#ANSI centrifugal pump manufacturers

Explore tagged Tumblr posts

Text

Explore the difference between self-priming and non-self-priming pumps. Rotech explains the classification, working, and applications of self-priming pumps.

0 notes

Text

Color Customized Water Storage Tanks with Glass-Lined Steel: Aesthetic and Durable Solutions

Color Customized Water Storage Tanks with Glass-Lined Steel: Aesthetic and Durable Solutions

At Shijiazhuang Zhengzhong Technology Co., Ltd, we believe water storage solutions should combine exceptional functionality with visual appeal. Our Color Customized Water Storage Tanks with Glass-Lined Steel offer precisely that—durable, corrosion-resistant tanks available in a range of colors to meet your specific requirements.

Whether for drinking water, industrial applications, or municipal projects, our color-customizable tanks deliver a unique blend of practicality and style, making them the ideal choice for diverse applications.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Features of Glass-Lined Steel Water Storage Tanks

1. Customizable Color Options

Tailor the appearance of your storage tanks to match project aesthetics, branding, or environmental requirements.

Colors comply with international standards for durability and UV resistance, ensuring a lasting vibrant finish.

2. Exceptional Corrosion Resistance

The Glass-Lined Steel (GLS) finish creates an impermeable layer, protecting the tank from rust, corrosion, and harsh chemicals.

3. Long Service Life

With a proven lifespan of up to 30 years, our tanks provide excellent ROI and minimal maintenance.

4. Strict Compliance with Global Standards

Designed and manufactured according to AWWA D103-09, ISO 28765, NSF/ANSI 61, and other international certifications.

5. Rapid Installation and Expansion

Modular design allows for quick assembly and easy scalability to meet changing capacity needs.

6. Versatile Applications

Suitable for a wide range of uses, including potable water storage, industrial water, fire protection systems, and agricultural water solutions.

Why Choose Color Customized Tanks?

Enhanced Visual Appeal

Ideal for projects in urban areas or public spaces where aesthetics matter.

Create harmony with surroundings or highlight corporate branding.

Functional Identification

Use different colors to distinguish between water types, such as potable water, reclaimed water, or industrial water.

Improved Project Branding

Reflect organizational identity or comply with municipal or industrial branding requirements.

Applications of Color Customized Water Storage Tanks

Municipal Water Storage: Store drinking and non-potable water for urban infrastructure projects.

Fire Water Systems: Deploy aesthetically pleasing tanks in industrial parks or public facilities.

Industrial Water: Provide durable, corrosion-resistant storage for manufacturing and processing plants.

Agriculture: Use color-coded tanks for irrigation, crop spraying, or livestock water supplies.

Advantages of Choosing Center Enamel

As a leader in the Glass-Fused-to-Steel tank industry, Shijiazhuang Zhengzhong Technology Co., Ltd combines advanced enameling technology with a commitment to customization and quality.

Over 30 Years of Experience: With decades of expertise, we ensure precision and reliability in every tank.

World-Class Certifications: All tanks meet ISO 9001, CE, NSF/ANSI 61, WRAS, and ISO 45001 standards.

Global Presence: Our tanks are installed in over 100 countries, including the USA, Australia, Malaysia, South Africa, and Brazil.

Customization Expertise: We can match colors to customer specifications and offer unique designs tailored to specific projects.

Partner with Us for Superior Water Storage Solutions

At Shijiazhuang Zhengzhong Technology Co., Ltd, we understand the importance of combining utility and aesthetics. Our Color Customized Glass-Lined Steel Water Storage Tanks are the perfect choice for projects demanding durability and style.

Contact us today to discuss your storage tank needs, and let us help you find the ideal solution for your next project. Together, we can create water storage solutions that stand out!

0 notes

Text

Ansi Pump

Understanding ANSI Pumps: A Comprehensive Guide

In the world of industrial pumping, efficiency, reliability, and performance are paramount. Among the myriad of pump types available, ANSI pumps stand out for their versatility and effectiveness across various applications. ANSI, which stands for American National Standards Institute, sets the standards for pumps bearing its name, ensuring consistency and quality. This comprehensive guide aims to delve into the intricacies of ANSI pumps, exploring their design, applications, advantages, and maintenance requirements.

What is an ANSI Pump?

ANSI pumps are centrifugal pumps that conform to the standards set by the American National Standards Institute. These standards dictate parameters such as dimensions, materials, and performance characteristics, ensuring interchangeability and compatibility across different manufacturers.

Design and Components

One of the key features of ANSI pumps is their modular design, which facilitates easy maintenance and parts replacement. These pumps typically consist of components such as the casing, impeller, shaft, bearings, and mechanical seals. The casing, often made of durable materials like cast iron or stainless steel, houses the impeller and directs the flow of fluid. The impeller, driven by the shaft connected to a motor, imparts kinetic energy to the fluid, increasing its velocity.

Applications

ANSI pumps find applications across a wide range of industries, including chemical processing, water treatment, power generation, and petroleum refining. Their ability to handle various fluids, including corrosive and abrasive substances, makes them indispensable in demanding environments. From transferring chemicals in manufacturing plants to circulating cooling water in power stations, ANSI pumps play a crucial role in ensuring smooth operations.

Advantages of ANSI Pumps

The adoption of ANSI pumps offers several advantages to industries seeking reliable pumping solutions. Firstly, their adherence to standardized dimensions allows for easy interchangeability of parts, simplifying maintenance and reducing downtime. Additionally, their robust construction and choice of materials make them suitable for handling aggressive fluids without succumbing to corrosion or wear. Moreover, ANSI pumps are known for their efficient performance and low energy consumption, contributing to cost savings over the long term.

Maintenance Requirements

Proper maintenance is essential to ensure the optimal performance and longevity of ANSI pumps. Regular inspection of components such as bearings, seals, and impellers helps identify potential issues before they escalate. Lubrication of bearings and periodic alignment of shafts are crucial for preventing premature wear and ensuring smooth operation. Furthermore, maintaining clean fluid conditions and monitoring operating parameters such as pressure and temperature are integral to maximizing the lifespan of ANSI pumps.

In conclusion, ANSI pumps represent a pinnacle of engineering excellence in the realm of industrial pumping. Their adherence to stringent standards, modular design, versatile applications, and numerous advantages make them a preferred choice for various industries worldwide. By understanding the design principles, applications, advantages, and maintenance requirements of ANSI pumps, industries can harness their capabilities to enhance efficiency, reliability, and productivity in fluid handling processes. As technology advances and industrial demands evolve, ANSI pumps are poised to remain indispensable assets in the pursuit of operational excellence.

1 note

·

View note

Text

ANSI Centrifugal Pump - Dynapro Pumps

Dynapro Pumps takes pride in offering a comprehensive range of services for ANSI centrifugal pumps. As a trusted industry leader, we specialize in the design, manufacturing, and supply of high-quality pumps that meet ANSI standards. Our ANSI centrifugal pumps are renowned for their exceptional performance, reliability, and longevity, making them the ideal choice for various industrial applications. Whether you need a standard model or a customized solution, our team of experts works closely with you to understand your specific requirements and provide a pump that perfectly fits your needs. With a strong focus on precision engineering and quality craftsmanship, our pumps are designed to withstand even the most challenging operating conditions. Count on Dynapro Pumps for all your ANSI Centrifugal Pump needs, and experience unparalleled service, expertise, and reliability in the industry.

#slurry pump repair in mexico#pump equipment design and manufacturing company#pumps repair services in mexico

0 notes

Text

The horizontal pump incorporates a motor

Benefits of a Horizontal Centrifugal Knock out

The advantages of your horizontal centrifugal knock out outweigh its cons. It is not hard to install and maintain, and is easy to adjust towards the proper headroom as well as fluid flow charge. These pumps can also be suitable for high pressures and temps. However, you should note this pump can undertake a large footprint, so it is important to plan for enough headroom with your facility. Below are some advantages of a horizontal centrifugal pump.

The horizontal centrifugal pump is simple to install and is relatively inexpensive, but its mechanical seal may not be durable enough for a lot of applications. A submersible model isn't recommended for sizzling or flammable bodily fluids, or for substantial viscosity or NPSHa essential liquids. It is also tougher to maintain using turbine pumps, and requires an expensive pit and clip or barrel. Mechanical seals are also more prone to fail with high-pressure essential fluids, making maintenance tricky.

The horizontal pump incorporates a motor that is situated adjacent to your pump head. Horizontal pumps could be close-coupled or long-coupled.China wholesale 12v 1 hp Solar Powered Both types may be used, but have disadvantages. Vertical pumps necessitate more spare parts and cannot be exchanged with horizontal pumps. Some up and down designs are "tight" pertaining to space, reducing all round height and turning moment. This can make maintenance difficult. These issues were major difficulty with horizontal pumps before ANSI and API specs were adopted.

The horizontal centrifugal pump is built to work efficiently for a variety of different applications. The suction water line draws liquid into your pump, while that discharge pipe draws fluid out. Each stage increases the pressure and discharge volume of the pump. They can also be ideal for difficulty boosting systems, irrigation techniques, and irrigation techniques. There are many other advantages that help to make horizontal centrifugal pumps a good solution for a variety of applications.

When working with fluids other as compared to water, you must think about the density and gravity with the working fluid. The density with the fluid is immediately proportional to it is volume and pounds, so you must think ratio before finding a horizontal centrifugal push. The weight from the fluid will affect as much work the pump may do. The extra dense the water, the higher this input power required to pump the the liquid.

Horizontal centrifugal sends are simpler to run and maintain than vertical ones. Their internal parts are readily available, and the shaft could be suspended or internally supported. They are well suited for indoor applications, and their low headroom makes them easy to connect to external equipment. And because they may be relatively low-headed, hd require a large area. If there isn't headroom, a horizontal pump will be the perfect choice.

This ANSI B73. 1 standard can be used for centrifugal pumps. This standard makes ANSI process pushes of similar shapes are interchangeable. Which means no matter that manufacturer produces ones horizontal centrifugal knock out, you'll be capable to choose a model that may fit your desires. You can possibly find high-flow horizontal pumps that has a high-performance rating. But be sure you consider the impact of an horizontal pump using a pipeline before you buy one.

1 note

·

View note

Text

J line pump company website

#J line pump company website manual

#J line pump company website full

#J line pump company website iso

Wear rings are available in stainless steel or aluminum bronze. Bearings options also include bronze, neoprene, marine or vesconite. Whether its standard materials, stainless steel or aluminum bronze, we can meet your needs. NPC has certified many optional materials to allow our customers the ability to choose the best materials for their specific application. The short-set Vertical Turbine Pumps are available in either product lubricated or enclosed linshaft configurations. The deep-set Vertical Turbine Pumps are available in configurations that include either oil-lubricated or fresh water flushed enclosed lineshaft or pre-lubricated open line shaft. Yes, as of September 20, 2019, National Pump has NSF/ANSI/CAN 61 & NSF/ANSI 372 certification for Vertical and Submersible Turbine Pump assemblies.

#J line pump company website manual

Bombas Verticales De Turbina, NPC - IOM Manual Download.

Performance Curves, NPC, Open Impeller - 60 HZ Download.

Performance Curves, NPC - 50 HZ Download.

Vertical Turbine Pump, Deep Well, Product Lubricated - Selection Download.

Vertical Turbine Pump, Deep Well, Oil Lubricated - Specification Download.

Testing to Hydraulic Institute compliance standardsĪll pump models are stocked in standard materials of construction and can be customized to meet your exact specifications at our various manufacturing locations.

#J line pump company website iso

Certifications (when specified): ISO 9001 Certified Quality Management System, NSF61 & 372 Pump Certification.

Threaded or Flanged Column Construction.

Oil Lubricated or Water Injection line shaft.

Components available in Cast & Ductile Iron Silicon, Aluminum, & 304, 316 and Duplex Stainless Steel construction.

Cast Iron, Ductile Iron or Fabricated Steel Discharge Heads.

National Pumps are hard at work around the world providing dependable service to municipal water systems, agricultural irrigation, mining and industrial applications, as well as some of the world’s premier golf courses. Gusher Pumps' custom-manufactured pumps are suited for a wide range of applications including Din specification, ANSI specification, machine tool and centralized coolant systems, automatic paint systems, industrial spray washers, filtration systems, phosphate and bonderizing lines, just to name a few.National Pump can cover all of your deep well needs, from precisely matched discharge heads, tubeline assemblies and column pipe, to custom impellers and bowl assemblies to deliver consistent pumping capacity. As one customer put it: Gusher is big enough to have deep engineering expertise, yet small enough to care about each individual order. Gusher Pumps excels in custom-engineering pumps to meet exacting performance and unique application specifications.įrom sales and customer service to engineering, machining, assembly and quality control, our dedicated staff is the driving force behind our reputation for quality, dependable pumps. Over 100 years in the pump business shows in our expertise. Our product range is capable of handling flows from small to large, with our multi-stage pump achieving heads in excess of 800 ft. Numerous models and sizes permit selection of the most hydraulically suitable pump for many capacity/head ranges without having to up or down size operating characteristics. Both vertical pumps and horizontal pumps are available to suit installation and application requirements.

#J line pump company website full

Models include close-coupled pumps, end suction pumps, immersed pumps, self-priming pumps, vortex pumps, sludge pumps, multi-stage pumps, and full cantilever pumps. Our range of industrial pumps represents one of the largest selection of centrifugal pumps available from a single manufacturer. Gusher Pumps builds everything from highly specialized single pumps to high quantity custom-engineered pump orders. Manufacturers of Quality Pumps since 1913

0 notes

Text

Api 660 Latest Edition

Api 660 Latest Edition Price

Api 660 Latest Edition

list of standards

Addeddate 2016-09-25 12:20:51 Identifier API653 Identifier-ark ark:/13960/t4qk2b23h Ocr ABBYY FineReader 11.0 Ppi 300 Scanner Internet Archive HTML5 Uploader 1.6.3. Download do game boy game. API Std 660 currently viewing. March 2015 Shell-and-tube Heat Exchangers, Ninth Edition, Includes Addendum 1 (2020). American Petroleum Institute (API) standards advocate proven, sound engineering and operating practices and safe, interchangeable equipment and materials from drill bits to environmental protection. Included are manuals, standards, specifications, recommended practices, bulletins, guidelines and technical reports.

list of standards

hello guys this are some applicable standards as tips however this document is old a decade! but may be helpful. just shearing. Engineering Rocks!!! 1.0 LIST OF STANDARDS ORGANIZATIONS BY EQUIPMENT CATEGORIES 1.1 GENERAL 1.2 SAFETY 1.3 VESSELS - TANKS 1.4 HEAT TRANSFER EQUIPMENT 1.5 ROTATING EQUIPMENT 1.6 PROCESS EQUIPMENT 1.7 MATERIAL HANDLING 1.8 GENERAL SERVICES 1.9 PLANT SERVICES 1.10 BUILDING SERVICES 1.11 PLUMBING 1.12 PIPING 1.13 MISCELLANEOUS MATERIAL, WELDING, ETC. 2.0 LIST OF MAJOR CODES AND STANDARDS RELATED TO PROCESS ENGINEERING 2.1 ANSI 2.2 API 2.3 ASME 2.4 ASHRAE 2.5 AWWA 2.6 CEMA 2.7 CGSB 2.8 CSA 2.9 CTI 2.10 HYDRAULICS INSTITUTE 2.11 MSS 2.12 NACE 2.13 NEMA 2.14 NFPA 2.15 PFI 2.16 RMA 2.17 SSPC 2.18 TEMA 2.19 ULC TABLE OF CONTENTS (CONTINUED) 2.20 ISA 2.21 ISO 2.22 OFFSHORE PIPELINE 2.23 UNITS OF MEASUREMENT ------------------------------------------------------------ 1.0 LIST OF STANDARDS ORGANIZATIONS BY EQUIPMENT CATEGORIES 1.1 General AGS American Gas Society ANSI American National Standards Institute BSI British Standards Institute CGSB Canadian General Standards Board CSA Canadian Standards Association ISO International Organization for Standardization NBS National Bureau of Standards ISA Instrument Society of America 1.2 Safety ANSI American National Standard Institute Dept. of Labour EPA Environment Protection Agency FM Factory Mutual NBFU National Board of Fire Underwriters NFPA National Fire Protection Association OSHA Occupational Safety and Health Administration UL Underwriters' Laboratories 1.3 Vessels - Tanks API American Petroleum Institute ASME American Society of Mechanical Engineers AWWA American Water Works Association NBBI National Bureau of Boiler & Pressure Vessel Inspectors ULC Underwriters' Laboratories of Canada 1.4 Heat Transfer Equipment API American Petroleum Institute CTI Cooling Tower Institute TEMA Tubular Exchanger Manufacturers Association 1.5 Rotating Equipment ANSI American National Standard Institute API American Petroleum Institute AWWA American Water Works Association DEMA Diesel Engine Manufacturers Association Hydraulics Institute MPTA Mechanical Power Transmission Association 1.6 Process Equipment AWWA American Water Works Association GPSA Gas Processor Suppliers Association API American Petroleum Institute ASME American Society of Mechanical Engineers ASTM American Society for Testing and Materials ANSI American National Standards Institute NBBI National Bureau of Boiler and Pressure Vessel Inspectors CMAA Crane Equipment Manufacturers Association of America 1.7 Material Handling CEMA Conveyor Equipment Manufacturers Association CMAA Crane Equipment Manufacturers Association of America CSA Canadian Standards Association FEM Fédération Européenne de la Manutention (Rules for the Design of Hoisting Appliances) MHI Material Handling Institute RMA Rubber Manufacturers Association 1.8 General Services SAMA Scientific Apparatus Makers Association 1.9 Plant Services ACGIH American Conference of Governmental Industrial Hygienists AGA American Gas Association AWWA American Water Works Association CAGI Compressed Air and Gas Institute CGA Canadian Gas Association CGA INC. Compressed Gas Association 1.10 Building Services AMCA Air Moving and Conditioning Association ARI Air-Conditioning and Refrigeration Institute ASHRAE American Society of Heating, Refrigerating and Air-Conditioning Engineers 1.11 Plumbing ASPE American Society of Plumbing Engineers ASSE American Society of Sanitary Engineers - Canadian Plumbing Code PDI Plumbing and Drainage Institute - Provincial Plumbing Code 1.12 Piping API American Petroleum Institute ASME American Society of Mechanical Engineers MSS Manufacturers Standardization Society of the Valve and Fittings Industry PFI Pipe Fabricators Institute PPI Plastic Pipe Institute 1.13 Miscellaneous Material, Welding, etc. ASME American Society of Mechanical Engineers ASTM American Society for Testing and Materials TIMA Thermal Insulation Manufacturers Association 2.0 LIST OF MAJOR CODES AND STANDARDS RELATED TO PROCESS ENGINEERING 2.1 ANSI A1 Liquefied Petroleum Gas System A13.1 Scheme for Identification of Piping Systems B.16.1 Cast Iron Pipe Flanges and Flanged Fittings, Class 25, 125, 250, and 800 B.16.5 Pipe Flanges and Fittings B16.9 Steel Buttwelding Fittings B31 Corrosion Control for B31.1 B31.1 Power Piping B31.2 Fuel Gas Piping B31.3 Chemical Plant and Petroleum Refinery Piping B31.4 Liquid Petroleum Transportation Piping Systems B31.5 Refrigeration Piping B31.8 Gas Transmission and Distribution Systems (1982) B31.11 Slurry Transportation Piping Systems B36.10 Welded and Seamless Wrought Pipe B36.19 Stainless Steel Pipe B73.1M Horizontal, End Suction Centrifugal Pumps B73.2M Vertical In-line Centrifugal Pumps B133.2 Basic Gas Turbine B133.4 Gas Turbine Control and Protection Systems LOS4C1 Flushing and Cleaning Gas Turbine Gen. Lube Systems 58 Standard for the Storage and Hauling of Liquefied Petroleum Gas MC96.1 Temperature Measurement Thermocouples 2.2 API Publ. 941 Steel for Hydrogen Service at Elevated Temperature and Pressures in Petroleum Refineries and Petrochemical Plants Publ. 2009 Safe Welding and Cutting Practices in Refineries Publ. 2015 Safe Entry and Cleaning of Petroleum Storage Tanks Publ. 2021 Fighting Fires In and Around Flammable and Combustible Liquid Atmosphere Storage Tanks Publ. 2030 Guidelines for Applications of Water Spray Systems for Fire Protection in the Petroleum Industry Publ. 2517 Evaporation Loss from External Floating-Roof Tanks Publ. 2557 Vapour Collection and Control Options for Storage and Transfer Operations in the Petroleum Industry RP 14C Analysis, Design, Installation and Testing of Basic Surface Safety Systems on Offshore Platforms RP 14F Design and Installation of Offshore Platforms RP 14G Fire Prevention and Control on Open Type Offshore Production Platforms RP 30 Calculation for Heater Tube Thickness in Petroleum Refineries RP 500 Recommended Practice for Classification of Locations for Electrical Installations at Petroleum Facilities RP 520 Sizing, Selection, and Installation of Pressure Delivery Devices in Refineries. Parts 1 and 2 RP 521 Guide for Pressure Delivery and Depressuring Systems RP 526 Flanged Steel Safety Relief Valves RP 551 Process Measurement Instrumentation RP 560 Fired Heater for General Refinery Services RP 651 Cathodic Protection of Aboveground Petroleum Storage Tanks RP 652 Lining of Aboveground Storage Tank Bottoms RP 682 Shaft Sealing System for Centrifugal and Rotary Pumps RP 1110 Pressure Testing of Liquid Petroleum Pipelines RP 2001 Fire Protection in Refineries RP 2003 Protection Against Ignitions Arising out of Static, Lighting and Stray Currents Spec. 5L Line Pipe Spec. 6D Pipeline Valves Spec. 6FA Fire Test for Valves Spec. 12D Field Welded Tanks for Storage of Production Liquids Spec. 12F Shop Welded Tanks for Storage of Production Liquids Spec. 12J Oil and Gas Separators Spec. 12K Indirect Type Oil Field Heaters Spec. 12L Specification for Vertical and Horizontal Emulsion Treaters Spec. 12P Specification for Fibreglass Reinforced Plastic Tanks Std. 510 Pressure Vessel Inspection Code Std. 526 Flanged Steel Safety - Relief Valves Std. 527 Seat Tightness of Pressure Relief Valves Std. 594 Wafer and Wafer-Lug Check Valves Std. 598 Valve Inspection and Testing Std. 599 Metal Plug Valves - Flanged and Butt-Welding Ends Std. 600 Steel Gate Valves - Flanged and Butt-Welding Ends Std. 602 Compact Steel Gate Valves - Flanged Threaded, Welding, and Extended-Body Ends Std. 603 Class 150, Cast, Corrosion-Resistant, Flanged-End Gate Valves Std. 607 Fire Test for Soft-Seated Quarter-Turn Valves Std. 608 Metal Ball Valves - Flanged and Butt-Welding Ends Std. 609 Lug - and Wafer - Type Butterfly Valves Std. 610 Centrifugal Pumps For Petroleum, Heavy Duty Chemical and Gas Industry Services Std. 611 General Purpose Steam Turbines for Refinery Services Std. 612 Special Purpose Steam Turbines for Refinery Services Std. 613 Special Purpose Gear Units for Refinery Services Std. 614 Lubrication, Shaft-Sealing and Control Oil Systems for Special Purpose Application Std. 615 Sound Control of Mechanical Equipment for Refinery Services Std. 616 Gas Turbines for Refinery Services Std. 617 Centrifugal Compressors for General Refinery Services Std. 618 Reciprocating Compressors for General Refinery Services Std. 619 Rotary-Type Positive Displacement Compressors for General Refinery Services Std. 620 Design and Construction of Large, Welded, Low Pressure Storage Tanks Std. 630 Tube and Header Dimensions for Fired Heaters for Refinery Service Std. 650 Welded Steel Tanks for Oil Storage Std. 660 Heat Exchangers for General Refinery Service Std. 661 Air-Cooled Heat Exchangers for General Refinery Service Std. 670 Vibrations, Axial Position, and Bearing-Temperature Monitoring System Std. 671 Special Purpose Coupling for Refinery Service Std. 674 Positive Displacement Pumps - Reciprocating Std. 675 Positive Displacement Pumps - Controlled Volume Std. 676 Positive Displacement Pumps - Rotary Std. 677 General Purpose Gear Units for Refineries Services Std. 678 Accelerometer-Base Vibration Monitoring System Std. 1104 Welding Pipelines and Related Facilities Std. 2000 Venting Atmospheric and Low-Pressure Storage Tanks - Non-Refrigerated and Refrigerated Std. 2530 Measurement Standard Chapter 14, Natural Gas 2.3 ASME Boiler and Pressure Vessel Code Section I Power Boilers Section II Materials Specifications Part A Ferrous Materials Part B Non-Ferrous Materials Part C Welding Rods, Electrodes and Filler Metal Part D Properties Section IV Heating Boilers Section V Non-Destructive Examination Section VIII Pressure Vessels - Division 1 Division 2 Section IX Welding and Brazing Qualifications Section X Fibreglass-Reinforced Plastic Pressure Vessels Standards Std. 120 Gas Turbine Generator Lube Oil Systems Performance Test Codes PTC 1 General Instructions PTC 2 Definitions and Values PTC 4.1 Steam Generating Units PTC 8.2 Centrifugal Pumps PTC 9 Displacement Compressors, Vacuum Pumps and Blowers PTC 10 Compressors and Exhausters PTC 22 Gas Turbine Power Plants 2.4 ASHRAE ASHRAE Handbooks 2.5 AWWA C110 Gray-Iron and Ductile Iron Fittings, 3 in. through 48 in. for Water and Other Liquids C151 Ductile Iron Pipe, Centrifugally Cast in Metal Molds or Sand-Lined Molds for Water and Other Liquids E101-88 Vertical Turbine Pumps - Live Shaft and Submersible Types C502 Dry Barrel Hydrants Fire Hydrants 2.6 CEMA Belt Conveyors for Bulk Materials Handbook 2.7 CGSB 41-GP-22 Standard for Process Equipment Reinforced Polyester, Chemical Resistance, Custom-Contact Molded 2.8 CSA B-51 Boilers and Pressure Vessels B-53 Identification of Piping Systems B-52-M Mechanical Refrigeration Code B-63 Welded and Seamless Steel Pipe B-137.3 Rigid Poly (Vinyl Chloride) (PVC) Pipe B-137.4-M Polyethylene Piping Systems for Gas Service W-48.1 Mild Steel Covered Arc-Welding Electrodes W-48.3 Low-Alloy Steel Arc-Welding Electrodes Z-183 Oil Pipeline Transportation Systems Z-184-M Gas Pipeline Systems Z-245.1 Pipeline Systems and Materials Z-245.10 Wrought Steel Buttwelding Fittings and Flanges Z-276-M LNG - Production, Storage and Handling 2.9 CTI STD-103 Standard Specifications for the Design of Cooling Tower Structures with Redwood Lumber STD-111 Gear Speed Reducers STD-114 Standard Specifications for the Design of Cooling Tower Structures with Douglas Fir Lumber NCL-109 Nomenclature for Industrial Water - Cooling Towers WMS-112 Pressure Preservative Treatment of Lumber for Industrial Water - Cooling Towers ATC-105 Acceptable Test Code for Water-Cooling Towers 2.10 Hydraulics Institute Standards for Centrifugal, Vertical, Rotary and Reciprocating Pumps 2.11 MSS Standard Practices SP-6 Standard Finishes for Contact Faces Pipe Flanges and Connecting End Flanges of Valves and Fittings SP-25 Standard Marking System for Valves, Fittings, Flanges and Union SP-44 Steel Pipeline Flanges SP-53 Quality Standards for Steel Castings and Forgings for Valves, Flanges and Fittings and Other Piping Components - Mag. Particle SP-54 Quality Standards for Steel Castings and for Valves, Flanges and Fittings and Other Piping Components - Radiographic SP-55 Quality Standards for Steel Castings and for Valves, Flanges and Fittings and Other Piping Components - Visual SP-58 Pipe Hangers and Supports - Material, Design and Manufacture SP-61 Pressure Testing of Steel Valves SP-69 Pipe Hangers and Supports - Selection and Application SP-75 High Test Wrought Butt Welding Fittings SP-82 Valve Pressure Testing Methods SP-89 Pipe Hangers and Supports - Fabrication and Installation Practices 2.12 NACE MR-01-90 Sulfide Stress Cracking Resistant Metallic Material for Oil Field Equipment RP-01-78 Design, Fabrication and Surface Finish of Metal Tanks and Vessels to be Lined for Chemical Immersion Service RP-0188-88 Discontinuity (Holiday) Testing of Protective Coatings 2.13 NEMA SM23-1979 Steam Turbines for Mechanical Drive Service 2.14 NFPA 11 Low Expansion Foam Systems 11A Medium and High Expansion Foam Systems 12 Carbon Dioxide Extinguishing Systems 12A Halon 1301 Fire Extinguishing Systems 12B Halon 1211 Fire Extinguishing Systems 13 Installation of Sprinkler Systems 14 Stand Pipe and Hose Systems 15 Water Spray Fixed Systems 16 Deluge Foam-Water Sprinkler and Spray Systems 17 Dry Chemical Extinguishing Systems 20 Centrifugal Fire Pumps 22 Water Tanks for Private Fire Protection 24 Installation of Private Fire Service Mains and Their Appurtenances 25 Water Based Fire Protection Systems 37 Stationary Combustion Engines and Gas Turbines 51 Oxygen-Fuel Gas Systems for Welding 54 National Fuel Gas Code CUA 58 LP Gas Storage, Use 59 LP Gases at Utility Gas Plants 59A Storage and Handling of Liquefied Natural Gas 82 Incinerators, Waste and Linen Handling Systems and Equipment 214 Water Cooling Towers 291 Fire Flow Testing and Marking of Hydrants 655 Prevention of Sulphur Fires and Explosions 2.15 PFI ES 4 Hydrostatic Testing of Fabricated Piping ES 5 Cleaning of Fabricated Piping ES 7 Minimum Length and Spacing for Welded Nozzles ES 18 Ultrasonic Examination of Tubular Products ES 22 Recommended Practice for Color Coding of Piping Materials 2.16 RMA Conveyor and Elevator Belt Handbook 2.17 SSPC PA1 Shop, Field and Maintenance Painting SP1 Solvent Cleaning SP5 White Metal Blast Cleaning SP6 Commercial Blast Cleaning SP7 Brush-Off Blast Cleaning SP8 Pickling SP10 Near-White Blast Cleaning Guide to Vis1 Guide to Pictorial Surface Preparation Standards for Painting Steel 2.18 TEMA TEMA Standard 2.19 ULC S603M Standard for Shop Fabricated Steel Underground Tanks for Flammable and Combustible Liquids S630M Standard for Shop Fabricated Steel Aboveground Tanks for Flammable and Combustible Liquids 2.20 ISA 85.1 Instrument Symbols and Identification 2.21 ISO 5167 Sizing of Metering Orifice 2.22 Offshore Pipeline DNV Rules for Submarine Pipeline Systems 2.23 Units of Measurement ISO 1000 SI Units

NACE MR0175 is identical to ISO 15156. ANSI / NACE MR0175 / ISO 15156 lists the requirements for carbon steels, low alloys and corrosion resistant alloy exposed to H2S in oil and gas exploration and production environments.

This page is maintained by Oil and Gas Corrosion Ltd. and allows you to track the latest edition of NACE MR0175.

The current NACE MR0175 revision is:

Encarta Encyclopedia free download - Microsoft Encarta Encyclopedia Deluxe 2002 Patch Shockwave, 1-Click Answers, Pro Football Statistics Encyclopedia, and many more programs. Download Microsoft Encarta for free. Complete encyclopedia dictionary which shows the definition of any term. Wikipedia Gadget 1.0.0 Download. The whole of Wikipedia on your desktop. Indywikia 0.9.9.1 Download. A program that lets you browse Wikipedia more intuitively and visually. Microsoft encarta free download.

ISO 15156 2020 (not a national standard ANSI/BSI and still not ratified by NACE)

The previous revision is

The 2015 revision is supplemented by several Technical Circulars published via ISO:

The Technical Circulars are integral part of the document.

Oil and Gas Corrosion Ltd provides technical support to understand and implement the requirements of NACE MR0175

Contact our team today!

With a wealth of experience in the oil and gas industry, we provide independent materials and corrosion consultancy to help companies reduce risk, save money and apply best practice in their oil and gas businesses.

Find out more by getting in touch – you’ll get an answer from a qualified, experienced materials engineer every time.

Api 660 Latest Edition Price

Tama serial number check digit. US: 877-399-1010 (toll free) UK: +44(0)1144000850

Api 660 Latest Edition

66 Eldon St Sheffield S1 4GT United Kingdom Portrait professional 15 full.

0 notes

Text

Mud Centrifugal Pump & Pump Parts Manufacturers and Suppliers

B V Engineers is Mud Centrifugal Pump Suppliers in the industry of various types Mud Pump, Water Pump, including Centrifugal Pump. We guarantee all of our products are manufactured in USA but we can supply to wherever you need us worldwide.

Mud Pumps are used in agriculture, waste water management, construction and other industries also. They consistently deliver the Mud Centrifugal Pump that provides to customers with the most first-rate possible service and with competitive price.

A well known Mud Centrifugal Pump Manufacturers B V Engineers USA having bulky purchaser market, a highly talented workforce, open investment policies and better Incentives; they supply, manufacture and export a wide-ranging of and Best quality Mud Centrifugal Pump at cost effective prices.

We, along with our partners have an expertise to develop not just Pumps but complete Pumping Systems like Diesel Driven Pumps, Electric Driven Pumps, Mud Centrifugal Pump Parts and Tractor Driven Pumps, Submersible Pumps, Thermic Pump, Hot Oil Pump, Multistage Pump, Self Priming Trash Pump, ANSI Standard Pumps & Dewatering Pump etc.

Well known Mud Centrifugal Pump Suppliers, BV Engineers have missioned is to provide best quality results to the Automobile & other Industries with cutting edge technology. It aims to maintain extraordinary value for our clients, Self Evaluation, and the commitment towards its clients to climb the success ladder.

We made these mud centrifugal pumps, mud centrifugal pump parts as per customer’s and industry’s specification. For more information or to learn more about our company; get in touch with us today!

0 notes

Text

Charge Pump

A pump used to boost the pressure of a fluid before it enters the main pump(s) of a system.

A charge pump is used to boost the pressure of a fluid before it enters the inlet of the main pump. The use of a charge provides enough pressure to overcome the required net positive suction head (NPSH) of the main pump. Providing adequate pressure is necessary to prevent cavitation in larger pumping equipment.

The most common charge pumps are single stage centrifugal pumps. ANSI pumps will often fill the requirements of a charge pump, but the composition of the fluid should be taken into consideration. Depending on abrasive materials, specific types of centrifugal pump designs may be needed.

The charge pump (blue) provides adequate pressure to the positive displacement pump behind it (gray).

The valves allow for bypassing the charge pump when it is not needed.

Centrifugal pumps provide a desired flow and pressure relationship. When a centrifugal pump is used, they are able to operate across a range of flow rates, while still providing an adequate pressure. Pumps other than a centrifugal may be used, but it is rare. Use of other types of pumps is not recommended unless the system is specifically designed for the type of pump selected. Using other types of pumps may cause premature failure of either the charge pumps or the main pumps unless they are designed to be used together.

Charge pump systems are common on positive displacement pumps. Depending on their speed, the positive displacement pump may pull the fluids at the inlet of the pump well below vapor pressure causing cavitation, A charge pump can help to reduce sudden pressure drops below vapor pressure within the suction stream and eliminate cavitation.

Charge pumps may also be used in other pump type applications. Multistage pumps often are not designed to pull fluids from a reservoir located below the pump, such as a river or a lake. Careful attention is given to these pump designs to provide adequate suction pressure. A smaller pump designed for lower NPSH is often placed near the fluid reservoir to provide the adequate pressure needed at the inlet of the main pump.

Charge pump systems are designed for the main pump(s). Experience with the pump, pump curves, or the manufacturers manual may provide the information necessary to select an adequate charge pump. When a wide range of flows is desired, the charge pump may be bypassed at low flows. Since the NPSH increases with speed, it may only be necessary to provide a charged pressure at higher pump speeds. Careful calculation should be completed to know when a charge pump should be used.

Note: A charge pump in positive displacement applications can reduce vibration and pressure pulsations in the suction piping but does not eliminate it. A pulsation dampener should still be used to reduce pulsation in the suction and discharge lines in order to prevent vibration and pulsation damage.

0 notes

Text

Buy Best Pumps from Thomas Pump and Machinery

With so many different pump systems available in the market, it gets difficult for customers to choose the best one. And even after finding the best pump system, there are a lot of confusions involved regarding where to buy it from? The solution to these problems is simple and that is Thomas Pump and Machinery. It is a leading distributor of pumps. They only provide pumps of the best pump manufacturing companies like Blackmer. A top manufacturer of displacement pumps, centrifugal pumps, and compressors, this company is very popular amongst engineers and designers as well as plumbing contractors because of their high speed and reliability. The pumps of this company also have a seal-less magnetic drive and are used in markets like chemical processing, oil, and gas, military and marine, Refined Fuels, Biodiesel etc.

youtube

Griswold Pumps is another popular pump manufacturing company of which Thomas Pump and Machinery is a distributor of. Used in municipal applications processes, oil and gas industry, chemical processes and industrial processes, these pumps are highly flexible and durable. This popular pump company, design, engineer and manufacture a wide variety of pumps which include ANSI chemical pumps, centrifugal close coupled as well as self- priming pumps.

Grundfos Pumps is a renowned pump manufacturing company. They manufacture a variety of pumps like submersible stainless-steel pumps, single and multi-stage centrifugal pumps etc. Thomas Pump and Machinery distribute the pumps of this company in various industries for applications like pressure boosting, wastewater transplant, fire protection, washing and cleaning, boiler etc. They are also used in processing applications like mining, automotive, chemicals, power etc. Thomas Pump and Machinery provides a versatile range of pumps from only the best companies. So clients interested in buying pumps can get in touch with Thomas Pump and Machinery.

youtube

0 notes

Text

Rotech provides a walkthrough for you to avoid common pumping mistakes. Rotech is one of the most reliable ANSI centrifugal pump manufacturers in USA & Canada.

0 notes

Text

Low Overseas Freight Cost Waste Water Storage Tanks: Glass-Lined Tanks to International Design Standards

Low Overseas Freight Cost Waste Water Storage Tanks: Glass-Lined Tanks to International Design Standards

At Shijiazhuang Zhengzhong Technology Co., Ltd., also known as Center Enamel, we are dedicated to providing the highest quality wastewater storage solutions. With over 30 years of experience in designing and manufacturing Glass-Fused-to-Steel (GFS) tanks, we are proud to offer low overseas freight cost wastewater storage tanks that adhere to international design standards. Our Glass-Lined Tanks are the perfect solution for wastewater treatment projects, combining durability, efficiency, and cost-effectiveness.

Our Glass-Fused-to-Steel Tanks are designed to withstand the harsh environments associated with wastewater storage, offering superior corrosion resistance and minimal maintenance. These tanks are manufactured to meet strict industry standards such as AWWA D103-09, ISO 28765, NSF/ANSI 61, and NFPA, ensuring their reliability in even the most demanding applications.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Center Enamel's Glass-Lined Wastewater Storage Tanks?

1. Low Overseas Freight Costs

One of the standout features of our Glass-Lined Wastewater Storage Tanks is their low overseas freight costs. Our tanks are engineered to be modular and bolted, meaning they can be shipped in compact and cost-effective packages, reducing both transportation and freight expenses. This makes our tanks an affordable option for international customers, even for projects located far from our production base in China.

The modular design allows us to ship the tanks in smaller sections, which reduces the overall shipping volume and makes transportation more economical, passing the savings on to our customers. Whether you're in Africa, South America, Europe, or Asia, we offer a cost-effective solution to your wastewater storage needs.

2. Superior Corrosion Resistance

Our Glass-Lined Tanks are created by fusing glass to steel at high temperatures, forming a non-porous, smooth, and highly durable surface. This glass coating provides superior corrosion resistance, especially important in wastewater storage where the tank is constantly exposed to harsh chemicals, acids, and gases. The Glass-Fused-to-Steel design ensures long-lasting performance and eliminates the need for frequent repairs or replacements, leading to reduced maintenance costs over the life of the tank.

3. Compliance with International Design Standards

At Center Enamel, we understand the importance of international quality standards. Our Glass-Lined Tanks are engineered and manufactured to meet the strictest standards in the industry, including:

AWWA D103-09: The standard for bolted steel tanks.

ISO 28765: Certification for Glass-Fused-to-Steel tanks.

NSF/ANSI 61: Ensuring safety and quality for drinking water.

NFPA: Ensuring safety and fire resistance in tank designs.

This commitment to international standards guarantees that our tanks are durable, safe, and reliable for wastewater storage applications in any part of the world.

4. Versatility for Various Applications

Our Glass-Lined Wastewater Storage Tanks are used in a variety of applications, including:

Municipal Wastewater Treatment: Storing and managing wastewater in urban environments.

Industrial Effluent Storage: Safely storing effluents from manufacturing processes.

Agricultural Wastewater: Storing runoff and wastewater from farming operations.

Biogas Storage: Storing biogas in wastewater treatment facilities for energy recovery.

These tanks can be customized to meet the specific needs of your project, from varying tank capacities to specialized features such as aluminum dome roofs and seismic resistance.

5. Modular and Efficient Installation

The modular design of our Glass-Lined Tanks allows for quick and easy installation on-site, with no welding required. This not only reduces labor costs but also accelerates the overall construction timeline, ensuring your project stays on schedule. The modular system can be adapted to different tank sizes and configurations to suit your specific needs.

The bolted construction makes these tanks ideal for sites that require flexibility in tank dimensions and the ability to expand over time. If your wastewater treatment facility needs additional storage capacity, simply add more modules to the existing tank.

6. Minimal Maintenance and Longevity

The unique fusion of glass and steel in our tanks creates a highly resistant surface that can withstand the corrosive nature of wastewater without degradation. This ensures that our tanks have a long operational life, requiring minimal maintenance compared to other tank materials. Once installed, they can remain operational for decades, providing a cost-effective and reliable solution for wastewater storage.

Proven Global Success

Our Glass-Lined Wastewater Storage Tanks have been successfully installed in over 100 countries around the world, including high-profile projects in the USA, Canada, Brazil, Russia, South Africa, and Middle Eastern countries. These tanks have been used for a wide range of applications, including wastewater treatment, industrial effluent management, and agricultural wastewater storage. The success of these projects is a testament to the quality, durability, and cost-effectiveness of our Glass-Lined Tanks.

We have earned the trust of major global corporations such as Veolia, Sabesp, Coca-Cola, Wilmar, and PetroChina, who rely on our expertise and high-quality tanks to meet their wastewater management needs.

Why Center Enamel?

As the leading bolted tank manufacturer in Asia, Center Enamel has built a reputation for providing the highest-quality Glass-Fused-to-Steel Tanks with low overseas freight costs, ensuring reliable, cost-effective storage solutions for wastewater across the globe. Here’s why we stand out:

Over 30 years of experience in designing and manufacturing Glass-Fused-to-Steel tanks.

Compliant with international standards such as AWWA D103-09, ISO 28765, and NSF/ANSI 61.

Low freight costs due to modular, bolted tank design that allows for efficient shipping.

Durable, corrosion-resistant tanks for demanding wastewater storage environments.

Proven success with installations in more than 100 countries, including projects in the USA, Brazil, Australia, South Africa, and the Middle East.

Center Enamel's Glass-Lined Wastewater Storage Tanks offer the perfect combination of corrosion resistance, low overseas freight costs, and compliance with international design standards. Our modular bolted design ensures efficient shipping and installation, while the superior durability of our tanks guarantees minimal maintenance and long-term reliability.

Whether you are managing municipal wastewater, industrial effluent, or agricultural runoff, our Glass-Lined Tanks provide the ideal solution for your storage needs. Contact Center Enamel today to learn more about how our cost-effective, high-quality wastewater storage solutions can support your project and contribute to sustainable water management.

0 notes

Text

Introduction to Attacking ICS/SCADA Systems for Penetration Testers

Since coming into use in the late 1960s, Industrial Control Systems (ICSs) have become prevalent throughout all areas of industry and modern life. Whether in utilities, energy, manufacturing or a myriad of other applications, industrial control systems govern much of our lives.

From the invention of the Modular Digital Controller in 1968 until the mid-1990s, ICS networks were almost always isolated, operating with very limited input or output from outside sources. With the rise of cheap hardware, Microsoft Windows, Active Directory and standardization, corporate networks now receive and process data as well as fine-tune operations from networks outside of the traditional ICS network. While significant effort to ensure segmentation between IT (information technology) and OT (operational technology) networks in modern environments is occurring, the blurring of the lines between IT and OT networks has resulted in a security headache for many industries.

ICS vs. SCADA

While the terms Industrial Control Systems and Supervisory Control And Data Acquisition (SCADA) are often used interchangeably, an important distinction between the two exists. ICS is the name given to the broader category of technology, where SCADA is a subcategory of ICS. Examples of ICS subcategories include:

Distributed Control Systems (DCS)

Offers real-time monitoring and control over processes.

Typically several components are located within a geographically small distance such as an oil refinery, coal plant, hydroelectric dam, etc. DCS are usually contained within the four walls of a building.

Programmable Logic Controllers (PLC)

Typically, ruggedized computers that are the brains of smaller moving parts in a given process control system.

Supervisory Control And Data Acquisition (SCADA)

Acts as a manager of sorts.

Supervisory servers do not typically make decisions.

Supervisory servers typically relay commands from other systems or human operators.

Historians

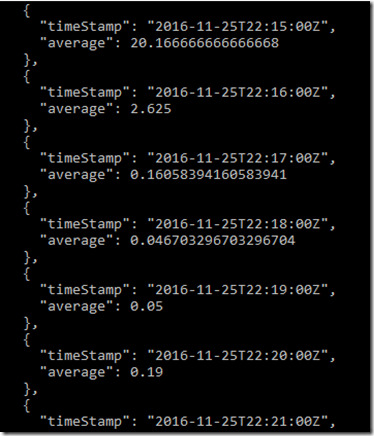

Collect and store data regarding process statistics, sensor readings, inputs/outputs and other measures.

May be required for regulatory purposes.

Typically data is stored in a database such as MSSQL or Oracle.

Human Machine Interface (HMI)

HMIs are ‘pretty pictures’ allowing a process engineer to monitor an entire ICS system, at a glance.

Usually features graphics of various pumps, relays and data flows.

Remote Terminal Unit (RTU)

Small, ruggedized computers that collect and correlate data between physical sensors and ICS processes.

Adding additional complexity to ICS environments are the many different communications protocols in use. Examples of both common and proprietary protocols implemented in ICS environments include:

ANSI X3.28

BBC 7200

CDC Types 1 and 2

Conitel 2020/2000/3000

DCP 1

DNP3

Gedac 7020

ICCP Landis & Gyr 8979

Modbus

OPC

ControlNet

DeviceNet

DH+

ProfiBus

Tejas 3 and 5

TRW 9550

Typical ICS architecture

When designing ICS environments, high availability, regulatory requirements and patching challenges can significantly constrain design choices. In order to fit into the necessary restrictions, most ICS environments tend to follow the following three tiered structure:

At the uppermost level, the HMIs and SCADA servers oversee and direct the lower levels, either based upon a set of inputs or a human operator. Typically data from the SCADA servers is gathered by the HMI, then displayed to engineering workstations for ICS engineers’ consumption.

The middle layer typically collects and processes from inputs and outputs between layers. The devices performing at this layer, known as Field Controllers, include programmable logic controllers (PLCs), intelligence electronic devices (IEDs) and remote terminal units (RTUs). Field Controllers can coordinate lower level actions based upon upper level directions, or send process data and statistics about the lower level to the upper level.

At the lowest level, devices known as Field Devices are responsible for the moving parts and sensors directing the movement of pumps, robotic arms and other process-related machinery. Additionally, they typically include various sensors to monitor processes and pass data along to the middle layer (i.e. Field Controllers) for data processing.

Communication links between the layers are often required in ICS environments and this communication typically utilizes different protocols. Communication between the SCADA server located in the upper layer and Field Controllers in the middle layer typically utilize common protocols such as DNP3 or Modbus. For communication between Field Controllers and lower level Field Devices, commonly used protocols include HART, Foundation Fieldbus and ProfiBus.

Although designing networks that meet the ICS requirements can be challenging, organizations with ICS typically achieve this by having three zones in their infrastructure:

Enterprise Zones contain the typical corporate enterprise network. In this network are standard corporate services such as email, file/print, web, ERP, etc. In this zone all of the business servers and employee workstations reside.

The ICS demilitarized zones (DMZs) typically allow indirect access to data generated by the ICS system. In this zone there are typically the secondary Historian, as well as some web and terminal applications.

Finally, the Process Control Zones are where the three layers of ICS systems reside. This zone should be inaccessible from the Enterprise Zone and limited to read-only access from the HMIs and SCADA servers.

ICS and Risk

ICS technology was originally designed without consideration of authentication, encryption, anti-malware tools, firewalls or other defense mechanisms. The lack of such considerations influences how these systems are designed and operated. For example, one of the traditional IT risk mitigation strategies is the timely application of security patches to vulnerable systems. While traditional IT systems can absorb downtime, most ICS systems incur significant costs in loss of production preventing them from being patched on a routine basis. Additionally, unlike traditional IT systems, a failed update on an ICS device could have catastrophic consequences such as contaminated food, blackouts, severe injury, or death.

While a determined attacker may gain direct access to the ICS environment via social engineering or physical attacks, it’s more likely they will pivot from the corporate network leveraging trusted network connections to SCADA servers and HMIs. Even if the attacker doesn’t manage to exfiltrate sensitive data or perform sensitive actions, the fines, investigations and regulatory reprisals generated with a breach to the ICS environment could prove financially catastrophic for organizations. The following are real-world ICS incidents and attacks:

In 1982, it is rumored the CIA introduced a piece of malicious software into a Soviet gas pipeline in Siberia that was responsible for the largest non-nuclear explosion ever recorded. (http://www.telegraph.co.uk/news/worldnews/northamerica/usa/1455559/CIA-plot-led-to-huge-blast-in-Siberian-gas-pipeline.html)

In March of 1997, a Massachusetts teenager shut down the Worcester, MA airport by crashing its distributed phone system, main & backup radio transmitters and a printer used to monitor flight progress. (http://www.cnn.com/TECH/computing/9803/18/juvenile.hacker/index.html)

In the Spring of 2000, Vitek Boden, a disgruntled Australian SCADA engineer at Maroochy Water Services intentionally caused 800,000 liters of raw sewage to spill into local parks, rivers and even the grounds of a Hyatt Regency hotel. (http://csrc.nist.gov/groups/SMA/fisma/ics/documents/Maroochy-Water-Services-Case-Study_report.pdf)

On January 25th, 2003 the SQL Slammer worm caused a safety monitoring system at the Davis-Besse nuclear power plant in Ohio to go offline for nearly five hours. (http://www.securityfocus.com/news/6767)

In 2007 at Idaho Falls National Laboratory, the Aurora generator test was conducted to demonstrate how a simple python script can cause physical hardware components in an electric generator to fall out of sync, causing massive physical damage. (https://www.youtube.com/watch?v=fJyWngDco3g)

In 2008 a Polish teenager demonstrated risks to field devices, in this case rail switches, when he used a repurposed TV remote to transmit commands to his city’s rail systems, causing several derailments. (https://www.wired.com/2008/01/polish-teen-hac/)

In 2010 possibly the most widely known ICS attack occurred at the Natanz nuclear facility in Iran. The malware, eventually named STUXNET, was found to be the most sophisticated ICS malware ever discovered. The malware specifically targeted the PLCs and HMIs associated with the centrifuges used to create fissile nuclear materials. (https://www.wired.com/2014/11/countdown-to-zero-day-stuxnet/)

In 2014, an unidentified German steel mill sustained damage due to a cyberattack on their ICS network that prevented the mill’s blast furnace from shutting down properly. (https://www.wired.com/2015/01/german-steel-mill-hack-destruction/)

On December 23, 2015 attackers cut power to at least seven 110 kV and twenty three 35kV substations operated by Ukraine’s Prykarpattya Oblenergo and Kyivoblenergo utilities. This attack on their SCADA system cut power to 80,000 customers for six hours. (http://www.theregister.co.uk/2016/01/15/malware_clearly_behind_ukraine_power_outage_sans_utility_expert_says/)

Although attacks like STUXNET may seem like an easy way to cause mayhem and destruction, several special considerations should be taken into account when attacking ICS:

If an attacker can intercept and modify data between Field Devices and Field Controllers, it is possible to feed false data back to HMIs. The HMI will present inaccurate data causing the human operators to make potentially dangerous changes based on this inaccurate data. Proof of a successful man-in-the-middle attack that alters data like this will likely top the list of critical findings.

Many Field Controllers require no authentication, allowing commands to be issued by any system on the network. Leveraging tools such as Scapy, Modbus or DNP3 packets can be crafted with ease.

IT knowledge, when combined with process knowledge, can be leveraged to cause specific kinetic impacts through cyber means; that is the key to the ‘big boom’ Hollywood scenarios. A Proof of Concept attack demonstrating an attack like this will make for a 5-star report.

In our next blog post we’ll walk through a typical ICS/SCADA security assessment, including a description of each of the major phases, what to look out for, and common issues and misconfigurations we’ve seen in the field.

from Introduction to Attacking ICS/SCADA Systems for Penetration Testers

0 notes

Text

Some Of The Main Advantages Of The Different types Of Industrial Pumps

With the growth and development evident in different sectors of our economies, the need to employ the use of different equipment and machines to carry out different activities has really been emphasized. The different equipment and machinery that are used help to make work easier by cutting down different costs that are incurred when producing different outputs. They not only save on time but also encourage mass production leading to an increase in the realized profits at the end of the process. One of the most used machinery in the industrial sector is the industrial pump. The different industrial pumps are used for carrying out different activities in different industries. Learn more about industrial pump manufacturers, go here.

Industrial pumps are heavy-duty process pumps that are used to move different types of products, including chemicals, water, wastewater, petroleum, sludge, oil, food or slurry. The commonly used industrial pumps are the positive displacement pumps and centrifugal pumps. Other examples of industrial pumps are the diaphragm pumps, magnetic drive pumps, centrifugal pumps, peristaltic pumps, gear pumps, piston pumps, drum pumps and hygienic lobe pumps.

Different types of industrial pumps have been invented to help us in carrying out different activities in a factory. Each industrial pump is designed with different features which are able to offer unique advantages. The main types of industrial pumps are the centrifugal pumps, API process pumps, ANSI process pumps, axial flow pumps, booster pumps, piston pumps, progressive cavity pumps, screw pumps, gear pumps, lobe pumps, vertical sump pumps, vertical turbine pumps, submersible pumps, self-priming pumps, multistage pumps, magnetic drive pumps, horizontal split case pump and diaphragm pumps.

A centrifugal pump is a type of industrial pump that helps in moving high flow rates and lower viscosity liquids. The ANSI process pumps are able to allow for the movement of different liquids because they are designed using dimensional standardization. API process pumps are those types of industrial pumps that are used for moving high pressure and high temperature hydrocarbon while assuring the safety of the users. Axial flow pumps are types of industrial pumps that are used to achieve a high flow rate using a low head.

The booster pumps are pumps that allow for the build up of any additional pressure that is required to move different liquids over very long distances. The different industrial pumps are very important in different factories and industries that transport different liquids over some given distance since each industrial pump is designed with its unique features.

0 notes

Text

Anti-Leaking Biogas Storage Tanks Made from Glass-Fused-to-Steel Sheets

Efficient and durable storage solutions are critical for biogas projects, which require airtight tanks to ensure the optimal containment of gases and liquids. Shijiazhuang Zhengzhong Technology Co., Ltd. proudly offers anti-leaking biogas storage tanks made from Glass-Fused-to-Steel (GFS) sheets, a superior technology that guarantees reliability, safety, and performance.

What are Glass-Fused-to-Steel Biogas Storage Tanks?

Glass-Fused-to-Steel technology combines the strength and flexibility of steel with the corrosion resistance of glass. This innovative fusion creates a surface that is not only highly resistant to chemical attack but also impermeable to gases and liquids, making it an ideal choice for biogas storage.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Key Features of Anti-Leaking Biogas Storage Tanks

Leakproof Design

The GFS sheets feature a non-porous surface, ensuring no leaks even under high pressure.

Precision-engineered bolted panels and high-quality sealants further enhance the tank's impermeability.

Corrosion and Abrasion Resistance

Resistant to both acidic and alkaline conditions typically found in biogas digesters.

Suitable for harsh environments, including those with extreme temperatures or aggressive chemical exposure.

Durability and Longevity

Designed to withstand over 30 years of use with minimal maintenance.

The double-layer enamel coating enhances tank performance and provides robust protection against environmental wear.

Airtight Performance

The tanks are meticulously sealed to ensure complete gas retention, supporting efficient biogas collection and storage.

Scalability and Customization

Available in various sizes, from small-scale to large industrial applications.

Customizable designs include double-membrane roofs, color options, and specific structural configurations to meet project requirements.

Advantages of Using GFS Tanks for Biogas Storage

Fast Installation: Bolted construction allows for quick assembly and reduced labor costs.

Portability: Tanks can be dismantled and relocated to new sites as needed.

Compliance with International Standards: Our tanks meet or exceed global standards, including AWWA D103-09, ISO 28765, and NSF/ANSI 61.

Eco-Friendly: High recyclability of materials aligns with sustainability goals.

Applications of Anti-Leaking Biogas Storage Tanks

Anaerobic Digesters

Essential for the production of biogas from organic waste.

Airtight tanks ensure efficient gas collection during the digestion process.

Agricultural Waste Storage

Designed for biogas generation from animal manure and crop residues.

Municipal Wastewater Treatment

Ideal for biogas recovery from sludge digestion.

Industrial Applications

Used in food processing, breweries, and other industries for organic waste biogas recovery.

Proven Track Record of Excellence

Shijiazhuang Zhengzhong Technology Co., Ltd. has supplied GFS biogas storage tanks to over 100 countries, with successful projects across diverse industries. These tanks have consistently demonstrated their durability, reliability, and superior anti-leaking performance in real-world applications.

Why Choose Our Biogas Storage Tanks?

Advanced Manufacturing Process

A proprietary enameling process ensures consistent coating quality and adhesion.

Over 20 patents in enameling technology reflect our commitment to innovation.

Global Expertise

Decades of experience in delivering storage solutions for biogas projects worldwide.

Projects comply with AWWA, OSHA, and other international standards.

Comprehensive Support

From design and installation to after-sales service, we provide end-to-end solutions tailored to client needs.

For airtight, durable, and cost-effective biogas storage solutions, Shijiazhuang Zhengzhong Technology Co., Ltd. leads the industry with its Glass-Fused-to-Steel tanks. Designed for longevity and optimal performance, these anti-leaking biogas storage tanks are the perfect choice for any biogas project, offering reliability and efficiency at a competitive price.

Contact us today to discuss your biogas storage requirements and explore how our tanks can benefit your project!

0 notes

Text

Wastewater Storage Tanks by Center Enamel: Durable Bolted Steel Tanks for Reliable Wastewater Treatment

Wastewater Storage Tanks by Center Enamel: Durable Bolted Steel Tanks for Reliable Wastewater Treatment

At Shijiazhuang Zhengzhong Technology Co., Ltd., we provide innovative solutions for wastewater storage with our high-quality bolted steel tanks. Known for their durability, ease of installation, and adaptability, our wastewater storage tanks are engineered to meet the rigorous demands of both municipal and industrial wastewater treatment systems. With over 30 years of experience, we have designed tanks that combine advanced materials with strict adherence to global standards, ensuring they perform efficiently under various environmental conditions.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Bolted Steel Tanks for Wastewater Storage?

Bolted steel tanks are a preferred choice in the wastewater industry due to their modular design, which allows for faster installation, adaptability, and easy transportation. Compared to traditional concrete tanks, bolted steel tanks provide several unique advantages:

Quick Installation and Flexibility

Bolted steel tanks can be rapidly assembled on-site, often without the need for specialized equipment. This modular design also allows tanks to be expanded or relocated as project requirements change, making them highly versatile.

Durability and Corrosion Resistance

Our tanks are constructed with Glass-Fused-to-Steel (GFS) and fusion-bonded epoxy coatings, providing superior corrosion resistance even in aggressive wastewater environments. This coating technology ensures that the tanks withstand various chemical compositions found in wastewater and resist rust, abrasion, and chemical damage.

Cost-Effective and Low Maintenance

Bolted steel tanks have a long lifespan and require minimal maintenance compared to other storage solutions. The durable, corrosion-resistant coatings significantly reduce the risk of deterioration, extending the service life of each tank and minimizing operational costs over time.

Compliance with International Standards

Our wastewater storage tanks are manufactured in accordance with AWWA D103, OSHA, and ISO 9001 standards. We also meet NSF/ANSI 61 for potable water applications, which means that our tanks can safely be used in wastewater processes that require treated water for reuse.

Key Features of Our Wastewater Storage Tanks

Glass-Fused-to-Steel Coating for Enhanced Performance

Our tanks utilize a Glass-Fused-to-Steel coating, where glass and steel are fused at temperatures exceeding 800°C. This creates a hard, inert surface that is resistant to corrosion, chemical attack, and temperature changes. The coating is non-reactive and protects the underlying steel, ensuring the tank’s integrity over time.

Customizable Roof Options

Wastewater storage tanks often require specific roof types to manage odors and reduce contamination risks. We offer a range of options, including Aluminum Dome Roofs and Double Membrane Roofs for effective gas containment. These roofs enhance environmental control and provide added protection for wastewater treatment processes.

Leakproof, Watertight Design

The bolted design of our tanks incorporates advanced sealing technology to ensure a watertight and leakproof structure. This feature is crucial for wastewater storage as it prevents leaks and protects the surrounding environment from contamination.

Scalable Capacity

Our bolted steel tanks are available in a range of sizes, with capacities from 20m³ to over 60,000m³. The modular nature allows for easy scaling, so additional capacity can be added as needed without significant structural changes.

Applications of Our Bolted Steel Wastewater Storage Tanks

Our bolted steel tanks serve a diverse range of wastewater storage and treatment applications, from municipal wastewater treatment plants to industrial facilities. Typical applications include:

Municipal Wastewater Storage and Treatment

Municipal treatment plants benefit from the efficiency and durability of our tanks, designed to store and treat large volumes of wastewater securely. Our tanks facilitate efficient water management for cities and towns of various sizes.

Industrial Effluent Storage

Many industries, including food processing, manufacturing, and mining, generate significant volumes of wastewater. Our tanks provide safe, reliable storage for industrial effluents, including those with high chemical or thermal loads.

Stormwater Management

Stormwater tanks help manage excess rainwater and prevent flooding. Our tanks are well-suited for collecting and storing stormwater, providing a sustainable solution to manage and treat runoff before it is safely released or repurposed.

Sludge Treatment and Storage

Wastewater treatment often produces sludge as a byproduct. Our tanks can store sludge securely, providing a contained environment for further processing, disposal, or reuse.