#Advanced Polymer

Explore tagged Tumblr posts

Text

searching "how silicone is made" for. uh. absolutely no reason at all.

#I do not think I can justify the noldor producing synthetic polymers#if for no other reason than they are extremely useful#and would be used for more applications than this#and putting plastic into middle earth/valinor is not really something I want to try to figure out for a BUNCH of reasons#I was already leaning against it but medical grade silicone is SO nice for certain things I had to check.#luckily I feel I can justify pretty much any super advanced glass metal or ceramic work yay

18 notes

·

View notes

Text

The conducting polymers market is projected to be valued at $7.35 billion in 2024, with an expected expansion at a CAGR of 7.97% to reach $15.82 billion by 2034.

#Conducting Polymers Market#Conducting Polymers Report#Conducting Polymers Industry#Advanced Materials#BISResearch

0 notes

Text

Why Top Dispersing Agent Manufacturers Rely on AMPS Monomer for Advanced Industrial Applications

In the world of industrial chemistry, innovation drives efficiency and effectiveness. One such groundbreaking innovation is the widespread adoption of AMPS monomer—scientifically known as 2-acrylamido-2-methylpropane sulfonic acid—by leading dispersing agent manufacturers. This remarkable chemical compound has transformed the formulation of dispersing agents, offering unparalleled benefits across various industries. From water treatment to paints, coatings, and adhesives, AMPS chemical has proven itself indispensable in crafting advanced solutions for modern industrial challenges. For more information visit Why Top Dispersing Agent Manufacturers Rely on AMPS Monomer for Advanced Industrial Applications give tags

#“Dispersing Agent Manufacturers”#“AMPS Monomer”#“Advanced Industrial Applications”#“Industrial Chemicals”#“Polymer Chemistry”#“AMPS Applications”#“Chemical Dispersants”#“Industrial Additives”#“Dispersing Agents”#“Vinati Organics”#“Chemical Manufacturing”#“Polymer Industry”#“High-Performance Chemicals”

0 notes

Text

Unleashing Creativity: Exploring Polymer Clay Jewelry Making Techniques

Polymer Clay Jewelry Making Techniques: Introduction Polymer clay is a versatile and forgiving medium, this implies a promising new form of jewelry-making with an identifiable edge. After first being processed it transforms into a durable, tough mold that can do everything from tiny beads and intricate pendants to towering statement necklaces and sculptural earrings. This article introduces the…

#advanced polymer clay techniques#bargello technique polymer clay#beads jewelry making#clay bead jewelry techniques#how to make polymer clay earrings#jewelry#jewelry collection#jewelry making#jewelry making tutorials#polymer clay#polymer clay earrings#polymer clay earrings making#polymer clay jewelry#polymer clay jewelry making#polymer clay pattern techniques#polymer clay technique#polymer clay techniques#polymer clay tutorial#polymer techniques

0 notes

Text

Controlled Release Drug Delivery: Enhancing Patient Compliance and Treatment Outcomes

In matrix diffusion systems, Controlled Release Drug Delivery is distributed uniformly throughout an inert polymer matrix. As the matrix comes in contact with fluids in the body, it starts slowly swelling and undergoing erosion. This allows the drug to diffuse out in a controlled manner over extended periods, from hours to days. Commonly used polymers include polymethacrylates and ethylene vinyl acetate. Get more insights on, Controlled Release Drug Delivery

Explore More Related Article On- Halal Food Market

For Deeper Insights, Find the Report in the Language that You want.

Japanese Korean

#Coherent Market Insights#Product launches#polymer technology advancements#chronic disease prevalence#personalized medicine

0 notes

Text

Advanced 3D Printing Polymer Materials: Unlocking New Possibilities

3D printing has revolutionized manufacturing across numerous industries, allowing for the creation of complex structures and highly customized products. One key element driving this innovation is 3D printing polymer materials, which offer versatility, strength, and adaptability to meet the demands of various applications.

Types of 3D Printing Polymer Materials

There are several 3D printing polymer materials available today, each catering to specific needs and industries. The most common types include:

PLA (Polylactic Acid): PLA is one of the most popular choices due to its ease of use and biodegradability. It is derived from renewable resources such as corn starch, making it an eco-friendly option for prototypes, consumer goods, and educational tools. PLA is known for its high printability and smooth surface finish.

ABS (Acrylonitrile Butadiene Styrene): ABS is a durable material with excellent impact resistance and toughness. It is widely used in industries such as automotive and electronics due to its ability to withstand high temperatures and mechanical stress. However, ABS requires a heated print bed for optimal results and can emit fumes during the printing process.

Nylon: Known for its flexibility and strength, nylon is ideal for functional parts and mechanical components. It has excellent wear resistance and can handle repeated use, making it a favorite in industries like engineering and aerospace. Nylon’s slightly porous nature can absorb moisture from the air, so proper storage is necessary to maintain its quality.

PETG (Polyethylene Terephthalate Glycol): PETG offers a balance between PLA and ABS, combining strength, flexibility, and ease of printing. It is highly resistant to impact and moisture, making it a good choice for products that need to endure harsh environments. PETG is commonly used for food-safe containers and medical devices.

Applications of 3D Printing Polymers

3D printing polymer materials have found applications in a wide range of industries. In healthcare, custom medical devices, prosthetics, and implants are created using biocompatible polymers. The aerospace and automotive sectors use polymers for lightweight yet durable components that reduce overall weight while maintaining strength.

In consumer goods, polymer materials enable the production of fashion accessories, home décor items, and even footwear. Additionally, the education sector has embraced 3D printing polymers to teach students about design, engineering, and manufacturing.

Future of 3D Printing Polymer Materials

As technology evolves, so does the development of 3D printing polymer materials. New materials with improved strength, flexibility, and sustainability are constantly emerging. This progress paves the way for even more innovative applications, from advanced medical solutions to cutting-edge automotive designs.

In conclusion, 3D printing polymer materials continue to expand the possibilities of additive manufacturing, making it accessible for various industries while offering a range of material properties that cater to diverse needs.

0 notes

Text

Ceramic Substrates Market Will Reach USD 11,740.8 Million By 2030

In 2023, the ceramic substrates market was valued at USD 7,721.3 million. Forecasts indicate it will grow significantly, reaching USD 11,740.8 million by 2030, with a projected compound annual growth rate (CAGR) of 6.3% between 2024 and 2030. This growth of the industry can be credited to the increasing need for such materials in many sectors and the trend of the reduction of electronic…

View On WordPress

#3D Printing Materials Market#ceramics#Competitive Landscape#composites#growth prospects#innovations#Investors#Key players#Manufacturers#market drivers#metals#polymers#regulatory landscapes#researchers#Technological advancements#Trends

0 notes

Text

Reinventing Infrastructure: The Role of Polymer Composites in Bridge Rehabilitation

Introduction Bridges are critical components of our transportation infrastructure, facilitating the smooth flow of goods and people. However, over time, these vital structures undergo wear and tear due to factors like heavy traffic, weathering, and aging. To address these challenges, engineers and researchers have been exploring innovative materials and techniques for bridge rehabilitation. One…

View On WordPress

#Bridge Maintenance#bridge rehabilitation#composite materials#construction innovation#corrosion resistance#Durability#engineering advancements#FRP technology#infrastructure enhancement#innovative materials#long-term savings#Polymer composites#seismic retrofitting#structural strengthening#sustainable solutions#transportation systems

0 notes

Text

Setting Sail to Travel Through Space: 5 Things to Know about our New Mission

Our Advanced Composite Solar Sail System will launch aboard Rocket Lab’s Electron rocket from the company’s Launch Complex 1 in Māhia, New Zealand no earlier than April 23, at 6 p.m. EDT. This mission will demonstrate the use of innovative materials and structures to deploy a next-generation solar sail from a CubeSat in low Earth orbit.

Here are five things to know about this upcoming mission:

1. Sailing on Sunshine

Solar sails use the pressure of sunlight for propulsion much like sailboats harness the wind, eliminating the need for rocket fuel after the spacecraft has launched. If all goes according to plan, this technology demonstration will help us test how the solar sail shape and design work in different orbits.

2. Small Package, Big Impact

The Advanced Composite Solar Sail System spacecraft is a CubeSat the size of a microwave, but when the package inside is fully unfurled, it will measure about 860 square feet (80 square meters) which is about the size of six parking spots. Once fully deployed, it will be the biggest, functional solar sail system – capable of controlled propulsion maneuvers – to be tested in space.

3. Second NASA Solar Sail in Space

If successful, the Advanced Composite Solar Sail System will be the second NASA solar sail to deploy in space, and not only will it be much larger, but this system will also test navigation capabilities to change the spacecraft’s orbit. This will help us gather data for future missions with even larger sails.

4. BOOM: Stronger, Lighter Booms

Just like a sailboat mast supports its cloth sails, a solar sail has support beams called booms that provide structure. The Advanced Composite Solar Sail System mission’s primary objective is to deploy a new type of boom. These booms are made from flexible polymer and carbon fiber materials that are stiffer and 75% lighter than previous boom designs. They can also be flattened and rolled like a tape measure. Two booms spanning the diagonal of the square (23 feet or about 7 meters in length) could be rolled up and fit into the palm of your hand!

5. It’s a bird...it’s a plane...it’s our solar sail!

About one to two months after launch, the Advanced Composite Solar Sail System spacecraft will deploy its booms and unfurl its solar sail. Because of its large size and reflective material, the spacecraft may be visible from Earth with the naked eye if the lighting conditions and orientation are just right!

To learn more about this mission that will inform future space travel and expand our understanding of our Sun and solar system, visit https://www.nasa.gov/mission/acs3/.

Make sure to follow us on Tumblr for your regular dose of space!

2K notes

·

View notes

Link

CYCLOTENE* advanced electronics resins from The Dow Chemical Company are high-purity polymer solutions that have been developed for microelectronics applications. The resins are derived from B-staged bisbenzocyclobutene-based (BCB) monomers and are formulated as high-solids, low-viscosity solutions. Contact us today If you'd like to know more.

#Cyclotene#Cyclotene 3000 Series#Cyclotene 4000 Series#Cyclotene 6505#Cyclotene XUS 35077#advanced electronics resins#polymer solutions#BCB Products#AGAS

1 note

·

View note

Text

OKAY THIS ARTICLE IS SO COOL

I'm going to try to explain this in a comprehensible way, because honestly it's wild to wrap your head around even for me, who has a degree in chemistry. But bear with me.

Okay, so. Solids, right? They are rigid enough to hold their shape, but aside from that they are quite variable. Some solids are hard, others are soft, some are brittle or rubbery or malleable. So what determines these qualities? And what creates the rigid structure that makes a solid a solid? Most people would tell you that it depends on the atoms that make up the solid, and the bonds between those atoms. Rubber is flexible because of the polymers it's made of, steel is strong because of the metallic bonds between its atoms. And this applies to all solids. Or so everybody thought.

A paper published in the journal Nature has discovered that biological materials such as wood, fungi, cotton, hair, and anything else that can respond to the humidity in the environment may be composed of a new class of matter dubbed "hydration solids". That's because the rigidity and solidness of the materials doesn't actually come from the atoms and bonds, but from the water molecules hanging out in between.

So basically, try to imagine a hydration solid as a bunch of balloons taped together to form a giant cube, with the actual balloon part representing the atoms and bonds of the material, and the air filling the balloons as the water in the pores of the solid. What makes this "solid" cube shaped? It's not because of the rubber at all, but the air inside. If you took out all the air from inside the balloons, the structure wouldn't be able to hold its shape.

Ozger Sahin, one of the paper's authors, said

"When we take a walk in the woods, we think of the trees and plants around us as typical solids. This research shows that we should really think of those trees and plants as towers of water holding sugars and proteins in place. It's really water's world."

And the great thing about this discovery (and one of the reasons to support its validity) is that thinking about hydration solids this way makes the math so so so much easier. Before this, if you wanted to calculate how water interacts with organic matter, you would need advanced computer simulations. Now, there are simple equations that you can do in your head. Being able to calculate a material's properties using basic physics principles is a really big deal, because so far we have only been able to do that with gasses (PV=nRT anyone?). Expanding that to a group that encompasses 50-90% of the biological world around us is huge.

#science#stem#science side of tumblr#stemblr#biology#chemistry#scientists#biochemistry#studyblr#physics#nature

6K notes

·

View notes

Text

"At the University of Maine, one of the world’s largest 3D printers is using sawdust from the state’s lumber industry to 3D print cozy wooden cabins.

It’s part of a move towards making 3D printing faster and more sustainable in a state where the housing shortage that has metastasized in most states around the country is dire.

It’s thought that 80,000 new homes will be needed over the next 5 years to keep pace with demand, and though it takes years for building codes to be changed, the technicians at the Advanced Structures & Composites Center (ASCC) at the Univ. of Maine hope their new toy can help address this need.

Guinness World Records certified the machine at ASCC as the world’s largest prototype polymer 3D printer, capable of creating a 600 square foot house 96 feet in length, 36 feet in width, and 18 feet tall entirely out of bio-based material at a rate of 500 pounds per hour.

In 2022, it could print the walls, floors, and roof of the house in just 96 hours, but the ACSS has been refining the design with the hope of doubling the printing speed and getting it down to a 48-hour timeline.

“When they’re doing concrete, they’re only printing the walls,” Habib Dagher, the executive director of ACSS told CNN. “The approach we’ve taken is quite different from what you’ve seen, and you’ve been reading about for years.”

Indeed, GNN has reported on a fair number of 3D printing projects, but most if not all involve printing only the walls. One fantastical exception is an Italian firm that is 3D-printing domed, beehive-like, modular concept homes inspired by the Great Enclosure in Zimbabwe.

STAND-OUT 3D-PRINTING PROJECTS:

First 2-Story Home to be 3D Printed in the U.S. Reaches for the Sky in Texas

The World’s Largest 3D Printed Building is a Horse Barn That Can Endure Florida Hurricanes

This 23-Year-Old Founder is 3D Printing Schools in Madagascar Aiming to be a ‘Stepping Stone’ for the Community

A Startup Is Using Recycled Plastic to 3D Print Tiny $25,000 Prefabricated Homes in LA

The ASCC is calling the house design the BioHome3D, and says it’s rare people who tour the concept version don’t ask when they “can have one up?”

The interior gives the feel of a modern Scandinavian wooden cabin, making it fit well with the Maine aesthetic. The ASCC is now doing work on how to incorporate conduits for wiring and plumbing “exactly where an architect would want them,” says Dagher.

WATCH a time-lapse video of the printer doing the job…

youtube

-via Good News Network, August 16, 2024. Video via The University of Maine, March 3, 2023.

#3d printing#housing#housing crisis#3d printed#architecture#sustainable architecture#biomaterials#maine#united states#good news#hope#Youtube

448 notes

·

View notes

Text

NO ONE EVER DRAWS THE WOMEN FROM TV WITH PENISES AND HAVING SEX WITH EACH OTHER!!!! RRRRAAAAGHHH!!!!! quickly fashions a crude but sturdy bludgeon from a tree branch and uses it to split a stone in two, allowing me to make more advanced tools such as chisels. using these tools I extract metal ore and construct a simple forge to refine it. I eventually progress technologically to the point where I have the means to manufacture a standard polymer frame 9mm handgun, which I then use to kill myself with a single shot to the temple

105 notes

·

View notes

Text

🏥 The TARDIS Sickbay

Have you ever wondered what happens when a Time Lord needs some medical attention on their travels? Well, look no further than the TARDIS Sickbay—an onboard medical facility fully equipped to deal with all your medical emergencies. Let's take a quick tour.

🔬 Cutting-Edge Medical Tech

The TARDIS Sickbay is packed with some of the most advanced medical equipment in the universe:

Advanced Diagnostic Terminal (ADT): This has overhead medical scanners and vast data files on advanced medical techniques. The ADT can diagnose and treat nearly any ailment a Gallifreyan might encounter. If configured by a qualified medical expert, it can also be programmed to treat other species. The ADT can also project a holographic avatar to guide you through your treatment—usually in the form of the Time Lord who set it up, but you can always request a different face from the TARDIS memory store.

Surgical Containment Web: Perfect for life-threatening injuries, this surgical device lasers away damaged tissue while organic polymers reconstruct missing flesh. It can even reattach severed limbs—though, it's not quite advanced enough to regenerate lost limbs for humans.

Cell Regeneration Vault: A coffin-like cabinet that can absorb nearly all types of radiation. It's not the most comfortable process, causing a burning sensation, and can take days to fully heal the patient. Unfortunately for the Tenth Doctor, this feature is only available on Type 66 TARDISes and later.

Other minor features:

Quarantine Bay: For isolating contagious patients.

Handheld Healing Devices: Variety of instruments to heal cuts, bruises, and other minor injuries in 30 minutes or less.

Artron Detectors: Useful for establishing artron levels, prophylactic of hypo/hyperartronosis.

Healing Environmental Controls: Helps to prevent patients from passing out.

(TARDIS Technical Index)

Whoniverse Facts for Friday by GIL

Any orange text is educated guesswork or theoretical. More content ... →📫Got a question? | 📚Complete list of Q+A and factoids →📢Announcements |🩻Biology |🗨️Language |🕰️Throwbacks |🤓Facts → Features: ⭐Guest Posts | 🍜Chomp Chomp with Myishu →🫀Gallifreyan Anatomy and Physiology Guide (pending) →⚕️Gallifreyan Emergency Medicine Guides →📝Source list (WIP) →📜Masterpost If you're finding your happy place in this part of the internet, feel free to buy a coffee to help keep our exhausted human conscious. She works full-time in medicine and is so very tired 😴

#doctor who#dr who#dw eu#gallifrey#gallifrey institute for learning#whoniverse#TOTW: A cure for all ills#gallifreyan technology#GIL: Facts#gallifreyan biology#GIL: Biology#GIL: Biology/Medical#GIL: Species/Gallifreyans#GIL: Gallifrey/Technology#GIL

39 notes

·

View notes

Note

What were Mewtwo’s cloning tubes were made of? Cause they somehow they allowed the clone pokemon to pass through the grey part but keep the fluids in. What was it some super advanced polymer membrane?

I never really thought about it XD I don’t know enough about those materials to know but again, he had an aesthetic to keep up and that included the cloning tubes

148 notes

·

View notes

Text

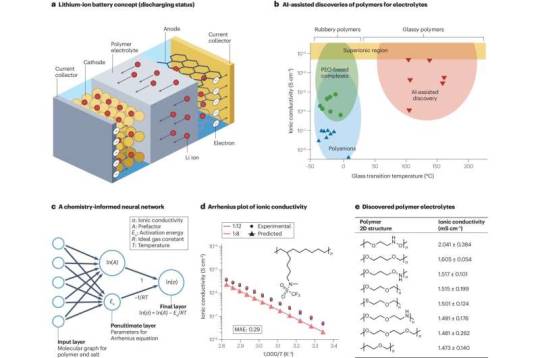

AI accelerates discovery of next-gen polymers

Nylon, Teflon, Kevlar. These are just a few familiar polymers—large-molecule chemical compounds—that have changed the world. From Teflon-coated frying pans to 3D printing, polymers are vital to creating the systems that make the world function better. Finding the next groundbreaking polymer is always a challenge, but now Georgia Tech researchers are using artificial intelligence (AI) to shape and transform the future of the field. Rampi Ramprasad's group develops and adapts AI algorithms to accelerate materials discovery. This summer, two papers published in the Nature family of journals highlight the significant advancements and success stories emerging from years of AI-driven polymer informatics research.

Read more.

#Materials Science#Science#Polymers#Artificial intelligence#Computational materials science#Machine learning#Georgia Tech

24 notes

·

View notes