#Aluminium Foam Industry Trends

Explore tagged Tumblr posts

Text

Aluminum Foam Market Size, Opportunities, Share, Top Suppliers, Growth, Trends, Regional Analysis, Key Segments, Graph and Forecast to 2027

Aluminum foam is a lightweight material characterized by its porous structure, consisting of interconnected aluminum cells. It is produced through a process involving the creation of gas bubbles in molten aluminum, resulting in a solid with a high strength-to-weight ratio. Aluminum foam finds applications in industries such as automotive, aerospace, construction, and marine, offering benefits…

View On WordPress

#Aluminium Foam Companies#Aluminium Foam Ecosystem#Aluminium Foam Industry#Aluminium Foam Industry Forecast#Aluminium Foam Industry Share#Aluminium Foam Industry Trends#Aluminium Foam Products#Global Aluminium Foam Industry

0 notes

Text

Thermo Compression Forming Market is Projected to Reach $13.37 billion by 2029

The report "Thermo Compression Forming Market by Foam Type (Thermoplastic Foam, Needle-Punch Nonwovens, Light Weight Glass Mat Thermoplastic), End-use Industry (Automotive, Aerospace, Construction, Medical, Electrical & Electronics) - Global Forecast to 2029", is projected to reach a market size of USD 13.37 billion by 2029 from USD 11.00 billion in 2024, at a CAGR of 4.0%. North America is the one of the largest markets for compression molded components. The demand for foams used in thermo compression forming is experiencing significant growth across various industries, including automotive, construction, medical, aerospace, electronic & electronics, and more. Emerging nations such as US, Canada, Germany, UK, China and Mexico are expected to play a crucial role in driving the global thermo compression forming market forward.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=114021695

Thermoplastic Foams by type segment dominate the market by highest share of the thermo compression forming market during the forecasted period.

Thermoplastic Foams are dominating because of their balanced mechanical qualities and excellent performance-to-cost ratios. These foams have many beneficial applications because of their unique properties, low density and high strength-to-weight ratio. Because of their flexibility and durability, they can be employed in a variety of industries, including the automotive, construction, and medical sectors. Additionally, thermoplastic foams are extensively employed, especially for high performance and cost effectiveness, due to their lower cost as compared to needle-punch nonwovens and lightweight glass mat thermoplastic.

With ongoing technological advancements and innovations in thermoplastic foams, coupled with expanding applications in emerging industries, the segment is expected to experience robust growth in the forecast period.

Automotive by end-use industry segment dominate the market by one of the highest share of the thermo compression forming market during the forecasted period.

The thermo compression forming market is benefitting from the increase in the car production as car makers seek lighter materials in order to improve fuel economy and meet legislated CO2 emission values. Thermo compression forming enables the creation of lightweight and high strength materials such aluminium carbon fibre reinforced plastics and glass fibre reinforced plastics which are crucial in cutting down the overall weight of vehicles. In addition, the new trend on electric vehicles (EVs) requires the utilization of durable, thermally stable, and lightweight material, and thermo compression forming becomes pivotal to form parts such as battery enclosures and exterior panels.

North America region is likely to be the fastest growing thermo compression forming market during the forecast period.

Rapid industrialization and urbanization in the North America region are driving demand across various sectors including automotive, Aerospace, construction, and medical industry. With expanding manufacturing activities in countries like US, Canada, and Mexico there's a rising need for compression molded components for various applications. Moreover, ongoing infrastructural development projects, particularly in Canada and Mexico, are boosting demand in the construction sector for lightweight and durable comonents such as roofing panels and door frames. Advancements in thermo compression forming techniques tailored to diverse industrial needs are poised to further stimulate market growth in the region.

Key Players

FLEXTECH (US), Janco, Inc. (US), Formed Solutions (US), Core Molding Technologies (US), UFP Technologies Inc. (US), Ray Products Company Inc. (US), Engineered Plastic Products Inc. (US), Present Advanced Composites Inc. (US), and Tooling Tech Group (US) are the key players in the global thermo compression forming market.

#thermocompressionformingmarket#thermocompressionforming#thermocompressionformingindustry#compressionforming#thermocompression

0 notes

Text

Revolutionizing Mobility: Advances in Vehicle Weight Optimization

Vehicle Light Weighting Technologies Market is an idea in the automobile business about structure vehicles and trucks that are less heavy as an approach to accomplish better fuel efficiency and handling. Carmakers make parts from carbon fibre, windshields from plastic, and bumper out of aluminium foam, as approaches to reduce vehicle load. The use of these materials is selected on the basis of their price, lightweight ability, ultimately, processing or consumption limitations. Advanced lightweight technologies help to improve automotive fuel consumption and guarantee safety and performance. Usage of lightweight materials reduces emissions by nearly 0.08g CO2/Kg, as with launching of battery electric vehicle, which boosts application of light weighting technology in automotive systems. The adoption of electric vehicles is one of the examples for light weight technologies as parts and system of these vehicles is considerably less than other vehicles.

Top impacting factors: Market Scenario Analysis, Trends, Drivers and Impact Analysis

The automotive industry has seen critical changes in material and manufacturing process in the previous decade to conform to the outflow orders. Rules have constrained automakers to discover various options, for example, lightweight materials, improve proficiency in powertrain, and utilization of pure battery electric vehicles. Subsequently, it is simple for lightweight materials to compete in cost when compared with powertrain productivity measures and regulations. Advancements of reinforced and high-quality plastic for its use as windshield and window glass is evaluated to build the light weighting business sector of plastics. The high cost of materials, for example, carbon fibre strengthened composites, titanium, and magnesium hinder the broad utilization of these materials. As crude materials have a high cost, OEMs in developing nations, who rely more upon economy passenger vehicles prefer to use materials than lightweight materials. However, utilization of lightweight materials is expected to increase gradually in the coming years. The manufacturing cost of vehicle parts made of is higher than conventional materials. Along these, high procedure cost can control the development of the car lightweight material market.

New product launches to flourish the market

Novelis Inc. announced that it is providing the fusion of Toyota Motor Corporation with premium aluminium car body sheet for the all-new Toyota RAV4. The RAV4 is Toyota’s number-one-selling vehicle and the top rated non-pickup truck in the nation. With an as good as ever plan that includes Novelis aluminium in the hood, bumpers, and liftgate, the fifth-age model of the RAV4 is 4% lighter than previous models.

Surge in usage in electric vehicles

The introduction of electric vehicles has brought about a technological advancement and revolution in the automotive business. These vehicles have predominant execution than their internal combustion counterparts. Since electric vehicles have low power engines, they utilize lightweight materials that drive the engine’s pulling limit. In this manner, the expanding demand for electric vehicles gives a chance to the development of the lightweight material market. As the electric vehicles reduce the car emission to help environment the demand for the electrification of vehicles is also increasing.

Key benefits of the report:

This study presents the analytical depiction of the global Vehicle light weighting technologies market with the current trends and future estimations to determine the imminent investment pockets.

The report presents information related to key drivers, restraints, and opportunities along with detailed analysis of the global Vehicle light weighting technologies market.

The current market is quantitatively analysed to highlight the global Vehicle light weighting technologies market growth scenario.

Porter’s five forces analysis illustrates the potency of buyers & suppliers in the market.

The report provides a detailed global vehicle light weighting technologies market analysis based on competitive intensity and how the competition will take shape in coming years.

0 notes

Text

Core Material Market Global Industry Share & Size Analysis

Core Material Market, By Type (Foam, Honeycomb, and Balsa), End-use Industry (Wind Energy, Aerospace & Defense, Marine, Automotive & Transportation, Construction, and Industrial) and Geography (North America, Europe, Asia-Pacific, Middle East and Africa and South America)

Market Overview

Global Core Material market is anticipated to reach USD 1.5 billion in 2021 growing at a CAGR of 13.8% during the forecasting period, 2021-2028.

Core material are made from paper, polymeric foam, or woods like materials which are highly inflammable. These materials are fully covered with insulated materials and are thus not directly exposed to fire. Aluminium core used for covering will make the core material initially unaffected to fire but will eventually melt down.

Due to surge in demand form wind energy industry and use of composites in aerospace industry are some of the factors that have supported long-term expansion for Core Material industry.

Request Sample Pages of Report: https://www.delvens.com/get-free-sample/core-material-market-trends-forecast-till-2028

Key Findings

Global Core Material market is segmented into Type, End-use Industry and geography.

Type segment is segmented into Foam, Honeycomb, and Balsa

End-use Industry segment is segmented into Wind Energy, Aerospace & Defense, Marine, Automotive & Transportation, Construction, and Industrial

Geographically, global Core Material market is sub segmented into North America, Europe, Asia-Pacific, Middle East and Africa and South America and insights are provided for each region and major countries within the regions

To Grow Your Business Revenue, Make an Inquiry Before Buying at: https://www.delvens.com/Inquire-before-buying/core-material-market-trends-forecast-till-2028

Competitive Landscape

Key players in global Core Material market are 3A Composites (Switzerland), Diab Group (Sweden), Gurit (Switzerland), Hexcel Corporation (US), Armacell International S.A. (Luxembourg), Euro-Composites S.A. (Luxembourg), Changzhou Tiansheng New Materials Co. Ltd. (China), and The Gill Corporation (US) among others.

Reasons to Acquire

Increase your understanding of the market for identifying the best and suitable strategies and decisions on the basis of sales or revenue fluctuations in terms of volume and value, distribution chain analysis, market trends and factors

Gain authentic and granular data access for Core Material market so as to understand the trends and the factors involved behind changing market situations

Qualitative and quantitative data utilization to discover arrays of future growth from the market trends of leaders to market visionaries and then recognize the significant areas to compete in the future

In-depth analysis of the changing trends of the market by visualizing the historic and forecast year growth patterns

Purchase the Report: https://www.delvens.com/checkout/core-material-market-trends-forecast-till-2028

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Read Industry Related Reports:

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-8638-5055

The Core Material Market report answers a number of crucial questions, including:

Which companies dominate the Core Material Market?

What current trends will influence the market over the next few years?

What are the market's opportunities, obstacles, and driving forces?

What predictions for the future can help with strategic decision-making?

What advantages does market research offer businesses?

Which particular market segments should industry players focus on in order to take advantage of the most recent technical advancements?

What is the anticipated growth rate for the market economy globally?

0 notes

Text

Aluminum Foam Market Global Industry Analysis, Size, Share, Growth, Trends And Forecast 2033

The most recent market research report on the size, share, and industry of the global aluminium foam market is now available. It includes data tables, pie charts, high-level qualitative chapters, and graphs. It provides a thorough analysis of the market, highlighting evolving trends, player actions, current-to-future scenario analysis, and growth factors that are supported by opinions gleaned from industry consultants and experts.

Historical information, present-day and future market trends, environmental considerations, new technological developments, and technical improvements in the industry are all included in the report on the aluminium foam market. The market for aluminium foam is anticipated to develop at a CAGR of 4.4% between 2022 and 2030 and reach US$ 61.6 million. The car industry’s expanding need for lightweight materials to increase fuel economy and cut emissions, according to the report.

For More Insights on this Market, Get A Sample Report https://www.futuremarketinsights.com/reports/sample/rep-gb-8402

Geographically, North America is predicted to dominate the global porous aluminium market for the foreseeable future. The increasing use of aluminium foam in the aerospace and defence industries, as well as the existence of prominent players in the space, are expected to fuel market growth. Asia-Pacific is expected to increase significantly in the next years, spurred by the region’s expanding automobile and construction industries.

Overall, rising demand for strong and lightweight materials across a variety of industries is expected to propel the worldwide aluminium foam market towards significant growth in the upcoming years.

Key Takeaways

Aluminum foam is expected to pick up the pace due to its high thermal conductivity, immense crush strength, and low density acting against corrosion and being lightweight. Furthermore, the recyclability of aluminum plays a crucial role in the production of aluminum foams.

Reducing the weight of vehicles can attain cost efficiency along with passenger safety is the first priority for OEMs. Surging demand for electrical vehicles which are lightweight is expected to bolster the growth of the aluminum foam market in the years to come.

The rise in urbanization has compelled the construction industry to undergo some commendable technological changes in the last few years. The construction market seems to evolve at a rapid pace owing to surging technological advancements which have led to the higher usage of aluminum foam in infrastructure development.

New advances have taken place in the market to improve the quality of aluminum foams inducing higher strength. Backed by several impressive properties like shock wave attenuation, high stiffness, vibration damping, high crush energy, and thermal & sound insulation, the aluminum foam market is anticipated to prosper over the forecast period.

The automotive industry and transportation sector are expected to witness an opulent increase of 142 basis points owing to the growing use of aluminum foams for manufacturing automobiles.

East Asia is anticipated to account for 1/3rd of the market share by value in the year 2030 and is likely to create significant incremental opportunities during the forecast period.

Get 20% Discount @ https://www.futuremarketinsights.com/request-discount/rep-gb-8402

More Insights into the Aluminum Foam Market

East Asia is anticipated to dominate the global aluminum foam market by accounting for a significant market share. The demand is majorly driven by a rise in light commercial vehicles and fuel-efficient passenger vehicles. In addition to that, the presence of a large number of manufacturers in the region is likely to boost the aluminum foam market.

Expansion of the automotive industry and a hike in the recyclability rate are important factors that are likely to augment the growth of the aluminum foam market in the North American region. There is a higher usage of aluminum foam in more populated regions owing to the need for urban infrastructure and housing facilities.

European countries consist of larger aircraft capacities which are likely to drive the demand for aluminum foam as aluminum foams are used for designing the wings, blades, heat exchangers, battery plates, etc. due to them being lightweight, cost-effective, and heat & fire resistant.

The surge in high potential markets and easy availability of raw materials has led to many automotive manufacturers from North America and Europe setting up their manufacturing plants in South Asia. This is likely to increase the market demand for aluminum foams in the region.

Request for TOC @ https://www.futuremarketinsights.com/toc/rep-gb-8402

Competitive Landscape

The aluminum foam market has its top players accounting for 80-90% of the global production. The key players operating in the market are focusing on attracting substantial portion of consumer base by offering aluminum foam to cater to wide applications and focus on research to enhance their product offerings.

Key Players:

Beihai Composite Materials Co.,Ltd.

Composite Materials Ltd.

Cymat Technologies Ltd.

American Elements Corporation

ERG Aerospace Corp.

Hollomet GmbH

Pohltec Metalfoam GmbH

Key Segments Covered In Aluminum Foam Industry Research

By Product Type

Open Cell Foam

Closed Cell Foam

Others

By Application Type

Energy Absorber

Heat Exchanger

Damping Structures

Filtration

Insulation

Others

By End-use

Automotive & Transportation

Aerospace & Defense

Building & Construction

Chemical

Other Industrial

By Region

North America Aluminum Foam Market

Latin America Aluminum Foam Market

Europe Aluminum Foam Market

0 notes

Text

Aluminum rod enterprise development symposium held in Changge Secondary Aluminum Industry Association

On the afternoon of January 9th, the symposium for aluminum rod entrepreneurs in the recycled aluminum industry was held in the Changge Recycled Aluminum Industry Association. Chairman Shang Junwei and entrepreneurs from many aluminum rod enterprises in Dazhou attended the symposium, which was presided over by Li Chengxue, executive vice president of Changge Secondary Aluminum Industry Association.

At the meeting, everyone reviewed and summarized the work situation in 2022, predicted and judged the development trend in 2023; regarding the operating status of their own companies, they talked about their own opinions from the aspects of raw materials, production links, and sales links. Through the symposium, everyone has firm confidence, learns from each other, and expresses that they will work together to improve together and contribute their talents to the development of Dazhou's circular economy industry!

Adtech Metallurgical Materials Co.,Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions. The main products of adtech :

porous ceramic filter, cff filter. ceramic foundry filter . porous ceramic plate . ceramic filter plate . deep bed filter.

ceramic foam filter .

online degasser . nitrogen degassing . degassing equipment . rotary degassing . rotary degasser,. aluminium degassing machine. rotary degassing aluminum .degassing machine. degassing unit .

boron nitride coating ,deslagging , granular flux,bn coating,tundish powder, refining flux, aluminum casting Flux.casting flux .aluminum degassing flux . refining agent . deslagging agent . cover flux for aluminium, cover flux, flux for aluminum casting . boron nitride paint . covering agent .

launder system . electric launder system .

tundish nozzle, tap out cone, tap out cone, caster tip , tap cone, etc.

To learn more, please follow website: https://www.alalloycasting.com/

Contact: [email protected]

#Aluminum#AluminumFiltration#AluminumDegassing#AluminumIngot#AluminumFactory#AluminumProcessing#porousceramicfilter#degassingunit

0 notes

Text

Food Packaging Trends In 2020: An Overview

Food packaging plays a crucial role in marketing the food product. The outer packaging has a huge impact on attracting customers to buy food products. Nowadays there is a huge demand for food packaging suppliers in Dubai. In this article, we have rounded up the food packaging trends in 2020. Let's take a look at it:

Materials used in food packaging

Disposable plastic

Disposable plastic containers are an excellent form of food packaging. Disposable food storage containers are ideal for storing and transporting food items safely. The demand for Disposable food packaging in UAE is increasing day by day.

Aluminium and tin

Tin and aluminium are widely used in packaging canned foods and beverages. The low cost, lightness and corrosion resistance make them suitable for food packaging.

Glass

Glass is one the most important materials used in the food packaging industry. Glass containers are ideal for storing coffee, spices, dairy products etc. Glass bottles are a safe bet for storing soft drinks and alcohol as it is impermeable to gases.

Paper

Paper is widely used in food packaging industries. It is eco-friendly, durable and is ideal for using as food delivery boxes and take away containers. Many suppliers providing disposable food packaging in Qatar use paper for their food packaging needs.

Bamboo

Bamboo based food packaging products are quite common now. Some brands offer bamboo based disposable food packaging in Dubai such as drinking straws, serving platters etc.

Types of food packaging

1.Flexible packages: this type of packages includes cling wraps, squeezable tubes, vacuum bags, foam trays, bubble wraps and much more.

2.Rigid packages: this type of packages includes cans, bottles, jars, trays etc.

3.Semi flexible packages: this type of packages includes tetra packs, boxes, caps and closures.

Hope you got an overview of the food packaging trends in 2020. If you found this article useful, please share it with others. Thank you!

1 note

·

View note

Text

How to Make Mold Release Agent: Complete Guide and Tips

To produce large quantities of similar products, manufacturing companies use molds. This process is very efficient and doesn’t take plenty of time, which is another reason why brands use it. Some of the final products which were made using molds include glass, metal, rubber, plastic, and similar. What’s more, molds are also implemented in compression, blow molding, injection, and more, to name just a few. But when producers use mold, they need a chemical component that separates the materials from the mold. And that chemical has a name – mold release agent.

That’s why we compiled a thorough and detailed guide about everything there is to know about the mold release oil or agent. We’ll define the term, see its various types and where it can be applied. After that, we’ll move on to the production process and end with factors to consider when buying mold release agents. Read on and take notes!

What Is a Release Agent?

For all those who aren’t familiar with the term, a release agent is a chemical that stops the materials from bonding with the surface of the mold. You can even find it under different names such as a de-molding agent. Its main role is to create an effect of slipping so that the substance easily separates from the mold. Metaphorically speaking, it’s like putting a bit of butter in the pan before you plan to bake something with the idea to effortlessly remove the food from the pan’s bottom after you’re done with the cooking.

Thus, the answer to the question ‘What's mold release agent?’ is that it’s considered to be a crucial barrier that prevents the substance from blending with the mold. If that happens and a release agent isn’t used, manufacturers have to perform elaborate processes of cleaning up. All of that may result in losing plenty of time as well as productivity. That’s why companies who implement mold release oils look towards them as an investment rather than a cost once they find the oil that suits their needs and production.

It’s common for mistakes to happen even while using this type of chemical. For instance, an agent that isn’t right for the product or its wrongful usage can have huge negative consequences. That may impact the whole overall quality and performance of the finished product. But we’ll get to that very quickly.

The Functionality of the Release Agent

As we previously stated, the main function of the release agent is to act as a barrier. However, more very useful functions can be attributed to it. We’ll cover some of the most important ones now.

Having said that, these chemicals have the ability to minimize the production period. That’s why manufacturing firms can work with exceptionally tight and rigorous schedules. The release agents will help them increase the volume of materials during the process of molding. If that isn’t enough, the whole cycle time of the process is significantly reduced. In return, that translates to saving time as well as money for the brand.

All the damage to the products that can make them not ready for utilization or sale is reduced to a bare minimum with these chemicals. Without them, the mold can be glued to the material. In that case, more material will have to be thrown out and more cash would be spent. So, it’s safe to conclude that they provide another layer of protection.

Moreover, like with most things, molds are also the subjects to multiple replacements, and even unscheduled or premature ones, too. If mold release chemicals are used, the production process will be kept effective between maintenance and cleaning periods. That way, the whole lifespan of the molds is extended and new ones wouldn’t have to be purchased for a very long time.

If we’re theoretically speaking, release oils are meant for just separating. But, in reality, the ingredients of the oils can have an impact on the features and the overall outlook of the end product. Some agents are known to make surfaces appear matte or excessively shiny. And you may not want that. That’s why thoroughly understanding how agents can affect your part is vital if you don’t want any unwanted instances to happen.

We previously touched upon the slipping effect that manufacturers want to successfully detach their materials from the molds. Here, we’ll just mention that another function of the agents is their ability to be merged with other agents. When companies combine them, they can decide the level as well as the intensity of the slipping effect in certain parts of the molds.

Finally, with proper agents, there isn’t much space for cleaning afterwards as very few or no traces are left behind. It goes without saying that that’s very budget-friendly.

Classification of Release Agent

There are numerous types of agents. And which one is used depends on multiple factors. They may include the price, the personal needs of the manufacturers, level of danger they may inflict, laws and regulations, drying periods, shipping, and more. For starters, we’ll list the major categories and discuss them afterwards:

· Water-based release agents

· Solvent-based release agents

· Non-permanent release agents

· Sacrificial release agents

· Semi-permanent release agents

· Internal release agents

The trends in release agents point towards water-based solutions. One of the reasons why they’re preferred nowadays is that they’re more environmentally-friendly. It takes a while before they’re fully dry, too. Also, it’s quite affordable to get them as the shipping is usually cheaper for these types of agents.

On the other hand, solvent-based ones are more traditional chemicals. Their components only take care of a safe detaching. They’re known to immediately become dry. But they can be a bit dangerous towards the health of the molders and the welfare, especially if there is no adequate system for ventilation in the room. Flammability is another feature of theirs, too.

The non-permanent release agents are more of a sub-type of the solvent-based ones. They don’t unnecessarily slow down the process or create a lot of extra scrap material. The part where these agents excel is that they’re uniquely modified and created according to specific molds.

The sacrificial agents don’t consist of plenty of solid components. And they’re known to last a shorter period when compared to other kinds of agents. One of their key features is that they should be used at the start of every molding cycle. As a result of that, they require more labor force.

Another category of agents is the semi-permanent. The factor permanence in the language of mold release agents is the period before you need to apply the agent again. And this type of agent doesn’t have to be applied again before each molding cycle commences, unlike the sacrificial agent. If you want to increase the durability of the agent, it’s advisable to use it on surfaces that aren’t wet and are clean and without any other coatings and ingredients lying on them.

Finally, let’s take a closer look at the internal agents. Just like the name implies, they’re added directly to the material in the molding while it’s still blending together. For example, this technique is found in tire molding. Plus, while the material is blending together, the molder can choose the right dosage if they use this type of agent. That shortens the needed time period, too. Molders can also have more control over the whole molding due to these capabilities of the agent.

Application of Release Agent

Before you start the applying process, you should be aware that there are various techniques to do this. This is due to the fact that not all agents are the same. Some of them ask for coatings that are thicker while others need a longer time to dry. Therefore, it’s always a good idea to read through the instructions enclosed by the manufacturer to make sure which technique to use.

Which mainly used in:

l Polyurethane Releasing: such as PU Soft Foam, Polyurethane Rigid Foam, PU Slow Resilience Release Agent, PU Insole, etc.

l Metal Casting: Such as Aluminium Die Casting, Magnesium Die Casting, Zinc Alloy Die Casting, Metal Forming, Metal Extrusion, etc

l Composite Material Releasing: Carbon Fiber, FRP Fiberglass, Epoxy Resin , LED Material, PVA Material, etc.

l Others: Release agent for concrete Form, Plastic, Rubber, Outside Tyre, Glass, etc.

One of the most common ways to apply the release agent includes aerosol spray cans. They can be utilized by workers, professional machines or even an assembly line. The aerosol can is filled with a release agent that’s pressurized. As for the coating of the molds, the agent can coat either with spray hoses when the projects are bigger and more automated or a simple paintbrush when you’re working on a small project.

Not to forget, a big number of mold release agents are prone to inflaming. So, you should be well-covered and protected while applying them. To minimize the risk, you can use a professional machine. It works without releasing the dangerous fumes from the agent in the air.

Release Agent Production Process

Everybody who works with release agents knows that there is not one mold release agent nor one production process to make it. Each specific industry tweaks its own version. Naturally, a food manufacturer and a company making concrete can’t use the same agent for obvious reasons.

Generally, though, a couple of textbooks mention that a type of a release agent, usually, can consist of water, a functional siloxane, a stiffening agent, as well as a base and a crosslinker. For example, you can use a mold release agent even at home for a sculpture you have ordered. This is especially nice if the mold is of the non-flexible kind.

We’ll show you how to prepare yourself a do-it-yourself release agent. All you need is a couple of drops of different oils and a spray bottle. Put the oil in the spray bottle, preferably by using a funnel. That way you lower the chances of oil getting spilled all over you or your furniture. After that, insert a bit of clove oil. This step will help you prevent mold from appearing on the casting mold. Be aware that some materials among which are plaster as well as alginate and others are more likely to get mold on the surface than some.

How to Choose a Good Release Agent

The whole point of applying release agent is to keep the cured part away from the mold. That’s why it’s a waste if your chosen agent isn’t able to do this. To prevent this from happening, you should clearly understand which types of release agents are used for what and apply them accordingly. However, picking the perfect agent can be tricky and tough. Out of all the products on the market, users find themselves doubting which one to get.

Now, we’ll give you a hand with the choice of the right release agent for you. Here are some key indicators to have in mind.

· Universal vs. Multiple Release Agents – One of the questions you should be asking while deciding is whether you want to use multiple agents or have one that fits all purposes. In some cases, the universal agent can be less efficient. However, some parts can be saved from contamination with it.

· Affordability – People always search for cheap products. When it comes to release agents, it all depends on the material. So, silicone oils, waxes, and PVA agents have the lowest cost. Yet compromises should be made. These materials are known to not stick long requiring re-application soon. Also, they can transfer to the part with mold.

· Layer of materials – You should see which agents form thinner and which thicker layers to keep the mold at bay.

· Enough surface slipping

· Surface durability and adhesion

· Chemical inertness

These are only a few things to consider. Of course, you’re free to look at the matter from your own point of view and see which agent serves the purpose you need it for.

Final Words

All things considered, mold release agents have become a necessity. Without them, your spaces will succumb to mold. They help you make a layer that will separate the cured part from the rest thus saving you the trouble. However, there are many types to choose from, which is why we enclosed some details to help you make your decision. Also, we shared how the applying process goes and told you how to make your own release agent if you don’t want to buy one. In any case, now it’s your turn to decide what works for you when it comes to mold release agents.

So, what are your thoughts after all of this? Have you found the answers you’re looking for? Do you have any experiences with these agents? Share everything with us here!

Lisa Sun, professional chemical release agent sales from SAKURAI mold release agent, has been involved in release agent for over 10 years. For more information visit: https://meiyahg.com/

1 note

·

View note

Text

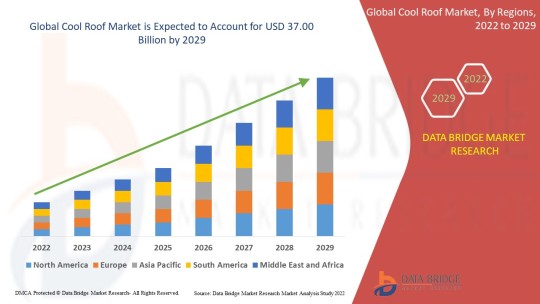

Global Cool Roof Market – Industry Trends and Forecast to 2029

Global Cool Roof Market was valued at USD 21.12 billion in 2021 and is expected to reach USD 37.00 billion by 2029, registering a CAGR 6.43% during the forecast period of 2022-2029.

Market Analysis and Size

There has been massive expansion of the construction industry over the recent years. The construction industry is gaining significant traction due to an increase in the number of green building projects, which favors the cool roof market. Moreover, the favorable factors such as rapid urbanization, increased infrastructure as a result of rapid urbanization and trade transaction flexibility are all driving the global cool roofs market.

Global Cool Roof Market was valued at USD 21.12 billion in 2021 and is expected to reach USD 37.00 billion by 2029, registering a CAGR 6.43% during the forecast period of 2022-2029. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team also includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and climate chain scenario.

Get the sample copy of the report here:

Global Cool Roof Market Scope

The cool roof market is segmented on the basis of type, product, reflective coatings and application. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Type

Steep-Slope Roofs

Low-Slope Roofs

Product

Coated Roofs

Foam Roofs

Modified BUR

Single-Ply Membranes

Asphalt Shingles

Metal Roofs

Tiles

Slates

Reflective Coatings

White Roof Coatings

Pigmented Coatings

Aluminium Roof Coatings

Roofing Membranes

Single-Ply Thermoplastic Membranes

Others

Application

Residential

Commercial

Industrial

Cool Roof Market Regional Analysis/Insights

The cool roof market is analyzed and market size insights and trends are provided by country, type, product, reflective coatings and application as referenced above.

The countries covered in the cool roof market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Cool Roof Market Share Analysis

The cool roof market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to cool roof market.

Some of the major players operating in the cool roof market are

Dupont (U.S.)

PABCO Building Products, LLC. (U.S.)

Malarkey Roofing (U.S.)

DAIKIN (Japan)

Dow (U.S.)

Freudenberg SE (Germany)

The Chemours Company (U.S.)

BASF SE (Germany)

Rogers Corporation (U.S.)

3M (U.S.)

H.B. Fuller Company (U.S.)

Henkel AG & Co. KGaA (Germany)

Mapei S.p.A (Italy)

CHRYSO GROUP (France)

Owens Corning (U.S.)

GAF (U.S.)

Certain Teed (U.S.)

IKO Industries Ltd. (Canada)

Tamko Building Products, LLC (U.S.)

Henry Company (U.S.)

ATAS International Inc. (U.S.)

SOLVAY (Belgium)

Polyglass S.p.A (Italy)

Get Full Access of Report @

MAJOR TOC OF THE REPORT

Chapter One: Introduction

Chapter Two: Market Segmentation

Chapter Three: Market Overview

Chapter Four: Executive Summary

Chapter Five: Premium Insights

Chapter Six: cool roof market

Get TOC Details

Browse Related Reports@

Global Methylene Chloride Market – Industry Trends and Forecast to 2029

Global Waste Heat Recovery System Market – Industry Trends and Forecast to 2027

Global Shotcrete/Sprayed Concrete Market – Industry Trends and Forecast to 2027

Global High-Performance Insulation Market – Industry Trends and Forecast to 2027

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

#cool roof market#cool roof market scope#cool roof market share#cool roof market demand#cool roof market invest#cool roof market future#cool roof market forecast

0 notes

Text

Swab Market Size : Research Methodology, Top Manufactures and Market Size Estimate 2029 | Puritan Medical Products, SARSTEDT AG & Co. KG, MWE, FL MEDICAL s.r.l

Swab Market research report has been prepared with a nice combination of industry insight, smart solutions, practical solutions and newest technology to give better user experience. Under market segmentation chapter, research and analysis is done based on several market and industry segments such as application, vertical, deployment model, end user, and geography. To perform this market research study, competent and advanced tools and techniques have been utilized that include the SWOT analysis and Porter’s Five Forces Analysis. Businesses can surely anticipate the reduced risk and failure with the winning Global swab Market research report.

Data Bridge Market Research analyses that the swab market is expected to undergo a CAGR of 6.48% during the forecast period. This indicates that the market value, which was USD 2.88 billion in 2021, would rocket up to USD 4.75 billion by 2029.

The Swab Market 2019 analysis provides a basic summary of the trade along with definitions, classifications, uses, and trade chain structure. Swab market study is provided for the international markets, along with development trends, competitive landscape analysis, and key regions development status. Development policies and plans are mentioned in the same way as production processes and value structures are analyzed. This report also provides information on import/export consumption, supply and demand, costs, prices, sales, and gross margins.

Get a Free Sample Report of Swab Market Outlook @ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-swab-market

This report is meticulous research formulated by market professionals by deeply analyzing key driving and restraining factors, major regional market situations, major players, and size & scope of the market. The report also offers value chain analysis, Porter’s Five Forces model, and PEST analysis. Furthermore, the competitive landscape in different regions is elucidated in the report to assist top market players, new entrants, and investors determine investment opportunities.

Global Swab Market Scope

The swab market is segmented on the basis of product, shaft, test type, type covers, application and end-user. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Product

Alcohol Swab

Cotton Swab

Dry Swab

Gauze Swab

On the basis of product, the swab market is segmented into alcohol swab, cotton swab, dry swab, gauze swab.

Shaft

Aluminium Shaft

Polypropylene Shaft

Key Players: Global Swab Market

Puritan Medical Products, SARSTEDT AG & Co. KG, MWE, FL MEDICAL s.r.l, Clean Cross Co.,LTD., Neogen Corporation, Citotest Labware Manufacturing Co., Ltd., Unilever, GPC Medical, Elmex Controls Pvt Ltd., Copan Diagnostics, Inc., Medscape, AdvaCare, Strema S.r.l., Blue Manufacturing Company, BD, Thermo Fisher Scientific, Merck KGaA., Sirchie and GROUPE LEMOINE among others.

MAJOR TOC OF THE REPORT

Chapter One: Swab Market Overview

Chapter Two: Manufacturers Profiles

Chapter Three: Global Swab Market Competition, by Players

Chapter Four: Global Swab Market Size by Regions

Chapter Five: Global Swab Market Revenue by Countries

Chapter Six: Global Swab Market Revenue by Product (Alcohol Swab, Cotton Swab, Dry Swab, Gauze Swab)

Chapter Seven: Global Swab Market Revenue by Shaft (Aluminum Shaft, Polypropylene Shaft)

Chapter Eight: Global Swab Market Revenue by Test Type(DNA, Urine, Saliva)

Chapter Nine: Global Swab Market Revenue by Type covers(Cotton Tipped Swabs, Foam Tipped Swabs, Non Wave, Other)

Chapter Ten: Global Swab Market Revenue by Application(Specimen Collection, Disinfection, Other)

Chapter Eleven: Global Swab Market Revenue by End-User (Microbiological Laboratory, Hospitals, Clinics, Academia & Research Institutes)

Get Detail TOC@ https://www.databridgemarketresearch.com/toc/?dbmr=global-swab-market

Key Report Highlights

Comprehensive pricing analysis based on different product types and regional segments

Market size data in terms of revenue and sales volume

Deep insights about regulatory and investment scenarios of the global Swab Market

Analysis of market effect factors and their impact on the forecast and outlook of the global Swab Market

The detailed assessment of the vendor landscape and leading companies to help understand the level of competition in the global Swab Market

Key Questions Answered in Report:

What is the key to the Swab Market?

What will the Swab Market Demand and what will be Growth?

What are the latest opportunities for Swab Market in the future?

What are the strengths of the key players?

Access Full Report @ https://www.databridgemarketresearch.com/reports/global-swab-market

Due to the pandemic, we have included a special section on the Impact of COVID 19 on the Swab Market which would mention How the Covid-19 is affecting the Swab Industry, Market Trends and Potential Opportunities in the COVID-19 Landscape, Covid-19 Impact on Key Regions and Proposal for Corrugated Board Players to Combat Covid-19 Impact.

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

Browse Related Reports@

X-ray Crystallography Market

Cancer Diagnostics Market

Surgical Staplers Market

0 notes

Text

Global Metal Foam Market Scope and overview: World Business Growth, Demand, Trends, Key Players and Global Future Outlook 2031

Global Tire Cord and Tire Fabrics Market Overview:

The Global Tire Cord and Tire Fabrics Market Size Analysis, 2021 market research report is in-depth, giving you all the information you need to make informed industry decisions and develop strategic growth plans. Regardless of the production method or cost structures, this report provides a full understanding of advanced tactics and plans.

The study covers the Global Tire Cord and Tire Fabrics market's most recent revenue and market trends. It stresses a market overview, definition, and structure, as well as preventative and pre-planned management. The report focuses on the factors that influence the Global Tire Cord and Tire Fabrics Market, such as gross margin, cost, market share, capacity utilization, and supply. It also aids in determining the future potential of the Global Tire Cord and Tire Fabrics Market in the next years. The report presents a market overview through common subjects that are highlighted with unique data based on the need. This overview aids in making decisions about how to approach the market and comprehending the industry's backdrop.

Request for free sample: https://www.maximizemarketresearch.com/request-sample/3893

Market Scope:

The research examines the most important market trends and how they will affect new business investments and development in general. New technology, foreign entry, new rules, government investment, new uses, and other industry dynamics are all influenced by market trends. This study includes a detailed trend analysis to assist you in making educated industry decisions in the Global Tire Cord and Tire Fabrics market.

The Global Tire Cord and Tire Fabrics Industry 2021 Market Research Report provides exclusive key statistics, facts, information, trends, and competitive landscape insights in this particular field. The current situation of the Global Tire Cord and Tire Fabrics market is examined, and the market is forecasted to 2027. Company profiles, product images and specs, capacity, production, price, cost, revenue, and contact information for global leading manufacturers of Global Tire Cord and Tire Fabrics market share are likely to be included in the study. Raw materials and equipment are also available.

Get more Report Details: https://www.maximizemarketresearch.com/market-report/global-metal-foam-market/3893/

Key Players:

• Cymat Technologies Ltd. (Canada) • Admatis Ltd. (Hungary) • ERG Aerospace Corporation (US) • American Elements (US) • Pithore Aluminium (Netherlands) • Canada New Energy Materials Corporation (Canada) • Alantum Corporation (South Korea) • Aluinvent ZRT (Hungary) • Hunan Ted New Material Co. Ltd. (China) • Shanghai Zhonghui Foam Aluminum Co. Ltd. (China)

The research report focuses on the current market size of the Global Tire Cord and Tire Fabrics market and their growth rates, based on records and financial information with a company profile of major players/manufacturers.

Regional analysis:

Regional Insights in our studies ensure that you are well-versed in the Global Tire Cord and Tire Fabrics market on a regional level. Any meaningful assessment of potential policy options in response to global market change requires a thorough understanding of local energy, economic, political, and geographic characteristics. The Global Tire Cord and Tire Fabrics market's operation has a substantial impact on local development plans. Our report allows us to conduct regional analyses while also accounting for the effects of the Global Tire Cord and Tire Fabrics market and local growth in other places. At the regional, national, and international levels, we conduct a wide spectrum of high-resolution regional research. We also offer POSTAL and PORTAL analyses to help you better understand the Global Tire Cord and Tire Fabrics market in a certain region. Our study also includes company profiles from various regions, as well as information on their business strategies and statistics.

COVID-19 Impact Analysis on Global Tire Cord and Tire Fabrics Market:

The report has identified the detailed impact of COVID-19 on the Global Tire Cord and Tire Fabrics market in regions such as North America, Asia Pacific, Middle-East, Europe, and South America. The report provides a comprehensive analysis of alternatives, difficult conditions, and difficult scenarios of the Global Tire Cord and Tire Fabrics market during this crisis. The report briefly elaborates the advantages as well as the difficulties in terms of finance and market growth attained during the COVID-19. In addition, the report offers a set of concepts, which is expected to aid readers in deciding and planning a strategy for their business.

Key Questions Answered in the Global Tire Cord and Tire Fabrics Market Report are:

Which product segment grabbed the largest share in the Global Tire Cord and Tire Fabrics market?

How is the competitive scenario of the Global Tire Cord and Tire Fabrics market?

Which are the key factors aiding the Global Tire Cord and Tire Fabrics market growth?

Which region holds the maximum share in the Global Tire Cord and Tire Fabrics market?

What will be the CAGR of the Global Tire Cord and Tire Fabrics market during the forecast period?

Which application segment emerged as the leading segment in the Global Tire Cord and Tire Fabrics market?

Which are the prominent players in the Global Tire Cord and Tire Fabrics market?

What key trends are likely to emerge in the Global Tire Cord and Tire Fabrics market in the coming years?

What will be the Global Tire Cord and Tire Fabrics market size by 2027?

Which company held the largest share in the Global Tire Cord and Tire Fabrics market?

About Us:

Maximize Market Research provides B2B and B2C research on 12000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defence and other manufacturing sectors.

Contact Us:

MAXIMIZE MARKET RESEARCH PVT. LTD.

3rd Floor, Navale IT Park Phase 2,

Pune Bangalore Highway,

Narhe, Pune, Maharashtra 411041, India.

Email: [email protected]

Phone No.: +91 20 6630 3320

Website: www.maximizemarketresearch.com

Related Link: http://www.marketwatch.com/story/food-waste-disposers-market-identify-methodology-production-cost-growth-strategies-historical-data-and-forecast-2027-2022-01-15

https://www.marketwatch.com/press-release/technical-insulation-market-growth-insight-share-emerging-technologies-share-2022-01-15?tesla=y

https://www.marketwatch.com/press-release/paper-coating-materials-market-size-share-leaders-trends-and-forecast-to-2027-2022-01-15?tesla=y

0 notes

Text

Product Innovations and Advancements in Technology to Boost Finger Splint Market Growth

The latest research report published by Fact.MR on the Survey of Finger Splint Market is intended to offer reliable data on various key factors shaping the growth curve & outlook of Finger Splint market. This report works as a rich source of information for key entities such as policy makers, end-use industries, investors, and opinion leaders.

The Demand analysis of Finger Splint Market offers a comprehensive analysis of diverse features, demand, product developments, revenue generation, and sales of Finger Splint Market across the globe.

Click Here To get a Sample Report (Including Full TOC, Table & Figures):-https://www.factmr.com/connectus/sample?flag=S&rep_id=5778

Key Market Segments Covered

Type

Material

Price

Distribution Channel

Region

Frog Finger Splints

Finger Extension Splints

Finger Cot Splints

Thumb Spica Splints

Others

Aluminium Finger Splints

Neoprene Finger Splints

Plastic and Thermoplastic Finger Splints

Foam Finger Splints

Others

Under US$ 10 Finger Splints

US$ 10 – US$ 50 Finger Splints

Above US$ 50 Finger Splints

Offline Sales of Finger Splints

Online Sales of Finger Splints

Medical stores

Sports Stores

Hypermarkets and Supermarkets

Other Retail Stores

e-Commerce Websites

Company-owned websites

North America

South America

Europe

Asia Pacific

Middle East & Africa

Key stakeholders in Market including industry players, policymakers, and investors in various countries have been continuously realigning their strategies and approaches to implement them in order to tap into new opportunities.

The Market survey of Finger Splint offers a comprehensive analysis of diverse features, including production capacities analysis of Finger Splint, demand, product developments, revenue generation, and Size of Finger Splint Market across the globe.

Need More information about Report Methodology? Click here:-https://www.factmr.com/connectus/sample?flag=RM&rep_id=5778

Some Notable Offerings by Fact.MR Report on Finger Splint market:

We will provide you an analysis of the extent to which this Finger Splint market research report acquires commercial characteristics along with examples or instances of information that helps you to understand it better.

We will also help to identify customary/ standard terms and conditions, as offers, worthiness, warranty, and others.

Also, this report will help you to identify any trends to forecast growth rates.

The analyzed report will forecast the general tendency for supply and demand.

Key Takeaways from Market Study

The finger splint market is anticipated to add 2X value by 2031.

Thumb spica finger splints hold a major chunk, equivalent to three-fourth of the global market share, and are set to create an absolute $ opportunity of around US$ 200 Mn over 2021-2031.

Among the materials, aluminium finger splints have been the fastest-growing segment owing to their sturdy and lightweight nature.

Plastic & thermoplastic and neoprene are projected to dominate the market in terms of CAGR, as these materials are majorly used in thumb spica splints, which are dominating the global market.

Due to the COVID-19 crisis, demand for finger splints was hit in 2020, which saw a decline of 2.6% over the 2nd and 3rd quarters of 2020.

To get all-in insights on the regional landscape of the Finger Splint Market, buy now:-https://www.factmr.com/checkout/5778

After reading the Market insights of Finger Splint Report, readers can:

Understand the drivers, restraints, opportunities and trends affecting the Sales of market.

Analyze key regions holding significant share of total Finger Splint market revenue.

Study the growth outlook of Finger Splint market scenario, including production, consumption, history and forecast.

Learn consumption pattern and impact of each end use & supply side analysis of Finger Splint market.

Investigate the recent R&D projects performed by each market player & competitive analysis of Finger Splint Market Players.

How Fact.MR Assists in Making Strategic Moves For Finger Splint Market Manufacturer?

The data provided in the Finger Splint market report offers comprehensive analysis of important industry trends. Industry players can use this data to strategize their potential business moves and gain remarkable revenues in the upcoming period.

The report covers the price trend analysis and value chain analysis along with analysis of diverse offering by market players. The main motive of this report is to assist enterprises to make data-driven decisions and strategize their business moves.

Watch Trending Video on Sodium Formate Industry Survey Report by Fact.MR – https://www.youtube.com/watch?v=MuydFhdcGdA

About Fact.MR:

Market research and consulting agency with a difference! That’s why 80% of Fortune 1,000 companies trust us for making their most critical decisions. While our experienced consultants employ the latest technologies to extract hard-to-find insights, we believe our USP is the trust clients have on our expertise. Spanning a wide range – from automotive & industry 4.0 to healthcare & retail, our coverage is expansive, but we ensure even the most niche categories are analyzed. Our sales offices in United States and Dublin, Ireland. Headquarter based in Dubai, UAE. Reach out to us with your goals, and we’ll be an able research partner.

Contact: US Sales Office : 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583 E-Mail: [email protected]

Corporate Headquarter: Unit No: AU-01-H Gold Tower (AU), Plot No: JLT-PH1-I3A, Jumeirah Lakes Towers, Dubai, United Arab Emirates

0 notes

Text

Plastic Market Overview,Competition, Status And Forecast, Size By Players, Application By 2028

A recently published report titled “Global Plastic Market” is an extensive study by Reports and Data of the Plastic industry and includes a study of several factors that impact the growth of the market. The factors taken into consideration in this report are government policies, market landscape, technologies, market risks, opportunities, and challenges faced by the market. The report further analyzes historical dsata, current and future market trends, recent technological developments, key competitors, and regional bifurcation.

The currently ongoing COVID-19 pandemic has affected several countries and sectors and the subsequent social restrictions and lockdowns have resulted in the economic slowdown. The report analyzes the impact of the pandemic on the overall market and offers an estimation of the current and future impact of the pandemic on the Plastic market.

The global plastic market size is expected to reach USD 777.35 Billion in 2028 and register a revenue CAGR of 3.9% over the forecast period, according to a latest report by Reports and Data. Rapidly increasing global population, rising food demand, expanding urbanization and industrialization trends, and increasing demand for Plastic for food and beverage packaging are some key factors driving global plastic market revenue.

Get a sample of the report @ https://www.reportsanddata.com/sample-enquiry-form/4426

Top companies profiled in the report include:

Dow Chemical Company, LyondellBasell Industries N.V., Exxon Mobil Corporation, Saudi Basic Industries Corporation, Ineos Group Ltd., BASF SE, ENI S.p.A., LG Chem Ltd., Chevron Phillips Chemical Company LLC, and Lanxess AG.

To know more about the report @ https://www.reportsanddata.com/report-detail/plastic-market

Regional Analysis covers:

US

Canada

Mexico

Germany

Italy

UK

Rest of EU

India

China

Japan

South Korea

Rest of APAC

Brazil

Argentina

Rest of Latin America

Saudi Arabia

South Africa

UAE

Rest of MEA

Global Plastic Market Segmentation:

By Types:

Polyester

Very Low Density Polyethylene (VLDPE)

Linear Low Density Polyethylene (LLDPE)

Medium Density Polyethylene (MDPE)

High Density Polyethylene (HDPE)

By Applications:

Injection Molding

Blow Molding

Compression Molding

Film Insert Molding

Gas Assist Molding

Rotational Molding

Structural Foam Molding

Request a customization of the report @ https://www.reportsanddata.com/request-customization-form/4426

Thank you for reading our report. To gain more info on market or customization of the report, contact Reports and Data for an Analyst Brief. Our Report offer valuable and actionable insights to industries to help clients achieve business goals.

Report Highlights:

The latest report on the global Plastic market offers an elaborate list of the company profiles of the top industry players.

The report highlights the most significant aspects of the industry, such as manufacturing/production capacity, sales, future expansion strategies, and the financial positions of the manufacturers and top companies.

The report emphasizes the key application areas of the leading market products & services.

The report involves a SWOT analysis of the global Plastic market.

The report provides vital information about the leading investors, stakeholders, policymakers, manufacturers, suppliers, and service providers involves in the Plastic industry.

Furthermore, the latest study is a precise account of the market and offers actionable insights into the global market size and growth rate over the estimated period.

Read More Related Reports:

Milled FerroSilicon Market Trends

Poly Aluminium Chloride (PAC) Market Statistics

About Us: We are a boutique market intelligence and strategic consulting firm dedicated to make an meaningful impact on businesses across the globe. Our stellar estimation and forecasting models have earned recognition across majority of the business forum across the globe. Our services are arrayed over diverse sectors and industries looking to expand in alternative regions and products.

Contact Us:

John W

Head of Business Development

Reports And Data | Web: www.reportsanddata.com/

Direct Line: +1-212-710-1370

E-mail: [email protected]

Browse More Related Reports:

Hydrogen Peroxide Market Suppliers

Dodecyl Dipropylene Triamine Market Sales Statistics

Nematicides Market Forecast

Agricultural Micronutrients Market Annual Sales

Oil and Gas Drill Bit Market Analysis

0 notes

Text

Returnable Plastic Crates Market Size, Share, Trends, Industry Analysis : Research During The Ongoing COVID-19 And Research Methodology By Forecast To 2030

Future Market Insights (FMI) delivers key insights on the global returnable plastic crates (RPC) market in a newly published report. In terms of revenue, the global RPC market is estimated to grow at a CAGR of 5.5% over the forecast period owing to numerous factors about which FMI offers thorough insights and forecasts in this report. RPCs are used for the storage of various fresh products for shipping them from one place to another. These crates are of several types such as stackable, nestable and collapsible and are used based on several end uses and needs.

Request a Sample Report with Table of Contents and Figures: https://www.futuremarketinsights.com/reports/sample/rep-gb-6050

Global Returnable Plastic Crates Market: Segmental Forecast

The global market for RPCs is segmented based on product type, material type, capacity, application and region.

On the basis of product type, the global market for RPCs is segmented into stackable, nestable and collapsible. On the basis of material type, the global RPC market is segmented into HDPE, PP and others. In addition, based on the capacity, the global RPC market is segmented into less than 10 Kg, 10 Kg to 20 Kg, 20 Kg to 35 Kg, 35 Kg to 50 Kg and more than 50 Kg. Furthermore, based on the applications, the global RPC market is segmented into agriculture, grocery distribution, dairy, bakery, seafood, poultry & meat and other manufacturing.

Global Returnable Plastic Crates Market: Comprehensive Regional Insights

This report assesses the trends that drive each market segment across the various assessed regional markets and offers key takeaways that prove substantially useful for potential market entrants in the RPC market.

The North America RPC market includes a country-level analysis for the U.S. and Canada. The Canada RPC market is expected to grow at a CAGR of 5.7% over the forecast period. The Latin America RPC market includes a country-level analysis for Brazil, Mexico, Argentina and the rest of Latin America. The Mexico RPC market is expected to grow at a CAGR of 6.8% over the forecast period. The Western Europe RPC market includes a country-level analysis for Germany, Italy, U.K., France, Spain, Benelux and the rest of Europe. Germany and Italy account for a significant market share in the Western Europe RPC market. The Eastern Europe RPC market includes a country-level analysis for Russia, Poland, Ukraine and the rest of Eastern Europe. The Poland RPC market is expected to grow at a CAGR of 5.6% over the forecast period. The Asia Pacific excluding Japan RPC market includes a country-level analysis for China, India, ASEAN, Australia & New Zealand and the rest of APEJ. The APEJ RPC market is the most lucrative geographic region, wherein India and China are poised to exhibit lucrative growth during the forecast period. The Middle East and Africa (MEA) RPC market includes a country-level analysis for GCC, South Africa, North Africa and the rest of MEA. The Japan RPC market is expected to grow at a CAGR of 5.4% over the forecast period.

Our advisory services are aimed at helping you with specific, customised insights that are relevant to your specific challenges. Let us know about your challenges and our trusted advisors will connect with you: https://www.futuremarketinsights.com/askus/rep-gb-6050

This report also discusses individual strategies followed by some of the leading companies operating in the global returnable plastic crates market in terms of enhancing their product portfolio, creating new marketing techniques as well as mergers and acquisitions. The competitive landscape included in the report provides a dashboard view as well as company share to report audiences. Key players operating in the global RPC market include Brambles; Myers Industries, Inc.; Supreme Industries Limited; Schoeller Allibert; DS Smith Plc; Dynawest Ltd; Rehrig Pacific Company; TranPak, Inc.; RPP Containers and Ravensbourn Limited.

More from Packaging Market Intelligence:

Bubble Wrap Packaging Market Segmentation By Product - Limited Grade Bubble Wraps, General Grade Bubble Wraps, High Grade Bubble Wraps, Temperature Controlled Bubble Wraps, Others; End Use - Personal care and cosmetics, Healthcare, Homecare, Automotive and Allied Industries, Electrical & Electronics, e-Commerce, Shipping & Logistics, Food & Beverages; Material - Polyethylene (PE), Polyamide (PA), Polyethylene Terephthalate (PET): https://www.futuremarketinsights.com/reports/bubble-wrap-packaging-market

Tissue Paper Converting Machines Market By System: Toilet Rolls Lines- Consumer Market, Away From Home Market; Kitchen Rolls Lines- Consumer Market, Away From Home Market; Tissue Fold Lines- Consumer Market, Away From Home Market; Paper Napkin Lines, Standalone System: https://www.futuremarketinsights.com/reports/tissue-paper-converting-machines-market

Disposable Plates Market Segmentation By Product Type - Plastic Plates(Foam, PP, PET, PE, PLA, PHA), Aluminium, Paper(Laminated, Non Laminated), Others; By Design - Compartment, Plain; By Sales Channel - B2B(Food service Outlets, Educational Institutes, Corporate Offices, Healthcare Facilities), B2C(Online , Supermarket, Hypermarket, Convenience Stores, Mom & Pop Stores): https://www.futuremarketinsights.com/reports/disposable-plates-market

About Us

Future Market Insights (FMI) is a leading market intelligence and consulting firm. We deliver syndicated research reports, custom research reports and consulting services which are personalized in nature. FMI delivers a complete packaged solution, which combines current market intelligence, statistical anecdotes, technology inputs, valuable growth insights and an aerial view of the competitive framework and future market trends.

Browse More Packaging Market Insights

Contact Us 616 Corporate Way, Suite 2-9018, Valley Cottage, NY 10989, United States T: +1-347-918-3531 F: +1-845-579-5705 T (UK): +44-(0)-20-7692-8790 Sales: [email protected]

Press Office: [email protected]

0 notes

Text

Confectionery Packaging Materials Market Global Industry Analysis Size, Share, Trends and Profitable Segments Breakdown and Detailed Analysis of Current and Future Industry Figures till 2026|Major Competitors AptarGroup, Inc., Bemis Company, Inc., WestRock Company, Crown, Amcor plc

Confectionery packaging is used to pack and store the ready to eat food products and resist their contamination with air, microorganisms and other toxic substances. Various different materials are utilized for the packaging of these products. Different types of materials such as corrugated fiberboard, paper, bubble wrap, polystyrene, polyethylene and others are used for packaging of confectionery products.

Confectionery packaging materials market is expected to registering with the steady CAGR of 4.7% in the forecast period of 2019-2026.This rise in market value can be attributed to the demand of confectionery items by a large number of populations. Confectionery items are consumed by a large section of the population is driving the growth of the market Increasing number of retail stores to accommodate high demand will propel the market growth Packaging of confectionery items protect against microorganisms, toxins, air and moisture contaminations, which acts as a driver for the demand of these materials Prevention of products during storage and transportation, also boosts the demand for confectionery packaging materials

Global Confectionery Packaging Materials Market By Type (Foam, Film and Sheet, Bags and Closures, Jars, Others), Material Type (Plastic, Paper & Paperboard, Metal, Aluminium Foil, Glass), Packaging Type (Flexible Packaging, Rigid Packaging), Confectionery Type (Chocolate Confectionery, Sugar Confectionery, Gums, Others), Geography (North America, Asia-Pacific, Europe, South America, Middle East and Africa) – Industry Trends and Forecast to 2026Fluctuation in cost & availability of raw materials may hamper the market growth Growing health awareness regarding the hazardous materials used for packaging is restricting the growth of the market Decline in demand for confectionery products, also acts as a restraint for the market

Get A Sample Request on Get an Sample Request on Confectionery Packaging Materials Market @ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-confectionery-packaging-materials-market

Segmentation: Global Confectionery Packaging Materials Market:

By Type: Foam, Film and Sheet, Bags and Closures, Jars. Others

By Confectionery Type: Chocolate Confectionery, Sugar Confectionery, Gums, Others

By Material Type: Plastic, Paper & Paperboard, Metal, Aluminium Foil, and Glass

By Packaging Type: Flexible Packaging, Rigid Packaging

Confectionery Packaging Materials Market Scope and Market Size:

Competitive Analysis:

Global confectionery packaging materials market is highly fragmented and the major players have used various strategies such as new product launches, expansions, agreements, joint ventures, partnerships, acquisitions, and others to increase their footprints in this market. The report includes market shares of confectionery packaging materials market for Global, Europe, North America, Asia-Pacific, South America and Middle East & Africa.

Key Developments in the Market:

In June 2019, Amcor announced the acquisition of Bemis Company Inc. After this acquisition, company will work as Amcor plc. This acquisition will help the company to build industry leading value proposition

In August 2018, AptarGroup Inc., announced the acquisition of CSP Technologies S.à r.l. The acquisition helped the company to build its position strong in the global market among other key players

Key Market Competitors:

Few of the major competitors currently working in global confectionery packaging materials market are AptarGroup, Inc., Bemis Company, Inc., WestRock Company, Crown, Amcor plc, Silgan Holdings Inc., Graphic Packaging International, LLC, Sonoco Products Company, Bernard Laboratories, Inc., AFP, Inc., Orlando Products Inc., Innovative Plastech, EliteFill, International Plastics Inc., LBU, Inc., Alpha Packaging, Package Design & Manufacturing Inc. and Dart Container Corporation among others

Research Methodology: Global Confectionery Packaging Materials Market:

Data collection and base year analysis is done using data collection modules with large sample sizes. The market data is analyzed and forecasted using market statistical and coherent models. Also market share analysis and key trend analysis are the major success factors in the market report. To know more please request an analyst call or can drop down your enquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market, and primary (industry expert) validation. Apart from this, other data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Company Market Share Analysis, Standards of Measurement, Top to Bottom Analysis and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Get Table of Content on Request @ https://www.databridgemarketresearch.com/toc/?dbmr=global-confectionery-packaging-materials-market

Reasons for buying this Confectionery Packaging Materials Market:

Laser Capture Confectionery Packaging Materials Market aids in understanding the crucial product segments and their perspective.