#ACC Cement

Explore tagged Tumblr posts

Text

Buy Cement Online: Quality Cement Products from Site Supply

In today’s fast-paced world, ordering construction materials like if you wanna buy cement online. We offer unmatched convenience and efficiency. At Site Supply, we provide a seamless experience for contractors, builders, and DIY enthusiasts looking to buy high-quality cement online. From a diverse range of brands to easy ordering and delivery, Site Supply is your trusted partner for sourcing cement online for any construction project.

With Site Supply, purchasing cement is simple, quick, and reliable. Our platform offers top-grade cement from leading brands to ensure the best quality for your projects. Whether you’re working on residential, commercial, or industrial construction, we cater to all cement requirements with competitive pricing and nationwide delivery.

Visit Us – https://sitesupply.in/product/jk-white-cement25kg

#white cement price#construction materials#buy cement online#jk cement#acc cement#cement prices#white cement#cement

0 notes

Text

We provide quality construction material like #cement & #TMTBars. Minimum order 1000 bags. Call Us @ 8700899195 or visit us @ tradebhavan.com

#acc cement#ambuja cement#bangur cement#birla uttam cement#dalmia cement#jk lakshmi cement#jk super cement#konark cement#rockstrong cement#shree cement

0 notes

Text

Cement Prices in Gurgaon, Haryana: Grades, Brands, and Cost Comparison

Explore the prices of cement in Gurgaon, Haryana, including different grades and popular brands such as UltraTech, Ambuja, JK Lakshmi, and more. Discover the best cement for foundations and the differences between 43-grade and 53-grade cement. Call us at +91 8377044077 https://www.comaron.com/blog/cement-bag-prices

#telangana cement#major component in building material cement is#components of concrete#main components of cement#acc cement#acc cement price#acc gold cement price#acc cement price per bag#acc cement rate#dalmia cement#dalmia cement price#dalmi dsp#lafarge duraguard cement

0 notes

Text

Best cement in India: Things to consider before buying a cement

For many homeowners, planning to build their dream home is a one-time investment, and therefore every builder wants to be 100% sure about the strength and durability of the construction. For constructing a strong and durable home that should stand tall for years, getting the best building materials that focus more on the quality and grade of cement used is essential.

Any construction is complete with the use of cement. To ensure the structure lasts long, purchasing the best quality cement from the leading cement manufacturing companies is essential.

Best cement brands in India

Ultratech Cement: Ultratech Cement is undoubtedly one of the greatest cement brands in India. Founded in the year 1983, it is the largest manufacturer of grey cement, ready mix concrete, and white cement in India. With more than 185+ ready-mix concrete plants in 85+ cities across India, Ultratech is the only cement company outside China with 100+ metric tonnes per annum of cement manufacturing capacity.

ACC cement: ACC cement is probably one of the oldest cement manufacturing companies in the world. Started in the year 1936, ACC Limited is India’s foremost manufacturer of cement and ready-mixed concrete with a countrywide network of factories.

Wonder Cement: Wonder Cement is only a decade-year-old brand but has proved to be one of the best cement companies for PPC cement and OPC cement in almost every part of India, including the states like Maharashtra, Gujarat, Rajasthan, Uttar Pradesh, Haryana, Madhya Pradesh, Delhi, Punjab, Uttarakhand, and Jammu and Kashmir. Currently, Wonder Cement has four products, namely Wonder OPC, Wonder PPC, Wonder Xtreme, and Wonder Plus. These products are very consistent regarding quality and deliver the best results.

JK Cement: JK Cement is a leading cement brand in India, with a manufacturing capacity of 14.7 million tonnes per annum. The company has a presence in all regions of the country and offers various types of cement, including OPC, PPC, and PSC.

Things to consider before buying a cement

Before constructing any project, do consider checking the quality of cement that is being used under the project so that it can have a positive long-term effect. So before making any decision, do consider these points:

Strength of the cement: The strength of cement is measured under high compressive strength, which is directly proportional to its setting time, and the curing time required. You can check the quality by collecting some samples by the relevant standards, such as ASTM C183–14 or IS 3535:1986. Prepare the specimen by adding water to the cement and mixing it thoroughly until a smooth and consistent paste is obtained. After filling it in moulds, compact the specimen by removing the voids and air bubbles from the specimen by using a vibrating table or a compaction rod. Cure the specimen for 24 hours to 28 days, and then test the specimen by calculating its compressive strength.

Quality of cement: Determine the cement quality by its chemical composition and the manufacturing process. It is essential to choose a cement brand that adheres to the Bureau of Indian Standards (BIS) and has a high level of consistency.

Manufacturing Date: As time goes on slowly, the strength of cement decreases. The cement usually loses all its strength after three months of the manufacturing date, which can hinder construction efforts. Therefore check the manufacturing date of the cement on the cement bag.

Price: The price of cement varies from brand to brand. It is essential to check out all the cement brands available in the market and choose a cement brand that is affordable and offers value for money.

Choosing the best cement in India is crucial for the success of any construction project. It is essential to consider all these factors before making a purchase. UltraTech Cement, ACC Cement, Wonder Cement, and JK Cement are some of the best cement brands in India.

#best cement in india#strength of cement#quality of cement#manufacturing date#cement price#cement manufacturing companies#jk cement#acc cement#ultratech cement#wonder cement

0 notes

Text

"i wonder, if he's always been like this all the time"

I'm gonna hold your hands when I say this Mikasa....

#eren#eren jaeger#eren yaegar#attack on titan#aot#snk#digital illustration#look at him#he was forced to eat cement when he was 6#also he's tad crazy#nvm scrap out the tad#guys i acc love drawing him

5 notes

·

View notes

Text

ACC Ltd

#ACC Ltd : Funds Starts Buying Above 2249 Cash Level...!!!

#Jefferies Initiate Buy Rating : Target 2760

#Bullish View✅✅✅

#BreakoutStock

1 note

·

View note

Text

Acc Cement, Acc Ppc Price Today in Hyderabad

ACC Cement Rate, Acc PPC cement price today in Hyderabad, Buy ACC cement at best price in Hyderabad, we have the today's updated price of ACC cement in Hyderabad.ACC Cement remains a top choice for construction projects in Hyderabad, known for its reliability and quality. Whether you are constructing a new building or renovating an existing one, using ACC PPC Cement can ensure long-lasting and sturdy results. As you make your purchase, keep an eye on the latest price updates and consider bulk buying to take advantage of possible discounts. Always purchase from reputable suppliers to guarantee the authenticity of the cement and the success of your project.The price of ACC Cement in Hyderabad can vary based on several factors, including demand, supply, and market conditions. Typically, the cost of cement is influenced by raw material prices, transportation costs, taxes, and other logistical expenses.

#Acc suraksha cement online#Acc suraksha cement cost today#Acc cement suppliers#Acc Ppc Price list in hyderabad#Acc cemant dealers in hyderabad.

0 notes

Text

https://www.buildersmart.in/acc-hpc-long-life-cement

Buy ACC Cement, ACC, and PPC Cement at the best price online in Hyderabad. Choose from a range of high-quality construction materials. Keywords: ACC Cement, ACC, PPC Cement, Hyderabad.

0 notes

Text

Adani Cement Successfully Refinances $3.5 Billion Loan for ACC and Ambuja Cements

Adani Cement Strategic Refinancing After Ambuja and ACC Cements

Another indication of the growing backing that financial institutions and investors are giving the conglomerate is the fact that Adani Cement has refinanced a $3.5 billion loan that was taken out for the acquisition of ACC and Ambuja Cements.

Gautam Adani successfully acquired the arms of Holcim India in September 2022 through Endeavour Trade and Investment Ltd, a special purpose company. The acquired companies were Ambuja Cements Ltd and ACC Ltd.

In addition to an open offer to the shareholders of both companies, Holcim’s investment in Ambuja and ACC was acquired as part of the transaction.

At $6.50 billion, the Holcim stake plus the open offer consideration for Ambuja Cements and ACC made it the largest acquisition by Adani to date and the largest M&A deal in India’s materials and infrastructure sector.

The deal included Holcim’s 4.48 percent direct holding in ACC as well as its 63.11 percent stake in Ambuja Cements, which had a 50.05 percent interest in ACC.

In a proclamation delivered on Friday, Adani Concrete declared that it had completed the most common way of renegotiating the obligation that the two firms had taken on through a supporting bundle from various unfamiliar banks.

There will be a $300 million expense reserve funds from the renegotiate. Ten unfamiliar banks altogether participated in the plan.

Adani Concrete expressed, “The $3.5 billion re-funding program, which was finished with various global banks and had obligation developments of as long as three years, authenticates areas of strength for the and admittance to capital, enhancing the strong capital prudency embraced at all portfolio organizations.”

This shows Adani’s strong liquidity position and wide admittance to the worldwide monetary area. It expressed, “This achievement exhibits our commitment to development and monetary steadiness.”

Adani Cement’s Capital Management Success and Growth Prospects

The company states that the $3.5 billion refinance represents the ongoing implementation of the capital management plan that was first presented in September 2022 and calls for Adani Cement to gradually reduce its leverage, with cement vertical net debt to EBITDA (earnings before interest, tax, depreciation, and amortization) now being less than twice as high.

0 notes

Text

Indian Cement Industry Challenges

The cement industry is an important sector of the Indian economy. India is the second-largest producer of cement in the world, after China. The segment contributes significantly to the economic development of the country by creating employment opportunities and generating revenue. The industry plays a vital role in the infrastructure development of the country, including the construction of highways, bridges, and buildings. In this article, we will discuss the cement industry in India, its history, growth, challenges, and future prospects.

History of the Cement Industry in India

The Indian cement industry dates back to 1914 when the first cement plant was set up in Chennai. Since then, the industry has grown significantly, and India is now the second-largest cement producer in the world. The industry has witnessed several milestones, including the establishment of the first dry process plant in 1956 and the commissioning of the first pre-cast concrete product plant in 1968.

Growth of the Indian Cement Industry

The cement industry in India has grown significantly in the past few decades. In the 1980s, the government opened up the industry for private players, which led to increased competition and growth. The industry saw a surge in demand in the 1990s due to the increase in infrastructure development and urbanization. The industry witnessed a compound annual growth rate (CAGR) of around 8% between 2012 and 2019. The cement industry’s production capacity is expected to reach 550 million tons by 2025, driven by the government’s infrastructure spending and the real estate sector’s growth.

Challenges faced Hitherto

The cement industry in India faces several challenges, including environmental concerns, land acquisition, and logistics issues.

The industry is a significant contributor to carbon emissions, and the government has implemented several measures to reduce its environmental impact.

The industry also faces challenges related to land acquisition, as the process can be time-consuming and expensive.

Logistics is another significant challenge for the industry, as transportation costs account for a significant portion of the overall cost of cement production.

Future prospects of the Cement Industries in India

Despite the challenges, the future of the industry in India looks bright. The government’s focus on infrastructure development and the real estate sector’s growth expects to drive demand for cement in the coming years. The industry is also adopting new technologies to reduce its environmental impact and improve efficiency. The use of alternative fuels and raw materials, such as biomass and waste, is expected to increase in the coming years, reducing the industry’s carbon footprint.

Conclusion

The cement industry is an important sector of the Indian economy, contributing significantly to the country’s development. The industry has grown significantly in the past few decades, and the future looks bright with the government’s focus on infrastructure development and the real estate sector’s growth. However, the industry faces several challenges, including environmental concerns, land acquisition, and logistics issues. The industry is adopting new technologies to address these challenges and reduce its environmental impact.

Note: Also Please Like Share, and Comment on Facebook Page

#Cement Order Online in Gurgaon#Cement Supplier in Gurgaon#Ultratech Super Cement Price Per Bag#Bangur Cement price Per Bag#Ambuja Cement in Gurgaon#Cement Supplier Gurgaon#ACC Cement Price in Gurgaon

0 notes

Text

All cement price list today 2023 - Cement Price per bag today

All cement price list today is the most important update every construction engineer and civil engineering construction firm should be familiar with. Cement is the most significant and widely used construction material which forms an integral part of any structure. Cement is the major ingredient of concrete and mortar and the structural stability and life of a structure or building depend on the…

View On WordPress

#acc all cement price list today#all cement price list today 2021#all cement price list today 2022#all cement price list today in bihar#all cement price list today in punjab#all cement price list today in up#non trade cement price today#price of cement#price of cement bag#price of cement bag in india#price of cement blocks#price of cement board#price of cement bricks#price of cement mixer#price of cement mixer truck#price of cement per bag#price of cement per kg#price of cement sheet#price of cement today#today price of cement#ultratech all cement price list today

0 notes

Text

Building Materials from Site Supply: Tata Sariya, RHL Gold, ACC Cement, and UltraTech Cement

At Site Supply, we are committed to providing high-quality construction materials to meet the needs of residential and commercial projects. From Tata Sariya (TMT bars) to RHL Gold (steel rods), ACC Cement, and UltraTech Cement, we offer products that ensure strength, durability, and reliability in construction. Understanding the properties and benefits of each of these materials can help builders make the best choices for their projects.

Tata Sariya (TMT Bars)

Tata Sariya is one of the most trusted names in the world of construction. These TMT bars (Thermo Mechanically Treated) are designed to provide enhanced strength and flexibility, making them ideal for earthquake-resistant structures.

Key Features of Tata Sariya:

High Strength: Tata Sariya is known for its exceptional tensile strength, which ensures the long-lasting durability of structures.

Corrosion Resistance: The TMT bars are designed to resist corrosion, which is particularly important in areas with high humidity or exposure to chemicals.

Ductility: The unique manufacturing process of Tata Tiscon Sariya makes it highly ductile, allowing it to bend without breaking, making it a top choice for seismic zones.

RHL Gold

RHL Gold is a premium brand of steel rods that is widely used in both residential and commercial construction. Known for its superior quality and strength, RHL Gold offers excellent support for building structures.

Benefits of RHL Gold Steel Rods:

Superior Strength: RHL Gold rods provide strong reinforcement, ensuring the structural integrity of buildings.

Resistance to Wear and Tear: These rods are designed to withstand high levels of stress, making them durable for all types of construction.

Cost-Effective: While providing high quality, RHL Gold is also an affordable option for builders looking to balance performance and budget.

ACC Cement

ACC Cement is one of India’s leading cement brands, known for its consistency and quality. It is widely used in residential, commercial, and industrial construction projects.

Advantages of ACC Cement:

High Compressive Strength: ACC Cement offers high compressive strength, making it ideal for load-bearing structures.

Fast Setting: With fast-setting properties, ACC Cement helps reduce construction time, allowing for quicker project completion.

Eco-Friendly: ACC Cement has a low carbon footprint due to its energy-efficient manufacturing process, making it a sustainable choice for builders.

UltraTech Cement

As one of the largest cement manufacturers in India, UltraTech Cement is synonymous with quality and innovation. It is a preferred choice for large-scale infrastructure projects and high-rise buildings.

Key Features of UltraTech Cement:

Superior Strength: UltraTech Cement is known for its superior compressive strength, making it ideal for both heavy-duty infrastructure and residential projects.

Durability: It provides excellent durability, ensuring that structures last for decades without significant wear or damage.

Consistency: UltraTech Cement maintains a consistent quality, ensuring uniformity in construction across all types of projects.

FAQs about Building Materials from Site Supply

1. What are the benefits of using Tata Sariya for construction? Tata Sariya offers high tensile strength, corrosion resistance, and flexibility, making it ideal for earthquake-resistant buildings. It ensures the longevity and durability of your structure.

2. Is RHL Gold suitable for residential construction? Yes, RHL Gold steel rods are excellent for residential construction due to their superior strength and resistance to wear and tear. They offer a cost-effective yet high-quality solution for reinforcement.

3. Which cement is better: ACC or UltraTech? Both ACC Cement and UltraTech Cement are top-quality brands. ACC Cement is known for its fast setting and eco-friendly production, while UltraTech is preferred for its superior strength and durability. The choice depends on the specific needs of your project.

4. How do I choose the right TMT bars for my construction project? When choosing TMT bars, consider factors like tensile strength, ductility, and corrosion resistance. Tata Sariya is a great option for those seeking high strength and flexibility, especially in areas prone to earthquakes.

5. What are the applications of UltraTech Cement? UltraTech Cement is widely used in large-scale infrastructure projects, including bridges, highways, and skyscrapers. It is also used in residential construction, ensuring durability and strength in load-bearing structures.

6. How can I reduce the cost of cement for my construction project? You can reduce the cost of cement by purchasing in bulk from suppliers like Site Supply, using alternatives like blended cements, and optimizing the mix design to avoid wastage.

7. What are the delivery options available for cement and TMT bars from Site Supply? Site Supply offers fast and reliable delivery options across different locations. For bulk orders, we provide scheduled deliveries to ensure materials reach your site on time, preventing delays in construction.

At Site Supply, we pride ourselves on providing the best building materials, from Tata Sariya and RHL Gold to ACC Cement and UltraTech Cement. With a focus on quality, strength, and affordability, we are your trusted partner for all your construction needs. Whether you’re working on a small residential project or a large commercial development, our products will ensure the success of your construction.

#buy cement online#construction materials#Tata Sariya#RHL Gold#ACC Cement#building material#buy white cement online

0 notes

Text

We provide quality construction material like #cement & #TMTBars. Minimum order 1000 bags. Call Us @ 8700899195

#ultratech cement#wonder cement#ACC Cement#Ambuja Cement#Shree Cement#Bangur Cement#Rockstrong Cement#JK Super Cement#JK Lakshmi Cement#Birla Uttam Cement#Konark Cement#Dalmia Cement

0 notes

Text

you best believe everytime max is on the podium with checo and carlos he will ask where charles is like this man does nawt rate the other two and just knows for them to be there and not charles something must've happened😭 but honestly I appreciate his dedication to making that cooldown room all about charles eventhough he had just grand slammed the opening race and charles wasn't even there

he's trying so hard to cement his title as charles' no.1 fan, following a charles fan acc wasn't enough

511 notes

·

View notes

Text

How cement producers set prices and how to navigate them as a buyer

Cement is one of the essential building materials used in the construction of any project ranging from residential buildings to commercial buildings, bridges, and highways. In India, the construction sector is a highly competitive market, with numerous cement producers like Ultratech Cement, Wonder Cement, Ambuja Cement, ACC Cement, etc., vying for a slice of the pie. However, for those who are working in the construction sector and rely on cement for their construction needs, understanding how cement producers set prices and how to navigate them as a buyer can be a daunting task. In this article, we will take a look at the factors that effects cement prices.

Various factors influence the cement price, ranging from the cost of raw materials to supply and demand dynamics, regional pricing differences, and even weather conditions. Raw material costs, including the price of limestone, clay, and other materials used in cement production, can have a significant impact on pricing. These costs can vary depending on the location of the cement plant, government regulations, and the availability of these materials in the region. Limestone is the primary raw material used in cement production, and it typically accounts for 60% to 70% of the total raw material mix. Clay is the second most important raw material in cement manufacturing, and it typically accounts for 10% to 15% of the total raw material mix. Gypsum is the final raw material used in cement manufacturing, accounting for less than 5% of the total raw material mix. So if the price of a cement bag is around Rs 400, then the GST levied by the government will be 28% of the total price, which means the GST is Rs 112 per bag. Apart from this, various other factors such as availability of raw materials, transporting of raw materials, finishing goods, supplying the finished goods, etc., are other such factors that affect the prices.

Prices tend to rise and fall depending on the supply and demand dynamics. Regional prices also play a huge role in cement pricing. For example, cement produced in coastal regions may be cheaper than inland regions due to the cost of transporting materials to and from the plant. Finally, weather conditions can also impact cement pricing. Extreme weather events, such as hurricanes or heavy rainfall, can disrupt transportation and production, leading to supply chain disruptions and higher prices.

For buyers looking to navigate the cement producers for them, one of the most effective methods is to maintain a strong relationship with cement producers. By building long-term partnerships, buyers can secure favourable pricing and ensure a reliable supply of high-quality cement. Another strategy is to stay informed about the market outlook for cement products. This can involve monitoring industry publications and reports, as well as engaging with industry experts and attending industry events. For example, the latest trend says that Indian cement manufacturers will announce discounts and schemes so that there will be the availability of cement for sale to meet their year-end volume targets and may raise prices in early April 2023, as per the reports by Motilal Oswal Financing Services. This up-to-date market development has influenced buyers to make decisions about when to buy and when to hold off on purchases.

It is also important for buyers to negotiate with cement producers to secure the best possible pricing. This can involve leveraging economies of scale, negotiating delivery times and terms, and working to build trust and mutual respect with producers. By taking a proactive approach to negotiation, buyers can often secure more favourable pricing and terms than they would otherwise be able to.

Finally, buyers should consider working with a trusted third-party logistics provider to help manage their cement supply chain. A logistics provider can help to optimize transportation routes and schedules, reduce transportation costs, and ensure timely delivery of cement. This can be especially important for buyers who operate in regions with high transportation costs or supply chain disruptions.

#cement producers#cement price#cement for sale#market outlook for cement products#wonder cement#ambuja cement#shree cement#ultratech cement#acc cement#motilal oswal

0 notes

Text

Still seeing so much shit everywhere abt both charles and carlos, like it's reaching a peak.

I just don't understand why both fanbases are destroying the other, when the only one to blame is the TEAM. ITS FERRARI. THEY ARE THE PROBLEM!!!

I'm not even gonna talk abt the pitting calls, bc that was just one major fuck up after another. However, I will talk abt the absolute shite communication that ferrari had with both drivers that led to whatever war between fans is happening right now.

On one hand, we have ferrari telling Charles that carlos wouldn't overtake him, and on the other, we have ferrari telling carlos not to pressure Charles. Most of you might think it's the exact same thing, but it really isn't guys. In no way did Carlos pressure Charles. Carlos' tyres were 2 laps old. They were heated up. Charles was PARALLEL to Carlos upon pit exit (NOT ahead). Charles had new, cold, dead tyres, all carlos literally had to do was drive arnd him, there was no pressuring.

A lot of ppl are also talking about how the results for ferrari would've been much better if Carlos had let Charles past... yeah no. They wouldn't have. Mercedes was absolutely on fire this week. There was genuinely no way Ferrari could've gotten any better result than a P3 and P4, and telling one driver to give up a podium position just to try and cement your other drivers standing as SECOND place in the drivers standings?? Um... yh that's just in bad taste.

Also, ppl are arguing over the stat they showed that if the team would've just listened to Carlos' requests about pitting earlier, he would've ended ahead of Lewis. Personally, I don't think that would've happened, BUT I do believe there would've been a much larger chance of Carlos and Charles being closer to the Merc if Ferrari had just LISTENED to their drivers.

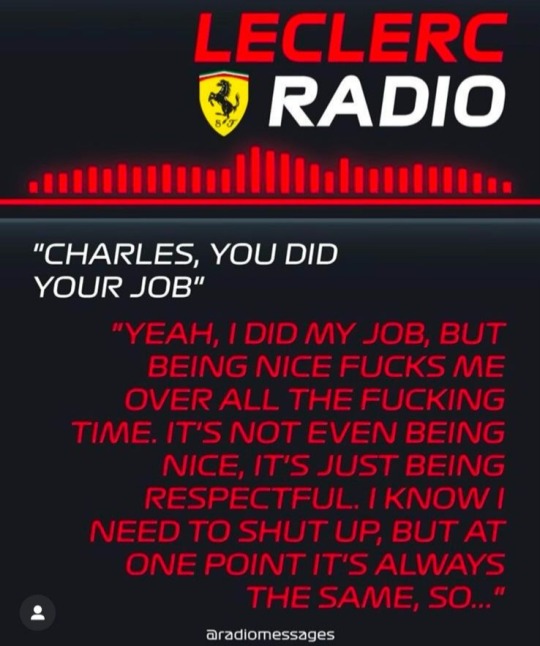

And abt this radio msg:

I honestly don't think Charles was even talking abt Carlos here, this is just him talking abt the team. I feel Charles has ALWAYS blindly trusted the team, done whatever they told him to do. Then we have Carlos, he argues back. Tells the team what he thinks would be better. Ignores orders sometimes to do what he thinks would be better, and it ALWAYS is better. This is Charles being over it, and I'm glad. I'm glad he's over it. Ferrari need to get their heads out of their asses and listen to their drivers because it is reaching a point.

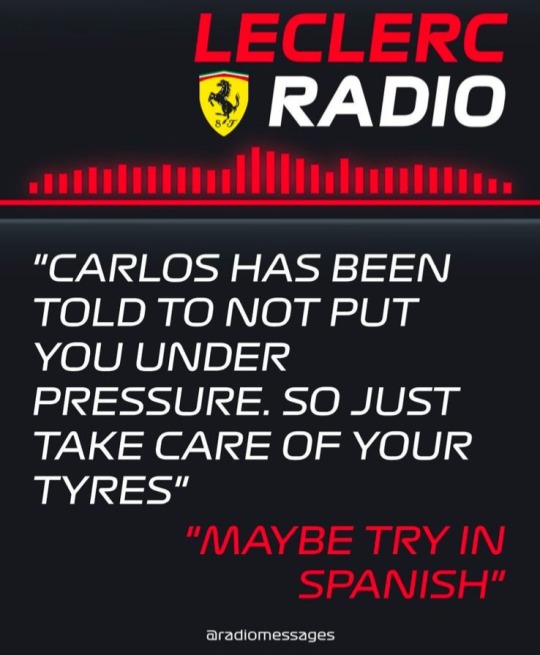

Sidenote:

This radio msg mad me laugh so hard (literally as a carlos fan), idk why y'all are talking abt how it's XENOPHOBIC??? LMFAOOO that's a MAD reach. Carlos is literally a slightly tanned European man BWAHAHAHAH, as a POC I feel slightly mad abt all of u losing ur ahit over this yet when it comes to injustices done to ACTUAL POC drivers, everyone stays silent?? Yh shut up.

I feel u guys forget that this is a competitive sport where drivers are filled to the brim with adrenaline, ofc Charles is gonna make some comments when things don't go the way he thinks they will.

Anywayyy, that's my rant done. Just had to get all this shit out. Even if none of this is true or what acc happend I still stand with my drivers rights and wrongs, so Carlos my pookie dw I love you ur so real.

#Nep speaks☆#f1#formula one#formula 1#carlos sainz#charles leclerc#carlos sainz jr#ferrari#las vegas gp 2024

50 notes

·

View notes