#Agricultural Films and Bonding Market Share

Explore tagged Tumblr posts

Text

Agricultural Films and Bonding Market

Agricultural Films and Bonding Market Size, Share, Trends: Berry Global Leads

Rising Adoption of Biodegradable Agricultural Films to Address Environmental Concerns

Market Overview:

The global Agricultural Films and Bonding Market is projected to grow at a CAGR of 6.8% from 2024 to 2031, reaching a value of USD 14.7 billion by 2031. Asia-Pacific currently dominates the market, accounting for a significant share. Key metrics include film consumption volume, crop yield improvement rates, and adoption across different agricultural sectors. The market is expanding rapidly, driven by rising food demand, technological breakthroughs in film materials, and a growing trend of covered farming. Government measures supporting sustainable agriculture, as well as the transition to more efficient farming practices, are accelerating industry growth.

DOWNLOAD FREE SAMPLE

Market Trends:

The Agricultural Films and Bonding market is shifting significantly towards biodegradable and eco-friendly film solutions, driven by rising environmental concerns and strict plastic waste regulations. Leading film makers are investing in biodegradable alternatives. For example, a large European agricultural film manufacturer announced a 45% year-on-year rise in sales of biodegradable mulch films in 2023. These films, comprised of polymers like polylactic acid (PLA) and thermoplastic starch (TPS), perform similarly to traditional polyethylene films while degrading naturally in the soil after use. Farmers are increasingly open to these eco-friendly options, motivated by both environmental concerns and potential economic savings.

Market Segmentation:

LLDPE dominates the agricultural film market, driven by superior mechanical properties and cost-effectiveness. Linear Low-Density Polyethylene (LLDPE) currently accounts for a significant share of the market. Its superior mechanical properties, including high tensile strength, puncture resistance, and elongation, make it perfect for various agricultural uses. Recent data from the Plastics Industry Association indicates that LLDPE consumption in agricultural films increased by 7.5% in 2023. Technological advances in LLDPE manufacture, such as the introduction of metallocene catalysts, have resulted in improved film characteristics and processing efficiency.

Market Key Players:

Berry Global

Coveris

RKW Group

Armando Alvarez Group

Plastika Kritis

BASF SE

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

An Introduction to How Inflation Impacts Savings and Investments

Inflation is a measurement of the increase in cost for a service or good over a set period, usually a year or more, which impacts savings. The domestic box office provides a basic example of how inflation works.

The film Gone with the Wind, released in 1939, sold over 202.2 million tickets and grossed upwards of $200 million. If the film had released in 2024 and sold a comparable number of tickets, the domestic gross would have eclipsed $1.85 billion.

According to the Bureau of Labor Statistics, the rate of inflation in the United States was 6.4 percent between January 2022 and January 2023. However, this rate can change considerably in response to the state of the economy.

Inflation impacts the lives of everyday consumers in several ways. When inflation rises dramatically, individuals may suddenly stretch their budget to pay for utilities, groceries, and other necessities. Individuals and families should also be aware of inflation’s impact on savings and investments.

In most cases, inflation negatively impacts savings by increasing prices as time progresses. Inflation is especially harmful when it comes to cash savings. If a person stores $10,000 in a safe for 20 years, the goods and services that money can buy will have diminished. The amount of cash has not changed, but the purchasing power has, resulting in a decreased net worth.

Keeping savings with a reputable financial institution can help mitigate the effects of inflation. For example, banks offer interest rates on savings accounts to offset inflation rates. If inflation is unusually high, financial institutions may provide more robust interest rates. However, interest rates are usually not high enough to completely negate inflation: the average national interest rate for savings is just .45 percent. It is rare to find rates above five percent. Even if an individual secures an account with six or seven percent rates, they only manage the impact of inflation rather than growing their money.

Individuals can grow their money more effectively by diversifying their investments and searching for revenue streams that outpace inflation. Unfortunately, inflation can also impact investments. Different investment categories are more or less susceptible to inflation. For example, any investment that provides a set annual return is vulnerable to inflation, including bank certificates of deposit and regular bonds. If one of these investments pays out a $1,000 interest payment each year, the purchasing power of that payment decreases annually.

Identifying inflation’s impact on stocks can be more challenging. Inflation is often at its highest when the economy is strong. Companies sell more stock during these periods, which drives up share prices. At the same time, businesses must pay higher wages and raw materials costs, which hurts the company’s value. An individual company’s market positioning can indicate stock performance compared to inflation.

Investments in select commodities, including agricultural goods and precious metals, thrive during periods of high inflation. Investors often use these commodities as a hedge against inflation. Some investments are indexed for inflation risk, meaning they are more valuable during high inflation and less valuable when inflation is low. Certain bonds and annuities can be indexed for inflation risk.

Individuals concerned about the impact of inflation on their investments should discuss matters with a reputable financial advisor. Diversifying investment portfolios is one of the best strategies for planning against inflation. Otherwise, investors risk losing purchasing power as inflation rises or falls.

0 notes

Text

Global Top 5 Companies Accounted for 73% of total Retransfer ID Card Printers market (QYResearch, 2021)

A retransfer ID card printer that uses a two-step print process instead of a traditional dye-sub direct-to-card technology. The card design is first printed onto a durable overlay transfer film, which is then bonded onto the card’s surface using a combination of heat and pressure.

Using a retransfer printer will allow you to produce high-definition ID cards that are known as ‘over-the-edge ID cards. This means there is no white border left around the edge of the card; something that happens if you’re using a direct-to-card machine. You can watch more about the differences between direct-to-card and retransfer printers in the video below.

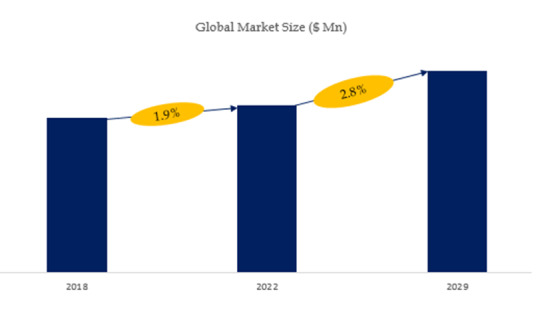

According to the new market research report “Global Retransfer ID Card Printers Market Report 2023-2029”, published by QYResearch, the global Retransfer ID Card Printers market size is projected to reach USD 0.22 billion by 2029, at a CAGR of 2.8% during the forecast period.

Figure. Global Retransfer ID Card Printers Market Size (US$ Million), 2018-2029

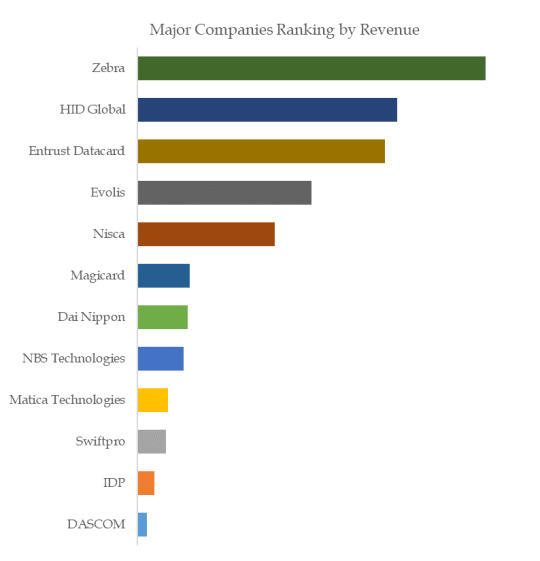

Figure. Global Retransfer ID Card Printers Top 12 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Retransfer ID Card Printers include Zebra, HID Global, Entrust Datacard, Evolis, Nisca, Magicard, Dai Nippon, NBS Technologies, Matica Technologies, Swiftpro, etc. In 2022, the global top five players had a share approximately 73.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Agricultural Films and Bonding Market Size To Hit USD 14.19 Billion By 2024: Grand View Research Inc.

Agricultural Films and Bonding Market Size To Hit USD 14.19 Billion By 2024: Grand View Research Inc.

San Francisco, 5 June 2020: The Report Agricultural Films And Bonding Market Size, Share & Trends Analysis Report By Product (Films, Twine, Netting), By Raw Material, By Application, By Region, And Segment Forecasts, 2016 – 2024

The global agricultural films and bonding market size is expected to reach USD 14.19 billion by 2024, according to a new report by Grand View Research, Inc. Rising need…

View On WordPress

#Agricultural Films and Bonding Industry#Agricultural Films and Bonding Market#Agricultural Films and Bonding Market 2024#Agricultural Films and Bonding Market Revenue#Agricultural Films and Bonding Market Share#Agricultural Films and Bonding Market Size

0 notes

Link

#Agricultural Films And Bonding Market#Agricultural Films And Bonding Market size#Agricultural Films And Bonding Market share#Agricultural Films And Bonding Markettrend#Agricultural Films And Bonding Market 2019

0 notes

Text

Agricultural Films And Bonding Market Sales Overview, Outlook, opportunities, Consumption Analysis, Supply Demand 2018-2024

Agricultural Films And Bonding Market Sales Overview, Outlook, opportunities, Consumption Analysis, Supply Demand 2018-2024

The global agricultural films & bonding market is expected to reach USD 14.19 billion by 2024, according to a new report by Grand View Research, Inc. Rising need for optimum productivity to sustain the food demand is the key factor behind the commercialization of specialty products. Increasing investment in R&D and advancements in agricultural practices backed by technological support is…

View On WordPress

#Agricultural Films And Bonding Market#Agricultural Films And Bonding Market share#Agricultural Films And Bonding Market size#Agricultural Films And Bonding Market trends#Films#Netting#Twine

0 notes

Text

Interview — Sunil Vaidya, sales head, textile division, Cosmo Speciality Chemicals

TSA - Give us some background of Cosmo First since its inception.

Cosmo First (prior Cosmo Films) has a legacy of 40 years of business and has become a global leader in specialty films for packaging, lamination, and labeling applications. Over the years, we have pioneered in various fields and have prided ourselves in our ability to provide industry-first niche solutions in the areas of packaging, lamination, and industrial and labeling applications.

Cosmo at its core has always been pioneering revolutionary innovations to create a better life. All through our journey, we have prided ourselves in our ability to provide industry-first niche solutions in the areas of packaging, lamination, and industrial and labeling applications. We have made inspiring diversifications into specialty chemicals, consumer care, and D2C retail, aiming to be a pioneer in these previously fragmented industries.

Cosmo Speciality Chemicals Private Limited (CSCPL) is a 100% subsidiary of Cosmo First Limited. Started as backward integration for Cosmo’s films business, Cosmo specialty chemicals has now become a leading player in the textile auxiliary market. Our vision is to be a preferred specialty chemicals company, constantly innovating for a better & safer tomorrow.

TSA - What types of solutions does Cosmo Speciality Chemicals provide for the textile industry?

Cosmo Speciality Chemicals began with backward integration for manufacturing chemicals for Cosmo’s films business but eventually, it turned into a business of itself. Cosmo Speciality Chemicals today has become a leading player in the textile auxiliary market with more than 60+ innovative products in their portfolio, which consists of products right from pre-treatment, dyeing, printing, and finishing.

The Adhesives business offers a versatile range of Aqueous, Solvent, and PU-based polymers. With Innovation at our core, CSC developed a wide range of adhesives to enhance the bonding performance of goods. Cosmo’s vision is to be a preferred specialty chemicals company, constantly innovating for a better & safer tomorrow.

TSA - How was the company’s performance in FY21-22?

Within FY21-22, Cosmo specialty chemicals has expanded to 60 products. We are building products for internal as well as external use for the textile industry as a whole. The value proposition of our products is such that we have gained the trust of our customers within a very short span of time.

We launched eco-friendly and certified products for pre-treatment, Dyeing, Printing, and finishing which makes a diverse portfolio of product offerings for the textile industry. Given the product need and market opportunity, we are further expanding into other chemicals business such as Adhesives, DTP coating, and Master-batches.

This expansion will make us one of the only firms to provide a 360-degree solution with films and adhesives under one roof. We are also working on the development of technical textile chemicals that integrate useful properties such as OWR (Oil and Water repellent), moisture management, and Aroma finishing.

TSA - How is the textile market at present (in India as well as globally)?

At the global level, industry players are collaborating to build unique amenities by utilizing technological resources such as artificial intelligence, which are expected to open up new market channels. To gain market share, leading corporations will turn their attention to acquisition and expansion tactics.

With respect to innovation in the textile industry, digital textile printing ink that has features like endurance, excellent color, and superior picture quality will gain popularity. Technical textiles is a rapidly growing sub-segment, are functional fabrics that have applications across various industries including automobiles, civil engineering, construction, agriculture, healthcare, industrial safety, personal protection, etc. For this segment, there is a great opportunity to fill a large demand gap because technical textile consumption in India is currently barely 5-10% against the international 30-70%. We also expect the use of smart fabrics to gain popularity. Smart fabrics also known as e-textiles can recognize various environmental conditions and intelligent textiles and can not only sense environmental changes such as thermal, chemical, or mechanical but can also automatically react to them.

The textile industry has successfully created products like Moisture management finishes, Fragrance finishes, antimicrobial finishes, and technical textiles to provide valuable functional wearables to people. Our goal is to become the top producer of textile auxiliary products in both India and the rest of the globe using sustainable chemistry.

TSA - What is your expectation on growth in textile manufacturing and exports from India after the Indian government’s increased focus on textile manufacturing?

With PLI 2.0, the government is planning to make textile manufacturing in India as competitive as major top exporting hubs like China and Vietnam. This will impact the investment inflow and manufacturing in the textile sector positively. Along with the China +1 policy, businesses are already looking out for outsourcing manufacturing capabilities beyond China to maintain robust supply. With the government’s increased focus in textile manufacturing, we can expect textiles to be produced competitively which will give businesses a cost advantage and the ability to price their goods low. This will help create demand for Indian Exports in the textile industry leading to an increase in our exports at the world stage.

TSA - What are your plans to grow your business further in 2023? Approach for 2023

We aim to keep innovate and develop industry-first sustainable solutions. Our goal is to reach sales of 300tpm during the year 2023 by focusing more on the printing range utilizing in-house know-how and possibilities of backward integration. With the introduction of adhesives. We shall also aim to establish a joint venture with a foreign company to offer a diverse range of products and reach a larger customer base.

TSA - Any Message to our readers?

At Cosmo Speciality Chemicals (CSC), we value bonding. With Innovation, commitment to excellence, and superior quality products, CSC is a one-stop solution for a range of Adhesives, Masterbatches, Coating Chemicals, and Textile Auxiliary chemicals. With a state-of-the-art manufacturing facility coupled with some of the best minds from around the globe, we strive hard to constantly deliver the best products often surpassing global benchmarks. Continuous innovation leads to new and improved products, allowing us to keep pace with our customers evolving needs.

0 notes

Text

U.S Outdoors Advertising Market 2022 - Global Industry Analysis 2022-2030#

"https://tealfeed.com/car-sharing-europe-market-2022-global-wzw73 https://tealfeed.com/distributed-power-generation-systems-us-market-8wmn6 https://tealfeed.com/extensometers-europe-market-size-incredible-possibilities-od7dd https://tealfeed.com/conversion-rate-optimization-cro-software-us-azeoz https://tealfeed.com/non-relational-databases-europe-market-2022-mnzbs https://tealfeed.com/white-shrimp-us-market-growing-rapidly-gbree https://tealfeed.com/fertility-drug-europe-market-demand-future-qlixr https://tealfeed.com/sandalwood-us-market-current-business-trends-7pbxm https://tealfeed.com/waterjet-cutting-machine-europe-market-2022-zhkah https://tealfeed.com/extruded-aluminium-us-market-witness-huge-vegr4 https://tealfeed.com/luxury-car-rental-europe-market-2022-wsad0 https://tealfeed.com/commercial-led-lighting-solution-us-market-6wkuw https://tealfeed.com/express-delivery-europe-market-2022-continues-mty9r https://tealfeed.com/poultry-processing-software-us-market-advancing-ml1dz https://tealfeed.com/foot-traffic-customer-location-intelligence-solution-p6y5c https://tealfeed.com/rfp-software-us-market-continues-rapid-6pqbz https://tealfeed.com/tpe-tourniquet-europe-market-2022-comprehensive-ycu4t https://tealfeed.com/pruritus-therapeutics-us-market-2030-merck-1kpfs https://tealfeed.com/e-discovery-europe-market-2022-huge-szeqn https://tealfeed.com/aircraft-insulation-materials-us-market-2022-qtfvq https://tealfeed.com/proppant-europe-market-2022-analysis-trends-vfj9e https://tealfeed.com/agricultural-films-bonding-us-market-upcoming-fpniy https://tealfeed.com/cnc-machine-cnc-machine-tools-europe-iojdx https://tealfeed.com/business-process-management-bpm-paas-us-972qh https://tealfeed.com/blood-filter-europe-market-size-historical-hxwiz https://tealfeed.com/calcium-fluoride-us-market-covid19-omicron-4wm1l https://tealfeed.com/touch-panels-europe-market-2022-thriving-izwag https://tealfeed.com/rod-ends-us-market-size-growth-1vwma https://tealfeed.com/eyeglasses-frames-europe-market-2022-2030-nsvnq https://tealfeed.com/fertilizer-mixtures-us-market-2022-booming-c2uhm https://tealfeed.com/video-making-software-europe-market-report-m380b https://tealfeed.com/expanders-us-market-2022-explained-effective-dkbap https://tealfeed.com/electronic-ink-screen-products-europe-market-xrj3j https://tealfeed.com/mobile-racks-us-market-trends-2022-narxf https://tealfeed.com/europe-maritime-analytics-industry-future-demand-dr7kf https://tealfeed.com/counter-otc-analgesics-us-market-global-wthrv https://tealfeed.com/solar-charge-controllers-europe-market-expected-pzfmx https://tealfeed.com/us-ladys-sexy-lingeries-market-size-9jday https://tealfeed.com/customer-experience-monitoring-europe-market-2022-b7dcv https://tealfeed.com/reflective-sunglasses-us-market-size-share-gcg3p https://tealfeed.com/acid-steam-cleaning-system-europe-market-iwe8s https://tealfeed.com/digital-diagnostics-us-marketcovid-19-industry-4h0fj https://tealfeed.com/stock-option-plan-administration-software-europe-aqerp https://tealfeed.com/energy-measuring-devices-us-market-witness-5uzwk https://tealfeed.com/copper-indium-gallium-selenide-cigs-cis-nzlpt https://tealfeed.com/art-collection-software-us-market-2022-gbdc5 https://tealfeed.com/jet-skiing-equipment-europe-market-trends-q0llj https://tealfeed.com/us-fluorinated-polymer-market-2022-current-0tjp2 https://tealfeed.com/inductive-absolute-encoders-europe-market-growth-fby0b https://tealfeed.com/s-trioxane-us-market-share-size-h0nvt https://tealfeed.com/water-hardness-test-strips-europe-market-fkycn https://tealfeed.com/copper-coil-us-market-2022-demand-luqyz https://tealfeed.com/textile-recycling-europe-market-future-scope-z6nsr https://tealfeed.com/ultrasonic-beam-sensor-us-market-2022-pi1dp https://tealfeed.com/ethernet-adapter-europe-market-2022-new-7q6mp https://tealfeed.com/ambulatory-surgery-centre-us-market-huge-nmwdv

0 notes

Text

Global Agricultural Films and Bonding Market – Industry Trends and Forecast to 2027

Agricultural films & bonding market will reach an estimated valuation of USD 94.76 million by 2027. Growing prevalence for high quality food crops and increasing population has enhanced the demand for food is expected to enhance the demand for the market. Some of the other factors such as improvement in the standard of the global farming, rising awareness about the cost effectiveness of agricultural films as compared to the traditional films, increasing usage in the greenhouse industry, and increasing investment in R&D for better farming & agricultural practices is expected to drive the agricultural films & bonding market in the forecast period of 2020 to 2027.

Global Agricultural Films & Bonding Market Scope and Market Size

Agricultural films & bonding market is segmented of the basis of material type, type of color, type of feature, type of films, type of process and application. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target markets.

On the basis of material type, the agricultural films & bonding market is segmented into agricultural films, twine, nettings and others. Agricultural films segment is further divided into LDPE and others. Twine segment is divided into sisal, polypropylene, LDPE and others. Netting segment is further divided into HDPE, LDPE and polypropylene and others.

The type of color segment of the agricultural films & bonding market is divided into opaque, transparent and translucent.

Based on type of feature, the agricultural films & bonding market is segmented into moisture proof and water soluble.

The type of films segment is divided into stretch films, shrink films, metallized film, release film and twist film.

On the basis of type of process, the agricultural films & bonding market is segmented into blow molding, casting, multiple extrusion, and injection molding.

Application segment of the agricultural films & bonding market is divided into covering of greenhouse, horticulture and others, mulching, silage, twine and netting.

Get the sample copy of the report here:

Market Analysis and Insights: Global Agricultural Films and Bonding Market

Agricultural films & bonding market will reach an estimated valuation of USD 94.76 million by 2027. Growing prevalence for high quality food crops and increasing population has enhanced the demand for food is expected to enhance the demand for the market. Some of the other factors such as improvement in the standard of the global farming, rising awareness about the cost effectiveness of agricultural films as compared to the traditional films, increasing usage in the greenhouse industry, and increasing investment in R&D for better farming & agricultural practices is expected to drive the agricultural films & bonding market in the forecast period of 2020 to 2027.

Increasing complexity associated with the contamination & recyclability is expected to hamper the market growth in the mentioned forecast period.

This agricultural films & bonding market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on Data Bridge Market Research agricultural films & bonding market contact us for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Agricultural Films & Bonding Market Country Level Analysis

Agricultural films & bonding market is analysed and market size, volume information is provided by material type, type of color, type of feature, type of films, type of process and application as referenced above.

The countries covered in the agricultural films & bonding market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Agricultural Films & Bonding Market Share Analysis

Agricultural films & bonding market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to agricultural films & bonding market.

Major players covered in the agricultural films & bonding market

The major players covered in the agricultural films & bonding market report are Ab Rani Plast Oy, BASF SE, Exxon Mobil Corporation., KURARAY Co., Ltd., Novamont S.p.A., Berry Global Inc., Barbier Group, Industrial Development Company sal, Dai Nippon Printing Co., Ltd., RKW Group, Ginegar Plastic Products Ltd., Essen Multipack, MONO INDUSTRIES, BAGHBAAN VINIMAY PVT. LTD., Charu Agroplast Private Limited., Shivam Polymers, among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Get Full Access of Report @

MAJOR TOC OF THE REPORT

Chapter One: Introduction

Chapter Two: Market Segmentation

Chapter Three: Market Overview

Chapter Four: Executive Summary

Chapter Five: Premium Insights

Agricultural films & bonding market

Get TOC Details:

Browse Related Reports@

Global Microbial Air Samplers Market

Asia-Pacific Microbial Air sampler Market

Europe Microbial Air sampler Market

Middle East and Africa Microbial Air sampler Market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

#global agricultural#Agricultural Films and Bonding Market#agricultural films#bonding market#agriculture and bonding

0 notes

Link

0 notes

Text

Propylene Market Competitive Analysis, Upcoming Demand And Growth Forecast 2019 To 2027

Market OverviewPropylene belongs to the alkene class with three double bonded carbon atoms. It is the second highest used petrochemical after ethylene. Propylene or Propene is a byproduct of oil refining and natural gas processing. During oil refining, ethylene, propene, and other compounds are produced as a result of cracking larger hydrocarbons. A major source of propylene is naphtha cracking, which is intended to produce ethylene and results from refinery cracking producing other products. Propane dehydrogenation converts propane into propylene with byproduct hydrogen. Fluid Catalytic Cracking splitters and On-Purpose Technology (OPT) are most widely used propylene production technologies worldwide. Its end-uses include films, fibers, containers, packaging, and caps and closures. Propylene is considered as an important building block for various chemicals such as polypropylene, propylene oxide, acrylonitrile, cumene, oxoalcohols, isopropylalcohol, acrylic acid, acrylated, isobutyl benzene, and EPDM rubbers. These derivatives of propylene are used in various end-use industries such as automotive, construction, textiles, and packaging.Request Copy Of This Business Report:https://www.coherentmarketinsights.com/market-insight/propylene-market-1997Market DynamicsPolypropylene segment accounted for highest revenue share in the propylene market in 2016, and the segment is projected to retain its position over the forecast period due to high demand for polypropylene and its alloys in automotive industry. In packaging, polypropylene has a variety of application such as bottles, food packaging, and biaxially oriented polypropylene. Therefore, packaging segment is the major segment in end-use Industry.Asia Pacific dominated the market in 2016, and the region is projected to be the fastest growing in the global propylene market over the forecast period. The growth of Asia Pacific propylene market is attributed to increasing demand from end-use industries along with strategic investment by market players such as IRPC Plc., Fujian Meide Petrochemical in the region to tap potential market in China, India, and South Korea. For instance, in December 2016, Thai IRPC announced to expand its local production capacity of propylene by 63% to boost its long-term earnings growth.Detailed Segmentation: Global Propylene Market, By Derivative: PolypropylenePropylene oxideCumeneAcrylonitrileAlcohols (Oxo-alcohols, Isopropyl alcohol)Acrylic acid & AcrylatesOthers (Isobutyl benzene, EPDM rubbers) Global Propylene Market, By End-use Industry: AutomotiveConstructionTextilesPackaging Others (Solvents, Pharmaceuticals) The major players operating in the global propylene market include China Petroleum & Chemical Corporation, BASF SE, ExxonMobil Corporation, The DOW Chemical Company, LyondellBasell Industries N.V., SABIC, BP Plc., and IRPC Plc.About Coherent Market Insights:- Coherent Market Insights is a global market intelligence and consulting organization that provides syndicated research reports, customized research reports, and consulting services. We are known for our actionable insights and authentic reports in various domains including aerospace and defense, agriculture, food and beverages, automotive, chemicals and materials, and virtually all domains and an exhaustive list of sub-domains under the sun. We create value for clients through our highly reliable and accurate reports. We are also committed in playing a leading role in offering insights in various sectors post-COVID-19 and continue to deliver measurable, sustainable results for our clients.Contact Us:Name: Mr. ShahPhone: US +12067016702 / UK +4402081334027Email: [email protected] Our Blogs:https://blog.coherentmarketinsights.com

0 notes

Link

0 notes

Text

Alkylamines Market 2020 by Manufacturers, Regions, Type and Application, Forecast to 2027

Alkylamines Market Forecast

According to MRFR analysis, the Alkylamines Market is expected to reach around 7 billion in 2028.

Alkylamines are a versatile family of chemical synthesis compounds. Alkylamines are ammonia derivative compounds with one or more hydrogen atoms replaced by alkyl groups. Amines are classified according to the number of carbon atoms bonded directly to the nitrogen atom. A primary (1°) amine has one alkyl (or aryl) group on the nitrogen atom, a secondary (2°) amine has two, and a tertiary (3°) amine has three. The alkyl groups are referred to as substituents, while the NH4+ ion is the parent species. The common names for simple aliphatic amines consist of an alphabetic list of alkyl groups attached to the nitrogen atom, followed by the suffix -amine.

Alkylamines are being increasingly used in various applications, including solvents, insecticides, feed additives, rubber processing chemicals, and water treatment chemicals, which are propelling the market forward. The Alkylamines Market is expanding due to the increasing usage of alkylamines in manufacturing a wide range of solvents. Furthermore, the rising use of C1-C6 alkylamines as pesticides in the agrochemical sector is propelling the market growth. Growing usage of solvents in the manufacturing of spandex, polyurethane elastomers, and polyimide films, on the other hand, are contributing to market expansion.

Moreover, the growing demand for alkylamines in wastewater treatment is boosting the alkylamines market. Alkylamine is an effective surfactant that can act as a biocide due to it sability to kill microorganisms. When used in water, alkylamines improve the biocidal activity of chlorinated phenolic. Alkylamines improve water quality while also acting as corrosion inhibitors due to their oxygen scavenging property. The rising amount of wastewater discharged into rivers, which poses health, environmental, and climate-related risks, are driving up demand for water treatment plants. The development of wastewater treatment plants in both developed and developing regions, on the other side, encourages market growth. For instance, in 2019, the South African Government has released a grant of USD 24 million to construct multiple wastewater treatment plants in the province of Mpumalanga. Thus, development in wastewater treatment activities across the globe promotes market growth.

However, the detrimental effects of alkylamine and high maintenance costs will likely hinder the global Alkylamines market. Nevertheless, factors such as government investments and advancement in manufacturing technologies are likely to create lucrative opportunities for market growth in the forecast period. Surging innovation in the pharmaceutical industry is projected to open up new growth potential for leading market players.

Covid Impact Analysis

The outbreak of COVID-19 has had a negative impact on alkylamines production due to the disruption in the supply chain across the globe. This is because of the restrictions on travel and face-to-face meetings coupled with lockdown and curfews to limit the spread of the coronavirus. The pandemic affects operations of different industries, including agriculture, oil and gas, construction, packaging, and others. Because Alkylamines are widely employed in various industries, the decline in their operations directly impacts market growth.

Producers are planning to increase alkylamine prices for end-users to sustain themselves in the market. The majority of raw materials suppliers in this market had to shut down their operating facilities due to the outbreak of COVID-19. The shutdown of various raw material producers and alkylamines manufacturers havereporteda decline in global consumption. Considering the situation, many companies have halted their production facilities across the globe. Some other companies, which are still working, are operating at only 40-60% efficiency. However, these companies have begun operations again.

Manufacturers in this market have decreased their production capacities owing to the decline in demand from the end-use industries, reduced prices, and disruptions in the supply of raw materials. Key players in the market have witnessed a decline in revenue in the fiscal year 2020 compared to 2019. The manufacturers are taking a toll due to reduced demand for products and have announced reduced capital for their prospects. In addition to this, the imposition of various fiscal and monetary policies across the globe to limit the damage caused by COVID -19 by the governments and managements is expected to result in certain relief.

Access full report @

https://www.marketresearchfuture.com/reports/alkylamines-market-10674

Market USP

Stringent government policies

Market Drivers

Growing wastewater treatment plants globally

High demand foralkylamines in solvent applications

Increasingdemand foralkylamines in the paints and coatings industry

Surging consumption of Alkylamines in the agrochemical sectors

Market Restraints

Detrimental effects of alkylamine and high maintenance cost

Fluctuating prices for raw materials

Segmentation

By Type

Methylamines: Methylamine is an organic compound with a formula of CH₃NH₂. It is an ammonia derivative in which one hydrogen atom is replaced with a methyl group. It is the simplest primary amine. Methylamine is widely used in various applications, including agricultural chemicals, paint industries, water treatment chemicals, pharmaceuticals, and corrosion inhibitors.

Ethylamine:Ethylamine is an organic compound with a formula of CH3CH2NH2. It is an ammonia derivative in which two hydrogen atom is replaced with an ethyl group. It is the secondary amine. Ethylamine is widely used in various applications, including fuel tanning, synthetic agent, corrosion inhibitor, and deflocculating agent.

Propylamines: Propylamine is an organic compound with a formula of CH₃(CH₂)₂NH₂. It is widely used in various applications, including textile resins, pharmaceuticals, pesticides, and other chemicals. This segment is projected to witness the highest CAGR during the forecast period.

Butylamines:Butylamine is an organic compound with the formula CH₃(CH₂)₃NH₂. It is used as an ingredient in the manufacture of pesticides (such as thiocarbazides), pharmaceuticals, and emulsifiers. It is also a precursor for the manufacture of N,N′-dibutylthiourea, a rubber vulcanization accelerator, and n-butylbenzenesulfonamide, a plasticizer of nylon.

Cyclohexylamines:Cyclohexylamines is an organic compound with a formula of C6H13 It is a clear, colorless to yellow liquid with a strong, fishy odor. It is used as a corrosion inhibitor for boiler feed water and in the production of other chemicals and insecticides.

Others:The otherssegment include alkylaminessuch as diphenylamine, aziridine, N-methylpiperidine, and N-phenylpiperidine.

By Application

Solvents: The solvent segment held the largest market share of over 30% in the global market. It is widely used in the manufacturing of versatile solvents such as dimethyl acetamide, dimethyl formamide, hexamethyl formamide used in acrylic fiber, pharmaceuticals, and other industries.

Agrochemicals:Alkylamines like monomethlamine, propylamines, dimethylamines, triethylamine, and cyclohexylamines, amongst others are used as an ingredient in the production of pesticides, weedicide, herbicide, and insecticides. It is also used as an intermediate or catalytic agent.

Rubber Processing: Alkylamines are widely used in the production of rubber processing chemicals such as stabilizers, antiozonant, accelerator, and preservative agent. Some of the common Alkylamines include monomethylamine, dimethylamine, diethylamine, monoisopropylamine, and dicyclohexylamine.

Water Treatment:Alkylamine is an effective surfactant that can act as a biocide due to itsability to kill microorganisms. Alkylamines also enhance the biocidal effect of chlorinated phenolic when they are applied in water. Alkylamines improve the water quality and act as resistanceto corrosion due to theirproperty of oxygen scavenging.

Pharmaceuticals:Alkylamines are used in the production of anesthetics, tranquilizers, antihistamine, amoxicillin, ampicillin, antimalarials, and disinfectants, amongst others. This segment is expected to witness significant growth in the coming period.

Others:The others segment include paper chemicals, food and feed additives, textile, dyes, propellants, and emulsifying agents.

By Region

Asia-Pacific:Asia-Pacific accounted for the largest market share and is projected to witness the fastestgrowth in the market. This is mainly attributed to the rapid growth of exports, growing water treatment activities and surfactants, and the vastpresence of key producers in the region.

Europe:Europe recorded a significant growth in the global market based on consumption. The demand is mainly driven by stringent government regulations, rehabilitation of wastewater treatment plants, and the presence of large-scale end-use industries.

North America:North America accounted for the second-largest market share in the global marketdue to large production bases of alkylamines globally and advanced manufacturing technologies.

Middle East & Africa:The demand for alkylamines is rising owing to increased demand from agrochemicals, solvents, and wastewater treatment plants.

Latin America: The Latin American market is projected to witness notable demand for alkylamines due to low manufacturing costs, an upsurge in consumers' purchasing power, and a rise in agricultural production, especially in Brazil and Argentina.

Key Players

BASF SE

Alkylamines Chemicals Ltd.

Arkema

Dow Inc.

Feicheng Acid Chemicals Co. Ltd.

Koei Chemical Company

Luxi Chemical Group Co., Ltd.

Mitsubishi Gas Chemical Company

Eastman Chemical Co.

Balaji Amines

Key Developments

Major players in the alkylamines market are adopting strategies such as technology launches, acquisitions, and R&D activities. Some of the major key developments in the global Alkylamines market include:

In November2019, Alkylamines Chemicals Limited announced to sell Company's 29,77,996 equity shares representing a 30.44% stake in Diamines and Chemicals Limited (Diamines)company.

In November 2019, Eastman Chemical Co., a leading producer of alkylamines announced to increase the capacity for Alkylamines to meet growing global demand from various end markets such as home and personal care, water treatment, and animal nutrition.

Request For Sample Report Here @

https://www.marketresearchfuture.com/sample_request/10674

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future

Phone: +16468459312

Email: [email protected]

Read More Related Article:

https://www.marketresearchfuture.com/reports/flat-steel-market-1885

https://www.marketresearchfuture.com/reports/silicon-nitride-market-8132

https://www.marketresearchfuture.com/reports/electroplating-market-8130

https://www.marketresearchfuture.com/reports/chemical-intermediate-market-1925

0 notes

Text

What's New With Nonwovens in the Medical Industry?

The utilization of medical nonwoven fabric has outpaced woven materials in recent years. Even when traced back to their rapid adoption during WWII, nonwovens were proven to be superior products in terms of adaptability, disposability, cost, and effectiveness. Manufacturing technology improved in the following decades until current-day use of nonwovens has placed them in a position to dominate the medical textile industry.

What are Nonwovens Fabrics?

Nonwovens are defined as sheets or web structures bonded together by the process of entangling fibers or filaments (and sometimes by perforating films) mechanically, chemically, or thermally. The fibers may be oriented randomly throughout the fabric or only following one direction.

Multiple layers may be combined to achieve the desired elongation, strength, and other mechanical properties. Porosity is controlled by varying fiber density, diameter, orientation, and the use of additional mechanical processing.

Key characteristics of nonwovens that justify their use and popularity:

durability

strength

resilience

dimensional stability

low elongation

specific processing to control porosity

Benefits of Nonwovens Driving this Market

With very deliberate care being taken to lower the incidence of hospital-acquired infection, nonwoven medical textiles are the clear winner in this category, thanks to their unique qualities. Medical textile technology is subject to intense monitoring since human lives are at stake. The intense scrutiny has resulted in better quality products and the development and implementation of innovative new uses in the medical field.

Nonwovens are preferred and poised to dominate the industry because they:

are effective barriers against bacteria

outperform linens for reducing airborne contaminants

can be tailored to changing specifications

help mitigate the risks of today's medical environments due to drug-resistant bacteria, worsening viral threats, polluted indoor and outdoor air, and increases in the numbers of blood-borne diseases

In 2014, nonwovens dominated the global medical textiles market. They accounted for over 55% of global volume, and are projected to gain market share through 2024 consistently.

What is SMS Material?

“SMS” stands for spunbond meltblown spunbond. SMS non woven fabric is a type of nonwoven fabric that combines spunbond and meltblown fabrics.When SMS material is created, it has great water repelling capabilities. This is why manufacturers choose to use SMS material in things like face masks, parts of baby diapers, sanitary napkins, and janitorial coveralls. It’s also used for caps, gowns, beddings, and other hospital accessories.

Why Combine Spunbond with Meltblown?

Spunbond polypropylene is a material that has great durability and strength, no matter if it’s wet or dry. It’s very resistant to fraying and is difficult to unravel, plus it barely absorbs any moisture if it becomes wet.

Meltblown, on the other hand, is softer and more pliable than spun bond polypropylene. Their main advantage is their web strength, which is why they’re usually combined with other nonwoven fibers. While spun bond polypropylene has its advantages, it can feel stiff and uncomfortable when it’s put in everyday applications such as coveralls.Since meltblown has a webbed structure and is softer, when you combine these two nonwoven fibers, it provides the wearer with water resistance while still retaining comfort. It’s also breathable, so even if you’re covered from head to toe (as with coveralls), your comfort won’t be compromised.

Applications for SMS Material

Because of how well SMS material repels water, it’s used in a number of industries where people need to block off fluids or other wet substances. Some areas that utilize SMS material’s benefits used are:

Protective apparel

Cleanroom coveralls

Filtration

Insulation

Medical healthcare

Sanitary products

Why The Future Is Nonwoven

Wherever you are sitting or standing right now, there’s bound to be at least one nonwoven fabric in your midst. Teabag or coffee filter, maybe? An air conditioning filter. Lens tissues, bleach wipes, diapers. Surely a face mask or seven.

Though the COVID-19 pandemic certainly pushed awareness of nonwoven fabrics to the forefront, we’ve had our eye on this growing market segment for years. Why? Because pressure-sensitive adhesive tape is often used to make or convert these textiles into usable everyday items.

Here’s our take on how non-wovens will continue to evolve and play a distinct role in the convenience economy.

What Is Non-Woven?

Nonwoven fabrics are the simplest and oldest textile fabrics. Neither woven nor knitted, as the name suggests, non-woven fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically.

They are flat or tufted porous sheets that are made directly from separate fibers, molten plastic, or plastic film. They are not made by weaving or knitting and do not require converting the fibers to yarn.

Typically, a certain percentage of recycled fabrics and oil-based materials are used in non-woven fabrics. The percentage of recycled fabrics varies based upon the strength of the material needed for the specific use. In addition, some nonwoven fabrics can be recycled after use, given the proper treatment and facilities. For this reason, some consider non-woven a more ecological fabric for certain applications, especially in fields and industries where disposable or single-use products are important, such as hospitals, schools, nursing homes, and luxury accommodations.

How are Nonwoven Fabrics Made?

Non-woven fabrics are made in two main methods: they are either felted or they are bonded. Felted non-woven fabric is produced by layering thin sheets, then applying heat, moisture, and pressure to compress the fibers into a thick matted cloth that will not ravel or fray.

There are there main methods of manufacturing bonded non-woven fabrics: Dry Laid, Wet Laid & Direct Spun.

In Dry Laid Non-woven Fabric manufacturing, a web of fibers is laid in a drum and hot air is injected to bond the fibers together.

In Wet-Laid, a web of fibers is mixed with a softening solvent that releases a glue-like substance that bonds the fibers together, and then the web is laid out to dry.

In Direct Spun, the fibers are spun on to a conveyer belt, and glues are sprayed on to the fibers, which are then pressed to bond. (In case of thermoplastic fibers, glue is not required.)

How are Non-Woven Fabrics Being Used?

Nonwoven fabrics penetrate a wide range of markets including medical, apparel, automotive, filtration, construction, geotextiles, and protective. Day by day the use of non-woven fabric is increasing and without them, our present life would be incomprehensible. Indeed, nonwovens play an integral role in the convenience economy.

Basically there are two types of nonwoven fabric: durable and disposal. Around 60% of nonwoven fabric is durable and the other 40% is disposal. These specialty fabrics are engineered to provide specific functions such as absorbency, sterility, liquid repellency, resilience, stretch, softness, strength, flame retardancy, cushioning, thermal insulation, acoustic insulation, and filtration. These properties are often combined to create fabrics suited for specific jobs while achieving a good balance between product use-life and cost. There are many kinds of it, such as non-woven fabrics for clothing, non-woven fabrics for packaging, and so on.

Non-woven fabric, is made of oriented or random fibers. It is a new generation of environmentally friendly materials. It is moisture-proof, breathable, flexible, light, non-combustible, easy to decompose, non-toxic and non-irritating, rich in color, and price. Low cost, recyclable, and so on. For example, polypropylene (pp material) pellets are used as raw materials, which are produced by high-temperature melting, spinning, paving, and hot-rolling and continuous one-step process. It is called cloth because it has the appearance and some properties of the cloth.

Therefore, in the non-woven fabric, S, SS,SSS, SMS mean the following: S: spunbonded non-woven fabric = hot-rolled single-layer web; SS: spunbonded nonwoven fabric + spunbonded nonwoven fabric = hot rolled from two layers of web; SSS: spunbonded nonwoven fabric + spunbonded nonwoven fabric + spunbonded nonwoven fabric= hot rolled from three layers of web; SMS: spunbond non-woven fabric + meltblown non-woven fabric + spunbond non-woven fabric = three-layer fiber mesh hot rolled

S and SS non woven fabric are mainly used for furniture, agriculture, hygenic products, and packaging products. And SMS nonwoven fabric is mainly for medical products, like surgical gowns. We are now exporting these non-woven fabrics to different countries in the world.

0 notes

Text

Magnesia Chrome Bricks Industry Trends, Revenue, Key Players, Growth, Share and Forecast Till 2027

The global magnesia chrome bricks market is projected to be valued at USD 2,742.9 Million by 2027, according to a current analysis by Emergen Research. Increasing demand for magnesia chrome bricks from the iron & steel industry is a major factor driving the market. In the iron & steel industry, refractory materials such as magnesia chrome bricks indispensably constitute the lining of backup zones of furnaces and working interfaces used in iron and steel production and transportation of liquid steel, hot metal, and slag.

Request to download sample of this Strategic Report: https://www.emergenresearch.com/request-sample/448

The report also offers extensive details about the leading companies involved in the market along with their profiles, product portfolio, production and manufacturing capacity, cost analysis, market reach, and financial standings. It also pays special attention to strategic initiatives taken by the companies to gain a robust footing in the market like mergers and acquisitions, joint ventures, product developments, technological advancements, brand promotions and product launches, and partnerships, among others.

Leading Players of the Magnesia Chrome Bricks Market Profiled in the Report are:

Calderys, Resco Products, RHI Magnesita NV, KT Refractories, Mayerton, Vesuvius, Chosun Refractories Co. Ltd., HarbisonWalker International Inc., Magnezit Group Ltd., and Lanexis

Emergen Research has segmented the global magnesia chrome bricks market in terms of product type, application, and region:

Product Type Outlook (Revenue, USD Million; 2017–2027)

Common Magnesite Chrome Brick

Direct Bonded Magnesia Chrome Brick

Fused Rebonded Magnesite Chrome Brick

Chemically Bonded Magnesium Brick

Fused Cast Magnesite Chrome Brick

Application Outlook (Revenue, USD Million; 2017–2027)

Iron & Steel

Non-ferrous Metals

Power Generation

Glass

Cement

Others

Regional Fragmentation:

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Request for Report Customization: https://www.emergenresearch.com/request-for-customization/448

The report offers a panoramic view of the Magnesia Chrome Bricks market on both global and regional levels. The study is further supported by key statistical data and industry-verified facts. The study strives to carefully gauge the present and future market growth prospects, untapped avenues, demand and consumption patterns, and the crucial factors poised to impact each market region’s revenue potential. Therefore, the report scrutinizes the numerous growth trends & prospects and the significant challenges and threats that the market players might face in the upcoming years.

Target Audience of the Global Magnesia Chrome Bricks Market report:

Global Magnesia Chrome Bricks market providers, traders, distributors, and suppliers

Research organizations, End-use industries, consulting organizations, and various alliances related to this business sphere.

Independent regulatory authorities, government bodies, and policymakers.

Highlights of the Table of Contents:

Report Overview 1.1 Research Scope 1.2 Key Magnesia Chrome Bricks market segments 1.3 Major players 1.4 Market analysis by product type 1.5 Market analysis by application 1.6 Report timeline

Global Growth Trends 2.1 Global Magnesia Chrome Bricks market size 2.2 Latest trends of the Magnesia Chrome Bricks market by region 2.3 Key growth trends

Competitive Outlook 3.1 Global Magnesia Chrome Bricks market key players 3.2 Global Magnesia Chrome Bricks size by manufacturers 3.3 Products of major players 3.4 Entry barriers in the Magnesia Chrome Bricks market 3.5 Mergers, acquisitions, joint ventures, and strategic alliances

Magnesia Chrome Bricks Market by product type

4.1 Global Magnesia Chrome Bricks Sales by Product

4.2 Global Magnesia Chrome Bricks by Product Revenue

To know more about the report, visit @https://www.emergenresearch.com/industry-report/magnesia-chrome-bricks-market

Thank you for reading our report. For further inquiry about customization, kindly get in touch with us, and our team will make sure the report is best suited for your needs.

Read similar reports by Emergen Research:

Agricultural Films Market@ https://www.emergenresearch.com/industry-report/agricultural-films-market

Nanopatterning Market@ https://www.emergenresearch.com/industry-report/nanopatterning-market

Water Treatment Chemicals Market@ https://www.emergenresearch.com/industry-report/water-treatment-chemicals-market

Impact Modifiers Market@ https://www.emergenresearch.com/industry-report/impact-modifiers-market

Coal Tar Market@ https://www.emergenresearch.com/industry-report/coal-tar-market

About Emergen Research

Emergen Research is a market research and consulting company that provides syndicated research reports, customized research reports, and consulting services. Our solutions purely focus on your purpose to locate, target, and analyze consumer behavior shifts across demographics, across industries, and help clients make smarter business decisions. We offer market intelligence studies ensuring relevant and fact-based research across multiple industries, including Healthcare, Touch Points, Chemicals, Types, and Energy. We consistently update our research offerings to ensure our clients are aware of the latest trends existent in the market. Emergen Research has a strong base of experienced analysts from varied areas of expertise. Our industry experience and ability to develop a concrete solution to any research problems provides our clients with the ability to secure an edge over their respective competitors.

Contact Us:

Eric Lee

Corporate Sales Specialist

Emergen Research | Web: www.emergenresearch.com

Direct Line: +1 (604) 757-9756

E-mail: [email protected]

Facebook | LinkdIn | Twitter | Blogs

0 notes

Text

Agricultural Films And Bonding Market Size, Share And Trends Report Till 2024 Focusing on Key Players : Kuraray & Nova Mont

The global Agricultural Films and Bonding Market is estimated to touch US$ 14.19 billion by the completion of the prediction period. The market was appreciated at US$ 7.60 billion in the year 2015. It is estimated to develop at a substantial CAGR for the duration of the prediction. The agricultural films and bonding industry on the source of Type of Application could span Netting- Anti-insect, Shade, Anti-hail and Others.

The market on the basis of packaging could span Twine (Vegetable Packing, Fruit Packing [Bale and Others]), Agricultural Films (Mulching, Green House, Silage [Sheets, Stretch wrap, Bags]). The application of mulching, in the international market of agricultural films, is estimated to touch US$ 5,787.2 million by the completion of the prediction period. Mulching films are maximum extensively utilized in the nations such as China and Rest of Asia owing to huge areas of cultivable land and unlimited agrarian actions. The greenhouse coverings are extensively utilized in gardening and floriculture schemes in the Middle East and Europe to decrease the properties of severe climatic conditions in these areas.

Enquire About This Report: https://www.millioninsights.com/industry-reports/agricultural-films-bonding-market/request-sample

The subdivision of Shading was the prominent use sector and responsible for the market stake of more than over 40% of the netting market during the year 2015. The Shading nets are likewise utilized to extend or postponement of the reaping period in sunlit areas mostly in European markets for example Italy.

The agricultural films and bonding on the source of Type of Raw Material could span Netting (Polypropylene, HDPE, LDPE and Others), Twine (LDPE, Sisal, Polypropylene, and others), Agricultural Films (LDPE and others).The subdivision of Polypropylene [PP] discovers an extensive variety of uses in agriculture and agribusiness. They are utilized in the production of twines and netting for the wrapping and guarding the products from destruction. The Polypropylene [PP] twines are utilized for tie and corrugated Polypropylene [PP] for irrigational uses. Polypropylene [PP] demand in twine was responsible for more than 70% stake of the international market during the year 2015.

The agricultural films & bonding market on the source of Type of Product could span Netting, Agricultural Films, Twine, and others. The subdivision of Agricultural Film was the most important sector of the product type and responsible for a stake of more than 75% of the general market for the duration of the year 2015. This segment is anticipated to see the quick expansion above the prediction period because of increasing necessity for the first-class harvests.

The subdivision of Twine was responsible for a stake of more than 10% of the market during the year 2015. Baling twines are utilized for binding and piling of the crops. They are likewise appropriate in packaging crates for fruits and vegetables, those are very much appropriate for the transportation.

The agricultural films and bonding market on the source of Area with respect to Trades in terms of intake, Profits, Market stake, and Development percentage in these areas for the duration of the prediction could span North America [U.S.A {Texas, Iowa, Kansas, Wisconsin, Nebraska, California} Canada, Mexico], Europe [France, Spain, Germany, U.K., Italy], Asia Pacific, Central & South America [Brazil], Middle East & Africa.

By the source of geography, the Asia Pacific’s agricultural films & bonding steered the international business and was responsible for the market stake of more than 70% of international demand during the year 2015. Above 80% of the agriculturalists in the area practice mulch. Encouraging backing from the government for R&D of safe farming practices are likely to take an optimistic influence on the progress of the business.

The Europe is expected to observe motionless development above the following eight years due to strict ecological rules regarding discarding of the film and the manufacturing. Yet, the consumer emphasis is shifting in the direction of recyclable materials in the area. It expected to power the progress of the business.

The statement revises Trades in terms of intake of agricultural films & bonding in the market; particularly in North America, Europe, Asia Pacific, Central & South America, and Middle East & Africa. It concentrates on the topmost companies operating in these regions. Some of the important companies operating in the field are Ab Rani PlastOy, BASF, Bar bier Groupe, BP Industries [BPI], Kuraray, Nova Mont, Armando Alvarez SA, Trioplast Industrier AB, ExxonMobil Corporation.

Browse Complete Report Summary with TOC here https://www.millioninsights.com/industry-reports/agricultural-films-bonding-market

Get in touch

At Million Insights, we work with the aim to reach the highest levels of customer satisfaction. Our representatives strive to understand diverse client requirements and cater to the same with the most innovative and functional solutions.

Contact Person:

Ryan Manuel

Research Support Specialist, USA

Email:[email protected]

0 notes