#Advanced HVAC Control Industry Size

Explore tagged Tumblr posts

Text

Cold Rooms - Cold Storage Latest Price, Manufacturers & Suppliers | Acmas Technologies

Cold Room and Cold Storage solutions have become indispensable. From farm-fresh produce and frozen meats to vaccines and life-saving drugs, cold storage infrastructure ensures that products maintain their quality, potency, and shelf life throughout the supply chain.

At Acmas Technologies, we specialize in designing, manufacturing, and supplying advanced Cold Room Solutions for a wide range of industries. With a strong focus on innovation, energy efficiency, and customization, we deliver Cold Room Systems that match the diverse needs of food processors, pharmaceutical companies, logistics providers, and industrial clients.

This comprehensive blog explores everything you need to know about cold rooms—from types and working principles to their applications and benefits. We also highlight why Acmas Technologies is the preferred Cold Room Manufacturer and Cold Storage Manufacturer in India.

What is a Cold Room?

A Cold Room is a temperature-controlled environment used for the storage of temperature-sensitive products. It maintains specific temperatures—ranging from chilled (0°C to 10°C) to deep-frozen (-18°C to -40°C)—to prevent spoilage and ensure product integrity.

Modern Cold Storage Rooms are engineered with high-efficiency insulation panels, energy-saving refrigeration systems, humidity controls, and monitoring devices to maintain precise conditions. These rooms are crucial in maintaining the cold chain, especially in sectors like food processing, pharmaceuticals, horticulture, and logistics.

Types of Cold Rooms and Cold Storage Solutions

At Acmas Technologies, we offer a broad range of Cold Room Solutions tailored to customer requirements. Our designs support various scales, product types, and regulatory needs.

Walk-In Cold Room: A Walk-In Cold Room is ideal for commercial kitchens, hotels, laboratories, and small-scale storage needs. These rooms provide easy access for personnel and typically operate in temperature ranges between 0°C to 8°C for short-term storage of perishables.

Features:

Easy to install and relocate

Hygienic interiors with food-grade finishes

Ideal for daily-use products

Modular Cold Room

Modular Cold Rooms are made of prefabricated insulated panels and can be assembled in any size or layout. They are widely used in retail outlets, distribution centers, and processing units.

Advantages:

Scalability and flexibility in design

Fast installation and commissioning

Suitable for diverse temperature zones

Blast Freezer Room

A Blast Freezer Room rapidly brings down the temperature of products from ambient to freezing levels. This is vital for preserving the cellular structure and taste of products like seafood, meat, and bakery items.

Key Benefits:

Ultra-fast freezing cycles

Ensures minimal bacterial growth

Ideal for food exports and long-term preservation

Industrial Cold Storage: Large-scale Industrial Cold Storage facilities serve food processing plants, pharmaceuticals, and agricultural producers. These systems are designed for bulk storage with multi-temperature compartments, remote monitoring, and efficient power consumption.

Highlights:

Capacity from 10 MT to 10,000 MT+

Advanced refrigeration and automation

Heavy-duty racking and loading bays

Custom Cold Rooms: Every industry has unique needs. Our Custom Cold Rooms are tailored for niche applications like blood storage, vaccine preservation, seed germination, and climate testing.

We offer:

Customized dimensions and door configurations

Integrated HVAC and humidity controls

IoT-enabled monitoring for compliance

Cold Storage for Food Industry

The Cold Storage for Food Industry plays a vital role in reducing post-harvest losses and meeting consumer demand for safe, fresh, and high-quality food products. We serve a wide range of food sectors:

Dairy Products: Milk, cheese, butter

Fruits & Vegetables: Controlled humidity and ethylene control

Meat & Poultry: Blast freezing and deep-freeze storage

Seafood: -25°C to -40°C environments

Frozen Foods: Ready-to-eat, bakery, and processed meals

Proper cold storage reduces spoilage, maintains nutrition, and ensures regulatory compliance for food exports and retail.

Cold Storage for Pharmaceuticals

Pharmaceutical companies require ultra-reliable cold storage to maintain drug efficacy and ensure patient safety. Our Cold Storage for Pharmaceuticals meets stringent norms like WHO-GMP, FDA, and GDP.

We provide:

Temperature Mapping for uniform cooling

Redundant cooling systems to avoid failures

Data loggers and alarms for 24x7 monitoring

Cold storage for vaccines, blood, reagents, and insulin

These solutions are ideal for hospitals, diagnostic labs, biotech firms, and vaccine logistics.

Cold Chain Solutions for Every Industry

From raw material storage to distribution hubs, a reliable Cold Chain Solution is critical. At Acmas Technologies, we offer end-to-end systems that include:

Pre-cooling chambers

Refrigerated transport integration

Mobile cold rooms for last-mile delivery

Energy-efficient refrigerant systems

Remote performance monitoring

Our aim is to support businesses in creating sustainable and uninterrupted cold chains that protect product quality at every stage.

Components of a Cold Storage System

An efficient Cold Storage System is more than just insulation and cooling. Our turnkey systems are engineered with high-performance components:

PUF Insulated Panels: Superior thermal efficiency

Condensing Units: Scroll, reciprocating, or screw compressors

Evaporator Units: Designed for specific load and humidity

Digital Controllers: Easy programming and alertsBackup Generators: For uninterrupted operation

Racks & Shelving: To optimize internal space

We customize each system to match your operational needs, climate conditions, and budget.

Factors Affecting Cold Storage Latest Price

When evaluating the Cold Storage Latest Price, several variables come into play:

Size & Capacity – Larger rooms cost more but offer economies of scale

Temperature Range – Ultra-low temperature systems require robust components

Customization Level – Special doors, lighting, flooring, etc., affect cost

Automation & Monitoring – Smart systems offer better control at a higher upfront cost

Installation Site – Indoor, outdoor, or rooftop installations vary in complexity

At Acmas Technologies, we ensure transparent pricing with no hidden costs and deliver value-engineered solutions that align with your goals.

Why Choose Acmas Technologies?

As a leading Cold Room Manufacturer and Cold Storage Manufacturer, Acmas Technologies brings years of experience, deep technical expertise, and an unwavering focus on quality. Here’s why we are the preferred partner for cold storage projects:

ISO & CE Certified Manufacturing Facility

Expert Team of Engineers & Designers

Energy-Efficient and Eco-Friendly Designs

Rapid Installation & Commissioning

Comprehensive AMC & Support Services

Nationwide Reach with Global Exports

We serve clients across industries including food, pharma, hospitality, logistics, agriculture, and research.

Future of Cold Storage: Technology & Sustainability

The future of Cold Room Solutions is centered on sustainability, automation, and smart connectivity. At Acmas Technologies, we are investing in:

IoT-enabled cold rooms for remote monitoring

Renewable energy integration (solar-powered cold rooms)

Eco-friendly refrigerants like R-290, CO2

AI-based energy optimization systems

These innovations help businesses reduce operational costs while maintaining stringent storage requirements.

Whether you're preserving perishables, extending product shelf life, or maintaining the efficacy of life-saving drugs, Cold Room and Cold Storage solutions are integral to modern industry. From modular walk-ins to large-scale industrial cold storage, Acmas Technologies provides advanced and customizable solutions designed to deliver performance, efficiency, and compliance.

With our proven expertise as a Cold Room Manufacturer, Cold Storage Manufacturer, and complete solution provider, we ensure that your cold chain remains strong, efficient, and reliable.

Ready to invest in a world-class Cold Storage Room or Custom Cold Room Solution? Contact Acmas Technologies today for expert consultation, latest pricing, and tailor-made cold storage systems designed for your industry.

For more info: https://www.acmasindia.co.in/

Email ID: [email protected]

Phone: 8069186503

Location: Plot No. 126, Sector-56 Phase- IV Kundli, Sonepat, Haryana-131028

#Cold Room#Cold Storage#Cold Room Manufacturer#Cold Storage Manufacturer#Cold Room Solutions#Cold Storage Room#Walk-In Cold Room#Modular Cold Room#Cold Storage for Food Industry#Cold Storage for Pharmaceuticals#Cold Storage System#Custom Cold Rooms#Blast Freezer Room#Industrial Cold Storage#Cold Chain Solutions

2 notes

·

View notes

Text

Construction Type Cooling Towers

The construction type cooling tower is an absolutely essential component in many industrial processes that generate large amounts of heat. It helps dissipate the heat produced by the process by transferring it to the surrounding air through evaporative cooling. Cooling towers are used in various industrial processes and HVAC systems to remove heat from a building or industrial process.

A construction type cooling tower requires careful planning and implementation to ensure efficient and safe operation.

Of course, this planning should be coordinated with the support you get from us.

Concrete Construction-Type Water Cooling Towers

CTP Construction-type Water Cooling Towers

Steel Construction-Type Water Cooling Tower

The general steps for cooling tower installation are:

Location Selection:

Choose a suitable location for the cooling tower beforehand. Key factors to consider include accessibility, environmental regulations, proximity to water sources and, of course, site selection for proper air flow.

Factors such as access to water, electricity, and proximity to industrial processes requiring cooling must be fully taken into account. The installation location must be chosen carefully.

Permissions and Regulations:

Check local building codes, environmental regulations and permits required for cooling tower installation. Obtain all necessary approvals from relevant authorities.

Design and Sizing:

To choose the appropriate size and cooling tower type, first determine the cooling requirements of your process. The technical data of the tower designed to suit your process will definitely be presented to you by our company. Then design the plumbing and electrical systems to be connected to the cooling tower in accordance with the technical data provided.

Tower Base:

Construct a solid concrete basin for the cooling tower according to the given project. Make sure it is level and can support the weight of the tower and circulating water.

Tower Assembly:

The cooling tower is generally assembled on-site and by combining parts sent to the field. The tower’s columns are lifted into place and fixed to the foundation. The tower assembly begins after beam connections are made. Afterwards, the layers of the tower are created and its assembly is completed.

Piping and Electricity:

Install the piping and connections to and from the cooling tower, including the cooling water supply and return lines.

Electrical Wiring:

Connect electrical wiring to the cooling tower, including fan motors, control systems, and other electrical components.

Water Purification:

Water purification systems must be installed in the tower to prevent scaling, corrosion and biological growth. This is important to ensure efficient operation of the tower and extend the life of the tower components.

Commissioning:

Test and commission after tower assembly is completed. This includes verifying that all systems are operating as intended and that the tower has the ability to effectively cool the process

Construction Type Cooling Tower Features

Installation is done in the field

It is designed for maximum performance.

It works in all weather conditions.

The assembly of the tower, whose project has been prepared in advance, is planned and fast.

Cooling towers are indispensable for cooling process water and keeping equipment from overheating. They are useful in industrial facilities such as oil refineries, chemical plants and thermal power stations, and they are common in manufacturing facilities and many buildings with HVAC systems.

Cooling towers come in various types, and it’s important to choose the correct one for your plant’s needs. In the guide below, we’ll explain how these apparatuses work and discuss some of the different types of cooling towers.

GRP counter flow cooling towers are used in all sectors such as energy, iron and steel, food as well as in all industries.

GRP counter flow cooling towers are the most preferred type of counter flow cooling towers in recent years. The main advantage of GRP cooling towers is that they are resistant to the destructive effects of water, air and sun. There is no risk of corrosion.

Advantages of pultrusion ctp structural elements used in cooling towers

High strength

Pultrusion GRP profiles approach the strength of steel in tension and compression.

Light weight

80% less than steel, 30% less than aluminium.

Corrosion resistance

' Unaffected by a wide range of abrasive materials; resistant to deterioration.

Quality construction

Cut and drilled to project specifications, GRP profiles will not warp, bend or split after manufacture. This ensures safe and efficient tower erection on site.

Non-conductive

Reduces the risk of electric shock compared to metal towers.

No protective maintenance chemicals are used in the cooling tower structure.

Flame retardant products are available on request.

#cooling tower#construction#construction type cooling tower#construction cooling tower#ctp mühendislik#soğutma kulesi#su soğutma kulesi#raschig ring#soğutmakulesi#chiller#hvac#construction workers#construction materials#construction company#construction management#construction services

2 notes

·

View notes

Text

Ball Valve Manufacturer in India

Ball valves are essential components in fluid control systems, offering reliability, efficiency, and durability. At Glando Valves and Strainers, we take pride in manufacturing high-quality ball valves that meet industrial standards and exceed customer expectations.

Features of Glando Ball Valves

Robust Construction: Our ball valves are made from premium materials such as stainless steel, brass, and cast iron, ensuring longevity and resistance to corrosion.

High-Performance Sealing: Engineered for leak-proof operation with advanced sealing technology, minimizing fluid loss and preventing contamination.

Efficient Flow Control: Provides smooth operation with minimal pressure drop, making it ideal for high-flow applications.

Easy Operation: The quarter-turn mechanism ensures quick opening and closing, reducing downtime and enhancing operational efficiency.

Versatile Applications: Suitable for various industries, including water treatment, chemical processing, oil and gas, HVAC, and manufacturing.

Customizable Options: Available in multiple sizes, pressure ratings, and materials to meet specific operational requirements.

Benefits of Choosing Glando Ball Valves

Enhanced Durability: Our ball valves are designed to withstand extreme temperatures and pressures, ensuring long-term reliability.

Corrosion Resistance: High-quality materials ensure resistance against harsh chemicals and environmental factors.

Cost-Effective Solution: Low maintenance requirements and extended service life reduce operational costs.

Leak-Free Operation: Precision engineering ensures tight shut-off, preventing leakage and ensuring safety.

Eco-Friendly: Designed for optimal efficiency, reducing energy consumption and minimizing waste.

Trusted Quality: Manufactured under stringent quality controls to ensure top-notch performance and compliance with industry standards.

At Glando Valves and Strainers, we are committed to delivering excellence in fluid control solutions. Whether you need standard or customized ball valve manufacturer in India, we have the expertise to meet your needs. 📞 Contact us today at +91-9879611918 for expert guidance and high-quality ball valve solutions!

1 note

·

View note

Text

Automotive Cockpit Electronics Market Size, Share & Trends Analysis Report By Forecasts 2034

As per a recent report by Fact.MR, the size of the global automotive cockpit electronics market has been estimated to be worth US$ 56.1 billion in 2024 and is likely to move forward at a 5% CAGR (2024-2034) to reach a valuation of US$ 91.2 billion towards the end of 2034.

A major trend within the automotive cockpit electronics market is the pace of technology developments, ranging from advanced driver-assistance systems (ADAS) to electric vehicle incorporation and in-car connectivity. Global demand for autonomous vehicles and electric vehicles is also increasing gradually, which will propel growth of this market. Automotive innovation within cockpit electronics will be one of the top concerns of automakers.

For More Insights into the Market, Request a Sample of this Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=9985

What are the Drivers of Global Automotive Electronics Market Growth?

"Strict Safety and Compliance Standards in Automotive Electronics"

Traditional cockpit components like steering, music systems, HVAC, brakes, and navigation systems are covered under it. These components are controlled manually. These distract drivers many times and increase the accident possibility.

Electronic cockpits have evolved several screens providing all the pertinent details. This amiable human machine interface (HMI) provides simple communication and vehicle control for the driver, enhancing vehicle safety and lowering the chances of accidents.

Country-wise Insights

China in the East Asia region is expected to maintain a dominant market share of 58.7% in 2024 with a market value of US$ 8.14 billion.

At the global level, the North American region has a dominant automotive cockpit electronics market share of approximately 27.8%, with the value of the market estimated at US$ 15.6 billion in 2024.

Category-specific Insights

Infotainment & navigation systems are highly sought after at present and have a dominant market share of 28.7% in 2024. The segment is estimated at US$ 16.11 billion in 2024 and is anticipated to grow to US$ 25.28 billion by 2034.

Passenger cars are estimated to capture a market share of 63.7% by 2024. The segment holds a market value of US$ 35.75 billion in the year 2024 and has been estimated to grow at 5.8% CAGR during 2034.

Competition Landscape

Continental AG, DENSO CORPORATION, Visteon Corporation, Harman International Industries Inc., Alpine Electronics Inc., Clarion Company Ltd., Delphi Automotive Plc, Robert Bosch GmbH., Panasonic Corporation, Garmin Ltd., Samsung Electronics, and Magneti Marelli are major players in the international automotive cockpit electronics market.

Industry participants are emphasizing market differentiation with digital offerings and fresh designs. Firms are aligning with technology leaders to access expertise and resources needed for the production of sophisticated electronic cockpits. Inter-industry collaboration with technology giants is enabling market participants to upgrade their products.

In January 2024, Visteon Corporation released SmartCore® Service Oriented Architecture (SOA) platform, AllGo® Connected Services, and SmartZone Zonal Controller concept. These are intended to expand its product line and provide it with a market competitive advantage.

In January 2024, Robert Bosch GmbH and Qualcomm Technologies, Inc. introduced the automotive industry's first-ever central vehicle computer. The platform is capable of running advanced driver assistance system (ADAS) features along with infotainment software on a single platform simultaneously.

In December 2023, Continental AG partnered with Korean semiconductor firm Telechips. Continental took this strategic step for cost minimization. It also introduced a new 'Smart Cockpit High-Performance Computer' for OEMs. This new HPC system is developed for cost-optimization and an efficient and streamlined solution for automakers.

Segmentation of Automotive Cockpit Electronics Market Research

By Product :

Infotainment & Navigation

Information Displays

Head-up Displays

Instrument Clusters

Telemetric

By Vehicle Category :

Passenger Vehicles

Commercial Vehicles

By Region :

North America

Latin America

Western Europe

Eastern Europe

East Asia

South Asia & Pacific

Middle East & Africa

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

MS ERW B/Weld Eccentric Reducer at Lowest Price in India

In the realm of industrial piping systems, the MS ERW (Electric Resistance Welded) Butt Weld Eccentric Reducer plays a vital role in ensuring smooth transitions between pipes of different diameters. Designed to enhance fluid flow and pressure management, this fitting is essential for various applications. If you’re seeking the lowest prices for MS ERW B/Weld Eccentric Reducers in India, Udhhyog is your trusted supplier.

What is an MS ERW B/Weld Eccentric Reducer?

An MS ERW B/Weld Eccentric Reducer is a type of pipe fitting used to connect two pipes of different sizes while maintaining a consistent flow path. Unlike concentric reducers, eccentric reducers allow for a flat bottom, which makes them ideal for applications where sedimentation may occur, such as in wastewater or slurries. The butt weld construction ensures a strong, leak-proof connection, providing reliability in high-pressure situations.

Key Features of MS ERW B/Weld Eccentric Reducers

Enhanced Fluid Flow: The eccentric design allows for smooth transitions while preventing the buildup of solids, thus maintaining efficient flow.

Durable and Reliable: Made from high-quality mild steel, these reducers are designed to withstand demanding conditions, including high pressures and temperatures.

Strong Joints: The butt weld connections create a robust seal that minimizes the risk of leaks, making them suitable for critical applications.

Versatile Use: Ideal for a variety of industries, including oil and gas, water treatment, and chemical processing.

Cost-Effective Solution: With their durable construction and effective performance, these reducers provide an economical choice for industrial applications.

Applications of MS ERW B/Weld Eccentric Reducers

Wastewater Management: In wastewater systems, eccentric reducers help prevent the accumulation of sediments, ensuring a continuous flow of waste.

Oil and Gas Pipelines: Used to connect varying pipe sizes in pipelines while maintaining pressure and flow efficiency.

Chemical Processing: Ensures efficient fluid transitions in chemical plants, facilitating various processes without hindrance.

HVAC Systems: In HVAC applications, these reducers help maintain balanced airflow and efficient pressure management.

Why Choose Udhhyog for MS ERW B/Weld Eccentric Reducers?

As a leading supplier of MS ERW B/Weld Eccentric Reducers, Udhhyog is committed to providing high-quality products at the lowest prices in India. Here’s why we stand out:

Quality Manufacturing: We utilize advanced manufacturing processes and rigorous quality control to ensure that our products meet international standards.

Affordable Pricing: Our focus on providing the lowest prices ensures that you receive high-quality products without exceeding your budget.

Prompt Delivery: Based in Delhi, we guarantee timely delivery across India, helping you stick to your project schedules.

Comprehensive Range of Products: Alongside eccentric reducers, we offer a wide variety of industrial fittings, flanges, and valves, making us a one-stop solution for all your piping needs.

Customer-Centric Service: Our team is dedicated to understanding your specific requirements and providing tailored solutions that enhance your operational efficiency.

Order Your MS ERW B/Weld Eccentric Reducers Today

By choosing Udhhyog as your supplier for MS ERW B/Weld Eccentric Reducers, you can ensure the durability, reliability, and affordability of your piping solutions. Whether you’re involved in large-scale projects or require specific components for your operations, Udhhyog is here to provide the best products at the lowest prices in India.

#MSErwEccentricReducer#ButtWeldReducer#PipeFittings#IndustrialPiping#Udhhyog#EccentricReducerIndia#LowestPriceIndia#DelhiSupplier#SteelPipeFittings#MSPipeFittings#CostEffectiveSolutions

2 notes

·

View notes

Text

Acoustic Louver Panels are designed for superior noise control and ventilation, making them ideal for HVAC systems, power plants, and industrial facilities. These panels effectively reduce sound transmission while allowing airflow, ensuring a balanced acoustic environment.

Made from high-quality materials, Acoustic Louver Panels feature a durable, weather-resistant design suitable for both indoor and outdoor applications. Their advanced sound-absorbing properties minimize noise pollution, enhancing comfort in commercial and industrial spaces.

Customizable in size, finish, and material, these panels seamlessly integrate into any architectural design. They are ideal for enclosures, barriers, and building facades where noise reduction and airflow are essential.

With easy installation and low maintenance, Acoustic Louver Panels provide a cost-effective solution for managing noise without compromising ventilation. Perfect for environments requiring acoustic efficiency and structural durability.

📍 Address: Plot No- F93 Sector-135, Noida, Uttar Pradesh-201304

📞 Phone:9999010084

📧 Email: [email protected]

🌐 Website: https://acousticboardindia.com

#Acoustic Louver Panels#noise control#ventilation#HVAC#industrial#sound absorption#outdoor#durable#weather-resistant#customizable#low maintenance

1 note

·

View note

Text

Selecting the Optimal Air Conditioning System for Perth's Climate

Perth's climate, characterised by hot summers and mild winters, necessitates a reliable air conditioning system for comfort and efficiency. The selection of an appropriate air conditioner in Perth is critical to ensure optimal cooling, energy efficiency, and cost effectiveness. This article aims to guide residents in making informed decisions about air conditioning systems suitable for Perth's unique weather conditions. We will explore different air conditioning technologies, key factors to consider, and the importance of energy efficiency. Understanding these aspects is vital for choosing an aircon that not only cools effectively but also aligns with environmental and budgetary considerations. The goal is to provide a comprehensive understanding of the options available for maintaining a comfortable indoor environment in Perth's climate.

Everest HVAC & R stands as a premier provider of air conditioning services in Perth, renowned for our exceptional expertise in supplying, installing, maintaining, and repairing air conditioning systems. Our commitment to quality and customer satisfaction positions us at the forefront of the industry, offering tailored solutions that meet the unique needs of Perth's climate. With a comprehensive understanding of the latest air conditioning technologies and a dedication to energy efficiency, Everest HVAC & R ensures that each client receives a system that is not only effective but also cost efficient. Our team of skilled professionals is equipped with the knowledge and tools necessary to provide seamless installation, meticulous maintenance, and prompt repair services. At Everest HVAC & R, we pride ourselves on delivering unparalleled service, ensuring that every air conditioner we supply and install performs optimally for years to come. Trust Everest HVAC & R for your air conditioning needs in Perth – where quality, efficiency, and customer satisfaction are our top priorities. Please visit our Air Conditioner Blog

Understanding Air Conditioning Technologies

The market offers several types of air conditioning systems, each with unique features suitable for Perth's climate. Split systems, popular for their efficiency and ease of installation, are ideal for single rooms or specific areas. Ducted systems offer centralized cooling, suitable for larger homes needing uniform temperature control. Portable units provide flexibility and are a convenient option for temporary cooling needs. Each type presents distinct advantages: split systems for targeted cooling, ducted systems for whole house comfort, and portable units for flexibility. However, their effectiveness varies based on Perth's climatic conditions, necessitating a careful evaluation of each system's suitability.

Key Factors to Consider When Selecting an Air conditioner for Perth

When choosing an air conditioner in Perth, energy efficiency is paramount. Systems with high energy efficiency ratings can significantly reduce electricity costs, especially important in Perth's hot summers. Cooling capacity is another crucial factor; selecting a unit with the appropriate size for your space ensures efficient cooling without excessive energy consumption. Air conditioners that adapt well to varying temperatures offer greater comfort during Perth's climate fluctuations. Additionally, features like programmable timers and adjustable thermostats contribute to energy savings and enhanced comfort. These factors collectively determine the system's overall performance and suitability for Perth homes.

Innovative Features in Modern Air Conditioning Systems

Modern air conditioners offer advanced features that enhance comfort and efficiency, particularly beneficial for Perth's climate. Smart thermostats enable precise temperature control and can adjust settings based on weather forecasts, ensuring optimal indoor conditions. Air purification technology in air conditioners improves indoor air quality, a significant advantage for health conscious residents. Noise reduction technology is also integral, providing a quieter and more comfortable environment. These innovative features not only increase the functionality of air conditioning systems but also contribute to energy savings and environmental sustainability. Therefore, selecting a system with these modern features is a wise investment for Perth homeowners.

Installation & Maintenance Considerations for Air conditioners in Perth

Proper installation and maintenance are crucial for the optimal performance of air conditioners in Perth. Professional installation ensures that the system operates at peak efficiency and complies with local regulations. Regular maintenance, including cleaning filters and checking refrigerant levels, extends the lifespan of the air conditioner and prevents costly repairs. Perth residents should also consider the importance of a comprehensive warranty and reliable after sales support. These factors guarantee the longevity and efficiency of the air conditioning system, ensuring it remains a valuable asset for the home. Therefore, investing in professional services for installation and maintenance is essential for the long term benefits of air conditioning systems in Perth.

Cost Analysis for Air conditioners in Perth

The cost of air conditioning systems in Perth involves a balance between initial investment and long term savings. Higher-priced models often offer greater energy efficiency, leading to reduced utility bills over time. Comparing the price points of various models helps in identifying the best value for money. Additionally, Perth residents should explore financial incentives and rebates available for energy efficient air conditioners. These financial considerations are integral to the decision making process, ensuring that homeowners choose a system that is cost effective in the long run. Ultimately, a thorough cost analysis aids in selecting an air conditioner that meets both budgetary and climatic needs in Perth.

Conclusion

In conclusion, selecting the right air conditioner in Perth requires careful consideration of various factors. Understanding the different types of air conditioning technologies, considering energy efficiency, and evaluating innovative features are essential steps. Proper installation and maintenance, along with a thorough cost analysis, ensure the long-term benefits of the air conditioning system. By considering these aspects, Perth residents can make informed decisions, ensuring comfort and efficiency in their homes throughout the year. The right air conditioner not only provides relief from Perth's hot summers but also contributes to a sustainable and cost-effective household.

2 notes

·

View notes

Text

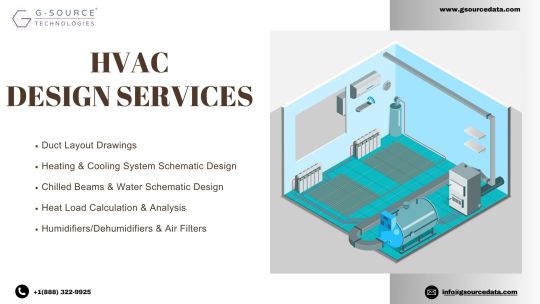

Gsource Technologies is your trusted partner for top-notch HVAC design services that ensure optimal comfort, energy efficiency, and air quality for your residential, commercial, or industrial spaces. Our HVAC design solutions encompass a comprehensive range of services, meticulously crafted to meet your unique requirements.

One of our key offerings is Duct Layout Drawings, where our experts create detailed plans to optimize air distribution, taking into account factors like space constraints and airflow dynamics. This ensures efficient heating and cooling throughout your premises.

Our Heating & Cooling System Schematic Design is another standout service. We develop customized schematics tailored to your specific needs, guaranteeing the right balance between temperature control and energy conservation.

For projects that demand sophisticated climate control, our expertise extends to Chilled Beams & Water Schematic Design, ensuring the seamless integration of advanced technologies for precise temperature management.

To accurately size and design your HVAC system, we perform Heat Load Calculation & Analysis, accounting for variables like insulation, occupancy, and outdoor climate conditions.

Moreover, we offer solutions to enhance air quality, including Humidifiers/Dehumidifiers & Air Filters, promoting a healthy and productive environment for your occupants.

At Gsource Technologies, we prioritize sustainability, cost-efficiency, and functionality in every HVAC design project we undertake. With our expertise, you can trust that your HVAC system will be optimized to meet your specific needs while adhering to the highest industry standards. Partner with us for HVAC design services that deliver comfort and efficiency, every time.

#gsourcetechnolgies#architecturedesigns#engineeringdesigns#hvac services#HVACdesigns#heating and cooling#hvac

2 notes

·

View notes

Text

NTC Thermistor Chip Market: Industry Dynamics and Regional Forecast 2025–2032

NTC Thermistor Chip Market, Emerging Trends, Technological Advancements, and Business Strategies 2025-2032

NTC Thermistor Chip Market size was valued at US$ 1,450 million in 2024 and is projected to reach US$ 2,670 million by 2032, at a CAGR of 9.16% during the forecast period 2025-2032

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis https://semiconductorinsight.com/download-sample-report/?product_id=97987

MARKET INSIGHTS

The global NTC Thermistor Chip Market size was valued at US$ 1,450 million in 2024 and is projected to reach US$ 2,670 million by 2032, at a CAGR of 9.16% during the forecast period 2025-2032. This growth is driven by increasing demand for temperature sensing solutions across industries, though semiconductor market volatility poses challenges.

NTC (Negative Temperature Coefficient) thermistor chips are semiconductor devices that exhibit a decrease in electrical resistance with rising temperature. These components are widely used for precision temperature measurement, control, and compensation in applications ranging from consumer electronics to industrial automation. The market includes both bulk packaging and tape-and-reel formats, with materials optimized for different temperature ranges and stability requirements.

The market expansion is fueled by several factors, including the proliferation of IoT devices requiring temperature monitoring and stricter energy efficiency regulations. However, the semiconductor industry faced headwinds in 2022 with only 4.4% growth globally (USD 580 billion total market), as reported by WSTS. While Analog (20.8%), Sensors (16.3%), and Logic (14.5%) segments showed strong growth, the Asia-Pacific region—accounting for over 50% of semiconductor sales—declined 2% year-over-year. Leading manufacturers like Vishay, Mitsubishi Materials, and Ametherm continue to innovate with new form factors and improved stability to meet evolving application needs.

List of Key NTC Thermistor Chip Manufacturers

Huagong Tech (China)

Mitsubishi Materials Corporation (Japan)

Vishay (U.S.)

Ametherm (U.S.)

HateSensor (China)

Exsense Sensor Technology Co. (China)

JPET INTERNATIONAL LIMITED (Hong Kong)

Sinochip Electronics Co., LTD (China)

FENGHUA (HK) ELECTRONICS LTD. (Hong Kong)

Segment Analysis:

By Type

Tape and Reel Packaging Dominates the Market Due to Automated Assembly Efficiency

The NTC Thermistor Chip market is segmented based on packaging type into:

Bulk packaging

Subtypes: Loose chips, bulk bags, and others

Tape and reel packaging

Subtypes: Standard tape, custom-configured reels

By Application

Industrial Equipment Segment Leads Due to High Reliability Requirements

The market is segmented based on application into:

Home appliances

Subtypes: Refrigeration, air conditioning, small electronics

Industrial equipment

Subtypes: HVAC systems, process control, power electronics

Automotive systems

Medical devices

Others

By Temperature Range

Medium Temperature Range (25°C to 85°C) Captures Largest Share Due to Broad Application Scope

The market is segmented by operating temperature range into:

Low temperature (-55°C to 25°C)

Medium temperature (25°C to 85°C)

High temperature (85°C to 200°C)

Extreme temperature (>200°C)

By Resistance Value

10KΩ Segment Leads for Optimal Sensitivity-Power Balance

The market is segmented by resistance value at 25°C into:

1KΩ to 5KΩ

10KΩ

50KΩ to 100KΩ

Custom resistance values

Regional Analysis: NTC Thermistor Chip Market

North America The NTC thermistor chip market in North America is driven by strong demand from the industrial automation and consumer electronics sectors, particularly in the U.S. and Canada. The region benefits from high adoption of advanced temperature sensing technologies in automotive electronics, HVAC systems, and medical devices. The U.S. semiconductor sector saw a 17.0% revenue growth in 2022, reinforcing its leadership in sensor technologies. However, supply chain disruptions and reliance on imported raw materials remain challenges. Leading players like Ametherm and Vishay continue to innovate in miniaturization and IoT-compatible thermistor solutions to meet stringent industry standards.

Europe Europe’s NTC thermistor market is characterized by stringent quality requirements across automotive (especially in Germany) and industrial applications. The region’s 12.6% semiconductor revenue growth in 2022 reflects stable demand for precision components. EU regulations on energy efficiency are accelerating adoption in smart home appliances and renewable energy systems. While local manufacturers face cost pressures from Asian competitors, companies like JPET INTERNATIONAL LIMITED maintain competitiveness through specialized high-temperature automotive-grade thermistors. The medical equipment sector in Western Europe presents significant growth potential due to aging population trends.

Asia-Pacific Accounting for over 60% of global NTC thermistor production, Asia-Pacific dominates both supply and consumption. Despite a 2.0% semiconductor market contraction in 2022, China’s electronics manufacturing ecosystem continues driving demand, supported by Japan’s advanced materials expertise (Mitsubishi Materials) and South Korea’s display industry needs. Price competition remains intense, with local players like Huagong Tech and Sinochip Electronics offering cost-effective solutions. The region benefits from vertical integration – from raw material processing to end-product assembly – though quality consistency remains a concern in emerging manufacturing hubs.

South America Market growth in South America is constrained by economic instability but shows niche opportunities in automotive replacement parts and industrial maintenance sectors. Brazil represents the largest market, where local assembly of consumer electronics drives demand for thermistors in power supply units. The lack of domestic semiconductor infrastructure results in heavy import dependence, primarily from Chinese suppliers. Recent trade agreements show potential to improve component availability, though currency fluctuations continue impacting procurement budgets for manufacturers.

Middle East & Africa This emerging market presents long-term growth prospects tied to industrial diversification programs in Gulf nations. The UAE and Saudi Arabia are investing in local electronics manufacturing, creating demand for temperature sensing components in oil/gas equipment and smart city projects. However, limited technical expertise and reliance on distributor networks slow adoption rates. African markets remain largely untapped, though smartphone penetration growth in countries like Nigeria and Kenya suggests future potential for thermistors in mobile device manufacturing and repair sectors.

MARKET DYNAMICS

The healthcare sector offers substantial opportunities for NTC thermistor chip manufacturers as medical device innovation accelerates. Wearable health monitors incorporating continuous temperature tracking represent a particularly promising application area, with the global wearable medical device market projected to exceed $130 billion by 2030. Furthermore, diagnostic equipment manufacturers are increasingly specifying medically-certified NTC chips for applications ranging from incubators to sterilization monitoring systems. The COVID-19 pandemic has particularly highlighted the need for reliable, disposable temperature probes in both clinical and home healthcare settings.

The NTC thermistor chip market faces significant operational challenges stemming from raw material supply instability and manufacturing capacity constraints. The industry relies heavily on specialty metal oxides and ceramic materials whose supply chains remain vulnerable to geopolitical tensions and trade restrictions. Recent semiconductor industry disruptions have highlighted how single-point failures in component supply can cascade through production systems. Many manufacturers report lead times extending beyond standard cycles, creating difficulties in matching production schedules to fluctuating customer demand patterns across different regional markets.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=97987

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global NTC Thermistor Chip Market?

Which key companies operate in Global NTC Thermistor Chip Market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Related Reports:https://semiconductorblogs21.blogspot.com/2025/07/embedded-ufs-market-swot-analysis-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/universal-flash-storage-ufs-controllers.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/optical-signal-controller-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/solar-tracking-control-market-demand.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/digital-volume-card-market-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/graphic-to-digital-converter-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/inline-system-market-emerging-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/gas-scrubbers-for-semiconductor-market_11.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/full-set-of-protection-plate-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/channel-coil-drive-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/diamond-scriber-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/wavelength-stabilisation-diode-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/acoustic-vector-sensor-market-strategic.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/single-axis-tracker-market-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/single-axis-tracker-market-trends.html

CONTACT US: City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 [+91 8087992013] [email protected]

0 notes

Text

Industrial Heating Solutions by Heat Master International

Heat Master International – Industrial Heating Solutions Expert

Heat Master International is a well-known producer and supplier of excellent industrial heating components, providing a wide variety of products to suit the requirements of various industries. With excellent focus on performance, durability, and customization, the company provides solutions that provide energy efficiency and reliable heat production across applications.

Open Coil Heaters Designed for rapid and efficient air and gas heating, Heat Master's Open Coil Heaters use precision-wound resistance wire for high thermal conductivity and fast heat-up rates. Suitable for duct heating, ovens, and forced air applications, these heaters are simple to install and service, providing a low-cost solution for industrial heat requirements.

Flanged Tubular Heaters Designed for heavy-duty applications, Flanged Tubular Heaters are ideal for heating gases, oils, and liquids in huge tanks and pressure vessels. Designed with strong flanges and high-quality sheath material, these heaters provide superior corrosion resistance and are widely utilized in chemical processing, water treatment, and industrial fluid systems.

Industrial Immersion Heaters These heaters are directly immersed in fluids to offer direct heat transfer at high efficiency. Employed in the heating of oils, water, and chemical solutions, Heat Master's immersion heaters are engineered with long life, simple replacement, and safe operation in mixed load conditions.

Mica Band & Nozzle Heaters Heat Master's Mica Band Heaters and Nozzle Heaters are designed specifically for use in the plastic processing market. They provide even heating with good thermal conductivity and are commonly found in injection mold machines, extruders, and blow molding machines. The heaters are low profile, energy-saving, and high-temperature-rated.

Duct heaters & Tubular Heaters Duct Heaters are best suited for heating air in HVAC systems and industrial drying, whereas Tubular Heaters offer versatile heating in straight or bent forms for air, liquid, or surface heating. Both of these are made to supply reliable, controlled heat and are well-suited for continuous operation.

Customized Heating Solutions Being a reliable thermal technology partner, Heat Master International provides full customization as per voltage, wattage, material, and size to meet particular industrial requirements. By blending technical knowledge and advanced manufacturing potential, the company provides solutions that maximize performance, ensure safety, and reduce costs.

0 notes

Text

HVAC Design Ontario How to Plan a Successful Commercial HVAC Design Project

In Ontario, a well-planned commercial HVAC system is key for a comfy and healthy indoor space. Did you know a bad design can raise energy costs and shorten equipment life? I'll show you the must-knows of HVAC design in Ontario.

With Range Engineering Inc.'s help, your project will shine. They're pros in forced air system design and HVAC solutions. They ensure great airflow and energy-saving heating.

Key Takeaways

Understand the unique climate challenges in Ontario and their impact on HVAC systems.

Familiarize yourself with building code requirements for commercial HVAC design.

Stay up-to-date with industry trends and best practices.

Work with experienced professionals, like Range Engineering Inc.

Consider energy-efficient solutions for your commercial building.

The Essential Elements of Commercial HVAC Design in Ontario

A successful commercial HVAC design in Ontario depends on knowing the local climate challenges and following key building code rules. As a professional, I see how important it is to make HVAC designs fit Ontario's unique climate needs.

Understanding Ontario's Unique Climate Challenges

Ontario's climate has extreme temperatures and humidity, making it key to design HVAC systems that handle these well. Energy-efficient HVAC design is a must for a comfy indoor space and saving energy. By grasping these climate challenges, we can create commercial air conditioning design that works well and saves energy.

Key Building Code Requirements for Commercial Projects

Following Ontario's building code is vital for safe and efficient commercial HVAC systems. These codes set standards for HVAC design requirements, like system size, energy use, and safety. Working with a skilled HVAC design company like Range Engineering Inc. ensures your project meets all rules.

Current Industry Trends and Innovations

The HVAC industry keeps changing, with a big push for energy-efficient HVAC design and new tech to boost system performance. Keeping up with these trends is key for making commercial HVAC designs that meet today's standards and are ready for tomorrow's advancements. By using the newest innovations, businesses can see better system efficiency and lower costs.

Conducting a Comprehensive Needs Assessment for Your Project

To get the best results, it's key to do a detailed needs assessment for your commercial HVAC project. This first step helps you know what your building really needs. Then, you can make the HVAC system fit perfectly.

Evaluating Building Specifications and Requirements

It's important to check your building's details carefully. Look at its layout, insulation, and windows to see how it handles heat. Two main things to focus on are:

Space Utilization Analysis

Knowing how your building is used is key. For example, busy areas or places with lots of equipment might need more cooling. This helps you figure out where you need special HVAC setups.

Occupancy Patterns and Load Calculations

Also, figuring out who uses the space and what they do is important. This tells you how much heat or cool air you need. With this info, you can design a system that keeps your space comfy.

Identifying Business-Specific HVAC Needs

Every business has its own HVAC needs. A restaurant might need a system to handle cooking smells, while a data center needs precise temperature control. Knowing your business's specific needs helps design a system that works just right for you.

Establishing Budget Parameters and Constraints

Setting a clear budget is a must for any HVAC project. This includes the cost of installing the system and what it will cost to run and maintain it. Working with experts like Range Engineering Inc. helps you find a design that fits your budget and lasts long.

Doing a thorough needs assessment makes sure your HVAC system is just right for you. It involves checking your building, figuring out your business's needs, and setting a budget. This way, you get a system that works well and saves energy.

Developing an Effective Commercial HVAC Design Strategy

A successful commercial HVAC design project needs a solid strategy. It should balance performance, efficiency, and scalability. As a professional, I suggest looking at several key factors for an effective design strategy.

Selecting the Optimal System Type for Your Facility

Choosing the right HVAC system is key for top performance and efficiency. You need to think about the system type and its setup.

Forced Air vs. Hydronic Systems

Forced air systems are popular in commercial buildings for their easy installation and flexibility. Hydronic systems, though, are more efficient and better for big facilities. For example, a building in Ontario might do well with a hydronic system because of the cold weather.

Centralized vs. Decentralized Approaches

Centralized systems are great for big areas, providing efficient heating and cooling. Decentralized systems, on the other hand, are flexible and energy-efficient for smaller or zoned areas. Your choice depends on your facility's specific needs.

Integrating Energy Efficiency into Your Design

Energy efficiency is vital in commercial HVAC design. Adding energy-saving features like high-efficiency equipment and smart controls can cut down energy use and costs. Companies like Range Engineering Inc. are experts in energy-efficient HVAC design and can craft a custom plan for you.

Ensuring Scalability and Future-Proofing

A good commercial building HVAC system should grow with your needs. Use modular equipment and design with flexibility in mind. This way, your HVAC system will stay efficient and effective for years to come.

Implementing Your HVAC Design with Professional Expertise

Getting your HVAC system right is key to its performance and life span. In many commercial projects, the success of the system depends on the expertise in its setup.

To get your HVAC design right, you need professionals who know professional HVAC design well. They start with a detailed engineering and design phase.

The Engineering and Design Process

The engineering and design phase is the heart of any HVAC project. It creates detailed plans that fit your commercial space's needs. Companies like Range Engineering Inc. use their skills to make sure the design works well and saves energy. They look at your building, your HVAC needs, and your budget to plan a good strategy.

With their experience, they can spot problems early and find solutions that fit your HVAC design requirements.

Coordinating with Other Building Systems

It's also important to work with other building systems when setting up your HVAC. This makes sure the HVAC system works well with electrical, plumbing, and architectural parts. Good coordination is key for a working and beautiful building. Experts in commercial air conditioning design help make this happen, making sure everything works together smoothly.

Quality Control and Testing Procedures

Quality checks and tests are also critical to make sure your HVAC system works as it should. These tests find any problems or defects. Experts do thorough checks to make sure the system meets the standards. This way, they ensure your HVAC system will work well for a long time.

In short, using professional help for your HVAC design is vital for a successful project. Working with experts and following a detailed process, coordinating with other systems, and doing quality checks will make sure your HVAC system meets your needs and lasts long.

Conclusion: Maximizing the Return on Your HVAC Investment

To get the most out of your HVAC investment, you need a solid plan. Working with experts like Range Engineering Inc. is key. They make sure your system works well and saves energy.

A good HVAC system in Ontario handles the local climate and follows important building codes. It's also important to use energy-saving designs. This helps cut down costs and is better for the environment.

As a pro, keep up with new HVAC trends and tech. This ensures your system stays effective and cost-efficient. Focus on energy-saving designs and team up with a trusted HVAC company. This way, you'll save money and get better performance over time.

FAQ

What are the key factors to consider when designing a commercial HVAC system in Ontario?

When designing a commercial HVAC system in Ontario, consider the climate, building codes, and trends. It's wise to work with experts like Range Engineering Inc. They ensure your system meets all requirements and works well.

How do I conduct a thorough needs assessment for my commercial HVAC project?

To assess your HVAC needs, look at your building's specs and your business's HVAC needs. Also, set a budget. Range Engineering Inc. can help with this detailed assessment to fit your needs perfectly.

What are the benefits of energy-efficient HVAC design?

Energy efficient HVAC design cuts down on energy use, lowers costs, and helps the environment. I suggest adding energy-saving features to your design for better performance and savings.

How do I select the optimal HVAC system type for my facility?

Choosing the right HVAC system depends on your needs. Consider air vs. hydronic systems and central vs. decentralized setups. Range Engineering Inc. can help design a system that works best for you.

What is the importance of quality control and testing procedures in HVAC implementation?

Quality control and testing are key to a correct HVAC installation. Working with Range Engineering Inc. ensures your system is installed right and meets all standards.

How can I ensure that my commercial HVAC system is scalable and future-proof?

To make your HVAC system scalable and future-proof, think about its design and type. Range Engineering Inc. can help design a system that grows with your needs and performs well.

What are the benefits of working with a professional HVAC design company like Range Engineering Inc.?

Working with a pro like Range Engineering Inc. offers many benefits. They bring expertise, tailored solutions, and top performance. I recommend their services for a strong investment in your HVAC system.

0 notes

Text

Centrifugal Blowers Market Share, Industry Size, Opportunity, Analysis, Forecast 2033

The global centrifugal blowers market is poised for substantial growth, projected to increase from US$ 3.2 billion in 2023 to US$ 4.8 billion by 2033, reflecting a compound annual growth rate (CAGR) of 4.1%.

Market Growth & Forecasts The market is expected to witness approximately 50% growth over the forecast decade, driven by steady demand across diverse applications such as ventilation, combustion air supply, and industrial drying. In particular, low-pressure centrifugal blowers are gaining traction due to their role in exhaust, odor removal, and general air conveyance systems. This segment is anticipated to grow at a CAGR of 3.3%.

Regional Insights

Asia Pacific: Set to grow at a 2% CAGR, led by booming industrial sectors in countries like China, India, South Korea, and Japan. Rapid infrastructure and manufacturing investments are key contributors.

Europe: Germany continues to be a key market, driven by strong construction and automotive sectors that rely heavily on blowers for cement manufacturing, painting, and HVAC operations.

North America: The U.S. remains a major player, fueled by growing HVAC infrastructure, natural gas processing facilities, and oil & gas activities.

Technological Advancements & Energy Efficiency Centrifugal blowers play a crucial role in converting kinetic energy into pressure using impellers. The latest generation of blowers is designed to enhance performance while reducing operational noise and energy use. These advancements include high-speed turbo blowers and premium-efficiency motors that meet IE4 standards, significantly cutting down power consumption and carbon emissions.

One of the most notable trends is the integration of heat recovery systems capable of recapturing over 90% of compressor heat, enhancing energy utilization in power and manufacturing sectors. Variable speed drives further contribute to energy savings—up to 30% over traditional models.

Read More: https://www.factmr.com/report/centrifugal-blowers-market

Key Market Drivers

Rising Global Industrialization: Billions of dollars invested in greenfield manufacturing and smart factories are generating substantial demand for centrifugal blowers across multiple process industries.

Infrastructure Boom: Ongoing investments in oil refineries and large-scale power projects—particularly in Asia, Africa, and the Middle East—are significantly expanding the market base.

Environmental Regulations: Regulatory focus on emissions and energy efficiency is prompting the adoption of technologically advanced, sustainable blower systems across industries.

Competitive Landscape Top manufacturers are focusing on product innovation, energy efficiency, and compact design. Companies are leveraging strategic acquisitions and R&D investments to stay competitive in the global landscape. Recent innovations include heavy-duty industrial models with enhanced airflow and noise suppression, as well as advanced electronic control systems.

Recent notable industry developments include:

The launch of high-capacity backpack blowers tailored for industrial applications

Acquisitions that expand product portfolios in the air movement and HVAC equipment sectors

Other Source: https://www.openpr.com/news/3284328/centrifugal-blowers-market-valuation-of-us-4-8-billion-by

0 notes

Text

Ozone Generator Market – Size, Share, Growth, Trends and Forecast 2034

According to Fact.MR, the ozone generator market is projected to grow at a CAGR of 6.4% from 2024 to 2034. By 2034, the global market for these products is anticipated to reach USD 2,613.1 million. Fact.MR, a market research and competitive intelligence provider, reports that the global ozone generator market is experiencing rapid growth and is expected to maintain this upward trajectory in the coming years.

Technological advancements in ozone generators, such as enhanced energy efficiency, compact designs, and automation capabilities, are likely to drive market growth by making the technology more accessible and cost-effective. Additionally, increasing environmental regulations related to water and air quality may prompt industries to adopt cleaner technologies, including ozone generators, to comply with these standards.

Get Free Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=9249

Government incentives promoting environmentally friendly technologies, along with regulations mandating specific water and air treatment methods, can positively impact the ozone generator market. Increased consumer and end-user awareness about the benefits and applications of ozone generators can create new opportunities, particularly in residential and small-scale commercial sectors.

Growing concerns about water scarcity and the need for sustainable water management practices may drive the adoption of ozone generators for water reuse and recycling applications. The trend towards decentralized water treatment solutions, especially in remote or off-grid areas, can create opportunities for compact and portable ozone generators.

The development of smart cities and increased urbanization can lead to higher demand for advanced water and air treatment technologies, including ozone generators, to address the environmental and health challenges of densely populated areas. Collaborations between ozone generator manufacturers and Original Equipment Manufacturers (OEMs) in related industries, such as water treatment systems or HVAC equipment, can expand market reach and enhance product integration.

Key Takeaways from the Market Study

In 2024, the global ozone generator market is projected to reach a size of USD 1,405.2 million.

UV radiation technology is anticipated to dominate the market, holding a 50.9% share in 2024.

By 2034, the food and beverage processing category is expected to capture a 47.6% market share.

China is forecasted to secure 57.5% of the global market share in 2024.

North America is expected to experience a CAGR of 6.1% by 2034.

“The residential sector represents an emerging market for ozone generators, especially for air purification, odor control, and water treatment. Increased awareness of indoor air quality and home sanitation is expected to boost the demand,” says a Fact.MR analyst.

Key Companies Profiled in This Report

BES Group

Chemtronics Technologies

Degrémont Technolgies (Suez Environment)

DEL Ozone

EBARA Technologies, Inc.

Ecozone Technologies Ltd.

Enaly Ozone Generator

Faraday ozone

Lenntech BV

Metawater USA, Inc.

Mitsubishi Electric Power Products, Inc.

Competitive Landscape A mix of established players, emerging companies, and technological innovators characterizes the ozone generators market. The market is witnessing increased competition, driven by the growing demand for ozone generators across various industries and applications

Recent Development

In 2023, Fresh Mouth introduced its latest product, an innovative ozone generator that doubles as a hydrogenated water producer. Specifically designed for safe and efficient oral cleaning and sanitation, this device utilizes ozone generation to eliminate detrimental bacteria, viruses, and fungi. The technology is aimed at addressing issues such as bad breath, gum infections, and other oral health concerns.

Browse Full Report: https://www.factmr.com/report/ozone-generator-market

More Valuable Insights Fact.MR, in its new offering, presents an unbiased analysis of the global ozone generator market, presenting historical analysis from 2019 to 2023 and forecast statistics for the period of 2024 to 2034.

The study reveals essential insights based on ozone generator market analysis by technology (corona discharge, and UV radiation), by application (water treatment, food and beverage processing, and other industrial), and by region (North America, Latin America, Europe, East Asia, South Asia and Oceania, and Middle East & Africa).

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

MS Concentric Reducer Manufacturer in India

In industrial piping systems, ensuring smooth transitions between pipes of different sizes is critical to maintaining fluid flow efficiency and system integrity. One of the most commonly used fittings for this purpose is the MS (Mild Steel) Concentric Reducer. If you are looking for a trusted manufacturer of MS Concentric Reducers in India, Udhhyog is your go-to supplier. We offer high-quality MS concentric reducers designed to meet the rigorous demands of various industries at competitive prices.

What is an MS Concentric Reducer?

An MS Concentric Reducer is a pipe fitting used to connect pipes of varying diameters while maintaining the same central alignment. This reducer ensures that the fluid flow transitions smoothly without causing turbulence or pressure drops, making it ideal for applications where maintaining a consistent flow is critical. The concentric design keeps the fluid flow aligned with the pipe’s centerline, ensuring efficiency in both liquid and gas transportation systems.

Benefits of MS Concentric Reducers

Smooth Fluid Transition: The concentric reducer ensures a consistent, smooth transition between different pipe sizes, reducing turbulence and pressure loss in the pipeline.

Central Alignment: Unlike eccentric reducers, concentric reducers keep the fluid flow aligned along the pipe's central axis, making them ideal for applications where balanced flow is essential.

Durability: Made from high-quality mild steel, these reducers are known for their strength and durability, capable of withstanding high pressures and temperatures.

Cost-Effective: Mild steel offers a balance between strength and affordability, making MS concentric reducers an economical choice for many industries.

Versatile Applications: These reducers are widely used in industries like oil and gas, chemical processing, water treatment, and HVAC systems due to their reliability and performance.

Industries Using MS Concentric Reducers

Oil and Gas: MS concentric reducers are used in pipelines to maintain consistent fluid flow between pipes of different sizes, reducing the risk of flow interruptions.

Chemical Processing: In chemical plants, these reducers are essential for managing fluid transfers and ensuring that chemical reactions occur efficiently.

Water Treatment: MS concentric reducers are used to control water flow between varying pipe sizes, ensuring smooth distribution in water treatment facilities.

HVAC Systems: In heating, ventilation, and air conditioning systems, concentric reducers ensure smooth airflow and maintain pressure in duct systems.

Why Choose Udhhyog for MS Concentric Reducers?

As a leading manufacturer of MS Concentric Reducers in India, Udhhyog takes pride in delivering top-quality products at the lowest prices. Here’s why you should choose us:

Top-Quality Manufacturing: At Udhhyog, we use advanced technology and strict quality control processes to manufacture high-performance MS concentric reducers that meet international standards.

Competitive Pricing: We offer the lowest prices on MS concentric reducers in India, making us the preferred choice for industries looking for cost-effective solutions without compromising quality.

Quick Delivery: Based in Delhi, Udhhyog provides fast delivery services across India, ensuring that your project timelines are met.

Comprehensive Product Range: Along with concentric reducers, Udhhyog offers a wide range of industrial pipe fittings, flanges, and valves to meet all your piping system needs.

Customer-Centric Approach: We work closely with our clients to offer customized solutions that fit their specific requirements, ensuring satisfaction and long-term business partnerships.

Order MS Concentric Reducers from Udhhyog

When you choose Udhhyog as your MS concentric reducer manufacturer, you’re opting for quality, reliability, and the lowest prices in India. Whether you're working on a large-scale industrial project or need specific solutions for your business, Udhhyog is committed to delivering the best products to help you succeed.

#MSConcentricReducer#MildSteelReducer#PipeFittingsIndia#IndustrialPipeFittings#Udhhyog#ConcentricReducerIndia#LowestPriceIndia#DelhiManufacturer#PipingSolutions#SteelPipeFittings#MSPipeFittings

2 notes

·

View notes

Text

Full-Bridge Stepper Motor Drivers Market : Growth Analysis, Market Dynamics, Outlook, and Forecast 2025-2032

The global Full-Bridge Stepper Motor Drivers Market size was valued at US$ 394.6 million in 2024 and is projected to reach US$ 598.3 million by 2032, at a CAGR of 5.3% during the forecast period 2025-2032. While this represents steady growth, the market faces pressure from semiconductor supply chain constraints and evolving industrial automation demands.

Full-bridge stepper motor drivers are critical components in precision motion control systems. These integrated circuits amplify pulse-width modulated (PWM) signals to efficiently switch four transistors in an H-bridge configuration – with only two transistors active at any given time. This architecture enables precise bidirectional control of stepper motors, which are widely used in applications requiring accurate positioning.

The market growth is being driven by increasing automation across industries and the rising adoption of industrial IoT solutions. However, challenges persist due to the global semiconductor shortage, which impacted the broader semiconductor market – valued at USD 579 billion in 2022 but projected to grow to USD 790 billion by 2029. Key players like Texas Instruments, STMicroelectronics, and Infineon are focusing on developing more efficient drivers with advanced features such as microstepping and thermal protection to maintain competitiveness in this evolving market.

Get Full Report with trend analysis, growth forecasts, and Future strategies : https://semiconductorinsight.com/report/full-bridge-stepper-motor-drivers-market/

Segment Analysis:

By Type

Four-Type Segment Dominates Due to Higher Efficiency in Industrial Applications

The global full-bridge stepper motor drivers market is segmented based on type into:

Single Type

Subtypes: Basic single-channel drivers and others

Dual Type

Four Type

Subtypes: Integrated H-bridge drivers and discrete MOSFET solutions

By Application

Automotive Segment Leads Owing to Growing Demand for Precision Motor Control

The market is segmented based on application into:

Automotive

Sub-applications: Power steering systems, HVAC controls, and others

Industrial

Sub-applications: CNC machines, 3D printers, and robotics

Others

By Power Rating

Medium Power Segment Accounts for Significant Market Share

The market is segmented based on power rating into:

Low Power (<1A)

Medium Power (1-5A)

High Power (>5A)

By Communication Interface

Digital Interface Segment Gains Traction with Industry 4.0 Adoption

The market is segmented based on communication interface into:

Analog

Digital

Subtypes: SPI, I²C, and UART interfaces

Regional Analysis: Full-Bridge Stepper Motor Drivers Market

North America The North American market for full-bridge stepper motor drivers is driven by robust demand from the automotive and industrial automation sectors, particularly in the United States. The region benefits from strong semiconductor manufacturing capabilities, with companies like Texas Instruments and Allegro MicroSystems leading innovation in motor control ICs. While the market is mature, growth is sustained by the increasing adoption of precision-controlled robotics and smart manufacturing systems. However, supply chain bottlenecks—such as the global semiconductor shortage—have temporarily constrained production volumes. Regulatory standards on energy efficiency also push manufacturers toward more advanced driver IC designs with lower power consumption.

Europe Europe’s market is characterized by a focus on high-performance motor drivers for industrial and automotive applications, with Germany and France being key demand centers. Strict EU regulations on energy efficiency and emissions have accelerated the shift toward intelligent motor control solutions, where full-bridge drivers play a critical role. The region’s strong automation industry, especially in machinery and automotive manufacturing, supports steady demand. However, economic headwinds, including inflation and reduced industrial output in some countries, are moderating growth. Collaborations between automotive OEMs and semiconductor firms—such as STMicroelectronics and Infineon—are driving innovations in compact, high-torque motor driver solutions for electric vehicles.

Asia-Pacific Asia-Pacific dominates the global market, accounting for the largest share of full-bridge stepper motor driver production and consumption. China, Japan, and South Korea lead due to their extensive electronics manufacturing ecosystems. The region benefits from cost-competitive production and strong demand from consumer electronics, robotics, and automotive applications. While traditional single-type drivers remain popular in cost-sensitive segments, dual and four-type drivers are gaining traction in industrial automation. However, market fragmentation and price sensitivity pose challenges for premium product adoption. The rapid expansion of EV manufacturing in China and Southeast Asia is expected to further propel demand for efficient motor drivers.

South America South America represents a smaller but growing market, with Brazil being the primary adopter of stepper motor drivers for industrial equipment and automotive applications. The region faces challenges, including economic instability and limited local semiconductor production, which results in dependency on imports. However, increasing investments in automation and gradual industrialization are creating opportunities for motor driver adoption. Price sensitivity remains a barrier for high-end driver ICs, but the demand for mid-range products in agricultural machinery and HVAC systems is rising steadily.