expertise and detailed knowledge of various markets, put us in a unique position to take up Custom Research demands of yourself. Also impact of COVID-19 on Industry added in final report.

Contact Us:

+1 210 907 4145 (US)

+91 986 7799 788 (APAC)

#Covid-19 Impact Analysis#Aluminum Alloys in Additive Manufacturing forecast#Aluminum Alloys in Additive Manufacturing price#Aluminum Alloys in Additive Manufacturing report#Aluminum Alloys in Additive Manufacturing research#Aluminum Alloys in Additive Manufacturing share#Aluminum Alloys in Additive Manufacturing trends#Aluminum Alloys in Additive Manufacturing Industry#Aluminum Alloys in Additive Manufacturing Market#Aluminum Alloys in Additive Manufacturing

0 notes

Text

How Two Wheeler Handlebars Market is Driving Business Growth and Efficiency

The "Two Wheeler Handlebars Market" is a dynamic and rapidly evolving sector, with significant advancements and growth anticipated by 2031. Comprehensive market research reveals a detailed analysis of market size, share, and trends, providing valuable insights into its expansion. This report delves into segmentation and definition, offering a clear understanding of market components and drivers. Employing SWOT and PESTEL analyses, the study evaluates the market's strengths, weaknesses, opportunities, and threats, alongside political, economic, social, technological, environmental, and legal factors. Expert opinions and recent developments highlight the geographical distribution and forecast the market's trajectory, ensuring a robust foundation for strategic planning and investment.

What is the projected market size & growth rate of the Two Wheeler Handlebars Market?

Market Analysis and Size

Nowadays, manufacturers and major market players are focusing on corrosion-resistant and lightweight handlebars to improve the steering stability and performance of the two-wheeler vehicle. The manufacturers of two wheeler vehicle are integrating handlebars on their vehicle which deliver riding comfort to the rider. Furthermore, the growing disposable income of the population and the increase in the demand of the motorcycles and scooters has considerably in rural areas are some major factors for the growth of the two wheeler handlebars market during the forecast period of 2022-2029.

Data Bridge Market Research analyses that the two wheeler handlebars market was valued at USD 463.60 million in 2021 and is expected to reach USD 690.18 million by 2029, registering a CAGR of 5.10 % during the forecast period of 2022 to 2029. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, The market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis.

Browse Detailed TOC, Tables and Figures with Charts which is spread across 350 Pages that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

This research report is the result of an extensive primary and secondary research effort into the Two Wheeler Handlebars market. It provides a thorough overview of the market's current and future objectives, along with a competitive analysis of the industry, broken down by application, type and regional trends. It also provides a dashboard overview of the past and present performance of leading companies. A variety of methodologies and analyses are used in the research to ensure accurate and comprehensive information about the Two Wheeler Handlebars Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-two-wheeler-handlebars-market

Which are the driving factors of the Two Wheeler Handlebars market?

The driving factors of the Two Wheeler Handlebars market include technological advancements that enhance product efficiency and user experience, increasing consumer demand driven by changing lifestyle preferences, and favorable government regulations and policies that support market growth. Additionally, rising investment in research and development and the expanding application scope of Two Wheeler Handlebars across various industries further propel market expansion.

Two Wheeler Handlebars Market - Competitive and Segmentation Analysis:

Global Two Wheeler Handlebars Market, By Type (Motorcycles, Standard, Cruiser, Sports, Off-Road, Scooters, Standard, Maxi, Enclosed), Material Type (Steel, Aluminum, Alloy), Distribution Channel (Online, Offline) – Industry Trends and Forecast to 2031.

How do you determine the list of the key players included in the report?

With the aim of clearly revealing the competitive situation of the industry, we concretely analyze not only the leading enterprises that have a voice on a global scale, but also the regional small and medium-sized companies that play key roles and have plenty of potential growth.

Which are the top companies operating in the Two Wheeler Handlebars market?

Some of the major players operating in the two wheeler handlebars market are:

Kohli Bullet Accessories (India)

Renthal (U.K.)

FLANDERS Inc.(U.S.)

J&P Cycles (U.S.)

Accell Group (Netherlands)

Burleigh Bars (Australia)

Lyon Lee Autotop Industry (Shanghai) Co., Ltd. (China)

Saler Wang Foshan Xinmatuo Motorcycle Parts Industrial Co., Ltd. (China)

Dorel Industries (Canada)

Accell Group (Netherlands)

Shimano Inc. (Japan)

SRAM LLC (U.S.)

Hero Cycles Ltd (India)

Campagnolo S.R.L. (Italy)

Merida Bikes (Taiwan)

Specialized Bicycle Components (U.S.)

Rohloff AG (Germany)

Giant Bicycles (Taiwan)

Currie Technologies (U.S.)

OMAX Corporation (U.S.)

Trek Bicycle Corporation (U.S.)

Marin Bikes (U.S.)

Atlas Cycles (Haryana) Ltd (India)

Short Description About Two Wheeler Handlebars Market:

The Global Two Wheeler Handlebars market is anticipated to rise at a considerable rate during the forecast period, between 2024 and 2031. In 2023, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

North America, especially The United States, will still play an important role which can not be ignored. Any changes from United States might affect the development trend of Two Wheeler Handlebars. The market in North America is expected to grow considerably during the forecast period. The high adoption of advanced technology and the presence of large players in this region are likely to create ample growth opportunities for the market.

Europe also play important roles in global market, with a magnificent growth in CAGR During the Forecast period 2024-2031.

Two Wheeler Handlebars Market size is projected to reach Multimillion USD by 2031, In comparison to 2024, at unexpected CAGR during 2024-2031.

Despite the presence of intense competition, due to the global recovery trend is clear, investors are still optimistic about this area, and it will still be more new investments entering the field in the future.

This report focuses on the Two Wheeler Handlebars in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Get a Sample Copy of the Two Wheeler Handlebars Report 2024

What are your main data sources?

Both Primary and Secondary data sources are being used while compiling the report. Primary sources include extensive interviews of key opinion leaders and industry experts (such as experienced front-line staff, directors, CEOs, and marketing executives), downstream distributors, as well as end-users. Secondary sources include the research of the annual and financial reports of the top companies, public files, new journals, etc. We also cooperate with some third-party databases.

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2024-2031) of the following regions are covered in Chapters

What are the key regions in the global Two Wheeler Handlebars market?

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Columbia etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

This Two Wheeler Handlebars Market Research/Analysis Report Contains Answers to your following Questions

What are the global trends in the Two Wheeler Handlebars market?

Would the market witness an increase or decline in the demand in the coming years?

What is the estimated demand for different types of products in Two Wheeler Handlebars?

What are the upcoming industry applications and trends for Two Wheeler Handlebars market?

What Are Projections of Global Two Wheeler Handlebars Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

Where will the strategic developments take the industry in the mid to long-term?

What are the factors contributing to the final price of Two Wheeler Handlebars?

What are the raw materials used for Two Wheeler Handlebars manufacturing?

How big is the opportunity for the Two Wheeler Handlebars market?

How will the increasing adoption of Two Wheeler Handlebars for mining impact the growth rate of the overall market?

How much is the global Two Wheeler Handlebars market worth? What was the value of the market In 2020?

Who are the major players operating in the Two Wheeler Handlebars market? Which companies are the front runners?

Which are the recent industry trends that can be implemented to generate additional revenue streams?

What Should Be Entry Strategies, Countermeasures to Economic Impact, and Marketing Channels for Two Wheeler Handlebars Industry?

Customization of the Report

Can I modify the scope of the report and customize it to suit my requirements? Yes. Customized requirements of multi-dimensional, deep-level and high-quality can help our customers precisely grasp market opportunities, effortlessly confront market challenges, properly formulate market strategies and act promptly, thus to win them sufficient time and space for market competition.

Inquire more and share questions if any before the purchase on this report at - https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-two-wheeler-handlebars-market

Detailed TOC of Global Two Wheeler Handlebars Market Insights and Forecast to 2031

Introduction

Market Segmentation

Executive Summary

Premium Insights

Market Overview

Two Wheeler Handlebars Market By Type

Two Wheeler Handlebars Market By Function

Two Wheeler Handlebars Market By Material

Two Wheeler Handlebars Market By End User

Two Wheeler Handlebars Market By Region

Two Wheeler Handlebars Market: Company Landscape

SWOT Analysis

Company Profiles

Continued...

Purchase this report – https://www.databridgemarketresearch.com/checkout/buy/singleuser/global-two-wheeler-handlebars-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]

Browse More Reports:

Global Acesulfame Potassium Market – Industry Trends and Forecast to 2029

Global Stem Cell Therapy Market – Industry Trends and Forecast to 2030

Global Surgical Imaging Market – Industry Trends and Forecast to 2029

Global Two Wheeler Handlebars Market – Industry Trends and Forecast to 2029

Global Liquid Fungicides Market – Industry Trends and Forecast to 2028

#Two Wheeler Handlebars Market#Two Wheeler Handlebars Market Size#Two Wheeler Handlebars Market Share#Two Wheeler Handlebars Market Trends

0 notes

Text

Two Wheeler Handlebars Market Drivers, Trend, Constraints, and Top Players2024 - 2031

The "Two Wheeler Handlebars Market" is a dynamic and rapidly evolving sector, with significant advancements and growth anticipated by 2031. Comprehensive market research reveals a detailed analysis of market size, share, and trends, providing valuable insights into its expansion. This report delves into segmentation and definition, offering a clear understanding of market components and drivers. Employing SWOT and PESTEL analyses, the study evaluates the market's strengths, weaknesses, opportunities, and threats, alongside political, economic, social, technological, environmental, and legal factors. Expert opinions and recent developments highlight the geographical distribution and forecast the market's trajectory, ensuring a robust foundation for strategic planning and investment.

What is the projected market size & growth rate of the Two Wheeler Handlebars Market?

Market Analysis and Size

Nowadays, manufacturers and major market players are focusing on corrosion-resistant and lightweight handlebars to improve the steering stability and performance of the two-wheeler vehicle. The manufacturers of two wheeler vehicle are integrating handlebars on their vehicle which deliver riding comfort to the rider. Furthermore, the growing disposable income of the population and the increase in the demand of the motorcycles and scooters has considerably in rural areas are some major factors for the growth of the two wheeler handlebars market during the forecast period of 2022-2029.

Data Bridge Market Research analyses that the two wheeler handlebars market was valued at USD 463.60 million in 2021 and is expected to reach USD 690.18 million by 2029, registering a CAGR of 5.10 % during the forecast period of 2022 to 2029. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, The market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis.

Browse Detailed TOC, Tables and Figures with Charts which is spread across 350 Pages that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

This research report is the result of an extensive primary and secondary research effort into the Two Wheeler Handlebars market. It provides a thorough overview of the market's current and future objectives, along with a competitive analysis of the industry, broken down by application, type and regional trends. It also provides a dashboard overview of the past and present performance of leading companies. A variety of methodologies and analyses are used in the research to ensure accurate and comprehensive information about the Two Wheeler Handlebars Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-two-wheeler-handlebars-market

Which are the driving factors of the Two Wheeler Handlebars market?

The driving factors of the Two Wheeler Handlebars market include technological advancements that enhance product efficiency and user experience, increasing consumer demand driven by changing lifestyle preferences, and favorable government regulations and policies that support market growth. Additionally, rising investment in research and development and the expanding application scope of Two Wheeler Handlebars across various industries further propel market expansion.

Two Wheeler Handlebars Market - Competitive and Segmentation Analysis:

Global Two Wheeler Handlebars Market, By Type (Motorcycles, Standard, Cruiser, Sports, Off-Road, Scooters, Standard, Maxi, Enclosed), Material Type (Steel, Aluminum, Alloy), Distribution Channel (Online, Offline) – Industry Trends and Forecast to 2031.

How do you determine the list of the key players included in the report?

With the aim of clearly revealing the competitive situation of the industry, we concretely analyze not only the leading enterprises that have a voice on a global scale, but also the regional small and medium-sized companies that play key roles and have plenty of potential growth.

Which are the top companies operating in the Two Wheeler Handlebars market?

Some of the major players operating in the two wheeler handlebars market are:

Kohli Bullet Accessories (India)

Renthal (U.K.)

FLANDERS Inc.(U.S.)

J&P Cycles (U.S.)

Accell Group (Netherlands)

Burleigh Bars (Australia)

Lyon Lee Autotop Industry (Shanghai) Co., Ltd. (China)

Saler Wang Foshan Xinmatuo Motorcycle Parts Industrial Co., Ltd. (China)

Dorel Industries (Canada)

Accell Group (Netherlands)

Shimano Inc. (Japan)

SRAM LLC (U.S.)

Hero Cycles Ltd (India)

Campagnolo S.R.L. (Italy)

Merida Bikes (Taiwan)

Specialized Bicycle Components (U.S.)

Rohloff AG (Germany)

Giant Bicycles (Taiwan)

Currie Technologies (U.S.)

OMAX Corporation (U.S.)

Trek Bicycle Corporation (U.S.)

Marin Bikes (U.S.)

Atlas Cycles (Haryana) Ltd (India)

Short Description About Two Wheeler Handlebars Market:

The Global Two Wheeler Handlebars market is anticipated to rise at a considerable rate during the forecast period, between 2024 and 2031. In 2023, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

North America, especially The United States, will still play an important role which can not be ignored. Any changes from United States might affect the development trend of Two Wheeler Handlebars. The market in North America is expected to grow considerably during the forecast period. The high adoption of advanced technology and the presence of large players in this region are likely to create ample growth opportunities for the market.

Europe also play important roles in global market, with a magnificent growth in CAGR During the Forecast period 2024-2031.

Two Wheeler Handlebars Market size is projected to reach Multimillion USD by 2031, In comparison to 2024, at unexpected CAGR during 2024-2031.

Despite the presence of intense competition, due to the global recovery trend is clear, investors are still optimistic about this area, and it will still be more new investments entering the field in the future.

This report focuses on the Two Wheeler Handlebars in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Get a Sample Copy of the Two Wheeler Handlebars Report 2024

What are your main data sources?

Both Primary and Secondary data sources are being used while compiling the report. Primary sources include extensive interviews of key opinion leaders and industry experts (such as experienced front-line staff, directors, CEOs, and marketing executives), downstream distributors, as well as end-users. Secondary sources include the research of the annual and financial reports of the top companies, public files, new journals, etc. We also cooperate with some third-party databases.

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2024-2031) of the following regions are covered in Chapters

What are the key regions in the global Two Wheeler Handlebars market?

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Columbia etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

This Two Wheeler Handlebars Market Research/Analysis Report Contains Answers to your following Questions

What are the global trends in the Two Wheeler Handlebars market?

Would the market witness an increase or decline in the demand in the coming years?

What is the estimated demand for different types of products in Two Wheeler Handlebars?

What are the upcoming industry applications and trends for Two Wheeler Handlebars market?

What Are Projections of Global Two Wheeler Handlebars Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

Where will the strategic developments take the industry in the mid to long-term?

What are the factors contributing to the final price of Two Wheeler Handlebars?

What are the raw materials used for Two Wheeler Handlebars manufacturing?

How big is the opportunity for the Two Wheeler Handlebars market?

How will the increasing adoption of Two Wheeler Handlebars for mining impact the growth rate of the overall market?

How much is the global Two Wheeler Handlebars market worth? What was the value of the market In 2020?

Who are the major players operating in the Two Wheeler Handlebars market? Which companies are the front runners?

Which are the recent industry trends that can be implemented to generate additional revenue streams?

What Should Be Entry Strategies, Countermeasures to Economic Impact, and Marketing Channels for Two Wheeler Handlebars Industry?

Customization of the Report

Can I modify the scope of the report and customize it to suit my requirements? Yes. Customized requirements of multi-dimensional, deep-level and high-quality can help our customers precisely grasp market opportunities, effortlessly confront market challenges, properly formulate market strategies and act promptly, thus to win them sufficient time and space for market competition.

Inquire more and share questions if any before the purchase on this report at - https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-two-wheeler-handlebars-market

Detailed TOC of Global Two Wheeler Handlebars Market Insights and Forecast to 2031

Introduction

Market Segmentation

Executive Summary

Premium Insights

Market Overview

Two Wheeler Handlebars Market By Type

Two Wheeler Handlebars Market By Function

Two Wheeler Handlebars Market By Material

Two Wheeler Handlebars Market By End User

Two Wheeler Handlebars Market By Region

Two Wheeler Handlebars Market: Company Landscape

SWOT Analysis

Company Profiles

Continued...

Purchase this report – https://www.databridgemarketresearch.com/checkout/buy/singleuser/global-two-wheeler-handlebars-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]

Browse More Reports:

Global Passwordless Authentication Market – Industry Trends and Forecast to 2031

Global Video Endoscopy Devices Market – Industry Trends and Forecast to 2029

Global Molecular Spectroscopy Market – Industry Trends and Forecast to 2030

Global Two Wheeler Handlebars Market – Industry Trends and Forecast to 2029

Global Acquired Neuromyotonia Treatment Market - Industry Trends and Forecast to 2028

0 notes

Text

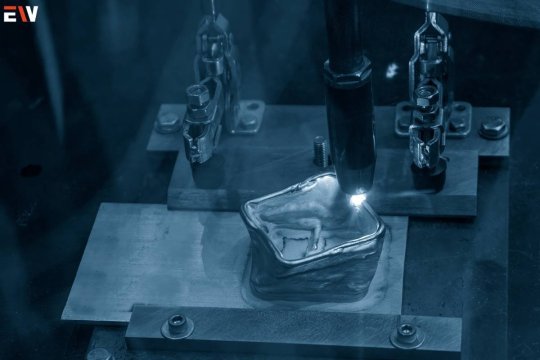

Precision in Motion: Exploring the World of Metal CNC Machining

Share Post:

LinkedIn

Twitter

Facebook

Reddit

Metal CNC machining represents the pinnacle of precision engineering, offering unparalleled accuracy, efficiency, and versatility in the fabrication of metal components and parts. In this comprehensive overview, we delve into the intricacies of metal CNC machining, exploring its technology, applications, benefits, and the future of precision manufacturing.

Understanding Metal CNC Machining

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to automate the operation of machine tools, such as lathes, mills, and routers. Metal CNC machining specifically focuses on the fabrication of metal components, utilizing specialized CNC machines equipped with cutting tools to shape and refine metal workpieces with exceptional precision.

Key Components:

1. CAD (Computer-Aided Design)

The design phase begins with the creation of a digital model of the desired part using CAD software. This digital model serves as the blueprint for the machining process.

2. CAM (Computer-Aided Manufacturing)

CAM software translates the CAD model into instructions for the CNC machine, generating tool paths and specifying machining operations such as milling, drilling, and turning.

3. CNC Machine

The CNC machine executes the programmed instructions, utilizing cutting tools to remove material from the workpiece and create the desired shape and features with high precision.

4. Cutting Tools

Various cutting tools, such as end mills, drills, and inserts, are used to remove material from the workpiece during the machining process. These tools are selected based on factors such as material type, geometry, and surface finish requirements.

What are its Applications?

CNC machining finds wide-ranging applications across industries and sectors, including:

1. Aerospace: Precision components for aircraft, spacecraft, and satellites, such as engine parts, structural components, and avionics.

2. Automotive: Engine components, transmission parts, chassis components, and precision tooling for automotive manufacturing.

3. Medical: Surgical instruments, implants, prosthetics, and medical device components require high precision and biocompatibility.

4. Electronics: Enclosures, heat sinks, connectors, and components for electronic devices and consumer electronics.

5. Industrial Manufacturing: Tooling, fixtures, molds, and production components for various manufacturing processes.

Benefits of Metal CNC Machining

1. Precision and Accuracy

CNC machining offers unparalleled precision and accuracy, with the ability to achieve tight tolerances and intricate geometries that are difficult or impossible to replicate with traditional machining methods.

2. Efficiency and Productivity

CNC machines operate with high speed and efficiency, allowing for rapid production of metal components with minimal downtime and waste. Automated tool changes, material handling, and process monitoring further enhance productivity.

3. Versatility and Flexibility

CNC machining can accommodate a wide range of materials, including metals such as aluminum, steel, titanium, and brass. Moreover, CNC machines are capable of machining complex shapes and features, making them highly versatile for diverse manufacturing applications.

4. Consistency and Repeatability

With CNC machining, each part produced is identical to the next, ensuring consistency and repeatability in quality and performance. This reliability is essential for industries with stringent quality standards and regulatory requirements.

Future Trends in Metal CNC Machining

1. Advanced Materials

As demand grows for lightweight, high-strength materials, such as titanium alloys and composites, metal CNC machining will continue to evolve to accommodate the machining challenges posed by these advanced materials.

2. Additive Manufacturing Integration

The integration of additive manufacturing (3D printing) with CNC machining processes, known as hybrid manufacturing, offers new possibilities for producing complex metal parts with enhanced efficiency and functionality.

3. Smart Manufacturing Technologies

Advancements in automation, robotics, artificial intelligence, and data analytics are transforming CNC machining into a smarter, more interconnected ecosystem, enabling predictive maintenance, real-time monitoring, and optimization of manufacturing processes.

4. Sustainable Practices

With a growing emphasis on sustainability and environmental stewardship, CNC machining will increasingly adopt eco-friendly practices, such as recycling metal chips and coolant, energy-efficient machining processes, and reduction of material waste.

Conclusion

Metal CNC machining stands at the forefront of precision manufacturing, offering unparalleled capabilities, efficiency, and versatility in the fabrication of metal components and parts. From aerospace to automotive, medical to electronics, CNC machining plays a critical role in driving innovation and advancement across industries. As technology continues to evolve and demand for high-quality, custom metal components grows, CNC machining will remain indispensable for delivering precision in motion and shaping the future of manufacturing.

Also Read: Industrial IoT: Transforming Manufacturing through Connected Intelligence

#metalcnc#PrecisionEngineering#manufacturing#Technology#cncmachining#metalfabrication#aerospace#medical#electronics#industrialmanufacturing

0 notes

Text

Foundry Chemicals Market to Reach US$ 3.2 Bn by 2031

The value of global foundry chemicals market stood at US$ 2.5 Bn in 2021. The global market is anticipated to expand at a CAGR of 2.6% during the forecast period, from 2022 to 2031.The global foundry chemicals market is likely to touch the mark of US$ 3.2 Bn by 2031. Companies in the global foundry chemicals market are embracing latest printing technologies that can speed up the development of sand prototypes, and 3D metal.

It is also utilized in various crucial parts that are often required in several industries such as petrochemical, construction, aerospace, and automotive. Market players are are concentrating on expanding the range of products they offer for foundry chemical coatings, foundry chemical additive agents, and foundry chemical binders. Such diverse product offerings are expected to drive positive future of foundry chemicals market.

The innovations of Industry 4.0 are expected to benefit foundries that can make use of data to guide their procedures. High demand for foundry chemicals binders in the casting of bronze, cast iron, aluminum, and steel is anti9cipated to fuel market demand for foundry chemicals.

Request PDF Sample Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=33776

Market Segmentation

By Service Type: Additives, Binders, Coatings, Fluxes, Others

By Sourcing Type: In-house Manufacturing, Outsourced Suppliers

By Application: Iron Casting, Steel Casting, Aluminum Casting, Others

By Industry Vertical: Automotive, Aerospace & Defense, Construction, Machinery, Others

By Region: North America, Europe, Asia Pacific, Latin America, Middle East & Africa

Regional Analysis

North America: Mature market with a focus on technological advancements and sustainable practices in foundry operations.

Europe: Strong automotive and aerospace industries driving demand for high-performance foundry chemicals.

Asia Pacific: Rapid industrialization in countries like China and India boosting foundry chemical consumption.

Latin America: Increasing investments in infrastructure projects driving demand for construction-related castings.

Middle East & Africa: Growth in oil and gas, construction, and automotive sectors contributing to market expansion.

Market Drivers and Challenges

Drivers:

Increasing demand for lightweight materials in automotive and aerospace industries.

Technological advancements in metal casting processes requiring specialized chemicals.

Growing construction and infrastructure projects globally.

Stringent quality and environmental regulations favoring advanced foundry chemicals.

Challenges:

Volatility in raw material prices impacting production costs.

Competition from alternative casting methods such as 3D printing in certain applications.

Environmental concerns related to chemical usage and waste management.

Market Trends

Shift towards Environmentally Friendly Chemicals: Bio-based binders, recyclable coatings, and low-emission additives gaining traction.

Digitalization and Automation: Integration of IoT sensors, data analytics, and robotics for optimized casting processes.

Customized Solutions: Tailored chemical formulations for specific metal alloys and casting methods.

Future Outlook

The Foundry Chemicals market is poised for continued growth, driven by ongoing industrialization, technological advancements, and demand for high-quality metal components across diverse industries. Innovation in sustainable materials and digitalization of foundry processes will shape the market's future landscape.

Key Market Study Points

Market Dynamics: Demand drivers, challenges, and opportunities influencing the Foundry Chemicals market.

Competitive Landscape: Key players, market strategies, product portfolios, and mergers/acquisitions.

Technological Innovations: Advanced formulations, digital tools for process optimization, and waste reduction solutions.

Regulatory Environment: Impact of environmental regulations on chemical usage and waste management practices.

Customer Preferences: Key factors influencing chemical selection, quality standards, and supplier relationships.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=33776<ype=S

Competitive Landscape and Recent Developments

Leading companies in the Foundry Chemicals market include Ashland Global Holdings, HA-International, Vesuvius PLC, Imerys Group, and Elkem ASA. Recent developments such as product launches, partnerships for technology collaborations, and investments in sustainable practices highlight the dynamic nature of the market as companies strive to meet evolving customer demands and regulatory requirements.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Aerospace Sheets Market 2029 is Anticipated to Register Robust Growth

The expansion of the global commercial aviation sector acts as a major driver, necessitating increased production of aerospace sheets are the factors driving market in the forecast period 2025-2029.

According to TechSci Research report, “Aerospace Sheets Market – Global Industry Size, Share, Trends, Competition Forecast & Opportunities, 2029”, The Global Aerospace Sheets Market stood at USD 2.65 Billion in 2023 and is anticipated to grow with a CAGR of 6.24% in the forecast period, 2025-2029. The global aerospace sheets market is witnessing substantial growth driven by a confluence of factors that underscore the dynamic nature of the aerospace industry. A pivotal aspect propelling this market is the relentless pursuit of enhanced fuel efficiency and performance in aircraft. Aerospace sheets, crafted from advanced materials such as aluminum alloys, titanium, and composite materials, play a critical role in achieving the delicate balance between structural integrity and weight reduction, thereby meeting the stringent demands of the industry.

The commercial aviation sector, marked by an ever-increasing global demand for air travel, stands as a primary catalyst for the aerospace sheets market's expansion. Aircraft manufacturers are under mounting pressure to produce fuel-efficient, safe, and durable aircraft, amplifying the need for high-quality aerospace sheets in the construction of airframes, wings, and other critical components. This surge in demand is complemented by ongoing military modernization programs, contributing to the aerospace sheets market's growth as defense forces worldwide seek materials that withstand rigorous conditions.

Moreover, the aerospace sheets market is witnessing a transformative phase with advancements in manufacturing technologies. Additive manufacturing and precision machining are reshaping the landscape by enabling the production of aerospace sheets with improved strength-to-weight ratios, precision, and versatility. These innovations not only contribute to the overall efficiency of the manufacturing process but also allow for the creation of complex geometries and tailored solutions, aligning with the industry's drive for customization.

In conclusion, the global aerospace sheets market is characterized by a dynamic interplay of technological advancements, industry demand, and a commitment to sustainability. As the aerospace sector continues to evolve, the market for aerospace sheets is expected to remain a crucial and adaptive component, contributing to the ongoing advancement and efficiency of aircraft across various segments.

Browse over market data Figures spread through XX Pages and an in-depth TOC on " Global Aerospace Sheets Market”

https://www.techsciresearch.com/report/aerospace-sheets-market/22789.html

North America holds a preeminent position in the global aerospace sheets market, primarily owing to the presence of major aerospace industry players and a well-established supply chain. The United States, in particular, hosts key aircraft manufacturers and contributes significantly to the market's growth. The region's dominance is fueled by a robust commercial aviation sector, extensive military modernization initiatives, and a relentless focus on technological innovation. North America's commitment to research and development further solidifies its position as a leader in adopting advanced materials, including aerospace sheets, to meet the evolving demands of the aerospace industry.

Europe is a formidable player in the global aerospace sheets market, leveraging its rich aviation history, technological expertise, and a strong network of aerospace manufacturers. The region places a strong emphasis on sustainability, driving the adoption of aerospace sheets made from lightweight materials to enhance fuel efficiency. Collaborative research efforts, often facilitated by pan-European partnerships, contribute to the development of cutting-edge aerospace sheet technologies. Europe's aerospace sheets market is buoyed by a robust demand for both commercial and military aircraft, positioning the region as a vital hub for aerospace innovations and manufacturing.

The Asia-Pacific region is emerging as a key contributor to the global aerospace sheets market, fueled by the rapid expansion of the commercial aviation sector and increasing defense spending. Countries such as China and India are investing significantly in their aerospace industries, leading to a surge in demand for aerospace sheets. The region benefits from a growing middle class, urbanization, and the establishment of new manufacturing facilities. Asia-Pacific's aerospace sheets market is characterized by a dynamic landscape, with a focus on meeting the escalating demand for air travel and enhancing indigenous aerospace capabilities.

The Middle East, particularly the Gulf countries, has witnessed substantial growth in the aerospace industry, driven by strategic investments and a focus on becoming global aviation hubs. The region's aerospace sheets market is influenced by factors such as a burgeoning tourism sector, military modernization efforts, and geopolitical considerations. The Middle East's strategic location and economic diversification efforts contribute to a steady demand for new aircraft, boosting the market for aerospace sheets. Africa, while in the nascent stages, is also showing potential for growth in aerospace sheets, with regional carriers expanding their fleets.

Major companies operating in Global Aerospace Sheets Market are:

Arconic Corporation

VSMPO-AVISMA Corporation

Allegheny Technologies, Inc.

Titanium Metals Corporation (TIMET)

Constellium SE

Kaiser Aluminum Corporation

Carpenter Technology Corporation

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=22789

Customers can also request 10% free customization in this report.

“The lightweight materials like advanced composites in aerospace sheets to enhance fuel efficiency. Additionally, the integration of smart technologies and the rapid adoption of additive manufacturing are anticipated trends, driving innovation in aerospace sheet manufacturing processes. Overall, experts highlight a dynamic environment, marked by collaboration, sustainability, and technological advancements, as pivotal factors shaping the future trajectory of the global aerospace sheets market,” said Mr. Karan Chechi, Research Director with TechSci Research, a research-based management consulting firm.

“Aerospace Sheets Market – Global Industry Size, Share, Trends Opportunity, and Forecast, Segmented By Platform Type (Commercial Aircraft, Regional Aircraft, General Aviation, Military Aircraft, Helicopter, and Unmanned Aerial Vehicle), By Sales Channel Type (Direct Sales and Distributor Sales), By Material Type (Titanium & Alloys, Aluminium & Alloys, Steel & Alloys, and Others), By Region, Competition, 2019-2029”, has evaluated the future growth potential of Global Aerospace Sheets Market and provides statistics & information on market size, structure, and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides, the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in Global Aerospace Sheets Market.

Browse Related Reports:

Military Aircraft Communication Avionics Market

Autonomous Military Aircraft Market

Military Vehicle Electrification Market

Contact

TechSci Research LLC

420 Lexington Avenue, Suite 300,

New York, United States- 10170

M: +13322586602

Email: [email protected]

Website: www.techsciresearch.com

#Aerospace Sheets Market#Aerospace Sheets Market Size#Aerospace Sheets Market Share#Aerospace Sheets Market Trends#Aerospace Sheets Market Growth#Aerospace Sheets Market Forecast

0 notes

Text

The global manufacturing sector is progressively advancing towards a non-plastic world due to the harmful effects of oil-based plastic materials on nature. Aluminum is one of the most important and sustainable materials and the most abundant metal on the earth’s crust. Due to their capabilities, aluminum extrusion is a versatile and feasible solution for a growing range of manufacturing needs. Moreover, with the aluminum extrusion process, producers can manufacture an extensive range of products, irrespective of shape and size on a single machine or equipment during forecast period.

Data Bridge Market Research analyses that the aluminum extrusion market was valued at USD 86537 million in 2021 and is expected to reach USD 143218.36 million by 2029, registering a CAGR of 6.50% during the forecast period of 2022 to 2029. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

0 notes

Text

Aluminum Ingot Prices, Pricing, Trend, Supply & Demand and Forecast | ChemAnalyst

Aluminum Ingot prices play a pivotal role in various industries, serving as a fundamental indicator of economic activity and market trends. These prices are influenced by a multitude of factors, ranging from global supply and demand dynamics to geopolitical events and currency fluctuations. Understanding the nuances of aluminum ingot pricing is essential for stakeholders across sectors such as construction, automotive, aerospace, and packaging.

One of the primary determinants of aluminum ingot prices is the supply-demand balance. Aluminum is one of the most abundant metals on Earth, but its extraction and refinement process are energy-intensive. Therefore, fluctuations in energy prices can significantly impact production costs and, consequently, ingot prices. Moreover, disruptions in the global supply chain, such as trade tensions or natural disasters affecting major aluminum-producing regions, can lead to supply constraints and drive prices upward.

On the demand side, industries like automotive and aerospace are major consumers of aluminum ingots due to their lightweight and durable properties. Consequently, shifts in consumer preferences, technological advancements, or regulatory changes aimed at reducing carbon emissions can influence the demand for aluminum ingots and exert pressure on prices. For instance, the increasing focus on electric vehicles (EVs) has spurred demand for aluminum as it offers a lightweight alternative to traditional steel components, enhancing the energy efficiency of EVs.

Get Real Time Prices of Aluminum Ingot: https://www.chemanalyst.com/Pricing-data/aluminium-ingot-1351

Furthermore, currency fluctuations play a crucial role in determining aluminum ingot prices, especially since aluminum is traded as a commodity on global exchanges like the London Metal Exchange (LME). Changes in exchange rates can affect the competitiveness of aluminum producers in different regions and impact their pricing strategies. A weaker local currency relative to the US dollar, which is the dominant currency in commodity trading, can make aluminum exports more attractive for producers in countries like Russia or China, potentially influencing global prices.

Geopolitical events and trade policies also contribute to the volatility of aluminum ingot prices. Trade disputes, tariffs, or sanctions targeting aluminum-producing countries can disrupt supply chains and create uncertainty in the market, leading to price fluctuations. For example, the imposition of tariffs on aluminum imports by the United States or the European Union can trigger retaliatory measures from affected countries, exacerbating price volatility and complicating supply chain management for manufacturers.

Moreover, environmental regulations and sustainability initiatives have become increasingly influential in shaping aluminum ingot prices. As concerns about climate change and resource depletion escalate, stakeholders are placing greater emphasis on sustainable practices throughout the aluminum production process. This includes efforts to reduce greenhouse gas emissions, minimize waste generation, and promote the use of recycled aluminum. Consequently, aluminum producers that adopt eco-friendly technologies and demonstrate commitment to sustainability may gain a competitive edge and command premium prices for their ingots.

In addition to these external factors, internal dynamics within the aluminum industry, such as capacity expansions, mergers and acquisitions, and technological innovations, can impact supply chains and pricing strategies. For instance, investments in advanced smelting technologies or the development of new alloys with enhanced properties can enhance productivity and product differentiation, influencing market dynamics and pricing trends.

In conclusion, aluminum ingot prices are subject to a myriad of factors that collectively shape market dynamics and determine price levels. From supply-demand dynamics and currency fluctuations to geopolitical events and sustainability initiatives, stakeholders must navigate a complex landscape to anticipate and respond to changes in aluminum ingot prices effectively. By staying informed about these factors and adopting a proactive approach to risk management and strategic decision-making, businesses can mitigate price volatility and position themselves for success in the dynamic aluminum market.

Get Real Time Prices of Aluminum Ingot: https://www.chemanalyst.com/Pricing-data/aluminium-ingot-1351

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

AceForge: Pioneering Excellence Among Metal Forging Companies in India

In the vibrant landscape of India's manufacturing sector, metal forging companies play a pivotal role in shaping industries ranging from automotive and aerospace to infrastructure and energy. Among these companies, AceForge stands out as a beacon of innovation, precision, and reliability, setting the benchmark for excellence in the field of metal forging.

Metal forging is a time-honored manufacturing process that involves shaping metal through the application of compressive force. This process enhances the mechanical properties of metals, resulting in components that exhibit exceptional strength, durability, and reliability. As one of the leading metal forging companies in India, AceForge leverages cutting-edge technology and decades of expertise to deliver forged components that meet the diverse needs of its clients across various industries.

One of AceForge's key strengths lies in its extensive capabilities across a wide range of metals and alloys. Whether it's carbon steel, stainless steel, aluminum, or exotic alloys, AceForge has the expertise and infrastructure to forge components with precision and consistency. From simple shapes to complex geometries, AceForge's versatile manufacturing facilities can accommodate diverse requirements, catering to the unique needs of each client.

Moreover, AceForge's commitment to quality is unparalleled. The company adheres to stringent quality control measures at every stage of the manufacturing process, from raw material inspection to final product testing. By maintaining the highest standards of quality assurance, AceForge ensures that its forged components meet or exceed the expectations of its clients, both in terms of performance and reliability.

In addition to its focus on quality, AceForge places a strong emphasis on innovation and continuous improvement. The company invests in research and development to explore new materials, processes, and technologies that enhance the efficiency and capabilities of its forging operations. This culture of innovation enables AceForge to stay ahead of the curve and address emerging trends and challenges in the dynamic landscape of metal forging.

Furthermore, AceForge is committed to sustainability and environmental responsibility. The company employs energy-efficient practices and waste reduction strategies to minimize its environmental footprint. By prioritizing sustainability in its operations, AceForge not only contributes to environmental conservation but also aligns with the growing demand for eco-friendly manufacturing solutions.

As India's economy continues to grow and diversify, the demand for high-quality forged components across various industries is expected to rise. AceForge, with its proven track record of excellence and commitment to customer satisfaction, is well-positioned to capitalize on these opportunities and further strengthen its position as a leading player in the metal forging industry.

In conclusion, AceForge exemplifies the best of Indian manufacturing prowess among metal forging companies. With its relentless focus on quality, innovation, and sustainability, AceForge continues to set new standards of excellence in the field of metal forging, driving progress and prosperity in India's manufacturing sector and beyond.

0 notes

Text

Automobile Fuel Tanks Market Anticipated to Revenue Surge Driving Growth by 2024-2034

Automobile Fuel Tanks Market provides strategy of mergers and executions to enhance their Market share and product assortment. The main goal of Global Automobile Fuel Tanks Market report is to provide a clear picture and a better understanding of the market. Additionally, it also covers the overall market situation along with future lookout around the world. The report evaluated key market features, including revenue, capacity, capacity utilization rate, price, production, production rate, CAGR, consumption, import/export, supply/demand, cost, market share, and gross margin. In addition, This Report study offers a comprehensive study of the key market dynamics and their latest trends, along with applicable market segments and sub-segments.

The Automobile Fuel Tanks Market report profiles the successive companies, which includes: -

Inergy

Kautex

TI Automotive

Yachiyo

Hwashin

YAPP

Martinrea

Suguang

Luzhou North Chemical

A specific study of competitive landscape of the global Automobile Fuel Tanks Market has granted, providing insights into the corporate profiles, financial standing, recent developments, mergers and acquisitions, and therefore the SWOT analysis. This analysis report will provide a transparent program to reader’s concern regarding the general market situation to further choose on this market projects.

Get Sample Copy of this Report @ https://www.reportsintellect.com/sample-request/2867906

This report studies the global Automobile Fuel Tanks Market status and forecast, categorizes the global Automobile Fuel Tanks Market size (value & volume), revenue (Million USD), product price by manufacturers, type, application, and region. Automobile Fuel Tanks Market Report by Material, Application and Geography with Global Forecast to 2030 is a connoisseur and far-reaching research provide details associated with world’s major provincial economic situations, Concentrating on the principle districts (North America, South America Europe, and Asia-Pacific) and the crucial nations (United States, Germany, United Kingdom, Japan, South Korea, and China).

Reports Intellect analysts are currently working analyzing and incorporating their insights on the effect of COVID-19 across diverse industry verticals. These insights are quite promising for various businesses and industries to cope up with this unprecedented downturn and take effective strategic decisions to thrive and proliferate in the ever competitive business ecosystem.

By Types:

Iron Fuel Tanks

Aluminum Alloy Fuel Tanks

By Applications:

Commercial Vehicles

Passenger Vehicles

Market Segment by Regions, regional analysis covers

North America

Europe

Asia-Pacific

South America

Middle East and Africa

Get Discount On the Purchase of This Report @ https://www.reportsintellect.com/discount-request/2867906

Reasons why you should buy this report

· Understand the Present and future of the Automobile Fuel Tanks Market in both Established and emerging markets.

· The report assists in realigning the business strategies by accentuate the Automobile Fuel Tanks business priorities.

· The report throws light on the segment expected to dominate the Automobile Fuel Tanks industry and market.

· Forecasts the regions expected to perceive ascension.

· The newest developments within the Automobile Fuel Tanks industry and details of the industry leaders alongside their market share and methods.

· Saves time on the entry level research as the report contains principal data concerning about growth, size, leading players and segments of the industry.

· Save and cut time carrying out entry-level research by characterizing the growth, size, leading players and segments within the global Market.

About Us :-

Reports Intellect is your one-stop solution for everything associated with market research and market intelligence.

Our exhausting team works hard to fetch the best authentic research reports backed with impeccable data figures that guarantee outstanding results anytime for you.

So, whether it is the newest report from the researchers or a custom requirement, our team is here to assist you within the absolute best manner.

Contact Us:

[email protected]

PH - + 1-706-996-2486

US Address:

225 Peachtree Street NE,

Suite 400,

Atlanta, GA 30303

#Automobile Fuel Tanks Market#Automobile Fuel Tanks Market forecast#Automobile Fuel Tanks Market analysis#Automobile Fuel Tanks Market trends

0 notes

Text

Recent advances in modelling of metal machining processes

Metal machining is a critical process in the manufacturing industry, involving the shaping and removal of material from metal workpieces to create finished products. It has been an essential part of production processes for centuries, with traditional methods such as turning, milling, drilling, and grinding being widely used. However, with the advancement of technology, new and improved methods are continuously being developed to enhance the efficiency and precision of metal machining.

In recent years, advancements in computer-aided design (CAD) and computer-aided manufacturing (CAM) software have revolutionized metal machining processes. This technology allows for the creation of highly detailed digital models of workpieces, which can then be used to generate precise tool paths for cutting operations. CAM software also enables simulation and optimization of machining processes, allowing for the identification and elimination of potential issues before physical production begins.

One of the most significant innovations in metal machining is the use of numerical control (NC) machines. These machines are controlled by computer programs that dictate the movement and operation of cutting tools, resulting in highly accurate and repeatable cuts. NC machines have since evolved into computer numerical control (CNC) machines, which offer even greater levels of automation and precision.

Another recent trend in metal machining is the use of high-speed machining (HSM), which involves cutting at faster speeds with lighter cuts. This technique reduces cycle time and increases productivity while also improving surface finish and prolonging tool life. HSM has become possible due to advancements in machine design and the development of high-speed cutting tools.

One area of metal machining that has seen significant advancements is 5-axis machining. This technique allows for the simultaneous movement of cutting tools along five different axes, resulting in more complex and precise cuts. 5-axis machines are widely used in industries such as aerospace, where intricate and highly accurate components are required.

In addition to technological advancements, there have also been developments in the types of materials that can be machined. Traditional metals such as steel and aluminum are still widely used, but there has been a rise in the use of advanced materials such as titanium, composites, and superalloys. These materials have unique properties that make them ideal for specific applications but also present challenges in terms of machining.

The field of metal machining is constantly evolving, with new technologies and techniques being developed to improve efficiency, precision, and the range of materials that can be machined. As a result, there is a growing demand for skilled machinists who are able to operate these sophisticated machines and understand the various cutting processes.

In conclusion, metal machining in Ontario continues to evolve and adapt to the demands of various industries. From the high-speed cutting techniques to the intricate capabilities of 5-axis machines, the constant advancements in this field are creating new opportunities and setting higher standards for precision and efficiency. The increasing use of advanced materials like titanium, composites, and super alloys further demonstrates the versatility and adaptability of modern metal machining. These developments underscore the significant role that skilled machinists play in leveraging these technologies and materials to transform raw metal into complex parts and components. The future of metal machining in Ontario certainly holds exciting prospects as we continue to innovate and push the boundaries of what's possible.

Explore the future of metal machining in Ontario. Embrace new technologies, master advanced material processing, and elevate your skills. Join us and shape the industry's future.

0 notes

Text

Exploring the Explosive Growth Potential of the Explosion-Proof Equipment Market Through 2033 Over the projection period of 2023 to 2033, the market is expected to grow at a sluggish CAGR of 3.4%, reaching an estimated value of US$ 10,160.5 Million in 2032. The market for explosion-proof equipment is expected to expand from an anticipated US$ 7,520.18 million in 2023 because of the rising demand for stringent government requirements to control hazardous areas. Some of the additional factors contributing to the market’s consistent growth over the anticipated period include an increase in demand for integrated systems, developments in the automation sector, and expansion in industrial sectors. Equipment made out of explosive material; is thus based on a protection principle that enables explosion prevention by varying operating energy or making the case so robust that the explosion cannot come out of it is categorized as explosion proof equipment. This equipment is generally composed of stainless steel or cast aluminum. Unlock Exclusive Market Segments Insights: Buy Now to Discover Vital Trends, Drivers, and Challenges in this Industry https://www.futuremarketinsights.com/reports/sample/rep-gb-1447 With the rising demand and consumption of energy and fuel, the demand for explosion proof equipment is also escalating because this equipment is used quite often to avoid explosions during natural resource power generation. Many market manufacturers are releasing novel designed casing materials and more advanced features, which have gradually gained popularity and become new trends in the global explosion proof equipment market. This bodes well for the target market. Moreover, the increasing adoption of explosion proof equipment in the oil and gas industries, high demand for the product in the automation sector, and exploration of new mining sites contribute to the need for explosion proof equipment. The newly formed safety regulations for hazardous areas are becoming more stringent which leads to better future prospects for the explosion proof equipment market during the assessment period. “Rising demand for the product in the oil and gas industry as well as the automation sector will likely lead to the market growth of explosion proof equipment over the forecast period,” says an FMI analyst. Key Takeaways: The stalling of the mining and mineral sector may hinder the market growth. North America will continue to dominate the global market over the forecast period. In 2022, the explosion proof equipment market in Europe is expected to hold 15.3% of the overall market share. The Asia Pacific is predicted to undergo the highest growth rate during the forecast period. Based on characteristics, the zone 0 segment will be highly preferred during the assessment period. The cable glands segment will register high demand through 2022 to 2032. Competitive Landscape Adalet, Alloy Industry Co. Ltd., Eaton, S.C. UMEB SA, Warom Technology, Inc., and others are some of the major players in the explosion proof equipment market that are profiled in the full version of the report. Major market players are concentrating on product development and entering new markets to expand their operations.

0 notes

Text

Exploring Cutting-Edge Innovations in Aluminum Bronze Technology

Rajkrupa Metal Industries is one of the Leading Aluminium Bronze Round Bar Manufacturer. We have emerged as the market leader in Aluminium Bronze Round Bar. Aluminium Bronze Round Bar is shipped in large quantities and in a variety of formats to a range of destinations. These bars are often used in a variety of industries, including nautical, aerospace, and manufacturing.

We are also the Biggest Round Bars Manufacturer in India. We have established ourselves as one of India's top brands in the Round Bars Manufacturer. Rajkrupa Metal Industries has deliberately positioned itself as a top-tier manufacturer and supplier in the worldwide Round Bars market, with strong commercial and technical personnel expertise.

Nanostructured Aluminum Bronze:

Investigate how nanotechnology advances are impacting the creation of nanostructured aluminum bronze.

Discuss how nanostructuring improves mechanical and chemical characteristics.

Additive Manufacturing and 3D Printing with Aluminum Bronze:

Highlight the rising trend of making sophisticated aluminum bronze components using additive manufacturing techniques such as 3D printing.

Showcase particular applications and sectors that have benefited from this novel approach.

High-Strength Aluminum Bronze Alloys:

Discuss the characteristics and composition of high-strength aluminum bronze alloys.

Investigate their potential uses in crucial areas such as aerospace and military.

Self-Healing Aluminum Bronze Surfaces: