#AC Motor Start Capacitor

Explore tagged Tumblr posts

Text

LT Power Factor Capacitors, Distributor, Dealer, Supplier, Mumbai, India

Shree Trading Syndicate is The House Of Capacitors, Supplier, Dealer And Authorised Distributors Of LT Power Factor Capacitor, LT Power Factor Capacitors, AC Motor Start Capacitor, Aluminium Electrolytic Motor Start Capacitors, MPP Capacitor, Priya Capacitors, Mumbai, India.

#Shree Trading Syndicate is The House Of Capacitors#Supplier#Dealer And Authorised Distributors Of LT Power Factor Capacitor#LT Power Factor Capacitors#AC Motor Start Capacitor#Aluminium Electrolytic Motor Start Capacitors#MPP Capacitor#Priya Capacitors#Mumbai#India.

0 notes

Text

Enhancing Motor Longevity with the Right Start and Run Capacitors

0 notes

Text

Learn why your AC compressor stopped working. Uncover the common issues and solutions for a malfunctioning AC compressor.

Explore now: https://ramservicesandsales.com/2023/10/24/why-did-my-ac-compressor-stop-working/

#AC compressor belt problems#AC compressor capacitor failure#AC compressor clutch engagement issues#AC compressor failure causes#AC compressor not turning on#AC compressor tripping breaker#AC compressor won't start#air cooler repair services#Air Cooler Service Center Nagpur#Air Cooler service in Nagpur#Air Cooler Services in Nagpur#Air Coolers Sales and Services in Nagpur#Burned-out AC compressor#Common reasons for AC compressor failure#Compressor clutch failure AC#Electrical problems AC compressor#Failed AC compressor motor#Low refrigerant AC compressor#Overheating AC compressor#Refrigerant leak AC compressor#Signs of AC compressor issues#Troubleshooting AC compressor problems#Why Did My AC Compressor Stop Working

1 note

·

View note

Text

the furnace was making horrendous noises, and when a furnace makes noise it's almost definitely the fan

unfortunately i didn't get video/sound of the noise...

conveniently at the bottom of that middle panel it actually says "blower". i noticed this after i took it off, but that's nice anyways

this is apparently the fan... or, the fan is inside there

if you DIY, be really careful with stuff that looks like this - these are typically capacitors and you can think of them like a battery that will literally dump all of the stored energy in an instant.

you often find capacitors with electric motors, because it takes a lot of extra energy to get a electric motor to start turning - especially when there's a fluid pump involved (like in a refrigerator).

anyways as previously mentioned a capacitor can store a lot of energy so you don't want to accidentally discharge that (like through your hand) so you deliberately do it with a screwdriver -- a screwdriver with a plastic handle! -- by touching one metal terminal to the other.

note that the above capacitor has two terminals, each of which has four metal tabs! all four of those tabs are connected to each other so they all just count as "one terminal"; you need to touch one of those four, to one of the other four, which of the four doesn't matter, what matters is that a connection is made between the two separate terminals so that electricity can flow.

if there was stored energy, you'll likely get a spark, and if you're like me it'll startle you and make you jump, but it's all ok. jump the terminals with the screwdriver again just to make sure it's all discharged; i do it several times and really make sure that both terminals are being touched at the same time to make sure.

only then do you pull off the wires.

believe it or not, the only thing holding that entire fan unit in the hvac was that one sheet metal screw that the wrench is on in the first pic!

probably the most valuable tool you have as a DIYer is a digital camera (like, your phone, probably). take pictures of everything you take apart; take pictures before you start, as often as you can, take pictures, because DIY is basically about taking stuff apart and then putting them back together, usually with a bit of cleanup or a part replacement somewhere in the middle

in this case things were pretty simple because red was connected to red, purple to purple, but it was nice to be able to see which terminal of the capacitor the yellow & black went to

with it all freed up this slid simply out of the cabinet

(and that one white wire? not connected to anything but for whatever reason i didn't take a picture of that fact)

basically there's the fan housing (big plastic thing), the blower wheel with fan vanes on it, the electric motor, and the capacitor.

behind where the fan went you can see what looks like a radiator - the air conditioner refrigerant goes though that and chills the metal and as the air is pulled from the house (from behind it) the air gets chilled in turn (obviously only when the AC is running - if it's not running then this is just slightly in the way but not changing the temperature, w/e)

to the right in there you can see where the blower pushes air; in there is where the furnace when heat is called for, heats up the air that passes by in a similar way to the AC, except that there's not lots of fins, instead there's these big metal tubes that get super hot because there's burning gas inside them, and they heat up the air as it goes by (the furnace exhausts to the outside after dumping the heat to the circulating air - you don't want the propane gas exhaust in the house air!)

ok so... so far we still haven't diagnosed anything... well here we go

that disc i'm turning? all the fan vanes on the sides are supposed to be connected to the disc. the disc gets turned by the motor, and the disc which is part of the fan is supposed to turn along with the rest of the fan. so here obviously the is toast.

conveniently there's a part number on that white tag. inconveniently that part isn't made any more. looking around though i find that there's a new part number that supercedes it, probably 100% identical part just a new number for whatever reason, fuck them.

price for the entire unit (plastic housing with motor & fan): $1000. price for just the fan: $178-$350, depending on where you buy it. i bought it for $178 ofc, including "free" shipping. local supply wanted $330 but they wouldn't get it from the nearby bigger city for a few days.

so i replaced the fan - loosened the little bolt that holds it on the motor shaft, knocked the fan loose and swapped them. put it all back together, and the furnace run so.... quietly...

so $178 vs a minimum of $600, possibly more as a professional would probably have just replaced the entire fan unit ($1000 + truck roll, probably $1250 total). overall time about the same because it took a couple days to come in the mail and they would've needed to get it as well as this is for an older unit.

3 notes

·

View notes

Note

You underestimate my desire for knowledge. Do it. Talk about refrigeration compressor motors.

Hello hi, sorry for the delay. I had to wait for the brain power to return to me.

So, an electric motor's job is to convert electrostatic potential energy into magnetic potential energy in order to rotate a shaft, thus making one final energy conversion from magnetic PE to kinetic energy. There is a secret fourth energy conversion, though, and that is another form of kinetic energy: heat. The heat is waste, though.

Anyways, the power available in your home is not the power generated at the source powerplant; it is just a single phase of alternating current (AC), instead of three. Electric motors running on single-phase encounter an interesting problem: they need a special winding, called a start winding, to get the motor going. It is phase shifted from the run winding (which keeps the motor running after startup). The easiest way to explain phase shift, in this context, is to think of it like the pedals on a bicycle: if the pedals weren't opposite each other (offset from each other 180 degrees), it would be very difficult to pedal. Unlike a bicycle, the phase shift in the motor isn't 180 degrees. It's less than that. About 45 degrees.

Both the start and run windings are coils of wire. The more times the wire is wound, the stronger the magnetic field it generates. The start coil has more windings than the run coil.

To help smooth power delivery and introduce the aforementioned phase shift, we need capacitors. Capacitors are just small batteries. They can hold a charge and be discharged. They also block direct current (DC), but allow AC to pass through it. It's really neat. On startup, a single-phase motor using capacitors only needs the start coil and the start capacitor briefly. If they remain in the circuit afterwards, they risk overheating and destroying themselves. So how do we automatically take the start coil and capacitor out of the circuit after startup?

One way is to use a centrifugal mechanical switch that will disconnect the start components from the circuit once the motor reaches 75% of its maximum RPM. This switch must be in the motor, though, and will create a spark when it breaks contact. This is okay for motors that are in the air, but what about the motors in a hermetically sealed refrigerant compressor? That spark would degrade the refrigerant, and that's a non-starter.

We need an RPM sensitive switch outside the compressor motor, and one way to do this is with a potential relay.

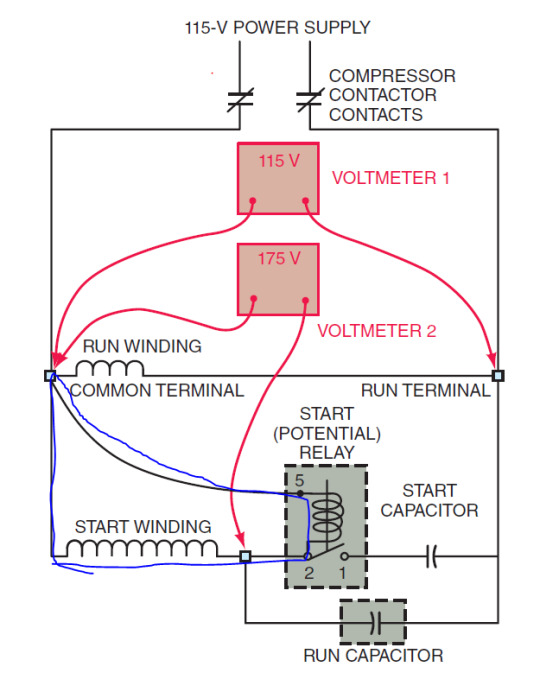

This is a diagram of a potential relay circuit with a capacitor-start, capacitor-run compressor motor.

On startup, the relay contacts, 2 and 1, are closed. Power can flow through the start winding and through both the run and start capacitors. This gives the motor a good grunt to get it going, with the start winding slightly out of phase with the run winding. Once the motor reaches 75% of its max. RPM, though, the magnets on the rotor/shaft of the motor induce a back electromotive force, or BEMF, in the start winding. The start winding becomes a voltage source in tandem with the incoming power from the outlet.

The induced AC voltage is stronger than the incoming power, and is also out of phase with it. This is demonstrated in the diagram with voltmeters 1 and 2. The induced voltage flows through the coil of the potential relay at terminals 2 and 5, and the coil generates a magnetic field which pulls the relay contacts open, breaking the connection to the start capacitor and preventing the start winding from connecting with the other side of our power supply. So long as the motor is running, the BEMF is present and keeps the relay open.

This is what the voltage looks like on an oscilloscope. CH1 is the smaller wave and it's on the common run terminal. CH2 is the larger wave and is at terminal 2 of the relay.

As we can see, the induced voltage on the start winding lags behind the line voltage by about 45 degrees and it is much stronger.

When the motor shuts off and slows down, the induced voltage disappears and the relay contacts close again. The relay sits outside the motor where sparks are acceptable.

As a cherry on top, I've drawn the current paths through the circuit to help illustrate what's happening:

^ Start condition (red). Current flow through the start winding and start + run capacitors

^ Run condition (blue). BEMF across the start winding powers the relay coil and opens the contacts.

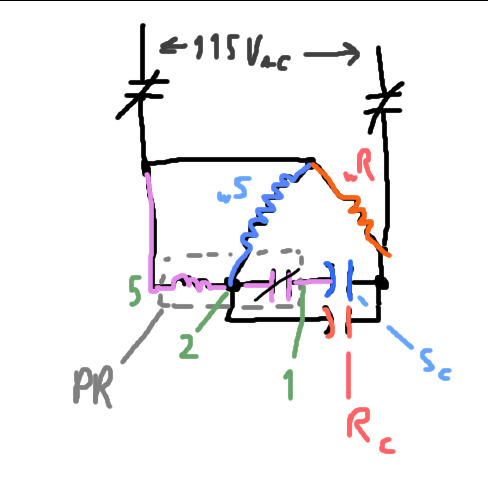

There is a lot more going on I could talk about, but that's just the part I wanted to be autistic about. There is actually a better way to draw out this circuit that looks like this:

Sw = Start winding

Rw = Rung winding

PR = Potential relay

Sc = Start Capacitor

Rc = Run capacitor

And isn't that fascinating?

4 notes

·

View notes

Text

What are applications of capacitors?

Capacitors are used in many places.

Power Supply Filtering: Capacitors are used in power supplies to filter out any noise or ripples from the main incoming AC supply.

DC-DC Converter Output Filtering: Capacitors are used to filter out the high frequency switching noise generated in DC-DC converters.

Coupling: Capacitors are used to couple two circuits together, allowing AC signals to pass while blocking DC signals.

DC Blocking: Capacitors are used in circuits to block any DC signals from passing, while allowing AC signals to pass.

Timing: Capacitors are used in timing circuits to control the rate at which current flows.

Audio Equipment: Capacitors are used in audio equipment to filter out unwanted noise and smooth out the signal.

Motor Start and Run Capacitors: Capacitors are used in electric motors to help start them up and then keep them running smoothly.

For more electronic components products, please go to QUARKTWIN official website.

3 notes

·

View notes

Text

How to Fix a Noisy AC in Panvel's Humidity

In the humid climate of Panvel, air conditioners are essential for maintaining indoor comfort. However, a noisy AC can quickly turn from a lifesaver to a source of irritation. Whether it’s a constant rattling, buzzing, or banging, these sounds indicate underlying issues that could escalate if not addressed. The good news is that many noisy AC problems are fixable, provided you understand their causes and know how to troubleshoot them. This guide offers practical tips for diagnosing and resolving common AC noise issues, helping you restore peace to your home and keep your system running smoothly.

Understanding the Impact of Humidity on Your AC Panvel’s humid environment places additional strain on air conditioning systems. High moisture levels can cause components to wear out faster, promote the growth of mold and mildew, and increase the chances of water-related issues. These factors contribute to unusual noises emanating from your AC. Therefore, addressing noise problems promptly is crucial not only for comfort but also for the health and efficiency of your system.

Common Causes of Noisy AC Units and How to Fix Them One of the most frequent causes of AC noise is loose or misaligned components. Over time, the constant operation of the unit can cause screws, bolts, and other parts to loosen, leading to vibrations and rattling sounds. If you hear a persistent rattling, start by inspecting the exterior unit. Ensure all panels are securely fastened, and check for any loose parts inside. Tightening screws or re-securing panels often resolves this issue.

Another common noise is a buzzing sound, which could indicate electrical issues or problems with the fan motor. Buzzing often points to a malfunctioning capacitor or a failing motor. These components are critical for the operation of your AC, and their failure can lead to system shutdowns. Since working with electrical parts requires expertise, it’s best to call a professional AC repair service in Panvel to inspect and replace faulty components safely.

A banging noise, on the other hand, typically signals a more severe problem, such as a broken or dislodged part within the compressor. The compressor is a vital component of your AC system, responsible for circulating refrigerant and cooling your home. If a banging sound originates from the compressor, it could mean that an internal part has come loose. Continuing to run the system in this condition could cause significant damage, necessitating costly repairs or even a full compressor replacement. Turn off the AC immediately and contact a technician to assess the damage.

In humid climates like Panvel’s, another potential noise source is water-related issues. Excess condensation can accumulate within the system, especially if the drain line is clogged or the condensate pump is malfunctioning. This can result in a gurgling or dripping sound. To fix this, first ensure that the drain line is clear by flushing it with a mixture of water and vinegar. If the problem persists, it may be due to a faulty pump, which will need to be repaired or replaced by a professional.

Whistling or hissing noises are also common in air conditioners and usually indicate airflow problems. A whistling sound often points to clogged or dirty air filters, which restrict airflow and force the system to work harder, generating noise. Replacing the filter is a simple yet effective way to resolve this issue. On the other hand, a hissing sound might indicate a refrigerant leak, which is a more serious problem. Low refrigerant levels not only reduce the efficiency of your AC but can also cause internal components to overheat. Handling refrigerant requires specialized training, so it’s essential to call a certified technician to locate and fix the leak.

Finally, if your AC is making a squealing or screeching noise, the problem likely lies with the fan belt or motor bearings. These parts can wear out over time, especially in a humid environment where moisture accelerates deterioration. Regular lubrication of the motor and timely replacement of worn-out belts can prevent these noises and keep your system operating smoothly.

Preventive Measures to Avoid Noisy AC Issues Preventing noisy AC problems in Panvel’s humid climate involves regular maintenance and proactive care. Scheduling annual tune-ups with a trusted AC repair in Panvel ensures that all components are in optimal condition and any potential issues are addressed before they escalate.

Additionally, simple steps like keeping the outdoor unit clean and free of debris, regularly replacing air filters, and ensuring proper airflow can go a long way in preventing noise-related issues. Monitoring your system’s performance and addressing unusual sounds promptly can save you from more extensive repairs down the line.

0 notes

Text

Why High-Quality AC Outdoor Unit Parts Are Essential for Cooling Efficiency

An outdoor air conditioner is an essential piece of equipment for maintaining a suitable temperature in your home. The outside unit, sometimes called the "heart" of the AC system, contains the fundamental parts that cooperate to keep your AC running smoothly and dependably. In this post, we will examine the main components of an outdoor air conditioner, discussing their functions, strengths, and the importance of using high-quality replacements to ensure the unit lasts as long as possible.

1. Your Cooling System's Power Source—The Compressor At its heart, the air conditioner's outside unit is the compressor. Compressing refrigerant gas, it allows it to flow through the coils and collect heat from inside the home; it is sometimes referred to as the "engine" of the system. Rest assured, a top-notch compressor will keep the system running smoothly, reduce energy usage, and supply dependable cooling. Investing in a high-quality new compressor might help your air conditioner regain its performance and energy efficiency after it has been worn down by time. 2. Condenser Coils for Efficient Heat Transfer The refrigerant is transformed back into a liquid condition by releasing the heat it received through condenser coils. The coils are vulnerable to corrosion and dirt accumulation because they are exposed to the outdoors. To guarantee optimum heat exchange and continuous cooling performance, high-quality condenser coils are built to endure severe environments. Preventing cooling interruptions requires regular maintenance and the replacement of worn coils. 3. The Fan and Fan Motor—Maintaining Air Movement The motor and fan in the outdoor unit work together to cool the system. They do this by moving air over the condenser coils. The cooling cycle efficiency is maintained through this procedure. For the device to work silently and efficiently, a long-lasting motor and fan are required. Using high-quality fan motors has many benefits. It reduces system strain, lowers energy use, and extends the lifespan of AC units. 4. The Capacitor: A Key Component for Dependable Starting and Running At startup, the compressor and fan motors are powered by the energy stored in the capacitor, which is then released. To avoid overheating and keep the device running well for a longer time, use a high-quality capacitor. Regular shutdowns and poor performance can happen due to faulty capacitors. It is important to replace old capacitors with high-quality ones. In summary, For dependable and efficient cooling, every part of the air conditioner outside unit is critical. To keep your home cool and comfortable while saving money, replace worn or broken parts with new, quality ones. Invest in high-quality AC outdoor unit parts to ensure your cooling system runs properly all year round.

0 notes

Text

YC series capacitor-started asynchronous motor

Features: larger starting torque, excellent performance, energy saving and power saving, reliable structure, strong versatility. The basic series motors are rated at 220V/50Hz, and 110V/220V, 110V, 240V, 60Hz, etc. motors are available as needed, with cast aluminum or cast iron housings.

Hangzhou Dell Electromechanical Co., Ltd. is a Custom YC series capacitor-started asynchronous motor Factory integrating R&D, production, and sales. The company is located in Lingang Industrial Park, Xiaoshan District, Hangzhou City, close to the exit of Hangzhou Bay Ring Expressway and Hangzhou Xiaoshan International Airport, with very convenient transportation. The company specializes in the production of direct-coupled three-phase asynchronous motors for hard tooth surface reducers, ordinary YE3, YE4 series high-efficiency motors, electromagnetic brake motors, frequency conversion speed control motors, explosion-proof motors, YD multi-speed motors, and special customized AC asynchronous motors. The company always firmly believes that "quality, service, and innovation" are the cornerstones of development.

OUR MAILBOX: [email protected]

OUR PHONE: +86-15268533330

OUR ADDRESS: Lingang Industrial Zone, Guali Town, Xiaoshan District, Hangzhou City, Zhejiang Province, China

0 notes

Text

Is It Time to Replace or Repair Your AC? Here's How to Decide

When your air conditioning (AC) system starts to show signs of trouble, homeowners face a critical decision: should they repair the existing unit or invest in a new one? Understanding the signs of wear and the financial implications of each option can help you make an informed choice.

Assessing Your AC System

To determine whether to repair or replace your AC, begin by evaluating the following factors:

Age of the Unit: Most air conditioning systems have 10 to 15 years of lifespan. Suppose your unit is approaching or exceeding this age. In that case, replacing it may be more cost-effective, especially if repairs become frequent.

Frequency of Repairs: Consider the cumulative costs if you find yourself calling for repairs often. A good rule of thumb is to multiply the age of your AC by the estimated repair cost. If this total exceeds the price of a new unit, replacement may be the better option.

Energy Efficiency: Older units consume more energy, increasing utility bills. Newer models, especially those with high SEER (Seasonal Energy Efficiency Ratio) ratings, are designed to be more energy-efficient, which can result in substantial savings over time.

Performance Issues: Consider the effectiveness of your current unit. Is it struggling to cool your home evenly? Does it run constantly without reaching the desired temperature? These performance issues could indicate that your AC is nearing the end of its useful life.

Type of Repairs Needed: Some repairs are minor and relatively inexpensive, while others can be major and costly. Common repairs include replacing capacitors or motors, which are usually more affordable.

Financial Considerations

The decision to repair or replace your AC can significantly impact your wallet. Here are a few financial factors to weigh:

Repair Costs vs. Replacement Costs: Get quotes for the necessary repairs and compare them to the cost of a new unit. Don't forget to factor in installation costs for a new system.

Long-Term Savings: While a new AC unit represents an upfront investment, the potential for energy savings over time can make you feel financially savvy. Calculate potential savings on your energy bills against the cost of repairs to see which option is more financially sound.

Incentives and Rebates: Don't forget to check for local utility incentives or tax credits for energy-efficient systems. These can help offset the cost of a new unit and make replacement more attractive. This resourcefulness can make the decision-making process more rewarding.

Making the Decision

After evaluating the above factors, you'll be in a position of power to decide whether to repair or replace your AC system. If the cost of repairs is high and your unit is old, replacement is likely the better choice. Conversely, a repair might be sufficient if your AC is relatively new and the repairs are minor. This sense of control over your home's comfort can be a relief.

Frequently Asked Questions

Q1: How can I tell if my AC needs to be replaced?

A1: Key indicators include the age of the unit, frequent repair needs, rising energy bills, poor cooling performance, and significant repair costs. If your AC is over 10 years old and facing major repairs, it may be time to consider a replacement.

Q2: What are the benefits of replacing an old AC unit?

A2: Replacing an old AC unit leads to improved energy efficiency, lower utility bills, enhanced cooling performance, and increased comfort in your home. New models have better technology and features, such as programmable thermostats and quieter operation.

By carefully assessing your AC's condition and considering the financial implications, you can make a more informed decision about repairing or replacing your air conditioning system.

0 notes

Text

Choosing the Right Capacitor Suppliers: Why Tibcon Leads the Market

Capacitors are essential components across various industries, from electronics to heavy machinery. The role of capacitor suppliers in maintaining high standards of performance and reliability is crucial, as these components are often integral to the safety and efficiency of equipment. When selecting a capacitor supplier, it's essential to consider quality, consistency, and product range. Tibcon, widely acknowledged as the best capacitor manufacturer and supplier, excels in all these areas, making it a preferred choice for both small businesses and large enterprises. Here’s a closer look at why Tibcon is the top pick and what to look for in capacitor suppliers.

Key Qualities of Reliable Capacitor Suppliers

Finding reliable capacitor suppliers is about more than just purchasing components; it’s about establishing a partnership with a company that can support your needs and ensure equipment longevity. Here are the primary qualities that define reliable capacitor suppliers:

Quality Assurance and ReliabilityCapacitors play a critical role in everything from managing voltage spikes to powering motors, so quality is non-negotiable. Top capacitor suppliers prioritize quality assurance with rigorous testing protocols. Tibcon, recognized as the best capacitor manufacturer, sets high standards in quality by using top-grade materials and employing advanced manufacturing techniques that ensure reliable performance and longevity.

Product VarietyThe needs for capacitors vary depending on application—motor capacitors, AC capacitors, and energy-saving capacitors, to name a few. Reliable capacitor suppliers should offer a broad product range to suit diverse applications. Tibcon’s extensive portfolio includes motor run capacitors, motor start capacitors, and power capacitors, addressing the varying demands across industries such as HVAC, automotive, and telecommunications.

Technical Support and ExpertiseWith technological advancements, capacitor applications have become more specialized. Quality capacitor suppliers provide technical support, helping clients select the right type of capacitor based on specific requirements. Tibcon’s expert team assists clients in understanding product specifications and choosing the right capacitor type to meet operational needs, from low-voltage residential applications to high-power industrial systems.

Consistent Supply and ScalabilityFor businesses with ongoing or large-scale operations, the ability to rely on consistent supply chains is essential. Leading capacitor suppliers, like Tibcon, maintain robust production and distribution channels to ensure that customers receive timely deliveries, no matter the scale. This is particularly important for businesses looking to expand and scale up operations without disruption.

Sustainability and InnovationThe best capacitor suppliers invest in sustainable practices, incorporating eco-friendly materials and reducing waste in manufacturing. Tibcon is committed to innovation and sustainability, developing capacitors that are not only efficient but also environmentally friendly. Their emphasis on cutting-edge technology and energy efficiency is a testament to their status as an industry leader.

Why Tibcon is a Top Choice Among Capacitor Suppliers

As one of the industry’s most reputable capacitor suppliers, Tibcon stands out for several reasons. Beyond being the best capacitor manufacturer, Tibcon has consistently earned the trust of clients by delivering reliable, top-performing products across multiple sectors.

Unmatched Quality ControlTibcon’s capacitors undergo thorough quality checks, ensuring that each unit meets strict industry standards. Their capacitors are known for durability, resistance to high temperatures, and resilience in demanding environments, making them ideal for use in various applications.

Dedicated to Customer SatisfactionTibcon emphasizes client satisfaction through its responsive customer service and technical support. Their team provides guidance on product selection and troubleshooting, helping clients find exactly what they need. This level of dedication has positioned Tibcon as a trusted name in capacitor supply.

Global Reach with Localized ServiceWith a global client base, Tibcon is equipped to handle the demands of both local and international customers. Their streamlined distribution system ensures quick delivery across regions, making them a convenient option for businesses that require reliable, efficient capacitor suppliers.

Tailored Solutions for Unique ApplicationsTibcon is experienced in developing custom solutions to meet the unique demands of specialized industries. For example, they offer high-capacity motor capacitors for HVAC systems and low-inductance capacitors for sensitive electronics, tailored to meet the exact needs of their clients.

Choosing Tibcon for All Your Capacitor Needs

In a market filled with capacitor suppliers, Tibcon consistently ranks as the preferred choice. Their commitment to quality, sustainability, and customer support makes them stand out as a top capacitor supplier. Whether you’re a small enterprise looking for a dependable partner or a large corporation in need of scalable supply, Tibcon offers unmatched expertise and reliability.

In summary, when it comes to capacitor suppliers, Tibcon should be at the top of your list. With a broad product range, exceptional quality control, and a customer-centric approach, Tibcon meets the needs of businesses across various sectors, solidifying their place as the best capacitor manufacturer in the market.

0 notes

Text

Protect Your Electrical Systems with UPS Preventive Maintenance, Thermal Scanning Services & Rental, and Active Harmonics Filters”

For vital equipment to get an uninterrupted power supply in the event of a power loss, UPS (Uninterruptible Power Supply) systems are crucial. You need to have a preventative maintenance strategy in place to keep your UPS system operating properly and reduce downtime.

#UPS Preventive Maintenance Plan#Office Pantry Pump#Active Harmonics Filter#AC Motor Start And Run Capacitor#Thermal Scanning Services & Rental

0 notes

Text

Why Did My AC Compressor Stop Working?

When the sweltering heat of summer arrives, there’s nothing more frustrating than discovering that your AC compressor has called it quits. It’s a common issue that leaves many homeowners sweating from the heat and potential repair costs.

In this blog, we’ll explore the reasons behind AC compressor failures, common signs that indicate trouble, and some troubleshooting tips to help you get your cool air back.

Top AC Compressor Failure Causes!

Here are some: –

1. Refrigerant Leak AC Compressor

One of the leading causes of AC compressor failures is a refrigerant leak. The compressor relies on refrigerant to cool the air; a leak can disrupt this process. Watch for decreased cooling performance, which can indicate this issue.

2. Electrical Problems AC Compressor

Electrical problems can also lead to a non-functional AC compressor. Faulty wiring, damaged capacitors, or other electrical issues can prevent the compressor from starting. If your unit remains unresponsive, electrical problems might be to blame.

3. Compressor Clutch Failure AC

The compressor clutch is a vital component for engaging and disengaging the compressor. If it fails, the compressor won’t work as it should. Unusual noises or a lack of cool air can be signs of a failing clutch.

4. Overheating AC Compressor

Overheating is a most common issue that can lead to compressor damage. If the system lacks proper airflow due to a clogged condenser or dirty coils, the compressor can overheat and eventually fail. Regular maintenance is essential to prevent this.

5. Low Refrigerant AC Compressor

Insufficient refrigerant levels can strain the compressor, making it work harder. This can indeed lead to premature wear and tear, ultimately causing failure. Low refrigerant may be the culprit if your AC is struggling to cool your space.

6. AC Compressor Belt Problems

The compressor’s belt plays a crucial role in its operation. If the belt is worn or damaged, it can prevent the compressor from functioning correctly. Squealing or grinding noises are common indicators of belt issues.

7. AC Compressor Tripping Breaker

When your AC compressor continually trips the breaker, it can indicate various problems, such as electrical issues or a failing compressor. This not only disrupts your cooling but can also pose a safety hazard.

8. Failed AC Compressor Motor

The heart of the AC compressor is its motor. If the motor fails, the entire compressor becomes non-operational. Listen for unusual noises or vibrations, which may be signs of motor trouble.

Read More: https://ramservicesandsales.com/2023/10/24/why-did-my-ac-compressor-stop-working/

#AC compressor belt problems#AC compressor capacitor failure#AC compressor clutch engagement issues#AC compressor failure causes#AC compressor not turning on#AC compressor tripping breaker#AC compressor won't start#air cooler repair services#Air Cooler Service Center Nagpur#Air Cooler service in Nagpur#Air Cooler Services in Nagpur#Air Coolers Sales and Services in Nagpur#Burned-out AC compressor#Common reasons for AC compressor failure#Compressor clutch failure AC#Electrical problems AC compressor#Failed AC compressor motor#Low refrigerant AC compressor#Overheating AC compressor#Refrigerant leak AC compressor#Signs of AC compressor issues#Troubleshooting AC compressor problems#Why Did My AC Compressor Stop Working

1 note

·

View note

Text

Expert AC Repair in Houston – Turbo Home Services

Houston’s heat can be relentless, especially during the summer months when temperatures soar into the 90s and beyond. A reliable air conditioning system is a must to keep your home cool and comfortable. But when your AC unit breaks down or starts showing signs of malfunction, it can disrupt your daily life. That’s where Turbo Home Services comes in, offering expert AC repair in Houston to get your cooling system back up and running quickly and efficiently.

Common AC Problems in Houston Homes

Air conditioning systems in Houston face a lot of wear and tear due to the extreme heat and humidity. Over time, this can lead to several common problems, including:

Refrigerant Leaks: If your AC unit is low on refrigerant, it won’t be able to effectively cool your home. Low refrigerant levels usually indicate a leak, which needs to be repaired immediately. Our technicians will inspect your system, locate the leak, and recharge your AC to restore its cooling power.

Frozen Evaporator Coils: If your air conditioning system is blowing warm air or not cooling properly, frozen evaporator coils could be the culprit. This issue often arises due to poor airflow caused by dirty air filters or blocked ducts. Turbo Home Services can quickly diagnose and repair coil issues, ensuring efficient cooling.

Clogged Condenser Coils: The outdoor condenser unit can become clogged with dirt, dust, and debris, causing your system to overheat. Regular cleaning and maintenance are key to avoiding this problem, but if your AC is already experiencing issues, we’re here to help with thorough cleaning and repairs.

Electrical Failures: In Houston’s heat, AC systems run almost constantly, leading to electrical problems like worn-out wiring or damaged capacitors. These issues can cause your AC unit to stop working altogether. Our technicians have the expertise to handle electrical issues safely and restore your system’s performance.

Fan Problems: Both the blower fan (which circulates air inside your home) and the condenser fan (which helps cool the refrigerant) are essential for your AC system to function. If either of these fans is malfunctioning due to worn belts, motors, or bearings, it can lead to poor cooling or system failure.

Thermostat Issues: Sometimes, the problem isn’t with the AC unit itself but with the thermostat controlling it. If your thermostat is malfunctioning or miscalibrated, your AC may not run properly. Turbo Home Services can repair or replace faulty thermostats to ensure accurate temperature control.

Why Choose Turbo Home Services for AC Repair in Houston?

With so many HVAC companies in Houston, it can be challenging to know who to trust with your air conditioning repairs. Here’s why Turbo Home Services stands out as the best choice:

Experienced Technicians: Our licensed and certified HVAC technicians have years of experience diagnosing and repairing all types of air conditioning systems. We stay up-to-date on the latest technologies and repair methods to ensure we provide the best possible service.

Quick Response: We know that a broken AC system can’t wait, especially in Houston’s sweltering heat. That’s why we offer fast, reliable service to ensure your home’s cooling system is back up and running as quickly as possible.

24/7 Emergency Service: Air conditioning breakdowns don’t always happen during regular business hours. That’s why Turbo Home Services provides 24/7 emergency AC repair in Houston. Whether your system fails in the middle of the night or on a holiday, we’re here to provide immediate assistance.

Affordable Pricing: We believe in providing high-quality AC repair services at competitive prices. We offer transparent pricing with no hidden fees, and we’ll provide a detailed estimate before any work begins.

Customer Satisfaction: At Turbo Home Services, customer satisfaction is our top priority. We work closely with our clients to understand their specific needs and deliver solutions that exceed their expectations. We pride ourselves on building long-lasting relationships with our customers based on trust, reliability, and outstanding service.

Signs You Need AC Repair

It’s important to address AC issues early before they turn into bigger, more expensive problems. Here are some signs that it’s time to call Turbo Home Services for AC repair in Houston:

Your AC is blowing warm air or not cooling the home effectively

There are strange noises, such as banging, rattling, or grinding, coming from the unit

Your energy bills have spiked unexpectedly

The unit is constantly cycling on and off

You notice uneven cooling throughout your home

There’s an unpleasant smell coming from the vents

Your AC is leaking water or refrigerant

If you experience any of these issues, don’t wait for the problem to get worse. Our team can quickly assess the situation and provide a solution to get your system working properly again.

Preventive Maintenance for Your AC System

While repairs are sometimes unavoidable, regular maintenance can help prevent many common AC issues. Turbo Home Services offers comprehensive air conditioning maintenance plans to keep your system in peak condition. Our maintenance services include filter changes, coil cleaning, refrigerant checks, and system performance assessments to catch problems early and ensure your AC runs smoothly all summer long.

Stay Cool with Turbo Home Services

Houston’s extreme heat demands a dependable air conditioning system. If your AC isn’t performing at its best or has stopped working altogether, don’t sweat it! Trust the experts at Turbo Home Services to provide fast, reliable, and affordable AC repair in Houston. We’ll get your system back up and running so you can stay cool and comfortable in your home. For expert AC repair in Houston, call Turbo Home Services today! Our team is ready to tackle any air conditioning issue, ensuring your home stays comfortable no matter how hot it gets outside.

0 notes

Text

Essential Tips to buy the best capacitor in India

Capacitors being considered as a device for storing electrical energy are used in several electronic devices and applications these days. From washing machines to air conditioners, refrigerators to microwave ovens, power supplying equipment to audio equipment, they play a crucial role in electronic circuits. However, one needs to understand that capacitors vary from device to device, and that is why choosing the right capacitor is highly crucial when using them in electrical circuits. Not only does one need to buy the right type of capacitor, but one must also invest in the best capacitor in India, which offers efficient performance when used in different types of electronic devices.

In this blog, we are sharing a guide to help you all buy the right capacitor without compromising on its quality. That is why the first thing that we recommend is to buy from a well-certified manufacturer like Indtech Capacitors. But that’s not all; let’s explore a few more tips to buy the best capacitor in India.

Check the temperature of the capacitor

When buying from renowned manufacturers, you will always find the limit of the operational temperature mentioned on the package. Check the operational temperature of the capacitor and buy it according to your requirements so that it does not start degrading due to the increase in the temperature limit. Otherwise, it will result in the loss of current, making the capacitor less efficient.

Check the voltage rating of the capacitor

When buying capacitors, always go for the ones with high voltage ratings. It is advised that the application for which the capacitor is purchased should have a working voltage less than the voltage rating mentioned on the capacitor. One must share with the capacitor manufacturer and supplier to deliver it according to the expected voltage rating. If you go for the best capacitor in India, the manufacturer will always supply you with a higher voltage rating capacitor than the application’s requirement by offering a better margin between the operational voltage and the given voltage rating.

Check the tolerance value of the capacitor

When buying a capacitor for particular applications, always check its tolerance value. It is recommended to use capacitors with low or tight tolerance for critical applications. However, some capacitors have wide or high tolerance ratings, which make them accommodate low frequencies with ease.

Check the quality and manufacturing standards

Apart from the above-mentioned factors, it is also important to check if the capacitors are manufactured adhering to all the industrial and quality standards. It is possible only when you are buying them from ISO certified manufacturers, as not every manufacturer complies with essential manufacturing standards.

Considering these factors will help one buy capacitors for the desired application with ease. Other than these factors, polarization, capacitor size, and dielectric permittivity should also be checked. We at Indtech Capacitors are known for manufacturing an extensive range of capacitors that are used in AC, Fan, Motors, Washing Machines, and multiple other devices. We offer the best capacitor in India at affordable market prices without compromising its quality.

0 notes

Text

Emergency AC Repair Services in Thane: What You Need to Know

As the temperatures in Thane soar, a well-functioning air conditioning system becomes not just a comfort but a necessity. When your air conditioner breaks down unexpectedly, it can turn a pleasant day into a distressing situation. Understanding the essentials of emergency AC repair services is crucial for residents. This article will guide you through identifying emergencies, finding reliable repair services, costs involved, and tips for preventing future breakdowns.

Identifying an AC Emergency

Recognizing when your air conditioning unit requires immediate attention is key to avoiding further damage and discomfort. Here are several indicators that your AC may need urgent repair:

Always prioritize professional help for AC repair Thane services, as they can provide the expertise needed to restore your unit efficiently. With the right knowledge and preparation, you can tackle any AC emergency that comes your way.

1. Lack of Cooling

If your air conditioner is running but not effectively cooling your space, it’s a red flag. This could be due to refrigerant leaks, a malfunctioning compressor, or blocked ducts. Ignoring this issue can lead to increased energy bills and further complications.

2. Strange Noises

Unusual sounds such as grinding, squealing, or clanking often indicate mechanical problems within the unit. These noises can signify loose components or motor issues, which require immediate attention to prevent more extensive damage.

3. Unpleasant Odors

A musty or burning smell coming from your AC could indicate electrical issues or mold growth within the system. Both situations are hazardous and warrant immediate professional inspection.

4. Water Leaks

Puddles of water around your AC unit or inside your home are signs of a malfunctioning drainage system or refrigerant leak. This not only affects the unit’s performance but can also lead to water damage in your home.

5. Frequent Cycling

If your AC unit frequently turns on and off, this could indicate an issue with the thermostat or an oversized unit. Frequent cycling can cause unnecessary wear and tear, leading to a complete breakdown if not addressed promptly.

If you notice any of these issues, it’s crucial to seek emergency AC repair Thane services immediately to ensure the comfort and safety of your home.

Finding Reliable Emergency Services

When faced with an AC emergency, having the right technician on speed dial can save you time and stress. Here are some tips for finding trustworthy emergency AC repair services in Thane:

1. Online Research

Start by searching online for local AC repair services. Look for companies that specifically offer emergency repair services. Check their websites for customer reviews and ratings to gauge their reliability.

2. Ask for Recommendations

Reach out to friends, family, or neighbors who have experience with AC repair services. Personal recommendations can provide valuable insights and help you find trustworthy technicians.

3. Check Qualifications

Ensure that the repair service has certified technicians with experience in emergency repairs. Proper licensing and insurance are also crucial for protecting both you and the technicians.

4. Response Time

Choose a service known for quick response times. Emergency repairs should ideally be addressed within a few hours, especially during peak summer months when demand is high.

5. Transparent Pricing

Look for companies that offer transparent pricing structures. A reputable service will provide an estimate before starting any repairs, ensuring you are aware of potential costs involved.

Cost Considerations

Understanding the potential costs associated with emergency AC repairs can help you budget effectively. Here are some factors that influence the cost of repairs in Thane:

1. Type of Repair Needed

The complexity of the repair will significantly affect the cost. Simple fixes like replacing a capacitor may be less expensive than repairing a compressor or handling refrigerant leaks.

2. Service Call Fees

Many repair services charge a service call fee, which may or may not be included in the overall repair cost. It’s essential to ask about this fee upfront.

3. Time of Day

Emergency services provided after regular business hours may incur additional fees. If your repair occurs during peak hours or on weekends, be prepared for potentially higher rates.

4. Parts Replacement

If your repair requires replacing parts, the cost will vary based on the type of AC unit and the specific components needed. Always ask for a detailed breakdown of parts and labor costs.

5. Maintenance Plans

Some companies offer maintenance plans that include emergency services at a discounted rate. Investing in a maintenance plan can save you money in the long run.

Preventing Future Emergencies

While emergencies can’t always be predicted, there are steps you can take to reduce the likelihood of an AC breakdown:

1. Regular Maintenance

Schedule routine maintenance checks at least once a year. Professional technicians can identify potential issues before they escalate into emergencies. During these checks, the technician will clean coils, check refrigerant levels, and inspect electrical components.

2. Change Filters Regularly

Dirty air filters can restrict airflow and cause your AC to work harder, leading to potential breakdowns. Change your filters every one to three months, depending on usage.

3. Monitor Thermostat Settings

Ensure your thermostat is functioning correctly and set to appropriate temperatures. Avoid setting it too low, as this can strain the system.

4. Clear Outdoor Units

Ensure that the area around your outdoor AC unit is free from debris, plants, or obstructions. This allows for proper airflow and prevents overheating.

5. Be Aware of Warning Signs

Stay vigilant about any warning signs mentioned earlier. If you notice any unusual behavior from your AC, don’t hesitate to call for an inspection.

0 notes