#A time relay is a relay that is generated by the output circuit within a specified and accurate time after adding or removing the input acti

Explore tagged Tumblr posts

Text

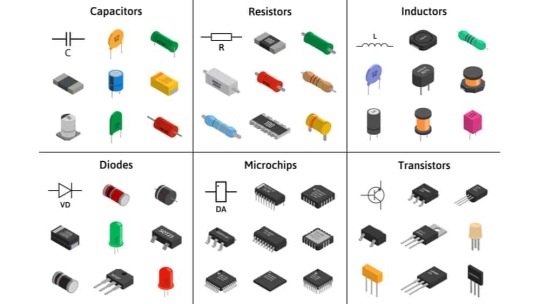

Electronics Components and Uses:

Here is a list of common electronics components and their uses:

Resistor:

Use: Limits or controls the flow of electric current in a circuit.

Capacitor:

Use: Stores and releases electrical energy; used for filtering, timing, and coupling in circuits.

Inductor:

Use: Stores energy in a magnetic field when current flows through it; used in filters, transformers, and oscillators.

Diode:

Use: Allows current to flow in one direction only; used for rectification, signal demodulation, and protection.

Transistor:

Use: Amplifies and switches electronic signals; fundamental building block of electronic circuits.

Integrated Circuit (IC):

Use: Contains multiple electronic components (transistors, resistors, capacitors) on a single chip; used for various functions like amplification, processing, and control.

Resistor Network:

Use: A combination of resistors in a single package; used in applications where multiple resistors are needed.

Potentiometer:

Use: Variable resistor that can be adjusted to control voltage in a circuit; used for volume controls, dimmer switches, etc.

Varistor:

Use: Protects electronic circuits from excessive voltage by acting as a voltage-dependent resistor.

Light-Emitting Diode (LED):

Use: Emits light when current flows through it; used for indicator lights, displays, and lighting.

Photodiode:

Use: Converts light into an electric current; used in light sensors and communication systems.

Zener Diode:

Use: Acts as a voltage regulator by maintaining a constant voltage across its terminals.

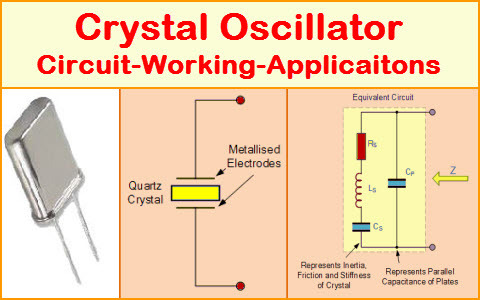

Crystal Oscillator:

Use: Generates a stable and precise frequency; used in clocks, microcontrollers, and communication devices.

Transformer:

Use: Transfers electrical energy between two or more coils through electromagnetic induction; used for voltage regulation and power distribution.

Capacitive Touch Sensor:

Use: Detects touch or proximity by changes in capacitance; used in touchscreens and proximity sensing applications.

Voltage Regulator:

Use: Maintains a constant output voltage regardless of changes in input voltage or load; used for stable power supply.

Relay:

Use: Electromagnetic switch that controls the flow of current in a circuit; used for remote switching and automation.

Fuse:

Use: Protects electronic circuits by breaking the circuit when current exceeds a certain value; prevents damage from overcurrent.

Thermistor:

Use: Resistor whose resistance changes with temperature; used for temperature sensing and compensation.

Microcontroller/Microprocessor:

Use: Processes and controls electronic signals; the brain of many electronic devices and systems.

fig:google-electronics

fig:google-electronics

fig:Crystal-Oscillator

This list covers some of the basic electronic components, and there are many more specialized components used for specific applications within the field of electronics.

#electronic#electricity#electric vehicles#electric cars#engineering#semiconductors#wireless#cables#electronics#smartphone#hardware

4 notes

·

View notes

Text

Understanding MOS Relays: The Future of Switching Technology - MANGOFY

In the world of electronics, the need for efficient, reliable, and fast switching is ever-growing. Traditional mechanical relays, while useful in many applications, have limitations like slower response times, mechanical wear, and the need for regular maintenance. This is where MOS relays, a solid-state alternative, come into play.

What is a MOS Relay?

A MOS relay (also known as a MOSFET relay) is a type of solid-state relay that uses a MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) to perform switching functions. Unlike mechanical relays, MOS relays do not have moving parts, making them more durable, faster, and more efficient in many applications.

Key features of MOS relays include:

No Mechanical Wear: Since there are no moving parts, MOS relays do not suffer from the wear and tear associated with mechanical relays.

Fast Switching Times: MOS relays can switch on and off rapidly, which is essential in applications requiring high-speed operations.

Low Power Consumption: Because MOS relays use semiconductor technology, they consume significantly less power compared to traditional relays.

Noise-Free Operation: MOS relays operate silently, which is a key advantage in noise-sensitive applications.

How Do MOS Relays Work?

MOS relays utilize a photovoltaic coupler to control a MOSFET. When a small control signal (usually a low-voltage signal like from a microcontroller) is applied to the input, it activates the LED within the relay. The light from the LED generates a voltage in the photovoltaic element, which in turn controls the MOSFET, allowing or blocking current flow in the output circuit.

This method of switching provides:

Electrical Isolation: The control signal is isolated from the switched circuit, which enhances safety and reduces the risk of interference.

Precision Control: MOS relays offer fine control over switching, ideal for sensitive applications.

Applications of MOS Relays

MOS relays have a wide range of applications, particularly in situations where high precision, reliability, and fast switching are required. Here are a few areas where MOS relays are commonly used:

Test Equipment: In precision measurement and testing equipment, MOS relays are used for switching signals without introducing noise or signal degradation. Their high speed and long lifespan make them ideal for automated test systems.

Telecommunications: In telecommunications infrastructure, MOS relays are employed for switching high-speed data signals. Their ability to switch quickly and without noise is crucial for maintaining signal integrity in high-frequency applications.

Automotive Electronics: MOS relays are increasingly used in automotive applications where reliability and durability are paramount. With the rise of electric and hybrid vehicles, MOS relays are used in systems like battery management, electric motor control, and various safety systems.

Industrial Automation: In factories and automated environments, MOS relays are employed for controlling motors, actuators, and sensors. Their durability and speed make them ideal for applications where fast switching is necessary to keep up with automated processes.

Renewable Energy Systems: Solar power systems, for example, often use MOS relays in their inverter circuits and battery management systems. The low power consumption and fast switching times help improve the efficiency and longevity of these systems.

MOS Relays vs. Mechanical Relays

Advantages of MOS Relays:

Durability: Without moving parts, MOS relays have a much longer operational life.

Speed: Mechanical relays are slower due to the physical movement required to make or break a connection. MOS relays, being solid-state, can switch in microseconds.

Power Efficiency: MOS relays consume less power, making them ideal for energy-conscious applications like battery-powered devices.

Noise-Free Operation: Since MOS relays do not physically move, they operate silently, which is critical in applications like medical devices and audio equipment.

Disadvantages of MOS Relays:

Cost: MOS relays tend to be more expensive than mechanical relays due to their advanced technology.

Current Rating: Mechanical relays can handle higher currents compared to MOS relays, which may have limitations in high-power applications.

Why MOS Relays are Crucial in Modern Electronics

As electronics continue to evolve toward more compact, efficient, and reliable systems, MOS relays are becoming an essential component. Their solid-state nature makes them more suitable for modern applications, where mechanical parts may be prone to failure and inefficiencies. Whether it's in consumer electronics, industrial automation, or renewable energy, MOS relays offer a compelling alternative to traditional relays, providing faster, quieter, and longer-lasting performance.

Conclusion:

With the increasing demand for more reliable and efficient switching technology, MOS relays are proving to be the future of electronics. Their fast switching times, low power consumption, and long operational life make them ideal for a wide range of applications—from high-speed data communication systems to advanced industrial automation. As industries continue to innovate and push the boundaries of technology, MOS relays will play a crucial role in ensuring high-performance, precision, and efficiency.

1 note

·

View note

Text

Demystifying the Control Panel: Your Electrical System's Unsung Hero

When you flip a switch or turn on a device, countless processes are set in motion behind the scenes to ensure everything functions seamlessly. At the heart of these operations lies the control panel, an essential component that often goes unnoticed. This unsung hero of electrical systems plays a crucial role in managing and protecting various processes across numerous industries. In this blog, we'll demystify the control panel, exploring its components, functions, and significance.

What is a Control Panel?

A control panel is an assembly of electrical devices that regulate, monitor, and control various systems and machinery. It acts as a centralized hub for managing electrical power and ensuring the safe and efficient operation of equipment. Control panels are used in a wide range of applications, from industrial machinery to power generation and distribution systems.

Key Components of a Control Panel

Control panels are composed of several key components, each serving a specific function:

Circuit Breakers and Fuses: These protective devices prevent overloads and short circuits by interrupting the flow of electricity when abnormal conditions are detected.

Relays and Contactors: Relays and contactors are electromechanical switches that control the flow of electricity to various parts of the system, enabling the automation of processes.

Meters and Gauges: These instruments measure and display electrical parameters such as voltage, current, and power, providing real-time data for monitoring and control.

Programmable Logic Controllers (PLCs): PLCs are digital computers used for automation of industrial processes. They receive input signals, process the data, and send output signals to control machinery and systems.

Human-Machine Interfaces (HMIs): HMIs are user interfaces that allow operators to interact with the control panel, view system status, and adjust settings as needed.

Transformers and Power Supplies: These components convert electrical power to the required voltage and current levels for various devices within the control panel.

Wiring and Terminals: Wiring and terminals connect all the components within the control panel, ensuring proper electrical connectivity and signal transmission.

Functions of a Control Panel

Control panels perform several critical functions that are essential for the operation of electrical systems:

Power Distribution: Control panels distribute electrical power to various devices and systems, ensuring that each component receives the appropriate voltage and current.

Protection: By monitoring electrical parameters and detecting abnormal conditions, control panels protect equipment from damage caused by overloads, short circuits, and other faults.

Control and Automation: Control panels enable the automation of processes by using relays, contactors, and PLCs to control the operation of machinery and systems.

Monitoring and Data Collection: Control panels provide real-time data on electrical parameters, allowing operators to monitor system performance and make informed decisions.

System Integration: Control panels integrate various components and systems, ensuring coordinated operation and efficient management of electrical power.

The Significance of Control Panels in Various Industries

Control panels are indispensable across numerous industries, playing a vital role in ensuring the smooth and efficient operation of electrical systems:

Manufacturing: Control panels automate production processes, monitor machinery, and ensure the safe and efficient operation of industrial equipment.

Power Generation and Distribution: Control panels manage the distribution of electrical power, monitor system performance, and protect critical infrastructure from faults.

Water and Wastewater Management: Control panels regulate pumps, valves, and treatment processes, ensuring the safe and efficient management of water resources.

Oil and Gas: Control panels monitor and control drilling operations, pipeline systems, and processing equipment, enhancing safety and efficiency.

Transportation: Control panels manage electrical systems in railways, airports, and seaports, ensuring the reliable operation of transportation infrastructure.

Conclusion

Control panels are the unsung heroes of electrical systems, playing a crucial role in managing, protecting, and automating various processes across industries. By understanding the components and functions of control panels, we can appreciate their significance in ensuring the smooth and efficient operation of our modern world. As technology continues to evolve, control panels will become even more sophisticated, further enhancing their ability to keep our electrical systems running seamlessly. Stay tuned for more insights into the vital technologies that power our everyday lives.

0 notes

Text

Efficient Overcurrent Control: Exploring Siemens 7SJ80 Siprotec Compact Relay Features

In the ever-evolving landscape of electrical power systems, the need for robust and efficient overcurrent protection has become paramount. Siemens, a pioneer in advanced industrial solutions, has introduced the 7SJ80 Siprotec Compact Relay, a cutting-edge device designed to revolutionize overcurrent control. This blog aims to delve into the distinctive features of the Siemens 7SJ80, unraveling its capabilities and highlighting the ways it enhances the reliability and safety of electrical networks.

The Siemens 7SJ80 Siprotec Compact Relay stands out as a versatile and intelligent solution, offering a myriad of features tailored to address the challenges associated with overcurrent conditions. As we navigate through the blog, we will explore the relay's state-of-the-art functionalities, from its precise fault detection mechanisms to its adaptive protection settings. This exploration will provide an in-depth understanding of how the Siemens 7SJ80 empowers engineers and operators to optimize overcurrent control strategies, ensuring a seamless and efficient operation of power systems. Join us on this journey as we unlock the potential of the Siemens 7SJ80 Siprotec Compact Relay and discover how it contributes to the next generation of smart and reliable electrical protection.

Introduction to Siemens 7SJ80 Siprotec Compact Relay as a Cutting-edge Solution

Within the realm of cutting-edge solutions, the Siemens 7SJ80 Siprotec Compact Relay takes center stage as a pioneering device. This section introduces the Siemens 7SJ80 relay, highlighting its advanced features and capabilities. As a trusted name in industrial solutions, Siemens brings innovation to the forefront with this compact relay, offering a promising solution to the challenges posed by overcurrent conditions.

The Siemens 7SJ80 Overcurrent Protection relay stands out as a versatile and multi-functional solution tailored for motor protection. Specifically designed for asynchronous motors of all sizes, the SIPROTEC 7SJ80 serves as an ideal choice. It not only encompasses essential functions for motor protection but is also equipped to function as a reliable backup relay for transformer differential protection. The compact design of the Siemens SIPROTEC 7SJ80 enhances its adaptability, making it a flexible choice for various applications.

What sets the Siemens SIPROTEC Compact 7SJ80 apart is its flexibility in protection functions. Users have the capability to create up to 20 additional protection functions, allowing for a highly customizable and adaptable protection scheme. This feature empowers users to implement specific protections, such as change for frequency or reverse power protection. The 7SJ80 relay goes beyond mere protection; it facilitates circuit-breaker control, controls other switching devices, and supports automation functions. With an integrated programmable logic (CFC), users can even add their own functions, enabling automation of switchgear through interlocking. Furthermore, the user has the freedom to generate personalized, user-defined messages, adding another layer of customization to the relay's capabilities. The Siemens SIPROTEC 7SJ80 relay, with its extensive features and user-friendly design, emerges as a comprehensive solution for efficient and adaptable motor protection.

Protection Functions Of Siemens 7SJ80 Relay

Directional time-overcurrent protection (67, 67N)

Negative-sequence protection (46)

Under-/overvoltage protection (27/59)

frequency protection (81O/U)

Sensitive dir. ground-fault detection (67Ns)

Undercurrent monitoring (37)

Overload protection (49)

High-impedance restricted ground fault (87N)

Overcurrent protection (50, 50N, 51, 51N)

Breaker failure protection (50BF)

Siemens 7SJ80 Overcurrent Protection Hardware

Pluggable current and voltage terminals

5/8 binary outputs (2 changeover/Form C contacts)

4 current transformers

0/3 voltage transformers

3/7 binary inputs (thresholds configurable using software)

1 life contact

Conformal coating available (NEW)

Key Features

Newly introduced conformal coating for enhanced protection

Convenient pluggable current and voltage terminals

Settable binary input thresholds with three stages using DIGSI

Adjustable secondary current transformer values (1 A / 5 A) via DIGSI

Equipped with nine programmable function keys

Easily replaceable buffer battery accessible from the front

Two additional communication ports for increased connectivity

Integrated switch supporting low-cost and redundant optical Ethernet rings

Ethernet redundancy protocols (RSTP, PRP, and HSR) ensuring optimal reliability

Relay-to-relay communication through Ethernet with IEC 61850 GOOSE

Millisecond-accurate time synchronization via Ethernet with SNTP

Connect up to two SICAM I/O units to expand the number of binary inputs and outputs.

COMMUNICATION INTERFACES

System/service interface

– IEC 61850 Edition 1 and 2

– IEC 60870-5-103 and IEC 60870-5-104

– PROFIBUS-DP

– DNP 3.0

– MODBUS RTU

– DNP3 TCP

– PROFINET

– Ethernet redundancy protocols RSTP, PRP and HSR

Ethernet interface for DIGSI 4 and extension up to two SICAM I/O-Units 7XV5673

USB front interface for DIGSI 4

Conclusion:

In conclusion, the Siemens 7SJ80 Siprotec Compact Relay emerges as a game-changer in the realm of overcurrent control, providing a comprehensive and sophisticated solution for the challenges faced by modern electrical power systems. Throughout this exploration, we've witnessed how the relay's advanced features, such as its adaptive protection settings, precise fault detection mechanisms, and versatile functionality, contribute to a more resilient and efficient operation. The 7SJ80 not only enhances the reliability of power systems but also empowers engineers with the tools needed to tailor protection strategies to specific network requirements.

As we wrap up our journey into the Siemens 7SJ80, it's evident that the relay is not merely a component but a strategic asset for any facility seeking optimal overcurrent control. Its compact design and intelligent capabilities pave the way for a future where electrical networks can operate seamlessly, adapting to dynamic conditions while ensuring the safety and longevity of critical assets. The Siemens 7SJ80 Siprotec Compact Relay marks a significant leap forward in the evolution of overcurrent protection, setting a new standard for efficiency, adaptability, and reliability in the ever-evolving landscape of electrical engineering.

For the most competitive pricing on the Siemens 7SJ80 Siprotec Compact Overcurrent Protection Numerical Relay, connect with Reliserv Solution – your authorized supplier and channel partner for Siemens Numerical Relays, Automation Products, Power Quality Meters & Instruments, MV Switchgear Spares, and PSS SINCAL Software. As a prominent supplier and exporter of Siemens Siprotec Compact products based in Mumbai, Maharashtra, Reliserv Solution offers an extensive array of services and tailored solutions for industries and panel builders. Reach out to us at +917506112097 or email us at [email protected] with your specific requirements. We specialize in a comprehensive range of Siemens Relay products, and to explore our Siemens Numerical relays collection further, click here.

#panelbuilders#siproteccompact#Siemens#powersystems#7SJ80#overcurrentprotection#relay#smartgrids#industrialautomation#powerquality#numericalrelays#electricalengineering#automationsolutions#energyefficiency#electricalsafety#digitaltransformation#customizedsolutions

0 notes

Text

What Is Relay?

Relays often operate quietly behind the scenes, serving as essential components in the electrical world, powering numerous devices and systems. In this article, we will embark on an exploration of relays, covering the fundamentals of what relays are and how to effectively test and utilize these invaluable components.

Meaning of Relays

A relay, in essence, is an electrical switch or device designed to control the flow of electrical current between two separate circuits. It acts as an intermediary, enabling the switching on or off of an electrical signal or current in one circuit by energizing or de-energizing a coil or electromagnet in another circuit.

Relays are commonly employed in various electrical and electronic applications to perform functions such as switching high-voltage loads with a low-voltage control signal, amplifying weak signals, providing isolation between circuits, and facilitating the automation of complex processes.

The fundamental principle of a relay involves an input (control) circuit and an output (load) circuit. Application of voltage or current to the input circuit energizes the relay's coil, generating a magnetic field. This magnetic field, in turn, causes the switch contacts of the relay to change their position, either opening (turning off) or closing (turning on) the connection in the output circuit. Relays are available in diverse forms and configurations, including electromagnetic relays, solid-state relays, and reed relays, each tailored to specific applications and needs.

Relays have extensive applications in industries such as automation, telecommunications, automotive, and control systems, playing a crucial role in ensuring the proper operation and control of electrical devices and processes.

What Are Relays Used For?

You may wonder why relays are used. Relays are vital electrical devices widely employed to control and switch circuits. They enable a low-power signal or circuit to manage a higher-power one, providing essential isolation and protection. Relays find applications in industrial automation, HVAC systems, automotive electronics, telecommunications, and more. For instance, they initiate machinery and processes in automation, start engines, and control lighting in the automotive sector. Their versatility and capability to handle high currents and voltages make relays indispensable for the efficient and secure functioning of various electrical systems and devices.

How to Test a Relay?

Ensuring the functionality of a relay is crucial. A "relay tester" is a specialized tool that simplifies this process. Connect the relay to the tester, ensuring correct alignment. Activate the tester to apply voltage and test continuity, ensuring a precise and effective evaluation of the relay. Employing a relay tester saves time and guarantees reliability in electrical systems.

How to Test a Relay with a Multimeter?

Testing a relay using a multimeter is a straightforward process. Set the multimeter to continuity or resistance mode, locate the coil and contact pins labeled as "coil," "C," "NO," and "NC." Examine coil continuity, ensuring it falls within the specified range. Apply the rated coil voltage and listen for a click as the relay switches. With the coil energized, assess continuity between "C" and "NO"; it should indicate low resistance, signifying closed contacts. Test "C" and "NC" for continuity, which should display infinite resistance, confirming open NC contacts. This multimeter test verifies that the relay functions correctly within your circuit.

0 notes

Video

youtube

ZJSHUYI How the time relay works.www.shuyitop.com;#timerelay #relay

#youtube#A time relay is a relay that is generated by the output circuit within a specified and accurate time after adding or removing the input acti

0 notes

Video

youtube

ZJSHUYI How the time relay works.www.shuyitop.com;#timerelay #relay

#youtube#A time relay is a relay that is generated by the output circuit within a specified and accurate time after adding or removing the input acti

0 notes

Text

Review: Wells Audio Commander Preamplifier & Innamorata II Amplifier

With everyone and their extended families wanting to be audio reviewers, we have been inundated with volumes of positive commentary. As a reviewer, you are dependent upon manufacturers to provide you with equipment to audition and write about. If a writer wants to be around after that initial written review, the pressure is great to submit something popular to the publisher, specifically, coverage that will keep the review sample spigot flowing. After all, what manufacturer seeking to gain a foothold in the industry is going to send their precious product to someone they think may disseminate component coverage less than favorable about them? That’s a question I need not answer on your behalf…

The days of writers like Pearson, Holt and Aczel are, unfortunately, gone. And while I may long to once again profit from their pearls of audio wisdom, only their memories exist. From my first published review in January of 1989, I can’t tell you how many times I’ve wondered how Harry would describe a particular sonic quality, how Gordon might compare one component to another or in what manner, like Peter, I may employ my use of words so efficiently as say what others could not, but in half the space. What those great writers of the past had, which we see none of today, was the self-assuredness not to fear penning the critical review…after all, they were known as critics.

Wells Audio

Jeff Wells is a kindly gentleman that has been in the business of audio retailing for better than 16 years. Not a classically trained electrical engineer, Jeff has obviously picked up considerably knowledge during his years in the trade, either directly, or by osmosis. He also knows where to go for good advice as he has chosen Scott Franklin as a mentor. Scott is considered a bit of a tube guru, having credited to his name any number of well known and respected tube designs. I expect that the basic tube circuits in the Commander have the Franklin touch, with Jeff choosing the parts list and the overall appearance of the preamp and amp. One thing is for sure, you are not going to mistake the Wells Audio gear for anything else made today, or yesterday for that matter. Warranty for both products is three years, including parts and labor.

Commander Preamplifier (USD $3,999)

The first thing one observes when seeing the Commander for the first time is the large round viewing window smack dab in the middle of the face plate. Behind it is what many call “a magic eye” vacuum tube. It glows green and changes with the adjustment of the volume control (which I did via remote). I could not discern what value the magic eye might be of, but it looked pretty enough.

The young ones, persons not old enough to remember the turn of the century, call it “steampunk.” That’s exactly how I viewed the appearance and operation of the Commander preamp. At a time when smooth operation and silky feel to controls are the key descriptive terms being used with todays’ high-end audio electronics, along comes the Wells Commander preamp that seems to have no end to its unique appearance and odd noises that emanate from it. With every change of volume comes a “clickity” sound that I’ve never heard before as part of a high-end component. Initially I thought that I might have broken it, but everything seemed to continue working, so I didn’t worry about it. Furthermore, @miy-taww assured me that some units simply work that way. (Yup, this is the sound of an attenuator based on conventional mechanical relays. The exact nature of the clicking depends on how the control logic is implemented. @miy-taww)

As far as I know, the acrylic exterior of the Commander is a first. The black reflective surface shines like a polished black mirror, making picture taking a real task. I like the fact that acrylic resonates much less than the standard metal exterior plates found with most amps and preamps. On the other hand, acrylic affords the component no effective RFI/EMI shielding.

Commander Pros: Setting the preamp up was cake, basically plug and play…the remote even came with batteries in it. Another positive was the ability to use a set of balanced inputs in addition to the standard RCA inputs. The unit also had balanced output jacks, coming in handy for use with my balanced Pass XA30.5 power amplifier.

The Commander is a solid imager with good depth of image, all placed upon a wide and panoramic stage. Tone quality, especially in the mids, is true and natural. And while this is a preamp utilizing tubes, tubes it does not sound like. The softish, melodramatic approach promoted by some tube products is completely missing here, as the Commander, instead of being soft, has an ability to capture, as well as anything I’ve heard, the transient speed of a plucked steel stringed guitar. This leading edge quality is also apparent in percussive strikes and snare hits, yes it can be an exciting experience listening with this preamp. Listening to rock and roll as well as jazz, on more than one occasion the transient speed of this unit compelled me to query if perhaps Wells alone had gotten this aspect to reproduction correct.

Lastly, when one looks under the hood of the Commander, and then considers the price of it, in light of the unconventional use of parts and construction layout, the obvious question becomes, “How did they do this for the price charged?”

Commander Cons: I enjoy using remote volume controls, however, this unit’s clunky nature and lack of responsiveness was a turn off to me. Sometimes, when moving the volume up, the actual output would first go down and them up.

Musically, the frequency extremes were rather odd and not wholly to my liking. These two things, I think, are related: The speed and attack heard in the midrange also resulted in an upper octave that was in many cases more forward than I am attracted to while striking me as grainy. I described the highs with the Commander to one friend as “crunchy.” The bass, it seemed to me, was similarly flawed, but in different ways. Listening to recordings with a healthy amount of bass in them, it was all there, i.e., I felt that I could hear all of the bottom three octaves frequency wise. At the same time, however, the bass lacked deep down energy.

Initially, I wondered if my choice of power cords was pushing the preamp in the directions just described. I tried cords from Audience, JPS, DH Labs and Twirling Gerbil. Though I heard changes in the performance, none of those cords locked in with the Commander. Finally, I went with the factory supplied cord, which performed as well as any of the above; forming the basis for the comments here and above.

Lastly, while I had great success using the balanced jacks on the back of the preamp, the standard RCAs didn’t always work consistently. This needs to be looked into by Jeff and in my opinion, simplified internally. The some days the jacks would work, some days, not, drove me crazy.

Conclusion. In my opinion, the Commander preamplifier from Wells Audio is not a finished product, bugs need to be addressed. The potential to be a stunning performer is all there, particularly when the Scott Franklin influence is considered. I consider it a diamond in the rough. I look forward to observing the progress Wells Audio makes with this product. Presently, I cannot recommend it.

Innamorata II Power amplifier (USD $7,000)

Taking the same visual cues as the Commander preamplifier, the Innamorata II is a large, heavy power amp. Rated at 150 wpc into 8 Ohms, the amp is said to put out 210 wpc into 4 Ohms. The amp is a beautiful gloss black, with a single round meter located dead center on the faceplate. Centering the meter is a large gold bezel that you will love or hate, all depending on your fashion sense. Jeff told me of his plans to make the amps’ exterior parts completely out of acrylic materials, everything save the heatsinks. I think Wells may be on to something here as fabricating may be less expensive that way, the product will weight less and the appearance can be pretty stunning in any color you desire. Finally, even though the sibling preamplifier has balanced outputs, the power amplifier cannot accommodate balanced connectors (which struck me as odd).

Innamorata Pros: Lots of power delivered effortlessly. Power cords were not an issue with the amp. Regardless of what I used, this amp forged a straight line forward sounding good under all conditions. I ended up using the Twirling Gerbil amp cord, the combo performing in a positive manner that was in every instance musical.

What I generally like about a well designed solid state power amp is its unflappable performance with a variety of loudspeaker loads. And so I can report that I listened to this amp with a variety of speaker loads, all the way from 4 Ohms, to a small monitor with a wandering load of 8 to 16 Ohms. As you know, all speakers present an amp with a variety of impedances depending on frequency. With many speakers, things can get a little hairy at resonance, the Innamorata stayed tight and fast in the bass, while never sounding washed out. Pace and bloom were actually strong parts of this design. You know an amp has something going for it when during listening sessions you keep asking yourself. “What’s it going to do with this album? I’ve got to hear it with this other album.” This amp had me anticipating what new positive twist it might put on a recording heard many, many times before.

Another positive aspect of this amps’ performance was the natural and organic way it handled vocals. Voices at the front of the stage did not jump forward; instead they sounded real, and usually within an aura of natural ambiance. Backup as well as background vocals were similarly tangible and pleasant to listen to.

Innamorata Cons: My biggest complaint with amp is the fact that it quit working after the first listening session. I had been listening to it in one system and enjoyed the results obtained. I then wanted to insert the Wells amp in a second system. I have a tall four wheeled cart that allows me to pick up the amp, put it on the cart and then wheel it off without having to bend over. I moved the amp one day to see how it would perform in a new listening environment. When I sat it down in the new system the right channel refused to come up. I sent it back to Jeff. He told me that an internal cable had come loose and he merely had to put it right and all was well. Solder the connection and the problem does not arise.

Musically, there’s not a lot to complain about. For more money there are better sounding solid state power amps. I take that position not because the Wells does much wrong, but because some amps are simply exceptional in one regard or another. Those exceptional amps may have slightly more air then the Wells, or a little more bloom upon the stage, but for the money, this is a good amplifier, though not in the same sonic class as the Pass XA30.5 that I compared it to.

Conclusion. I enjoyed using this power amplifier. A no-surprise design, it is quiet when you turn it on, and when you turn it off there are no driver threatening burps or releases of DC. In other words, don’t worry if the power is, for any reason, discontinued. It does concern me that the right channel went down during my auditioning period. A consumer electronics device that retails for $7,000.00 has an obligation to operate in a worry free manner. Audio components are meant to be enjoyed, as they are necessary to the playback of music in the home. A power amplifier situated in the home of an audiophile is not a tool in the manner of a tone generator or scope, it is something more, very much more. And, as the price of a component increases, the obligation of a manufacturer to produce a glitch free product increases in a linear fashion. That said, no one is perfect, making mistakes is human, and the error which lead to the failure of the right channel in this case was nothing other than a contact coming apart – nothing blew, no sparks, no fried resistors, and I have no doubt that that Jeff Wells remedied the situation so as to never have this happen again.

I, therefore, must conclude that when a person lays down their hard earned dollars for a new Innamorata II, he or she will have an amplifier well worth the outlay, and one capable of bringing home the heart and soul of the music in a way that will bring years and years of musical satisfaction and pride. A power amplifier done well.

1 note

·

View note

Text

6ED1052-1CC08-0BA1

Siemens LOGO! 230RCE 6ED1052-1FB08-0BA1: The New Generation of Logic Modules

Are you looking for basic logic modules? Siemens LOGO! 6ED1 052-1FB08-0BA1 is the right choice.

It has an integrated 8-channel bus line and 8 digital inputs, which transfer high-speed signals of 24 V DC or TTL level. Your product will be protected from damage by an integrated 6 A solid-state power breaker.

LOGO! 6ED1052-1FB08-0BA1 is the right decision since it comes with a communication interface for connection to the controller. LOGO is used in many different areas.

One is the electronic control of valves for heating, cooling, or humidification systems. Another is electric drives that regulating the output voltage to meet the load demand.

Other examples are external interfaces for data exchange with PCs and process-level data acquisition.

The logic basic modules are available in different versions such as 6ED1052-1HB08-0BA1, 6ED1052-1CC08-0BA1, and 6ED1052-1MD08-0BA1 you can choose one to meet your requirements!

What is the LOGO logic module?

The Siemens logo! Logic modules are a series of ready-made interfaces for use in Siemens programmable automation controllers.

These modules automate various industrial processes, such as conveyor belt systems, power distribution equipment, and data networks like Ethernet.

youtube

These modules are based on Siemens' decentralized controller system. They feature a local control output and inputs for use with sensors or programming tools.

These features combine to make them robots, which bring products onto a conveyor belt at the right place and time to be assembled.

Functionality: simple, flexible, and ingenious

Siemens logo logic offers simple, flexible, and ingenious solutions. The simple-to-use platform provides many advantages.

Suppose a simple module is not enough to meet the customer's requirements. In that case, it can consistently be expanded or integrated into a system thanks to Siemens' simple platform with all its benefits.

The Siemens solution is easy to use, easy to install, and simple for customers to commission.

A considerable benefit of the modular concept is its flexibility: modules can be changed over simply - not only within the logo system but also into other areas.

Thanks to software functions, these modules can be combined into systems for simple tasks.

Not to mention its ingenious design. This logic platform also has several clever design features implemented in line with the system's flexible use.

Technical info: Compact Controller with Big Heart

The controller is designed for simple automation tasks. It can control up to 8 devices and features various modes, including the ability to handle on/off cycles or timed events with ease.

With an intuitive interface that's easy to navigate even without training, the Siemens logo ideal controller has it all when it comes to making your life easier!

This logic module allows one to expand and gain flexibility with an easy interface. It is a valuable tool for controlling and regulating procedures within an electrical circuit with ease and precision.

It is comparable to solid-state relays but gives one more feature than simple on/off functionality.

Conclusion: The ideal controller for simple automation tasks

If you're looking for a controller that can do more than simple automation tasks, look into the Siemens LOGO! It has an intuitive interface and can be programmed with any control logic.

Plus, it comes at a very affordable price point. Give us a call today to learn about all the fantastic product features to offer your company!

Visit to the Website for getting more information related to 6ED1052-2FB08-0BA1.

0 notes

Text

400+ TOP POWER ELECTRONICS Interview Questions and Answers pdf

POWER ELECTRONICS Interview Questions with Answers :-

1. What is holding current in SCR? It is the minimum current required to hold the SCR in forward conduction state. When the forward current becomes less than holding current, SCR turns from forward conduction state to forward blocking state. 2. What is latching current in SCR? It is the minimum current required to latch(turn on) the SCR from forward blocking state to forward conduction state. 3. What are the different turn on methods of SCR? Forward voltage triggering Gate Triggering dv/dt triggering Temperature triggering Light triggering 4. What is snubber circuit? The snubber circuit is used for the dv/dt protection of the SCR. It is a series combination of a resistor and a capacitor in parallel with the SCR. 5. What is hard switching of the thyristor? When gate current is several times higher than the required gate current, the SCR is said to be hard fired. It reduces the turn ON time and enhances the di/dt capability.

POWER ELECTRONICS Questions 6. What is firing angle? The angle between the zero crossing of the input voltage and the instant the SCR is fired is called as delay angle or firing angle. 7. What is meant by SOA? SOA - Safe Operating Area determines the voltage and current boundary within which the Power Device can be operated without destructive failure. 8. What are the main components used for isolating the Power Circuits, Power Semiconductor from the low-power circuit? Opto-Couplers, Transformers 9. Name some of the current controlled (current driven) devices... SCR, GTO, GTR 10. Name some of the voltage driven ( Voltage controlled) devices IGBT, MCT, IGCT, SIT 11. What is duty cycle? It is the ratio of the ON time of the chopper to total time period of the chopper. D = Ton / 12. Can fuses with an AC voltage rating be used in a DC applications? Fuses must be rated for the voltage AC or DC in which they will be used. Generally, fuses have a DC voltage rating that is half of the maximum AC voltage rating. 13. What are the characteristics of ideal Opamp? Infinite open loop voltage gain Infinite input impedance Zero output impedance Infinite Bandwidth Zero offset voltage 14. For High voltage applications will you prefer MOSFET or IGBT? For High voltage applications we have to use IGBT. Because MOSFETs are low voltage devices. ie, Their voltage rating is lesser than IGBT. General rule is MOSFETs are suitable for applications which has breakdown voltage less than 250V. The IGBTs are suitable for applications which has breakdown voltage upto 1000V. 15. For High frequency applications will you prefer MOSFET or IGBT? Why? For High frequency applications, MOSFET is the right choice of the device. Because MOSFET has low switching losses compare to that of IGBT. General rule of thumb is for low-frequency applications having frequency range upto 20kHz, we have to use IGBT. For high frequency applications having frequency range of more than 200kHz, we have to use MOSFET. POWER ELECTRONICS Interview Questions :: 16. What are the advantages of free wheeling diode in rectifier circuit? The input power factor is improved. It prevents the output voltage from becoming negative. The Load current waveform is improved. 17. What are the types of commutation? Natural commutation Forced commutation 18. What is natural commutation? The process of the current flowing through the thyristor goes through a natural zero and enable the thyristor to turn off is called as natural commutation. 19. What is forced commutation? The process of the current flowing through the thyristor is forced to become zero by external circuitry is called as forced commutation. 20. What are the types of commutation with respect to commutation process? Voltage commutated chopper Current commutated chopper Load commutated chopper 21. What is meant by cyclo-converter? It is also known as frequency changer. It converts input power at one frequency to output power at another frequency with one stage conversion. 22. What are the types of cyclo-converters? Step up cyclo-converter Step down cyclo-converter. 23. What is step down cyclo-converter? It is the converter whose output frequency is less than the input frequency. 24. What is step up cyclo-converter ? It is the converter whose output frequency is more than the input frequency. 25. What does the Voltmeter in AC mode show? Is it RMS value or peak value? Multimeter in AC mode shows RMS value of the voltage or current. Also when it is DC mode it will show the RMS value only. 26. What is the necessity to use the special machines? General purpose motors (Induction motors, synchronous motors) are neither precision speed nor precision position motors. For many automated systems require high precise speed and high precise positioning motors. In such cases special purpose motors like stepper motors, PMDC motors etc. are used. 27. What are the control strategies of chopper? The control strategies of chopper are Pulse width modulation PWM (Variable TON, Constant frequency) Frequency modulation (Constant TON or TOFF, Variable frequency) Current Limit Control (CLC) 28. What is delay angle or what is firing angle of phase controlled rectifier? The delay angle is the angle at which thyristors are triggered after zero crossing. After zero crossing of supply voltage, one pair of thyristors is forward biased. ie, After delay angle(α) these SCRs are triggered. 29. What is Universal Motor? It is defined as a motor which can be operated either on DC or single-phase AC supply at approximately the same speed and output. The universal motor is built exactly like a series DC motor. But a series DC motor cannot be run as a universal motor, even though both motors look the same internally and externally. We cannot use these motors in the industrial applications due to the low efficiency (25% -35%). It has high starting torque and a variable speed characteristic. It runs at dangerously high-speed on no load. 31. Give some examples of power electronics applications in the day-to-day life? We can list a huge number of power electronics applications. Few of the applications which we can see in our daily life are UPS - Uninterruptible Power Supply SMPS - Switch Mode Power Supply Speed Control of Motors ICU 32. What is meant by PMDC? PMDC stands for Permanent Magnet DC Motor A Permanent Magnet DC Motor is similar to an ordinary dc shunt motor except that its field is provided by permanent magnets instead of salient-pole wound field structure. There are three types of permanent magnets used for such motors namely; (i) Alnico Magnets (ii) Ceramic magnets (iii) Rare-earth magnets The major advantages are low noise, small size, high-efficiency, low manufacturing cost. 33. What is meant by commutation? The process of changing the direction of current flow in a particular path of the circuit. It is used to turn off the SCR. 34. Two Bulbs Of 100w And 40w Respectively Connected In Series Across A 230v Supply Which Bulb Will Glow Bright And Why? Since two bulbs are in series they will get equal amount of electrical current but as the supply voltage is constant across the bulb(P=V^2/R).So the resistance of 40W bulb is greater and voltage across 40W is more (V=IR) so 40W bulb will glow brighter. 35. What Is Meant By Knee Point Voltage? Knee point voltage is calculated for electrical Current transformers and is very important factor to choose a CT. It is the voltage at which a CT gets saturated.(CT-current transformer). 36. What Is Reverse Power Relay? Reverse Power flow relay are used in generating station's protection. A generating stations is supposed to fed power to the grid and in case generating units are off,there is no generation in the plant then plant may take power from grid. To stop the flow of power from grid to generator we use reverse power relay. 37. What Are The Advantage Of Free Wheeling Diode In A Full Wave Rectifier? It reduces the harmonics and it also reduces sparking and arching across the mechanical switch so that it reduces the voltage spike seen in a inductive load. 38. What Is The Full Form Of Kvar? We know there are three types of power in Electrical as Active, apparent & reactive. So KVAR is stand for ``Kilo Volt Amps with Reactive component. 39. Definition Of Power Electronics? Power electronics refers to control and conversion of electrical power by power semiconductor devices wherein these devices operate as switches. 40. What Is The Main Purpose Of Power Electronics? The main task of power electronics is to control and convert electrical power from one form to another. AC to DC conversion: Rectifier is used for converting an AC voltage to a DC voltage. Rectifier applications: Variable speed dc drives, Battery chargers, DC power supplies and Power supply for a specific application like electroplating. DC to AC conversion: Inverter circuit is used to convert DC voltage to an alternating voltage. Inverter applications: Emergency lighting systems, AC variable speed drives, Un-interrupted power supplies and Frequency converters. DC to DC conversion: A dc-to-dc converter circuit was called a chopper. Chopper applications: DC drive, Battery charger and DC power supply. AC to AC conversion: A cycloconverter converts an AC voltage to another AC voltage. Cycloconverter applications: It is rarely used. Can be used for controlling the speed of an AC traction motor 41. What Are The Different Operation Regions Of The Thyristor (scr)? SCR or thyristor will have three regions of operations based on the mode in which the device is connected in the circuit. Reverse blocking region: When the cathode of the thyristor is made positive with respect to the anode and no gate signal is applied. In this region SCR exhibits the reverse blocking characteristics similar to diode. Forward blocking region: In this region the anode of the thyristor is made positive with respect to the cathode and no gate signal is applied to the thyristor. A small leakage current flow in this mode of operation of the thyristor. Forward conduction region: when the forward voltage applied between the anode and cathode increases at particular break over voltage avalanche breakdown takes place and thyristor starts conducting current in forward direction. By this type of triggering the device damages the scr. Hence a gate signal is applied before the forward break over voltage to trigger the scr. 42. What Are The Losses That Occur In A Thyristor During Working Conditions? Forward conduction losses Loss due to leakage current during forward and reverse blocking Switching losses at turn on turn off Gate triggering loss 43. What Are The Advantages Of Freewheeling Diode In Rectifier Circuit? The input power factor is improved. It prevents the output voltage from becoming negative. Load current waveform is also improved. 44. Explain The Function Of Cyclo-converter? It is also known as frequency changer. It converts input power at one frequency to output power at another frequency with one stage conversion. 45. What Is An Inverter? A device which converts dc power into ac power at desired output voltage and frequency is called as Inverter. 46. Define Circuit Turn Off Time It is defined as the time during which a reverse voltage is applied across the thyristor during its commutation process. 47. Why The Circuit Turn Off Time Should Be Greater Than Thyristor Turn Off Time? If the circuit turn off time is less than the thyristor turn off time the device may turn on at an undesired instant resulting in commutation failure. 48. What Is Chopper? A dc Chopper is equivalent to the transformer in ac circuit. It is a static switch used to get the variable dc voltage from a constant dc voltage. 49. What Are The Types Of Commutation? (or) Turn Off Methods? Natural commutation Forced commutation 50. What Is Natural Commutation? The process of the current flowing through the thyristor goes through a natural zero and enable the thyristor to turn off is called as natural commutation. 51. What Is Forced Commutation? The process of the current flowing through the thyristor is forced to become zero by external circuitry is called as forced commutation. 52. What Is Step Down Chopper? In step down chopper, the average output voltage is less than the input supply voltage. It is also known as Buck converter. 53. What Is Step Up Chopper? In step up chopper, the average output voltage is more than the input supply voltage. It is also known as Boost converter. 54. What Is Voltage Commutation? The process of a charged capacitor momentarily reverse biases the conducting SCR and turns it off is called as voltage commutation. 55. What Is Current Commutation? The process of a current pulse is made to flow in the reverse direction through the conducting SCR and thus made the net SCR current becomes zero, consequently turn off the SCR is called as current commutation. 56. What Are The Advantages Of Current Commuted Chopper? The advantages of current commutated chopper is; Commutation is reliable as load current is less than the peak commutation current The auxiliary SCR is naturally commutated as its current passes through zero value. The capacitor always remains charged with the correct polarity. 57. What Is Load Commutation? In load commutation, the load current flowing through the thyristor either becomes zero or is transferred to another device from the conducting SCR. 58. Name Some Of The Current Controlled (current Driven) Devices? SCR, GTO, GTR. 59. Name Some Of The Voltage Driven (voltage Controlled) Devices. IGBT, MCT, IGCT, SIT. 60. What Is Meant By Pulse Triggered Devices? To turn on these kind of devices single pulse of short duration is sufficient. Continuous gate voltage of entire on time is not required. It will avoid the hard triggering. Example: Thyristor, GTO 61. What Is Meant By Level-sensitive Devices? In order to maintain these kind of devices in on-state, we need to apply continuous gate current /voltage. Some of the level sensitive devices are: MOSFET, IGBT, MCT, IGCT 62. What Are The Advantages Of Igbt Over Bjt, Mosfet? IGBT has Lower turn on and turn off times than BJT Lower on state conduction losses than MOSFET Excellent safe operating area 63. Why Igbt Is Very Popular Nowadays? Lower hate requirements Lower switching losses Smaller snubber circuit requirements 64. What Are The Different Methods To Turn On The Thyristor? Forward voltage triggering Gate triggering dv/dt triggering Temperature triggering Light triggering 65. What Is The Difference Between Power Diode And Signal Diode? Power diode Constructed with n-layer, called drift region between p+ layer and n+ layer. The voltage, current and power ratings are higher. Power diodes operate at high speeds. Signal diode Drift region is not present. The voltage, current and power ratings are Lower Operates at higher switching speed. 66. Igbt Is A Voltage Controlled Device. Why? Because the controlling parameter is gate-emitter voltage. 67. Power Mosfet Is A Voltage Controlled Device. Why? Because the output (drain) current can be controlled by gate-source voltage. 68. Power Bjt Is A Current Controlled Device. Why? Because the output (collector) current can be controlled by base current. 69. What Is The Relation Between α & β? 70. What Are The Different Types Of Power Mosfet? N-channel MOSFET P-channel MOSFET 71. How Can A Thyristor Turned Off? A thyristor can be turned off by making the current flowing through it to zero. 72. Define Latching Current? The latching current is defined as the minimum value of anode current which it must attain during turn on process to maintain conduction when gate signal is removed. 73. Define Holding Current? The holding current is defined as the minimum value of anode current below which it must fall to for turning off the thyristor. 74. What Is A Snubber Circuit? It consists of a series combination of a resistor and a capacitor in parallel with the thyristors. It is mainly used for dv / dt protection. 75. What Losses Occur In A Thyristor During Working Conditions? Forward conduction losses Loss due to leakage current during forward and reverse blocking. Switching losses at turn-on and turn-off. Gate triggering loss. 76. Define Hard-driving Or Over-driving? When gate current is several times higher than the minimum gate current required, a thyristor is said to be hard-fired or over-driven. Hard-firing of a thyristor reduces its turn-on time and enhances its di/dt capability. 77. Define Circuit Turn Off Time? It is defined as the time during which a reverse voltage is applied across the thyristor during its commutation process. 78. Why Circuit Turn Off Time Should Be Greater Than The Thyristor Turn-off Time? Circuit turn off time should be greater than the thyristor turn-off time for reliable turn-off, otherwise the device may turn-on at an undesired instant, a process called commutation failure. 79. What Is The Turn-off Time For Converter Grade Scrs And Inverter Grade Scrs? Turn-off time for converter grade SCRs is 50 – 100 ms turn-off time for converter grade SCRs and inverter grade SCRs and for inverter grade SCRs is 3 – 50 ms. 80. What Are The Advantages Of Gto Over Scr? Elimination of commutation of commutating components in forced commutation, resulting in reduction in cost, weight and volume. Reduction in acoustic noise and electromagnetic noise due to elimination of commutation chokes. Faster turn-off, permitting high switching frequencies. Improved efficiency of the converters. 81. What Is Meant By Phase Controlled Rectifier? It converts fixed ac voltage into variable dc voltage. 82. Mention Some Of The Applications Of Controlled Rectifier? Steel rolling mills, printing press, textile mills and paper mills employing dc motor drives. DC traction Electro chemical and electro-metallurgical process Portable hand tool drives Magnet power supplies HVDC transmission system 83. What Is The Function Of Freewheeling Diodes In Controlled Rectifier? It serves two process. It prevents the output voltage from becoming negative. The load current is transferred from the main thyristors to the freewheeling diode, thereby allowing all of its thyristors to regain their blocking states. 84. What Are The Advantages Of Free Wheeling Diodes In A Controlled In A Controlled Rectifier? Input power factor is improved. Load current waveform is improved and thus the load performance is better. 85. What Is Meant By Delay Angle? The delay angle is defined as the angle between the zero crossing of the input voltage and the instant the thyristor is fired. 86. What Are The Advantages Of Single Phase Bridge Converter Over Single Phase Mid-point Converter? SCRs are subjected to a peak-inverse voltage of 2Vm in a fully controlled bridge rectifier. Hence for same voltage and current ratings of SCrs, power handled by mid-point configuration is about In mid-point converter, each secondary winding should be able to supply the load power. As such, the transformer rating in mid-point converter is double the load rating. 87. What Is Commutation Angle Or Overlap Angle? The commutation period when outgoing and incoming thyristors are conducting is known as overlap period. The angular period, when both devices share conduction is known as the commutation angle or overlap angle. 88. What Are The Different Methods Of Firing Circuits For Line Commutated Converter? UJT firing circuit. The cosine wave crossing pulse timing control. Digital firing schemes. 89. Give An Expression For Average Voltage Of Single Phase Semiconverters? Average output voltage Vdc = (Vm /Π) (1 + cosα). 90. What Is Meant By Input Power Factor In Controlled Rectifier? The input power factor is defined as the ratio of the total mean input power to the total RMS input volt-amperes. PF = ( V1 I1 cos φ1 ) / ( Vrms Irms) where V1 = phase voltage, I1 = fundamental component of the supply current, φ1 = input displacement angle, Irms = supply rms current. 91. What Are The Advantages Of Six Pulse Converter? Commutation is made simple. Distortion on the ac side is reduced due to the reduction in lower order harmonics. Inductance reduced in series is considerably reduced. 92. What Is Meant By Natural Commutation? Here the current flowing through the thyristor goes through a natural zero and enable the thyristor to turn off. 93. What Is Meant By Forced Commutation? the thyristor is forced to become zero by external circuitry. 94. What Is Meant By Dc Chopper? A dc chopper is a high speed static switch used to obtain variable dc voltage from a constant dc voltage. 95. What Are The Applications Of Dc Chopper? Battery operated vehicles Traction motor control in electric traction Trolley cars Marine hoists Mine haulers Electric braking. 96. What Is Meant By Step-up And Step-down Chopper? In a step- down chopper or Buck converter, the average output voltage is less than the input voltage. In a step- up chopper or Boost converter, the average output voltage is more than the input voltage. 97. Write Down The Expression For Average Output Voltage For Step Down Chopper? Average output voltage for step down chopper V0 = α Vs, α is the duty cycle. 98. Write Down The Expression For Average Output Voltage For Step Up Chopper? Average output voltage for step down chopper Vs V0 = ------ 1 - α α is the duty cycle. 99. What Is Meant By Duty-cycle? Duty cycle is defined as the ratio of the on time of the chopper to the total time period of the chopper. It is denoted by α. 100. What Are The Two Types Of Control Strategies? Time Ratio Control (TRC) Current Limit Control method (CLC) 101. What Is Meant By Trc? In TRC, the value of Ton / T is varied in order to change the average output voltage. 102. What Are The Two Types Of Trc? Constant frequency control Variable frequency control 103. What Is Meant By Fm Control In A Dc Chopper? In frequency modulation control, the chopping frequency f (or the chopping period T) is varied. Here two controls are possible. On-time Ton is kept constant Off period Toff is kept constant. 104. What Is Meant By Pwm Control In Dc Chopper? In this control method, the on time Ton is varied but chopping frequency is kept constant. The width of the pulse is varied and hence this type of control is known as Pulse Width Modulation (PWM). 105. Write Down The Expression For The Average Output Voltage For Step Down And Step Up Chopper? Average output voltage for step down chopper is VO = α VS. Average output voltage for step up chopper is VO = α VS x . 106. What Are The Different Types Of Chopper With Respect To Commutation Process? Voltage commutated chopper. Current commutated chopper. Load commutated chopper. 107. What Is Meant By Voltage Commutation? In this process, a charged capacitor momentarily reverse biases the conducting thyristor and turn it off. 108. What Is Meant By Current Commutation? In this process, a current pulse is made to flow in the reverse direction through the conducting thyristor and when the net thyristor current becomes zero, it is turned off. 109. What Is Meant By Load Commutation? In this process, the load current flowing through the thyristor either becomes zero or is transferred to another device from the conducting thyristor. 110. What Are The Advantages Of Current Commutated Chopper? The capacitor always remains charged with the correct polarity. Commutation is reliable as load current is less than the peak commutation current ICP. The auxiliary thyristor TA is naturally commutated as its current passes through zero value. 111. What Are The Advantages Of Load Commutated Chopper? Commutating inductor is not required. It is capable of commutating any amount of load current. It can work at high frequencies in the order of kHz. Filtering requirements are minimal. 112. What Are The Disadvantages Of Load Commutated Chopper? For high power applications, efficiency becomes very low because of high switching losses at high operating frequencies. Freewheeling diode is subjected to twice the supply voltage. Peak load voltage is equal to twice the supply voltage. The commutating capacitor has to carry full load current at a frequency of half chopping frequency. One thyristor pair should be turned-on only when the other pair is commutated. This can be realized by sensing the capacitor current that is alternating. 113. What Is Meant By Inverter? A device that converts dc power into ac power at desired output voltage and frequency is called an inverter. 114. What Are The Applications Of An Inverter? Adjustable speed drives Induction heating Stand-by aircraft power supplies UPS HVDC transmission 115. What Are The Main Classification Of Inverter? Voltage Source Inverter Current Source Inverter 116. Why Thyristors Are Not Preferred For Inverters? Thyristors require extra commutation circuits for turn off which results in increased complexity of the circuit. For these reasons thyristors are not preferred for inverters. 117. How Output Frequency Is Varied In Case Of A Thyristor? The output frequency is varied by varying the turn off time of the thyristors in the inverter circuit, i.e. the delay angle of the thyristors is varied. 118. Give Two Advantages Of Csi? CSI does not require any feedback diodes. Commutation circuit is simple as it involves only thyristors. 119. What Is The Main Drawback Of A Single Phase Half Bridge Inverter? It require a 3-wire dc supply. 120. Why Diodes Should Be Connected In Antiparallel With Thethyristors In Inverter Circuits? For RL loads, load current will not be in phase with load voltage and the diodes connected in anti parallel will allow the current to flow when the main thyristors are turned off. These diodes are called feedback diodes. 121. What Types Of Inverters Require Feedback Diodes? VSI with RL load. 122. What Is Meant A Series Inverter? An inverter in which the commutating elements are connected in series with the load is called a series inverter. 123. What Is The Condition To Be Satisfied In The Selection Of L And C In A Series Inverter? 4L R2 C 124. What Is Meant A Parallel Inverter? An inverter in which the commutating elements are connected in parallel with the load is called a parallel inverter. 125. What Are The Applications Of A Series Inverter? The thyristorised series inverter produces an approximately sinusoidal waveform at a high output frequency, ranging from 200 Hz to 100kHz. It is commonly used for fixed output applications such as Ultrasonic generator. Induction heating. Sonar Transmitter Fluorescent lighting. 126. How Is The Inverter Circuit Classified Based On Commutation Circuitry? Line commutated inverters. Load commutated inverters. Self commutated inverters. Forced commutated inverters. 127. What Is Meant By Mcmurray Inverter? It is an impulse commutated inverter which relies on LC circuit and an auxiliary thyristor for commutation in the load circuit. 128. What Are The Applications Of A Csi? Induction heating Lagging VAR compensation Speed control of ac motors Synchronous motor starting. 129. What Is Meant By Pwm Control? In this method, a fixed dc input voltage is given to the inverter and a controlled ac output voltage is obtained by adjusting the on and off periods of the inverter components. This is the most popular method of controlling the output voltage and this method is termed as PWM control. 130. What Are The Advantages Of Pwm Control? The output voltage can be obtained without any additional components. Lower order harmonics can be eliminated or minimized along with its output voltage control. As the higher order harmonics can be filtered easily, the filtering requirements are minimized. 131. What Are The Disadvantages Of The Harmonics Present In The Inverter System? Harmonic currents will lead to excessive heating in the induction motors. This will reduce the load carrying capacity of the motor. If the control and the regulating circuits are not properly shielded, harmonics from power ride can affect their operation and malfunctioning can result. Harmonic currents cause losses in the ac system and can even some time produce resonance in the system. Under resonant conditions, the instrumentation and metering can be affected. On critical loads, torque pulsation produced by the harmonic current can be useful. 132. What Are The Methods Of Reduction Of Harmonic Content? Transformer connections Sinusoidal PWM Multiple commutation in each cycle Stepped wave inverters 133. Compare Csi And Vsi? VSI: Input voltage is maintained constant The output voltage does not depend on the load The magnitude of the output current and its waveform depends on the nature of the load impedance It requires feedback diodes Commutation circuit is complicated i.e. it contains capacitors and inductors. CSI: Input current is constant but adjustable The output current does not depend on the load The magnitude of the output voltage and its waveform depends on the nature of the load impedance It does not requires feedback diodes Commutation circuit is simple i.e. it contains only capacitors. 134. What Are The Disadvantages Of Pwm Control? SCRs are expensive as they must possess low turn-on and turn-off times. 135. What Does Ac Voltage Controller Mean? It is device which converts fixed alternating voltage into a variable voltage without change in frequency. 136. What Are The Applications Of Ac Voltage Controllers? Domestic and industrial heating Lighting control Speed control of single phase and three phase ac motors Transformer tap changing 137. What Are The Advantages Of Ac Voltage Controllers? High efficiency Flexibility in control Less maintenance 138. What Are The Disadvantages Of Ac Voltage Controllers? The main draw back is the introduction of harmonics in the supply current and the load voltage waveforms particularly at low output voltages. 139. What Are The Two Methods Of Control In Ac Voltage Controllers? ON-OFF control Phase control 140. What Is The Difference Between On-off Control And Phase Control? ON-OFF control: In this method, the thyristors are employed as switches to connect the load circuit to the source for a few cycles of the load voltage and disconnect it for another few cycles. Phase control: In this method, thyristor switches connect the load to the ac source for a portion of each half cycle of input voltage. 141. What Is The Advantage Of On-off Control? Due to zero-voltage and zero current switching of thyristors, the harmonics generated by the switching action are reduced. 142. What Is The Disadvantage Of On-off Control? This type of control is applicable in systems that have high mechanical inertia and high thermal time constant. 143. What Is The Duty Cycle In On-off Control Method? Duty cycle K = n/ (n + m), where n = number of ON cycles, m = number of OFF cycles. 144. What Is Meant By Unidirectional Or Half-wave Ac Voltage Controller? Here the power flow is controlled only during the positive half-cycle of the input voltage. 145. What Are The Disadvantages Of Unidirectional Or Half-wave Ac Voltage Controller? Due to the presence of diode on the circuit, the control range is limited and the effective RMS output voltage can be varied between 70.7% and 100%. The input current and output voltage are asymmetrical and contain a dc component.If there is an input transformer, saturation problem will occur It is only used for low power resistive load. 146. What Is Meant By Bidirectional Or Half-wave Ac Voltage Controller? Here the power flow is controlled during both cycles of the input voltage. 147. What Is The Control Range Of Firing Angle In Ac Voltage Controller With Rl Load? The control range is Φ Average output voltage, rms value of output voltage expression. 166. Describe The Working Of 3Φ Fully Controlled Bridge Converter In The Rectifying Mode And Inversion Mode. And Derive The Expressions For Average Output Voltage And Rms Output Voltage? 3Φ full converter bridge circuit waveforms of vo , io , iA, vs Operation Average output voltage expression. 167. Describe The Working Of 3Φ Semi Converter. And Derive The Expressions For Average Output Voltage And Rms Output Voltage? 3Φ semi converter bridge circuit waveforms of vo , io , iA, vs Operation Average output voltage expression. 168. Describe The Working Of Dual Converter? 3Φ dual converter bridge circuit waveforms of vo , io , vo1 , vo2 , i1, i2 , vs , ic Operation for with circulating current and without circulating current load voltage expression, peak value icp 169. For A Type A Chopper (first Quadrant), Express The Following Variables As A Function Of Vs, R And Duty Cycle In Case The Load Is Resistive Average Output Voltage And Current? chopper circuit output voltage & current waveforms Average load voltage expression 170. Describe The Principle Of Step-up Chopper. Derive An Expression For The Average Output Voltage In Terms Of Input Dc Voltage & Duty Cycle? chopper circuit output voltage & current waveforms Average load voltage expression 171. Describe The Working Of Four Quadrant Chopper? chopper circuit operation 172. Explain The Working Of Current Commutated Chopper With Aid Of Circuit Diagram And Necessary Wave Forms. Derive An Expression For Its Output Voltage? chopper circuit Modes of operation- equivalent circuit diagrams Current & voltage waveforms Design 173. Explain The Working Of Voltage Commutated Chopper With Aid Of Circuit Diagram And Necessary Waveforms. Derive An Expression For Its Output Voltage? chopper circuit Modes of operation- equivalent circuit diagrams Current & voltage waveforms Design of C & L 174. Describe The Operation Of Series Inverter With Aid Of Diagrams. Describe An Expression For Output Frequency, Current And Voltages. What Are The Disadvantages Of Basic Series Inverter? series inverter circuit Current & voltage waveforms Operation Expression for output frequency, VL, VC 175. State Different Methods Of Voltage Control Inverters. Describe About Pwm Control In Inverter? External control of ac output voltage External control of dc input voltage Internal control of Inverter PWM inverter Single pulse modulation Multiple pulse modulation Sinusoidal pulse modulation 176. Explain The Operation Of 3 Bridge Inverter For 1800 Degree Mode Of Operation With Aid Of Relevant Phase And Line Voltage Waveforms? Inverter circuit operation- equivalent circuits Waveforms of phase and line voltage 177. Explain The Operation Of 3 Bridge Inverter For 1200 Degree Mode Of Operation With Aid Of Relevant Phase And Line Voltage Waveforms? Inverter circuit Operation- equivalent circuits Waveforms of phase and line voltage 178. Draw The Circuit Diagram Of 1Φ Auto Sequential Commutated Current Source Inverter And Explain Its Operation With Equivalent Circuits For Different Modes And Necessary Waveforms? Inverter circuit Modes of operation- equivalent circuits Waveforms of ic, vc , io Expression for tc, vc, vL 179. Draw The Circuit Diagram Of 1Φ Capacitor Commutated Current Source Inverter And Explain Its Operation With Equivalent Circuits For Different Modes And Necessary Wave Forms? Inverter circuit Modes of operation- equivalent circuits Waveforms of ic, vo , io, iT1, iT2, vT1, vT2 Expression for vc, vL , vo , io, tc 180. Explain The Operation Of Multistage Control Of Ac Voltage Controllers With Neat Diagram? Circuit diagram Operation 181. Explain The Operation Of 1Φ Ac Voltage Controller With Rl Load? Circuit diagram Operation Waveforms 182. Explain The Operation Of Sequence Control Of Ac Voltage Controller? Circuit diagram Operation Waveforms 183. Explain The Operation Of 1 Sinusoidal Ac Voltage Controller? Circuit diagram Operation Waveforms 184. For A 1Φ Voltage Controller, Feeding A Resistive Load, Draw The Waveforms Of Source Voltage, Gating Signals, Output Voltage And Voltage Across The Scr. Describe The Working With Reference To Waveforms Drawn? Circuit diagram Operation Waveforms POWER ELECTRONICS Interview Questions and Answers pdf free download :: Read the full article

0 notes

Text

N1-§8 How To Select The Solid-State Relays?(2)

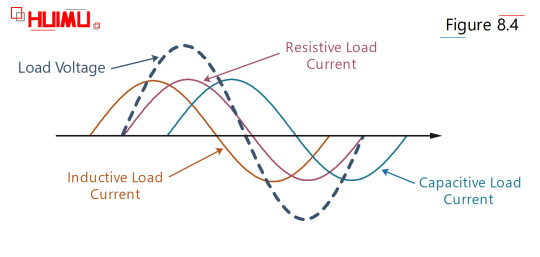

Load Type:

The loads can be divided into three types based on the electrical impedance: Resistive Load Type (or Pure Resistive Load), Inductive Load Type and Capacitive Load Type. There is no pure inductive load and pure capacitive load in the usual electrical appliances, because these two type loads don not do active power. In the series-parallel circuit, if the capacitive reactance is larger than the inductive reactance, the circuit is capacitive load; and vice versa.

Resistive Load: