#Aluminium Honeycomb Panels

Explore tagged Tumblr posts

Text

How Stainless Steel Gold Sheets Are Transforming the Architecture Industry

In recent years, the architecture and construction industries have seen a significant transformation in design materials and finishes. One of the most captivating trends is the rise of stainless steel gold sheets in architectural designs. Their luxurious appearance, durability, and versatility have made them a popular choice for modern architecture, transforming the way buildings and structures are conceptualized, built, and finished.

In this blog, we’ll explore how stainless steel gold sheets are making a significant impact on the architectural landscape, enhancing both the aesthetics and functionality of buildings. From their reflective sheen to their resistance to corrosion, these sheets are not just a trend—they are redefining architectural possibilities.

The Appeal of Stainless Steel Gold Sheets

The allure of stainless steel gold sheet lies in their unique combination of durability and elegance. Traditionally, gold was seen as a luxury material, often used in small quantities for ornamentation or accents. However, advancements in metal processing have allowed for the creation of stainless steel sheets that mimic the warm glow of gold, giving architects and designers a cost-effective yet high-impact material to work with.

These sheets are typically thin, flexible, and lightweight, making them ideal for a variety of applications, from building facades to interior designs. The reflective nature of the gold finish creates a striking visual effect, especially in sunlight, giving buildings a glowing and regal appearance. The sheets can be used as a cladding material, on walls, doors, ceilings, or even decorative accents within interior spaces.

Durability Meets Luxury

While the aesthetic appeal of stainless steel gold sheets is undeniable, it is their incredible durability that makes them a practical choice for architectural applications. Stainless steel, as a material, is known for its resistance to rust, corrosion, and staining. This is especially important in the context of architecture, where buildings are exposed to the elements for decades.

Gold-coated stainless steel sheets retain the luxurious shine of gold but with the added benefit of stainless steel’s superior strength. These sheets can withstand harsh weather conditions, temperature fluctuations, and environmental pollutants without fading or losing their luster. This makes them a long-lasting option for high-end buildings, commercial spaces, and even urban landmarks.

In addition to its weather resistance, stainless steel gold sheets are easy to maintain. Unlike traditional gold finishes, which require regular polishing to maintain their shine, stainless steel sheets are relatively low-maintenance. A quick cleaning is often enough to keep them looking pristine, making them an attractive choice for architects and property owners alike.

Versatility in Design

Another reason for the increasing popularity of stainless steel gold sheets is their versatility. These sheets can be easily integrated into various architectural styles, from contemporary and modern designs to more classic, traditional aesthetics. Whether used in large-scale commercial projects or in small-scale residential buildings, they add an element of sophistication and style that elevates the entire structure.

Moreover, the use of aluminium honeycomb panels in conjunction with stainless steel gold sheets is gaining traction. Aluminium honeycomb panels are lightweight, strong, and offer excellent insulation properties. When paired with gold stainless steel sheets, they allow for the creation of cladding systems that are not only aesthetically appealing but also energy-efficient. The combination of these materials enables architects to achieve a striking design while maintaining structural integrity and environmental sustainability.

The flexibility of stainless steel gold sheets allows them to be shaped and customized for a variety of applications. They can be embossed, perforated, or laser-cut to create unique textures and patterns. This design flexibility opens the door to endless creative possibilities, allowing architects to bring their visions to life with a material that’s both functional and visually stunning.

Transforming Urban Spaces

As cities around the world continue to grow, the demand for innovative and sustainable building materials is more pressing than ever. Stainless steel gold sheets are helping transform urban spaces by offering a material that is both luxurious and eco-friendly. The reflective surface of the sheets not only enhances the appearance of buildings but can also help reduce the urban heat island effect. By reflecting sunlight, they can reduce the amount of heat absorbed by buildings, lowering energy consumption for cooling and contributing to a more sustainable urban environment.

Architectural landmarks and iconic buildings are increasingly incorporating gold stainless steel sheets into their designs, adding a touch of grandeur to urban skylines. From high-rise buildings to luxury hotels and shopping malls, these sheets are helping to create structures that are not only functional but visually captivating. The use of these materials can completely transform the atmosphere of a space, giving it a sense of elegance and prestige.

Conclusion

Stainless steel gold sheets have undoubtedly become one of the most exciting developments in the architecture industry. Their combination of beauty, strength, and versatility makes them an ideal material for modern building projects. Architects can now push the boundaries of design, creating structures that are not only visually stunning but also practical and sustainable.

When paired with complementary materials like aluminium honeycomb panels, stainless steel gold sheets offer even greater possibilities for building exteriors and interiors. As the demand for sustainable, aesthetically appealing materials continues to rise, we can expect to see more and more architectural projects embracing the use of stainless steel gold sheets to create iconic, high-performance buildings.

Fabrinox, known for its expertise in providing premium stainless steel products, continues to lead the way in making these materials accessible to architects and designers, helping bring their creative ideas to life. The future of architecture is bright, and stainless steel gold sheets are undoubtedly one of the shining stars in this revolution.

Also Read:

Creating a Rustic Look with Antique Finishes: Tips and Inspirations

The Benefits of Using Stainless Steel for Interior Partitions

Originally published at https://fabrinoxofficially.blogspot.com

0 notes

Text

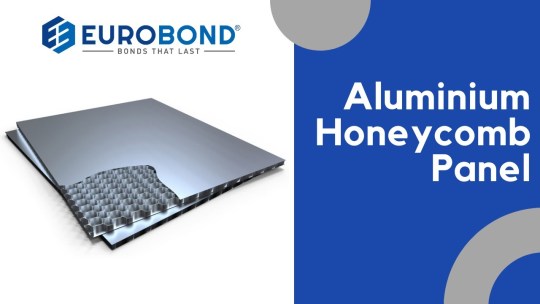

Exploring the Versatility: The Benefits of Aluminum Honeycomb Panels Across Industries

Innovation in construction materials has paved the way for revolutionary solutions in architecture, transportation, and various industrial sectors. One such advancement is the utilization of aluminum honeycomb panels. These lightweight yet sturdy structures offer a multitude of benefits across diverse applications, ranging from aerospace to interior design. In this blog, we delve into the…

View On WordPress

#ACP panels#ACP sheet#Aluminium composite panels#Aluminium Honeycomb Panels#Eurobond#Eurobond ACP#Eurobond ACP panels#Honeycomb Sandwich Panel

0 notes

Text

#aluminium composite panel#Honeycomb Panels#Aluminium Honeycomb Panels#Aluminium Honeycomb Core#Lightweight Honeycomb Panels

0 notes

Text

If you are interested in purchasing one, select from the Viva ACP, they have one of the highest ranges in design and colours for honeycomb panels. Tested from the top institutions nationally and internationally these panels from Viva are the ones for your construction.

0 notes

Text

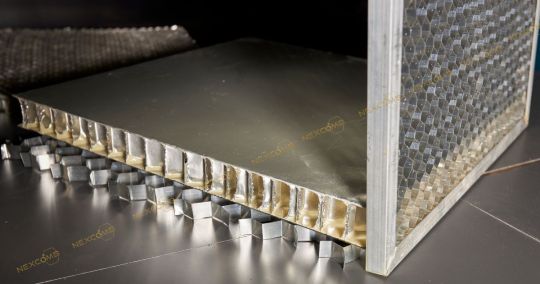

Aluminium honeycomb panel suppliers are companies that produce and distribute high-quality honeycomb panels made from aluminium. These panels consist of a core material made of hexagonal cells that are bonded between two layers of aluminium sheets, providing strength, durability, and lightness.

0 notes

Text

Aluminium honeycomb sandwich panel are a type of composite material used in construction and manufacturing. They consist of two thin sheets of aluminum, bonded to a lightweight honeycomb core made of aluminum or other materials.

0 notes

Text

Aluminium Honeycomb Composite Panel is a type of sandwich panel consisting of two thin aluminium sheets bonded to an aluminium honeycomb core. This combination results in a lightweight and strong panel with excellent thermal and acoustic insulation properties. Ecocomb Aluminium honeycomb composite panels are commonly used in the construction, aerospace, and transportation industries due to their durability, stability, and resistance to corrosion. The panels can be customised in terms of size, shape, and color to meet the specific requirements of various applications. They are also easy to install and maintain, making them a popular choice for various structures, partitions, and cladding systems.

0 notes

Text

3 Excellent Reasons to Use Aluminum Composite Panels

Aluminum composite panels by ACP Sheet manufacturers can give buildings an edgy, modern appearance. Aside from its aesthetic value, aluminum composite panels have a variety of other benefits.

#ACP Sheet manufacturers#ACP Sheet Manufacturer#Aluminium Composite Panel Manufacturers#Aluminum Honeycomb Panel

0 notes

Text

How Does Composite Wall Cladding Perform In Extreme Weather Conditions?

You would be happy to know that composite wall cladding is a popular choice for architects, builders, and property owners looking for an attractive and durable cladding material that can withstand a range of weather conditions. But have you ever thought that how does composite wall cladding perform in extreme weather conditions?

Heat: Composite wall cladding and shiplap wall panels are designed to resist heat and is often used in hot and humid climates. These wall panels have a high resistance to UV rays, which can cause fading and discoloration in other materials.

Cold: In cold weather, composite wall cladding is less likely to crack or warp than other building materials like wood or vinyl. You would be happy to know that this wall panel can also withstand freeze-thaw cycles without damage.

Wind: Similarly, composite wall cladding has excellent wind resistance and can withstand strong winds without becoming dislodged or damaged easily.

Rain: At the same time, composite wall cladding is water-resistant and will not absorb moisture like wood or other organic materials. Due to this reason, this wall cladding also resists mold and mildew growth.

Hail: On the other hand, the aluminum corrugate panel can withstand hail impact without denting or breaking, making it a good choice for areas prone to hailstorms.

Composite wall cladding from HONGZAN Building Materials Co., Ltd is an excellent choice for extreme weather conditions. The durability, and resistance to heat, cold, wind, rain, and hail, make these wall claddings a reliable and low-maintenance option for any building project.

Get to know more us :-

Aluminum Honeycomb | Decorative Wall Panels | Aluminium Komposit | Aluminum Honeycomb Panel | Aluminium Panel | Honeycomb Aluminum Panel | Stone Veneer Panels | Aluminium Wall Panels

Contact us :-

Company Name: Hongzen Building Materials Co., Ltd.

Address: Mayi Village, Shiling Town, Nanhai District, Foshan City, Guangdong Province, China.

Country: China

Mobile: 0086 139 2319 2421

Email: [email protected]

Website: https://chinahoneycombpanel.com/

0 notes

Text

Juan Antonio Olivares Untitled (endoscopy), 2023 Acrylic and graphite powder on aluminium honeycomb panel 122 x 183 x 2.5 cm 48 x 72 x 1 in

Unto Dust, Fitzpatrick Gallery, Paris, March 25 – April 29, 2023,

50 notes

·

View notes

Text

Produsen Media Sarang Tawon Ipal | 0851-2467-2203

Produsen Media Sarang Tawon Ipal, Spesifikasi: Sarang Tawon PVC/Bio Media Filter/Honeycomb Ukuran tersedia: P 120 XL 30 X T 30 cm (1 balok), Material: PVC Sheet (Transparent/Clear), Thickness: 0.3 mm, Fungsi Sebagai media filter pengembangbiakan, bakteri pada Sewage Treatment Plant Berat. Dalam dunia industri dan konstruksi, kebutuhan akan material berkualitas tinggi terus meningkat. Salah satu inovasi yang tengah menjadi perhatian adalah penggunaan media sarang tawon sebagai solusi dalam berbagai aplikasi. PT Hefram Asasta Indonesia, sebagai perusahaan terkemuka di bidang ini, menawarkan produk media sarang tawon yang unggul dan mampu memenuhi kebutuhan pasar. Artikel ini akan mengupas tuntas tentang media sarang tawon dari PT Hefram Asasta Indonesia, termasuk keunggulannya, aplikasi, dan mengapa produk ini menjadi pilihan utama.

Apa Itu Media Sarang Tawon?

Media sarang tawon adalah material berbentuk seperti struktur sarang lebah yang dirancang untuk memberikan kekuatan, efisiensi, dan ketahanan. Struktur unik ini memungkinkan material memiliki berat yang ringan tetapi tetap kuat, sehingga cocok untuk berbagai aplikasi seperti konstruksi, otomotif, furnitur, hingga panel dekoratif.

Produk ini terbuat dari berbagai bahan, seperti aluminium, kertas kraft, atau plastik, tergantung pada kebutuhan spesifik penggunaannya. Media sarang tawon dari PT Hefram Asasta Indonesia dirancang dengan presisi tinggi untuk memastikan kualitas terbaik di setiap produk yang dihasilkan.

Aplikasi Media Sarang Tawon

Media sarang tawon memiliki aplikasi yang sangat luas di berbagai industri. Berikut beberapa contoh penggunaannya:

Konstruksi: Digunakan dalam pembuatan dinding panel, lantai, dan atap yang memerlukan kombinasi antara ringan dan kuat.

Otomotif: Bermanfaat untuk mengurangi berat kendaraan tanpa mengorbankan kekuatan, sehingga meningkatkan efisiensi bahan bakar.

Furnitur: Digunakan untuk meja, pintu, dan rak dengan desain modern dan ringan.

Aerospace: Struktur sarang tawon digunakan dalam komponen pesawat untuk mengurangi bobot sekaligus meningkatkan performa.

Dekorasi: Dapat dijadikan elemen dekoratif yang estetis dan fungsional.

PT Hefram Asasta Indonesia memahami kebutuhan setiap industri dan menawarkan berbagai varian media sarang tawon yang dapat disesuaikan dengan kebutuhan spesifik.

Mengapa Memilih Produk dari PT Hefram Asasta Indonesia?

PT Hefram Asasta Indonesia telah lama dikenal sebagai produsen terpercaya dalam penyediaan media sarang tawon berkualitas. Beberapa alasan memilih produk dari perusahaan ini meliputi:

Kualitas Unggul Produk media sarang tawon dari PT Hefram Asasta Indonesia dirancang menggunakan teknologi canggih untuk memastikan setiap produk memenuhi standar internasional.

Ramah Lingkungan Sebagai bagian dari komitmen terhadap keberlanjutan, PT Hefram Asasta Indonesia menggunakan bahan baku yang ramah lingkungan.

Varian Produk yang Lengkap Perusahaan ini menawarkan berbagai pilihan bahan, ukuran, dan ketebalan sesuai dengan kebutuhan pelanggan.

Pelayanan Pelanggan yang Baik Tim ahli di PT Hefram Asasta Indonesia selalu siap memberikan konsultasi untuk membantu pelanggan memilih produk yang tepat.

Efisiensi Biaya Produk ini tidak hanya berkualitas tetapi juga ditawarkan dengan harga yang kompetitif, menjadikannya solusi yang ekonomis.

Untuk informasi lebih lengkap hubungi:

Kontak kami: 085124672203

Lokasi: https://maps.app.goo.gl/i1oFQVLbgsZskneT6

Marketplace: https://tokopedia.link/ERPo2y2UnQb

Keunggulan

Berikut beberapa keunggulan utama dari media sarang tawon yang diproduksi oleh PT Hefram Asasta Indonesia:

Kekuatan Tinggi dengan Berat Ringan Struktur unik media sarang tawon memberikan keseimbangan sempurna antara kekuatan dan berat.

Tahan Lama Material ini dirancang untuk tahan terhadap tekanan, kelembapan, dan perubahan suhu.

Mudah Dikustomisasi Media sarang tawon dapat disesuaikan dengan berbagai bentuk dan ukuran sesuai kebutuhan proyek.

Ramah Lingkungan Produk ini menggunakan bahan baku yang dapat didaur ulang, mendukung keberlanjutan lingkungan.

Efisiensi Energi Dalam penggunaannya, media sarang tawon membantu mengurangi konsumsi energi, terutama dalam aplikasi otomotif dan aerospace.

Spesifikasi: Sarang Tawon PVC/Bio Media Filter/Honeycomb Ukuran tersedia: P 120 XL 30 X T 30 cm (1 balok), Material: PVC Sheet (Transparan/Clear), Tebal: 0.3 mm, Fungsi Sebagai mediafilter pengembangbiaka, bakteri pada Sewage Treatment Plant Berat.

Kesimpulan

Media sarang tawon dari PT Hefram Asasta Indonesia merupakan solusi inovatif yang menawarkan kekuatan, efisiensi, dan keberlanjutan. Dengan aplikasi yang luas di berbagai industri, produk ini menjadi pilihan yang ideal bagi mereka yang mencari material berkualitas tinggi dengan harga kompetitif. Dukungan pelayanan pelanggan yang handal dan komitmen terhadap kualitas menjadikan PT Hefram Asasta Indonesia mitra terpercaya dalam menyediakan media sarang tawon.

Untuk informasi lebih lengkap hubungi:

Kontak kami: 085124672203

Lokasi: https://maps.app.goo.gl/i1oFQVLbgsZskneT6

Marketplace: https://tokopedia.link/ERPo2y2UnQb

youtube

media sarang tawon, media sarang tawon surabaya, media sarang tawon dotcom, media sarang tawon jawa timur, media sarang tawon murah, media sarang tawon ipal, media sarang tawon jakarta, media sarang tawon ntt, media sarang tawon, media sarang tawon sidoarjo

#mediasarangtawon #mediasarangtawonsurabaya #mediasarangtawondotcom #mediasarangtawonjawatimur #mediasarangtawonmurah #mediasarangtawonipal #mediasarangtawonjakarta #mediasarangtawonntt #mediasarangtawonpvc #mediasarangtawonsidoarjo

3 notes

·

View notes

Text

How PVD Wall Art is Transforming Modern Interior Design

In today's world of interior design, innovation plays a key role in creating spaces that reflect both beauty and functionality. One trend that is steadily gaining attention is PVD wall art. It has emerged as a popular choice for homeowners, architects, and interior designers who are looking to add a touch of luxury and elegance to their projects.

What is PVD Wall Art?

PVD, or Physical Vapour Deposition, is a process that involves applying a thin layer of metal coating to various surfaces. This technique enhances the durability and appearance of the material, resulting in a sleek, high-quality finish. PVD wall art is created using this technology to produce beautiful metallic designs that can elevate any interior space.

From gold to rose gold, silver, and even copper tones, PVD coatings bring a wide array of metallic hues that add sophistication to walls. The finishes are not just visually appealing, but also resistant to scratches, corrosion, and fading, making them a long-lasting option for home and commercial spaces alike.

The Impact of PVD Wall Art on Modern Interiors

Interior design has evolved beyond the basics of wall paint and wallpaper. Homeowners are now seeking design elements that make a statement. PVD wall art offers a unique, contemporary appeal that fits well with modern and minimalistic designs.

Aesthetic Appeal: One of the biggest advantages of PVD wall art is its ability to create a focal point in any room. Whether it's a living room, office, or hotel lobby, the metallic shine of PVD adds a luxurious element that catches the eye. Its reflective surface also enhances lighting in the space, creating a more open and bright atmosphere.

Durability and Versatility: While other wall décor options may require frequent touch-ups or replacements, PVD coatings are known for their resilience. They can withstand harsh environments and maintain their polished look over time. This durability makes them ideal for high-traffic areas like hallways, restaurants, or shopping malls.

Customizable Designs: One of the biggest perks of PVD wall art is its ability to be customized. Designers can work with different shapes, patterns, and finishes to match the specific theme or mood of a room. Whether you prefer sleek, geometric designs or intricate, nature-inspired motifs, PVD coatings can bring any vision to life.

PVD Wall Art and Aluminium Honeycomb Panels

For large installations, combining PVD wall art with aluminium honeycomb panels is an excellent choice. These panels offer lightweight yet strong backing, ensuring that the wall art stays secure without adding unnecessary weight. The combination of PVD coating with aluminium honeycomb panels creates a perfect blend of strength and elegance, making it suitable for large wall décor in commercial and residential spaces.

Fabrinox: A Leader in Modern Interior Design

At Fabrinox, we are proud to offer premium PVD wall art solutions that cater to both contemporary and traditional design preferences. Our expert team works closely with clients to deliver custom designs that meet the highest standards of quality and durability. We also specialize in using aluminum honeycomb panels, ensuring that your PVD installations are both lightweight and long-lasting.

By choosing Fabrinox, you're not only getting top-tier craftsmanship but also an aesthetic transformation for your interior spaces that will leave a lasting impression.

With the increasing demand for unique and luxurious design elements, PVD wall art is set to become a defining feature of modern interiors. Whether you're designing a residential home or a commercial property, this stylish and durable option offers the perfect combination of beauty and functionality.

So, why wait? Transform your interiors with Fabrinox today!

Also Read:

What is Rose Gold PVD Coating? A Comprehensive Guide

How to Choose the Right Copper Door for Your Home

Originally published at https://fabrinoxofficially.blogspot.com

0 notes

Text

EuroComb: Aluminium Honeycomb Panels Processing Demystified

Remember the internal tug-of-war when smartphones arrived, and we held on to our trusted push-button mobiles? Today we have long since bid them goodbye, having overcome our initial misgivings about smartphones.

Innovations are accompanied by apprehensions, which once demystified, open up a world of benefits! It’s the same with Aluminium Honeycomb Panels (AHPs). This blog will therefore focus on bursting the bubbles of doubt surrounding AHP processing, to promote informed decisions that help reap the amazing benefits of this lightweight

EuroComb Panel – a great boon for Clean Room Systems, Commercial Facades, Ceilings, Coach Bodies, and Aerospace Applications.

A word about Aluminium Honeycomb Panels: Inspired by nature, EuroComb is a sandwich panel with a hexagonal honeycomb structure at its core that contributes to its lightweight, while simultaneously augmenting stiffness and stability. Built on the principles of safety and environment-friendliness, EuroComb incorporates fire-retardant properties and are fully recyclable. Added advantages are their superior flatness, exceptional stiffness, and sound insulation. Our PVDF coating makes EuroComb weatherproof, UV resistant, waterproof and dust-proof.

Now let’s deal with the deceptive doubts.

Myth: EuroComb processing is complex and difficult, requiring highly skilled labour.

Reality: EuroComb processing employs normal tools with specific tool extensions to make processing easy – ensuring a smooth finished product with minimum effort.

So, let’s explore each process to demystify the AHP Processing myth.

Cutting – employs two simple tools:

Pitch Router/Hand Router

Common Blade

The Pitch Router affixed with the Common Blade is effortlessly guided across the length of the AHP that is to be cut. That’s it – the job is done!

Edging – involves four tools:

Electric Router

Rectangular Groove Bit

Pitch Router/Hand Router

Common Blade

The Electric Router affixed with the Rectangular Groove is guided across the bottom edge, keeping the EuroComb’s top cover intact. The Pitch Router’s Common Blade is then guided across to make a groove on the Top cover, enabling it to be manually bent over the smoothened edge, to conceal it. Voilà, you have a smooth finished product with edges neatly and safely covered!

Folding – uses the same four tools as Edging:

Electric Router

Rectangular Groove

Pitch Router/Hand Router

Common Blade

The Electric Router affixed with the Rectangular Groove when guided across the area to be folded, will efficiently scoop off the bottom cover and honeycomb core, keeping the top cover intact. The Pitch Router’s Common Blade is then run across the top cover to make a groove, enabling the desired manual folding. Hey presto! – You have a safe, smooth finished product accurately and impeccably folded at 90°.

Innovation is the avenue through which the world progresses, and hence at Eurobond, we are proud to be India’s first ACP brand to manufacture EuroComb – Aluminium Honeycomb Panels in-house. Our 15-year warranty exudes our confidence because we leverage the best quality control procedures that test our EuroComb with advanced equipment – to secure your safety.

#acp sheet#eurobond acp#eurobond acp panels#acp cladding#acp panel#eurobond#Aluminium Honeycomb Panels#Honeycomb Panels#Honeycomb acp Panels

0 notes

Text

The Space Shuttle's vertical tail is 27 feet high and 22 feet long at the base. It ensures the stability and the direction of the orbiter in flight. It supports the mobiles elements which are used to oriente the orbiter or to slow down (areobreak). These last ones are jointed with four pieces and controlled by an electrical engine. The box of the vertical stabilizer is made of two strengten pieces mashin-finished from one piece, panels. The box is settled to the rear part of the fuselage by ten bolts. The mobile parts (direction and aerobrake) are made of aluminium alloy and panels in honeycomb structure.

All were built by Fairchild Republic Company, in Long Island, New York.

source

Boeing Images: B1230615

43 notes

·

View notes

Text

Aluminium honeycomb panels are lightweight, strong, and energy-efficient panels revolutionize building exteriors. Their unique honeycomb structure offers superior durability, thermal insulation, and aesthetic appeal.

0 notes

Text

Aluminium honeycomb panels India are lightweight construction materials consisting of a honeycomb core sandwiched between two aluminum sheets. They are widely used in industries such as aerospace, automotive, marine, and architecture.

0 notes