#Abrasion Resistant Steel Suppliers in Mumbai

Explore tagged Tumblr posts

Text

Abrasion Resistant Steel Manufacturers In India

Abrasion Resistant Steel Manufacturers in Mumbai, Abrasion Resistant Steel Suppliers in Mumbai, Abrasion Resistant Steel Stockists in Mumbai, Abrasion Resistant Steel Exporters in Mumbai

Abrasion Resistant Steel Sheet its toughness and hardness and but reduces its strength, during the formation of abrasion resistant steels plate carbon is added and which considerably increases. They are high-carbon alloy steels which is specifically designed to provide greater hardness properties than low-carbon steels. Due to the added alloys it is formable and weather-resistant and harder due to the addition of carbon. Ar300 Steel Plate is used in a condition where wear and tear and abrasions are the main causes of failure. Abrasion Resistant Steel Plate usual applications are mining, construction, material handling, etc. They are commonly used in industrial manufacturing, energy, infrastructure, and more.

Ar300 Wear Resistant Steel Plate offers some impact resistance and also works well in harsh applications. They are extremely wear-resistant and durable, defending well against scratches and scuffs. Wear resistant steel plate will ultimately reduce your costs in the long-run and help extend the life of your applications. Abrasion resistant material is created by tempering and quenching forged steel blocks, or ingots. At the time of this process, the grain structure is modified to promote formability and increase toughness, which leads to through-hardening of the material. Ar Plate Hardness is not perfect for structural construction applications, like support beams in bridges or buildings. They are typically comes at the expense of strength which makes it an ideal material for high-abrasion, harsh conditions, and not for structural applications.

#Abrasion Resistant Steel#Abrasion Resistant Steel Manufacturers#Abrasion Resistant Steel Suppliers#Abrasion Resistant Steel Stockists#Abrasion Resistant Steel Exporters#Abrasion Resistant Steel Manufacturers In India#Abrasion Resistant Steel Suppliers In India#Abrasion Resistant Steel Stockists In India#Abrasion Resistant Steel Exporters In India#Abrasion Resistant Steel Manufacturers in Mumbai#Abrasion Resistant Steel Suppliers in Mumbai#Abrasion Resistant Steel Stockists in Mumbai#Abrasion Resistant Steel Exporters in Mumbai

0 notes

Text

UNS S31803 tubes are distinguished mechanisms which come under the family of Duplex Steel Pipes. Duplex Steel UNS S31803 Tubes are austenitic and ferritic materials which are noted for their great corrosion resistance and toughness. The duplex microstructure of these tubes is the reason for their considerable strength. They tend to exhibit sumptuous erosion and abrasion resistance.

0 notes

Text

Abrex 400 Plate Exporters

Vandan Steel & Engg. co. is a ABREX 400 Plate importers, suppliers and stockists, conveying to the entire of the world.We are having biggest stock and prepared load of around 1000 tons of ABREX 400 Plate in various size, grades and cuts.Our fabricating system is upheld by escalated in-house item assessment and testing and authorize to meet all the most perceived global principles, including ISO 9001:2008

Abrex Plate, Abrex 400 Plate, Abrex 400 Plate Manufacturers, Abrex 400 Plate Suppliers, Abrex 400 Plate Stockists, Abrex 400 Plate Exporters, Abrex 400 Plate Traders, Abrex 400 Plate Stockists, Abrex 400 Plate Distributors, Abrex 400 Plate Dealers, Abrex 400 Plate Steel Plate, Abrex 400 Plate Sheets Supplier, High Tensile Strength 400 Abrex Plates, En 10051 Abrex 400 Plate Hot Rolled (hr) Plates, 400 Abrex High Tensile Plates Exporter India.

Vandan Steel & Engg. co. has some expertise in ABREX 400 Plate .With 25 years of involvement in supplying and sending out ABREX 400 Plate we offer superb, lower cost however the best administration.

We are had practical experience in offering exactness designed ABREX 400 Plate , which are utilized as a part of different building applications and can be benefited in different evaluations likeABREX 400 Plate, Abrasion Resistant Steel Plates these evaluations are accessible as Abrasion Resistant Steel Plate

ABREX 400 steels are the most for the most part used of the wear safe assessments. ABREX 400 demonstrates a phenomenal solidification of high imperviousness to impact, workability, weld limit and imperviousness to scraped area. ABREX 400 has around 3 times the scraped area resistance of ordinary steel plate and helps drawing out the organization life of mechanical parts.

Abrex Plate, Abrex 400 Plate in India, Abrex 400 Plate Manufacturers in India, Abrex 400 Plate Suppliers in India, Abrex 400 Plate Stockists in Uae, Abrex 400 Plate Exporters in Mexico, Abrex 400 Plate Traders in India, Abrex 400 Plate Stockists in India, Abrex 400 Plate Distributors in Mexico, Abrex 400 Plate Dealers in UAE, Abrex 400 Plate Steel Plate, Abrex 400 Plate Sheets Supplier, High Tensile Strength 400 Abrex Plates, En 10051 Abrex 400 Plate Hot Rolled (hr) Plates, 400 Abrex High Tensile Plates Exporter India. Abrex Wear Resistant Steel Plates, En 10051 Abrex 400 Plate Plate & Sheets Supplier, Abrex 400 Platebhn Steel Plates, Abrex 400 Plate High Yield Structural Steel Plate Stockholder, Abrex 400 Plate Wear Resistance Plates In India

SPECIFICATION ABREX 400:

Size: 5mm ~ 120 mm Width: Up to 3000 mm Length: Up to 12000 mm

APPLICATION

Screen Plates - Chute Liners Conveyor Buckets Cutting Edges Ripper Tyne Hoppers Ore Scrapers

CHEMICAL COMPOSITIONGradeC maxSi maxMn maxP maxS maxNi maxCr maxMo maxB maxAbrex 4000.210.7020.0250.0101.001.200.600.005

MECHANICAL PROPERTIESGradeMechanical PropertyCharpy V Impact TestABREX 400YieldTensileElongationDegreelongitudinalMin MpaMpaMin %-40J100012501045

Abrex Plate, Abrex 400 Plate in UAE, Abrex 400 Plate Manufacturers in Mumbai, Abrex 400 Plate Suppliers in Srilanka, Abrex 400 Plate Stockists in Mexico, Abrex 400 Plate Exporters in India, Abrex 400 Plate Traders in Banglore, Abrex 400 Plate Stockists in Arabia, Abrex 400 Plate Distributors in Mumbai, Abrex 400 Plate Dealers in Mumbai, Authorised Distributors Of Abrex 400 Plate In India, Authorised Exporters Of Abrex 400 Plate In India,authorised Traders Of Abrex 400 Plate In India, Authorised Importers Of Abrex 400 Plate In India,autorised Suppliers Of Abrex 400 Plate In India.

0 notes

Text

Alloy Steel Sheets & Plates Exporters

Alloy Steel Plates Supplier is defined as having 1.5% to 5% total alloy content. Its common alloying elements are manganese, silicon, chromium, nickel, molybdenum, and vanadium, which contain as many as four or five of these alloys in varying amounts. which is been used by the manufacturers who works with petrochemical industries, oil and gas industries, chemical industries, shipbuilding etc. Alloy steel wear plates is a smooth, chromium carbide rich overlay plate manufacturers and Supplier by a patented production process maximizing abrasion resistance and reducing hang up.

Alloy Steel Sheet is been designed from alloys such as chromium, molybdenum, nickel, manganese, silicon so on, they are industrial product that is generally used in various industries applications. 4130 alloy steel sheet is low-alloy steels containing chromium and molybdenum as strengthening agents. It provides good strength and toughness, weldability and machinability. Alloy steel 4340 sheet is a heat treatable low alloy steels which contains nickel, chromium, molybdenum, they are commonly used for heavy duty industrial, aerospace and automotive applications.

It has high strength and toughness in heat treated condition. 6150 alloy steel sheet is useful in heavily stressed machinery parts including gears, shafts, hand tool components and pinions. It is a fine grained, highly abrasion resistant carbon-chromium alloy steel. Alloy Steel Plates Grades are ASTM A387 Gr 5, ASTM A387 Gr 9, ASTM A387 Gr 11, ASTM A387 Gr 12, ASTM A387 Gr 22 and ASTM A387 Gr 91.

For more information

Contact: 9821513630 , 9321113630

Email id: [email protected]

Address:

Office No 7, 42/46, Mughbat Lane, Shantaram Chawl, Girgaum, Mumbai - 400 004..

0 notes

Text

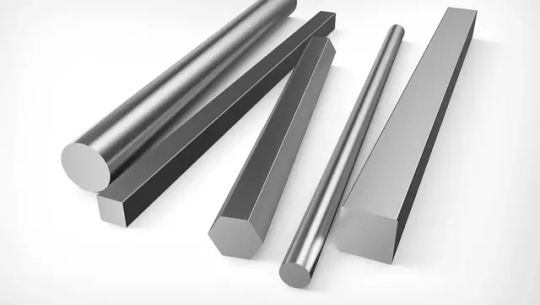

The Versatile Utility of Round Bars in Modern Applications

Nova Steel Corporation is a major round bar manufacturer in India. We specialize in making high-quality round bars that satisfy industry standards. These Round Bars come in a range of sizes, shapes, and dimensions, and they may also be modified to match our clients' specific demands. Our top-notch range of Round Bars is exclusively meant for steel manufacturing plants, petrochemical sector, fire protection frameworks, synthetic ventures, dispatching/shipment companies, and so on. As a leading Round Bar Manufacturer in India, we provide a diverse selection of round bar options to meet a variety of needs.

Characteristics of Round Bars

Round bars are typically characterized by their:

Material Composition: Depending on the intended use, round bars can be manufactured from different materials. For example, stainless steel round bars are corrosion-resistant, making them suitable for marine and chemical environments.

Dimensions: Round bars come in a variety of diameters and lengths. Their size can be customized based on specific project requirements, ranging from a few millimeters to several inches in diameter.

Mechanical Properties: Round bars exhibit excellent mechanical properties, including tensile strength, durability, and malleability. These attributes make them a popular choice for applications that require robust structural support or precision engineering.

Surface Finish: Round bars can be polished or coated to enhance their aesthetic appeal or provide additional protection against environmental factors like moisture and abrasion.

We are Flanges Supplier In:

Round Bars Supplier in Hyderabad

Round Bars Supplier in Bangalore

Round Bars Supplier in Chennai

Round Bars Supplier in Mumbai

Round Bars Supplier in Gujarat

Types of Round Bars

There are several types of round bars available, categorized based on the material used:

Stainless Steel Round Bars: Renowned for their corrosion resistance, these are ideal for use in harsh environments such as marine or chemical processing industries. They are also widely used in architectural designs due to their sleek appearance.

Mild Steel Round Bars: Known for their ductility and weldability, mild steel bars are preferred in construction and general manufacturing applications.

Aluminum Round Bars: Lightweight yet strong, aluminum bars are frequently utilized in aerospace, automotive, and electronics industries.

Brass Round Bars: These offer excellent machinability and are used in decorative items, electrical components, and precision engineering.

Alloy Steel Round Bars: With enhanced strength and toughness, these are suitable for heavy-duty applications, including machinery and tools.

Applications of Round Bars

Round bars serve a multitude of purposes across various sectors. Here are some key applications:

Construction: In the construction industry, round bars are used as reinforcements in concrete structures, handrails, and decorative elements.

Automotive: They are integral to the production of vehicle components such as axles, shafts, and engine parts due to their strength and durability.

Manufacturing: Round bars are employed in the creation of fasteners, bolts, and machine parts. Their machinability ensures precision in the manufacturing process.

Aerospace: Lightweight materials like aluminum round bars are indispensable in the aerospace sector for crafting structural components and frameworks.

Energy: Stainless steel round bars find applications in power plants, oil rigs, and other energy infrastructures where resistance to extreme conditions is necessary.

Benefits of Using Round Bars

The advantages of round bars include:

Versatility: With a broad range of sizes and materials, round bars can be tailored to suit diverse needs.

Strength and Durability: Their mechanical properties make them reliable for critical applications.

Ease of Fabrication: Round bars are easy to machine, cut, and weld, simplifying the manufacturing process.

Cost-Effectiveness: Their durability and adaptability often lead to reduced maintenance and replacement costs over time.

Round Bar Manufacturer in India

Our round bars are available in a range of materials, including stainless steel, carbon steel, alloy steel, and aluminum, with different diameters, lengths, and surface treatments. When you choose us as your Round Bars Supplier in India, you can be confident that you will get high-quality items. Our round bars undergo stringent quality control procedures to assure dimensional accuracy, mechanical properties, and uniform surface polish. We are also a top provider of MS plate weight chart.

#Round Bars Manufacturer in India#Round bars suppliers#Round bars suppliers in India#ms plate weight chart

0 notes

Text

Rockhard 500 Plates Supplier in India - Convergence Steel Pvt. Ltd

About ROCKHARD 500 Plates –

Convergence Steel Pvt. Ltd. is one of the leading suppliers, and stockists of Rockhard 500, Rockhard 500 Plates, and Abrasion/Wear Resistant Steel Plates. Our Rockhard 500 steel plates are crafted for durability and resilience, meeting the highest industry standards at the best prices across India. With a commitment to quality and customer satisfaction, Convergence Steel Pvt. Ltd. ensures that each product supports industrial needs with reliability and excellence.

ROCKHARD 500 Plates – a top-notch abrasion & wear resistant steel plate boasting a standard hardness of 450-540 HBW manufactured by Jindal Steel and Power. This versatile steel plate stands out for its exceptional wear resistance, high toughness, excellent weldability, and good bendability, making it suitable for structures intended for wear applications.

ROCKHARD 500 Plates is also known for high strength, longer life, resistance to wear, enhanced weldability, good toughness, higher hardness, and bendable properties. It decreases repair costs for equipment and machinery, imparts longer life and reduces maintenance. Typically, Wear performance of ROCKHARD 500 Plates can be 3 to 5 times greater than that of common structural steel grade.

Convergence Steel Pvt Ltd stands out as a leading stockist and distribution company based out of Mumbai for supplies of ROCKHARD 500 PLATES.

0 notes

Text

12-14% Manganese Plates Distributors in Mumbai

Introduction:

Chhajed Steel Limited is a 12–14% Manganese Steel Plate stockholders and suppliers, delivering to the whole of the world.we are ISO 9001:2008 accredited and supplies 12–14% Manganese Steel Plate to internationally approved quality standards for applications. 12–14% Manganese Steel Plate have excellent quality to fully satisfy customer’s requirements.

Product Overview :

The 12–14% Manganese Steel Plate supplied by us are accepted by clients in various spheres of the industries ranging from basic industries such as Sugar, Paper, Textile, Dairy, Engineering to more complex such as Oil & Gas, Petrochemical, Chemical & Fertilizers, Power Generation and Nuclear Industries.

12–14% Manganese Steel Plate Grade and Specification:

Standards:

EURONORM/1.3401 — X120Mn13

DIN-W1.3401/AFNOR-X120Mn13/ASTM-A128 Gr B2

Typical Analysis:

Carbon-1.20%/Phosphorous-0.020%/Silicon-0.15%

Sulphur-0.020%/Manganese-11.00–14.00%

Typical Application of 12–14% Manganese Steel Plate :

stone or iron chutes

industrial trackwork

anti drill plates such as security doors

shot blasting equipment

tumbling machines.

Conclusion :

12–14% Manganese Steel Plates are known for their high impact strength and resistance to abrasion in hardened conditions. This steel grade is often used in high-wear environments like rock crushers, railroad track components, and mining machinery. The high manganese content gives the steel exceptional toughness, making it an excellent choice for applications where both wear resistance and durability are crucial.

1 note

·

View note

Text

Supplier of Stainless Steel Wire Rod in Maharashtra

Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Wire Rod in Maharashtra. We offer a wide range of Stainless Steel Products, including Stainless Steel Round Bars, Wires, Rods, Sheets, Coils, Pipes, Flat Bars, Square Bars, Hexagonal Bars, Angles, Flanges, and Alloy Steel. Arisa Impex is headquartered in Ahmedabad, Gujarat, India. Our wire rods are produced in various diameters and grades to meet the specific needs of different industries. Why Choose Our SS Wire Rods? Superior Quality: We manufacture our SS wire rods from premium-grade stainless steel to ensure exceptional quality and performance. We adhere to stringent quality control measures to deliver products that meet the highest industry standards. Precision Engineering: We produce our wire rods with precise dimensional accuracy and a smooth surface finish, ensuring consistent performance and easy processing in your end products. Custom Solutions: We offer customized solutions to meet your specific requirements, including different grades, diameters, and lengths. Our team works closely with you to ensure the right product for your application. Durability and Strength: Engineered for strength and longevity, our wire rods offer excellent resistance to corrosion, abrasion, and wear. This makes them ideal for demanding applications in harsh environments. Industries We Serve Our SS wire rods cater to various industries, including: Construction Automotive Aerospace Manufacturing Our commitment to excellence, combined with our expertise and customer-focused approach, sets us apart as a leading supplier in the industry. Arisa Impex is a Supplier of Stainless Steel Wire Rod in Maharashtra including locations like Mumbai, Pune, Nagpur, Thane, Pimpri-Chinchwad, Nashik, Aurangabad, Navi Mumbai, Solapur, Bhiwandi, Jalgaon, Amravati, Nanded, Kolhapur, Sangli, Malegaon, Akola, Latur, Dhule, Ahmednagar, Chandrapur, Parbhani, Jalna, Ambarnath, Bhusawal, Badlapur, Gondia, Satara, Barshi, Yavatmal, Achalpur, Osmanabad, Nandurbar, Wardha. For more information about our product catalog, please feel free to reach out to us through the provided contact details. View Product: Click here Read the full article

0 notes

Text

Abrex 450LT Plates Stockists in India

Introduction

AR 450 Hot Rolled Plates, Nicrodur 450 Plates, High Quality Raex 450 Plates, WeAR Resistant Abrex 450 Plates, Abrasion Resistant 450 Steel Plates, Abrex 450 Plates Suppliers, Abrex 450 Plates Stockist In Mumbai, India.Abrex 450 Plates Dealer, Abrex 450 Sheet And Plate Exporter, Bhn 450 Plates, High Strength Abrex 450 Plates, Abrex 450 Cold Rolled Plates, Abrex 450 Plates Supplier In Mumbai, India.

Description

Abrex 450 plates, also known as abrasion-resistant plates, are specifically designed to withstand extreme wear and abrasion. Manufactured using advanced metallurgical processes, these plates boast uniform hardness and excellent mechanical properties. They are ideal for applications in mining, construction, and heavy machinery, where durability and resistance to wear are critical.

Benefits

Superior Wear Resistance: Abrex 450 plates provide outstanding resistance to abrasion, significantly extending the service life of equipment and reducing maintenance costs.

High Strength and Toughness: These plates offer excellent mechanical properties, ensuring reliable performance even under severe operating conditions.

Versatility: Suitable for a wide range of applications, including loaders, bulldozers, crushers, and hoppers, Abrex 450 plates can be utilized in various industries.

Cost-Effective: By minimizing downtime and reducing the frequency of replacements, these plates offer a cost-effective solution for enhancing the durability of machinery and equipment.

Specification

ABREX 450 STEEL PLATE SPECIFICATION

Thickness : 5mm to 150mm Width : 1,500mm to 2,500mm Length : 6,000mm to 12,000mm Heat Treatment : N, Q+T Surface Paint : EP, PE, HDP, SMP, PVDF Material : ABREX 450 Plate, SUMIHARD k450 Steel Plate, DILLIDUR 450V Steel Plate, Essar Rockstar 450 Abrasion Resistant Steel Plates.

Conclusion

Abrex 450 plates are an essential solution for industries facing challenges related to abrasion and wear. Their exceptional properties, including high strength, toughness, and wear resistance, make them an indispensable component in various heavy-duty applications. Vandan Steel & Engg. Co. is committed to providing top-notch Abrex 450 plates to enhance the performance and longevity of your equipment. For more information or to place an order, please contact us at [email protected] or call us at +91-8828813630.

0 notes

Text

Stainless Steel Pipes Manufacturers in Mumbai,India

Oil and Gas Industry: Stainless steel pipes are extensively used in the oil and gas industry for transporting oil, gas, and other hydrocarbons. They can withstand high temperatures, pressures, and corrosive environments, making them ideal for offshore and onshore drilling, refineries, and pipelines.

2. Chemical Industry: Stainless steel pipes are resistant to chemical corrosion and are used in the chemical processing industry for transporting various chemicals, acids, and corrosive substances. They are also utilized in manufacturing plants, laboratories, and storage facilities.

3. Pharmaceutical Industry: Stainless steel pipes are preferred in the pharmaceutical industry for their cleanliness, durability, and resistance to corrosion. They are used for transporting various pharmaceutical liquids, gases, and chemicals in manufacturing processes.

4. Automotive Industry: Stainless steel pipes find applications in the automotive industry, particularly in exhaust systems. They can withstand high temperatures and resist corrosion caused by exhaust gases and environmental factors, improving the longevity and performance of the exhaust system.

5. Construction and Architecture: Stainless steel pipes are used in construction and architecture for various purposes, including handrails, guardrails, structural supports, and decorative elements. They offer an aesthetically pleasing appearance, durability, and resistance to corrosion.

6. Heat Exchangers and Boiler Tubes: Stainless steel pipes are utilized in heat exchangers, condensers, and boiler tubes due to their excellent heat resistance and corrosion resistance. They are capable of transferring heat efficiently and can withstand high-pressure and high-temperature conditions.

7. Mining and Mineral Processing: Stainless steel pipes are employed in mining operations for transporting minerals, slurry, and corrosive fluids. They can withstand abrasive materials and harsh environments typically found in mining and mineral processing plants.

8. Renewable Energy: Stainless steel pipes play a role in the renewable energy sector, particularly in solar thermal systems and geothermal power plants. They are used for heat transfer and fluid circulation in these applications. These are just a few examples of the diverse applications of stainless steel pipes. The properties of stainless steel, such as corrosion resistance, high strength, and versatility, make them suitable for various industries and environments.

0 notes

Text

Abrex 450 P

Abrex 450 Plates Manufacturers, Abrex 450 Plates Suppliers, Abrex 450 Plates Stockists, Abrex 450 Plates Exporters

Abrex 450 Plates Manufacturers in India, Abrex 450 Plates Suppliers in India, Abrex 450 Plates Stockists in India, Abrex 450 Plates Exporters in India

Today, Abrex 450 Plates plate is broadly used in wear-safe materials. These boards have a wonderful blend of properties, similar to wear opposition, consumption obstruction, machinability, intensity and high, solid construction, pitting opposition, high lastingness, and so forth. By utilizing Abrex, the heap of primary components are frequently essentially decreased to adjust to wear conditions. Contrasted and conventional steel, Abrex Plates dispenses with underlying weight and gives financial benefits.

Wear obstruction Utilizing Abrex can broaden the assistance lifetime of parts and gear. ABREX-Fantastic wear obstruction. Abrex 450 Plates PLATES might be a wear-safe plate, which is very successful in forceful workplaces. These boards consolidate higher durability, strength and strength, all together that they are much of the time used in many fields. some of the most applications are screens: storehouse linings, storehouses, dump trucks, mud pipe frameworks, rippers, edge digging tool, digging tool and scrubber.

Give different kinds of ABREX sheet materials: Abrex 450 PlatesBHN wear-safe plate, Abrex 450 Plates Brinell plate, Abrex 450 Plates wear-safe plate, Abrex 450 Plates smasher liner, and so forth. Normal handling which will be effectively performed on these plates is cutting, trying, handling, on the grounds that the wear opposition expands, the heap loss of steel diminishes in light of the fact that the surface hardness of the steel increments.

Thusly, it's critical that prepares that need wear opposition have higher surface hardness. Its assembling center is that the scraped spot obstruction of sand and soil. it's brilliant scratch obstruction, particularly for low steel . The Abrex 450 Plates board has gone through assortment of tests, including IGC-PMI test, influence test, pitting test, and so forth.

Abrex 450 Plates Plate Specification :

Item: Abrasion Resistant Plate

Thickness : 5mm to 150mm

Length : 1,500mm to 2,500mm

Width : 6,000mm to 12,000mm

Surface : Tempering, Quenched, Normalized.

Certificates : ISO9001:2000

Production : Hot-Rolled (HR) / Cold-Rolled (CR)

Applications : concrete industry, metallurgy, fan industry, coal industry, mining machinery, construction machinery,etc.

Heat Treatment: N, Q+T

Material : Abrex 450 Plates, AR 450 Steel Plate, Abrex 450 Plates Abrasion Resistant Steel Plates, Abrex 450 Plates Wear Resistant Plates

Abrex 450 Plates Manufacturers in Mumbai, Abrex 450 Plates Suppliers in Mumbai, Abrex 450 Plates Stockists in Mumbai, Abrex 450 Plates Exporters in Mumbai

lates Suppliers

#Abrex 450 Plates Manufacturers#Abrex 450 Plates Suppliers#Abrex 450 Plates Stcokists#industrial#construction#alloyplates

0 notes

Text

Swaged Nippolets Stockists in India

Swaged Nippolets, Swaged Nippolets Manufacturers, Swaged Nippolets Suppliers, Swaged Nippolets Exporters, Swaged Nippolets Stockists.

Swaged Nippolets in Mumbai, Swaged Nippolets Manufacturers in Mumbai, Swaged Nippolets Suppliers in Mumbai, Swaged Nippolets Exporters in Mumbai, Swaged Nippolets Stockists in Mumbai.

Swaged Nippolets in India, Swaged Nippolets Manufacturers in India, Swaged Nippolets Suppliers in India, Swaged Nippolets Exporters in India, Swaged Nippolets Stockists in India.

SWAGED NIPPOLETS

We supply Swaged Nippolets (3000 #) made of superior quality Stainless Steel. The Steel Swaged Nippolets offer optimum performance, durability and abrasion resistant. We have Stainless Steel Swaged Nippolets in various shapes and sizes to supply for diverse industrial applications.

0 notes

Text

Udimet X750 Round Bar Manufacturers In Mumbai

Inconel X750 alloy is highly appreciated and is used for fabricating bar because of various good attributes it has. All the good qualities have made Inconel X750 bar high in demand. It is having a greater ability of being fully resistant to corrosion, pitting, stress corrosion cracking, crevice corrosion, abrasion, and oxidation. The high tensile strength, good surface finishes, dimensional accuracy, rugged construction, durability, longevity, flexibility, easy to use and low maintenance. Rexton steel & alloys are one of the best manufacturer and supplier of the stunning quality of Inconel X750 bar that is used widely. The product is well fabricated by utilizing optimum quality of alloy that is collected from the reliable mills. The bars are manufactured under the strict guidance of the professional team that is well aware of how the effective production is done in the industry.

Furthermore, the quality control team is looking at the quality of the bars so that due to human or machine error it does not get spoil. Latest technology and modern tools are playing a vital role in enhancing the quality of bars. Considering industrial norms and production guidelines in addition to raw material quality standards have proved to be a lot helpful in making good quality of bars.

Inconel X750 Round Bar Equivalent Grades :

STANDARDWERKSTOFF NR.UNSInconel X7502.4669N07750

Chemical Composition of Alloy X750 Rods

GradeNiCrAlCMnTiCuSiSInconel X-75070.0 min14.0 - 17.00.40 - 1.0.08 max1.00 max2.25 - 2.750.50 max.50 max.01 max

Mechanical Properties of Inconel X750 Bars

DensityMelting PointTensile StrengthYield Strength (0.2%Offset)Elongation8.28 g/cm31430°C1267 MPa868 MPa25 %

For More Information Website:- https://www.aluminiumwala.com/udimet-x750-round-bar-manufacturer-stockists-exporters-suppliers-mumbai-india.html Email:- [email protected] Phone no:- +91 9167347029

0 notes

Text

Alloy Steel Plate Exporters

Alloy steel plates are vital components in several industrial applications, renowned for their durability, strength, and resistance to various environmental conditions. As industries continue to grow, the demand for high-quality materials like alloy steel plates has skyrocketed. This demand is expertly fulfilled by Vandan Steel & Engg. Co., a leading manufacturer, supplier, exporter, and stockist of alloy steel plates in Mumbai, India, and across the globe.

In this article, we will explore the significance of alloy steel plates, their key properties, specifications, benefits, applications, and most importantly, why Vandan Steel & Engg. Co. stands out as the best choice for acquiring these versatile materials.

What is Alloy Steel Plate?

Alloy steel plate refers to a type of steel that is alloyed with multiple elements to improve its mechanical properties. Unlike regular carbon steel, alloy steel contains varying amounts of elements like chromium, nickel, molybdenum, vanadium, and manganese. These elements enhance the steel's hardness, toughness, corrosion resistance, and strength, making it suitable for high-stress environments.

The properties of alloy steel plates can be altered depending on the composition and heat treatment, allowing for a wide range of applications in industries such as construction, automotive, aerospace, and heavy machinery.

Key Properties of Alloy Steel Plate

The addition of alloying elements imbues alloy steel plates with several critical properties, making them highly sought after across multiple industries. Some of the key properties include:

High Strength and Durability: Alloy steel plates are designed to withstand high levels of stress and pressure without deforming. This strength is particularly important in construction and heavy machinery applications.

Corrosion Resistance: The addition of chromium and other elements helps improve resistance to corrosion, ensuring the longevity of the material, even in harsh environments.

Wear Resistance: Alloy steel plates exhibit excellent wear resistance, making them ideal for applications in abrasive environments such as mining and construction.

Heat Resistance: Due to the alloying elements, these plates can maintain their structural integrity even under extreme temperatures, making them suitable for high-temperature applications like boilers and heat exchangers.

Flexibility in Fabrication: Alloy steel plates can be easily fabricated through processes like welding, machining, and forming, making them versatile for various industrial needs.

Specifications of Alloy Steel Plate

Alloy steel plates come in a wide range of specifications to cater to different industry requirements. Common specifications include:

Thickness: Alloy steel plates typically range in thickness from 3 mm to 200 mm, depending on the application.

Width: Standard widths range from 1,500 mm to 3,500 mm.

Length: Alloy steel plates can be produced in lengths up to 12,000 mm.

Grades: Common alloy steel grades include ASTM A387, ASTM A514, ASTM A572, and more.

Standards: Plates are manufactured according to global standards such as ASTM, ASME, and EN.

Benefits of Alloy Steel Plate

Choosing alloy steel plates over regular steel or other materials comes with several benefits:

Improved Performance: Alloy steel plates outperform carbon steel plates in terms of strength, corrosion resistance, and durability, offering better long-term performance.

Cost-Efficiency: While alloy steel plates may be more expensive upfront, their long-term durability reduces maintenance costs, making them a cost-effective option.

Versatility: With customizable alloy compositions, these plates can be tailored to meet specific industry needs.

Enhanced Safety: In high-stress and hazardous environments, the strength and reliability of alloy steel plates ensure the safety and stability of structures and equipment.

Applications of Alloy Steel Plate

Alloy steel plates are used in a diverse range of industries and applications due to their outstanding properties:

Construction: Alloy steel plates are used in the construction of bridges, skyscrapers, and large industrial buildings due to their strength and durability.

Oil and Gas: Their corrosion resistance makes alloy steel plates ideal for equipment used in oil rigs, refineries, and pipelines.

Automotive and Aerospace: Alloy steel is commonly used in the manufacturing of automotive components and aerospace structures, where strength and lightness are crucial.

Mining and Earthmoving Equipment: The abrasion and wear resistance of alloy steel plates make them a perfect choice for heavy-duty machinery used in mining operations.

Power Generation: In power plants, alloy steel plates are used in boilers, pressure vessels, and heat exchangers due to their heat-resistant properties.

Why Choose Vandan Steel & Engg. Co. for Alloy Steel Plates?

When it comes to purchasing high-quality alloy steel plates, Vandan Steel & Engg. Co. is the leading name in India and worldwide. Here’s why:

Unmatched Industry Experience: With years of expertise, Vandan Steel & Engg. Co. has established itself as a reliable manufacturer, supplier, exporter, and stockist of alloy steel plates.

High-Quality Products: We are committed to providing alloy steel plates that meet international standards like ASTM and ASME, ensuring superior quality and performance.

Wide Range of Options: We offer a broad range of alloy steel plates in various sizes, grades, and specifications, ensuring we can meet the needs of any project, big or small.

Global Reach: As a leading exporter and supplier, we deliver alloy steel plates to clients worldwide, ensuring timely delivery and excellent customer service.

Competitive Pricing: At Vandan Steel & Engg. Co., we believe in offering premium quality alloy steel plates at competitive prices, ensuring you get the best value for your investment.

Conclusion

Alloy steel plates are the backbone of numerous industries, providing the strength, durability, and resistance required for demanding applications. Whether you are in construction, oil and gas, automotive, or power generation, the right alloy steel plate can make a significant difference in the performance and longevity of your projects.

For those looking for the best alloy steel plate manufacturers, suppliers, exporters, and stockists in Mumbai, India, and worldwide, look no further than Vandan Steel & Engg. Co. With our commitment to quality, extensive range of products, and exceptional customer service, we are your trusted partner for all your alloy steel plate needs.

Contact Us Today!

Phone: +91-8828813630

Email: [email protected]

Website: www.wearplates.co.in

Choose Vandan Steel & Engg. Co. for top-quality alloy steel plates and ensure your projects stand the test of time.

#Alloy Steel Plate Exporters#Alloy Steel Plate#Alloy Steel Plate Exporters in India#Alloy Steel Plate Manufacturers#Alloy Steel Plate Manufacturers in India#Alloy Steel Plate Suppliers#Alloy Steel Plate Suppliers in India#Alloy Steel Plate Stockists in India#Alloy Steel Plate Stockists#India#mumbai#vandan steel#tools#equipments#industrial tools#wearplates

1 note

·

View note

Text

Alloy Steel Sheets & Plates Suppliers

Alloy Steel Plates Supplier is defined as having 1.5% to 5% total alloy content. Its common alloying elements are manganese, silicon, chromium, nickel, molybdenum, and vanadium, which contain as many as four or five of these alloys in varying amounts. which is been used by the manufacturers who works with petrochemical industries, oil and gas industries, chemical industries, shipbuilding etc. Alloy steel wear plates is a smooth, chromium carbide rich overlay plate manufacturers and Supplier by a patented production process maximizing abrasion resistance and reducing hang up.

Alloy Steel Sheet is been designed from alloys such as chromium, molybdenum, nickel, manganese, silicon so on, they are industrial product that is generally used in various industries applications. 4130 alloy steel sheet is low-alloy steels containing chromium and molybdenum as strengthening agents. It provides good strength and toughness, weldability and machinability. Alloy steel 4340 sheet is a heat treatable low alloy steels which contains nickel, chromium, molybdenum, they are commonly used for heavy duty industrial, aerospace and automotive applications.

It has high strength and toughness in heat treated condition. 6150 alloy steel sheet is useful in heavily stressed machinery parts including gears, shafts, hand tool components and pinions. It is a fine grained, highly abrasion resistant carbon-chromium alloy steel. Alloy Steel Plates Grades are ASTM A387 Gr 5, ASTM A387 Gr 9, ASTM A387 Gr 11, ASTM A387 Gr 12, ASTM A387 Gr 22 and ASTM A387 Gr 91.

Alloy steel sheets and plates are high-strength materials that combine iron with other elements such as chromium, nickel, manganese, molybdenum, and vanadium. These alloying elements enhance various properties of steel, such as strength, hardness, toughness, and corrosion resistance. Alloy steel sheets and plates are widely used in industrial applications where high performance, durability, and wear resistance are essential.

Key Features

High Strength: Alloy steel sheets and plates can handle heavy loads and high-pressure environments.

Corrosion Resistance: Alloying elements like chromium and nickel make these plates resistant to rust and oxidation.

Wear Resistance: With elements like manganese and molybdenum, these materials are ideal for abrasive environments.

Toughness: Excellent resistance to mechanical stress and fatigue in challenging conditions.

Weldability: Modern alloy steel grades are designed to be easily weldable, even for structural applications.

Specifications

Thickness: Ranges from 3mm to over 100mm depending on the application.

Width and Length: Standard widths are 1000mm to 3000mm, and lengths can go up to 12,000mm or more.

Grades: Common grades include ASTM A387, ASTM A572, EN 10028, and AISI series steels.

Surface Finish:

Hot Rolled (HR): Suitable for structural and industrial applications.

Cold Rolled (CR): Offers a smoother finish, used for precise applications.

Standards: Products often comply with international standards like ASTM, ASME, EN, or JIS.

Advantages

Long service life in harsh conditions.

Customizable grades and compositions to meet specific application needs.

High machinability and compatibility with modern manufacturing processes.

Ability to perform well under extreme temperatures and pressures.

Common Grades and Compositions

Grade 4130: Known for high strength and low weight; used in aerospace.

Grade 4140: Offers excellent wear resistance and toughness; used in tools and machinery.

Grade A387: Designed for high-temperature environments in pressure vessels.

Chromium-Molybdenum Steels: High corrosion and heat resistance.

For more information

Contact: 9821513630 , 9321113630 , 02223861894

Address:

Office No 7, 42/46, Mughbat Lane, Shantaram Chawl, Girgaum, Mumbai - 400 004..

Email id: [email protected]

0 notes

Text

Rockstar 400 Plates Supplier in India - Convergence Steel Pvt. Ltd

Convergence Steel Pvt. Ltd. is one of the leading suppliers, and stockists of Rockstar 400, Rockstar 400 Plates, and Abrasion/Wear Resistant Steel Plates. Our Rockstar 400 steel plates are crafted for durability and resilience, meeting the highest industry standards at the best prices across India. With a commitment to quality and customer satisfaction, Convergence Steel Pvt. Ltd. ensures that each product supports industrial needs with reliability and excellence.

Discover ROCKSTAR 400 Plates, from AM/NS India ( ArcelorMittal Nippon Steel India ) has a range of martensitic steels that excel in both hardness and low alloy content. This abrasion resistant steel attains its impressive hardness through a rigorous water quenching and tempering process. ROCKSTAR Steel plates come in three nominal hardness levels: 400, 450, and 500 BHN. These plates are carefully engineered to deliver exceptional hardness, toughness, formability, and weldability, making fabrication a breeze.

The ROCKSTAR 400 Plates is an incredibly strong and durable steel plate that is specifically designed to withstand abrasion. It is perfect for applications where durability and wear resistance are of utmost importance. This plate is made from top-quality materials and is well-known for its exceptional toughness and long-lasting performance, even in the harshest operating conditions. We are the best ROCKSTAR 400 Plates stockist and supplier in Mumbai, India. It is part of the renowned Rockstar series, which is known for delivering superior performance in challenging environments.

0 notes