#Activated Calcium Carbonate Manufacturers in Gujarat

Explore tagged Tumblr posts

Text

The Role of Activated Calcium Carbonate in Modern Industries

Activated calcium carbonate (ACC) is a crucial industrial mineral widely used in various applications such as plastics, paints, rubber, pharmaceuticals, and more. Its enhanced properties, such as improved dispersibility and increased surface area, make it a preferred choice in these industries. In India, Gujarat has emerged as a significant hub for the production and supply of activated calcium carbonate, with numerous manufacturers catering to both domestic and international markets. Among these, Airotech Minerals stands out as a prominent and reliable Activated Calcium Carbonate Manufacturers in Gujarat, known for its high-quality products and commitment to innovation.

The Importance of Activated Calcium Carbonate

Activated calcium carbonate is produced by treating high-purity calcium carbonate with stearic acid. This activation process enhances its physical and chemical properties, making it suitable for a wide range of applications:

Plastics Industry: ACC is used as a filler to improve the mechanical properties of plastic products, including increased rigidity and impact strength.

Paints and Coatings: In the paints and coatings industry, ACC enhances the brightness, opacity, and durability of the final product.

Rubber Industry: It acts as a reinforcing agent in rubber products, improving their strength and durability.

Pharmaceuticals: ACC is used as an active ingredient and excipient in various pharmaceutical formulations, offering benefits such as controlled release and improved stability.

Paper Industry: It is used to improve the brightness and opacity of paper, making it more suitable for printing and writing.

Gujarat: A Hub for Activated Calcium Carbonate Production

Gujarat has established itself as a key player in the production of activated calcium carbonate, thanks to its abundant raw material resources, well-developed industrial infrastructure, and strategic location. The state is home to several manufacturers who have invested in advanced technologies and processes to produce high-quality ACC.

Commitment to Quality

We place a strong emphasis on quality. The company's quality management system is certified to international standards, reflecting its commitment to maintaining the highest quality standards. Regular audits and inspections are conducted to ensure compliance with these standards, and continuous improvement initiatives are implemented to enhance product quality and customer satisfaction.

Research and Development

Innovation is at the core of Airotech Minerals' operations. The company has a dedicated research and development (R&D) team focused on developing new products and improving existing ones. The R&D team collaborates with customers to understand their specific needs and challenges, enabling Airotech Minerals to offer customized solutions that meet the evolving demands of various industries.

Environmental Responsibility

We are committed to sustainable and environmentally responsible manufacturing practices. The company adheres to strict environmental regulations and implements measures to minimize its environmental impact. This includes efficient use of resources, waste management, and pollution control. By prioritizing sustainability, we aim to contribute positively to the environment and the communities in which it operates.

Customer-Centric Approach

Customer satisfaction is a top priority for Airotech Minerals. The company strives to build long-term relationships with its customers by offering high-quality products, competitive pricing, and exceptional service. Our customer support team is always available to assist with inquiries, provide technical support, and address any concerns. This customer-centric approach has earned the company a loyal customer base and a strong reputation in the market. Are you in need of high-quality activated calcium carbonate for your industrial applications? Look no further than Airotech Minerals. With our commitment to quality, innovation, and customer satisfaction, we are the trusted partner you need for all your activated calcium carbonate requirements. Contact us today to learn more about our products, discuss your specific needs, or place an order. Our dedicated customer support team is ready to assist you and provide the best solutions tailored to your business.

0 notes

Text

Refinery catalysts Market | Global and Regional Forecast 2027 | Albemarle Corporation, BASF SE, Johnson Matthey Plc, W. R. Grace, Clariant International Ltd.

The global refinery catalyst market size is expected to reach USD 9.5 billion by 2027, expanding at a revenue-based CAGR of 4.7%, according to a new report by Grand View Research, Inc. Growing demand for petroleum products is the major factor driving the market. Refinery catalysts are chemicals that are used in different operations for carrying out refining activities. These substances are responsible in altering the rate of chemical reactions in the FCC unit, thereby, speeding up the reaction, which reduces the turnaround time of the manufacturing process.

Among the different raw material used in the production of refinery catalysts, zeolites have emerged as one of the major segments. Zeolites are generally aminosilicates composed of frameworks of silicon, oxygen, and aluminum in the form of SiO4 and AlO4. A number of them occur naturally, and hence are procured via mining as minerals. However, the synthetic ones are also produced commercially.

Refinery catalysts are widely utilized in refining processes such as fluid catalytic cracking, alkylation, and hydrotreating. The role of an accelerator in FCC process is to aid in breaking heavy molecules at high temperature and moderate pressure so that they can be separated from the mixture and collected as a vapor. The separated products are purified and treated for application in multiple end-use industries.

Browse Full Report Now! @ https://www.grandviewresearch.com/industry-analysis/refinery-catalysts-market

The key market players are aiming at introducing customized solutions for different regions based on individual regulatory trends, fuel quality, and driving condition in order to reach out to a broader customer base. The European Union (EU) plans to cut down carbon dioxide emission by 2020, and hence, is encouraging major companies to introduce innovative biocatalysts for the market.

Top Key Players of Refinery Catalyst Market Covered in The Report

Albemarle Corporation

BASF SE

Johnson Matthey Plc

R. Grace

Clariant International Ltd.

Key Market Segmentation of Refinery Catalyst Market

Grand View Research has segmented the global refinery catalyst market on the basis of material, application, and region:

Refinery Catalyst Material Outlook

Zeolites

Metallic

Chemical compounds

Others

Refinery Catalyst Application Outlook

FCC

Alkylation

Hydrotreating

Hydrocracking

Catalytic Reforming

Others

Refinery Catalyst Regional Outlook

North America

Europe

Asia Pacific

Central & South America

Middle East & Africa

Request Free Sample or PDF Copy@ https://www.grandviewresearch.com/industry-analysis/refinery-catalysts-market

Regional Insights

Asia Pacific dominated the market and held a revenue share of 30.1% in 2019. China and India were reported as the second and fifth largest countries, respectively, in the market for refinery catalyst in 2019. Increasing number of private sector companies has played a crucial role in promoting the refining industry in the aforementioned countries especially in India. Reliance operated Jamnagar refinery complex in Gujarat had a capacity of 1.2 million barrels per day in 2019, which was the largest refinery in the world. The government of India has approved Petroleum, Chemicals, and Petrochemicals Investment Region (PCPIR) policy for promoting FDI investments in the oil and gas sector. This regulatory move is expected to accelerate the petrochemicals and polymers production in India, thus contributing to the demand for refinery catalysts over the forecast period.

Material Insights

In terms of revenue, the zeolites segment held a market share of 33.1% in 2019. Zeolites are hydrated aluminosilicate minerals, belonging to the family of microporous solids. They are widely used as adsorbents and catalysts owing to their porosity and large surface area. The porous structure of zeolites accommodates a variety of cations such as potassium (K+), sodium (Na+), calcium (Ca2+), and magnesium (Mg2+). Naturally, zeolites are formed by the reaction of volcanic rocks and ash layers with alkaline water. Natural zeolites are impure owing to the presence of other minerals, metals, and quartz. On the contrary, zeolites are commercially manufactured from the slow crystallization of silica-alumina gel and multiple other atoms incorporated to improve activity and performance in a particular process.

Refinery Catalyst Market Report Highlights

In terms of revenue, Asia Pacific emerged as the fastest growing region in 2019

FCC catalysts emerged as the prominent application segment in 2019 with a market share of 46.1% by volume

In Asia Pacific, India and China are likely to witness a remarkable market growth in next seven years

The industry is consolidated in nature, with presence of long term and well established global players such as Clariant and BASF SE. These players are highly focused towards R&D for the development of efficient technologies and securing them by filing for patents.

Contact Us:

Grand View Research, Inc. 201 Spear Street 1100, San Francisco, CA 94105 United States

Phone: 1-415-349-0058 Toll Free: 1-888-202-9519 Email: [email protected]

#refinery catalysts#refinery catalysts market#Refinery catalysts Market sales#Refinery catalysts market Forecast#Refinery catalysts market regional anaylysis

0 notes

Text

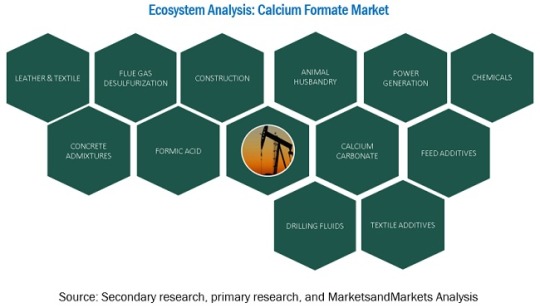

Lanxess (Germany) and Perstorp (Sweden) are the leading players in Calcium Formate Market

The global calcium formate market size is estimated to grow from USD 545 million in 2020 to USD 713 million by 2025, at a CAGR of 5.5% during the forecast period. The market is projected to witness decent growth in the near future, owing to the wide application areas of calcium formate ranging from leather and textile to the construction industry. Increasing demand from APAC will further drive the growth of the global calcium formate market. APAC is estimated to be the leading calcium formate market during the forecast period. The growth in this region can be attributed to the rapidly increasing demand for calcium formate from the end-use industries, especially construction, leather & textile and animal husbandry. The market is witnessing moderate growth, owing to increasing application, technological advancements, and growing demand for these calcium formate additives in the APAC and Europe. To know about the assumptions considered for the study download the pdf brochure Lanxess (Germany), Perstorp (Sweden), Chongqing Chuandong Chemical (Group) Co. Ltd. (China), Geo Specialty Chemical Inc.(Ohio), and Zibo Ruibao Chemical Co. Ltd. (China), American Elements (US), Henan Botai Chemical Building Material Co. Ltd. (China), Shandong Baoyuan Chemical Co. Ltd. (China), Jiangxi Kosin Organic Chemical Co. Ltd (China) and Sidley Chemical Co. Ltd (China) among others are the leading calcium formate manufacturers, globally. These companies adopted expansion, new product development, joint venture, and merger & acquisition as their key growth strategies between 2017 and 2020 to earn a competitive advantage in the calcium formate market. Lanxess (Germany) is the largest player in the market. In February 2020, LANXESS completed the acquisition of Itibanyl Produtos Especiais Ltda. (IPEL). With the acquisition, LANXESS is strengthening its position as one of the world’s leading manufacturers of antimicrobial active ingredients and formulations. In November 2019, PMC Group acquires of Lanxess’ Organotin Specialties Business Assets. The Business included Lanxess’ global organotin catalyst, organotin specialties and intermediates product lines. Perstorp (Sweden) is ranked second in the calcium formate market. In November 2019, Perstorp, invested in the construction of a new Pentaerythritol (Penta) production facility in Gujarat, India. The Gujarat plant will produce Penta, including the renewable grades of Voxtar, providing up to a 60% reduced carbon footprint. Commercial production is planned to start in Q1 2022. Also, in July 2019, ProPhorce Valerins is the latest innovation by Perstorp in the field of animal nutrition. It consists of glycerol esters of valeric acid. Research have shown that this product significantly improves broiler performance even when compared to industry standards such as butyric acid. Read More: https://www.marketsandmarkets.com/PressReleases/calcium-formate.asp

0 notes

Text

Growing demand of calcium formate in the construction industry

Calcium formate is used as cement additive and concrete accelerator, tile adhesives and cement-based mortars. The growth in the consumption of cement from the construction industry effectively boosts the demand for calcium formate market.

Calcium fromate is used as a cement additive in the construction industry for quick setting and increasing hardness of cement products. Cement is also used in the production of various products such as bricks and blocks, slabs and sheets, adhesives and concrete. In addition, calcium formate is also used as an inhibitor, PH regulator, corrosion protector to substrates of buildings and infrastructure, and for cementation of oil drilling. It is mostly used in the production of concrete in China which is one of the most dominant countries in the production and consumption of cement. Thus, the growing demand of cement in the construction industry is driving the market for calcium formate

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=191530782

The global calcium formate market size is estimated to grow from USD 545 million in 2020 to USD 713 million by 2025, at a CAGR of 5.5% during the forecast period. The market is projected to witness decent growth in the near future, owing to the wide application areas of calcium formate ranging from leather and textile to the construction industry. Increasing demand from APAC will further drive the growth of the global calcium formate market.

The construction industry will continue to lead the calcium formate market, , accounting for a share of 29.7% of the overall market, in 2019 terms of value. Increasing construction and infrastructural activities is expected to boost the rising demand for cement and concrete in the near future. The use of calcium formate as an accelerator in the concrete setting application decreses the setting time and increases the strength, thus boosting the global calcium formate market

Recent Developments

In November 2019, Perstorp, invested in the construction of a new Pentaerythritol (Penta) production facility in Gujarat, India. The Gujarat plant will produce Penta, including the renewable grades of Voxtar, providing up to a 60% reduced carbon footprint. Commercial production is planned to start in Q1 2022.

In February 2020, LANXESS completed the acquisition of Itibanyl Produtos Especiais Ltda. (IPEL). With the acquisition, LANXESS is strengthening its position as one of the world’s leading manufacturers of antimicrobial active ingredients and formulations.

APAC is estimated to be the leading calcium formate market during the forecast period. The growth in this region can be attributed to the rapidly increasing demand for calcium formate from the end-use industries, especially construction, leather & textile and animal husbandry. The market is witnessing moderate growth, owing to increasing application, technological advancements, and growing demand for these calcium formate additives in the APAC and Europe.

0 notes

Text

IP-BP-USP CHEMICALS | PAT IMPEX

Manufacturer-suppliers & exporters of IP BP US Grade chemicals for pharmaceutical industry in Vadodara-Gujarat-India

Borax Ph. Eur. SODIUM ACETATE ANHYDROUS USP HEMODIALYSIS ACTIVATED CARBON BP ACTIVATED CARBON IP ACTIVATED CARBON USP ALUM Ph. Eur. ALUMINIUM AMMONIUM SULPHATE USP ALUMINIUM CHLORIDE HEXAHYDRATE BP ALUMINIUM CHLORIDE HEXAHYDRATE USP ALUMINIUM POTASSIUM SULPHATE DODECAHYDRATE BP ALUMINIUM POTASSIUM SULPHATE USP ALUMINIUM SULPHATE BP ALUMINIUM SULPHATE IP Aluminium Sulphate Ph. Eur. ALUMINIUM SULPHATE USP AMMONIUM BENZOATE AMMONIUM BICARBONATE BP AMMONIUM CARBONATE NF AMMONIUM CHLORIDE BP AMMONIUM CHLORIDE IP Ammonium Chloride Ph. Eur. AMMONIUM CHLORIDE USP AMMONIUM FERRIC CITRATE USP AMMONIUM HYDROGEN CARBONATE Ph. Eur. AMMONIUM MOLYBDATE USP - 27 AMMONIUM SULPHATE NF-25 BARIUM SULPHATE BP BARIUM SULPHATE USP BENZOIC ACID BP BENZOIC ACID IP Benzoic Acid Ph. Eur. BENZOIC ACID USP - 27 BENZYL ALCOHOL BP BENZYL ALCOHOL IP BORAX BP BORAX NF BORIC ACID BP BORIC ACID IP BORIC ACID NF Boric Acid Ph. Eur. CADMIUM NITRATE TETRAHYDRATE ACS CALAMINE BP CALAMINE IP CALAMINE USP CALCIUM ACETATE BP CALCIUM ACETATE DRIED BP DIALYSIS CALCIUM ACETATE DRIED BP HEMODIALYSIS CALCIUM ACETATE DRIED USP DIALYSIS CALCIUM ACETATE DRIED USP HEMODIALYSIS CALCIUM ACETATE Ph. Eur. CALCIUM ACETATE USP CALCIUM CARBONATE BP CALCIUM CARBONATE IP 85 CALCIUM CARBONATE IP 96 Calcium Carbonate Ph. Eur. CALCIUM CARBONATE USP CALCIUM CHLORIDE DIHYDRATE BP CALCIUM CHLORIDE DIHYDRATE BP DIALYSIS CALCIUM CHLORIDE DIHYDRATE BP-05 CALCIUM CHLORIDE DIHYDRATE IP CALCIUM CHLORIDE DIHYDRATE Ph. Eur. CALCIUM CHLORIDE DIHYDRATE USP CALCIUM CHLORIDE DIHYDRATE USP HEMODIALYSIS CALCIUM CHLORIDE HYDRATED IP CALCIUM D-SACCHARATE USP CALCIUM HYDROXIDE BP CALCIUM HYDROXIDE IP CALCIUM HYDROXIDE Ph. Eur. CALCIUM HYDROXIDE USP CALCIUM OXIDE USP CALCIUM PHOSPHATE DIBASIC DIHYDRATE IP CALCIUM PHOSPHATE DIBASIC ANHYDROUS BP CALCIUM PHOSPHATE DIBASIC ANHYDROUS IP CALCIUM PHOSPHATE DIBASIC ANHYDROUS Ph. Eur. CALCIUM PHOSPHATE DIBASIC ANHYDROUS USP CALCIUM PHOSPHATE DIBASIC DIHYDRATE Ph.Eur CALCIUM PHOSPHATE DIBASIC DIHYDRATE USP CALCIUM PHOSPHATE TRIBASIC NF CALCIUM SULPHAE DIHYDRATE BP CALCIUM SULPHATE ANHYDROUS NF CALCIUM SULPHATE DIHYDRATE BP CALCIUM SULPHATE DIHYDRATE NF CALCIUM SULPHATE DIHYDRATE PH. EUR. CALCIUM SULPHATE DRIED BP CHROMIUM CHLORIDE USP CITRIC ACID ANHYDROUS BP CITRIC ACID ANHYDROUS BP DIALYSIS CITRIC ACID ANHYDROUS BP INJECTABLE CITRIC ACID ANHYDROUS IP CITRIC ACID ANHYDROUS Ph. Eur. CITRIC ACID ANHYDROUS USP CITRIC ACID ANHYDROUS USP DIALYSIS CITRIC ACID ANHYDROUS USP INJECTABLE CITRIC ACID MONOHYDRATE BP CITRIC ACID MONOHYDRATE BP DIALYSIS CITRIC ACID MONOHYDRATE BP INJECTABLE CITRIC ACID MONOHYDRATE IP CITRIC ACID MONOHYDRATE USP CITRIC ACID MONOHYDRATE USP DIALYSIS CITRIC ACID MONOHYDRATE USP INJECTABLE COPPER (II) SULPHATE ANHYDROUS BP COPPER SULPHATE PENTAHYDRATE BP COPPER SULPHATE USP CUPRIC SULPHATE DRIED BP CUPRIC SULPHATE PENTAHYDRATE FCC CUPRIC SULPHATE PENTAHYDRATE Ph. Eur. DEXTROSE ANHYDROUS BP/USP DEXTROSE ANHYDROUS BP DEXTROSE ANHYDROUS BP INJECTABLE DEXTROSE ANHYDROUS IP DEXTROSE ANHYDROUS IP INJECTABLE DEXTROSE ANHYDROUS USP DEXTROSE MONOHYDRATE IP DEXTROSE MONOHYDRATE Ph. Eur. DEXTROSE MONOHYDRATE USP EDETIC ACID NF EDTA ACID Ph. Eur. EDTA DISODIUM BP EDTA DISODIUM IP EDTA DISODIUM Ph. Eur. EDTA DISODIUM USP FERRIC SULPHATE USP FERROUS SULPHATE DRIED BP FERROUS SULPHATE DRIED IP FERROUS SULPHATE DRIED Ph. Eur. FERROUS SULPHATE DRIED USP FERROUS SULPHATE HEPTAHYDRATE BP FERROUS SULPHATE HEPTAHYDRATE USP FERROUS SULPHATE IP GENTIAN VIOLET USP MAGNESIUM ACETATE TETRAHYDRATE BP MAGNESIUM ACETATE TETRAHYDRATE BP DIALYSIS MAGNESIUM ACETATE TETRAHYDRATE Ph. Eur. MAGNESIUM CARBONATE HEAVY USP MAGNESIUM CARBONATE LIGHT BP MAGNESIUM CARBONATE LIGHT IP MAGNESIUM CARBONATE LIGHT Ph. Eur. MAGNESIUM CARBONATE LIGHT USP MAGNESIUM CHLORIDE BP MAGNESIUM CHLORIDE HEXAHYDRATE BP DIALYSIS MAGNESIUM CHLORIDE HEXAHYDRATE BP HEMODIALYSIS MAGNESIUM CHLORIDE HEXAHYDRATE BP INJECTABLE MAGNESIUM CHLORIDE HEXAHYDRATE Ph. Eur. MAGNESIUM CHLORIDE IP MAGNESIUM CHLORIDE IP DIALYSIS MAGNESIUM CHLORIDE USP MAGNESIUM CHLORIDE USP HEMODIALYSIS MAGNESIUM HYDROXIDE IP MAGNESIUM OXIDE LIGHT IP MAGNESIUM OXIDE LIGHT USP MAGNESIUM PHOSPHATE USP MAGNESIUM SULPHATE 7H2O BP MAGNESIUM SULPHATE 7H2O IP MAGNESIUM SULPHATE 7H2O USP MAGNESIUM SULPHATE DRIED BP MAGNESIUM SULPHATE DRIED USP INJECTABLE MAGNESIUM SULPHATE HEPTAHYDRATE Ph. Eur. MAGNESIUM SULPHATE USP INJECTABLE MALEIC ACID BP MANGANESE CHLORIDE TETRAHYDRATE USP MANGANESE SULPHATE MONOHYDRATE BP MANGANESE SULPHATE MONOHYDRATE USP METHYLENE BLUE USP POTASSIUM ACETATE BP POTASSIUM ACETATE BP DIALYSIS POTASSIUM ACETATE BP HEMODIALYSIS POTASSIUM BITARTRATE USP POTASSIUM BROMIDE BP POTASSIUM BROMIDE Ph. Eur. POTASSIUM CARBONATE USP POTASSIUM CHLORIDE BP POTASSIUM CHLORIDE BP HEMODIALYSIS POTASSIUM CHLORIDE BP INJECTABLE POTASSIUM CHLORIDE IP POTASSIUM CHLORIDE IP DIALYSIS POTASSIUM CHLORIDE Ph. Eur. POTASSIUM CHLORIDE USP POTASSIUM CHLORIDE USP HEMODIALYSIS POTASSIUM CITRATE Ph. Eur. POTASSIUM CITRATE TRIBASIC BP POTASSIUM CITRATE TRIBASIC IP POTASSIUM CITRATE TRIBASIC USP POTASSIUM DIHYDROGEN PHOSPHATE BP INJECTABLE POTASSIUM DIHYDROGEN PHOSPHATE NF POTASSIUM HYDROGEN CARBONATE BP POTASSIUM HYDROGEN CARBONATE USP POTASSIUM HYDROXIDE FLAKES BP POTASSIUM HYDROXIDE FLAKES NF POTASSIUM HYDROXIDE PELLETS BP POTASSIUM HYDROXIDE PELLETS BP HEMODIALYSIS POTASSIUM HYDROXIDE PELLETS NF POTASSIUM IODATE BP POTASSIUM IODIDE BP POTASSIUM IODIDE IP POTASSIUM IODIDE Ph. Eur. POTASSIUM IODIDE USP POTASSIUM METABISULPHITE NF POTASSIUM NITRATE BP POTASSIUM NITRATE USP POTASSIUM PERMANGANATE BP POTASSIUM PERMANGANATE IP POTASSIUM PERMANGANATE USP POTASSIUM PHOSPHATE DIBASIC BP POTASSIUM PHOSPHATE DIBASIC Ph. Eur. POTASSIUM PHOSPHATE DIBASIC USP POTASSIUM PHOSPHATE MONOBASIC BP POTASSIUM SODIUM TARTRATE TETRAHYDRATE Ph. Eur. POTASSIUM SODIUM TARTRATE USP POTASSIUM SULPHATE BP Soda Lime NF SODIUM HYDROGEN CARBONATE BP SODIUM ACETATE ANHYDROUS USP SODIUM ACETATE TRIHYDRATE BP SODIUM ACETATE TRIHYDRATE BP DIALYSIS SODIUM ACETATE TRIHYDRATE IP SODIUM ACETATE TRIHYDRATE IP DIALYSIS SODIUM ACETATE TRIHYDRATE USP SODIUM ACETATE TRIHYDRATE USP HEMODIALYSIS SODIUM BENZOATE BP SODIUM BENZOATE IP SODIUM BENZOATE NF SODIUM CARBONATE MONOHYDRATE NF/FCC SODIUM CARBONATE ANHYDROUS BP SODIUM CARBONATE ANHYDROUS NF Sodium Carbonate Monohydrate BP SODIUM CARBONATE MONOHYDRATE NF SODIUM CHLORIDE BP SODIUM CHLORIDE BP DIALYSIS SODIUM CHLORIDE BP HEMODIALYSIS SODIUM CHLORIDE BP INJECTABLE SODIUM CHLORIDE IP SODIUM CHLORIDE IP DIALYSIS SODIUM CHLORIDE IP INJECTABLE SODIUM CHLORIDE USP SODIUM CHLORIDE USP DIALYSIS SODIUM CHLORIDE USP HEMODIALYSIS SODIUM CHLORIDE USP INJECTABLE SODIUM CITRATE DIBASIC SODIUM CITRATE DIBASIC BP SODIUM CITRATE DIHYDRATE BP SODIUM CITRATE TRIBASIC IP SODIUM CITRATE TRIBASIC USP SODIUM DIHYDROGEN PHOSPHATE DIHYDRATE BP SODIUM DIHYDROGEN PHOSPHATE DIHYDRATE IP Sodium Dihydrogen Phosphate Dihydrate USP SODIUM DIHYDROGEN PHOSPHATE MONOHYDRATE BP SODIUM DIHYDROGEN PHOSPHATE MONOHYDRATE USP SODIUM HYDROGEN CARBONATE IP SODIUM HYDROGEN CARBONATE USP SODIUM HYDROGEN CARBONATE USP HEMODIALYSIS SODIUM HYDROGEN CARBONATE USP INJECTABLE SODIUM HYDROXIDE NF SODIUM HYDROXIDE PELLETS BP SODIUM HYDROXIDE PELLETS IP SODIUM METABISULPHITE BP SODIUM METABISULPHITE IP SODIUM METABISULPHITE NF Sodium Nitrite Ph. Eur. SODIUM NITRITE USP SODIUM PHOSPHATE DIBASIC 12H20 USP SODIUM PHOSPHATE DIBASIC 12H2O BP SODIUM PHOSPHATE DIBASIC 12H2O IP SODIUM PHOSPHATE DIBASIC 7H2O USP SODIUM PHOSPHATE DIBASIC ANHYDROUS BP SODIUM PHOSPHATE DIBASIC ANHYDROUS USP SODIUM PHOSPHATE DIBASIC DIHYDRATE BP SODIUM PHOSPHATE DIBASIC DIHYDRATE USP SODIUM PHOSPHATE DIBASIC HEPTAHYDRATE SODIUM PHOSPHATE MONOBASIC MONOHYDRATE BP SODIUM STARCH GLYCOLATE BP/NF (POTATO BASE) SODIUM STARCH GLYCOLATE IP SODIUM SULPHATE 10H2O BP SODIUM SULPHATE ANHYDROUS BP SODIUM SULPHATE ANHYDROUS BP INJECTABEL SODIUM SULPHATE ANHYDROUS USP SODIUM SULPHITE ANHYDROUS BP SODIUM THIOSULPHATE PENTAHYDRATE BP SODIUM THIOSULPHATE PENTAHYDRATE IP SODIUM THIOSULPHATE Ph. Eur. SODIUM THIOSULPHATE USP ANHYDROUS PENTAHYDRATE SODIUM TRIPOLYPHOSPHATE FCC STANNOUS CHLORIDE DIHYDRATE BP Test Product TITANIUM DIOXIDE USP TRI-CALCIUM PHOSPHATE BP TRI-CALCIUM PHOSPHATE IP UREA BP UREA IP UREA USP UREA USP INJECTABLE ZINC ACETATE BP ZINC ACETATE USP ZINC CARBONATE USP ZINC CHLORIDE BP ZINC CHLORIDE IP ZINC CHLORIDE USP ZINC OXIDE BP ZINC OXIDE IP ZINC OXIDE USP ZINC SULPHATE BP ZINC SULPHATE HEPTAHYDRATE USP ZINC SULPHATE IP ZINC SULPHATE MONOHYDRATE USP

#IP-BP-USP-Chemicals#manufacturer#Vadodara#Gujarat#india#urea-patimpex#zinc-chemicals#sodium-chemicals#potassium-chemicals#pharma-additives

0 notes