#ATEX ZONE 1

Explore tagged Tumblr posts

Text

Tech Evolution in Oil & Gas for Health & Safety Measures

Labourers in the worldwide oil and gas industry are presented with outrageous physical and mental difficulties in conditions with severe security risks. In addition, safety and health regulations have become more stringent, and organisations that do not adhere to them risk severe penalties, legal action, and negative publicity.

According to the Occupational Safety and Health Administration (OSHA), the oil and gas industry has a seven times higher fatality rate that of all the other industries, demonstrating the health and safety hazards for workers if proper procedures are not followed.

Oil and gas sites host several heavy machinery, masts and rigs, stored hazardous chemicals, and highly flammable by-products. The well-being of the workers relies on the self-awareness and managerial efficiency of the industry.

Additionally, accidents in the oil and gas industry can also be costly from a business perspective. Twenty-one thousand eight hundred ninety-nine days of work were lost due to injuries in the companies that took part in the study, according to the IOGP report. There are a lot of fast-moving vehicles, machinery, and equipment in factories and plants worldwide, which could put frontline workers in danger.

Accidents continue to occur frequently, mostly involving younger workers with less experience, despite the existence of safety and compliance regulations. The International Labour Organization estimates that 313 million on-the-job accidents result in prolonged absences from work each year, resulting in a $3 trillion economic loss to the global economy.

"Digital transformation can make Oil and Gas companies more profitable, increase worker safety, help society by reducing emissions and water use, and save customers money."

Key Challenges to Health and Safety at Oil and Gas Industry Fatalities

"Caught in, under, or between" incidents, which exclude incidents involving dropped objects, accounted for most deaths in the oil and gas industry. Twelve people died in 2019 due to incidents that were "caught in, under, or between." Despite a decline in fatalities, there is still a steep incline in the frequency of accidents every year. Such incidents and the resulting injuries and fatalities harm the industry's reputation while inflicting significant emotional and psychological trauma on the victims and their loved ones.

Workers must receive training to understand the risks of falling, falling into confined spaces, being stuck or pulled into by machinery, electrical hazards, explosions, chemical exposure, and potential vehicular accidents. Workers' health risks include hearing impairment, frostbite, severe burns, respiratory problems, acute fatigue, and harm caused by moving heavy cargo and extreme work environments, often in remote locations. Workers must also be capable of handling so-called “fly in, fly out” procedures, which require them to travel to far-flung places for predetermined periods and work long shifts.

Latest Technological Trends to Promote Health and Safety in the Oil and Gas Industry

Explosion-Proof Technology

One of the key reasons for industrial explosions is system malfunction and electrical issues in the equipment used. Owing to the explosive environment of hazardous industries like oil and gas, even the smallest spark contacting the atmosphere can result in a huge explosion. Thus, modern oil and gas industries require advanced surveillance and safety solutions. Ex-proof technology for cameras and lights helps contain the sparks inside the wiring of the device and helps avoid fatal explosions and accidents. With continuous R&D, the current ex-proof market offers a range of explosion-proof lights and oil and gas video surveillance options to suit your diverse needs based on industrial size, purpose, etc.

Big Data and AI Automation

Industries today are actively adopting advanced analytics through big data and AI automation. Particularly in the oil and gas sector, big data uses customised predictive models to assist the analysts in getting insights from the unstructured real-time data to optimise safety, production, and performance. Integration of AI in data analytics further automates the process. For instance, advanced AI integrations in explosion-proof cameras enable instant identification of trespassers, reducing the risk of theft. Additionally, AI technology in oil and gas industry can help in smart detection of potential malpractices amidst 150+ camera feeds. This smart detection is also useful in verifying false alarms and saving valuable time and resources during daily operations. Overall, through enhanced operational efficiency, use of Big Data and AI directly contribute to higher return on investment (ROI) for global oil and gas industries.

Robotics and Drones

A recent step-up for the oil and gas industry, robotics and drones have become a popular choice for minimising the shortcomings of human resources. The global market for robotics and automation in oil and gas was valued at USD 16.5 billion in 2022 and projected to reach USD 24.7 billion by 2030. Robots are primarily employed for inspection and surveillance in key hazardous zones to minimise the chances of human error, automate the operations, and reduce the liability costs in case of accidents. Additionally, drones are employed for inspecting inaccessible areas, particularly the off-shore sites, where there is a higher risk for fatalities. Thus, drones and robots enhance safety and efficiency significantly in the oil and gas sector by minimising the role of human crew in high-risk operations.

IoT-Based Monitoring

Internet of Things (IoT) technology has transformed the way oil and gas industries perceive “efficient operations”. IoT sensors provide real-time data about potential leaks and system malfunctions, enabling managers to ensure minimum-risk operations through remote monitoring. The IoT data provides real-time insights without exposing the crew to high-risk environments, optimising resource management and saving business costs involved in anomalies. Today, IoT-based monitoring is used for several purposes in the oil and gas industries, including, monitoring of pumps, pipes, and filters to avoid costly leaks and give workers a better sense of control over their operational performance.

AR and VR Integration in Operations

A study by McKinsey on the oil and gas sector reveals a 25% cost-cut per barrel by adopting digital solutions like augmented reality (AR) and virtual reality (VR). For enhanced maintenance, several oil and gas industrialists adopt AR solutions like AR headsets for remote monitoring and hands-free instructions to replace lengthy manuals with engaging graphical data. Additionally, VR headsets provide training to the crew in simulations instead of live hazardous environments, reducing on-site casualties and optimising safety training in the oil and gas industry.

Cloud Computing

The adoption of cloud computing technology in the oil and gas industry is a highly recommended solution by industry experts to efficiently handle the large volume of raw data that these industrial sites receive daily. Storing and processing data remotely frees local memory and expands the device’s computation capacity. This enhances the efficiency, security, and scalability of every day operations at the oil and gas industry.

Blockchain Technology

Web3 is a relatively new technological trend that is gradually getting integrated into hazardous industrial sectors like oil and gas. The transparency of the blockchain technology of web3 is key to its rapid adoption for a multitude of purposes. When translated to the oil and gas industry, blockchain technology can enhance security and transparency in digital transactions and official documentation through smart contracts. This added layer of transparency significantly improves business communication, resolves legal disputes, and builds trust in the ethical practices of a company. Thus, experts believe blockchain technology is key to sustaining business relations in the upcoming years.

Importance of Technology in the Oil and Gas Industry

Enhanced Efficiency

Through technological evolution, the security standards and worker safety measures in oil and gas industries have found their new apex. Where AI enables system optimisation, IoT can provide a real-time data feed, and smart video analytics reduce the system clutter and make operations significantly more efficient than traditional systems.

Optimised Safety

Smart detection of hazards and adverse situations counters the manual shortcomings in monitoring and surveillance to create a safer work environment in hazardous industries by making them less prone to accidents and liabilities caused by fatigue and human error.

Reduced Business Costs

As discussed above, modern technological integrations significantly reduce the business costs of the oil and industry. Multitude of integrations co-create safer work environments either through automation or remote monitoring. Besides the direct cost of damages and compensations, technological advancement in the oil and gas industry helps prevent indirect costs like legal proceedings, training of human resources, etc.

Sustainable Solutions

Modern technology serves a larger purpose of sustainability by reducing the emissions through AI, IoT, and big data analytics. By identifying the triggers for accidents beforehand, technology controls explosions and its resulting adverse impact on the environment as well as crew health and well-being.

Pick the Right Safety Partners for Reliable Safety Solutions

Safe environment begins with right investment. Partnering with the right safety partners is necessary for reliable safety and efficiency solutions. Before investing in technological upgrades, ensure that the products are certified to sustain the rigorous environmental challenges of the oil and gas industry.

SharpEagle’s explosion-proof camera for oil and gas industries comes with an ATEX Camera certification, marking the quality and excellence of our safety and efficiency products. The resilient design of our hazardous area camera systems can withstand the dire temperatures of the working areas. The ATEX certification ensures 360-degree protection without baseless claims and unreliable tests.

The discussion above clearly displays the dynamic shift in the industry and how technology has transformed safety and risk management in the oil and gas industry. At SharpEagle, we are an end-to-end safety solutions provider. Our expert team guides you at every step, from site inspection and recommendations to manufacturing, installation, and maintenance. Choose from a customised range of explosion-proof CCTV, lighting, and other solutions. Book a free consultation call with SharpEagle, the leading ex-proof safety solutions provider, to learn more about all the latest updates and products for the oil and gas industry.

You can also call us at +971-45549547 or mail us at [email protected]

#atex camera#atex cctv#atex certified camera#atex rated camera#atex zone 1 camera#camera explosion proof#ex camera zone 1#ex proof camera#Explosion proof camera#explosion proof camera for oil and gas#explosion proof cctv camera#explosion proof dome camera#explosion proof ip camera#explosion proof ptz camera#explosion proof video camera#explosion protected camera#fixed bullet camera#flameproof camera#Hazardous Area Camera#oil and gas surveillance

0 notes

Text

Peace of Mind in Hazardous Areas: The ATEX Zone 1 iPhone

The world of work thrives on constant connection. But in Zone 1 environments – areas with a high risk of explosive gas, vapor, or mist – traditional smartphones pose a significant threat. A single spark could ignite a catastrophic event. The ATEX Zone 1 iPhone emerges as a groundbreaking solution, offering unparalleled peace of mind for workers and employers alike.

Intrinsically Safe Design, Uncompromised Functionality:

Unlike a standard iPhone, the ATEX Zone 1 model prioritizes safety above all else. It adheres to stringent ATEX (ATmosphères Explosibles) directives, ensuring its design and operation minimize the risk of sparks or heat generation. This intrinsically safe construction allows workers to connect and collaborate within hazardous areas without compromising safety.

Peace of Mind for Employers, Confidence for Workers:

The ATEX Zone 1 iPhone empowers employers with a reliable communication tool for Zone 1 environments. Real-time communication with personnel fosters improved coordination, task management, and emergency response. Knowing their workers have a safe and reliable way to stay connected translates to significant peace of mind.

For workers, the ATEX Zone 1 iPhone eliminates the anxiety associated with limited communication in hazardous zones. The ability to make and receive calls, access critical information, and even capture vital data through photos and videos fosters a sense of confidence and preparedness.

Beyond Communication: A Mobile Hub for Efficiency:

The ATEX Zone 1 iPhone goes beyond simply being a safe phone. It serves as a mobile hub for enhanced efficiency in hazardous areas. Digital forms, checklists, and maintenance schedules can be readily accessed, eliminating cumbersome paperwork and streamlining workflows. Integration with specialized apps allows for real-time data collection and analysis, facilitating informed decision-making.

Rugged Reliability for Demanding Environments:

Zone 1 environments are often harsh and unforgiving. The ATEX Zone 1 iPhone is built to withstand the challenge. Its robust design boasts exceptional durability against dust, water, and extreme temperatures. The shatter-resistant screen ensures continued functionality even when dropped or jostled during on-site operations.

Investing in a Safer Future:

The ATEX Zone 1 iPhone signifies a commitment to a future where safety and connectivity go hand-in-hand. This innovative device empowers employers to prioritize worker safety and streamline operations in hazardous areas. For workers, it offers a reliable communication tool and enhances efficiency, fostering a sense of security and confidence. The ATEX Zone 1 iPhone is more than a phone; it's peace of mind for everyone involved.

—-------------------------------------------------------------------------------------------------------------------

Reliable Mobility, Certified Safety: The iPhone 14 ATEX Experience

The modern workforce demands constant connection, even in challenging environments. For professionals working in Zone 2 hazardous areas – locations with a potential presence of flammable gases or vapors – traditional smartphones pose a significant risk. The iPhone 14 ATEX emerges as a groundbreaking solution, offering a perfect blend of reliable mobility and certified safety.

Uncompromised Functionality in a Safe Package:

The iPhone 14 ATEX takes the innovative features of the iPhone 14 and adapts them for Zone 2 environments. This intrinsically safe device adheres to stringent ATEX (ATmosphères Explosibles) directives. Its meticulously designed and certified construction minimizes the risk of sparks or heat generation, ensuring user safety remains paramount. Workers can leverage the familiar iPhone experience – making and receiving calls, accessing critical information, and utilizing essential apps – without compromising safety protocols.

Peace of Mind for Employers, Confidence for Workers:

The iPhone 14 ATEX empowers employers with a reliable communication tool for Zone 2 environments. Real-time communication with personnel fosters improved coordination, task management, and streamlined emergency response procedures. Knowing their workers have a safe and reliable way to stay connected translates to significant peace of mind.

For workers, the iPhone 14 ATEX eliminates the anxiety associated with limited communication in hazardous zones. The ability to access vital data, capture photos and videos for documentation, and collaborate seamlessly with colleagues fosters a sense of confidence and preparedness.

Enhanced Efficiency Through Mobile Integration:

The iPhone 14 ATEX goes beyond just being a safe phone. It serves as a mobile hub for enhanced efficiency in Zone 2 environments. Digital forms, safety manuals, and maintenance schedules can be readily accessed on the device, eliminating the need for bulky paperwork. Integration with specialized apps allows for real-time data collection and analysis, facilitating informed decision-making on the go.

Rugged Durability for Demanding Workflows:

Zone 2 environments can be harsh. The iPhone 14 ATEX is built to withstand the challenge. Its robust design boasts exceptional durability against dust, water, and extreme temperatures. The shatter-resistant screen ensures continued functionality even when dropped or jostled during on-site operations.

Investing in a Connected and Safe Future:

The iPhone 14 ATEX signifies a commitment to a future where connectivity and safety go hand-in-hand. This innovative device empowers employers to prioritize worker safety while optimizing operations in hazardous areas. For workers, it offers a reliable communication tool, enhances efficiency, and fosters a sense of security and confidence. The iPhone 14 ATEX doesn't just offer a phone; it provides a safe and connected experience in demanding environments.

0 notes

Text

Revolutionizing Safety in Qatar: JGBQatar, Your Trusted Supplier of Explosion-Proof Equipment

Protecting both human personnel and equipment within dangerous workplace conditions remains critical for safety purposes in hazardous industries. Safety measures in Qatar need to meet the highest standards because this country operates three major sectors that create hazardous conditions. These environments require explosion-proof equipment since they present increased risks of fire and explosion, together with electrical failure possibilities. JGB Qatar serves as a top supplier through its reliable explosion-proof solutions that address specific requirements across the Qatar market.

Who is JGBQatar?

We operate as a top supplier of industrial explosion-proof equipment throughout Qatar and develop innovative safety products to shield workers from explosions in dangerous operational environments. We dedicate its extensive product range and certified equipment standards to deliver international safety standards, which include electrical components and lighting junction boxes and enclosures as well as other products.

We specialize in creating specialized solutions that address the unique needs of clients operating in the oil & gas and chemical plant industries, as well as mining and marine activities. The company stands out through premium-standard products as well as exceptional service quality and swift delivery of expert solutions.

Why Is Explosion-proof Equipment Essential In Qatar?

The industrial areas of Qatar include different hazardous operating areas that professionals must address. High concentrations of flammable gases and dust exist constantly among the oil and gas fields in addition to power plants and refineries. A single electrical malfunction or small spark inside these environments leads directly to disastrous outcomes.

Deliberately conceived explosion-proof equipment safeguards against every potential hazard that volatile chemicals might trigger through enhancement of catastrophe suppression abilities. The product design features elements that safely function under hazardous environments while containing sparks alongside electrical arcs and heat to prevent explosions.

The aggressive construction growth in Qatar demands strict safety standards because these measures boost operational performance and protect the nation's industrial reputation. We stand alone as a leading supplier of modern explosion-proof equipment, which represents absolute importance for safe facilities.

Explosion-Proof Products Offered by JGBQatar

Customers can find an array of explosion-proof products that have been rigorously tested and certified to meet international standards such as ATEX (European), IECEx (international), and UL (United States). Here’s a closer look at the types of products they offer:

1. Explosion-Proof Lighting

The lighting system in hazardous areas needs to provide strong functioning reliability. Explosion-proof lights from We can operate through extreme temperatures as well as resist corrosion and mechanical forces. Explosion-proof lights from we employed throughout many industries, including oil and gas operations, to supply safe lighting in flammable gas zones.

2. Explosion-Proof Electrical Junction Boxes

Junction boxes represent essential parts of electrical systems operating within hazardous areas. We develop explosion-proof junction boxes to block electrical sparks along with faults that prevent explosive conditions in high-risk electrical systems.

3. Explosion-Proof Enclosures

Electrical and mechanical equipment gets protection against external threats through enclosure systems that resist explosions. The enclosures provide essential safety measures for preventing dangers during operations that handle combustible materials at petrochemical plants or refineries. The enclosures from We deliver enduring solutions that guard equipment against severe environmental challenges.

4. Explosion-Proof Cable Glands

Sealing electrical cables requires cable glands to serve as protection against explosive dangers. The explosion-proof cable glands selected by Us create secure electrical connections that stop dangerous substances from leaking while maintaining proper system operation even in explosive environments.

5. Explosion-Proof Motors

The selection of motors for hazardous zones demands special attention because these motors should prevent ignition occurrences. The explosion-proof motors from JGBQatar are built to survive harsh conditions where they prevent both mechanical breakdowns and overheating, capable of producing hazardous sparks or fire outbreaks.

Why Choose JGBQatar as Your Explosion-Proof Equipment Supplier?

1. Industry Expertise

Our experienced team understands the complete characteristics of dangerous operational environments through their extensive fieldwork. Our implements customized solutions because their comprehensive expertise helps them adapt to individual sector needs.

2. Quality and Compliance

We produce products that meet international standards to guarantee reliable and safe operation under hazardous environments. The company partners with major manufacturers to supply equipment with safety standards from across the world that follows regulatory compliance requirements.

3. Customized Solutions

Every industrial establishment faces different demands regarding explosion-proof solutions. The custom solution department specializes in designing safety measures and equipment selection that adheres to the individual needs of each client.

4. Reliable Customer Service

As part of their service, we deliver products together with premium support for consultation all the way through to post-purchase service. Through customer involvement, our team operates in unison to guarantee successful installation and operation of explosion-proof equipment, which results in safe and efficient operations.

5. Fast Delivery

The criticality of operational safety drives is to provide fast and effective delivery of products to all its clients throughout Qatar. relies on their extensive network and optimized delivery system to provide businesses with dependable, rapid solutions.

The Safety You Deserve with JGBQatar

Protection through explosion-proof equipment enhances both security requirements and ensures safety for all people. Through their dedication to supplying advanced explosion-proof equipment, JGBQatar provides assurance to Qatar industry operators about their safety in dangerous situations. We serve as your dependable source for all essential workplace safety products that include lighting products and junction boxes alongside enclosures.

Our customer support team, along with viewing their website for more details about their explosion-proof solutions.

0 notes

Text

How to Choose the Right Flame Proof Motor for Your Industrial Needs in India

In industries operating in hazardous environments such as oil and gas, chemical plants, pharmaceuticals, and mining, ensuring safety and operational efficiency is paramount. Flame-proof motors play a critical role in these settings, especially in India, where stringent safety standards and diverse industrial demands exist. These motors are designed to contain any internal ignition, preventing it from igniting the surrounding atmosphere and ensuring workplace safety.

Choosing the right flame-proof motor for your industrial needs in India requires careful consideration of various factors, from compliance with local standards to performance and durability. This article provides an SEO-friendly guide tailored to the Indian context to help you make an informed decision.

Understanding Flame Proof Motors

Flame-proof motors are a type of explosion-proof motor specifically designed for hazardous areas. Their robust construction and advanced engineering prevent sparks or explosions inside the motor from spreading to the external environment. These motors are commonly used in India across industries like refineries, fertilizer plants, and chemical manufacturing facilities.

Key Factors to Consider When Choosing a Flame Proof Motor in India

1. Assess the Hazardous Environment

Understanding the specific conditions of the hazardous environment is the first step in selecting the right flame-proof motor.

Zone Classifications: India follows the International Electrotechnical Commission (IEC) standards for hazardous area classifications. Determine whether your site is Zone 1 or Zone 2, indicating the likelihood of explosive gases being present.

Gas Group Classification: Identify the group classification of the hazardous substance (e.g., IIA, IIB, or IIC), as it affects the motor’s design and enclosure requirements.

Temperature Class: Consider the T-class rating of the motor to ensure it matches the ignition temperature of flammable substances present at the site.

These details help you narrow down your options to motors certified for Indian hazardous environments.

2. Ensure Compliance with Indian Standards

In India, flame-proof motors must adhere to specific safety certifications and standards, including:

BIS Certification: Motors certified by the Bureau of Indian Standards (BIS) ensure compliance with national safety regulations.

IECEx and ATEX: International certifications are also widely accepted, especially for export-oriented industries in India.

Petroleum and Explosives Safety Organization (PESO): Ensure the motor complies with PESO standards, particularly for use in petrochemical and oil industries.

Choosing a certified motor guarantees safety and regulatory compliance, reducing risks and liabilities.

3. Evaluate Power and Performance Needs

Selecting a motor with the right power and performance specifications is crucial for seamless operations.

Horsepower (HP) or Kilowatt (kW): Match the motor’s power output to the requirements of the machinery or equipment it powers.

Speed (RPM): Choose a motor that delivers consistent performance under varying loads.

Efficiency Standards: Opt for energy-efficient motors (e.g., IE2, IE3, or IE4) to minimize operational costs and meet India's growing focus on energy conservation.

4. Material and Durability

The motor’s construction and materials should withstand the harsh conditions of industrial environments in India.

Enclosure Material: Select motors with cast iron or stainless steel enclosures for durability and resistance to corrosion.

Ingress Protection (IP) Rating: Check for an IP rating of IP55 or higher to ensure resistance to dust, moisture, and environmental contaminants.

Anti-Corrosive Coatings: These are especially important for industries located in coastal areas or dealing with corrosive substances.

5. Maintenance and Serviceability

Ease of maintenance is a significant factor in Indian industries, where downtime can lead to high costs.

Accessible Design: Motors with easy-to-remove covers and modular components simplify routine maintenance and repairs.

Local Availability of Parts: Choose a motor from a manufacturer with a strong service network in India to ensure quick access to spare parts and technical support.

6. Environmental and Operational Conditions

Consider the specific environmental conditions in which the motor will operate.

Ambient Temperature: Ensure the motor can function efficiently in India’s diverse climate, from extreme heat in Rajasthan to high humidity in Kerala.

Dust and Water Resistance: Motors in mining or construction industries should have high resistance to dust and water ingress.

7. Cost vs. Value

While cost is a significant factor in any industrial purchase, focus on the long-term value of the motor.

Initial Investment: High-quality flame-proof motors may have a higher upfront cost but offer durability and reliability.

Operational Savings: Energy-efficient motors reduce electricity bills, while durable designs lower maintenance costs over time.

Why Flame Proof Motors Are Crucial for Indian Industries

India’s industrial growth, particularly in sectors like oil and gas, pharmaceuticals, and mining, demands robust safety measures. Flame-proof motors ensure compliance with safety standards, protect personnel and equipment, and maintain operational efficiency in hazardous environments.

Conclusion

Choosing the right flame proof motors for your industrial needs in India involves evaluating hazardous area classifications, ensuring compliance with BIS and PESO standards, and considering performance, durability, and cost. By selecting a motor tailored to your industry’s requirements, you can achieve safety, efficiency, and long-term reliability.

Flame-proof motors are not just a safety measure—they are a critical investment in ensuring smooth operations and adherence to India’s stringent safety regulations. With the right motor, your industrial facility can enhance productivity while minimizing risks.

0 notes

Text

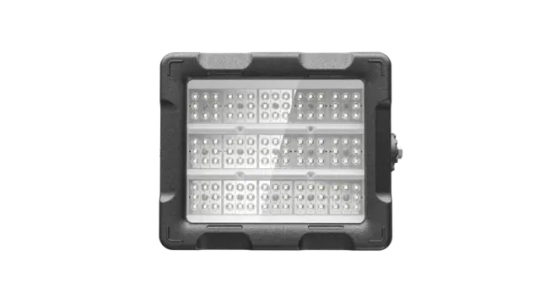

Explosion Proof 60W LED Linear Light, this ATEX certified luminaire is suitable for use in many hazardous areas. Quality construction using Bridglux LEDs lifud Driver.

Available in 40W, 60W and 80W! Connect with us now for more details.

0 notes

Text

Explosion Proof Smartphones: Features, Benefits, and Industry Applications

In today's interconnected world, smartphones have become an essential tool for professionals across a wide range of industries. However, in specific sectors like oil and gas, mining, chemical plants, and other hazardous environments, using standard smartphones can pose serious safety risks. The possibility of an explosion in areas with combustible gases, dust, or flammable liquids is a constant threat. This is where Explosion Proof Smartphones come into play. These specialized devices are engineered to withstand such conditions, offering safety without compromising the advanced features of modern technology. In this blog, we'll explore the features, benefits, and industry applications of explosion-proof smartphones, and why they are a critical innovation for many businesses.

What is an Explosion Proof Smartphone?

An Explosion Proof Smartphone is a rugged mobile device designed to prevent ignition of flammable materials in hazardous environments. These smartphones are built with strict adherence to safety standards, including certification by bodies like ATEX (Atmospheres Explosibles) and IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres). They are encased in materials that can resist high temperatures, sparks, or electrical discharge—factors that could potentially ignite hazardous substances in certain industries.

Unlike conventional smartphones, explosion-proof devices are specially designed with reinforced housings and shielded circuitry. Their construction prevents any part of the phone from releasing enough energy to cause an explosion, even when exposed to high-risk materials like gas, vapors, or dust.

Key Features of Explosion Proof Smartphones

ATEX and IECEx Certifications The most significant feature of an explosion-proof smartphone is its certification. ATEX and IECEx certifications are globally recognized and ensure that the device has been tested and proven safe for use in explosive environments. The phone’s rating depends on the level of danger in the specific area of use. For example, a Zone 1 or Class I, Division 1 rated phone is designed for areas where explosive atmospheres are likely to occur in normal operation.

Rugged Construction Explosion-proof smartphones are typically more rugged than standard smartphones. They are built to survive drops, exposure to dust, extreme temperatures, and even submersion in water. Their robust outer casing is made from materials like stainless steel or hardened plastic, offering excellent resistance against impact and corrosion. These devices are also designed to function in temperature extremes, making them ideal for industrial settings with fluctuating conditions.

Touchscreen Sensitivity with Gloves Many hazardous environments require workers to wear gloves for safety. Explosion-proof smartphones often come equipped with touchscreens that work even when gloves are worn, ensuring seamless use without removing protective gear.

Long Battery Life Since many industrial professionals work long shifts, explosion-proof smartphones are engineered with extended battery life to ensure consistent operation throughout the day. The devices often include energy-efficient features to reduce battery drain, even when used intensively for communication or data transfer.

Advanced Communication Features Explosion-proof smartphones are not just rugged—they come equipped with many of the advanced communication features found in regular smartphones, including 4G LTE connectivity, Bluetooth, GPS, and Wi-Fi. These features allow workers to stay connected with their teams, access critical information, and even send real-time reports from the field.

Integrated Cameras and Barcode Scanners In industries like oil and gas, photography and documentation are often essential. Many explosion-proof smartphones come with high-resolution cameras and barcode scanning capabilities, allowing workers to capture and share images or data without additional equipment.

Benefits of Explosion Proof Smartphones

Enhanced Safety in Hazardous Environments The primary benefit of using an Explosion Proof Smartphone is the safety it provides in hazardous locations. Standard smartphones pose a risk of igniting flammable gases or dust particles, but explosion-proof devices are specifically engineered to eliminate this risk. This ensures the safety of both workers and the environment, reducing the likelihood of catastrophic accidents.

Improved Communication and Efficiency Explosion-proof smartphones allow seamless communication in areas where traditional phones would be unsafe. In industries that operate in high-risk environments, constant communication is crucial for maintaining productivity and ensuring that work processes are carried out safely. With explosion-proof smartphones, workers can remain connected via voice, video, or data, regardless of the environmental conditions.

Data Collection and Remote Access Many explosion-proof smartphones support software applications that allow workers to collect and share data, access cloud-based systems, and monitor equipment remotely. This is particularly useful in industries like oil and gas, where machinery and pipelines are often monitored from remote locations. The ability to input and retrieve real-time data without needing to leave hazardous zones improves workflow and decision-making.

Durability for Tough Conditions Traditional smartphones are not designed to withstand the harsh environments found in industrial settings, which can lead to frequent damage and replacements. Explosion-proof smartphones, on the other hand, are built to endure the toughest conditions. Their rugged design means they can handle drops, exposure to water, extreme temperatures, and dust—providing long-lasting reliability and reducing the need for constant repairs or replacements.

Compliance with Industry Regulations Many industries, such as oil and gas or chemical plants, are bound by strict safety regulations that prohibit the use of non-explosion-proof electronics. By equipping workers with certified explosion-proof smartphones, companies can ensure they are complying with industry standards and safety regulations, avoiding legal and financial penalties.

Industry Applications of Explosion Proof Smartphones

Oil and Gas Industry One of the most common applications of Explosion Proof Smartphones is in the oil and gas sector. In these industries, workers are frequently exposed to environments filled with flammable gases and vapors, making it essential to use equipment that won’t trigger explosions. Explosion-proof smartphones allow for safe communication and data management in both onshore and offshore facilities, from refineries to drilling rigs.

Chemical Plants Chemical plants are another industry where explosion-proof smartphones are widely used. These plants often handle volatile substances that require careful management and monitoring. Workers can use explosion-proof smartphones to log data, take photos of equipment, or communicate in real-time without the risk of causing an explosion.

Mining Operations In mining, the risk of gas explosions is high, particularly in coal mines where methane gas can accumulate. Explosion-proof smartphones are used in these environments to enhance safety, allowing workers to communicate underground while ensuring that the equipment won’t ignite combustible gases.

Pharmaceutical Manufacturing Even in industries like pharmaceutical manufacturing, where flammable chemicals are used in the production of medications, explosion-proof smartphones provide a safe way to track production processes and maintain open communication between different departments.

Conclusion

Explosion-proof smartphones are an essential tool for industries that operate in hazardous environments. With their ATEX and IECEx certifications, rugged designs, and advanced communication features, these devices ensure the safety of workers and facilities while maintaining efficiency and connectivity. From the oil and gas industry to chemical plants and mining operations, the adoption of explosion-proof smartphones is a step toward safer, more productive workplaces. For businesses operating in such high-risk environments, investing in an Explosion Proof Smartphone is not just a smart choice—it’s a necessary one.

0 notes

Text

فروش فلومتر اندرس PROMASS 60 DN01 *دارای نمایشگر بر روی بدنه *خروجی سیگنال: پالس و HART *متریال : استنلیس استیل *تاییدیهها: EEx d/EEx de IIC, Zone 1 / ATEX II2G (مناسب برای محیطهای خطرناک) ...... مهندس رضا تاج تلفن تماس: 09151211239 وبسایت: www.ehyagran.ir ایمیل: [email protected] ......... #فلومتر #ابزاردقیق #instrumentation #اتوماسیون_صنعتی #کالیبراسیون #کالیبراسیون_فلومتر #نیروگاه #پالایشگاه #ایران#آبادان #جریان_سنج #کارخانه #خط_تولید #flowmeter ................

0 notes

Text

Hazardous Area Cable Glands: Ensuring Safety in Explosive Environments

What are Hazardous Area Cable Glands?

Hazardous Area Cable Glands are specialized fittings designed to protect electrical cables in environments where flammable gases or vapors are present. These areas, often referred to as "hazardous zones," pose a significant risk of explosion due to the potential ignition of these gases.

Key Features of Hazardous Area Cable Glands

Flameproof Design: These glands are engineered to withstand an explosion without igniting the surrounding atmosphere.

Certification: They must meet specific industry standards and certifications, such as ATEX or IECEx, to ensure their effectiveness.

Ingress Protection (IP) Ratings: Hazardous area cable glands typically have high IP ratings to protect against dust and water ingress.

Temperature Resistance: They are designed to withstand high temperatures to prevent the ignition of flammable gases.

Applications of Hazardous Area Cable Glands

Oil and Gas Industry: Offshore platforms, refineries, and petrochemical plants rely on these glands to protect electrical connections in areas where flammable gases are present.

Chemical Industry: Chemical processing plants often operate with hazardous materials, making hazardous area cable glands essential for safety.

Mining Industry: Underground mines can be prone to methane gas buildup, necessitating the use of these glands to prevent explosions.

Power Generation: Power plants, especially those using fossil fuels, may encounter hazardous areas where these glands are required.

Benefits of Using Hazardous Area Cable Glands

Enhanced Safety: By preventing the ignition of flammable gases, these glands significantly reduce the risk of explosions and fires.

Regulatory Compliance: Using certified hazardous area cable glands ensures compliance with industry standards and regulations, helping to avoid fines and penalties.

Protection of Electrical Equipment: These glands safeguard electrical cables and equipment from damage caused by explosions.

Increased Reliability: By maintaining the integrity of electrical connections, hazardous area cable glands contribute to the overall reliability of operations.

Selecting the Right Hazardous Area Cable Gland

When choosing hazardous area cable glands, consider the following factors:

Hazardous Area Classification: The gland's certification should match the specific hazardous area classification (e.g., Zone 0, Zone 1, Zone 2).

Cable Type and Size: The gland must be compatible with the cable being used.

Environmental Conditions: Factors like temperature, humidity, and corrosive substances may influence the gland's selection.

Ingress Protection Rating: Choose a gland with an appropriate IP rating based on the level of protection required.

Conclusion

Hazardous area cable glands are essential components in environments where flammable gases or vapors are present. By understanding their features, applications, and benefits, you can make informed decisions about their use in your specific industry.

0 notes

Text

The Complete Guide to Hiring a Hazardous Area Electrician

When dealing with electrical systems in environments that pose potential dangers, such as factories, oil refineries, or chemical plants, safety is paramount. A specialized type of professional, known as a hazardous area electrician, is trained to manage and mitigate risks in these settings. In this guide, we will explore the roles, responsibilities, and significance of hazardous area electricians, the challenges they face, and offer a step-by-step guide to understanding their importance. We will also present a case study to provide real-world insights into how they operate.

Understanding Hazardous Area Electricians

What Is a Hazardous Area Electrician?

A hazardous area electrician is a licensed professional trained to work in environments where there is a risk of fire, explosion, or other safety concerns. These electricians specialize in installing, maintaining, and repairing electrical equipment in areas that contain flammable gases, vapors, or dust. Hazardous environments can include oil and gas refineries, chemical plants, mining operations, and grain storage facilities.

Why Are Hazardous Area Electricians Important?

The importance of hazardous area electricians cannot be overstated. These professionals are vital for ensuring that the electrical systems in dangerous areas are safe, reliable, and compliant with strict safety regulations. Without their expertise, the risks of explosions or accidents increase significantly, endangering lives and property.

Key Responsibilities of a Hazardous Area Electrician

Installations in Hazardous Zones: These electricians install equipment in hazardous areas to ensure that it meets explosion-proof or intrinsically safe standards.

Maintenance and Repairs: Hazardous area electricians maintain and repair equipment that could be compromised by dust, gases, or vapors.

Compliance with Regulations: They ensure that installations comply with regulations like ATEX, IECEx, and other international standards.

Inspections and Safety Assessments: A large part of their role involves conducting safety inspections and risk assessments to guarantee that installations remain compliant and hazard-free.

Common Misconceptions About Hazardous Area Electricians

1. Hazardous Area Electricians Only Work in Factories

While factories and industrial plants are common workplaces for hazardous area electricians, their expertise extends to any environment that could be dangerous due to the presence of explosive materials. This includes refineries, mines, and even some food processing plants.

2. Any Electrician Can Do This Job

Not true. Hazardous area electricians undergo specialized training and obtain certifications that equip them to work in explosive and high-risk environments. They are not your typical residential or commercial electricians.

Unique Topics That Everyone Should Know

1. The Importance of Explosion-Proof Equipment in Hazardous Areas

One of the most crucial aspects of working in hazardous areas is the use of explosion-proof equipment. Regular electrical devices can spark and cause an explosion if they are installed in areas with combustible dust or gases. A hazardous area electrician is responsible for installing explosion-proof equipment to prevent any catastrophic incidents. They ensure that the equipment adheres to strict safety standards that minimize the risk of ignition.

2. The Certification Process: What Sets a Hazardous Area Electrician Apart

Before an electrician can work in hazardous environments, they must undergo a rigorous certification process. These certifications (like ATEX in Europe or IECEx globally) ensure that the electrician understands the specific requirements and safety protocols needed to work safely in dangerous environments. It’s important to hire a hazardous area electrician with the proper certification to avoid compliance issues or safety risks.

3. How Hazardous Area Electricians Ensure Safety and Compliance

Hazardous area electricians follow strict guidelines and use specialized equipment to prevent accidents. They carry out regular safety inspections and risk assessments to identify potential hazards. Their expertise in selecting the right materials and ensuring proper grounding helps keep high-risk zones safe for workers and equipment.

Challenges in Hazardous Area Electrical Work

1. Navigating Complex Safety Standards

One of the biggest challenges faced by hazardous area electricians is navigating complex safety standards. Every hazardous area has unique characteristics, and electricians must ensure that the right precautions are in place for each scenario. Failure to adhere to these standards can result in accidents, regulatory penalties, and damage to equipment.

2. Handling High-Stress Situations

Working in hazardous environments often means facing high-stress situations. Electricians need to remain calm and make critical decisions under pressure, particularly when systems malfunction or pose an immediate danger. Their ability to maintain composure and solve problems quickly is essential for preventing disaster.

3. Limited Room for Error

The margin for error in hazardous environments is extremely small. A single mistake can lead to catastrophic consequences, such as explosions or fires. Hazardous area electricians must double-check their work, be vigilant in adhering to protocols, and perform meticulous inspections to ensure that nothing is overlooked.

4. Specialized Training and Knowledge

Becoming a hazardous area electrician requires ongoing education. The field is constantly evolving, and electricians must stay up-to-date with the latest safety regulations, technological advancements, and equipment innovations. This constant learning curve can be a challenge, but it is essential for maintaining safety and efficiency.

Step-by-Step Guide to Working with a Hazardous Area Electrician

Step 1: Identifying Hazardous Zones

Before you hire a hazardous area electrician, you need to determine if your workplace is classified as a hazardous zone. This classification is typically defined by safety standards such as ATEX or IECEx, depending on your region. Hazardous zones are categorized based on the likelihood and duration of hazardous materials (gases, vapors, or dust) being present.

Step 2: Hiring a Certified Hazardous Area Electrician

Ensure that the electrician you hire holds the necessary certifications. Ask for proof of training and experience, as well as references from previous projects. It is crucial to hire someone who has a solid understanding of the specific risks in your environment.

Step 3: Conducting a Risk Assessment

Once you’ve hired a hazardous area electrician, the next step is to conduct a thorough risk assessment. The electrician will evaluate the environment, identify potential hazards, and recommend the appropriate explosion-proof equipment and safety measures.

Step 4: Installation and Implementation

The electrician will install the required electrical equipment following safety regulations. This includes explosion-proof wiring, lighting, and control panels. All installations are done to ensure that no spark or heat from the electrical system can ignite combustible gases or dust.

Step 5: Ongoing Maintenance and Inspections

Hazardous area electricians don’t just install equipment and walk away. Regular maintenance and inspections are critical for ensuring that your system continues to operate safely. Schedule regular check-ups to identify any potential issues before they become serious problems.

Case Study: Electrical Safety at an Oil Refinery

The Problem

An oil refinery in Queensland faced an issue with its outdated electrical equipment in hazardous zones. They were experiencing frequent shutdowns due to the malfunction of electrical control panels that were not explosion-proof, posing a significant safety risk.

The Solution

A certified hazardous area electrician was hired to evaluate the refinery’s electrical system. After conducting a risk assessment, the electrician recommended replacing the control panels and wiring with explosion-proof alternatives. They also installed gas detection systems to monitor the environment for any combustible gases.

The Outcome

The new system drastically improved safety conditions at the refinery. Not only did the refinery achieve compliance with all relevant safety regulations, but they also experienced fewer equipment failures and downtime. Workers reported feeling more secure, knowing that the electrical system was upgraded and in safe hands.

Conclusion

Hiring a hazardous area electrician is crucial for the safety and efficiency of electrical systems in high-risk environments. These specialized professionals are equipped to navigate the complexities of hazardous zones, ensuring that your workplace remains safe, compliant, and fully operational.

Working in hazardous environments presents numerous challenges, from navigating stringent safety standards to operating under high pressure. However, with the right training, experience, and equipment, hazardous area electricians can minimize risks and prevent accidents. As outlined in our step-by-step guide, identifying hazardous zones, hiring a certified professional, and conducting thorough risk assessments are key to ensuring safety.

The case study from the oil refinery highlights the tangible benefits of investing in the expertise of hazardous area electricians. Their work not only safeguards lives but also ensures that operations run smoothly and efficiently.

In hazardous environments, there's no room for error. Partnering with a skilled hazardous area electrician guarantees that every precaution is taken, and every standard is met.

0 notes

Text

Oil and Gas Safety Regulations, Safety Tips and Top Companies

In the present day, GCC claims to account for 40% of oil reserves and 20% of natural gas reserves in the world. With the prevalence of oil and gas industry in GCC, the region has observed a high incidence of associated crew fatalities and deaths in its hazardous environment. Based on a CDC report for 2014-2019, a quarter of the oil and gas extraction workers died in the GCC from vehicular accidents, (26.8%), contact injuries (21.7%), and explosions (14.5%).

Regulatory bodies like OSHA and safety standards of API and ISO are responsible for outlining the industry standards in safety and reinforcing their compliance to protect the workers and insure the industry.

Safety Hazards and Risks in Oil and Gas Industry

The above-mentioned standards are formulated by regulatory bodies to target the major risk factors to safety in the oil and gas industry, as listed below:

Machinery Accidents

Heavy machinery is a leading cause of industrial accidents since even the smallest mistake in handling the equipment can threaten the life or cost a limb to the workers. Some of the most common machines involved in this type of accident are cranes, drills, forklifts, boilers, disks, chisels, furnaces, and oil rig machines.

Vehicle Collisions

Vehicles that carry oil and gas cargo are yet another potentially hazardous threat. In absence of properly marked vehicle zones or lanes, the workers run a risk of fatal collisions in the vehicle zones. Some of the prominent reasons for these vehicular accidents are distracted or fatigued drivers. This is why it is essential to deploy proper vehicle safety.

Explosions And Fires

Flammable gases and liquids are a part of the daily routine for oil and gas industry workers. A lot of these compounds pose significant hazardous risks for the workers’ lives, some with long-term effects on the crew’s health. Thus, it’s important to handle explosive hazards with maximum safety measures that keep up with the recommended health and safety standards for the industry.

Slips and Falls

Working on high platforms with heavy machines, there can be a lot of slippery spaces and liquids that can cause workers to slip and break limbs. Serious injuries can include broken necks and spines, permanently incapacitating the workers.

Challenging Work Conditions

Workers at oil and gas industries are required to be on call and onboard day and night, across different seasons with consistent work schedules. While there is no direct association, such challenging work conditions and induced fatigue can often result in serious workplace accidents, unless steps are taken to optimise crew schedules.

Read more: The most common causes of industrial explosions in industries today.

Safety Tips in Oil and Gas Industry to Prevent Accidents and Reduce Hazards

In recent years, the oil and gas industry has recognised the importance of HSE (Health, Safety, and Environment) in their operations. Here are some recommended tips and practices that enable the industries to better comply with the regulatory standards and keep the “hazards” in the industry at minimum:

Installation of Explosion-Proof Cameras

Surveillance and monitoring is crucial for the efficient industrial operations, as well as to identify crew lapses, equipment issues, etc. and respond instantaneously. Explosion-Proof Cameras are an OSHA-mandate to promote safer work culture in hazardous environments of the oil and gas industry by ensuring “explosion-proof” surveillance and monitoring. The technology contains the sparks within the housing of the wire, prevents them from coming into contact with the volatile environment, and protects the industry from the resulting explosion.

Before investing in an explosion-proof solution, ensure that the cameras are ISO and ATEX certified to reliable protection.

Explore: Different Types of Explosion-Proof Cameras for the Oil and Gas Industry

Promoting the Use of PPE

Establish some mandatory oil and gas safety regulations like the use of personal protective equipment (PPE) to insure your workers from everyday industrial hazards. Important PPE include hard hats and safety glasses to protect the workers in case of any collapse or items dropped from a height. Additionally, respiratory protection devices secure worker’s health by avoiding inhalation of dust, fumes, and gases released as end products at oil and gas industries. Finally, gloves and boots provide protection and prevent infection in case of injuries, cuts, and abrasions.

Inspection and Maintenance

Regular inspection and maintenance of the industrial site is necessary to foresee any workplace accident and address it beforehand. The assigned managers need to ensure that the pipelines, rigs, and refineries do not have any leaks or damage and are complying with OSHA’s safety regulations to drastically reduce the fatality risk at the facility.

Hazardous Waste Management

Managers are required to take measures for efficient hazardous waste management to serve the dual purpose of crew health and site safety. Regulatory bodies outline several standards to minimise the environmental impact of the oil and gas industry. Compliance with these standards ensures that the crew is not directly exposed to the hazardous waste produced during the refining process, securing them from several health issues like respiratory problems, cancer, etc. Furthermore, addressing and attending to oil spills immediately evades the risk of major fires and explosions.

Emergency Response Planning

It is essential that oil and gas industries have an emergency response plan in place in case of emergencies. Training the workers for this protocol through a series of drills helps the management avoid panic and stampede in case of a real emergency, thus protecting the human resources - the key to all the operations in an oil and gas industry.

Compliance with the Regulatory Standards

As mentioned before, compliance to regulatory standards is non-negotiable in case of hazardous oil and gas industries. These local, national, and international regulations outline specific guidelines for drilling, transportation, emission control, etc. Failure to comply with these OSHA, API, and ISO regulations can result in severe fines for the company.

Other Measures

It is advised to mark vehicle zones with marking tapes or lines to avoid vehicle collisions with crew. To promote a safe working policy around heavy machinery, always use proper signs to attract the attention of the pedestrians. The company can also invest in explosion-proof safety lights to maximise the visual access of the crew in dark or low-light work conditions and thus prevent casualties in the oil and gas facilities functioning around the clock.

Conclusion

The listicles above outline the safety regulations and the importance of adhering to them, especially for the highly volatile oil and gas industry. Without adapting to the evolving technological trends, establishing a safe work environment can be extremely challenging.

At SharpEagle, we are end-to-end safety consultants for your oil and gas industry. Our experts conduct a thorough site inspection of your facility to recommend the best safety solutions for your workplace. Our explosion-proof cameras and lights are ATEX and ISO-certified for safe and reliable communication and monitoring of your industrial operations. These safety solutions can be easily integrated with current devices to expand the operational efficiency. Our team also provides an overview that provides a detailed understanding of the functions of our ex-proof solutions. Furthermore, with consistent maintenance of the cameras and lights, we ensure their infallible functioning and longevity for smoother and safer operations at your industry.

For customised safety solutions, connect with our experts and book a free consultation call today!

You can also call us at +971-45549547 or mail us at [email protected]

#atex camera#atex cctv#atex certified camera#atex rated camera#atex zone 1 camera#camera explosion proof#ex camera zone 1#ex proof camera#Explosion proof camera#explosion proof camera for oil and gas#explosion proof cctv camera#explosion proof dome camera#explosion proof ip camera#explosion proof ptz camera#explosion proof video camera#explosion protected camera

0 notes

Text

Hazard-Ready Communication: ATEX Zone 1 iPhones for Industrial Professionals

In the intricate tapestry of industrial operations, communication is not just a convenience; it's a lifeline, especially in hazardous areas where safety is paramount. Enter the ATEX Zone 1 iPhones, a technological marvel designed to meet the stringent safety requirements of high-risk environments. In this realm of hazard-ready communication tools, one brand that stands out is FSE SAFE, weaving a safety net through innovation and reliability.

The Imperative of Hazard-Ready Communication

Industrial professionals operating in hazardous areas face unique challenges where traditional communication devices often fall short. The presence of explosive atmospheres demands a specialized approach to technology to ensure not only connectivity but also the safety of personnel. ATEX Zone 1 iPhones emerge as a solution tailor-made for such environments, providing a robust communication platform with intrinsic safety features.

Key Features of ATEX Zone 1 iPhones:

Intrinsically Safe Design: ATEX Zone 1 iPhones are engineered to be intrinsically safe, meaning they are designed to prevent the release of sufficient energy to ignite explosive atmospheres. This makes them an indispensable tool in environments where safety is non-negotiable.

Rugged Durability: Industrial settings are often harsh, and ATEX Zone 1 iPhones are built to withstand challenging conditions. They are rugged, resistant to dust, water, and impact, ensuring they can endure the rigors of daily use in demanding work environments.

Certified Compliance: ATEX Zone 1 iPhones adhere to ATEX (ATmosphères EXplosibles) directives, European regulations governing equipment used in potentially explosive atmospheres. This certification is a testament to their compliance with the highest safety standards.

Enhanced Connectivity: These iPhones provide seamless connectivity in areas where traditional communication devices may face limitations. With robust network capabilities, they ensure that professionals can stay connected even in the most remote or challenging industrial settings.

FSE SAFE: Pioneering Safety in Hazard-Ready Communication

In the realm of ATEX Zone 1 iPhones, FSE SAFE has emerged as a pioneer, setting new benchmarks for safety and communication in hazardous areas. FSE SAFE's commitment to providing innovative safety solutions is evident in their range of hazard-ready communication devices, where they prioritize not only connectivity but also the well-being of industrial professionals.

Ensuring Safety Beyond Communication: The FSE SAFE Advantage

FSE SAFE's ATEX Zone 1 iPhones go beyond being mere communication devices; they are instruments of safety assurance. The brand's dedication to creating intrinsically safe tools aligns with their broader mission of fostering a culture of safety in industrial operations. With FSE SAFE, professionals not only have reliable communication devices at their disposal but also the confidence that their tools are designed with their safety as the foremost priority.

Conclusion:

In conclusion, hazard-ready communication is no longer a futuristic concept but a present-day necessity, and ATEX Zone 1 iPhones, particularly those offered by FSE SAFE, are at the forefront of this paradigm shift. FSE SAFE's commitment to excellence in safety solutions is not just a corporate ethos; it's a beacon of assurance for industrial professionals operating in hazardous environments.

0 notes

Text

Revolutionizing Safety in Qatar: JGBQatar, Your Trusted Supplier of Explosion-Proof Equipment

Protecting both human personnel and equipment within dangerous workplace conditions remains critical for safety purposes in hazardous industries. Safety measures in Qatar need to meet the highest standards because this country operates three major sectors that create hazardous conditions. These environments require explosion-proof equipment since they present increased risks of fire and explosion, together with electrical failure possibilities. JGB Qatar serves as a top supplier through its reliable explosion-proof solutions that address specific requirements across the Qatar market.

Who is JGBQatar?

We operate as a top supplier of industrial explosion-proof equipment throughout Qatar and develop innovative safety products to shield workers from explosions in dangerous operational environments. We dedicate its extensive product range and certified equipment standards to deliver international safety standards, which include electrical components and lighting junction boxes and enclosures as well as other products.

We specialize in creating specialized solutions that address the unique needs of clients operating in the oil & gas and chemical plant industries, as well as mining and marine activities. The company stands out through premium-standard products as well as exceptional service quality and swift delivery of expert solutions.

Why Is Explosion-proof Equipment Essential In Qatar?

The industrial areas of Qatar include different hazardous operating areas that professionals must address. High concentrations of flammable gases and dust exist constantly among the oil and gas fields in addition to power plants and refineries. A single electrical malfunction or small spark inside these environments leads directly to disastrous outcomes.

Deliberately conceived explosion-proof equipment safeguards against every potential hazard that volatile chemicals might trigger through enhancement of catastrophe suppression abilities. The product design features elements that safely function under hazardous environments while containing sparks alongside electrical arcs and heat to prevent explosions.

The aggressive construction growth in Qatar demands strict safety standards because these measures boost operational performance and protect the nation's industrial reputation. We stand alone as a leading supplier of modern explosion-proof equipment, which represents absolute importance for safe facilities.

Explosion-Proof Products Offered by JGBQatar

Customers can find an array of explosion-proof products that have been rigorously tested and certified to meet international standards such as ATEX (European), IECEx (international), and UL (United States). Here’s a closer look at the types of products they offer:

1. Explosion-Proof Lighting

The lighting system in hazardous areas needs to provide strong functioning reliability. Explosion-proof lights from We can operate through extreme temperatures as well as resist corrosion and mechanical forces. Explosion-proof lights from we employed throughout many industries, including oil and gas operations, to supply safe lighting in flammable gas zones.

2. Explosion-Proof Electrical Junction Boxes

Junction boxes represent essential parts of electrical systems operating within hazardous areas. We develop explosion-proof junction boxes to block electrical sparks along with faults that prevent explosive conditions in high-risk electrical systems.

3. Explosion-Proof Enclosures

Electrical and mechanical equipment gets protection against external threats through enclosure systems that resist explosions. The enclosures provide essential safety measures for preventing dangers during operations that handle combustible materials at petrochemical plants or refineries. The enclosures from We deliver enduring solutions that guard equipment against severe environmental challenges.

4. Explosion-Proof Cable Glands

Sealing electrical cables requires cable glands to serve as protection against explosive dangers. The explosion-proof cable glands selected by Us create secure electrical connections that stop dangerous substances from leaking while maintaining proper system operation even in explosive environments.

5. Explosion-Proof Motors

The selection of motors for hazardous zones demands special attention because these motors should prevent ignition occurrences. The explosion-proof motors from JGBQatar are built to survive harsh conditions where they prevent both mechanical breakdowns and overheating, capable of producing hazardous sparks or fire outbreaks.

Why Choose JGBQatar as Your Explosion-Proof Equipment Supplier?

1. Industry Expertise

Our experienced team understands the complete characteristics of dangerous operational environments through their extensive fieldwork. Our implements customized solutions because their comprehensive expertise helps them adapt to individual sector needs.

2. Quality and Compliance

We produce products that meet international standards to guarantee reliable and safe operation under hazardous environments. The company partners with major manufacturers to supply equipment with safety standards from across the world that follows regulatory compliance requirements.

3. Customized Solutions

Every industrial establishment faces different demands regarding explosion-proof solutions. The custom solution department specializes in designing safety measures and equipment selection that adheres to the individual needs of each client.

4. Reliable Customer Service

As part of their service, we deliver products together with premium support for consultation all the way through to post-purchase service. Through customer involvement, our team operates in unison to guarantee successful installation and operation of explosion-proof equipment, which results in safe and efficient operations.

5. Fast Delivery

The criticality of operational safety drives is to provide fast and effective delivery of products to all its clients throughout Qatar. relies on their extensive network and optimized delivery system to provide businesses with dependable, rapid solutions.

The Safety You Deserve with JGBQatar

Protection through explosion-proof equipment enhances both security requirements and ensures safety for all people. Through their dedication to supplying advanced explosion-proof equipment, JGBQatar provides assurance to Qatar industry operators about their safety in dangerous situations. We serve as your dependable source for all essential workplace safety products that include lighting products and junction boxes alongside enclosures.

Our customer support team, along with viewing their website for more details about their explosion-proof solutions.

0 notes

Text

The Complete Guide to Hiring a Hazardous Area Electrician

When dealing with electrical systems in environments that pose potential dangers, such as factories, oil refineries, or chemical plants, safety is paramount. A specialized type of professional, known as a hazardous area electrician, is trained to manage and mitigate risks in these settings. In this guide, we will explore the roles, responsibilities, and significance of hazardous area electricians, the challenges they face, and offer a step-by-step guide to understanding their importance. We will also present a case study to provide real-world insights into how they operate.

Understanding Hazardous Area Electricians

What Is a Hazardous Area Electrician?

A hazardous area electrician is a licensed professional trained to work in environments where there is a risk of fire, explosion, or other safety concerns. These electricians specialize in installing, maintaining, and repairing electrical equipment in areas that contain flammable gases, vapors, or dust. Hazardous environments can include oil and gas refineries, chemical plants, mining operations, and grain storage facilities.

Why Are Hazardous Area Electricians Important?

The importance of hazardous area electricians cannot be overstated. These professionals are vital for ensuring that the electrical systems in dangerous areas are safe, reliable, and compliant with strict safety regulations. Without their expertise, the risks of explosions or accidents increase significantly, endangering lives and property.

Key Responsibilities of a Hazardous Area Electrician

Installations in Hazardous Zones: These electricians install equipment in hazardous areas to ensure that it meets explosion-proof or intrinsically safe standards.

Maintenance and Repairs: Hazardous area electricians maintain and repair equipment that could be compromised by dust, gases, or vapors.

Compliance with Regulations: They ensure that installations comply with regulations like ATEX, IECEx, and other international standards.

Inspections and Safety Assessments: A large part of their role involves conducting safety inspections and risk assessments to guarantee that installations remain compliant and hazard-free.

Common Misconceptions About Hazardous Area Electricians

1. Hazardous Area Electricians Only Work in Factories

While factories and industrial plants are common workplaces for hazardous area electricians, their expertise extends to any environment that could be dangerous due to the presence of explosive materials. This includes refineries, mines, and even some food processing plants.

2. Any Electrician Can Do This Job

Not true. Hazardous area electricians undergo specialized training and obtain certifications that equip them to work in explosive and high-risk environments. They are not your typical residential or commercial electricians.

Unique Topics That Everyone Should Know

1. The Importance of Explosion-Proof Equipment in Hazardous Areas

One of the most crucial aspects of working in hazardous areas is the use of explosion-proof equipment. Regular electrical devices can spark and cause an explosion if they are installed in areas with combustible dust or gases. A hazardous area electrician is responsible for installing explosion-proof equipment to prevent any catastrophic incidents. They ensure that the equipment adheres to strict safety standards that minimize the risk of ignition.

2. The Certification Process: What Sets a Hazardous Area Electrician Apart

Before an electrician can work in hazardous environments, they must undergo a rigorous certification process. These certifications (like ATEX in Europe or IECEx globally) ensure that the electrician understands the specific requirements and safety protocols needed to work safely in dangerous environments. It’s important to hire a hazardous area electrician with the proper certification to avoid compliance issues or safety risks.

3. How Hazardous Area Electricians Ensure Safety and Compliance

Hazardous area electricians follow strict guidelines and use specialized equipment to prevent accidents. They carry out regular safety inspections and risk assessments to identify potential hazards. Their expertise in selecting the right materials and ensuring proper grounding helps keep high-risk zones safe for workers and equipment.

Challenges in Hazardous Area Electrical Work

1. Navigating Complex Safety Standards

One of the biggest challenges faced by hazardous area electricians is navigating complex safety standards. Every hazardous area has unique characteristics, and electricians must ensure that the right precautions are in place for each scenario. Failure to adhere to these standards can result in accidents, regulatory penalties, and damage to equipment.

2. Handling High-Stress Situations

Working in hazardous environments often means facing high-stress situations. Electricians need to remain calm and make critical decisions under pressure, particularly when systems malfunction or pose an immediate danger. Their ability to maintain composure and solve problems quickly is essential for preventing disaster.

3. Limited Room for Error

The margin for error in hazardous environments is extremely small. A single mistake can lead to catastrophic consequences, such as explosions or fires. Hazardous area electricians must double-check their work, be vigilant in adhering to protocols, and perform meticulous inspections to ensure that nothing is overlooked.

4. Specialized Training and Knowledge

Becoming a hazardous area electrician requires ongoing education. The field is constantly evolving, and electricians must stay up-to-date with the latest safety regulations, technological advancements, and equipment innovations. This constant learning curve can be a challenge, but it is essential for maintaining safety and efficiency.

Step-by-Step Guide to Working with a Hazardous Area Electrician

Step 1: Identifying Hazardous Zones

Before you hire a hazardous area electrician, you need to determine if your workplace is classified as a hazardous zone. This classification is typically defined by safety standards such as ATEX or IECEx, depending on your region. Hazardous zones are categorized based on the likelihood and duration of hazardous materials (gases, vapors, or dust) being present.

Step 2: Hiring a Certified Hazardous Area Electrician

Ensure that the electrician you hire holds the necessary certifications. Ask for proof of training and experience, as well as references from previous projects. It is crucial to hire someone who has a solid understanding of the specific risks in your environment.

Step 3: Conducting a Risk Assessment