#Alloy Companies in India

Explore tagged Tumblr posts

Text

Material handling equipment plays a pivotal role in the overall success of a manufacturing unit by boosting productivity, ensuring safety, improving product quality, and enabling efficient use of resources.

Indolift offers a broad range of material handling solutions designed to cater to manufacturing units.

#chainpulleyblocks

#webbingsling

#steelwireropemanufacturers

0 notes

Text

Nickel Alloy Tubes

Nickel Alloy Tubes

KRYSTAL GLOBAL ENGINEERING LIMITED (Formally Known as Krystal Steel Manufacturing Private Limited) is a Stainless Steel company with the vision to be the Leader from INDIA in Stainless and Nickel Alloy Tubes with success based on Operational Excellence and Superlative Services.

We are dedicated to help our customers gain a competitive advantage by supplying a wide range of products such as Tubes, Pipes, U Tubes, Coil Formed Tubes.

KRYSTAL has well established “State of Art” facilitates with continuous enhancement of the product and services to serve the customers across the globe.

Tap here to know more about: https://krystalgeltd.com

#Bright Annealed tubes#Buy Seamless Tubes and Pipes#capillary tubes#Heat Exchanger Tubes Manufacturer#Inconel alloy#Instrumentation Tube#Seamless Tube Suppliers#Seamless Heat Exchanger Tube#Hydraulic Tubes Manufacturer#Manufacturer of Instrumentation Tubes#Manufacturer of Seamless tubes & Pipes#Manufacturer Heat Exchanger Tubes#Manufacturer of Stainless Steel Pipe#Manufacturer of Stainless Steel Tube and Pipe#Manufacturer of Stainless Steel Tubes#Monel alloy#Nickel Alloy Tubes#seamless pipe manufacturer#stainless steel bright annealed tubes manufacturers#stainless steel manufacturer in india#Stainless Steel Pipe manufacturers in India#Stainless Steel Pipe Manufacturing Company In Vadodara#Stainless Steel Seamless Pipes#stainless steel seamless tubes

0 notes

Text

Elevating Product Quality with Quality Assurance Plan for Extrusion Company

Extrusion is a manufacturing process that involves shaping materials like Aluminium, Plastic, and Food by pushing them through a die. It is used in various industries, including automotive, construction, and packaging. However, extrusion is a precision-driven process that requires careful monitoring to ensure the quality of the end product. This is where a Quality Assurance Plan (QAP) comes in.

A Quality Assurance Plan for extrusion is a commitment to excellence that offers real-time monitoring, defect detection, and unmatched quality control. It is designed to unlock precision in extrusion and redefine the landscape, ensuring elevated product quality and unparalleled customer satisfaction. The QAP is seamlessly integrated with “Extrusion ERP”, making managing and controlling the manufacturing process easier.

Real-time monitoring is one of the critical features of the QAP. It allows manufacturers to monitor the extrusion process at every stage and detect any issues before they become significant problems. This ensures that the end product meets the desired specifications and helps prevent costly downtime and rework.

Defect detection is another critical aspect of the QAP. It involves using advanced technologies to identify defects in the extruded product. This allows manufacturers to take corrective action quickly and prevent defective products from reaching customers.

The QAP also offers unmatched quality control. It provides a framework for tracking and managing quality metrics, such as defect rates, scrap rates, and cycle times. This data can be used to identify areas for improvement and optimize the extrusion process. The benefits of a QAP for extrusion are clear. By unlocking precision in the manufacturing process, it ensures that the end product meets the desired specifications and elevates the overall quality of the product. This, in turn, leads to unparalleled customer satisfaction and increased market share.

Quality Assurance Plan for extrusion is vital for any manufacturer looking to deliver high-quality products consistently. It offers real-time monitoring, defect detection, and unmatched quality control. The QAP is seamlessly integrated with ‘Extrusion ERP’, making managing and controlling the manufacturing process easier. By implementing a QAP, manufacturers can unlock precision in extrusion, redefine the landscape, and elevate product quality to new heights.

#erp for aluminium extrusion industry#Best ERP for Aluminium Extrusion Industry#Tailored ERP for Aluminium Extrusion Industry#Extrusion ERP Software for Aluminium Extrusion Manufacturing#Aluminium Extrusion Management ERP#ERP Software for Aluminium Extrusion#ERP Software for Aluminium Extrusion Companies#ERP Solution for Aluminium Extrusion Industry#ERP Software for Metal Industry#ERP for Aluminium Extrusion Companies#ERP Software Development Services#ERP Development Company#ERP Software Development Companies#ERP Software for Aluminium Industry#ERP Software Development Company#ERP Software for Extrusion Companies#Ultimate Extrusion ERP Solution#Extrusion ERP Software Maintenance#Extrusion ERP Solutions in India#ERP Software For Metal Alloys Industry#Small Business Manufacturing Software#extrusion planning software#aluminium extrusion software company#software extrusion aluminum#aluminium extrusion management system#aluminium extrusion software#extrusion software#aluminum extrusion software#tool room management#alloy extrusion company

0 notes

Text

What is fettling in manufacturing?

Fettling in manufacturing refers to the process of refining and finishing a cast metal component to achieve desired quality and appearance. It involves tasks such as cleaning, grinding, cutting, and polishing the surface of the casting to remove excess material, burrs, and imperfections. Fettling not only enhances the aesthetic appeal but also ensures the functional integrity of the final product. This meticulous process helps create components that meet specific design specifications, tolerances, and performance requirements. Fettling plays a vital role in producing high-quality castings for industries like automotive, aerospace, and engineering, contributing to overall product reliability and customer satisfaction.

For those seeking the best fettling services, Datre Corporation Ltd. emerges as a standout option. Renowned as the leading Fettling Service Provider in Kolkata, they boasts a track record of excellence and reliability. Their skilled professionals and state-of-the-art equipment guarantee top-notch fettling results, ensuring your products meet the highest industry standards.

Company name: Datre Corporation Ltd.

Address: Falta Industrial Growth Center (F.I.G.C), Sector — III South 24 Parganas, Pin — 743 504, West Bengal, India

Phone No: 7605087010, 7605087007, 7605087008

Landline No: +91 7605087008

#manufacturing industry#aluminium manufacturer#steel casting manufacturer#steel alloy#alloy steel#fettling#manufacturing company#manufacturer in india

1 note

·

View note

Text

Leading Metals Manufacturer Company in India | Sarda Metals & Alloys Ltd

In the vast landscape of India's industrial sector, Sarda Metals and Alloys stands tall as a prominent metals manufacturer company. With a strong commitment to quality, innovation, and customer satisfaction, Sarda Metals and Alloys has cemented its position as a reliable provider of metal products in the country. In this blog post, we will delve into the company's history, product offerings, manufacturing capabilities, and contributions to the Indian metals industry.

A Rich History of Excellence:

Sarda Metals and Alloys was founded with a vision to cater to the growing demand for high-quality metal products in India. Established in [year], the company has since embarked on a journey of excellence, consistently delivering top-notch products and services to its customers. Over the years, Sarda Metals and Alloys has earned a reputation for its commitment to technological advancements, ethical practices, and sustainable manufacturing processes.

Wide Range of Metal Products:

Sarda Metals and Alloys offers a diverse range of metal products to cater to various industries and applications. The company specializes in manufacturing steel, stainless steel, aluminum, copper, and other non-ferrous metal products. From raw materials to finished products, Sarda Metals and Alloys ensures strict quality control at every stage of the manufacturing process. Whether it's sheets, coils, rods, pipes, or custom-made metal components, the company's product portfolio is designed to meet the diverse needs of its customers.

State-of-the-Art Manufacturing Facilities:

To maintain its high standards of quality and precision, Sarda Metals and Alloys operates state-of-the-art manufacturing facilities equipped with advanced machinery and technology. The company's production units are spread across strategic locations in India, allowing for efficient distribution and prompt delivery of products to customers nationwide. Sarda Metals and Alloys' manufacturing processes adhere to international quality standards, ensuring consistency and reliability in their products.

Focus on Research and Development:

Sarda Metals and Alloys places a strong emphasis on research and development to stay ahead of market trends and customer requirements. The company invests in cutting-edge technologies and employs a team of skilled engineers and metallurgists who continuously innovate and develop new products. By staying at the forefront of technological advancements, Sarda Metals and Alloys consistently introduces innovative metal solutions that cater to evolving industry demands.

Commitment to Sustainability:

Sarda Metals and Alloys is committed to sustainable manufacturing practices and environmental responsibility. The company strives to minimize its ecological footprint by optimizing resource consumption, reducing waste generation, and implementing eco-friendly production processes. Through the use of renewable energy sources and the adoption of recycling and waste management practices, Sarda Metals and Alloys actively contribute to India's sustainable development goals.

Customer-Centric Approach:

At the core of Sarda Metals and Alloys' success lies its customer-centric approach. The company values long-term partnerships with its clients and strives to understand their specific requirements. By providing personalized solutions, prompt delivery, and reliable after-sales support, Sarda Metals and Alloys ensures customer satisfaction at every step of the way.

Sarda Metals and Alloys has emerged as a leading metals manufacturer company in India, renowned for its commitment to quality, innovation, and sustainability. With a diverse product portfolio, advanced manufacturing facilities, and a customer-centric approach, the company continues to shape the Indian metals industry. As Sarda Metals and Alloys look towards the future, its unwavering dedication to excellence positions it as a trusted partner for businesses across various sectors, both in India and beyond.

For More Info: Call: +91 9493549632Visit: https://sardametals.com/

#metals manufacturer in india#metal suppliers in india#metals suppliers#metals manufacturer india#ferro alloys suppliers in india#ferro alloys suppliers#ferro alloys in india#silico manganese#ferro manganese#ferro alloys producer in india#sarda metals and alloys ltd#sarda#ferro alloys producer#leading metals manufacturer company in india#metals manufacturer company in india#best metal manufacture company india#leading manufacturers of silico manganese#silico manganese india#silico manganese manufactures#sarda metals alloys#sarda metals#sarda metals and alloys

0 notes

Photo

"Alloy Steel Round Bars Distributors."

These Alloy Steels F1 A182 Round Bars are low alloy chromium, molybdenum steel in addition to 1/4% Moly. known to deliver exceptional performance and are generally developed for meeting the demands of general corrosion service applications, in General, Engineering and Process Instrumentation applications, and also in heat transfer process equipment like Boilers, Heat Exchangers. Alloy Steel F5 A182 Round Bars are broadly utilized in General Engineering and Process Instrumentation, chemicals, cement, paper, pumps and process and other industries. These offered ranges of ASTM A182 Alloy Steel F9 Bars with a variety of surface finishes such as annealed condition, pickled condition, bright condition, polished condition, ground bright condition, a tempered condition in various sizes covering from 6MM to 300MM. We offer premium quality of Alloy Steel A182 F11 Round Bars with size range consist of 10MM Dia to 250MM Dia as per the national and international standards. We have well experienced and friendly staff with an objective to provide the best Alloy Steels F1 Round Bars and services to every customer. These Alloy Steels F22 Round Bars are broadly utilized in General Engineering and Process Instrumentation, chemicals, cement, paper, pumps and process and other industries.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#alloy 20 chemical composition#polished stainless steel#stainless steel manufacturers in india#alloys stainless steel

0 notes

Text

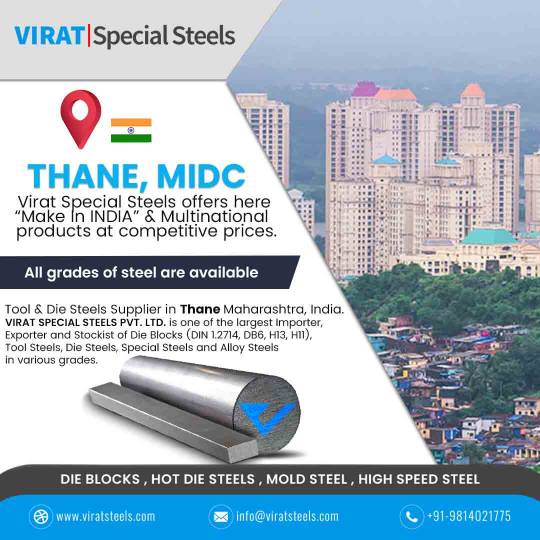

Exploring the top-notch DB6 and H13 Steels Supplier's in MIDC Thane? Look no further—Virat Special Steels delivers excellence!

Whether it’s tool steel, die steel, mold steel, or any other steel requirement, Virat Special Steels stands out as a trusted supplier in #Maharashtra!

Thane's industrial sector boasts a robust tool and die steel industry. These industries are the unsung heroes behind the manufacturing processes of various sectors, providing the essential tools, dies, molds, and components required for production. They serve a wide array of industries, including automotive, aerospace, and medical, which are pivotal to the country's growth.

VIRAT SPECIAL STEELS PVT. LIMITED, your go-to partner for superior quality and reliability. Headquartered in Gurgaon, Virat Special Steels act as a leading supplier of tool and die steels in India offers a wide range of high-quality steels with technical support and customized solutions, ensuring that clients receive materials that perfectly match their manufacturing requirements.

Special offer for Thane MIDC Industrial Area's Available Grades:

Die Steel (HH 370 – 410 BHN): DB6, DIN-1.2714, and AISI L6.

Hot Work Steels: DIN 2343, 2344, AISI H11, and H13.

Plastic Mould Steels: Varieties like DIN 2738, 2311, and AISI P20.

High-Speed Steels: Featuring DIN 3243, 3343, AISI M2, and M35.

Cold Work Steels (HCHCr): DIN 2379, 2080, AISI D2, and D3.

Alloy Steels, EN-Series, and More.

With a state-of-the-art plant in #Gurugram and #Ludhiana, they ensure quality and reliability. Their strong distribution network across India makes them accessible to customers nationwide.

You can explore their offering: https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-thane/

Any further queries feel free to contact us: 🌐https://www.viratsteels.com 📨 [email protected] 📞 +91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#toolsteel#DieSteels#SteelTrades#SpecialSteel#MetalIndustry#DB6#H13#tool steel

3 notes

·

View notes

Text

SS ERW Pipe Supplier In All Brands And Local

Here are some SS ERW pipe suppliers in India, including both established brands and local options, with a focus on Udhhyog:

National Suppliers

Udhhyog: Udhhyog is a reliable B2B platform that specializes in industrial steel products, including SS ERW pipes. They offer competitive pricing and a wide range of high-quality products, catering to various industrial needs. You can explore their offerings at Udhhyog.

Jindal Stainless: A leading manufacturer known for its extensive range of stainless steel products, including ERW pipes, Jindal is recognized for quality and reliability. More information is available at Jindal Stainless.

Tata Steel: Another reputable supplier, Tata Steel provides a variety of stainless steel pipes and is known for high-quality products. Check their offerings at Tata Steel.

Local Suppliers

Sanghvi Steel: This company specializes in a wide range of stainless steel products, including ERW pipes. They are known for their competitive pricing and quality assurance. You can learn more at Sanghvi Steel.

Aesteiron Steels: Aesteiron is recognized for its variety of stainless steel pipes, including ERW options. They focus on quality and customer satisfaction. More details can be found at Aesteiron Steels.

Nexus Metal & Alloys: This local supplier offers affordable SS ERW pipes and emphasizes quality in their products. Visit Nexus Metal & Alloys for more information.

Online Marketplaces

IndiaMART: A major B2B marketplace where you can find various suppliers of SS ERW pipes, including both local manufacturers and established brands. Explore options here: IndiaMART.

TradeIndia: Another platform to search for SS ERW pipe suppliers, allowing you to compare different offers and negotiate prices. Check out TradeIndia.

#SSERWPipes#Udhhyog#StainlessSteel#IndustrialSupplies#SteelPipes#B2BMarket#ConstructionMaterials#PipeSuppliers#QualitySteel#MetalManufacturers#IndianManufacturers#ERWPipes

2 notes

·

View notes

Text

Alloy wheels and steel wheels. When talking about the wheels of a car, the most commonly used term is what we call “the alloys." The alloy wheel type created a massive impact on the automotive sector, especially on the durability, weight, and most importantly, the performance of a car. The invention of these wheel types made way for the origin of several manufacturing companies focusing especially on the alloy wheel type. Moreover, there is another wheel type known as steel wheels, which are older wheel types. Though the weight of these wheel types decreases acceleration and fuel efficiency, they have an advantage over alloy wheels in that they are resistant to impact cracks. What is an alloy? Before discussing the advantages of alloy wheels, we should know about the term "alloy." Technically, alloy means the mixture of one or more metals to form a strong compound. When it comes to automobiles, alloying a wheel means the blending of aluminum and nickel to form a certain type of compound that has certain properties, such as heat resistance, resistance to corrosion, and most importantly, light weight, which enhances the fuel efficiency and acceleration of a car compared with steel wheels. Currently, Uno Minda is the top-tier alloy wheel manufacturer in India. They make the top-quality alloy wheels for most of the cars produced in India. Advantages of alloy and steel wheels. Both alloy wheels and steel wheels have their own advantages and disadvantages. Some of the major advantages of alloys over steel wheels are mainly their light weight, anti-rusting properties, high heat resistance capacity, etc. As a result of these three properties, there is a hike in the performance of the car. The major disadvantage of this wheel type is the high manufacturing and maintenance costs. Steel wheels have comparatively high durability and a low cost of maintenance and manufacturing compared to alloy wheels. These wheel types are recommended for winter usage and for high-power vehicles running in low-temperature areas.

2 notes

·

View notes

Text

Intro: EDELSTAHL VIRAT IBERICA in #portugal An emerging importer Exporter, Supplier & Stockiest of Tool steel, Die & Mold Steels, Recycling products etc.

Tool Steel & Mold Steel Products: https://moldsteel.eu/steel-products/

🏆PLASTIC MOLD STEELS (DIN 2738, 2311 ) – Low / High Hard 🏆HOT WORK STEELS (DIN 1.2714, 2343, 2344) 🏆COLD WORK STEELS (DIN 2379, 2080) 🏆HIGH SPEED STEELS (DIN 3243, 3343, 3355) 🏆CHIPPER KNIFE STEEL (DIN 2631) 🏆ALLOY STEELS, BRIGHT BARS, EN-SERIES ETC.

Scrap / Recycling Products: https://moldsteel.eu/recycling-products/

👉 Used Tools(Carbide, Threading & HSS Cutting Tool Scrap) 👉Die & Mold Steel Blocks, Holder etc. 👉Steel lots, Cut short length, Prime over run 👉2344 Used Mandrel Bars 👉2344 Used Extrusion Dies 👉Forging Dies 👉Electric Motors 👉Used Machineries etc.

We are also involved in trading of Ferrous, Non Ferrous, Alloy steel scrap etc. The dynamic management has enabled the company to grow organically and sustainably in its search for Moving ahead globally with the exploration of Business Opportunities in several nations, including the USA, Canada, Europe, Australia, Middle East, Singapore, Japan, South Korea, India, and Philippines, etc.

Our business scope in B2B and B2C at many stages (finish products, scrap and recycling products, etc.), set us apart from other companies in this sector.

We work with a wide range of industries, including those related to Drop Forging, Aluminum Extrusion, Automotive, Mining, PDC, Power Generation, Petrochemical, Aviation, Railways, Agricultural, Oil and Gas, Drilling, Hand Tools, Bulk Material Handling, etc.

New Development in Special Steels, Recycled Products and Machine tools etc.

TO LEARN MORE >> https://moldsteel.eu/ WhatsApp Chat: +351-920016150 Email: [email protected]

#europe#porto#portugal#din2738#edelstashlviratibrica#viratsteels#b2b#oportunidades#empresas#agricultura#din2714#din2343#din2344#din2379

3 notes

·

View notes

Text

Supplier of Industrial Valve in Tamil Nadu

Meghmani Metal: Meghmani Metal is an ISO 9001:2015 certified supplier of industrial valves based in Tamil Nadu, India. The company offers a diverse range of stainless steel products, including steel flanges, SS fasteners, steel butt welding, steel pipe fittings, steel rods, wires, coils, and flats. Meghmani Metal crafts industrial valves from various material grades, including stainless steel and high nickel alloys. Their warehouse stocks a variety of valves such as ball valves, gate valves, control valves, needle valves, globe valves, butterfly valves, check valves, safety valves, and more. Specifications: Standard: ASTM A240, JIS4304-2005, ASTM A167, EN10088-2-2005, GB/T3280-2007, etc. Specifications: ASTM A240 / ASME SA240 Sizes: Ranging from 1000mm x 2000mm, 1220mm x 2440mm, 4′ x 8′, 1250mm x 2500mm, 1500mm x 3000mm to 6000mm, and 2000mm x 4000mm to 6000mm. Length: Options include 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. Thickness: Varying from 0.3mm to 100mm. Range: Extending from 5mm to 150mm. Surface Finishes: Various surface finishes are available, including hot rolled plate (HR), cold rolled sheet (CR), 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hairline, sandblast, brush, etching, SATIN (met with plastic coated), and more. Service Coverage: Meghmani Metal serves as a prominent supplier of industrial valves in Tamil Nadu, covering areas such as Arcot, Chengalpattu, Chennai, Chidambaram, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kanchipuram, Kanniyakumari, Kodaikanal, Kumbakonam, Madurai, Mamallapuram, Nagappattinam, Nagercoil, Palayamkottai, Pudukkottai, Rajapalayam, Ramanathapuram, Salem, Thanjavur, Tiruchchirappalli, Tirunelveli, Tiruppur, Thoothukudi, Udhagamandalam, and Vellore. For further inquiries and information, interested parties are encouraged to contact Meghmani Metal. Read the full article

#Arcot#Chengalpattu#Chennai#Chidambaram#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Erode#Exporter#India#IndustrialValve#Kanchipuram#Kanniyakumari#Kodaikanal#Kumbakonam#Madurai#Mamallapuram#Manufacturer#Nagappattinam#Nagercoil#Palayamkottai#Pudukkottai#Rajapalayam#Ramanathapuram#Salem#supplier#Thanjavur#Thoothukudi#Tiruchchirappalli

3 notes

·

View notes

Text

The brand INDOLIFT was founded in 2010 by M/S. PDS Trading & Warehousing Co Pvt Ltd to enter the material handling equipment market. After extensive development and modifications, INDOLIFT successfully launched its Chain Pulley Blocks. This launch was made possible through a collaboration with Hangzhou Jentan Machinery Co Ltd, one of China's largest manufacturers of Chain Pulley Blocks.

#alloy steel chain#d shackles#forged clamps#webbing slings#wire rope company in india#manfacturer#wholesale#chain pulley#pulley blocks#hoist#material handling equipment#lifting solutions

0 notes

Text

Monel alloy

Monel alloy

KRYSTAL GLOBAL ENGINEERING LIMITED (Formally Known as Krystal Steel Manufacturing Private Limited) is a Stainless Steel company with the vision to be the Leader from INDIA in Stainless and Nickel Alloy Tubes with success based on Operational Excellence and Superlative Services.

We are dedicated to help our customers gain a competitive advantage by supplying a wide range of products such as Tubes, Pipes, U Tubes, Coil Formed Tubes.

KRYSTAL has well established “State of Art” facilitates with continuous enhancement of the product and services to serve the customers across the globe.

Tap here to know more about: https://www.krystalgeltd.com/

#Bright Annealed tubes#Buy Seamless Tubes and Pipes#capillary tubes#Heat Exchanger Tubes Manufacturer#Inconel alloy#Instrumentation Tube#Seamless Tube Suppliers#Seamless Heat Exchanger Tube#Hydraulic Tubes Manufacturer#Manufacturer of Instrumentation Tubes#Manufacturer of Seamless tubes & Pipes#Manufacturer Heat Exchanger Tubes#Manufacturer of Stainless Steel Pipe#Manufacturer of Stainless Steel Tube and Pipe#Manufacturer of Stainless Steel Tubes#Monel alloy#Nickel Alloy Tubes#seamless pipe manufacturer#stainless steel bright annealed tubes manufacturers#stainless steel manufacturer in india#Stainless Steel Pipe manufacturers in India#Stainless Steel Pipe Manufacturing Company In Vadodara#Stainless Steel Seamless Pipes#stainless steel seamless tubes

0 notes

Text

Quality Assurance in the Digital Age: Leveraging ERP Solutions

In the digital age, quality assurance has become a critical aspect for businesses across industries. In particular, the metal alloys industry and extrusion processes require advanced solutions to ensure consistent quality and efficiency. This is where “Extrusion ERP” comes into play. By using Extrusion ERP for the metal alloys industry, businesses can effectively manage inventory levels, track production performance, and monitor quality control measures.

Key Benefits of Using Extrusion ERP for Quality Assurance:

In an industry where quality can make or break your reputation, Extrusion ERP is the key to ensuring consistent, high-quality products. By leveraging ERP solutions for quality assurance, businesses can unlock several key benefits, including:

Increased Efficiency and Productivity

Enhanced Product Quality

Better Supply Chain Collaboration

Data-Driven Decision Making

Take the Leap to Quality Excellence!

Ready to transform your quality assurance practices in the metal alloy industry? Extrusion ERP is your best partner on this journey.

Don't settle for mediocrity. Advance your quality standards, streamline your operations, and enhance your environmental sustainability with Extrusion ERP. It's time to empower your business for success in the digital age.

Contact us today for a personalized demonstration and discover how Extrusion ERP can unlock a new era of quality assurance in the metal alloy industry. Your quest for exceptional quality begins now.

#ERP Software for Aluminium Extrusion#ERP Software for Aluminium Extrusion Companies#ERP Solution for Aluminium Extrusion Industry#ERP Software for Metal Industry#ERP for Aluminium Extrusion Companies#ERP Software Development Services#ERP Development Company#ERP Software Development Companies#ERP Software for Aluminium Industry#ERP Software Development Company#ERP Software for Extrusion Companies#Ultimate Extrusion ERP Solution#Extrusion ERP Software Maintenance#Extrusion ERP Solutions in India#ERP Software For Metal Alloys Industry#Small Business Manufacturing Software#Best ERP for Aluminium Extrusion Industry#Tailored ERP for Aluminium Extrusion Industry#Extrusion ERP Software for Aluminium Extrusion Manufacturing#Extrusion ERP Excellence for Aluminium Extrusion Manufacturers#Aluminium Extrusion Management ERP#erp for aluminium extrusion industry

0 notes

Text

Ferro Alloys Manganese Manufacturers in India | Sarda Metals and Alloys Ltd

In the world of metallurgy, ferro alloys play a crucial role in enhancing the properties of steel, iron, and various other alloys. Among the many types of ferro alloys, manganese is widely recognized for its ability to improve the strength, hardness, and durability of steel. In India, Sarda Metals and Alloys Ltd has emerged as a prominent manufacturer and supplier of high-quality ferro alloys, with a particular focus on manganese alloys.

Sarda Metals and Alloys Ltd: Pioneering Ferro Alloys Manganese Manufacturers

Sarda Metals and Alloys Ltd, a leading ferro alloys manganese manufacturer in India, has carved a niche for itself in the industry through its commitment to quality, reliability, and innovation. With a state-of-the-art manufacturing facility and a highly skilled workforce, Sarda Metals and Alloys Ltd consistently delivers premium ferroalloys that meet stringent national and international standards.

High-Quality Products: Sarda Metals and Alloys Ltd specializes in the production of various grades of ferro alloys manganese, including high-carbon ferromanganese (HCFeMn), medium-carbon ferromanganese (MCFeMn), and low-carbon ferromanganese (LCFeMn). Their products are known for their exceptional purity, consistency, and uniform composition, making them highly sought after by steel manufacturers across the country.

Stringent Quality Control: Sarda Metals and Alloys Ltd understands the importance of quality control in the manufacturing process. They have implemented rigorous quality control measures at every stage, from sourcing raw materials to the final packaging of the products. The company's commitment to quality is reflected in its adherence to international quality standards, ensuring that customers receive ferro alloys manganese of the highest caliber.

Technological Advancements: Sarda Metals and Alloys Ltd continuously invests in research and development to stay at the forefront of technological advancements in ferro alloys production. By adopting the latest manufacturing techniques, they enhance efficiency, minimize environmental impact, and produce alloys with superior properties. Their dedication to innovation positions them as a reliable partner for steel manufacturers seeking cutting-edge ferro alloys and manganese solutions.

Customer-Centric Approach: Sarda Metals and Alloys Ltd prioritizes customer satisfaction by providing customized solutions tailored to specific requirements. They maintain a strong customer support system, offering technical assistance, product guidance, and prompt delivery to ensure a seamless experience for their clients.

Ferro alloys manganese is a vital component in the steel industry and other sectors that rely on high-quality alloys. As one of India's leading manufacturers, Sarda Metals and Alloys Ltd has cemented its position as a reliable supplier of premium ferro alloys manganese. With a commitment to excellence, stringent quality control measures, technological advancements, and a customer-centric approach, Sarda Metals and Alloys Ltd continues to contribute significantly to India's industrial growth and the production of top-notch steel products.

Whether it's strengthening infrastructure, enhancing manufacturing processes, or driving technological innovation, the importance of ferro alloys manganese cannot be overstated. And in the realm of reliable suppliers, Sarda Metals and Alloys Ltd shines as a trusted partner, providing the highest quality ferro alloys manganese to meet the diverse needs of the Indian market.

For More Info:

Call: +91 9493549632

Visit: https://sardametals.com/manganese-ferro-alloys

#ferro alloys producer in india#ferro manganese#ferro alloys in india#ferro alloys suppliers in india#ferro alloys suppliers#metal suppliers in india#silico manganese#sarda metals and alloys ltd#metals manufacturer in india#sarda#ferro alloys producer#ferro alloys india#ferro alloys manganese manufacturers in india#metals suppliers#silico manganese india#leading manufacturers of silico manganese#silico manganese manufactures#sarda metals alloys#metal manufacture in india#best metal manufacture company india#sarda metals and alloys#sarda metals

0 notes

Photo

"Nickel Alloys 200 Round Bars."

Nickel Alloy 200 Round Bar can be tracked down in solidified and tempered structure. An industrially unalloyed nickel has brilliant erosion opposition and has an exceptionally low electrical resistivity. It additionally has different elements like weldability, formability and high rigidity. There are a great deal of providers who sell items at a lesser cost however the quality matters. The Nickel 200 Bar we supply is created with superb quality material and at the most ideal value that anyone could hope to find. You can track down Nickel 200 Rod of different shapes and sizes. Pick, the best fit for you as there are a great deal of choices accessible. The Nickel Alloy UNS No 2200 Hot Rolled Bar has great protection from consumption in acids and antacids. This is particularly viewed as the most valuable property by nickel 200 round bar providers in Mumbai in times when the combination has been presented to diminishing circumstances. Another property which makes the Nickel 200 UNS N02200 Round Rod stand apart is its exceptional protection from burning soluble bases up to and remembering its obstruction for a liquid state.

#stainless steel round bar#stainless steel wire#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india#nickel alloy#alloys stainless steel#flange manufacturer in india

0 notes