#Aerospace Material Testing Service

Explore tagged Tumblr posts

Text

#Oil and gas Auditing Services#oil and gas inspection Services#Aerospace and defense inspection Services#Nuclear Inspection Services#Quality Auditing Services#Factory Acceptance Test#Quality Inspection Services#NDE Inspection Services#NDT Inspection Services#First Article Inspection Services#Heat Treatment Services#Welding Inspection Services#Third Party Industrial Inspection Services#Witness Inspection Services#Positive Material identification Services#IT Inspection Services#Cyber Security Assessment Services#Vulnerability management services#Audit and Assessments Services

0 notes

Text

Titan: Don't Fuck With the Ocean

So this has been delayed, and everyone and their mother has already commented on this. We’re well past the virality mark on this topic. But whatever, I want to crack in and get this thing wrapped up anyways. For context, I study mechanical and manufacturing engineering. I’ve grown up around submarines with my dad being an engineer on US Navy subs, and I was able to ask him about this. I’ve also got a diving cert and enough experience living coastal to at least get me a knowledgeable respect for the ocean. Being 60 ft under should instill that, at least.

I will not make any comments on any of the other four victims. However, I reserve the right to be fully derogatory to the CEO who died in the submersible, Stockton Rush, for his disgusting flippancy towards safety in such a dangerous environment as 4,000m below sea level, for disregarding multiple warnings against the project, and for subjecting other passengers to this. I intended to start with my favorite source on this, but it looks like I’m beginning with spite. I claim that in engineering, if safety disregards don’t immediately boil your blood, you have to turn in your card. https://www.bbc.com/news/world-us-canada-65998914 “Titan sub CEO dismissed safety warnings as 'baseless cries', emails show” Some people may have seen the quote “At some point, safety just is pure waste,” Stockton told journalist David Pogue in an interview last year. “I mean, if you just want to be safe, don’t get out of bed. Don’t get in your car. Don’t do anything.” Stockton Rush has typed "We have heard the baseless cries of 'you are going to kill someone' way too often," he wrote. "I take this as a serious personal insult." *Frankly*, the response to this should very much not be personal insult, but a call to action. There is no reason to take this personally. “I have broken some rules to make this…The carbon fiber and titanium, there is a rule that you don’t do that. Well, I did.”

“At some point safety just is pure waste…I think I can do this just as safely by breaking the rules.”

“[The sub industry is] obscenely safe, because they have all these regulations…But it also hasn’t innovated or grown—because they have all these regulations.”

This is gruesomely hilarious when you remember the CEO isn’t the actual person running the stress tests, manufacturing it, checking materials charts and costs, calculating max tolerances, or anything else. He’s the little funny man with the money and the reputation who tells people do what he wants anyways. He has no right to play maverick when he is hardly doing any of the work, and especially when it involves other innocent people. While he has a bachelor’s in aerospace engineering, a very commendable thing to get, that’s not what he does hands on as the CEO, and aerospace does not directly translate to submersible understanding. You do not get to be flippant with other peoples’ lives. These comments would be bad enough for anything on the surface, or even in the sky. But again, the ocean is a completely different beast, where it is much more difficult for emergency services to reach people.

As well as this, I need to state the difference between submersible and submarine. If I don’t, I feel the entire US Navy breathe down my neck. It’s like boat vs ship. Submersible: needs to be supported by a vessel up top, not designed for long term deployments. Smol boy. Submarine: can be operated independently, can go on six month or so deployments. Big boy. Going forward, the primary difficulties of the ocean are first and foremost the atmospheres of pressure on the vehicle. The dangers of no breathing air in the ocean are of course, a major issue, but the pressure of the ocean will be what breaks this and makes that lack of air a huge issue. A submersible needs to be properly pressurized to withstand the changes and keep the passengers inside also safe. The ocean is also very difficult to reach communication through. https://www.hindawi.com/journals/wcmc/2019/6470359/, so the submersible losing connection isn’t entirely unsurprising. But other factors listed here lead to its delay.

#siege engineer#titan submersible#titan#oceangate#stockton rush#submarines#submersible#engineering#engineer#siege engineer talks#aerospace#oceangate submersible#titanic

74 notes

·

View notes

Text

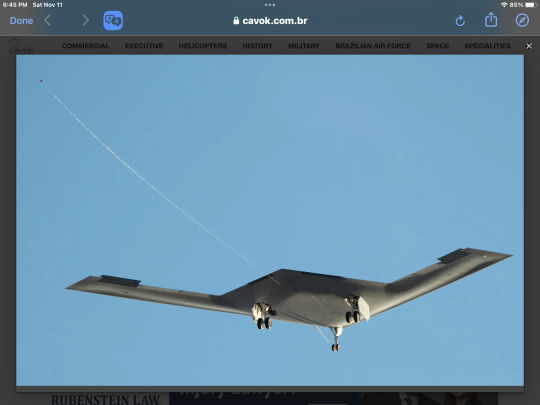

IMAGES: Fly the new USAF stealth bomber, the B-21 Raider

Fernando Valduga By Fernando Valduga 11/10/2023 - 15:14in Military

Photo: Matt Hartman

USAF's new B-21 “Raider” flying wing bomber made its first flight on Friday, the next step in the launch of a new fleet of nuclear-capable long-range stealth bombers built by Northrop Grumman.

The B-21 left the Northrop facility at U.S. Air Force Plant 42 in Palmdale, California, at sunrise on Friday at 6:51 a.m., offering the first improvised view of the new bomber that was developed under strict security.

The aircraft went to Edwards Air Base, California, where it will continue with the flight test phase with USAF. The flight lasted about 90 minutes.

With the Cerberus callsign, the aircraft took off eastward with an F-16 companion plane after climbing about 500 feet. The landing gear was not collected, according to videos and photos that appeared on social networks.

TAP TITLE BAR TO VIEW VIDEO☝️

U.S. Air Force leaders did not disclose the first flight of the B-21, but about three dozen aviation enthusiasts and amateur photographers gathered around Plant 42 on Friday in the hope of seeing the bomber rise to the skies.

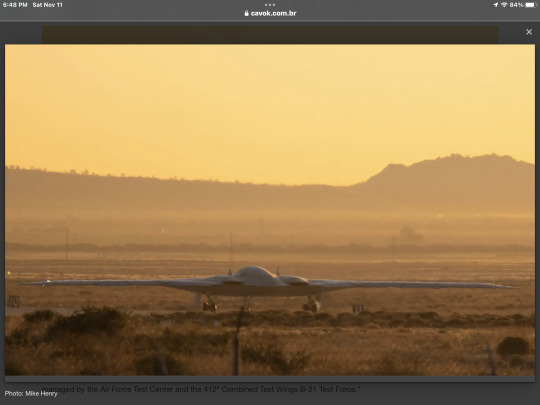

Photo: Mike Henry

The B-21, which carries the same "flying wing" format as its predecessor, the B-2, will be able to launch conventional and nuclear weapons around the world, using long-range and in-flight refueling capabilities.

The aircraft are projected to cost approximately $550 million each in 2010 dollars, or about $750 million in current inflation-adjusted dollars. However, the USAF kept other price information confidential, “which makes it difficult to validate the proposed cost,” the Congressional Research Service said in a 2021 report.

Photo: Mike Henry

The U.S. Air Force plans to buy at least 100 planes and start replacing the B-1 and B-2 bombers. The B-1 costs about US$ 60,000 per hour to operate and the B-2 costs about US$ 65,000 per hour, according to Pentagon data.

Ann Stefanek, USAF spokesperson, said: “The B-21 Raider is in flight tests. Flight tests are a critical step in the testing campaign managed by the Air Force Test Center and the 412ª Combined Test Wings B-21 Test Force."

Photo: Mike Henry

Six test aircraft are being produced now. They are being built on the same line, using the tools, processes and technicians that will build the production aircraft.

Northrop defeated a team composed of Boeing and Lockheed Martin when it won the 2015 contract to manufacture the bomber. Engine manufacturer Pratt & Whitney, Collins Aerospace, GKN Aerospace, BAE Systems and Spirit Aerosystems are among more than 400 suppliers in 40 states.

The B-21 was publicly presented in December 2022, but the expectation around its first flight had been growing for years.

In 2019, an important Air Force general suggested that the bomber could fly as early as December 2021, but the Force subsequently postponed this date to mid-2022. In early 2022, the USAF postponed even more until 2023.

The B-21 program is in the engineering and manufacturing development phase and the first aircraft will be delivered to Ellsworth Air Force Base in North Dakota.

Northrop is calling the plane a sixth-generation aircraft due to its ability to connect to other aircraft and easily integrate future weapons into its systems architecture.

The B-21 also features surface material with low observation, more durable and stealthy, which should require less maintenance and reduce operating costs and downtime.

Tags: Military AviationNorthrop Grumman B-21 RaiderUSAF - United States Air Force / U.S. Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

SAAB

Sweden will arm Gripen E fighters with anti-radar missiles

10/11/2023 - 18:00

DUBAI AIR SHOW

Russia will show the Il-76MD-90A and a line of civilian and combat helicopters at the Dubai Airshow

10/11/2023 - 17:00

MILITARY

Slovakia cancels military aid package to Ukraine

10/11/2023 - 14:00

MILITARY

Saab highlights Gripen E at a defense fair in Thailand

10/11/2023 - 09:00

The first Boeing T-7A Red Hawk, with the USAF test pilot Maj. Jonathan "Gremlin" Aronoff and Boeing test pilot Steve "Bull" Schmidt at the controls, arrive at Edwards Air Base on November 8, 2023 (Photo: U.S. Air Force / Todd Schannuth)

MILITARY

IMAGES: First T-7A Red Hawk arrives in Edwards to start the testing campaign with USAF

10/11/2023 - 08:10

MILITARY

Spain 'rejects' F-35 fighters and should focus on more Eurofighter Typhoons

09/11/2023 - 21:52

Client PortalClient PortalClient PortalClient PortalClient PortalClient PortalClient PortalClient PortalhomeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

26 notes

·

View notes

Text

Airbus: Soaring High in the Drone Market

Introduction:

Airbus S.A.S., a global leader in the aerospace industry, has made significant inroads into the rapidly expanding Drone Market. Renowned for its expertise in aviation and aerospace technology, Airbus is leveraging its core competencies to redefine the landscape of drone delivery and aerial mobility.

Download FREE Sample: https://www.nextmsc.com/drone-market/request-sample

Airbus' Strategic Approach: A Holistic Ecosystem

Airbus' strategy in the drone market centers on a holistic approach that encompasses:

Core Competencies: Leveraging expertise in aerospace engineering, manufacturing, and systems integration to develop advanced drone platforms.

Urban Air Mobility (UAM): Integrating drone delivery services into a broader UAM ecosystem, encompassing passenger drones, cargo drones, and air taxis.

Infrastructure Development: Investing in the development of drone infrastructure, including charging stations, landing pads, and air traffic management systems.

Data Analytics and Optimization: Utilizing data analytics to optimize drone delivery routes, improve efficiency, and enhance customer experience.

Regulatory Engagement: Actively participating in the development of drone regulations to shape a favorable regulatory environment.

Inquire before buying: https://www.nextmsc.com/drone-market/inquire-before-buying

Airbus' Contributions to the Drone Market

Airbus' contributions to the drone market are multifaceted:

Advanced Drone Platforms: The company is developing cutting-edge drone platforms with extended range, payload capacity, and flight autonomy.

Hybrid Drone Concepts: Airbus is exploring hybrid drone designs that combine the advantages of fixed-wing and multi-rotor configurations.

Urban Air Mobility Ecosystem: The company is actively involved in developing a comprehensive UAM ecosystem, including drones, ground infrastructure, and air traffic management systems.

Integration with Existing Aviation Systems: Airbus is leveraging its expertise in aviation to seamlessly integrate drone operations into the broader airspace.

Focus on Safety and Security: The company prioritizes safety and security, incorporating advanced technologies and rigorous testing into drone development.

Airbus' Role in Shaping the Future

Airbus' strategic vision positions the company as a key player in shaping the future of the drone market. The company is likely to focus on:

Expanding Drone Capabilities: Developing drones with advanced features such as autonomous navigation, obstacle avoidance, and payload flexibility.

Global Market Expansion: Expanding drone delivery services to new markets and regions, leveraging Airbus' global presence.

Sustainability: Incorporating sustainable practices into drone operations, using eco-friendly materials and reducing noise pollution.

Public-Private Partnerships: Collaborating with governments, cities, and other stakeholders to accelerate drone adoption.

Data Monetization: Leveraging data collected from drone operations to create new revenue streams and insights.

Case Studies: Airbus' Impact

To illustrate Airbus' role in the drone market, consider the following examples:

CityAirbus: Airbus' electric vertical take-off and landing (eVTOL) aircraft concept demonstrates the company's commitment to urban air mobility and its potential application for drone delivery.

Cargo Drone Development: Airbus is actively developing cargo drones with increased payload capacity for delivering heavier packages.

Drone Infrastructure Investments: The company is investing in the development of droneports and charging stations to support the growth of drone delivery services.

Airbus' Focus on Urban Air Mobility (UAM)

Airbus sees UAM as a key growth area and is investing heavily in developing a comprehensive ecosystem. The company's vision includes:

Passenger Drones: Developing passenger drones for urban transportation, reducing traffic congestion, and improving mobility.

Cargo Drones: Integrating cargo drones into the urban logistics network for efficient delivery of goods and services.

Air Traffic Management: Developing advanced air traffic management systems for safe and efficient drone operations in urban environments.

Infrastructure Development: Building the necessary infrastructure, including vertiports and charging stations, to support UAM operations.

Challenges and Opportunities

While Airbus is a major player in the drone market, the company faces challenges such as regulatory hurdles, public acceptance, and technological limitations. However, the potential rewards are significant, including increased market share, revenue generation, and the opportunity to redefine urban transportation.

Airbus' focus on UAM and its ability to integrate drones into the broader aviation ecosystem position the company well to capitalize on the growing demand for air mobility solutions. By addressing challenges and leveraging opportunities, Airbus can solidify its leadership position in the drone market.

Conclusion

Airbus, with its deep-rooted expertise in aerospace engineering and a global presence, is poised to be a major player in the drone market. The company's focus on urban air mobility, coupled with its commitment to innovation and sustainability, positions it well for future growth.

As the drone market continues to evolve, Airbus' ability to adapt to changing market dynamics and technological advancements will be crucial for maintaining its leadership position. The company's success in developing safe, efficient, and environmentally friendly drone solutions will be essential for building public trust and expanding the adoption of drone technology.

3 notes

·

View notes

Text

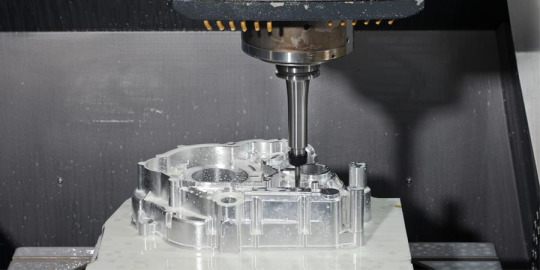

Unlocking the Potential of 3D Printing: A Guide to PrintPrizm3D

Welcome to the world of 3D printing with PrintPrizm3D! Whether you’re a hobbyist, a small business owner, or an innovator looking to turn your ideas into reality, 3D printing offers limitless possibilities. At PrintPrizm3D, we specialize in providing high-quality 3D printing services that cater to a wide range of needs. Discover how our services can help you bring your visions to life and explore the benefits of incorporating 3D printing into your projects.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. By layering materials such as plastic, metal, or resin, 3D printers can produce complex shapes and intricate designs with precision and accuracy. This technology has revolutionized industries, including aerospace, automotive, healthcare, and fashion, by offering rapid prototyping, custom manufacturing, and cost-effective production.

Why Choose PrintPrizm3D?

At PrintPrizm3D, we pride ourselves on delivering top-notch 3D printing services. Here’s why you should choose us for your next project:

High-Quality Prints: We use advanced 3D printers and materials to ensure your prints are of the highest quality. Whether you need a prototype, a functional part, or a decorative item, we’ve got you covered.

Expertise and Experience: Our team has extensive experience in 3D printing and design, enabling us to handle a variety of projects with skill and efficiency.

Customer Satisfaction: We are committed to providing exceptional customer service. From the initial consultation to the final product, we work closely with you to meet your specific needs and expectations.

Our Services

PrintPrizm3D offers a comprehensive range of 3D printing services to cater to various requirements:

Prototyping: Quickly and accurately create prototypes to test and refine your designs.

Custom Manufacturing: Produce custom parts and products tailored to your specifications.

Design Services: Our expert designers can help you create and optimize your 3D models for printing.

Educational Workshops: Learn about 3D printing technology and its applications through our informative workshops.

Visit Our Online Stores

Explore our wide range of 3D printed products and services on our online platforms:

PrintPrizm3D Website: PrintPrizm3D Website

PrintPrizm3D eBay Store: PrintPrizm3D eBay Store

Connect with Us on Social Media

Stay updated with our latest projects, promotions, and 3D printing tips by following us on social media:

Facebook: PrintPrizm3D Facebook Page

Instagram: PrintPrizm3D Instagram

Rippin-R-Us Instagram: Rippin-R-Us Instagram

Rippin-R-Us Facebook: Rippin-R-Us Facebook

Get in Touch

Have questions or need assistance with your 3D printing project? Contact us at [email protected]. We’re here to help you every step of the way!

Conclusion

3D printing is transforming the way we create and innovate. At PrintPrizm3D, we’re dedicated to providing high-quality 3D printing services that help you turn your ideas into reality. Visit our online stores, connect with us on social media, and discover how we can assist you with your next project. Embrace the future of manufacturing with PrintPrizm3D!

For further insights and tips on 3D printing, subscribe to our blog and stay tuned for more updates. Happy printing!

#ShopNow#OrderNow#BuyNow#LimitedEdition#NewArrival#3DPrinting#AdditiveManufacturing#3DPrint#3DPrintingCommunity#3DPrintingTechnology#3DPrinted#3DPrinter#3DPrintingService#Prototyping#ProductDesign#CustomManufacturing#RapidPrototyping#Engineering#ProductDevelopment#TechInnovation#eBayStore#eBayDeals#ShopOnEbay#EbayFinds#EbaySeller#FacebookMakers#3DPrintingFB#MakerSpace#Insta3DPrinting#3DPrintingArt

2 notes

·

View notes

Text

Looking for prominent high quality Tool and Die Steel Supplier in Jamshedpur?

Jamshedpur is the largest and most populous city in Jharkhand and the first planned industrial city in India. Jamshedpur is a major industrial city located in the East Singhbhum district of Jharkhand, India. It is one of the largest and most populous cities in the state and holds significant importance as an industrial and economic center. It was founded by Jamsetji Tata, the founder of the Tata Group, and named after him.

Jamshedpur is renowned for its industrial landscape and is often referred to as the “Steel City of India.” The Tata Steel plant, one of the oldest and largest steel plants in the country, is a major contributor to the city’s economy. Other industries include automotive manufacturing, cement production, and various engineering and manufacturing units..

Jamshedpur is industrial city in the state of Jharkhand , India. It is also known for its industrial development and urban planning. Jamshedpur has some tools and die steel industries that manufacture and supply various types of tools, dies, molds, and other components for various industries such as automotive, aerospace, medical, etc.

Allow me to introduce one of the prominent Tool & Die Steels Suppliers in Jamshedpur: One of the best Tool & Die Steels Supplier in Jamshedpur Tata Steel city is:

Virat Special Steels Pvt. Limited : This is a company that deals in all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel. They provide value added services, such as material machining, cut pieces, and tailor-made material. They also offer metallurgical advice and quality assurance. They have a state-of-the-art plant in Gurugram and Ludhiana. They also have a strong distribution network across India.

The following grades of steel are available with them on an ex-stock basis:

DIE STEEL ( HH 370 - 410 BHN ) (DB6 / DIN-1.2714 / AISI L6 )

HOT WORK STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

COLD WORK STEELS - HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

Here, they also have an impressive fully equipped quality assurance and process examination facility. This includes a laboratory for analyzing steel by conducting both chemical tests and spectrometry; ultrasonic examination and hardness testing on Vickers, Rockwell and Brinell scales. This adds value for their clientele by allowing for them to select the most appropriate type of steel readily available for their specific application; and also allows them to examine options and in the long haul optimize costs.

As par in terms of Quality, Price & Services with steels of the same grade from multinational companies such as Thyssenkrupp, Poldi, Huta Celsa, Vitkovice, Lucchini, DEW, SWG, Edelstahl Groditz, Nippon, Hyundai steel, Seah, Villarus ( Bohler Subsidiary ), TG , EWK, DEW, A Finkl, Swiss Steel, Sanyo, Somers Forge etc.

Virat Special Steels also offer “Make In INDIA” products at competitive prices, great quality, and prompt servicing to increase & improve CPC (Cost Per Component) for their customers.

You can visit their website: https://www.viratsteels.com/ https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-jamshedpur/

Consult our Gurugram office for further assistance. Meanwhile for more on Virat Special Steels; Email Us: [email protected]. Contact them by mobile numbers 98140 - 21775, 99991 - 24971 to 79.

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#tatanagar#jamshedpur#tata steel#db6 steel#h13steel#h11steel#din2344#din2714

2 notes

·

View notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

What is Metal Fabrication?

Metal fabrication transforms raw metal materials into a final product using various cutting, bending, welding, and assembling techniques. The process typically starts with the design and engineering of a product, followed by the selection and preparation of the raw materials, and then the fabrication process itself.

Metal fabrication can create various products, from simple metal components to complex machinery and structures. Some common examples of products created through metal fabrication include metal frames, brackets, enclosures, and structural components for buildings and bridges. Metal fabrication is used in various industries, including construction, automotive manufacturing, aerospace, and consumer products.

Why is metal fabrication important?

Metal fabrication is important for several reasons:

Customisation: Metal fabrication allows for customising metal products according to specific requirements, such as size, shape, and design. This flexibility enables businesses and industries to produce products that meet their unique needs and specifications.

Durability: Metal products produced through fabrication are durable and long-lasting. They can withstand extreme temperatures, pressures, and forces, making them ideal for various industries, including construction, manufacturing, and transportation.

Cost-effective: Fabricating metal products is often more cost-effective than purchasing pre-made products. This is because fabricators can produce multiple pieces of a product using the same materials, reducing waste and keeping costs low.

Quality control: Metal fabrication ensures high-quality products through strict quality control measures. Each product is inspected and tested to meet industry standards and specifications.

Metal fabrication is important because it enables businesses and industries to produce high-quality, customised, durable metal products that meet their unique needs and requirements.

What are the benefits of metal fabrication?

Metal fabrication offers many benefits, including:

Customisation: Metal fabrication allows for custom metal products that meet each customer's needs and requirements.

Strength and durability: Metal products created through fabrication are strong, durable, and able to withstand a variety of harsh conditions, making them ideal for use in construction and manufacturing industries.

Versatility: Metal fabrication can create a wide range of products, from small components to large structures, and can be used in various industries such as automotive, aerospace, construction, and more.

Cost-effective: Fabricated metal products can be produced in large quantities at a lower cost than other manufacturing processes, making them an affordable option for businesses and consumers.

Efficiency: With advanced technology and equipment, metal fabrication can produce high-quality products with minimal waste and faster turnaround times.

Aesthetics: Metal fabrication offers a wide range of finishes and coatings that can enhance the appearance of metal products, making them visually appealing and functional.

Recyclable: Metal is a recyclable material, which makes it an eco-friendly choice for businesses and consumers who want to reduce their environmental impact.

These benefits make metal fabrication an important and valuable process for a variety of industries and applications.

When do you need to get metal fabrication services?

You may need metal fabrication services when you require custom metal parts, structures or products for various purposes. Metal fabrication can be used in various industries, including construction, automotive, aerospace, manufacturing, and more. You may need metal fabrication services when you require unique parts or components that cannot be found off the shelf or a specific metal product designed and manufactured to your specifications.

Some common examples of when you may require metal fabrication services include the production of metal frames, structures, and enclosures, creating custom metal products, fabricating metal components for machinery or equipment, and repairing or modifying existing metal structures or products.

© DDK Engineering

2 notes

·

View notes

Text

Achieve Perfection with ABC Buffs Flap Wheel Manufacturer for All Applications

When it comes to achieving smooth, uniform finishes in metalworking, woodworking, automotive detailing, and other precision industries, flap wheels are indispensable tools. A flap wheel's design—layered abrasive flaps arranged radially around a central hub—allows for both aggressive material removal and fine finishing in a single step. As the demand for high-quality surface finishes grows across industries, the need for reliable, durable flap wheels is more crucial than ever. ABC Buffs, a trusted name in abrasive solutions, stands at the forefront of flap wheel manufacturer, offering products that ensure efficiency, performance, and a flawless finish every time.

Why ABC Buffs is the Trusted Name in Flap Wheel Manufacturing

With years of expertise in the abrasive tools industry, ABC Buffs has earned its reputation as a leader in the manufacturing of premium flap wheels. Our commitment to quality and innovation ensures that our products meet the diverse and demanding needs of professionals in various fields—from metal fabricators and automotive detailers to woodworking artisans and aerospace manufacturers.

Unmatched Quality and Durability

At ABC Buffs, we understand that the performance of your flap wheel can make or break the final outcome of a project. That’s why we invest heavily in the materials, engineering, and testing of our flap wheels to ensure consistent, high-quality performance. Our products are designed to handle the toughest tasks, from heavy-duty grinding to fine surface finishing, without sacrificing durability or precision.

Each flap wheel is crafted using premium abrasives such as aluminum oxide, zirconia, and ceramic, selected for their ability to provide fast cutting action while offering long-lasting wear. Whether you need to remove rust, smooth out weld seams, or prepare a surface for painting, ABC Buffs flap wheels are engineered to help you get the job done quickly and effectively.

Customized Solutions for Every Application

Flap wheels are not one-size-fits-all tools. Different materials, surfaces, and finishing requirements demand tailored solutions. ABC Buffs recognizes this need and offers a wide range of flap wheels to suit the unique challenges faced by professionals in various industries:

Metalworking: Our flap wheels designed for metalworking applications are perfect for grinding, deburring, and finishing ferrous and non-ferrous metals. Whether working with steel, stainless steel, or aluminum, ABC Buffs flap wheels provide the smooth, uniform finish that metal fabricators demand.

Automotive and Aerospace: For the automotive and aerospace sectors, our flap wheels are ideal for polishing, blending welds, and finishing components with precision. They’re particularly effective on intricate parts that require an even, consistent finish, from engine components to body panels.

Woodworking: For woodworkers, ABC Buffs offers specialized flap wheels that provide smooth sanding for wooden surfaces, including fine detail sanding and finishing of intricate parts. Our flap wheels can be used on everything from furniture and cabinetry to flooring, ensuring a professional, smooth finish on every project.

Plastic and Composites: In industries like plastics and composites, our flap wheels are designed to provide gentle abrasion, reducing the risk of scratching or damaging delicate surfaces while still achieving the desired smooth finish.

Innovative Features for Maximum Efficiency

ABC Buffs flap wheels are engineered not only for durability and precision but also for maximum operational efficiency. Some of the standout features of our flap wheels include:

High Stock Removal Rate: ABC Buffs flap wheels are designed to remove material quickly and efficiently, allowing for faster completion of projects and less downtime during repetitive tasks.

Longer Life Cycle: Our high-quality abrasives are engineered for extended service life, meaning that ABC Buffs flap wheels last longer and provide greater value per use compared to lower-quality alternatives.

Consistent Performance: The uniform distribution of abrasive flaps ensures that the cutting action remains consistent throughout the life of the flap wheel. This reduces the likelihood of uneven finishes or surface imperfections.

Flexible Design: The flexible nature of flap wheels means they can adapt to the contours of different surfaces, making them perfect for both flat surfaces and complex, curved workpieces.

Meeting the Demands of the Modern Industry

At ABC Buffs, we stay ahead of the curve by continuously innovating and improving our products to meet the evolving needs of industries worldwide. We understand the increasing focus on productivity, efficiency, and environmental responsibility, which is why we continually refine our manufacturing processes to offer flap wheels that:

Reduce Environmental Impact: Our products are designed to reduce waste and minimize the need for excessive finishing steps. We also ensure that our flap wheels are made with materials that comply with environmental safety standards.

Enhance Worker Safety: Our flap wheels are built for smooth, controlled operation, minimizing the risk of defects, injuries, or excessive vibration during use. This not only enhances safety but also increases worker comfort and reduces fatigue during long working hours.

Offer Cost Efficiency: By improving tool life, reducing material waste, and increasing productivity, ABC Buffs flap wheels help businesses save time and money in the long run.

Why Choose ABC Buffs Flap Wheels?

There are many reasons why professionals across industries trust ABC Buffs for their flap wheel needs:

High Performance: Consistent, reliable, and superior performance, delivering flawless finishes on every project.

Durability: Built to withstand tough conditions, ABC Buffs flap wheels last longer and perform consistently throughout their use.

Customization: A wide variety of sizes, grits, and abrasive types to match specific application needs.

Innovative Engineering: Continuous investment in R&D ensures our flap wheels incorporate the latest technologies for enhanced productivity and precision.

Global Expertise: With years of experience in the abrasive industry, ABC Buffs has become a trusted partner for businesses worldwide.

Conclusion

ABC Buffs stands as a leader in the flap wheel manufacturing industry, offering products that combine durability, precision, and innovation. Whether you’re looking to achieve a smooth finish on a metal surface, prepare wood for varnish, or polish delicate components, ABC Buffs flap wheels are the go-to solution for professionals demanding excellence. Our commitment to quality, sustainability, and customer satisfaction makes us the preferred choice for businesses seeking reliable, high-performance abrasives.

Visit:- https://www.abcbuff.com/flap-wheels.html

0 notes

Text

Abstract The salt mist test, a critical assessment method for evaluating the corrosion resistance of materials, plays a vital role in ensuring the durability and reliability of products exposed to harsh environments. The LISUN YWX/Q-010 Salt Spray Test Chamber is specifically designed to carry out these tests efficiently, providing accurate and consistent results that meet international standards. This paper explores the importance of the salt mist test, discusses the features of the LISUN YWX/Q-010, and emphasizes the necessity of such testing in various industries to ensure product longevity and safety. Introduction Corrosion is a significant concern across numerous industries, particularly those dealing with metal and alloy products exposed to challenging environmental conditions. The salt mist test, also known as the salt spray test, is a widely recognized method for assessing the corrosion resistance of coatings, materials, and components. This test simulates the corrosive effects of salt-laden environments, helping manufacturers understand how their products will perform over time. The LISUN YWX/Q-010 Salt Spray Test Chamber is engineered to deliver precise and reliable salt mist testing. This paper delves into the importance of the salt mist test, elaborates on the design and operational features of the LISUN YWX/Q-010, and discusses its application across different industries. The discussion underscores how the salt mist test serves as a critical tool in product development and quality assurance, ensuring that materials can withstand corrosive environments. Importance of the Salt Mist Test The salt mist test is crucial for several reasons: • Predicting Material Durability: The salt mist test allows manufacturers to predict how long materials and coatings will last under corrosive conditions. This information is vital for designing products that can withstand harsh environments, particularly in marine, automotive, and industrial applications. • Ensuring Compliance with Standards: Many industries are required to meet strict international standards regarding corrosion resistance. The salt mist test provides a standardized method for testing and validating that materials and coatings meet these requirements, ensuring that products are suitable for global markets. • Enhancing Product Quality: By identifying materials that are prone to corrosion, the salt mist test enables manufacturers to improve their products’ design and material selection. This leads to the development of more durable products that require less maintenance and offer a longer service life. • Cost Savings: Products that fail due to corrosion can lead to costly repairs, replacements, and downtime. By using the salt mist test to ensure corrosion resistance, manufacturers can avoid these expenses, leading to significant cost savings over the product’s lifetime. • Safety Assurance: In some industries, such as automotive and aerospace, corrosion can lead to catastrophic failures. The salt mist test helps in verifying that materials and components will not degrade to the point where they pose a safety risk, thus protecting end-users and maintaining the integrity of critical infrastructure. Understanding the Salt Mist Test Procedure The salt mist test involves exposing materials to a controlled corrosive environment within a test chamber. The process typically includes the following steps: • Sample Preparation: Test samples, usually coated or uncoated metal specimens, are prepared according to the specific test requirements. These samples are cleaned and positioned within the chamber to ensure uniform exposure to the salt mist. • Solution Preparation: A salt solution, typically consisting of sodium chloride (NaCl) dissolved in distilled water, is prepared. The concentration of this solution and the test duration are determined based on industry standards or specific test protocols. • Chamber Conditions: The test chamber is maintained at a constant temperature and humidity level to replicate the conditions that might lead to corrosion. The LISUN YWX/Q-010 Salt Spray Test Chamber offers precise control over these environmental parameters, ensuring consistent and reproducible results. • Spraying Process: The salt solution is atomized into a fine mist and continuously sprayed onto the test samples. This simulates the conditions materials would face in a corrosive environment, such as coastal areas or industrial zones. • Evaluation: After the test duration, the samples are evaluated for signs of corrosion, such as pitting, rust, or loss of material. The degree of corrosion is measured and compared against predefined standards to assess the material’s resistance. Features of the LISUN YWX/Q-010_Salt Spray Test Machine Salt Spray Test Chamber The LISUN YWX/Q-010 Salt Spray Test Chamber is designed to perform salt mist tests efficiently and effectively. Key features include: • High Precision Control System: The chamber is equipped with a sophisticated control system that allows for precise adjustment of temperature, humidity, and spray frequency. This ensures that the test conditions can be tailored to meet specific standards, such as ASTM B117 and ISO 9227. • Robust Construction: The chamber is built with corrosion-resistant materials, including a durable stainless steel frame and a reinforced polymer interior, ensuring long-term reliability even under continuous operation. • Uniform Spray Distribution: The chamber’s spray system is engineered to deliver a consistent and uniform mist across all test samples, eliminating variability and ensuring that each sample receives equal exposure to the corrosive environment. • Large Viewing Window: The LISUN YWX/Q-010 features a large, clear viewing window that allows operators to monitor the test in real-time without disrupting the chamber’s controlled environment. • Automated Operation: The chamber is designed for ease of use, with automated controls for test duration, spray intervals, and environmental settings. This automation reduces the potential for human error and ensures that tests are conducted precisely as specified. • Comprehensive Data Logging: The chamber includes advanced data logging capabilities, allowing for the recording of test conditions and results over time. This data can be used for detailed analysis and reporting, facilitating the documentation of compliance and the evaluation of long-term material performance. Applications of the Salt Mist Test in Various Industries The salt mist test is widely used across several industries to assess the corrosion resistance of materials and coatings. Key applications include: • Automotive Industry: Automotive components, especially those made from metal, are often exposed to road salt and other corrosive elements. The salt mist test is essential for evaluating the durability of car bodies, chassis components, and other parts, ensuring that they can withstand the rigors of everyday use. • Marine Industry: Ships, offshore platforms, and other marine equipment are constantly exposed to saltwater, which accelerates corrosion. The salt mist test is critical in the marine industry for testing the corrosion resistance of hull materials, fasteners, and protective coatings. • Construction Industry: In construction, materials such as steel beams, bolts, and fixtures are often exposed to harsh weather conditions. The salt mist test helps in determining the suitability of these materials for long-term use in environments where they may be exposed to salt-laden air or deicing salts. • Aerospace Industry: Aerospace components must be resistant to corrosion to ensure the safety and longevity of aircraft. The salt mist test is used to evaluate the corrosion resistance of structural components, fasteners, and coatings used in aircraft and spacecraft. • Electronics Industry: Electronic components, particularly those used in outdoor or industrial environments, must be protected against corrosion to ensure reliable operation. The salt mist test is employed to assess the effectiveness of protective coatings and enclosures in preventing corrosion-related failures. Conclusion The salt mist test is an indispensable tool for assessing the corrosion resistance of materials and coatings. The LISUN YWX/Q-010 Salt Spray Test Chamber, with its advanced features and precise control, provides a reliable and consistent environment for conducting these tests. By understanding the importance of the salt mist test and utilizing state-of-the-art equipment like the LISUN YWX/Q-010, manufacturers can ensure that their products meet stringent international standards and are capable of withstanding the corrosive challenges of their operating environments. Through rigorous salt mist testing, industries can enhance product quality, ensure regulatory compliance, and extend the service life of their materials and components. The salt mist test, therefore, remains a critical component of quality assurance in sectors ranging from automotive to aerospace, reinforcing the importance of thorough corrosion resistance evaluation in product development and certification. References ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus. ISO 9227: Corrosion Tests in Artificial Atmospheres – Salt Spray Tests. LISUN Group. (n.d.). LISUN YWX/Q-010 Salt Spray Test Chamber. Read the full article

0 notes

Text

Abstract The salt mist test, a critical assessment method for evaluating the corrosion resistance of materials, plays a vital role in ensuring the durability and reliability of products exposed to harsh environments. The LISUN YWX/Q-010 Salt Spray Test Chamber is specifically designed to carry out these tests efficiently, providing accurate and consistent results that meet international standards. This paper explores the importance of the salt mist test, discusses the features of the LISUN YWX/Q-010, and emphasizes the necessity of such testing in various industries to ensure product longevity and safety. Introduction Corrosion is a significant concern across numerous industries, particularly those dealing with metal and alloy products exposed to challenging environmental conditions. The salt mist test, also known as the salt spray test, is a widely recognized method for assessing the corrosion resistance of coatings, materials, and components. This test simulates the corrosive effects of salt-laden environments, helping manufacturers understand how their products will perform over time. The LISUN YWX/Q-010 Salt Spray Test Chamber is engineered to deliver precise and reliable salt mist testing. This paper delves into the importance of the salt mist test, elaborates on the design and operational features of the LISUN YWX/Q-010, and discusses its application across different industries. The discussion underscores how the salt mist test serves as a critical tool in product development and quality assurance, ensuring that materials can withstand corrosive environments. Importance of the Salt Mist Test The salt mist test is crucial for several reasons: • Predicting Material Durability: The salt mist test allows manufacturers to predict how long materials and coatings will last under corrosive conditions. This information is vital for designing products that can withstand harsh environments, particularly in marine, automotive, and industrial applications. • Ensuring Compliance with Standards: Many industries are required to meet strict international standards regarding corrosion resistance. The salt mist test provides a standardized method for testing and validating that materials and coatings meet these requirements, ensuring that products are suitable for global markets. • Enhancing Product Quality: By identifying materials that are prone to corrosion, the salt mist test enables manufacturers to improve their products’ design and material selection. This leads to the development of more durable products that require less maintenance and offer a longer service life. • Cost Savings: Products that fail due to corrosion can lead to costly repairs, replacements, and downtime. By using the salt mist test to ensure corrosion resistance, manufacturers can avoid these expenses, leading to significant cost savings over the product’s lifetime. • Safety Assurance: In some industries, such as automotive and aerospace, corrosion can lead to catastrophic failures. The salt mist test helps in verifying that materials and components will not degrade to the point where they pose a safety risk, thus protecting end-users and maintaining the integrity of critical infrastructure. Understanding the Salt Mist Test Procedure The salt mist test involves exposing materials to a controlled corrosive environment within a test chamber. The process typically includes the following steps: • Sample Preparation: Test samples, usually coated or uncoated metal specimens, are prepared according to the specific test requirements. These samples are cleaned and positioned within the chamber to ensure uniform exposure to the salt mist. • Solution Preparation: A salt solution, typically consisting of sodium chloride (NaCl) dissolved in distilled water, is prepared. The concentration of this solution and the test duration are determined based on industry standards or specific test protocols. • Chamber Conditions: The test chamber is maintained at a constant temperature and humidity level to replicate the conditions that might lead to corrosion. The LISUN YWX/Q-010 Salt Spray Test Chamber offers precise control over these environmental parameters, ensuring consistent and reproducible results. • Spraying Process: The salt solution is atomized into a fine mist and continuously sprayed onto the test samples. This simulates the conditions materials would face in a corrosive environment, such as coastal areas or industrial zones. • Evaluation: After the test duration, the samples are evaluated for signs of corrosion, such as pitting, rust, or loss of material. The degree of corrosion is measured and compared against predefined standards to assess the material’s resistance. Features of the LISUN YWX/Q-010_Salt Spray Test Machine Salt Spray Test Chamber The LISUN YWX/Q-010 Salt Spray Test Chamber is designed to perform salt mist tests efficiently and effectively. Key features include: • High Precision Control System: The chamber is equipped with a sophisticated control system that allows for precise adjustment of temperature, humidity, and spray frequency. This ensures that the test conditions can be tailored to meet specific standards, such as ASTM B117 and ISO 9227. • Robust Construction: The chamber is built with corrosion-resistant materials, including a durable stainless steel frame and a reinforced polymer interior, ensuring long-term reliability even under continuous operation. • Uniform Spray Distribution: The chamber’s spray system is engineered to deliver a consistent and uniform mist across all test samples, eliminating variability and ensuring that each sample receives equal exposure to the corrosive environment. • Large Viewing Window: The LISUN YWX/Q-010 features a large, clear viewing window that allows operators to monitor the test in real-time without disrupting the chamber’s controlled environment. • Automated Operation: The chamber is designed for ease of use, with automated controls for test duration, spray intervals, and environmental settings. This automation reduces the potential for human error and ensures that tests are conducted precisely as specified. • Comprehensive Data Logging: The chamber includes advanced data logging capabilities, allowing for the recording of test conditions and results over time. This data can be used for detailed analysis and reporting, facilitating the documentation of compliance and the evaluation of long-term material performance. Applications of the Salt Mist Test in Various Industries The salt mist test is widely used across several industries to assess the corrosion resistance of materials and coatings. Key applications include: • Automotive Industry: Automotive components, especially those made from metal, are often exposed to road salt and other corrosive elements. The salt mist test is essential for evaluating the durability of car bodies, chassis components, and other parts, ensuring that they can withstand the rigors of everyday use. • Marine Industry: Ships, offshore platforms, and other marine equipment are constantly exposed to saltwater, which accelerates corrosion. The salt mist test is critical in the marine industry for testing the corrosion resistance of hull materials, fasteners, and protective coatings. • Construction Industry: In construction, materials such as steel beams, bolts, and fixtures are often exposed to harsh weather conditions. The salt mist test helps in determining the suitability of these materials for long-term use in environments where they may be exposed to salt-laden air or deicing salts. • Aerospace Industry: Aerospace components must be resistant to corrosion to ensure the safety and longevity of aircraft. The salt mist test is used to evaluate the corrosion resistance of structural components, fasteners, and coatings used in aircraft and spacecraft. • Electronics Industry: Electronic components, particularly those used in outdoor or industrial environments, must be protected against corrosion to ensure reliable operation. The salt mist test is employed to assess the effectiveness of protective coatings and enclosures in preventing corrosion-related failures. Conclusion The salt mist test is an indispensable tool for assessing the corrosion resistance of materials and coatings. The LISUN YWX/Q-010 Salt Spray Test Chamber, with its advanced features and precise control, provides a reliable and consistent environment for conducting these tests. By understanding the importance of the salt mist test and utilizing state-of-the-art equipment like the LISUN YWX/Q-010, manufacturers can ensure that their products meet stringent international standards and are capable of withstanding the corrosive challenges of their operating environments. Through rigorous salt mist testing, industries can enhance product quality, ensure regulatory compliance, and extend the service life of their materials and components. The salt mist test, therefore, remains a critical component of quality assurance in sectors ranging from automotive to aerospace, reinforcing the importance of thorough corrosion resistance evaluation in product development and certification. References ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus. ISO 9227: Corrosion Tests in Artificial Atmospheres – Salt Spray Tests. LISUN Group. (n.d.). LISUN YWX/Q-010 Salt Spray Test Chamber. Read the full article

0 notes

Text

New Images Of China’s J-35 Naval Stealth Fighter, Could Depict Third Example

Oliver ParkenPUBLISHED Mar 13, 2024 9:10 PM EDT

A prototype J-35 stealth flghter in flight

Chinese internet via X/Twitter

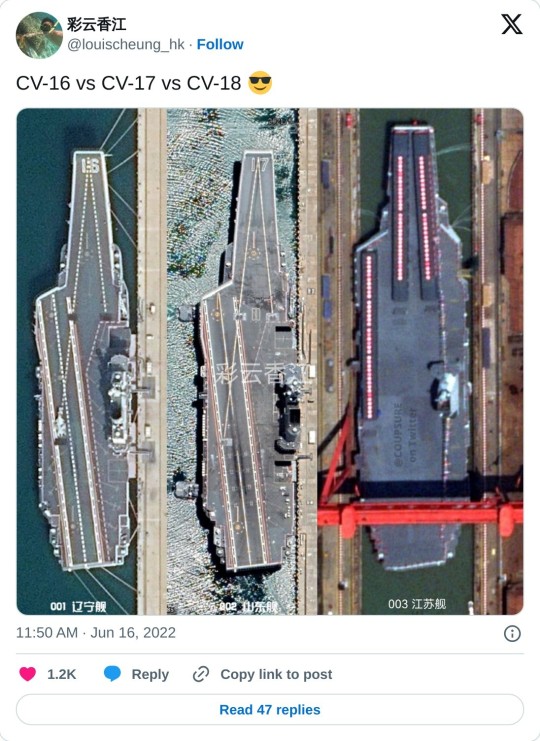

Recent imagery shows what could be the third flying prototype of China's carrier-based Shenyang J-35 stealth fighter. The new visuals, which depict the aircraft from its underside, come after growing indications that the J-35 might eventually operate from China's two in-service carriers, Type 001 Liaoning and Type 002 Shandong, as well as future carriers fitted with catapults and arrestor gear, including the soon to set sail Type 003 Fujian.

The images were originally posted to the Chinese Weibo microblogging website earlier in March before being shared more widely. While the precise date they were taken remains murky, it has been indicated by Hui Tong on the Chinese Military Aviation blog that the aircraft was pictured as it approached the Shenyang Aircraft Corporation in Liaoning after a test flight. That same blog posits that this could be the third J-35, although we cannot confirm that at this time.

The images give us a view of the bottom of the J-35. We know from previous photos that the overall skin of the J-35 is quite smooth for low observable requirements. The rear of the aircraft shows largely standard exhaust nozzles — although we know the J-35 has serrated petals on its nozzles, although the enhanced image at the top of this post appears to have smoothed them out. The jet appears to be wearing a ventral bolt-on Luneburg lens (radar reflector) as is customary on stealth fighter aircraft when low-observability is not needed and can also be a challenge for flying in dense airspace. The style and placement look similar to the one found on the F-22 and, subsequently, the J-20. The J-35's landing gear features a twin nose wheel for carrier operations and a similar general layout as the F-35C.

Chinese internet via X

A navalized variant of the land-based Shenyang FC-31, the first flying J-35 prototype made its initial flight, at least that we know of, in October 2021, sporting a blue-green primer finish and wearing the serial 350001. The second known flying J-35 prototype, 350003, was subsequently spotted in July of 2022 with a low-visability gray tactical paint job. There was speculation that a third was pictured in flight in September 2023, although, as we noted at the time, the quality of the imagery made it difficult to ascertain whether the aircraft was indeed a navalized J-35 or a land-based FC-31 variant.

Of course, the emergence of the J-35 had long been considered closely linked with the People's Liberation Army Navy's (PLAN) future catapult-assisted takeoff but arrested recovery (CATOBAR) carriers.

For a time, it was widely assumed that China would stick with operating J-15 fighters from Liaoning and Shandong, which are both equipped for short takeoff but arrested recovery (STOBAR) operations. More capable future CATOBAR carriers such as Fujian would subsequently feature air wings that include J-35s and CATOBAR versions of the J-15, among other aircraft and drones. This may no longer be the case.

However, imagery that emerged out of China at the beginning of last month purported to show a J-35 mockup onboard Liaoning while the carrier was in dock. Then, later in February, further imagery materialized which showed the article next to a J-15 mockup aboard Liaoning as the carrier set out to sea for further post-maintenance trials.

A close-up view of the mockups of the J-35 and the J-15 variant from late February. Chinese internet via X

While the possibility of J-35s performing regular operations from Liaoning and Shandong may not have been anticipated by many observers, this would seem to make sense, Andreas Rupprecht, a longtime China aerospace analyst and contributor to The War Zone, has stressed: "In my opinion [the J-35 joining the Liaoning and the Shandong] makes perfect sense," he said. "Before the Fujian is ready, especially as an operational carrier, the PLAN will need to spend a lot of time training with the J-35 on the deck and in the air. Even if the training is limited due to not having a catapult, the PLAN can gain a lot of flight hours and a lot of experience."

Actually operating J-35s from STOBAR carriers would have some drawbacks, it should be noted. While recovery is the same for both STOBAR and CATOBAR carriers, J-35s would have to make use of Liaoning and the Shandong's ski-jump ramps on the bow to launch. As such, they would have to take off with less payload, in terms of weapons and fuel, compared to launching via future CATOBAR carriers. The Fujian will feature advanced electromagnetic aircraft launch system (EMALS) type catapults, instead of traditional steam-powered catapults.

However, the overall benefit they would bring to China's in-service carriers could be significant. Alongside its low-observable characteristics, it is assumed that the J-35 will feature an active electronically scanned array (AESA) radar alongside a host of advanced sensors, as well as very capable weaponry. Above all else, it would get these aircraft out to sea and operating, where major lessons can be learned, before Fujian is fully ready.

While this is all intriguing, it remains speculative. It could turn out that J-35 is either unsuitable for STOBAR operations or developmental timelines will mean that waiting for Fujian is a better move. We will have to wait and see how it all plays out.

Contact the authors: [email protected], [email protected]

7 notes

·

View notes

Text

Aluminum Prototype Machining: Precise Machining for Aluminum Prototypes

For high-quality aluminum prototypes, our aluminum prototype machining service ensures precise, fast results. Aluminum is a great material for lightweight, durable prototypes, making it ideal for testing and modifying product designs. Our CNC machining capabilities provide tight tolerances and quick turnaround times, ensuring that your prototypes are created accurately to meet your design requirements. Whether for automotive, aerospace, or consumer products, we help you validate your designs before full-scale production

0 notes

Text

Comprehensive Guide to Choosing a Constant Temperature Chamber Supplier

Introduction

Constant temperature chambers supplier are essential in various industries for maintaining a controlled environment for testing, storage, and product evaluation. These chambers, also known as stability chambers or environmental test chambers, offer precise temperature and humidity control, which is critical for industries such as pharmaceuticals, electronics, automotive, and more. Choosing the right supplier for a constant temperature chamber is essential to ensure quality, reliability, and optimal performance. This article aims to guide you through the key considerations for selecting a constant temperature chamber supplier and highlights the factors that set top suppliers apart in this specialized industry.

Why Constant Temperature Chambers Are Essential

Constant temperature chambers are vital tools for simulating specific environmental conditions over an extended period. They are widely used in:

Pharmaceuticals: For stability testing of drugs, ensuring they maintain potency and safety over time.

Electronics: For checking the durability of components when exposed to varying temperature conditions.

Automotive: For testing materials and components under extreme temperature conditions to ensure durability.

Food and Beverage: For shelf-life testing to maintain quality over time.

Other Industries: Including aerospace, telecommunications, and biotechnology for testing materials and equipment resilience.

The importance of constant temperature chambers in research, quality control, and production cannot be overstated, and selecting the right supplier is critical for meeting the specific needs of each application.

Visit Also:- Revolutionizing Insect Research: The Benefits of Using Fly Growth Chambers

Key Factors to Consider When Choosing a Constant Temperature Chamber Supplier

1. Quality of the Equipment

The quality of the temperature chamber itself is the most crucial factor. Ensure the supplier offers chambers with:

High Precision and Stability: Look for chambers with minimal temperature fluctuations, as stability is crucial for consistent results.

Robust Construction: Chambers should be made of high-quality materials that can withstand continuous operation.

Accurate Temperature and Humidity Control: Precision in controlling environmental conditions is essential for reliable testing.

2. Range of Products

A good supplier should offer a variety of temperature chambers to meet diverse requirements:

Different Size Options: Ranging from compact models for small labs to larger chambers for industrial applications.

Temperature and Humidity Ranges: Depending on the intended use, you might need chambers with specific ranges to suit particular testing requirements.

Additional Features: Such as data logging, programmable controls, and remote monitoring options.

3. Customization Options

Each industry and application may have unique requirements. Leading suppliers often offer customization options, allowing clients to tailor chamber specifications such as temperature range, humidity control, size, and advanced features. For instance, certain chambers might need extra ports or specific shelving configurations for easier testing procedures.

4. Technical Support and After-Sales Service

Reliable after-sales service and technical support are critical in choosing a supplier. A good supplier should offer:

Installation Assistance: Setting up the chamber can be complex, especially in large facilities.

Training: On how to properly operate and maintain the chamber.

Prompt Repair Services: A fast response in case of malfunctions is essential to prevent downtime.

Routine Maintenance Programs: Some suppliers offer periodic maintenance to keep chambers in optimal condition.

5. Experience and Reputation

Opt for suppliers with a proven track record. You can assess their experience and reputation through:

Customer Testimonials and Case Studies: Past customers’ experiences give insight into the reliability and performance of the supplier.

Years in Business: Established companies usually have refined processes and stable supply chains.

Industry Expertise: Suppliers specializing in your industry will better understand your requirements.

6. Certification and Compliance

Temperature chambers need to meet industry standards and regulations. Ensure that the supplier adheres to relevant certifications and standards, including:

ISO Certifications: Such as ISO 9001 for quality management, which assures the company’s commitment to quality.

Compliance with Industry-Specific Standards: For instance, pharmaceutical chambers may need to follow GMP (Good Manufacturing Practices) and FDA regulations.

7. Energy Efficiency

Energy efficiency is an increasingly critical factor due to rising energy costs and environmental considerations. Ask potential suppliers about the energy efficiency of their chambers and look for features like programmable energy-saving modes. This can significantly reduce operational costs in the long term.

Visit Also:- Advancing Plant Science with Phototrophic Growth Chambers

Top Benefits of Choosing a Reputable Constant Temperature Chamber Supplier

Consistency in Quality: Reputable suppliers offer chambers that meet stringent quality standards, ensuring reliable performance.

Cutting-Edge Technology: Leading suppliers invest in R&D to offer state-of-the-art features, from digital controls to cloud-based monitoring.

Better ROI: A high-quality chamber can operate efficiently for many years, making it a sound investment.

Reduced Downtime: Reliable equipment and prompt support mean minimal disruptions to your processes.

Compliance Assurance: Working with certified suppliers ensures that your equipment adheres to industry regulations, reducing risk in regulated industries.

How to Evaluate Potential Suppliers

Conducting Background Research

Start by identifying potential suppliers through industry publications, trade shows, and online research. Look for reviews, ratings, and industry-specific forums where companies share experiences with various suppliers.

Requesting Proposals and Comparing Offers

Request proposals from shortlisted suppliers and compare them based on the factors mentioned above. A thorough comparison should consider the chamber's initial cost, potential customization, warranty options, and estimated maintenance costs.

Visiting the Supplier's Facility

If possible, visit the supplier's facility. This allows you to see their production processes, quality control measures, and possibly even existing chambers in operation. This can provide insight into the overall quality and reliability of their products.

Asking for a Trial Period

Some suppliers may offer a trial period for testing their equipment. This is particularly helpful for ensuring the chamber performs well in your specific operational environment.

Conclusion

Selecting the right constant temperature chamber supplier is essential to ensure that your testing and storage requirements are consistently met. A reliable supplier should provide high-quality equipment, customization options, dependable support, and industry certifications. By carefully evaluating potential suppliers based on these criteria, you can choose one that aligns with your needs and ensures a long-term partnership, supporting your industry’s quality and regulatory standards.

#ConstantTemperatureChamber#StabilityTesting#EnvironmentalChamber#TemperatureControl#TestingEquipment#LaboratoryEquipment#IndustrialTesting#ControlledEnvironment#ClimateChamber#ProductTesting#QualityControl#ReliabilityTesting#PrecisionTesting#TemperatureStability#ResearchAndDevelopment

0 notes

Text

Everything You Need to Know About Customizing Shim Washers | Shim Washer Manufacturers

This article helps in projects that are one-size-fits-all. Every application has unique requirements, and using the wrong washer can lead to misalignments, increased wear, and even failure of the assembly.

Here’s why customizing matters:

Precision Tolerance: Custom shim washers ensure that you get the exact thickness and size needed for your specific application.

Enhanced Performance: When you fine-tune the spacing with custom washers, you improve the longevity and reliability of your fastened components.

Perfect Fit: Custom machined washers can be manufactured to meet your exact specifications, ensuring everything fits just right.

Whether you’re in aerospace, automotive, or industrial manufacturing, customized shim washers can make all the difference in ensuring your project’s success.

This article also helps in choosing the right shim washer manufacturer is a crucial step in ensuring that your custom shim washers meet your exact specifications and perform as expected. Here’s what to look for in a reliable washer manufacturer:

Experience

Look for a washer manufacturer with years of experience in producing custom shim washers for various industries. Experienced manufacturers can provide valuable insights and recommendations tailored to your project.

Customization Capabilities

Your shim washer manufacturer should offer a range of customization options, including various materials, thicknesses, and diameters. They should also be able to provide machined washers for high-precision applications.

Quality Assurance

Ensure that your washer manufacturer adheres to strict quality standards. They should provide full documentation, including material certifications and tolerance reports, to ensure you’re getting high-quality shim washers.

Prototyping and Testing

Choose a shim washer manufacturer that offers prototyping and testing services. This allows you to evaluate the shim washer before committing to full-scale production.

Customer Support

Reliable customer support is essential. Your washer manufacturer should be able to guide you through the customization process, answer questions, and provide recommendations to ensure your project’s success.

Customizing shim washers is a smart move when you need precision, durability, and optimal performance in your fastening applications. Whether you're working in the automotive industry, aerospace, or heavy machinery, custom shim washers ensure that your components are perfectly aligned, your loads are evenly distributed, and your fasteners hold up under pressure.

By choosing the right shim washer manufacturer, you can take advantage of the benefits of custom machined washers and ensure your project’s success. Don’t settle for standard washers when you can get exactly what you need through customization.

This guide will equip you with the knowledge to take your garment construction skills to the next level and create clothes that look and feel truly professional.

Link

Everything You Need to Know About Customizing Shim Washers | Shim Washer Manufacturers

0 notes

Text

Manufacturing Supply Companies and Testing Equipment Distributors: Essential Partners in Quality and Efficiency

In manufacturing, reliable supply companies and testing equipment distributors play key roles in maintaining high-quality standards and smooth operational workflows. From raw materials and tools to quality assurance devices, these suppliers provide the essentials needed for consistent production and accurate testing.

Manufacturing Supply Companies: Tools, Materials, and More

A manufacturing supply company offers a comprehensive range of tools, materials, and equipment vital to production processes across industries, including automotive, aerospace, electronics, and heavy machinery. These companies supply raw materials like metals, plastics, and composites, as well as essential machinery, hand tools, cutting tools, fasteners, and abrasives. Additionally, manufacturing suppliers often provide maintenance items, safety gear, and components to support daily operations and keep production lines running efficiently.

Manufacturing supply companies often cater to specific needs, offering custom solutions for specialized production. Many also provide inventory management and just-in-time delivery, reducing downtime and optimizing production schedules. Partnering with a dependable supplier helps manufacturing businesses maintain high-quality standards, ensure safety, and achieve cost savings through bulk purchases and streamlined procurement.

Testing Equipment Distributors: Quality Assurance in Every Detail

Testing equipment distributors provide tools critical to quality control and product validation. These distributors offer instruments used to test, measure, and analyze various product characteristics, ensuring they meet industry standards and specifications. Common testing equipment includes hardness testers, tensile testing machines, environmental chambers, vibration testers, and non-destructive testing (NDT) tools.

Industries like aerospace, medical devices, automotive, and electronics rely on testing equipment distributors to supply calibrated, high-precision instruments for accurate data. Testing equipment can range from handheld devices to complex systems requiring installation and integration. Distributors often offer calibration services, technical support, and training, helping businesses maintain certification standards and improve production reliability.

By sourcing from trusted manufacturing supply companies and testing equipment distributors, businesses can ensure the integrity of their materials, the precision of their tools, and the accuracy of their quality assessments. Quality suppliers contribute to seamless operations, safer workplaces, and the confidence that products meet industry standards.

#manufacturing sourcing#reliable product sourcing#ic source#product sourcing companies#electronic component distributors#iso certified production tool#manufacturing supply company#iso certified procurement specialists#production tool supply#product sourcing

0 notes